ACURA NSX 1997 Service Repair Manual

Manufacturer: ACURA, Model Year: 1997, Model line: NSX, Model: ACURA NSX 1997Pages: 1503, PDF Size: 57.08 MB

Page 1051 of 1503

TCS Indicato r Ligh t

Troubleshootin g

Temporary Drivin g Conditions :

1 . Th e TC S indicato r ligh t wil l com e o n an d th e contro l uni t memorize s th e Diagnosti c Troubl e Cod e (DTC ) unde r certai n

temporar y conditions :

• Th e spar e tir e is installed , o r a tir e o f th e imprope r siz e is installed .

• Th e tir e pressure s ar e no t correct .

2 . I f th e TC S indicato r ligh t doe s no t com e bac k o n afte r correctin g th e tir e o r tir e pressur e problem , th e TC S syste m is

OK .

3. Remov e th e CLOC K (7. 5 A ) fus e fo r a t leas t thre e second s t o clea r th e DT C fro m th e TC S contro l uni t memory .

NOTE : Disconnectin g th e CLOC K fus e als o cancel s th e radi o prese t station s an d th e cloc k setting . Mak e not e o f th e

radi o preset s befor e removin g th e fus e s o yo u ca n rese t them .

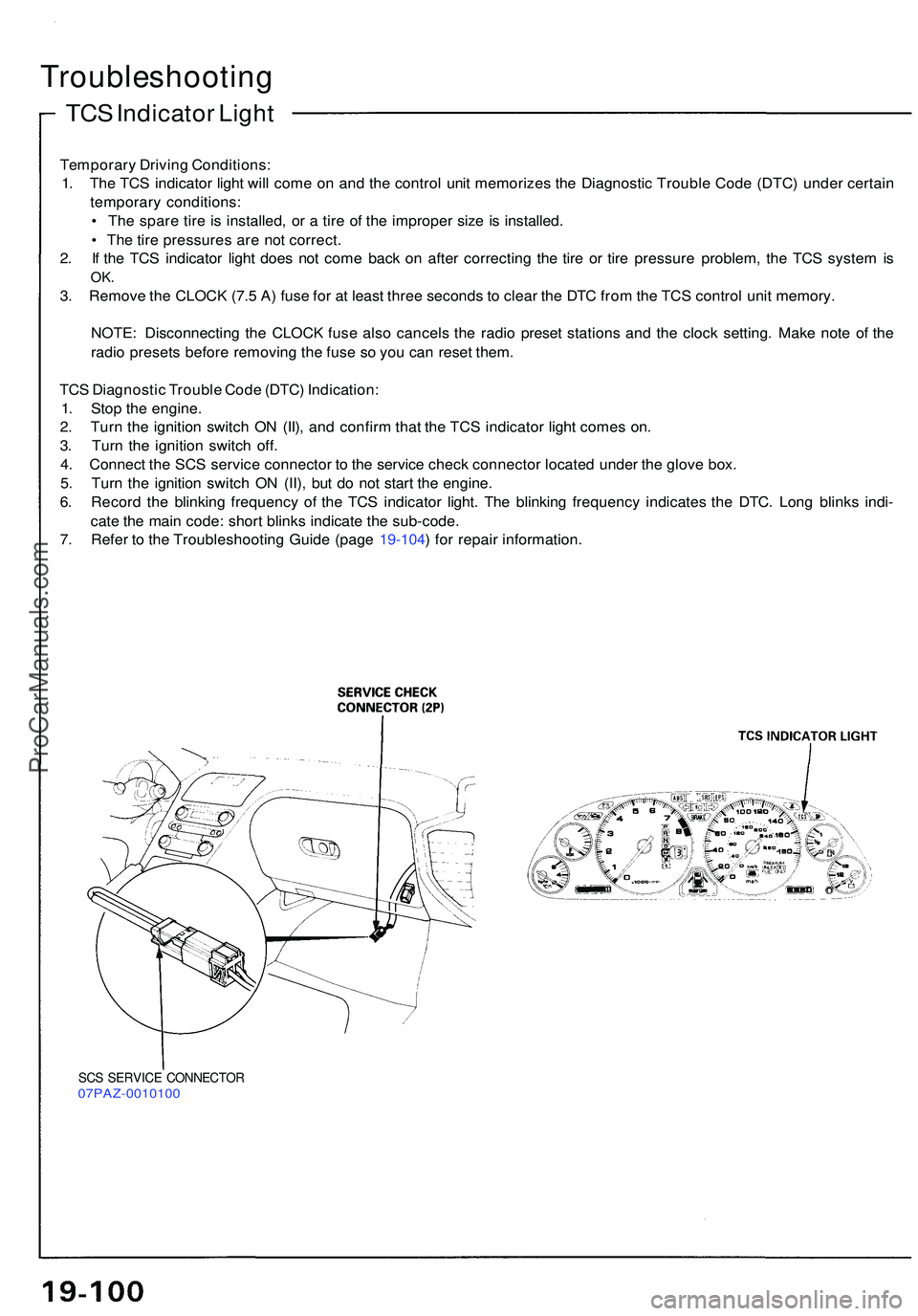

TC S Diagnosti c Troubl e Cod e (DTC ) Indication :

1 . Sto p th e engine .

2 . Tur n th e ignitio n switc h O N (II) , an d confir m tha t th e TC S indicato r ligh t come s on .

3 . Tur n th e ignitio n switc h off .

4 . Connec t th e SC S servic e connecto r t o th e servic e chec k connecto r locate d unde r th e glov e box .

5 . Tur n th e ignitio n switc h O N (II) , bu t d o no t star t th e engine .

6 . Recor d th e blinkin g frequenc y o f th e TC S indicato r light . Th e blinkin g frequenc y indicate s th e DTC . Lon g blink s indi -

cat e th e mai n code : shor t blink s indicat e th e sub-code .

7 . Refe r t o th e Troubleshootin g Guid e (pag e 19-104 ) fo r repai r information .

SCS SERVIC E CONNECTO R07PAZ-001010 0

ProCarManuals.com

Page 1052 of 1503

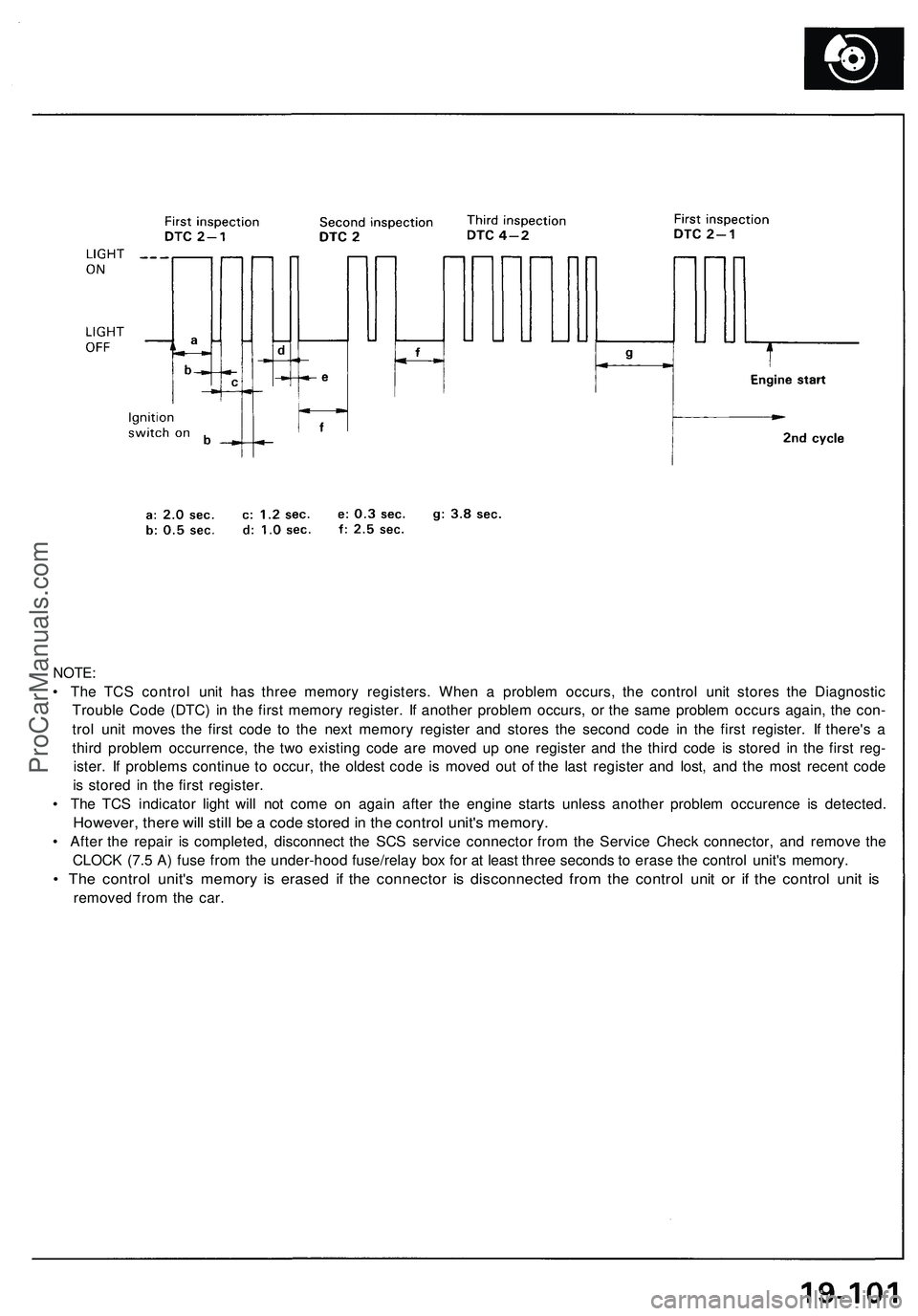

NOTE:

• The TCS control unit has three memory registers. When a problem occurs, the control unit stores the Diagnostic

Trouble Code (DTC) in the first memory register. If another problem occurs, or the same problem occurs again, the con-

trol unit moves the first code to the next memory register and stores the second code in the first register. If there's a

third problem occurrence, the two existing code are moved up one register and the third code is stored in the first reg-

ister. If problems continue to occur, the oldest code is moved out of the last register and lost, and the most recent code

is stored in the first register.

• The TCS indicator light will not come on again after the engine starts unless another problem occurence is detected.

However, there will still be a code stored in the control unit's memory.

• After the repair is completed, disconnect the SCS service connector from the Service Check connector, and remove the

CLOCK (7.5 A) fuse from the under-hood fuse/relay box for at least three seconds to erase the control unit's memory.

• The control unit's memory is erased if the connector is disconnected from the control unit or if the control unit is

removed from the car.ProCarManuals.com

Page 1053 of 1503

19-103

19-105

19-106

19-107

19-110

19-113

19-116

19-118

19-119

19-121

19-122

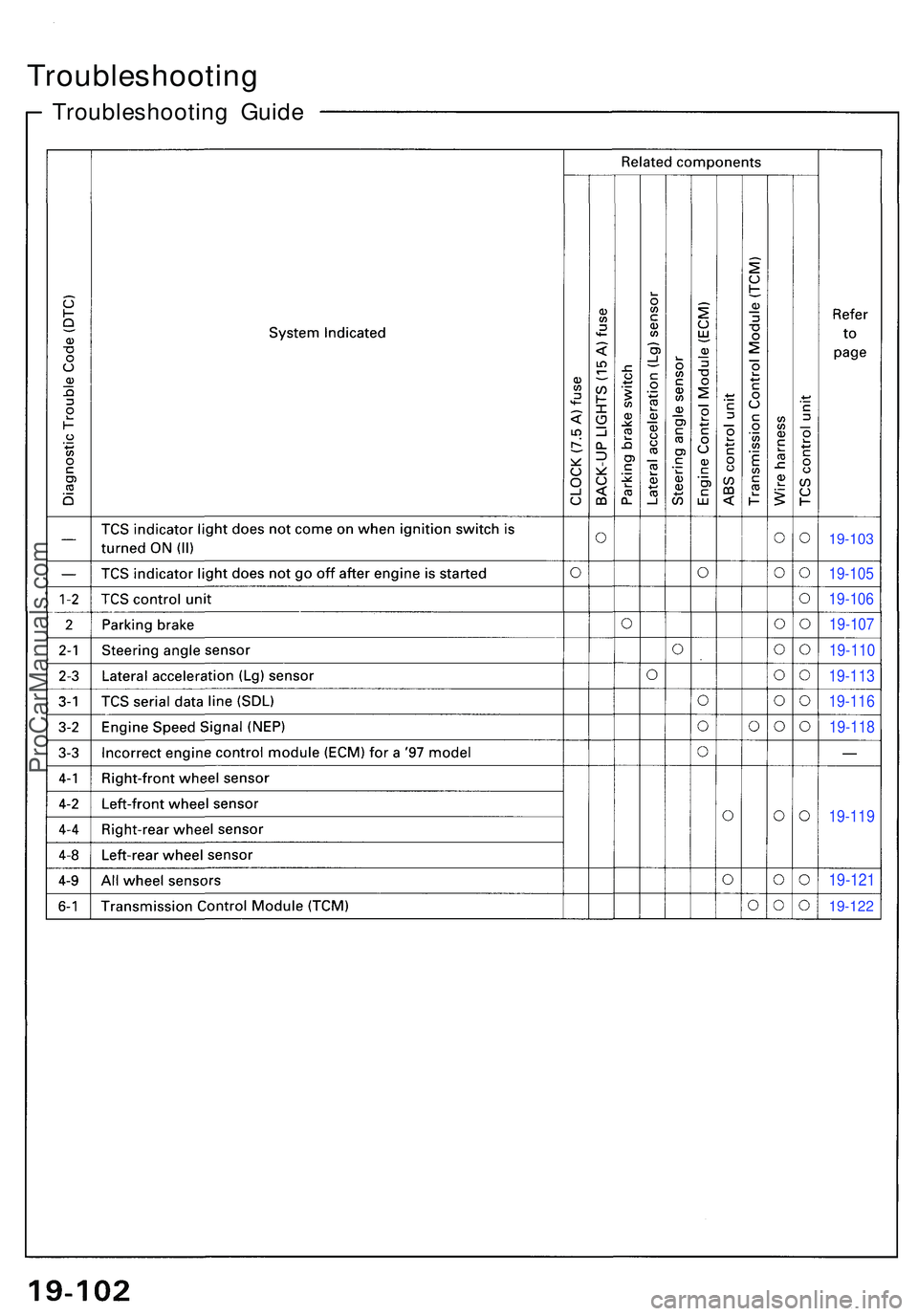

Troubleshootin g Guid e

Troubleshootin g

ProCarManuals.com

Page 1054 of 1503

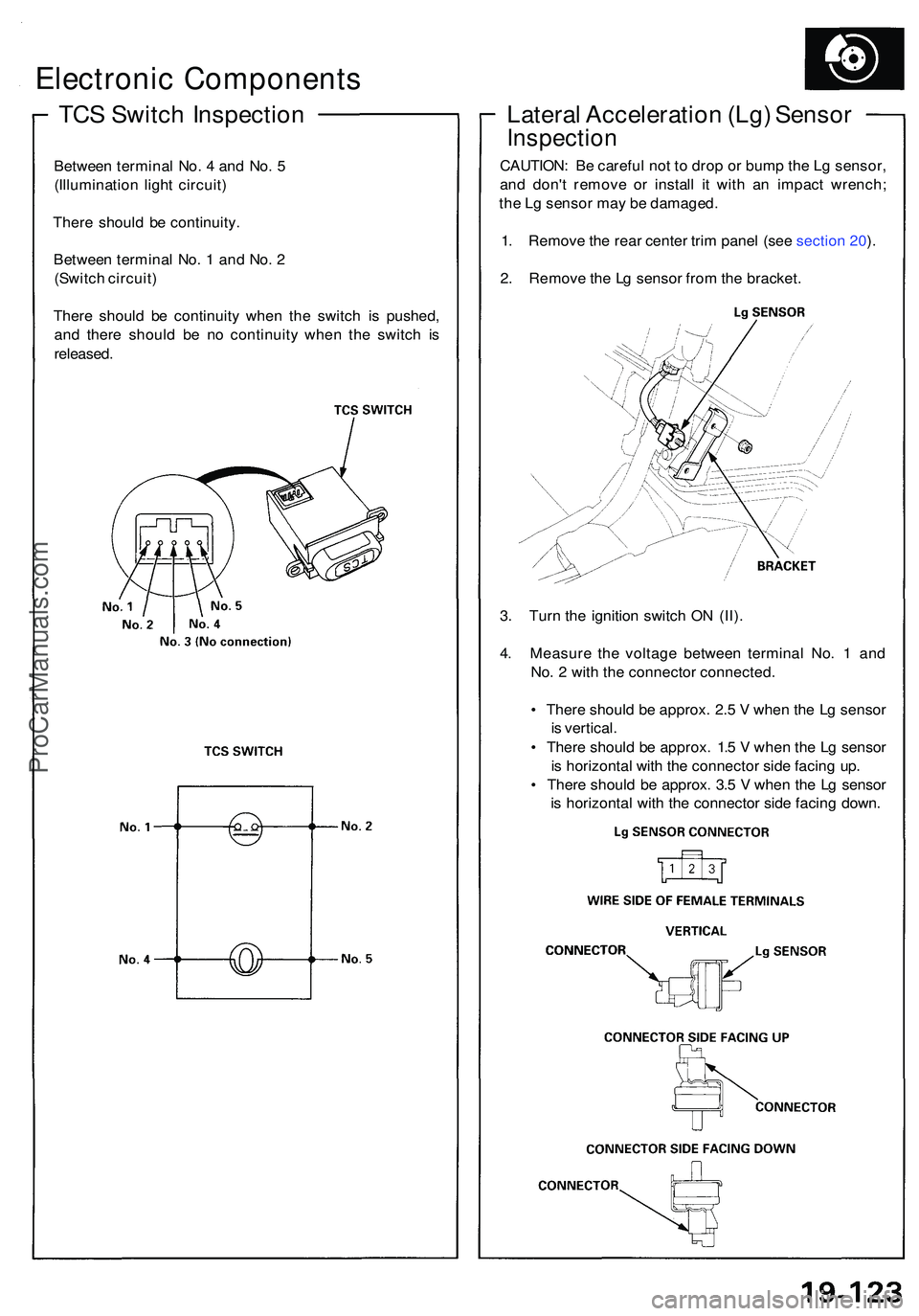

TCS Switc h Inspectio n

Electronic Component s

Between termina l No . 4 an d No . 5

(Illuminatio n ligh t circuit )

Ther e shoul d b e continuity .

Betwee n termina l No . 1 an d No . 2

(Switc h circuit )

Ther e shoul d b e continuit y whe n th e switc h i s pushed ,

an d ther e shoul d b e n o continuit y whe n th e switc h i s

released .

Lateral Acceleratio n (Lg ) Senso r

Inspectio n

CAUTION : B e carefu l no t t o dro p o r bum p th e L g sensor ,

an d don' t remov e o r instal l i t wit h a n impac t wrench ;

th e L g senso r ma y b e damaged .

1 . Remov e th e rea r cente r tri m pane l (se e sectio n 20 ).

2 . Remov e th e L g senso r fro m th e bracket .

3 . Tur n th e ignitio n switc h O N (II) .

4 . Measur e th e voltag e betwee n termina l No . 1 an d

No . 2 wit h th e connecto r connected .

• Ther e shoul d b e approx . 2. 5 V whe n th e L g senso r

i s vertical .

• Ther e shoul d b e approx . 1. 5 V whe n th e L g senso r

i s horizonta l wit h th e connecto r sid e facin g up .

• Ther e shoul d b e approx . 3. 5 V whe n th e L g senso r

i s horizonta l wit h th e connecto r sid e facin g down .

ProCarManuals.com

Page 1055 of 1503

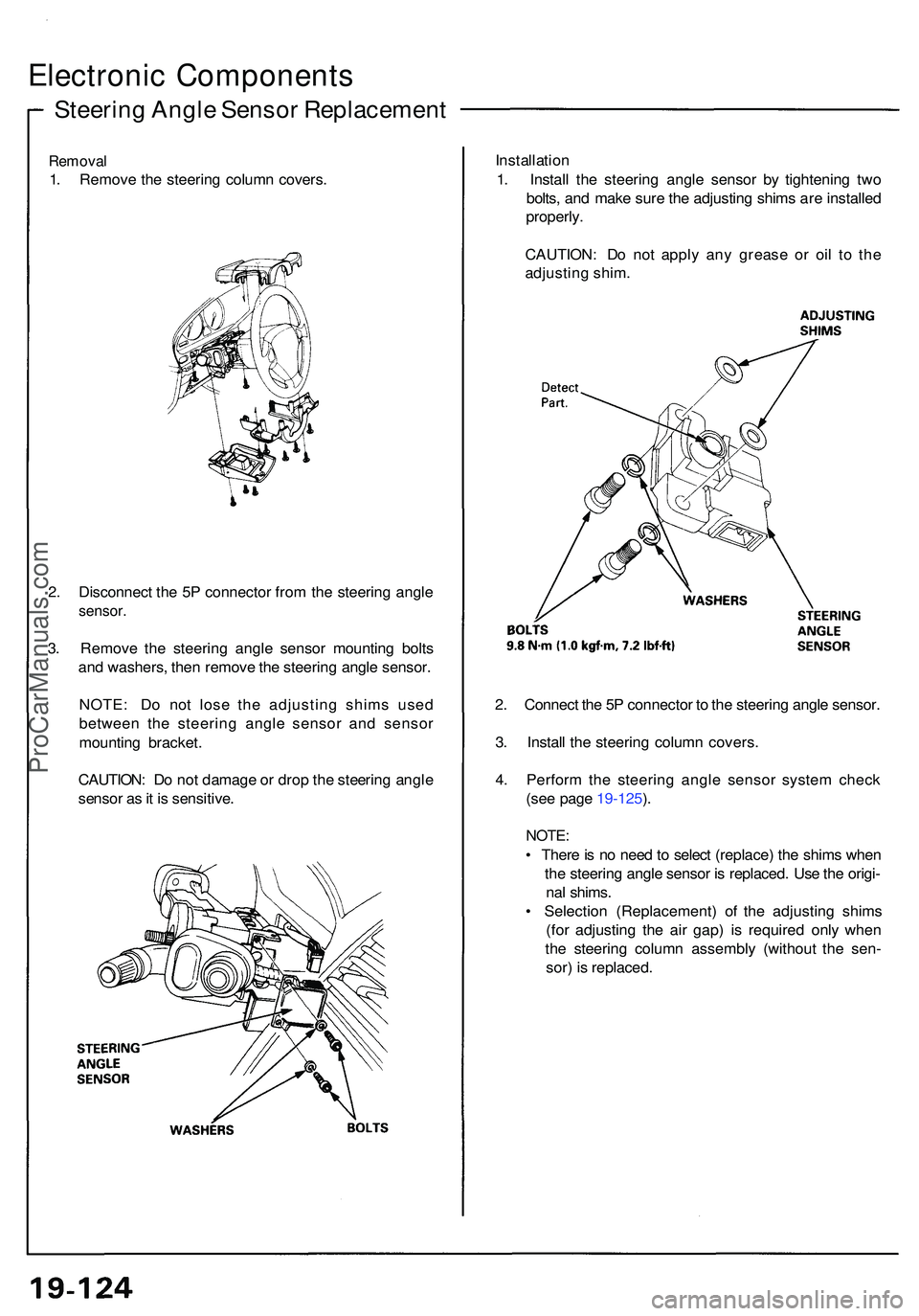

Steering Angl e Senso r Replacemen t

Electronic Component s

Removal

1. Remov e th e steerin g colum n covers . Installatio

n

1 . Instal l th e steerin g angl e senso r b y tightenin g tw o

bolts , an d mak e sur e th e adjustin g shim s ar e installe d

properly .

CAUTION : D o no t appl y an y greas e o r oi l t o th e

adjustin g shim .

2 . Connec t th e 5 P connecto r t o th e steerin g angl e sensor .

3 . Instal l th e steerin g colum n covers .

4 . Perfor m th e steerin g angl e senso r syste m chec k

(se e page 19-125 ).

NOTE :

• Ther e is n o nee d to selec t (replace ) th e shim s whe n

th e steerin g angl e senso r i s replaced . Us e th e origi -

na l shims .

• Selectio n (Replacement ) o f th e adjustin g shim s

(fo r adjustin g th e ai r gap ) i s require d onl y whe n

th e steerin g colum n assembl y (withou t th e sen -

sor ) i s replaced .

2

. Disconnec t th e 5 P connecto r fro m th e steerin g angl e

sensor .

3. Remov e th e steerin g angl e senso r mountin g bolt s

an d washers , the n remov e th e steerin g angl e sensor .

NOTE : D o no t los e th e adjustin g shim s use d

betwee n th e steerin g angl e senso r an d senso r

mountin g bracket .

CAUTION : D o no t damag e o r dro p th e steerin g angl e

senso r a s it i s sensitive .

ProCarManuals.com

Page 1056 of 1503

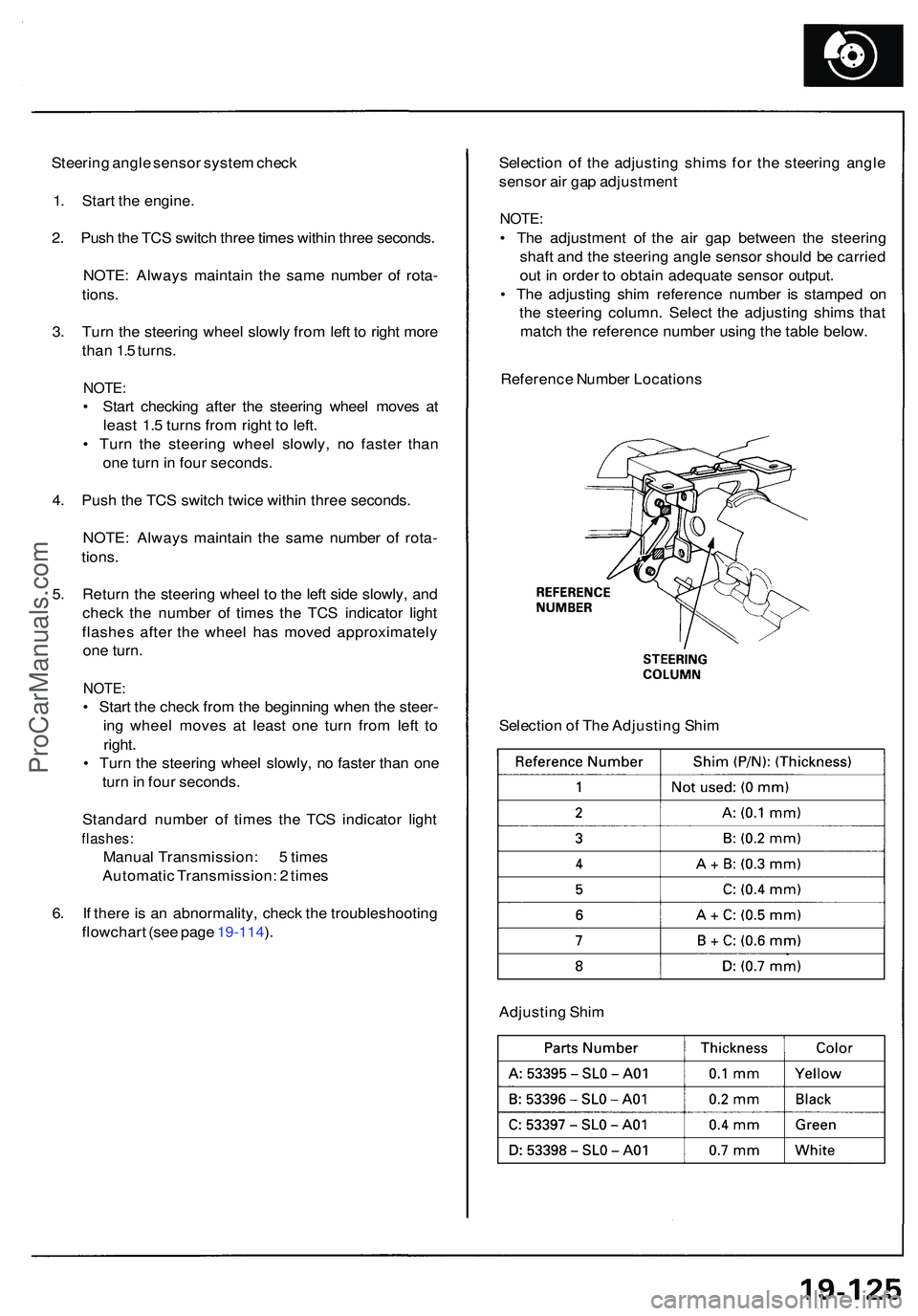

Steering angl e senso r syste m chec k

1 . Star t th e engine .

2 . Pus h th e TC S switc h thre e time s withi n thre e seconds .

NOTE : Alway s maintai n th e sam e numbe r o f rota -

tions .

3 . Tur n th e steerin g whee l slowl y fro m lef t t o righ t mor e

tha n 1. 5 turns .

NOTE :

• Star t checkin g afte r th e steerin g whee l move s a t

leas t 1. 5 turn s fro m righ t t o left .

• Tur n th e steerin g whee l slowly , n o faste r tha n

on e tur n in fou r seconds .

4 . Pus h th e TC S switc h twic e withi n thre e seconds .

NOTE : Alway s maintai n th e sam e numbe r o f rota -

tions .

5 . Retur n th e steerin g whee l t o th e lef t sid e slowly , an d

chec k th e numbe r o f time s th e TC S indicato r ligh t

flashe s afte r th e whee l ha s move d approximatel y

on e turn .

NOTE :

• Star t th e chec k fro m th e beginnin g whe n th e steer -

in g whee l move s a t leas t on e tur n fro m lef t t o

right .

• Tur n th e steerin g whee l slowly , n o faste r tha n on e

tur n in fou r seconds .

Standar d numbe r o f time s th e TC S indicato r ligh t

flashes :

Manual Transmission : 5 time s

Automati c Transmission : 2 time s

6 . I f ther e is a n abnormality , chec k th e troubleshootin g

flowchar t (se e pag e 19-114 ). Selectio

n o f th e adjustin g shim s fo r th e steerin g angl e

senso r ai r ga p adjustmen t

NOTE:

• Th e adjustmen t o f th e ai r ga p betwee n th e steerin g

shaf t an d th e steerin g angl e senso r shoul d b e carrie d

ou t i n orde r t o obtai n adequat e senso r output .

• Th e adjustin g shi m referenc e numbe r i s stampe d o n

th e steerin g column . Selec t th e adjustin g shim s tha t

matc h th e referenc e numbe r usin g th e tabl e below .

Referenc e Numbe r Location s

Selectio n o f Th e Adjustin g Shi m

Adjustin g Shi m

ProCarManuals.com

Page 1057 of 1503

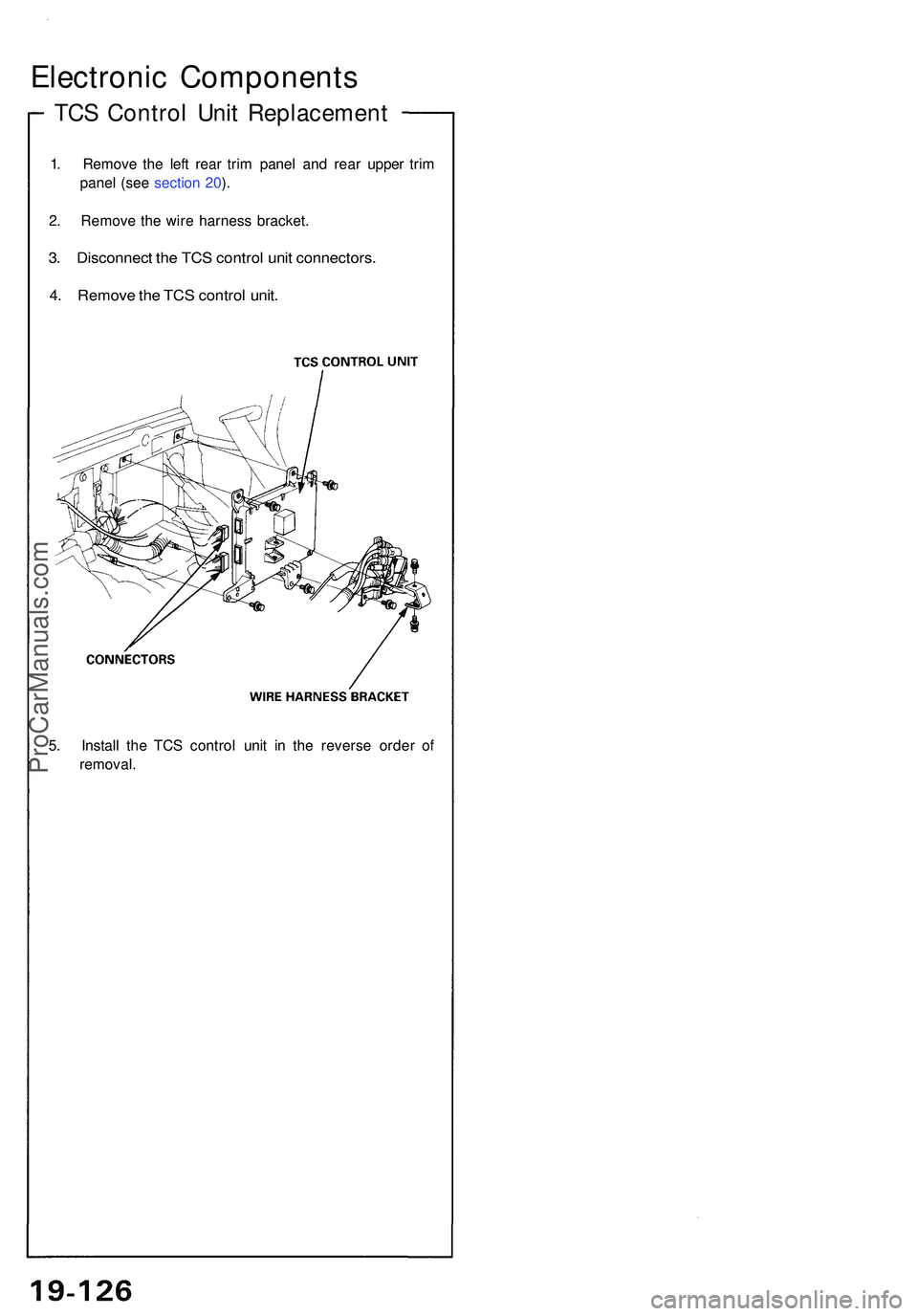

TCS Contro l Uni t Replacemen t

Electronic Component s

1. Remov e th e lef t rea r tri m pane l an d rea r uppe r tri m

pane l (se e sectio n 20 ).

2 . Remov e th e wir e harnes s bracket .

3. Disconnec t th e TC S contro l uni t connectors .

4 . Remov e th e TC S contro l unit .

5. Instal l th e TC S contro l uni t i n th e revers e orde r o f

removal .

ProCarManuals.com

Page 1058 of 1503

20-55, 20-5 6

Specia l Tool s

ProCarManuals.com

Page 1059 of 1503

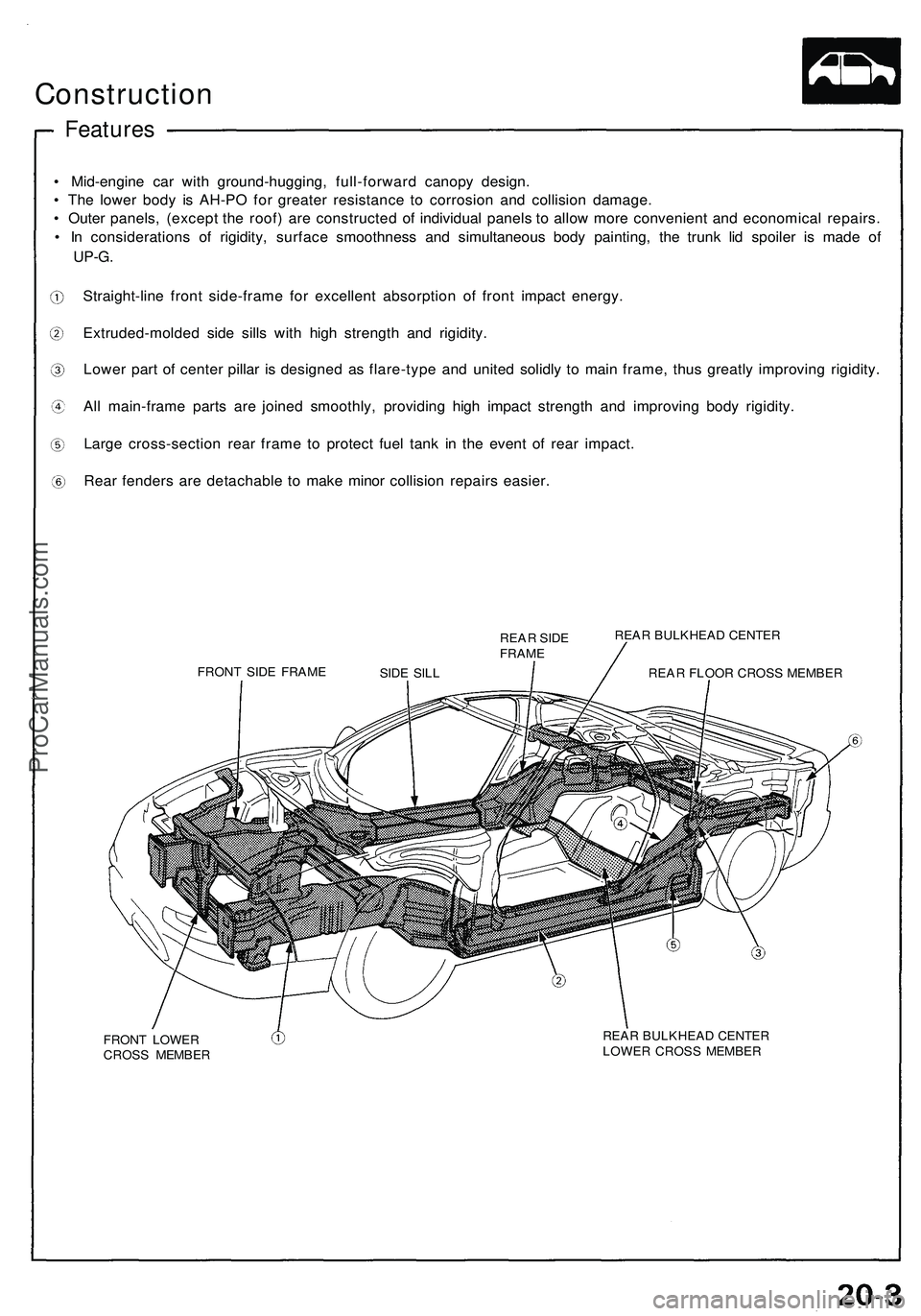

Construction

• Mid-engin e ca r wit h ground-hugging , full-forwar d canop y design .

• Th e lowe r bod y i s AH-P O fo r greate r resistanc e t o corrosio n an d collisio n damage .

• Oute r panels , (excep t th e roof ) ar e constructe d o f individua l panel s t o allo w mor e convenien t an d economica l repairs .

• I n consideration s o f rigidity , surfac e smoothnes s an d simultaneou s bod y painting , th e trun k li d spoile r i s mad e of

UP-G .

Straight-lin e fron t side-fram e fo r excellen t absorptio n o f fron t impac t energy .

Extruded-molde d sid e sill s wit h hig h strengt h an d rigidity .

Lowe r par t of cente r pilla r i s designe d a s flare-typ e an d unite d solidl y t o mai n frame , thu s greatl y improvin g rigidity .

Al l main-fram e part s ar e joine d smoothly , providin g hig h impac t strengt h an d improvin g bod y rigidity .

Larg e cross-sectio n rea r fram e t o protec t fue l tan k i n th e even t o f rea r impact .

Rear fender s ar e detachabl e t o mak e mino r collisio n repair s easier .

REAR SID E

FRAM E

FRON T SID E FRAM E REA

R BULKHEA D CENTE R

REA R FLOO R CROS S MEMBE R

FRON T LOWE R

CROS S MEMBE R REA

R BULKHEA D CENTE R

LOWE R CROS S MEMBE R

Features

SIDE SIL L

ProCarManuals.com

Page 1060 of 1503

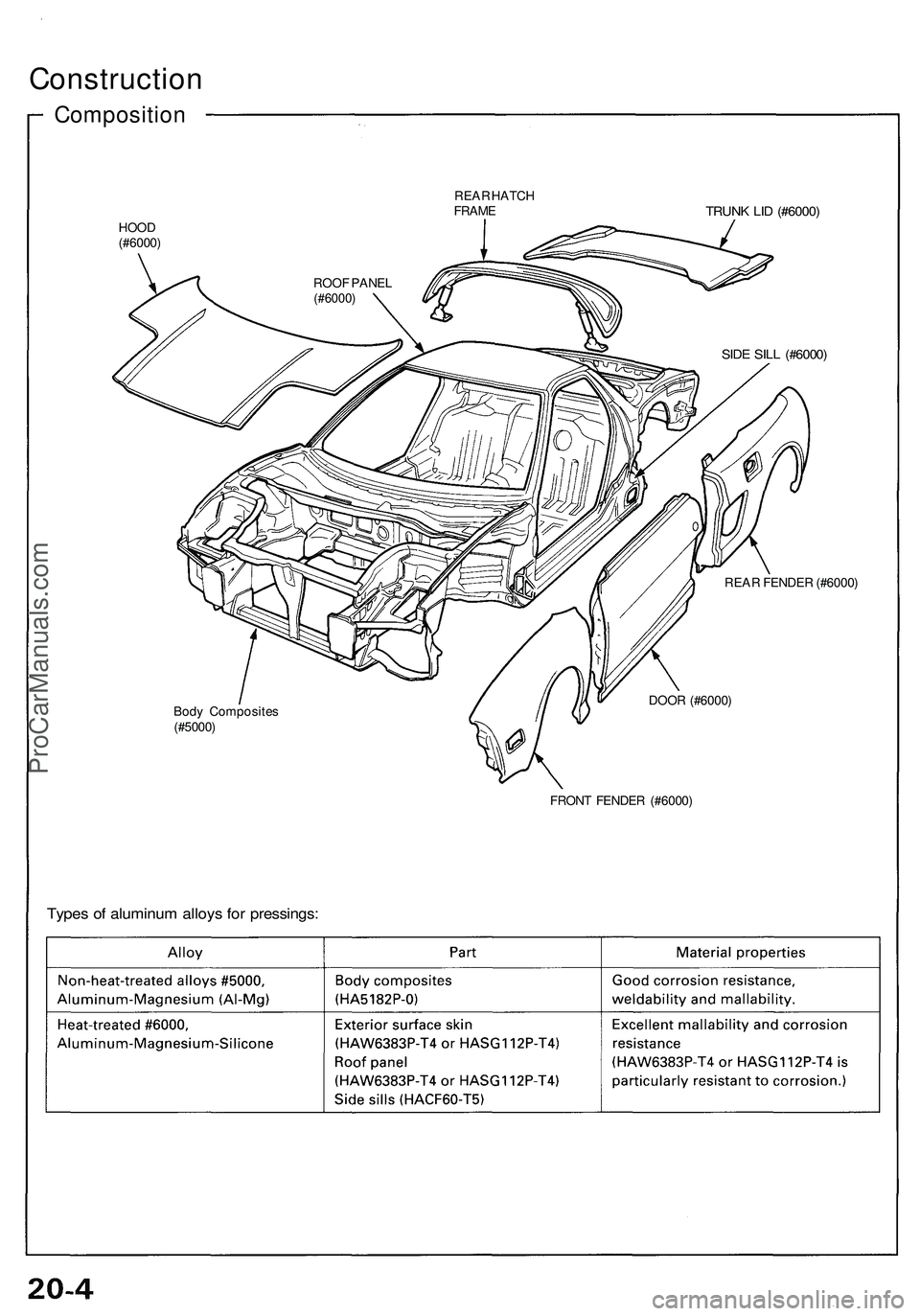

Construction

Composition

REAR HATCH

FRAME

TRUNK LID (#6000)

HOOD

(#6000)

SIDE SILL (#6000)

REAR FENDER (#6000)

Body Composites

(#5000)

DOOR (#6000)

FRONT FENDER (#6000)

Types of aluminum alloys for pressings:

ROOF PANEL

(#6000)ProCarManuals.com