ACURA RL KA9 1996 Service Repair Manual

Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 351 of 1954

Charging System

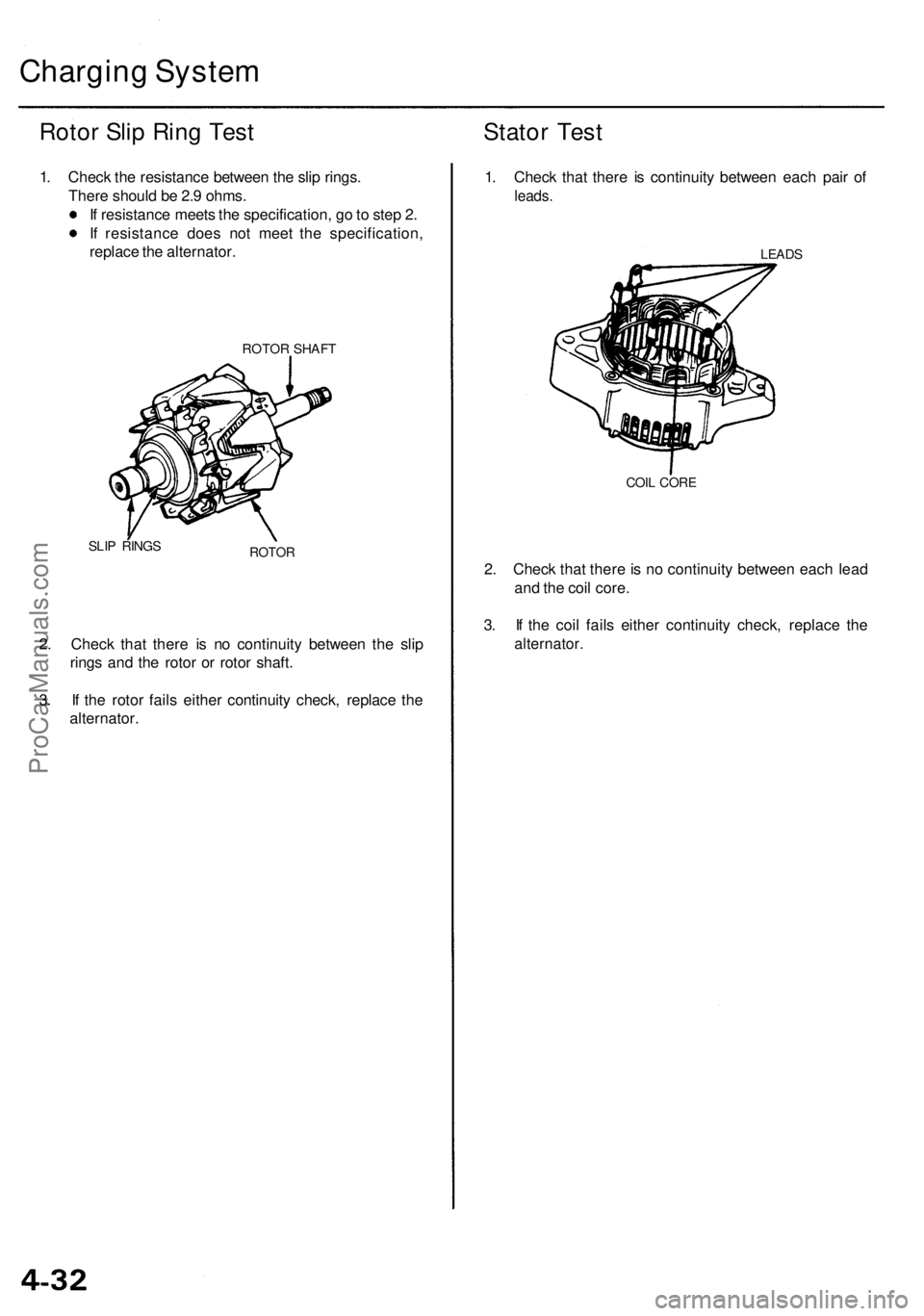

Rotor Slip Ring Test

1. Check the resistance between the slip rings.

There should be 2.9 ohms.

If resistance meets the specification, go to step 2.

If resistance does not meet the specification,

replace the alternator.

ROTOR SHAFT

SLIP RINGS

ROTOR

2. Check that there is no continuity between the slip

rings and the rotor or rotor shaft.

3. If the rotor fails either continuity check, replace the

alternator.

Stator Test

1. Check that there is continuity between each pair of

leads.

LEADS

COIL CORE

2. Check that there is no continuity between each lead

and the coil core.

3. If the coil fails either continuity check, replace the

alternator.ProCarManuals.com

Page 352 of 1954

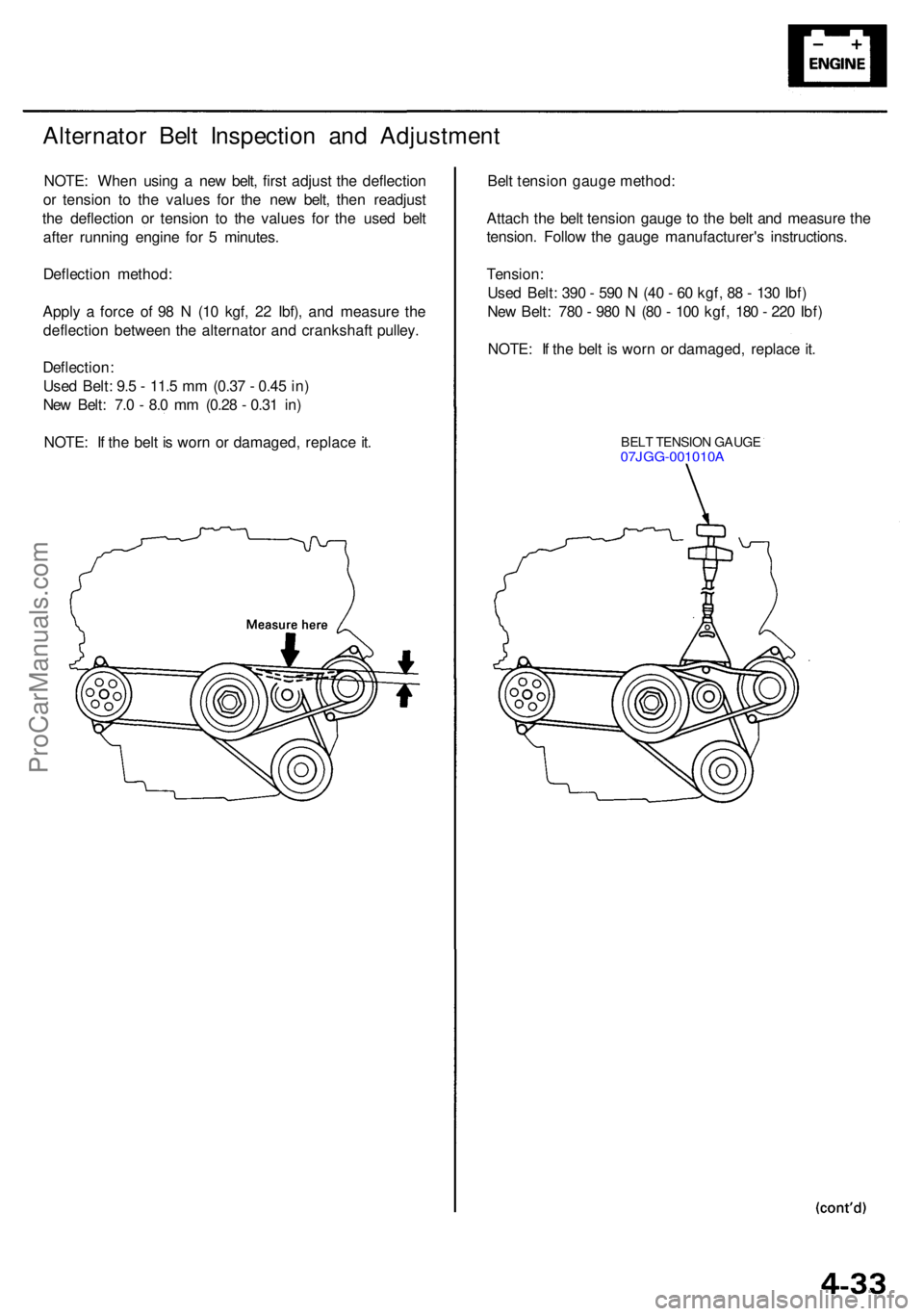

Alternator Bel t Inspectio n an d Adjustmen t

NOTE: Whe n usin g a ne w belt , firs t adjus t th e deflectio n

o r tensio n t o th e value s fo r th e ne w belt , the n readjus t

th e deflectio n o r tensio n t o th e value s fo r th e use d bel t

afte r runnin g engin e fo r 5 minutes .

Deflectio n method :

Appl y a forc e o f 9 8 N (1 0 kgf , 2 2 Ibf) , an d measur e th e

deflectio n betwee n th e alternato r an d crankshaf t pulley .

Deflection :

Use d Belt : 9. 5 - 11. 5 m m (0.3 7 - 0.4 5 in )

Ne w Belt : 7. 0 - 8. 0 m m (0.2 8 - 0.3 1 in )

NOTE : I f th e bel t i s wor n o r damaged , replac e it . Bel

t tensio n gaug e method :

Attac h th e bel t tensio n gaug e t o th e bel t an d measur e th e

tension . Follo w th e gaug e manufacturer' s instructions .

Tension :

Use d Belt : 39 0 - 59 0 N (4 0 - 6 0 kgf , 8 8 - 13 0 Ibf )

Ne w Belt : 78 0 - 98 0 N (8 0 - 10 0 kgf , 18 0 - 22 0 Ibf )

NOTE : I f th e bel t i s wor n o r damaged , replac e it .

BEL T TENSIO N GAUG E07JGG-001010 A

ProCarManuals.com

Page 353 of 1954

Charging Syste m

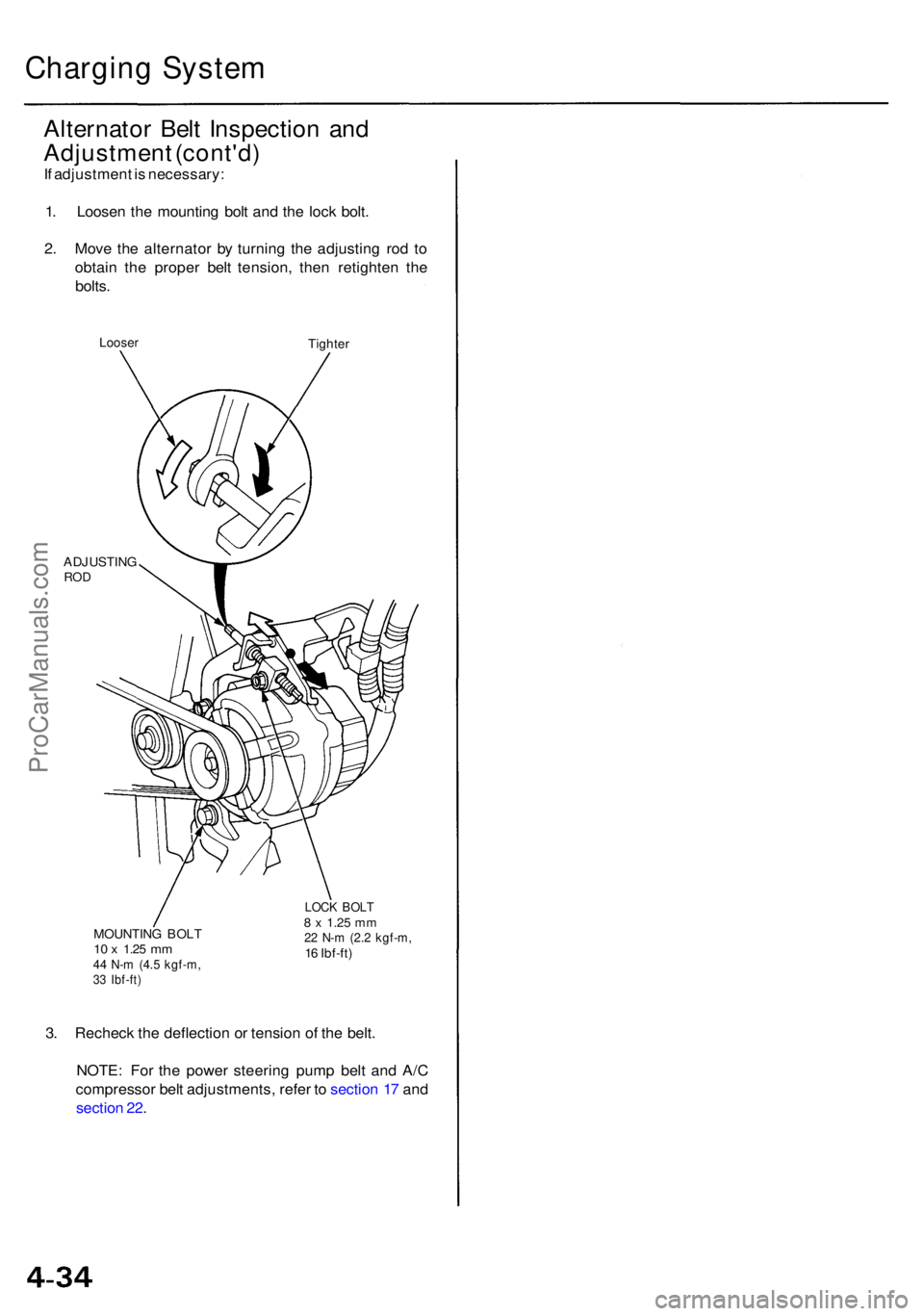

Alternato r Bel t Inspectio n an d

Adjustmen t (cont'd )

If adjustmen t i s necessary :

1 . Loose n th e mountin g bol t an d th e loc k bolt .

2 . Mov e th e alternato r b y turnin g th e adjustin g ro d t o

obtai n th e prope r bel t tension , the n retighte n th e

bolts .

Loose rTighte r

ADJUSTIN G

ROD

MOUNTIN G BOL T10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,33 Ibf-ft )

LOCK BOL T8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,16 Ibf-ft )

3. Rechec k th e deflectio n o r tensio n o f th e belt .

NOTE : Fo r th e powe r steerin g pum p bel t an d A/ C

compresso r bel t adjustments , refe r t o sectio n 1 7 an d

sectio n 22 .

ProCarManuals.com

Page 354 of 1954

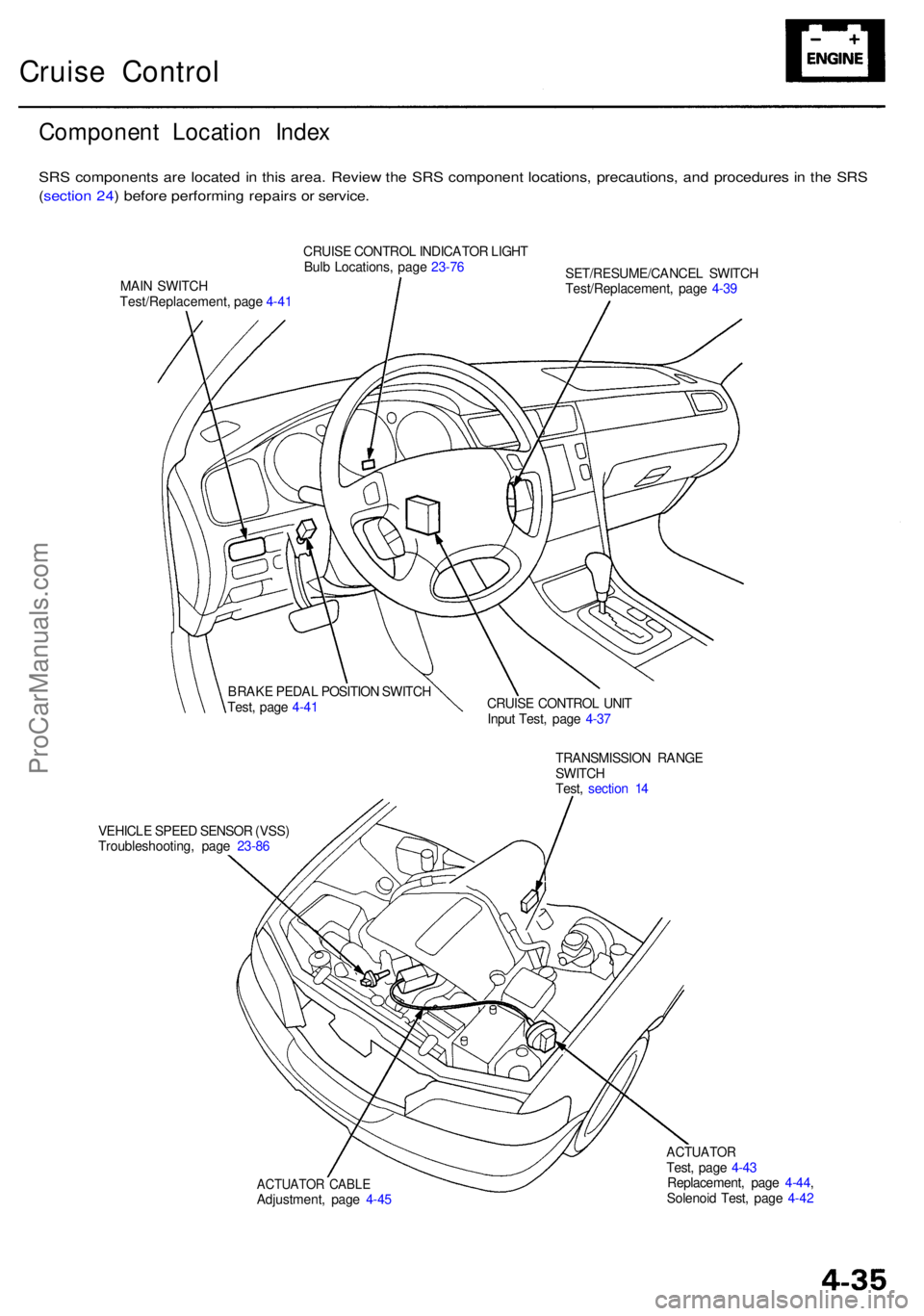

Cruise Contro l

Componen t Locatio n Inde x

SRS component s ar e locate d i n thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s i n th e SR S

( sectio n 24 ) befor e performin g repair s o r service .

CRUISE CONTRO L INDICATO R LIGH T

Bul b Locations , pag e 23-7 6

MAI N SWITC H

Test/Replacement , pag e 4-4 1 SET/RESUME/CANCE

L SWITC H

Test/Replacement , pag e 4-3 9

CRUIS E CONTRO L UNI T

Inpu t Test , pag e 4-3 7

VEHICL E SPEE D SENSO R (VSS )

Troubleshooting , pag e 23-86 TRANSMISSIO

N RANG E

SWITC H

Test , sectio n 1 4

ACTUATO R CABL EAdjustment , pag e 4-4 5

ACTUATO RTest, pag e 4-4 3

Replacement , pag e 4-44 ,

Solenoi d Test , pag e 4-4 2

BRAK

E PEDA L POSITIO N SWITC H

Test , pag e 4-4 1

ProCarManuals.com

Page 355 of 1954

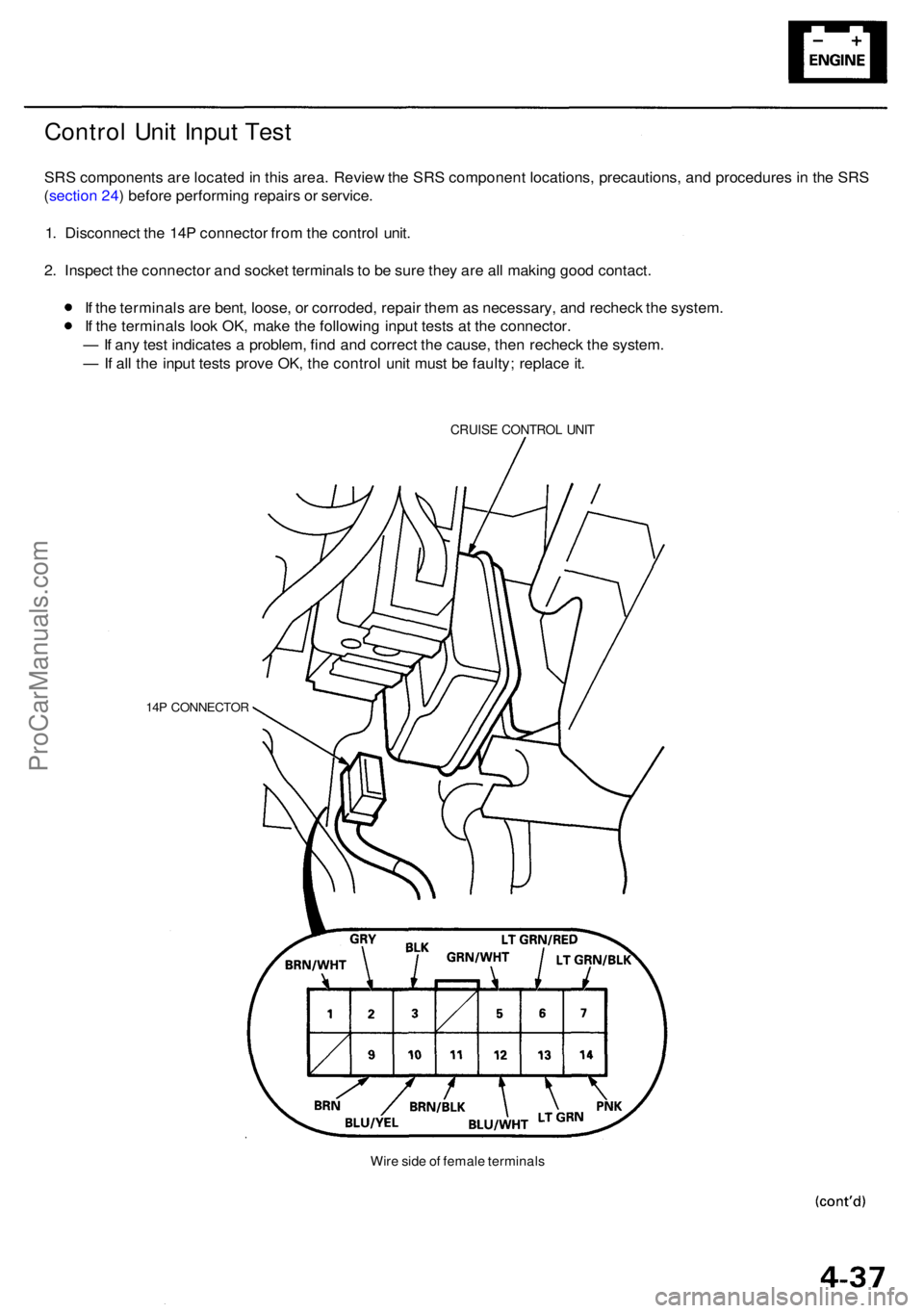

Control Uni t Inpu t Tes t

SRS component s ar e locate d in thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s i n th e SR S

( sectio n 24 ) befor e performin g repair s o r service .

1 . Disconnec t th e 14 P connecto r fro m th e contro l unit .

2 . Inspec t th e connecto r an d socke t terminal s t o b e sur e the y ar e al l makin g goo d contact .

I f th e terminal s ar e bent , loose , o r corroded , repai r the m as necessary , an d rechec k th e system .

I f th e terminal s loo k OK , mak e th e followin g inpu t test s a t th e connector .

— If an y tes t indicate s a problem , fin d an d correc t th e cause , the n rechec k th e system .

— If al l th e inpu t test s prov e OK , th e contro l uni t mus t b e faulty ; replac e it .

CRUIS E CONTRO L UNI T

14P CONNECTO R

Wire sid e o f femal e terminal s

ProCarManuals.com

Page 356 of 1954

Cruise Control

Control Unit Input Test (cont'd)

Cavity Wire

Test condition

Test: Desired result

Possible cause if result is not obtained

3

13

7

6

14

12

2

5

10

9

11

1

BLK

LT GRN

LT GRN/BLK

LT GRN/RED

PNK

BLU/WHT

GRY

GRN/WHT

BLU/YEL

BRN

BRN/BLK

BRN/WHT

Under all conditions

Ignition switch ON (II) and

main switch ON

Resume button pushed

Cancel button pushed

Set button pushed

Cancel button pushed

Shift lever in , or

Ignition switch ON (II), and

main switch ON; raise the

front of the vehicle, and rotate

one wheel slowly while

holding the other wheel.

Ignition switch ON (II), main

switch ON; brake pedal

pressed, then released

Brake pedal pressed then

released

Ignition switch ON (II)

Under all conditions

Under all conditions

Under all conditions

Check for continuity to ground:

There should be continuity.

Check for voltage to ground:

There should be battery voltage.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 7, there

should be no voltage on terminal No. 6.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 7, there

should be voltage on terminal No. 6.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 6, there

should be no voltage on terminal No. 7.

Check for voltage to ground:

There should be battery voltage.

When testing terminal No. 6, there

should be voltage on terminal No. 7.

Check for continuity to ground:

There should be continuity.

NOTE: There should be no continuity

when the shift lever is in other positions.

Check for voltage between the

BLU/ WHT and BLK terminals:

There should be cycle 0 - 5 V or

battery voltage.

Check for voltage to ground:

There should be 0 V with the pedal

pressed, and battery voltage with

the pedal released.

Check for voltage to ground:

There should be battery voltage with

the pedal pressed, and 0 V with the

pedal released.

Attach to ground:

The cruise light in the gauge assembly

should come on.

Check for resistance to ground:

There should be 80 -120

Check for resistance to ground:

There should be 70 -110

Check for resistance to ground:

There should be 40 - 60

• Poor ground (G401, G402)

• An open in the wire

• Blown No. 20 (20 A) fuse in the

under-dash fuse/relay box

• Faulty main switch

• An open in the wire

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Short between LT GRN/BLK and

LT GRN/RED wires

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Short between LT GRN/BLK and

LT GRN/RED wires

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty horn relay

• Faulty set/resume/cancel switch

• Faulty cable reel

• An open in the wire

• Faulty A/T gear position switch

• Poor ground (G401, G402)

• An open in the wire

• Faulty vehicle speed sensor (VSS)

• An open in the wire

• Short to ground

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty brake switch

• An open in the wire

• Blown No. 39 (15 A) fuse in the

under-hood fuse/relay box

• Faulty brake switch

• An open in the wire

• Blown bulb

• Faulty gauge circuit

• An open in the wire

• Faulty actuator solenoid

• An open in the wireProCarManuals.com

Page 357 of 1954

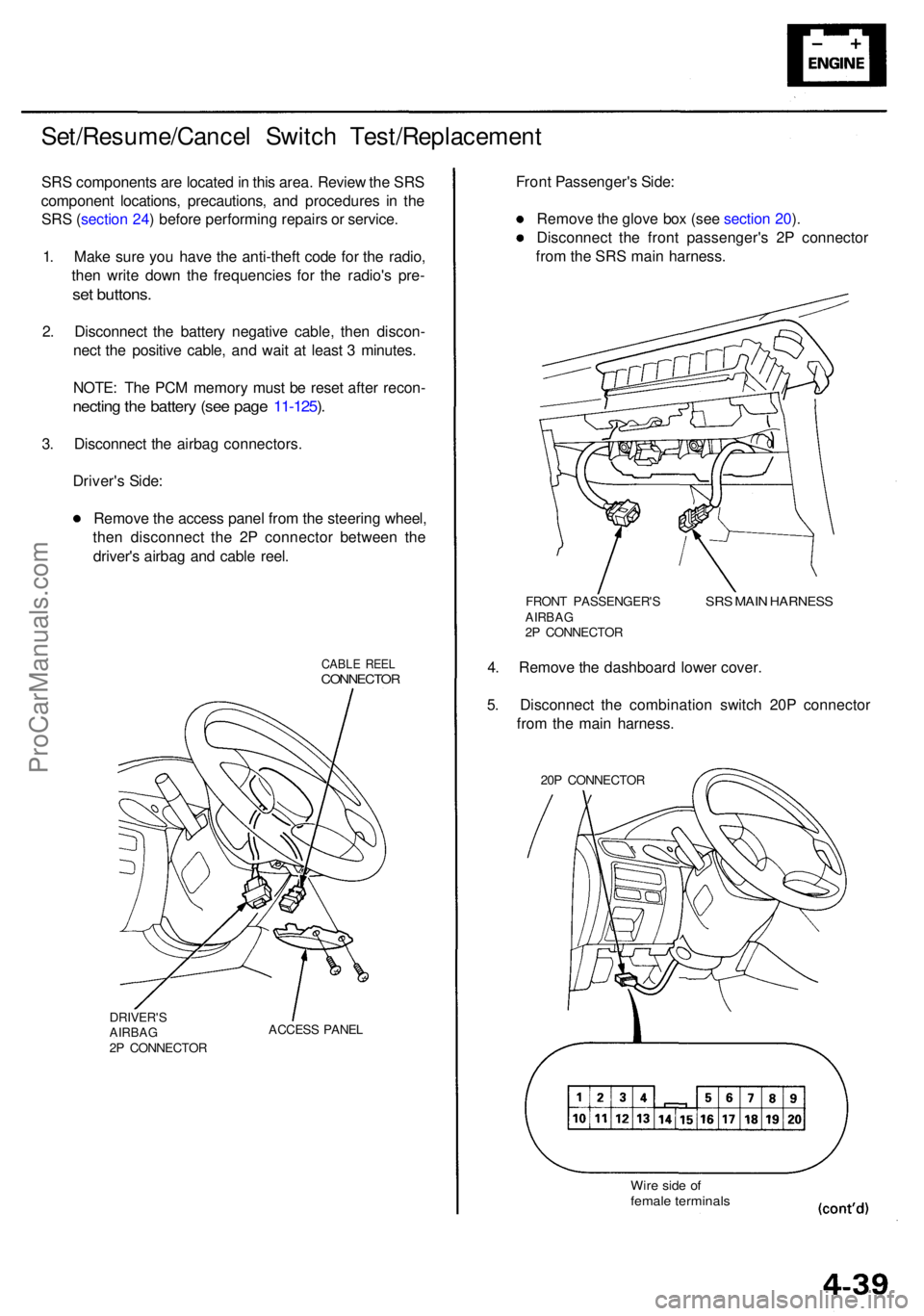

Set/Resume/Cancel Switc h Test/Replacemen t

SRS component s ar e locate d in thi s area . Revie w th e SR S

componen t locations , precautions , an d procedure s i n th e

SR S (sectio n 24 ) befor e performin g repair s o r service .

1 . Mak e sur e yo u hav e th e anti-thef t cod e fo r th e radio ,

the n writ e dow n th e frequencie s fo r th e radio' s pre -

set buttons .

2. Disconnec t th e batter y negativ e cable , the n discon -

nec t th e positiv e cable , an d wai t a t leas t 3 minutes .

NOTE : Th e PC M memor y mus t b e rese t afte r recon -

necting th e batter y (se e pag e 11-125 ).

3 . Disconnec t th e airba g connectors .

Driver' s Side :

Remov e th e acces s pane l fro m th e steerin g wheel ,

the n disconnec t th e 2 P connecto r betwee n th e

driver' s airba g an d cabl e reel .

CABL E REE LCONNECTO R

DRIVER'SAIRBAG2P CONNECTO RACCES

S PANE L

Front Passenger' s Side :

Remov e th e glov e bo x (se e sectio n 20 ).

Disconnec t th e fron t passenger' s 2 P connecto r

fro m th e SR S mai n harness .

FRONT PASSENGER' SAIRBAG2P CONNECTO R

SRS MAI N HARNES S

4. Remov e th e dashboar d lowe r cover .

5 . Disconnec t th e combinatio n switc h 20 P connecto r

fro m th e mai n harness .

20P CONNECTO R

Wire sid e o ffemal e terminal s

ProCarManuals.com

Page 358 of 1954

Cruise Control

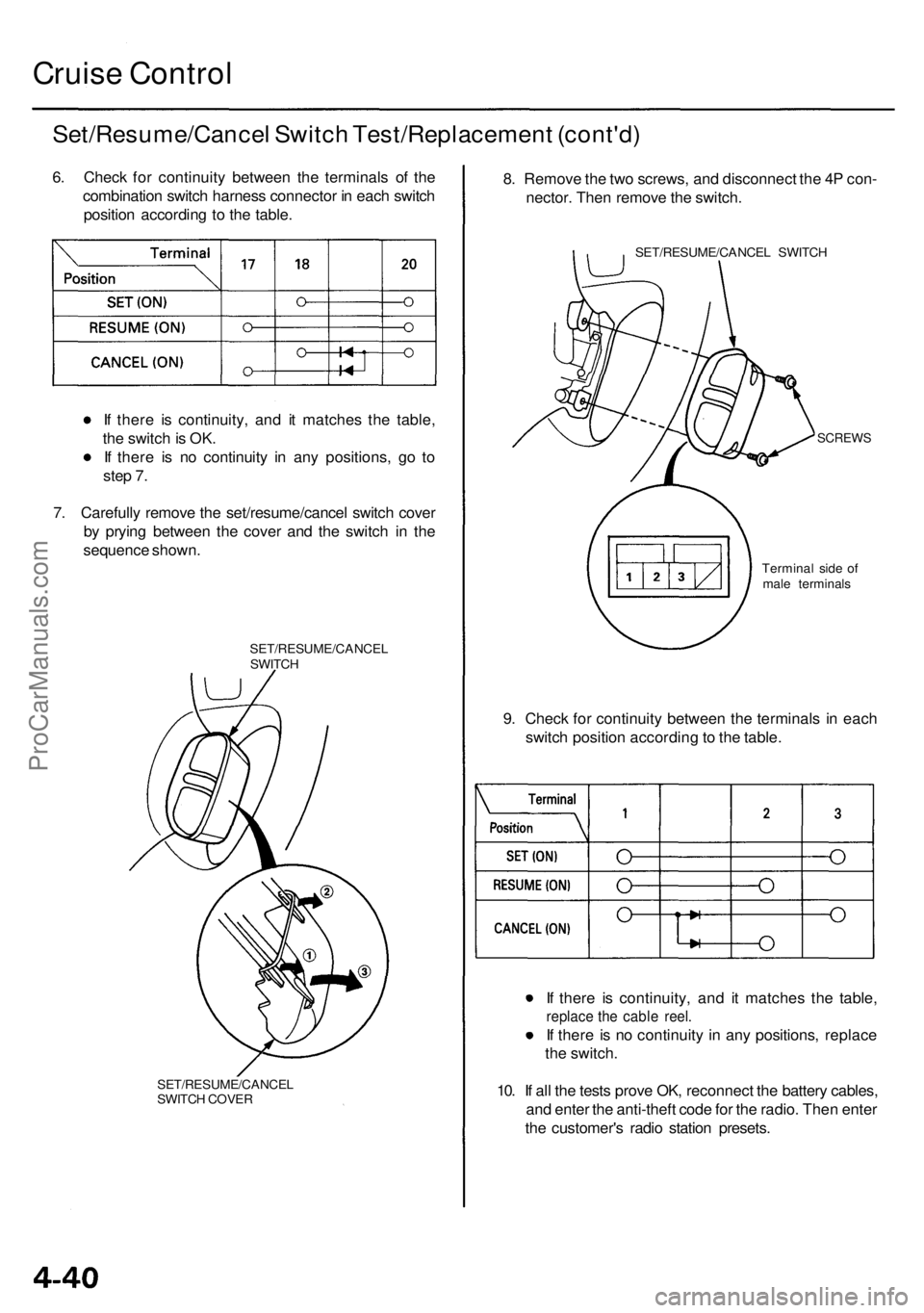

Set/Resume/Cancel Switch Test/Replacement (cont'd)

6. Check for continuity between the terminals of the

combination switch harness connector in each switch

position according to the table.

If there is continuity, and it matches the table,

the switch is OK.

If there is no continuity in any positions, go to

step 7.

7. Carefully remove the set/resume/cancel switch cover

by prying between the cover and the switch in the

sequence shown.

SET/RESUME/CANCEL

SWITCH

SET/RESUME/CANCEL

SWITCH COVER

8. Remove the two screws, and disconnect the 4P con-

nector. Then remove the switch.

SET/RESUME/CANCEL SWITCH

SCREWS

9. Check for continuity between the terminals in each

switch position according to the table.

If there is continuity, and it matches the table,

replace the cable reel.

If there is no continuity in any positions, replace

the switch.

10. If all the tests prove OK, reconnect the battery cables,

and enter the anti-theft code for the radio. Then enter

the customer's radio station presets.

Terminal side of

male terminalsProCarManuals.com

Page 359 of 1954

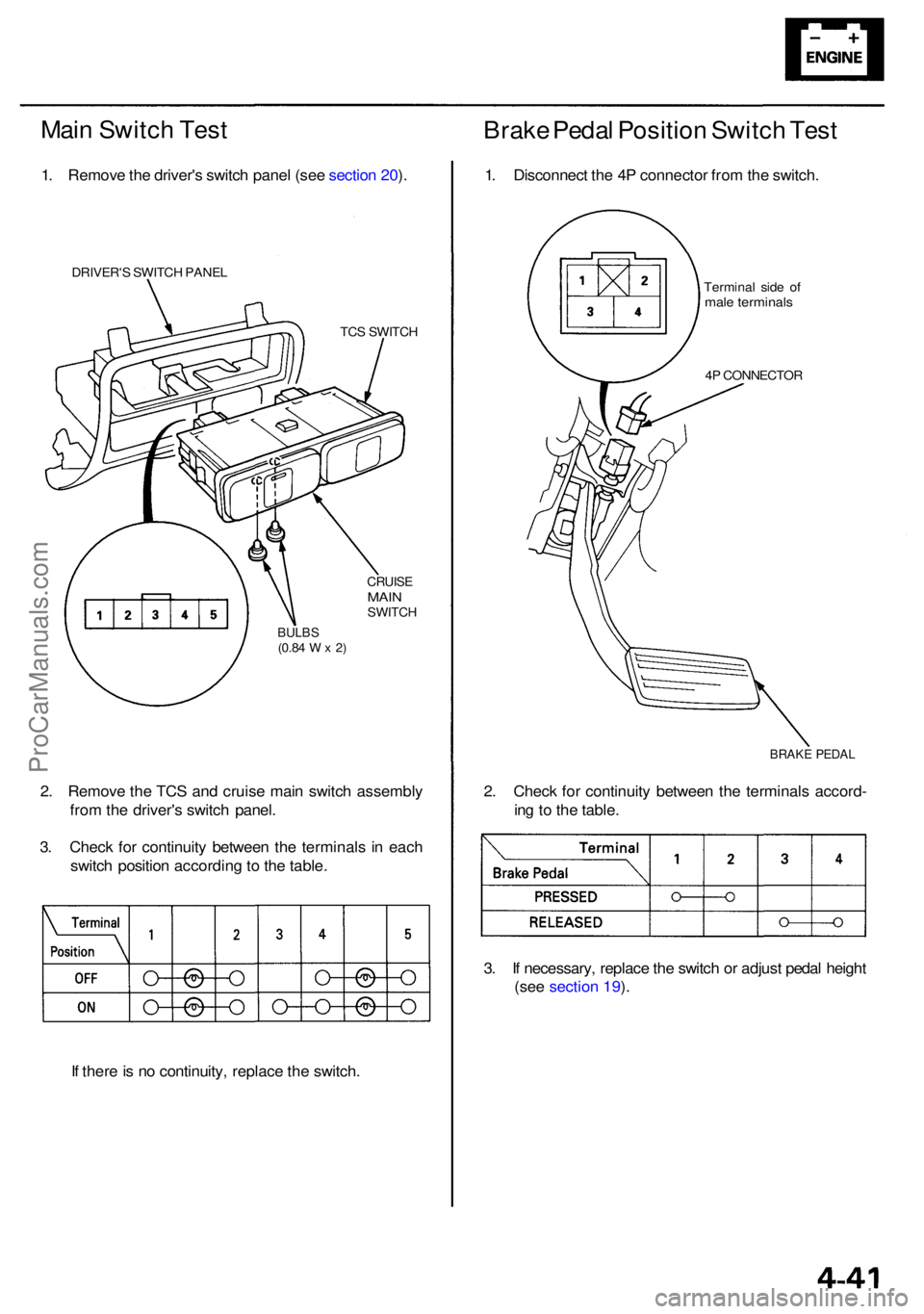

Main Switc h Tes t

1. Remov e th e driver' s switc h pane l (se e sectio n 20 ).

DRIVER' S SWITC H PANE L

TCS SWITC H

CRUISEMAINSWITC H

BULBS(0.84 W x 2)

2. Remov e th e TC S an d cruis e mai n switc h assembl y

fro m th e driver' s switc h panel .

3 . Chec k fo r continuit y betwee n th e terminal s i n eac h

switc h positio n accordin g to th e table .

I f ther e is n o continuity , replac e th e switch .

Brake Peda l Positio n Switc h Tes t

1. Disconnec t th e 4 P connecto r fro m th e switch .

Termina l sid e o fmal e terminal s

4P CONNECTO R

BRAKE PEDA L

2. Chec k fo r continuit y betwee n th e terminal s accord -

in g t o th e table .

3 . I f necessary , replac e th e switc h o r adjus t peda l heigh t

(see section 19 ).

ProCarManuals.com

Page 360 of 1954

Cruise Control

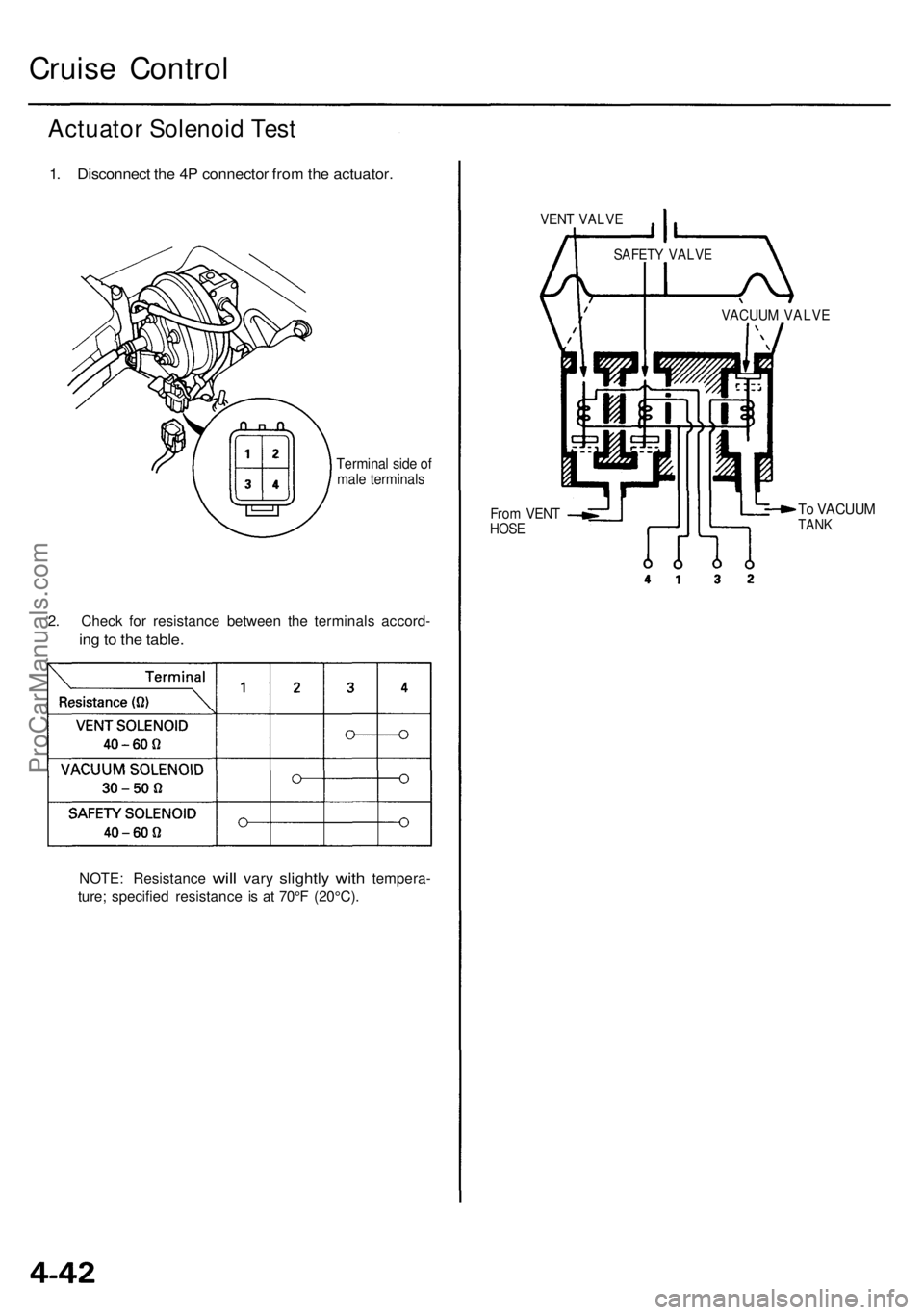

Actuator Solenoid Test

1. Disconnect the 4P connector from the actuator.

Terminal side of

male terminals

2. Check for resistance between the terminals accord-

ing to the table.

NOTE: Resistance

will

vary

slightly

with

tempera-

ture; specified resistance is at 70°F (20°C).

VENT VALVE

From VENT

HOSE

To VACUUM

TANK

VACUUM VALVE

SAFETY VALVEProCarManuals.com