TOYOTA RAV4 2006 Service Repair Manual

Manufacturer: TOYOTA, Model Year: 2006, Model line: RAV4, Model: TOYOTA RAV4 2006Pages: 2000, PDF Size: 45.84 MB

Page 761 of 2000

EM–1242GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

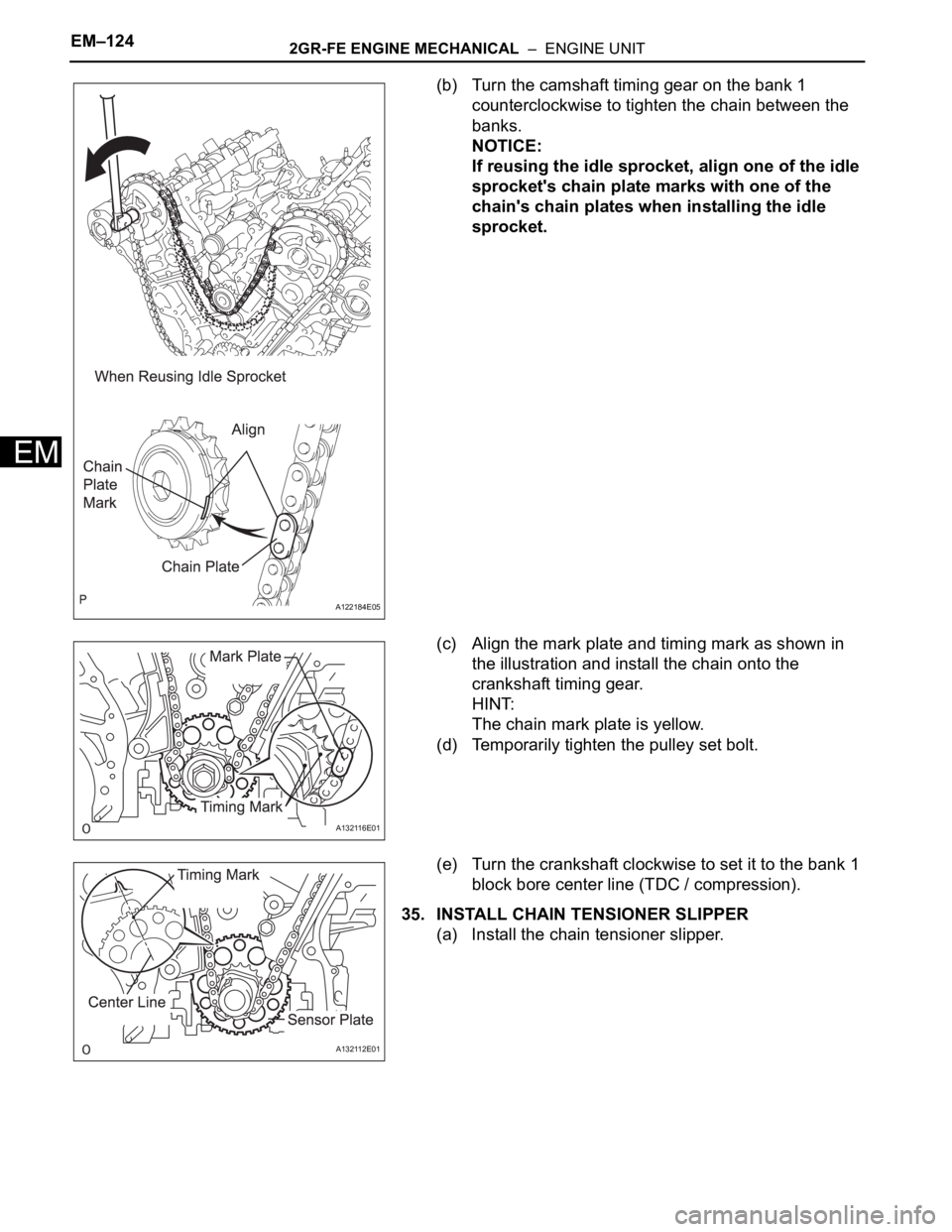

(b) Turn the camshaft timing gear on the bank 1

counterclockwise to tighten the chain between the

banks.

NOTICE:

If reusing the idle sprocket, align one of the idle

sprocket's chain plate marks with one of the

chain's chain plates when installing the idle

sprocket.

(c) Align the mark plate and timing mark as shown in

the illustration and install the chain onto the

crankshaft timing gear.

HINT:

The chain mark plate is yellow.

(d) Temporarily tighten the pulley set bolt.

(e) Turn the crankshaft clockwise to set it to the bank 1

block bore center line (TDC / compression).

35. INSTALL CHAIN TENSIONER SLIPPER

(a) Install the chain tensioner slipper.

A122184E05

A132116E01

A132112E01

Page 762 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–125

EM

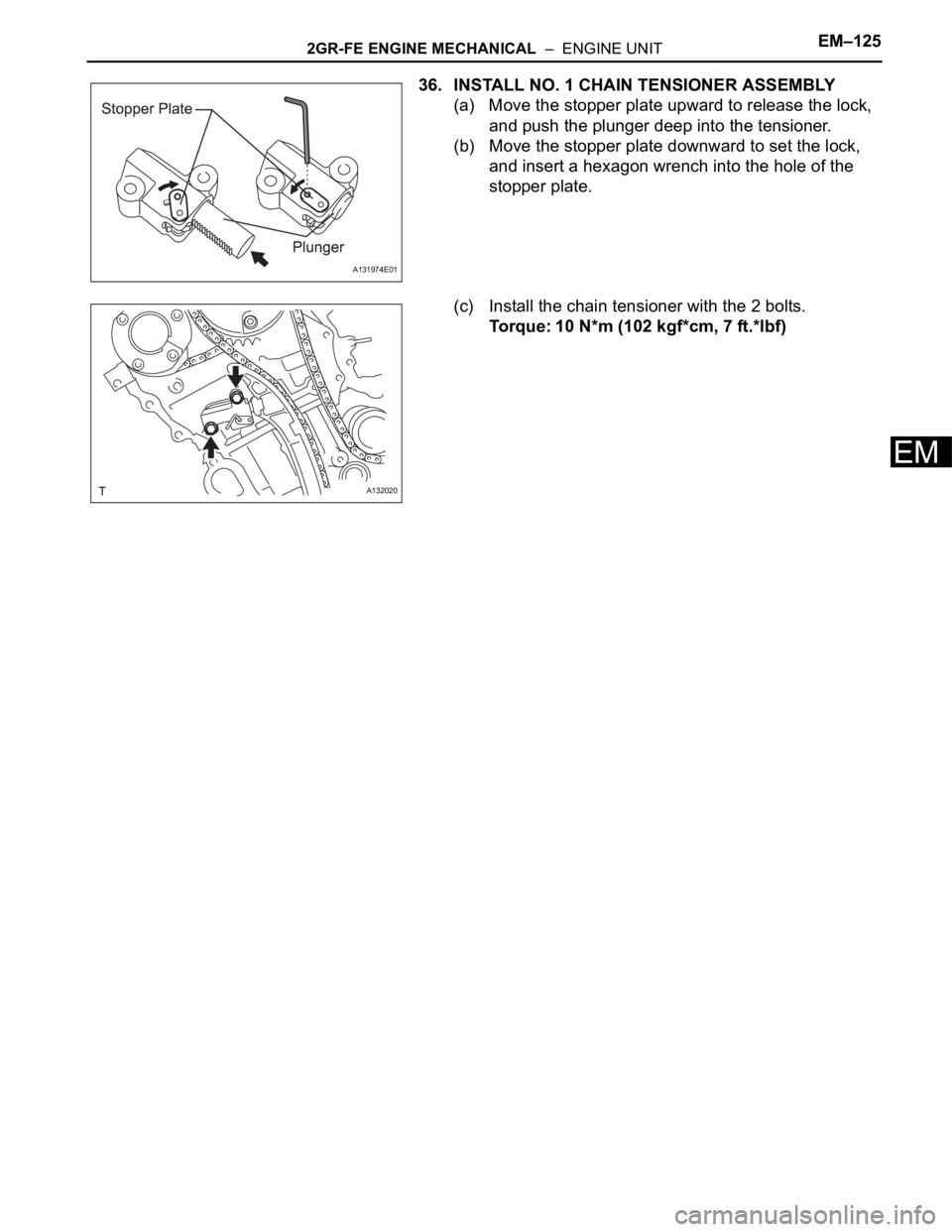

36. INSTALL NO. 1 CHAIN TENSIONER ASSEMBLY

(a) Move the stopper plate upward to release the lock,

and push the plunger deep into the tensioner.

(b) Move the stopper plate downward to set the lock,

and insert a hexagon wrench into the hole of the

stopper plate.

(c) Install the chain tensioner with the 2 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

A131974E01

A132020

Page 763 of 2000

EM–1262GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

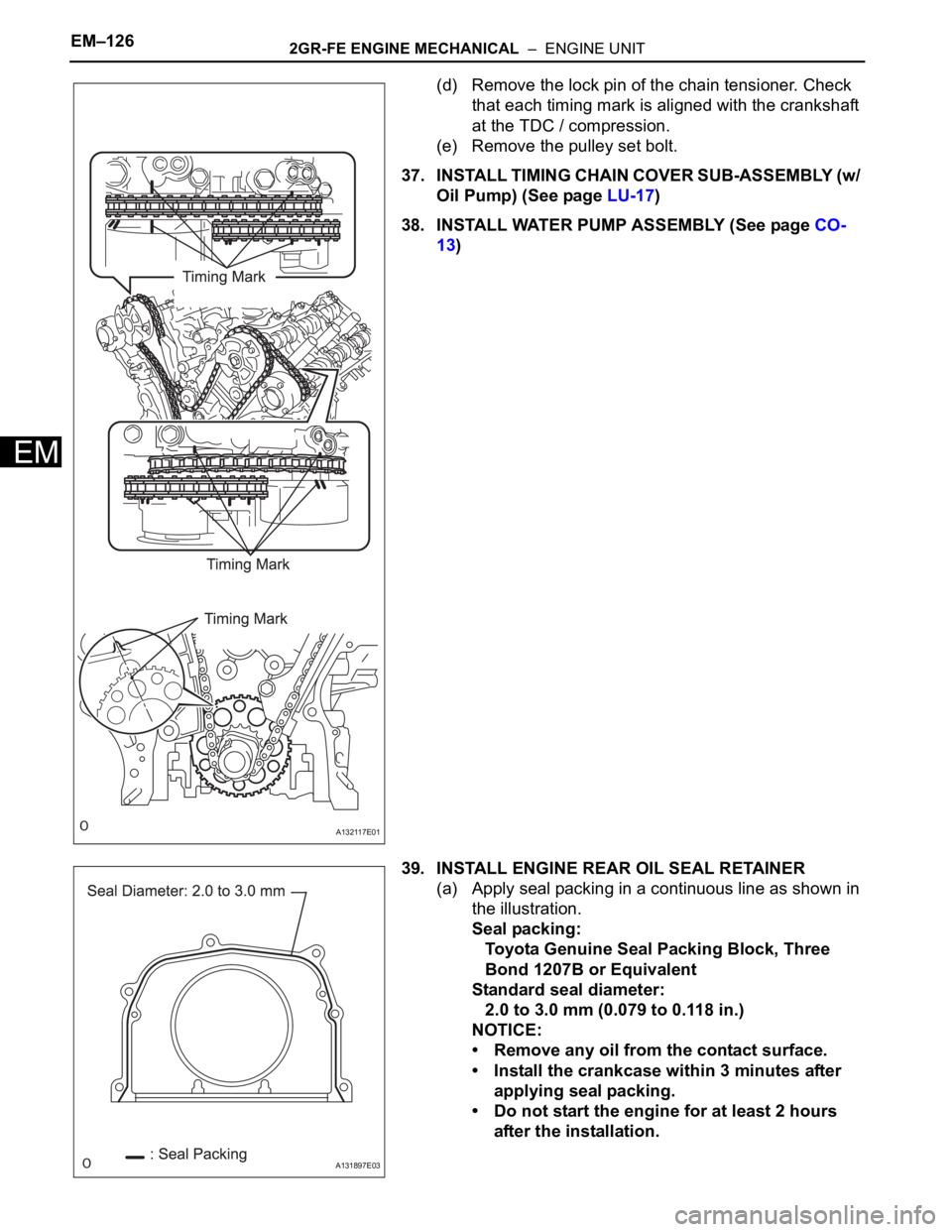

(d) Remove the lock pin of the chain tensioner. Check

that each timing mark is aligned with the crankshaft

at the TDC / compression.

(e) Remove the pulley set bolt.

37. INSTALL TIMING CHAIN COVER SUB-ASSEMBLY (w/

Oil Pump) (See page LU-17)

38. INSTALL WATER PUMP ASSEMBLY (See page CO-

13)

39. INSTALL ENGINE REAR OIL SEAL RETAINER

(a) Apply seal packing in a continuous line as shown in

the illustration.

Seal packing:

Toyota Genuine Seal Packing Block, Three

Bond 1207B or Equivalent

Standard seal diameter:

2.0 to 3.0 mm (0.079 to 0.118 in.)

NOTICE:

• Remove any oil from the contact surface.

• Install the crankcase within 3 minutes after

applying seal packing.

• Do not start the engine for at least 2 hours

after the installation.

A132117E01

A131897E03

Page 764 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–127

EM

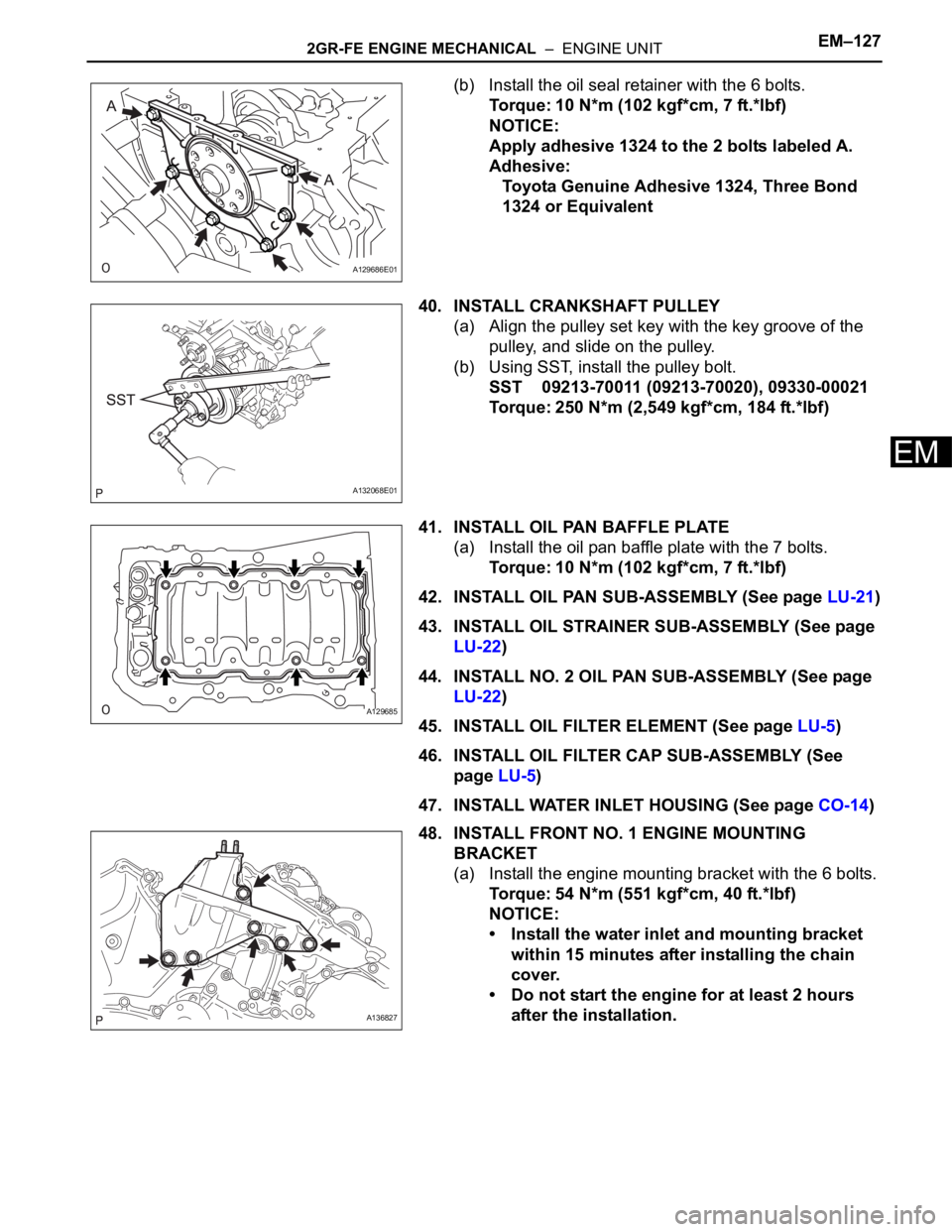

(b) Install the oil seal retainer with the 6 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

NOTICE:

Apply adhesive 1324 to the 2 bolts labeled A.

Adhesive:

Toyota Genuine Adhesive 1324, Three Bond

1324 or Equivalent

40. INSTALL CRANKSHAFT PULLEY

(a) Align the pulley set key with the key groove of the

pulley, and slide on the pulley.

(b) Using SST, install the pulley bolt.

SST 09213-70011 (09213-70020), 09330-00021

Torque: 250 N*m (2,549 kgf*cm, 184 ft.*lbf)

41. INSTALL OIL PAN BAFFLE PLATE

(a) Install the oil pan baffle plate with the 7 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

42. INSTALL OIL PAN SUB-ASSEMBLY (See page LU-21)

43. INSTALL OIL STRAINER SUB-ASSEMBLY (See page

LU-22)

44. INSTALL NO. 2 OIL PAN SUB-ASSEMBLY (See page

LU-22)

45. INSTALL OIL FILTER ELEMENT (See page LU-5)

46. INSTALL OIL FILTER CAP SUB-ASSEMBLY (See

page LU-5)

47. INSTALL WATER INLET HOUSING (See page CO-14)

48. INSTALL FRONT NO. 1 ENGINE MOUNTING

BRACKET

(a) Install the engine mounting bracket with the 6 bolts.

Torque: 54 N*m (551 kgf*cm, 40 ft.*lbf)

NOTICE:

• Install the water inlet and mounting bracket

within 15 minutes after installing the chain

cover.

• Do not start the engine for at least 2 hours

after the installation.

A129686E01

A132068E01

A129685

A136827

Page 765 of 2000

EM–1282GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

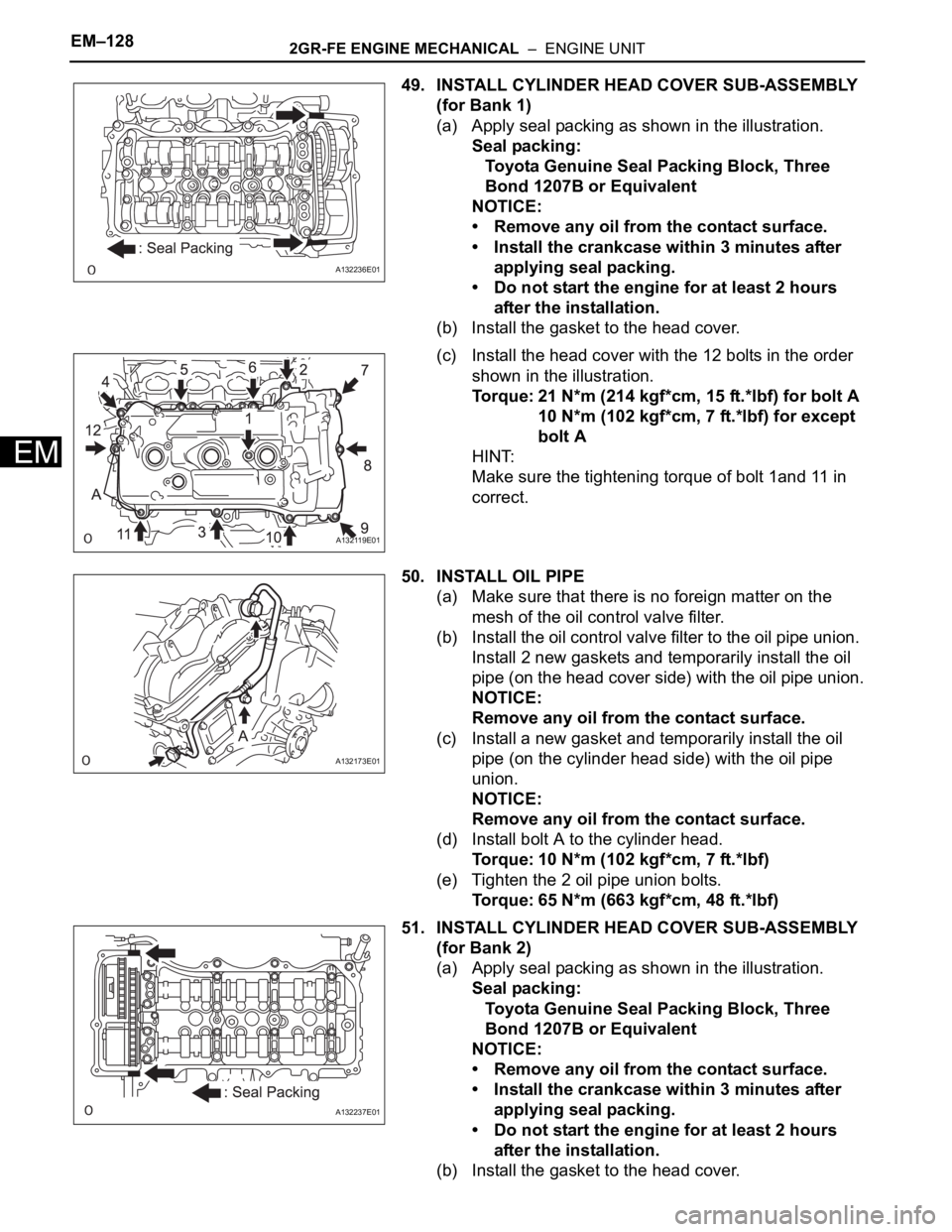

49. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

(for Bank 1)

(a) Apply seal packing as shown in the illustration.

Seal packing:

Toyota Genuine Seal Packing Block, Three

Bond 1207B or Equivalent

NOTICE:

• Remove any oil from the contact surface.

• Install the crankcase within 3 minutes after

applying seal packing.

• Do not start the engine for at least 2 hours

after the installation.

(b) Install the gasket to the head cover.

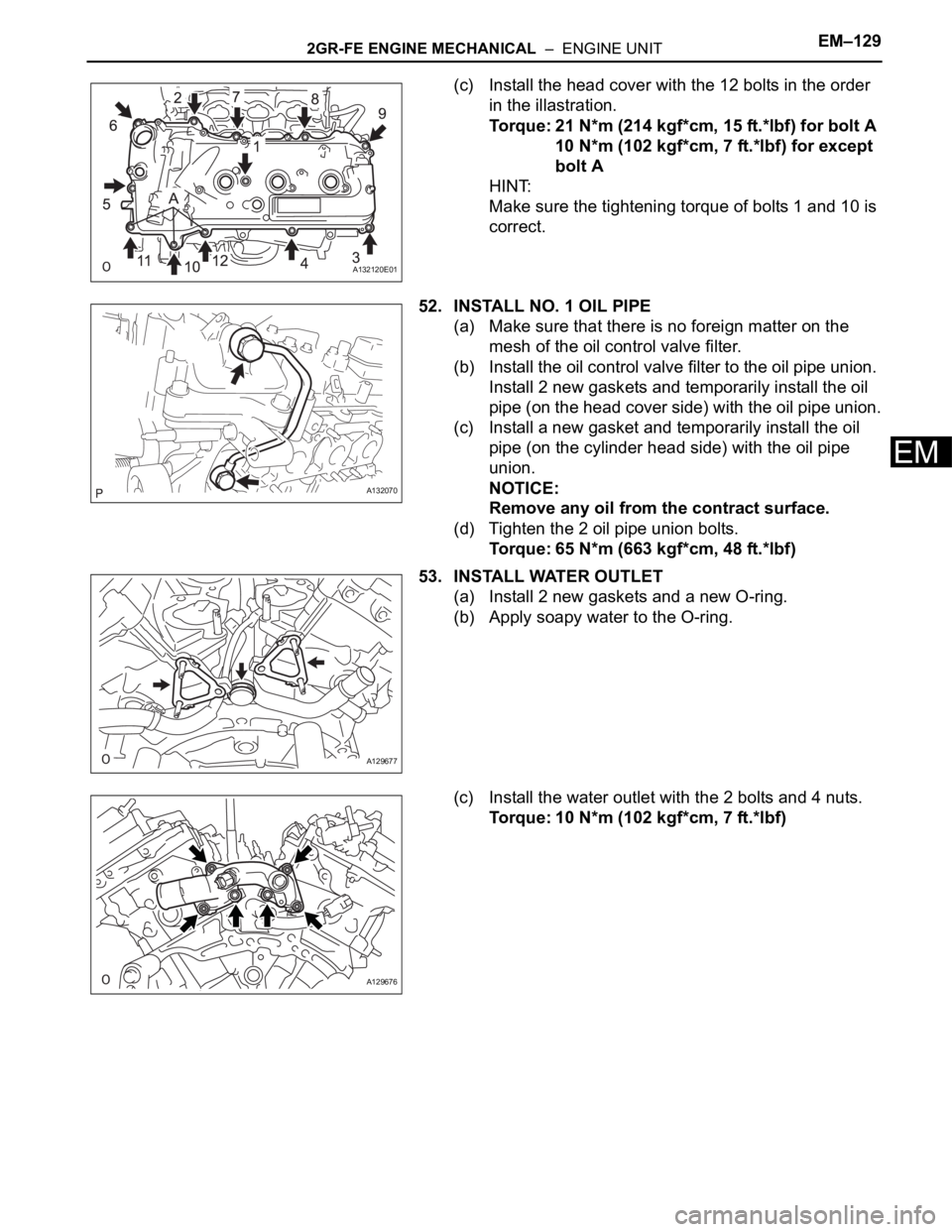

(c) Install the head cover with the 12 bolts in the order

shown in the illustration.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf) for bolt A

10 N*m (102 kgf*cm, 7 ft.*lbf) for except

bolt A

HINT:

Make sure the tightening torque of bolt 1and 11 in

correct.

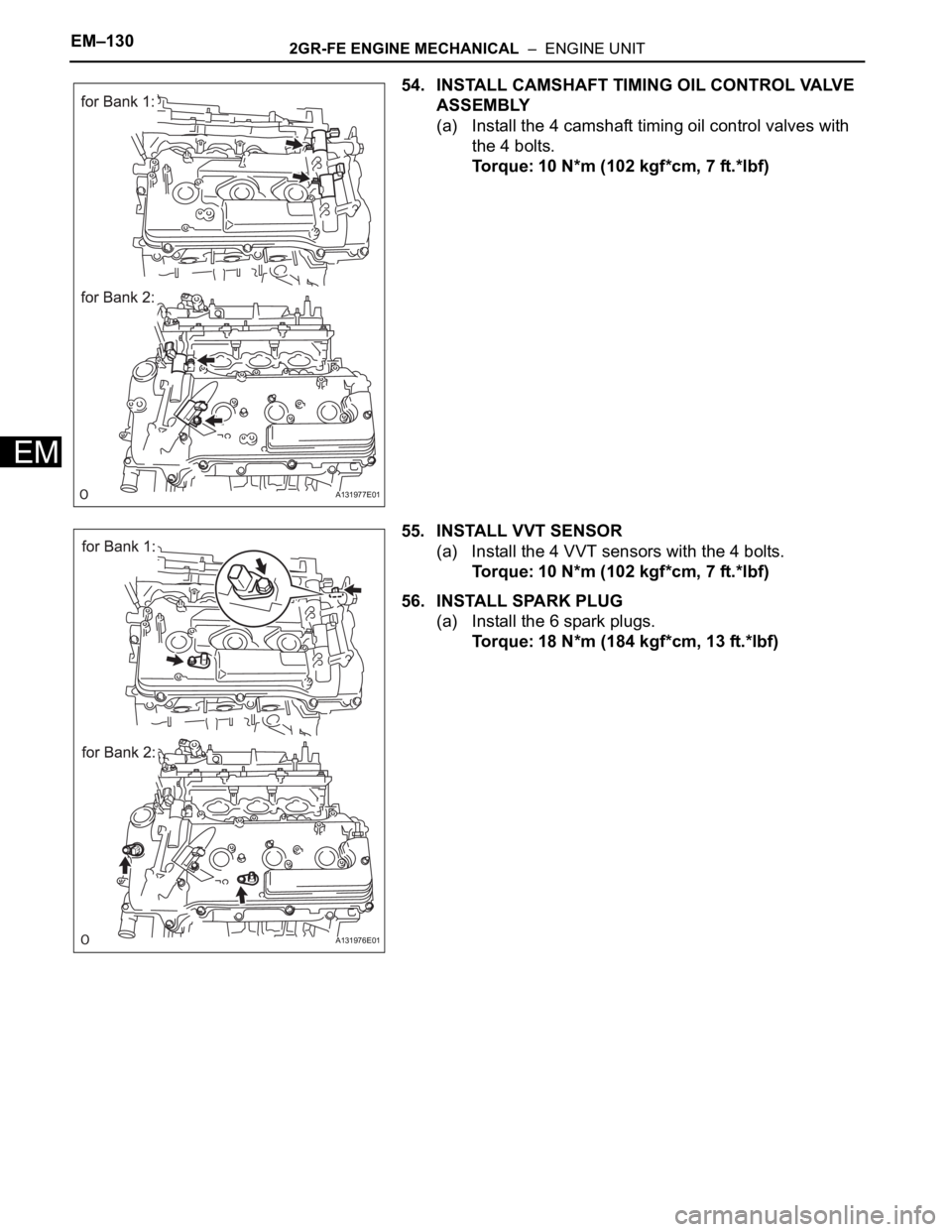

50. INSTALL OIL PIPE

(a) Make sure that there is no foreign matter on the

mesh of the oil control valve filter.

(b) Install the oil control valve filter to the oil pipe union.

Install 2 new gaskets and temporarily install the oil

pipe (on the head cover side) with the oil pipe union.

NOTICE:

Remove any oil from the contact surface.

(c) Install a new gasket and temporarily install the oil

pipe (on the cylinder head side) with the oil pipe

union.

NOTICE:

Remove any oil from the contact surface.

(d) Install bolt A to the cylinder head.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

(e) Tighten the 2 oil pipe union bolts.

Torque: 65 N*m (663 kgf*cm, 48 ft.*lbf)

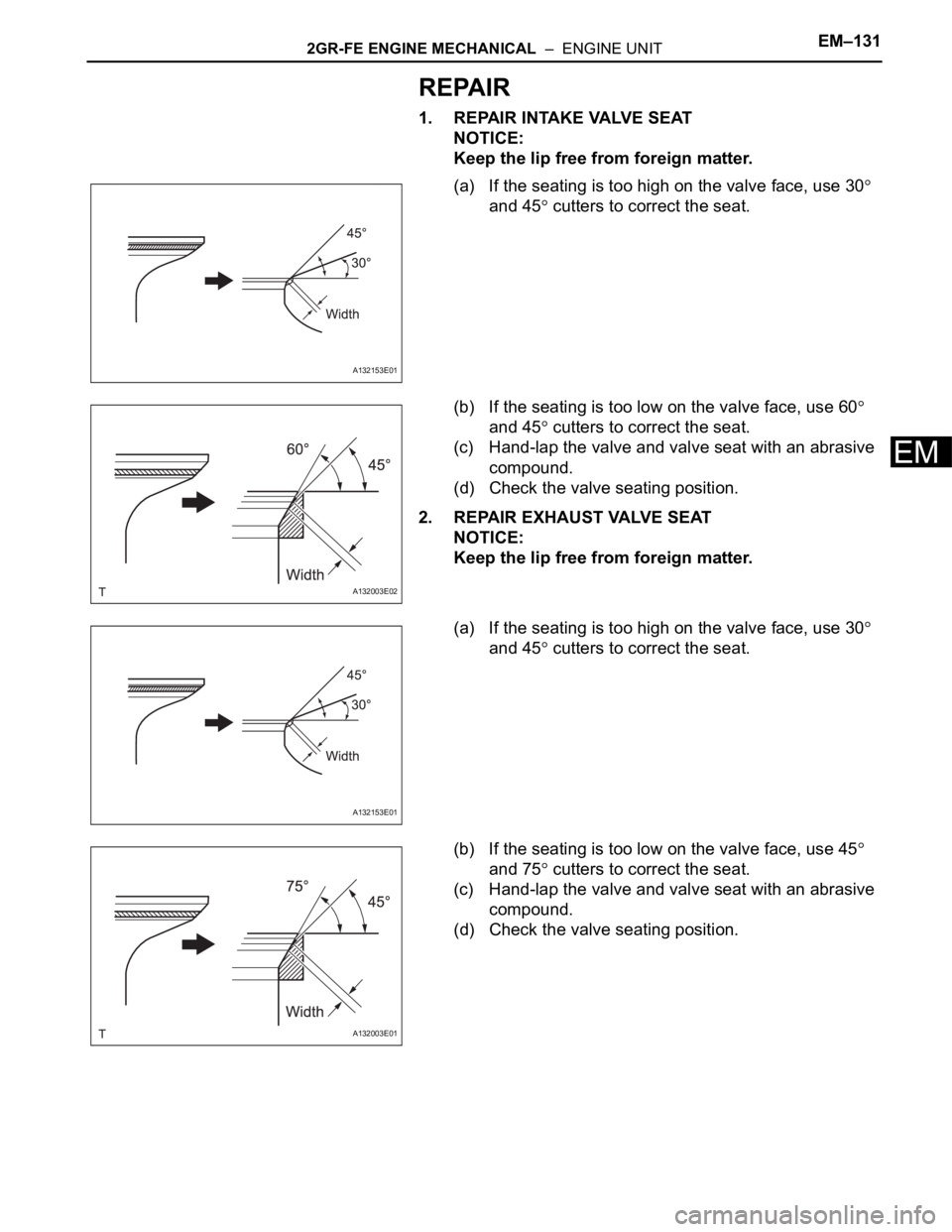

51. INSTALL CYLINDER HEAD COVER SUB-ASSEMBLY

(for Bank 2)

(a) Apply seal packing as shown in the illustration.

Seal packing:

Toyota Genuine Seal Packing Block, Three

Bond 1207B or Equivalent

NOTICE:

• Remove any oil from the contact surface.

• Install the crankcase within 3 minutes after

applying seal packing.

• Do not start the engine for at least 2 hours

after the installation.

(b) Install the gasket to the head cover.

A132236E01

A132119E01

A132173E01

A132237E01

Page 766 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–129

EM

(c) Install the head cover with the 12 bolts in the order

in the illastration.

Torque: 21 N*m (214 kgf*cm, 15 ft.*lbf) for bolt A

10 N*m (102 kgf*cm, 7 ft.*lbf) for except

bolt A

HINT:

Make sure the tightening torque of bolts 1 and 10 is

correct.

52. INSTALL NO. 1 OIL PIPE

(a) Make sure that there is no foreign matter on the

mesh of the oil control valve filter.

(b) Install the oil control valve filter to the oil pipe union.

Install 2 new gaskets and temporarily install the oil

pipe (on the head cover side) with the oil pipe union.

(c) Install a new gasket and temporarily install the oil

pipe (on the cylinder head side) with the oil pipe

union.

NOTICE:

Remove any oil from the contract surface.

(d) Tighten the 2 oil pipe union bolts.

Torque: 65 N*m (663 kgf*cm, 48 ft.*lbf)

53. INSTALL WATER OUTLET

(a) Install 2 new gaskets and a new O-ring.

(b) Apply soapy water to the O-ring.

(c) Install the water outlet with the 2 bolts and 4 nuts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

A132120E01

A132070

A129677

A129676

Page 767 of 2000

EM–1302GR-FE ENGINE MECHANICAL – ENGINE UNIT

EM

54. INSTALL CAMSHAFT TIMING OIL CONTROL VALVE

ASSEMBLY

(a) Install the 4 camshaft timing oil control valves with

the 4 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

55. INSTALL VVT SENSOR

(a) Install the 4 VVT sensors with the 4 bolts.

Torque: 10 N*m (102 kgf*cm, 7 ft.*lbf)

56. INSTALL SPARK PLUG

(a) Install the 6 spark plugs.

Torque: 18 N*m (184 kgf*cm, 13 ft.*lbf)

A131977E01

A131976E01

Page 768 of 2000

2GR-FE ENGINE MECHANICAL – ENGINE UNITEM–131

EM

REPAIR

1. REPAIR INTAKE VALVE SEAT

NOTICE:

Keep the lip free from foreign matter.

(a) If the seating is too high on the valve face, use 30

and 45

cutters to correct the seat.

(b) If the seating is too low on the valve face, use 60

and 45

cutters to correct the seat.

(c) Hand-lap the valve and valve seat with an abrasive

compound.

(d) Check the valve seating position.

2. REPAIR EXHAUST VALVE SEAT

NOTICE:

Keep the lip free from foreign matter.

(a) If the seating is too high on the valve face, use 30

and 45

cutters to correct the seat.

(b) If the seating is too low on the valve face, use 45

and 75

cutters to correct the seat.

(c) Hand-lap the valve and valve seat with an abrasive

compound.

(d) Check the valve seating position.

A132153E01

A132003E02

A132153E01

A132003E01

Page 769 of 2000

2AZ-FE FUEL – FUEL INJECTORFU–9

FU

REMOVAL

1. DISCHARGE FUEL SYSTEM PRESSURE

CAUTION:

• DISCHARGE FUEL SYSTEM PRESSURE

procedures must be performed before

disconnecting any part of the fuel system.

• After performing the DISCHARGE FUEL SYSTEM

PRESSURE procedures, pressure will remain in

the fuel line. When disconnecting the fuel line,

place a cloth or equivalent over fittings to reduce

the risk of fuel spray.

(a) Remove the console box (see page IR-83).

(b) Disconnect the connector.

(c) Start the engine. After the engine has stopped, turn

the ignition switch off.

HINT:

DTC P0171 (system too lean) may be set.

(d) Check that the engine does not start.

(e) Remove the fuel tank cap, and let the air out of the

fuel tank.

(f) Connect the connector.

(g) Install the console box (see page IR-90).

2. DISCONNECT CABLE FROM NEGATIVE BATTERY

TERMINAL

CAUTION:

Wait at least 90 seconds after disconnecting the

cable from the negative (-) battery terminal to

prevent airbag and seat belt pretensioner activation.

3. REMOVE NO. 1 ENGINE COVER (See page ES-410)

4. REMOVE AIR CLEANER CAP SUB-ASSEMBLY (See

page ES-411)

A128750E01

A128750E01

Page 770 of 2000

FU–102AZ-FE FUEL – FUEL INJECTOR

FU

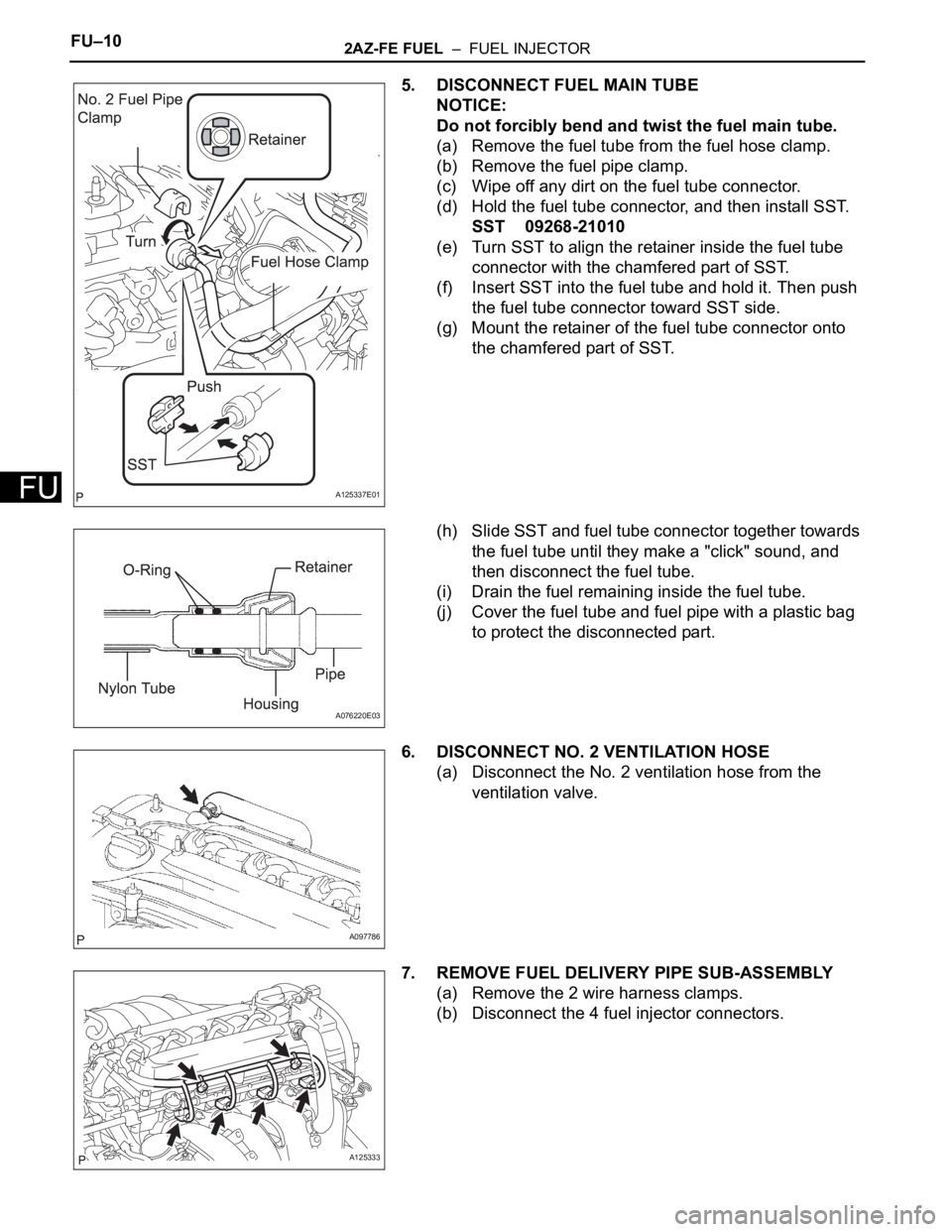

5. DISCONNECT FUEL MAIN TUBE

NOTICE:

Do not forcibly bend and twist the fuel main tube.

(a) Remove the fuel tube from the fuel hose clamp.

(b) Remove the fuel pipe clamp.

(c) Wipe off any dirt on the fuel tube connector.

(d) Hold the fuel tube connector, and then install SST.

SST 09268-21010

(e) Turn SST to align the retainer inside the fuel tube

connector with the chamfered part of SST.

(f) Insert SST into the fuel tube and hold it. Then push

the fuel tube connector toward SST side.

(g) Mount the retainer of the fuel tube connector onto

the chamfered part of SST.

(h) Slide SST and fuel tube connector together towards

the fuel tube until they make a "click" sound, and

then disconnect the fuel tube.

(i) Drain the fuel remaining inside the fuel tube.

(j) Cover the fuel tube and fuel pipe with a plastic bag

to protect the disconnected part.

6. DISCONNECT NO. 2 VENTILATION HOSE

(a) Disconnect the No. 2 ventilation hose from the

ventilation valve.

7. REMOVE FUEL DELIVERY PIPE SUB-ASSEMBLY

(a) Remove the 2 wire harness clamps.

(b) Disconnect the 4 fuel injector connectors.

A125337E01

A076220E03

A097786

A125333