TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 751 of 2000

EM–1142GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

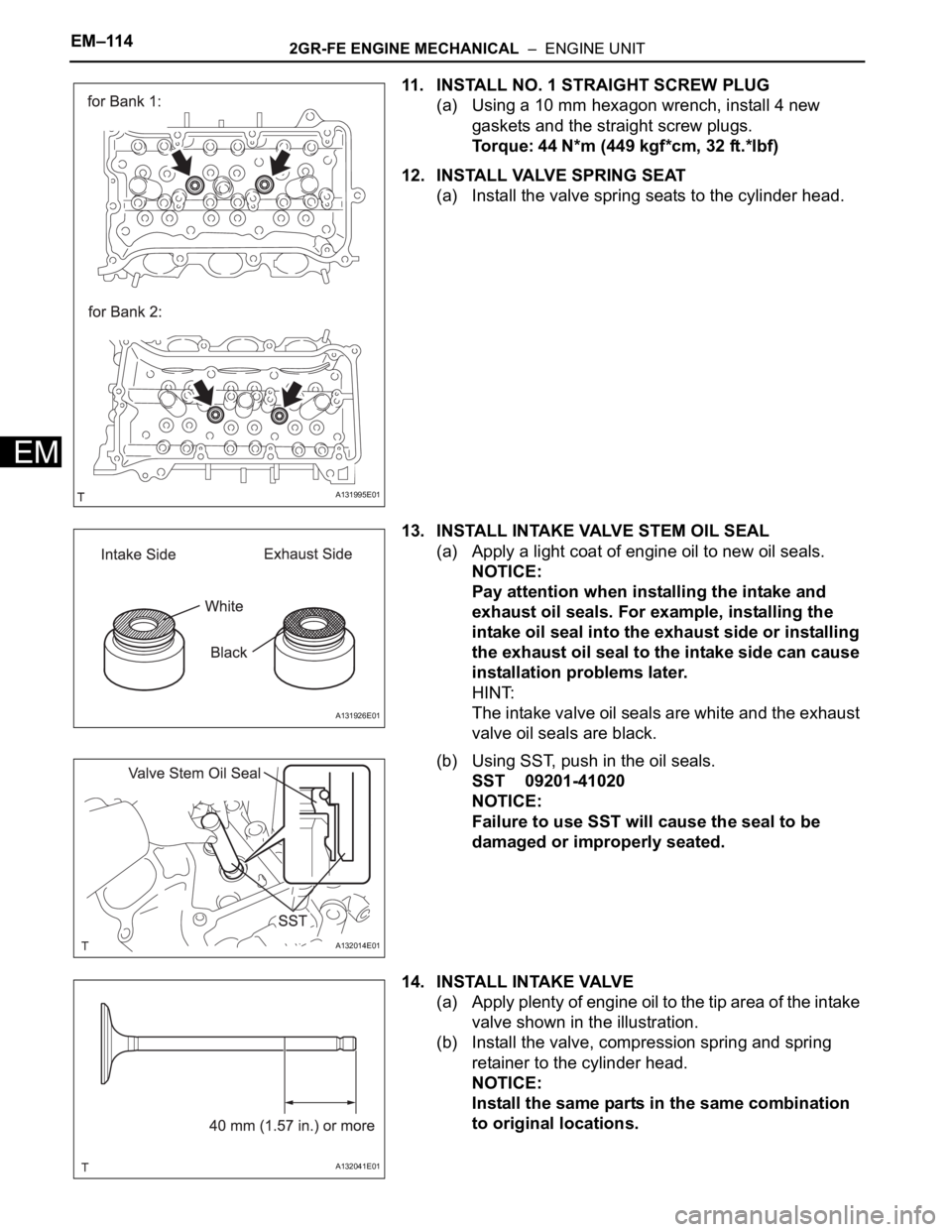

11. INSTALL NO. 1 STRAIGHT SCREW PLUG

(a) Using a 10 mm hexagon wrench, install 4 new

gaskets and the straight screw plugs.

Torque: 44 N*m (449 kgf*cm, 32 ft.*lbf)

12. INSTALL VALVE SPRING SEAT

(a) Install the valve spring seats to the cylinder head.

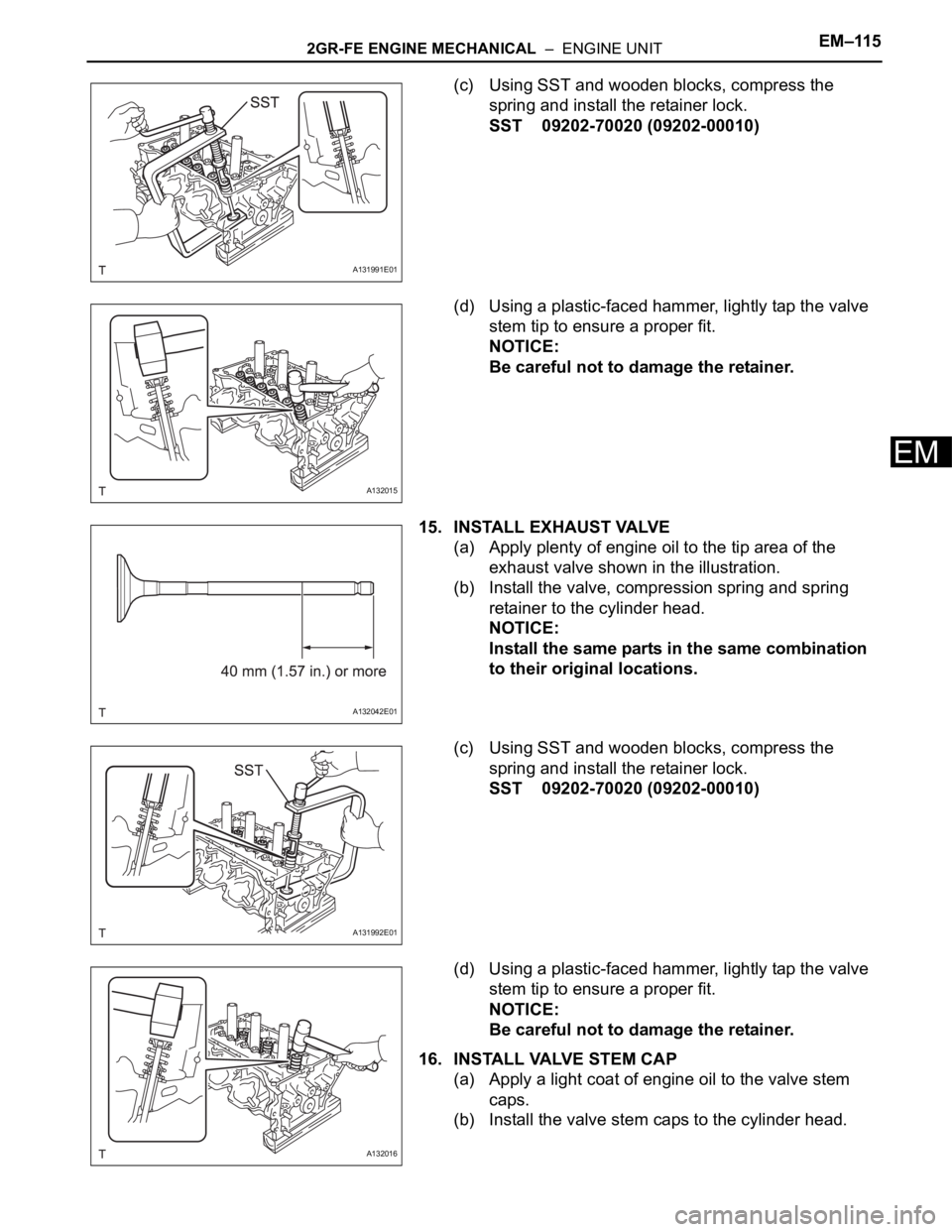

13. INSTALL INTAKE VALVE STEM OIL SEAL

(a) Apply a light coat of engine oil to new oil seals.

NOTICE:

Pay attention when installing the intake and

exhaust oil seals. For example, installing the

intake oil seal into the exhaust side or installing

the exhaust oil seal to the intake side can cause

installation problems later.

HINT:

The intake valve oil seals are white and the exhaust

valve oil seals are black.

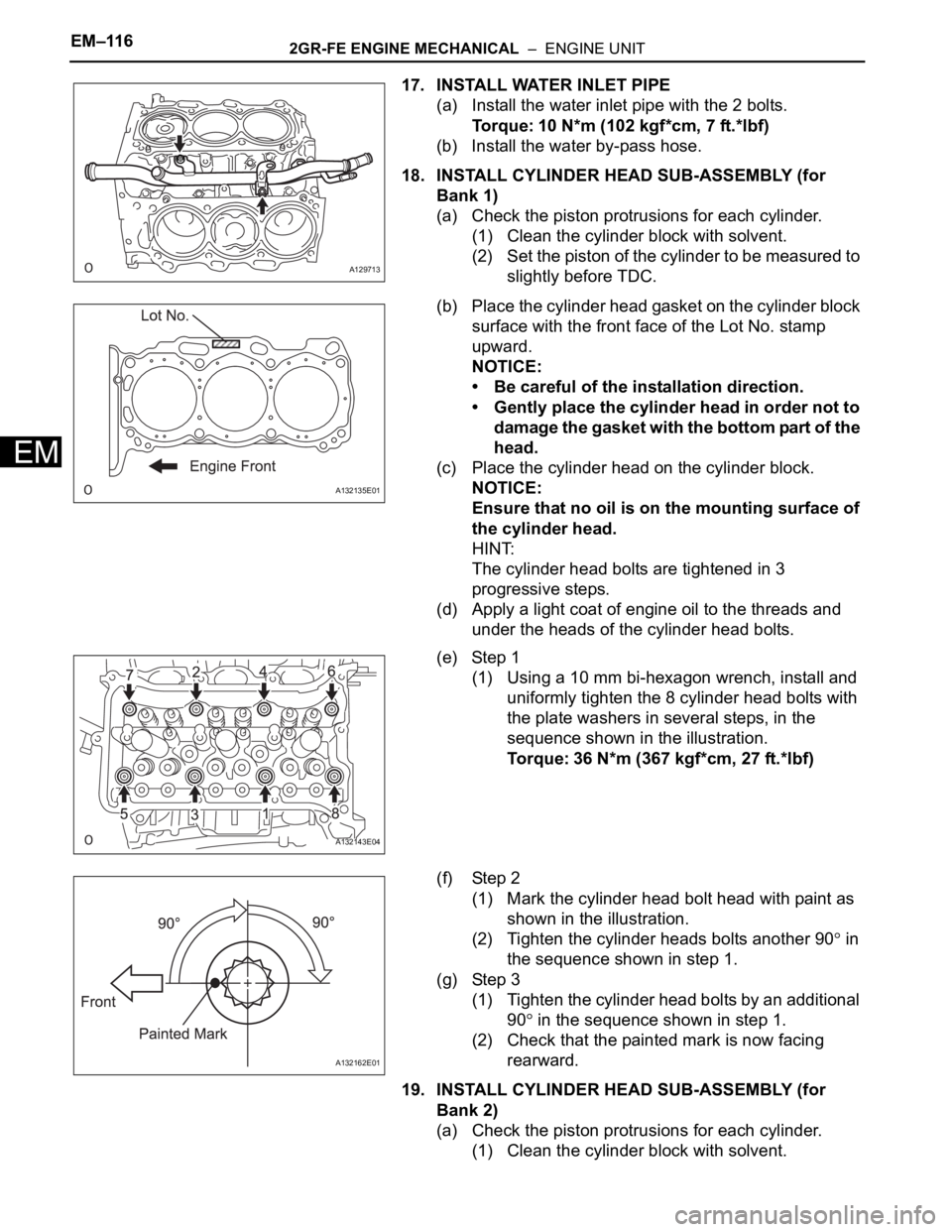

(b) Using SST, push in the oil seals.

SST 09201-41020

NOTICE:

Failure to use SST will cause the seal to be

damaged or improperly seated.

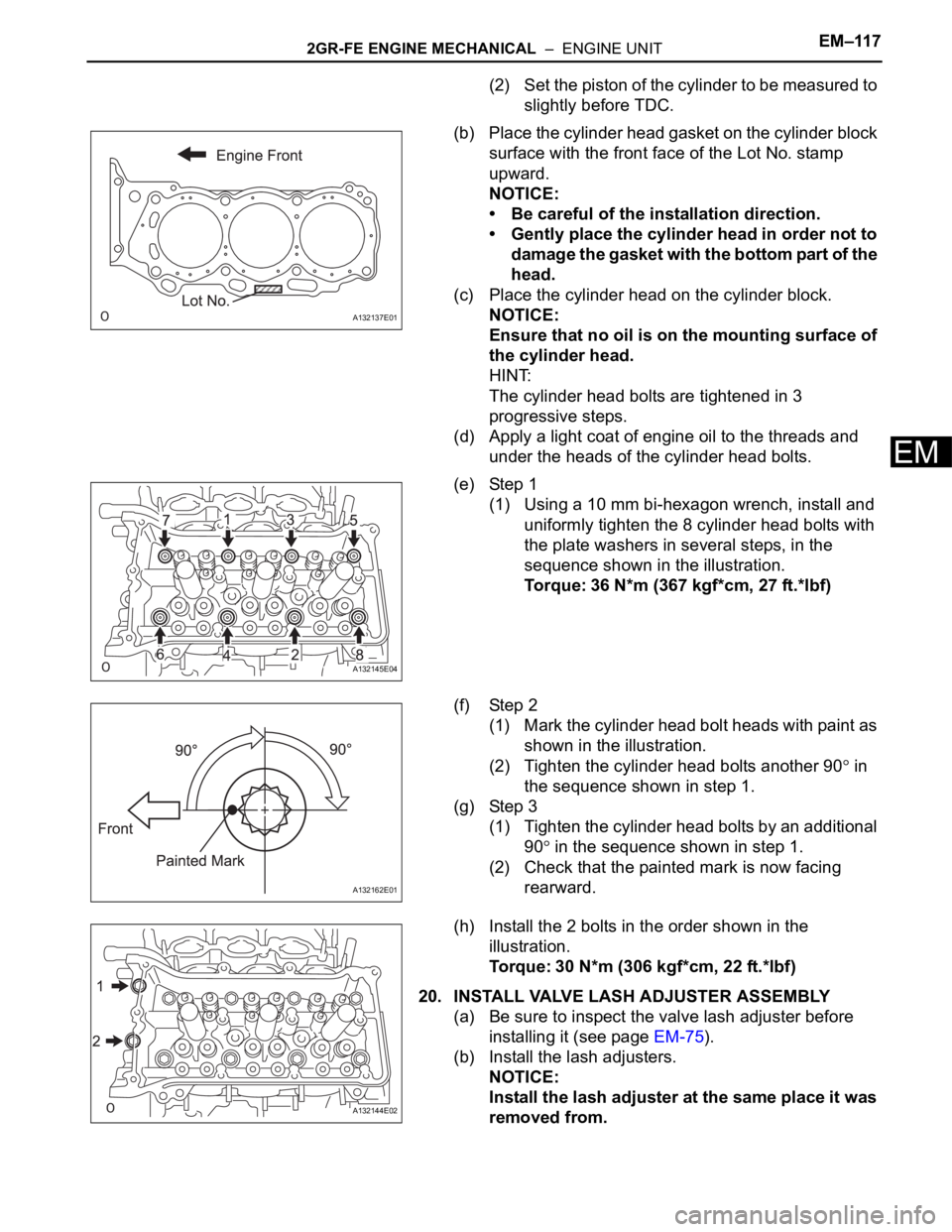

14. INSTALL INTAKE VALVE

(a) Apply plenty of engine oil to the tip area of the intake

valve shown in the illustration.

(b) Install the valve, compression spring and spring

retainer to the cylinder head.

NOTICE:

Install the same parts in the same combination

to original locations.

A131995E01

A131926E01

A132014E01

A132041E01

Page 752 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–115

EM

(c) Using SST and wooden blocks, compress the

spring and install the retainer lock.

SST 09202-70020 (09202-00010)

(d) Using a plastic-faced hammer, lightly tap the valve

stem tip to ensure a proper fit.

NOTICE:

Be careful not to damage the retainer.

15. INSTALL EXHAUST VALVE

(a) Apply plenty of engine oil to the tip area of the

exhaust valve shown in the illustration.

(b) Install the valve, compression spring and spring

retainer to the cylinder head.

NOTICE:

Install the same parts in the same combination

to their original locations.

(c) Using SST and wooden blocks, compress the

spring and install the retainer lock.

SST 09202-70020 (09202-00010)

(d) Using a plastic-faced hammer, lightly tap the valve

stem tip to ensure a proper fit.

NOTICE:

Be careful not to damage the retainer.

16. INSTALL VALVE STEM CAP

(a) Apply a light coat of engine oil to the valve stem

caps.

(b) Install the valve stem caps to the cylinder head.

A131991E01

A132015

A132042E01

A131992E01

A132016

Page 753 of 2000

EM–1162GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

17. INSTALL WATER INLET PIPE

(a) Install the water inlet pipe with the 2 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(b) Install the water by-pass hose.

18. INSTALL CYLINDER HEAD SUB-ASSEMBLY (for

Bank 1)

(a) Check the piston protrusions for each cylinder.

(1) Clean the cylinder block with solvent.

(2) Set the piston of the cylinder to be measured to

slightly before TDC.

(b) Place the cylinder head gasket on the cylinder block

surface with the front face of the Lot No. stamp

upward.

NOTICE:

• Be careful of the installation direction.

• Gently place the cylinder head in order not to

damage the gasket with the bottom part of the

head.

(c) Place the cylinder head on the cylinder block.

NOTICE:

Ensure that no oil is on the mounting surface of

the cylinder head.

HINT:

The cylinder head bolts are tightened in 3

progressive steps.

(d) Apply a light coat of engine oil to the threads and

under the heads of the cylinder head bolts.

(e) Step 1

(1) Using a 10 mm bi-hexagon wrench, install and

uniformly tighten the 8 cylinder head bolts with

the plate washers in several steps, in the

sequence shown in the illustration.

Torque: 36 N*m (367 kgf*cm, 27 ft.*lbf)

(f) Step 2

(1) Mark the cylinder head bolt head with paint as

shown in the illustration.

(2) Tighten the cylinder heads bolts another 90

in

the sequence shown in step 1.

(g) Step 3

(1) Tighten the cylinder head bolts by an additional

90

in the sequence shown in step 1.

(2) Check that the painted mark is now facing

rearward.

19. INSTALL CYLINDER HEAD SUB-ASSEMBLY (for

Bank 2)

(a) Check the piston protrusions for each cylinder.

(1) Clean the cylinder block with solvent.

A129713

A132135E01

A132143E04

A132162E01

Page 754 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–117

EM

(2) Set the piston of the cylinder to be measured to

slightly before TDC.

(b) Place the cylinder head gasket on the cylinder block

surface with the front face of the Lot No. stamp

upward.

NOTICE:

• Be careful of the installation direction.

• Gently place the cylinder head in order not to

dama ge the gaske t wi th t he b ottom part of t he

head.

(c) Place the cylinder head on the cylinder block.

NOTICE:

Ensure that no oil is on the mounting surface of

the cylinder head.

HINT:

The cylinder head bolts are tightened in 3

progressive steps.

(d) Apply a light coat of engine oil to the threads and

under the heads of the cylinder head bolts.

(e) Step 1

(1) Using a 10 mm bi-hexagon wrench, install and

uniformly tighten the 8 cylinder head bolts with

the plate washers in several steps, in the

sequence shown in the illustration.

Torque: 36 N*m (367 kgf*cm, 27 ft.*lbf)

(f) Step 2

(1) Mark the cylinder head bolt heads with paint as

shown in the illustration.

(2) Tighten the cylinder head bolts another 90

in

the sequence shown in step 1.

(g) Step 3

(1) Tighten the cylinder head bolts by an additional

90

in the sequence shown in step 1.

(2) Check that the painted mark is now facing

rearward.

(h) Install the 2 bolts in the order shown in the

illustration.

Torque: 30 N*m (306 kgf*cm, 22 ft.*lbf)

20. INSTALL VALVE LASH ADJUSTER ASSEMBLY

(a) Be sure to inspect the valve lash adjuster before

installing it (see page EM-75).

(b) Install the lash adjusters.

NOTICE:

Install the lash adjuster at the same place it was

removed from.

A132137E01

A132145E04

A132162E01

A132144E02

Page 755 of 2000

EM–1182GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

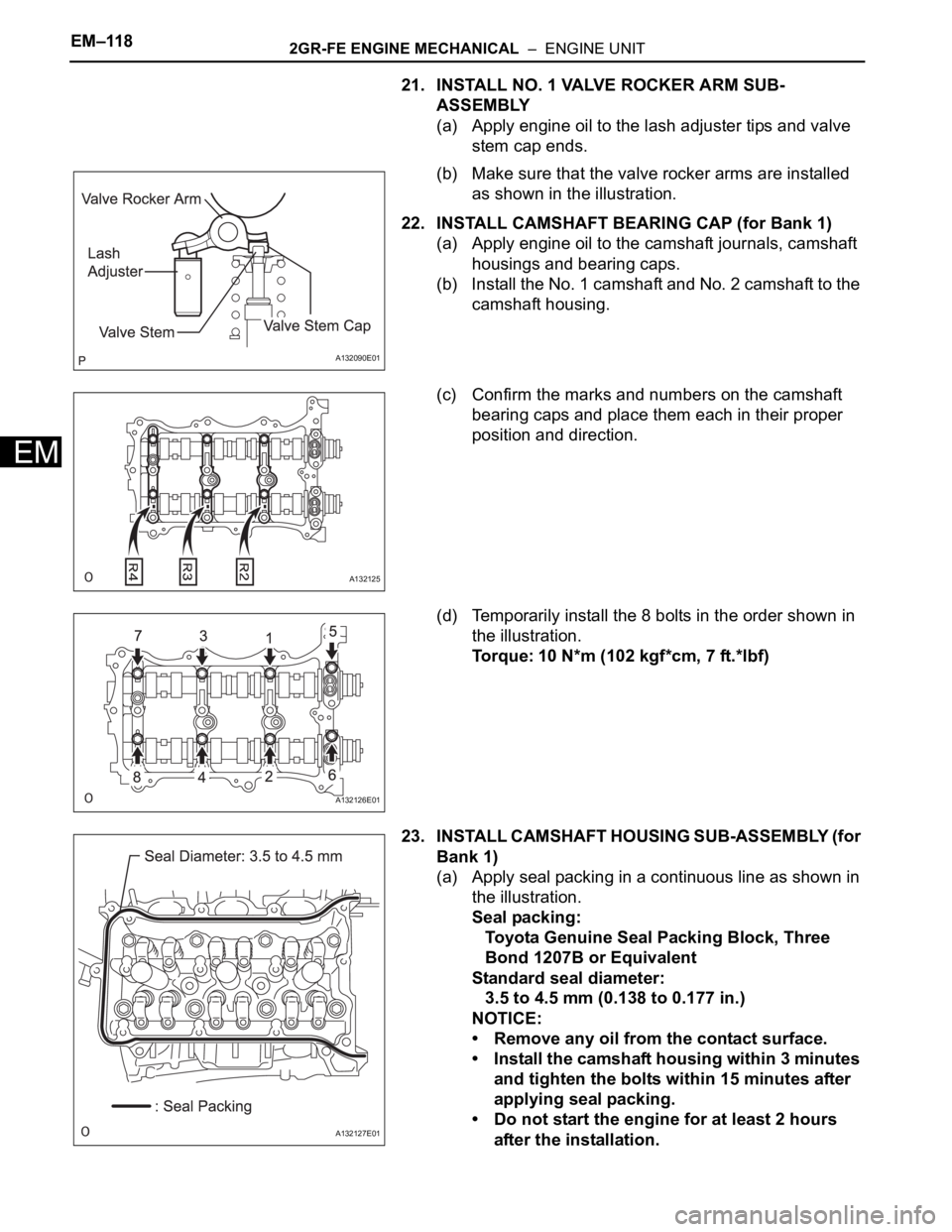

21. INSTALL NO. 1 VALVE ROCKER ARM SUB-

ASSEMBLY

(a) Apply engine oil to the lash adjuster tips and valve

stem cap ends.

(b) Make sure that the valve rocker arms are installed

as shown in the illustration.

22. INSTALL CAMSHAFT BEARING CAP (for Bank 1)

(a) Apply engine oil to the camshaft journals, camshaft

housings and bearing caps.

(b) Install the No. 1 camshaft and No. 2 camshaft to the

camshaft housing.

(c) Confirm the marks and numbers on the camshaft

bearing caps and place them each in their proper

position and direction.

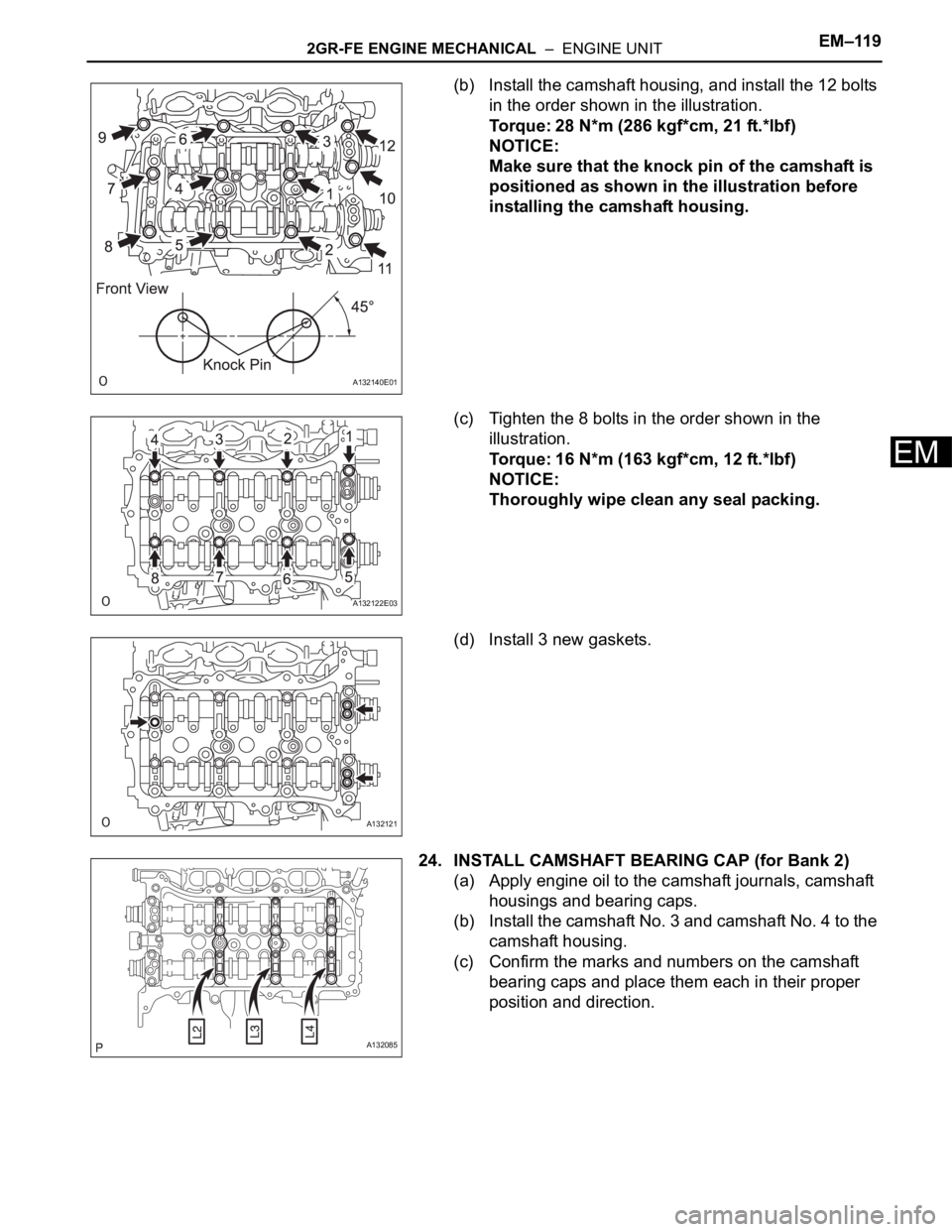

(d) Temporarily install the 8 bolts in the order shown in

the illustration.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

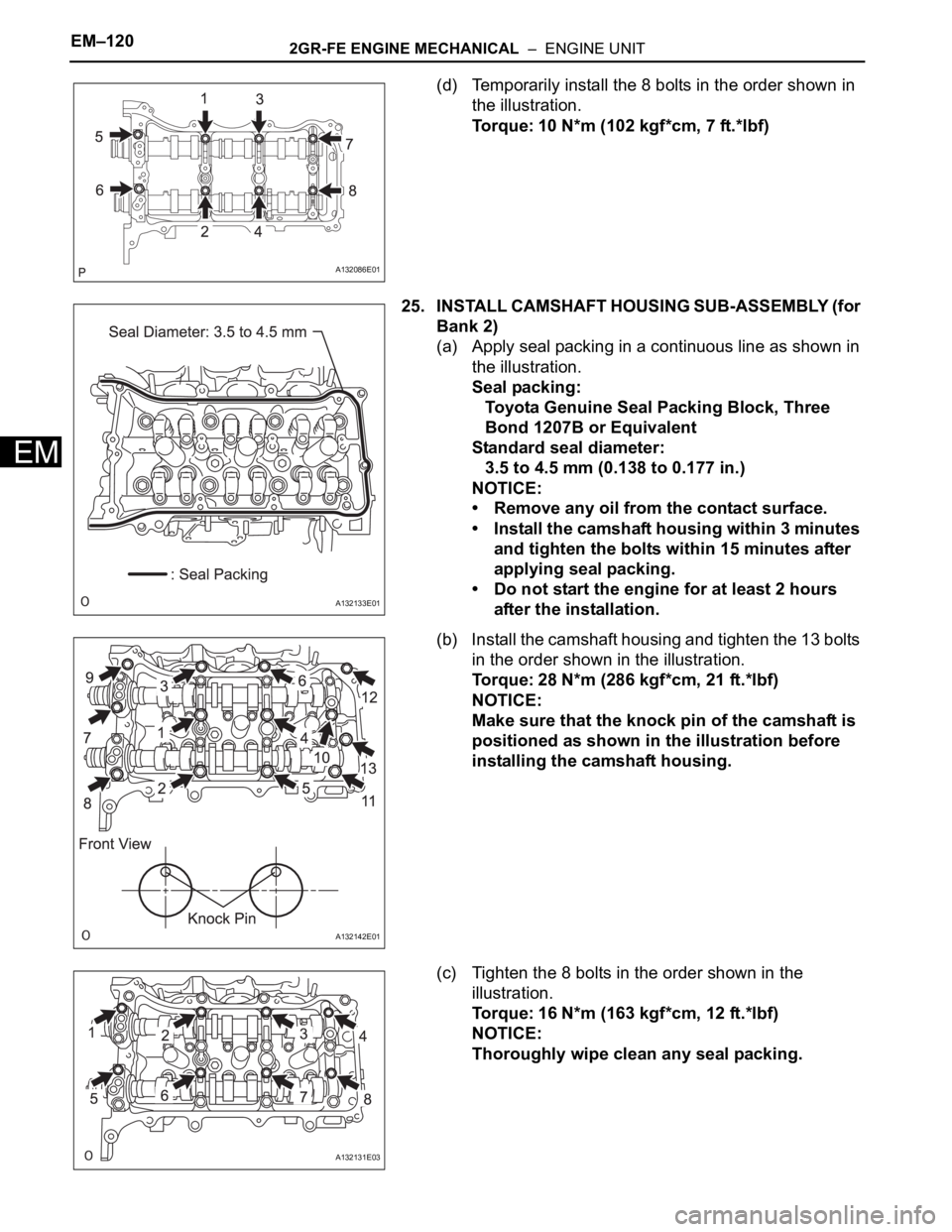

23. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY (for

Bank 1)

(a) Apply seal packing in a continuous line as shown in

the illustration.

Seal packing:

Toyota Genuine Seal Packing Block, Three

Bond 1207B or Equivalent

Standard seal diameter:

3.5 to 4.5 mm (0.138 to 0.177 in.)

NOTICE:

• Remove any oil from the contact surface.

• Install the camshaft housing within 3 minutes

and tighten the bolts within 15 minutes after

applying seal packing.

• Do not start the engine for at least 2 hours

after the installation.

A132090E01

A132125

A132126E01

A132127E01

Page 756 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–119

EM

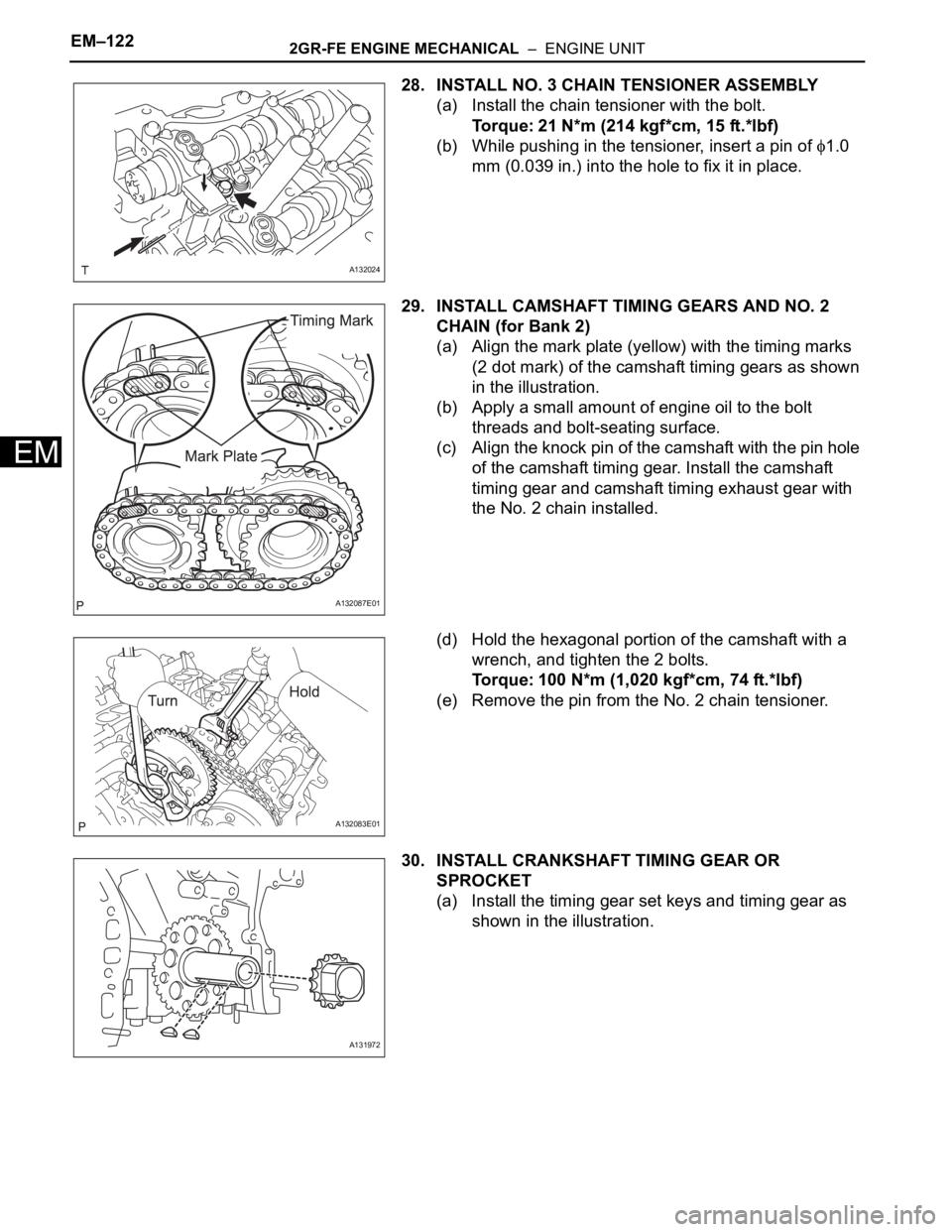

(b) Install the camshaft housing, and install the 12 bolts

in the order shown in the illustration.

Torque: 28 N*m (286 kgf*cm, 21 ft.*lbf)

NOTICE:

Make sure that the knock pin of the camshaft is

positioned as shown in the illustration before

installing the camshaft housing.

(c) Tighten the 8 bolts in the order shown in the

illustration.

Torque: 16 N*m (163 kgf*cm, 12 ft.*lbf)

NOTICE:

Thoroughly wipe clean any seal packing.

(d) Install 3 new gaskets.

24. INSTALL CAMSHAFT BEARING CAP (for Bank 2)

(a) Apply engine oil to the camshaft journals, camshaft

housings and bearing caps.

(b) Install the camshaft No. 3 and camshaft No. 4 to the

camshaft housing.

(c) Confirm the marks and numbers on the camshaft

bearing caps and place them each in their proper

position and direction.

A132140E01

A132122E03

A132121

A132085

Page 757 of 2000

EM–1202GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

(d) Temporarily install the 8 bolts in the order shown in

the illustration.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

25. INSTALL CAMSHAFT HOUSING SUB-ASSEMBLY (for

Bank 2)

(a) Apply seal packing in a continuous line as shown in

the illustration.

Seal packing:

Toyota Genuine Seal Packing Block, Three

Bond 1207B or Equivalent

Standard seal diameter:

3.5 to 4.5 mm (0.138 to 0.177 in.)

NOTICE:

• Remove any oil from the contact surface.

• Install the camshaft housing within 3 minutes

and tighten the bolts within 15 minutes after

applying seal packing.

• Do not start the engine for at least 2 hours

after the installation.

(b) Install the camshaft housing and tighten the 13 bolts

in the order shown in the illustration.

Torque: 28 N*m (286 kgf*cm, 21 ft.*lbf)

NOTICE:

Make sure that the knock pin of the camshaft is

positioned as shown in the illustration before

installing the camshaft housing.

(c) Tighten the 8 bolts in the order shown in the

illustration.

Torque: 16 N*m (163 kgf*cm, 12 ft.*lbf)

NOTICE:

Thoroughly wipe clean any seal packing.

A132086E01

A132133E01

A132142E01

A132131E03

Page 758 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–121

EM

(d) Install 3 new gaskets.

26. INSTALL NO. 2 CHAIN TENSIONER ASSEMBLY

(a) Install the chain tensioner with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(b) While pushing in the tensioner, insert a pin of

1.0

mm (0.039 in.) into the hole to fix it in place.

27. INSTALL CAMSHAFT TIMING GEARS AND NO. 2

CHAIN (for Bank 1)

(a) Align the mark plate (yellow) with the timing marks

(1 dot mark) of the camshaft timing gears as shown

in the illustration.

(b) Apply a small amount of engine oil to the bolt

threads and bolt-seating surface.

(c) Align the knock pin of the camshaft with the pin hole

of the camshaft timing gear. Install the camshaft

timing gear and camshaft timing exhaust gear with

the No. 2 chain installed.

(d) Hold the hexagonal portion of the camshaft with a

wrench, and tighten the 2 bolts.

Torque: 100 N*m (1,020 kgf*cm, 74 ft.*lbf)

(e) Remove the pin from the No. 2 chain tensioner.

A132130

A132023

A132080E01

A132073E01

Page 759 of 2000

EM–1222GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

28. INSTALL NO. 3 CHAIN TENSIONER ASSEMBLY

(a) Install the chain tensioner with the bolt.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf)

(b) While pushing in the tensioner, insert a pin of

1.0

mm (0.039 in.) into the hole to fix it in place.

29. INSTALL CAMSHAFT TIMING GEARS AND NO. 2

CHAIN (for Bank 2)

(a) Align the mark plate (yellow) with the timing marks

(2 dot mark) of the camshaft timing gears as shown

in the illustration.

(b) Apply a small amount of engine oil to the bolt

threads and bolt-seating surface.

(c) Align the knock pin of the camshaft with the pin hole

of the camshaft timing gear. Install the camshaft

timing gear and camshaft timing exhaust gear with

the No. 2 chain installed.

(d) Hold the hexagonal portion of the camshaft with a

wrench, and tighten the 2 bolts.

Torque: 100 N*m (1,020 kgf*cm, 74 ft.*lbf)

(e) Remove the pin from the No. 2 chain tensioner.

30. INSTALL CRANKSHAFT TIMING GEAR OR

SPROCKET

(a) Install the timing gear set keys and timing gear as

shown in the illustration.

A132024

A132087E01

A132083E01

A131972

Page 760 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–123

EM

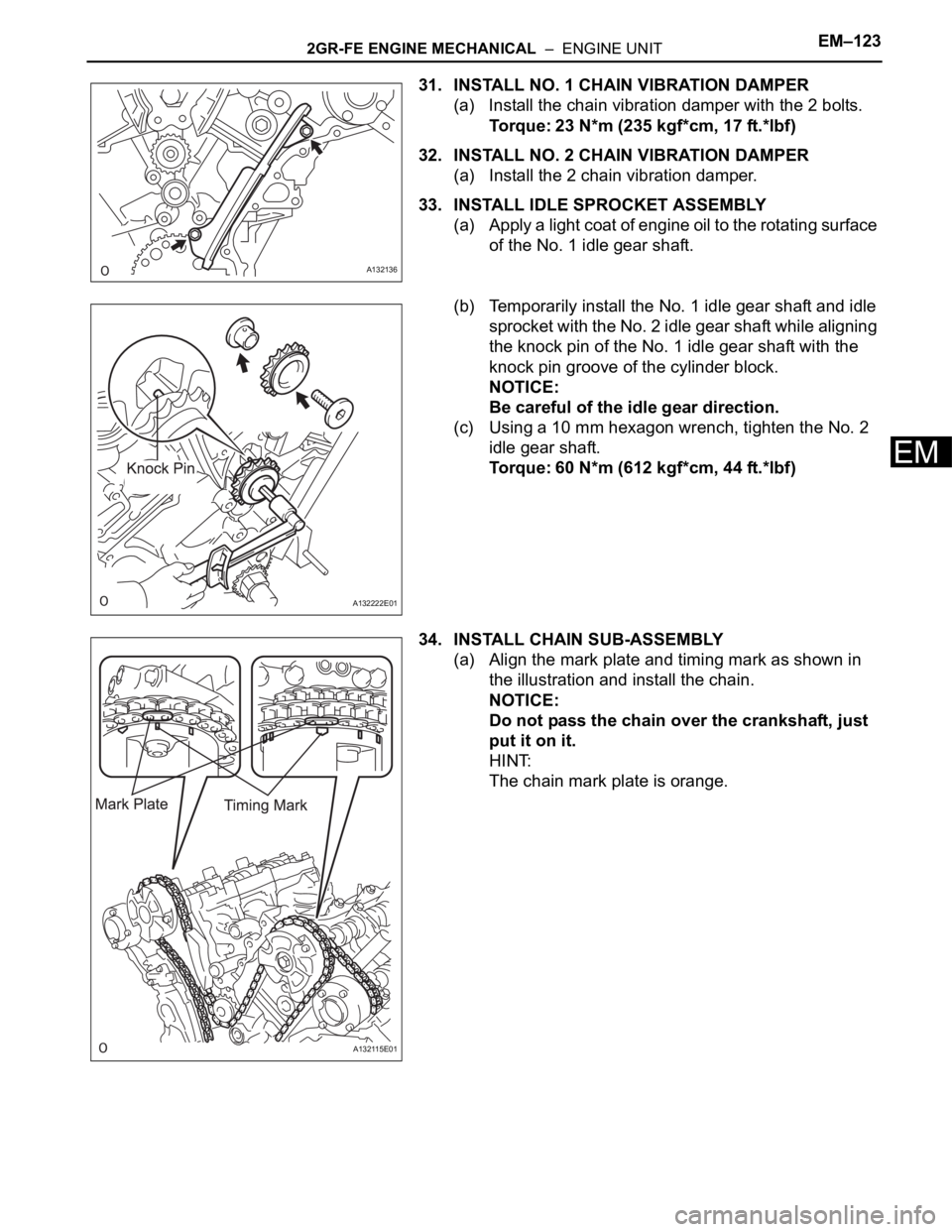

31. INSTALL NO. 1 CHAIN VIBRATION DAMPER

(a) Install the chain vibration damper with the 2 bolts.

Torque: 23 N*m (235 kgf*cm, 17 ft.*lbf)

32. INSTALL NO. 2 CHAIN VIBRATION DAMPER

(a) Install the 2 chain vibration damper.

33. INSTALL IDLE SPROCKET ASSEMBLY

(a) Apply a light coat of engine oil to the rotating surface

of the No. 1 idle gear shaft.

(b) Temporarily install the No. 1 idle gear shaft and idle

sprocket with the No. 2 idle gear shaft while aligning

the knock pin of the No. 1 idle gear shaft with the

knock pin groove of the cylinder block.

NOTICE:

Be careful of the idle gear direction.

(c) Using a 10 mm hexagon wrench, tighten the No. 2

idle gear shaft.

Torque: 60 N*m (612 kgf*cm, 44 ft.*lbf)

34. INSTALL CHAIN SUB-ASSEMBLY

(a) Align the mark plate and timing mark as shown in

the illustration and install the chain.

NOTICE:

Do not pass the chain over the crankshaft, just

put it on it.

HINT:

The chain mark plate is orange.

A132136

A132222E01

A132115E01