ACURA RL KA9 1996 Service Repair Manual

Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 371 of 1954

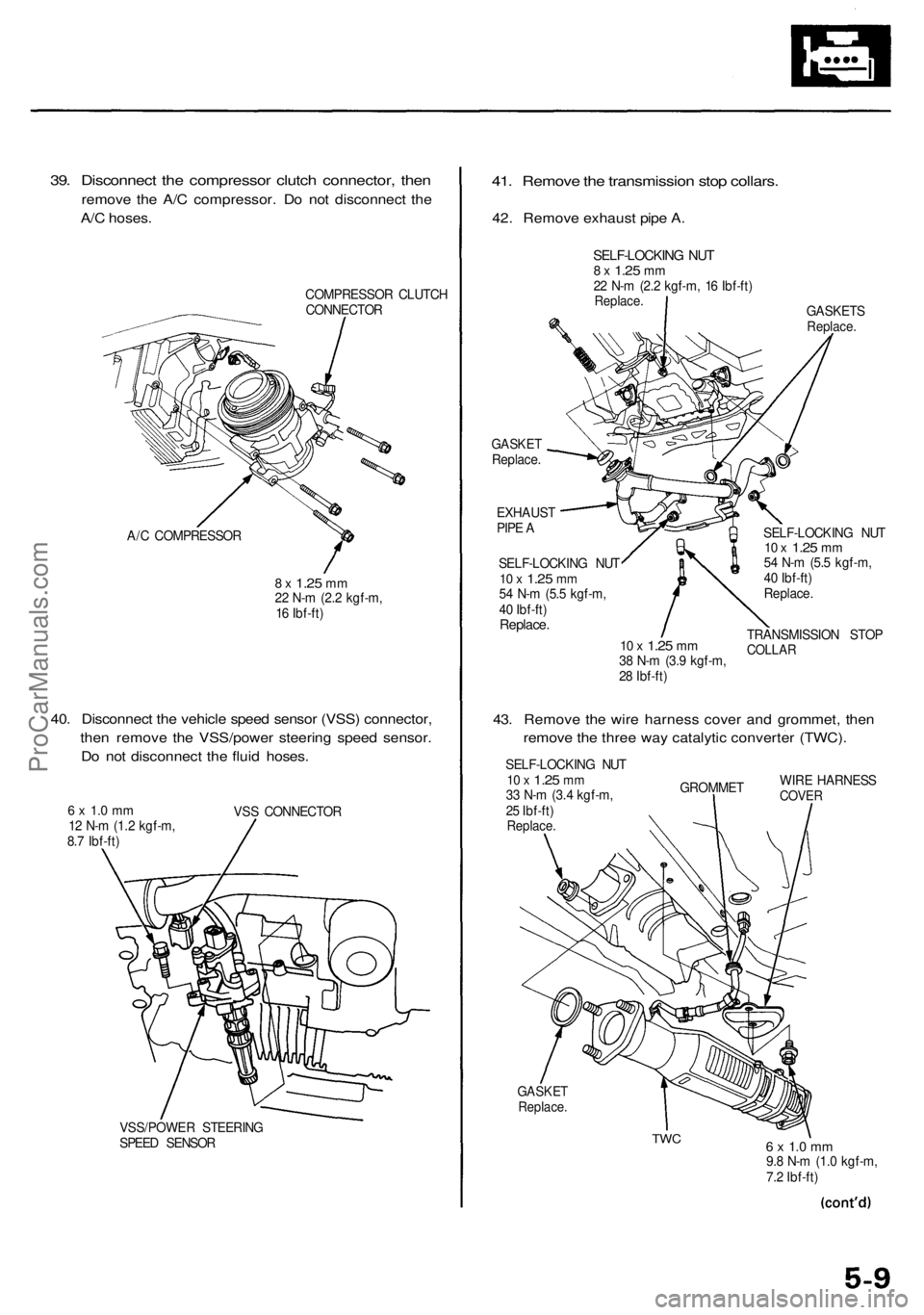

39. Disconnect the compressor clutch connector, then

remove the A/C compressor. Do not disconnect the

A/C hoses.

COMPRESSOR CLUTCH

CONNECTOR

A/C COMPRESSOR

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

40. Disconnect the vehicle speed sensor (VSS) connector,

then remove the VSS/power steering speed sensor.

Do not disconnect the fluid hoses.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

VSS CONNECTOR

VSS/POWER STEERING

SPEED SENSOR

41. Remove the transmission stop collars.

42. Remove exhaust pipe A.

GASKETS

Replace.

GASKET

Replace.

EXHAUST

PIPE A

SELF-LOCKING NUT

10 x

1.25

mm

54 N-m (5.5 kgf-m,

40 Ibf-ft)

Replace.

10 x

1.25

mm

38 N-m (3.9 kgf-m,

28 Ibf-ft)

SELF-LOCKING NUT

10 x

1.25

mm

54 N-m (5.5 kgf-m,

40 Ibf-ft)

Replace.

TRANSMISSION STOP

COLLAR

43. Remove the wire harness cover and grommet, then

remove the three way catalytic converter (TWC).

SELF-LOCKING NUT

10 x

1.25

mm

33 N-m (3.4 kgf-m,

25 Ibf-ft)

Replace.

GROMMET

WIRE HARNESS

COVER

GASKET

Replace.

TWC

6 x 1.0 mm

9.8 N-m (1.0 kgf-m,

7.2 Ibf-ft)

SELF-LOCKING NUT

8 x

1.25

mm

22 N-m (2.2 kgf-m, 16 Ibf-ft)

Replace.ProCarManuals.com

Page 372 of 1954

Engine Removal/Installatio n

Removal (cont'd )

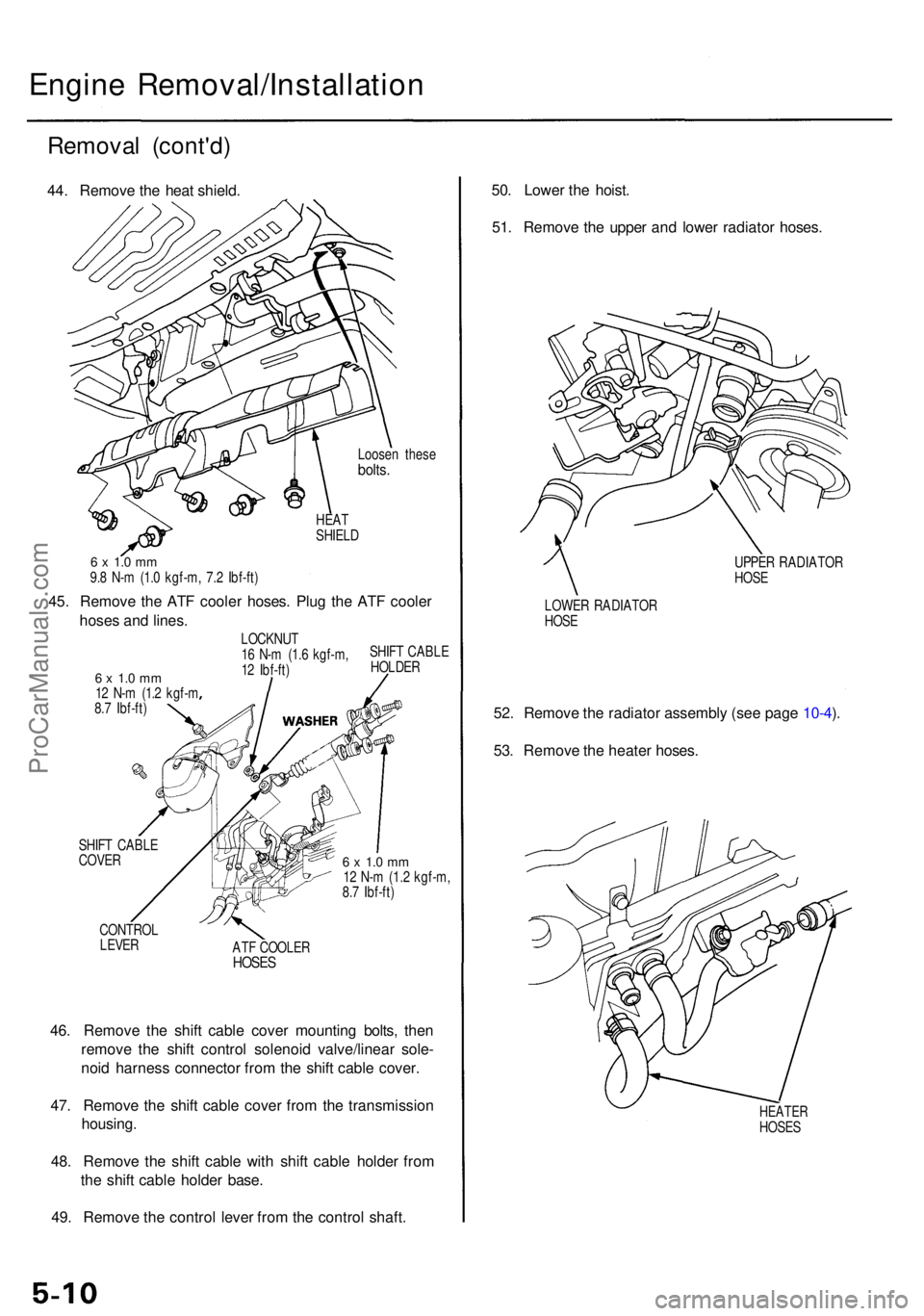

44. Remov e th e hea t shield .

Loosen thes ebolts.

HEATSHIEL D

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

45. Remov e th e AT F coole r hoses . Plu g th e AT F coole r

hose s an d lines .

6 x 1. 0 m m12 N- m (1. 2 kgf- m

8. 7 Ibf-ft ) LOCKNU

T

1 6 N- m (1. 6 kgf-m ,

1 2 Ibf-ft ) SHIF

T CABL E

HOLDE R

SHIF T CABL E

COVE R

CONTRO L

LEVER

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

AT F COOLE R

HOSES

46. Remov e th e shif t cabl e cove r mountin g bolts , the n

remov e th e shif t contro l solenoi d valve/linea r sole -

noi d harnes s connecto r fro m th e shif t cabl e cover .

47 . Remov e th e shif t cabl e cove r fro m th e transmissio n

housing .

48 . Remov e th e shif t cabl e wit h shif t cabl e holde r fro m

th e shif t cabl e holde r base .

49 . Remov e th e contro l leve r fro m th e contro l shaft . 50

. Lowe r th e hoist .

51 . Remov e th e uppe r an d lowe r radiato r hoses .

UPPER RADIATO R

HOS E

LOWE R RADIATO R

HOS E

52. Remov e th e radiato r assembl y (se e pag e 10-4 ).

53 . Remov e th e heate r hoses .

HEATE RHOSES

ProCarManuals.com

Page 373 of 1954

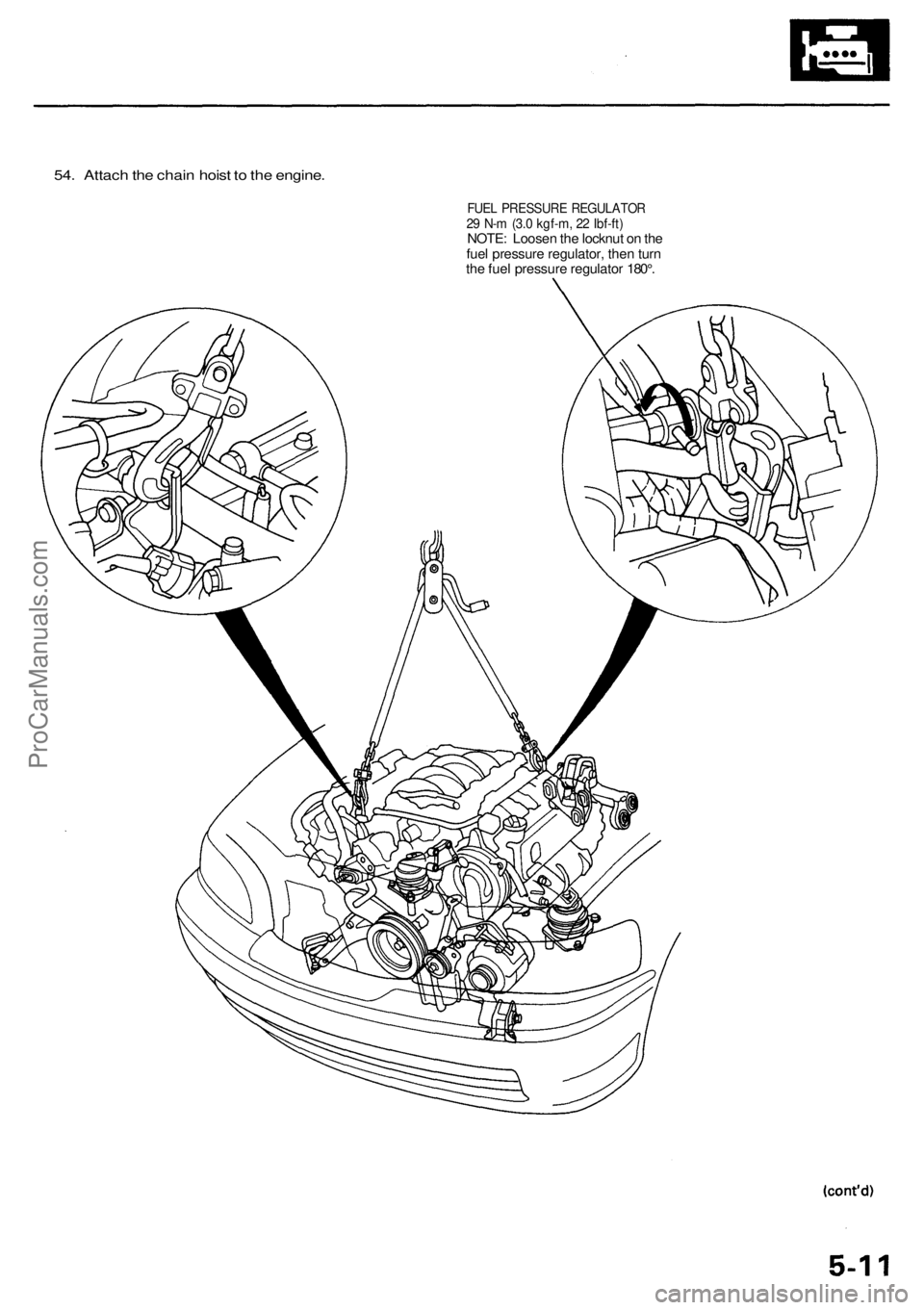

54. Attach the chain hoist to the engine.

FUEL PRESSURE REGULATOR

29 N-m (3.0 kgf-m, 22 Ibf-ft)

NOTE: Loosen the locknut on the

fuel pressure regulator, then turn

the fuel pressure regulator 180°.ProCarManuals.com

Page 374 of 1954

Engine Removal/Installatio n

Removal (cont'd )

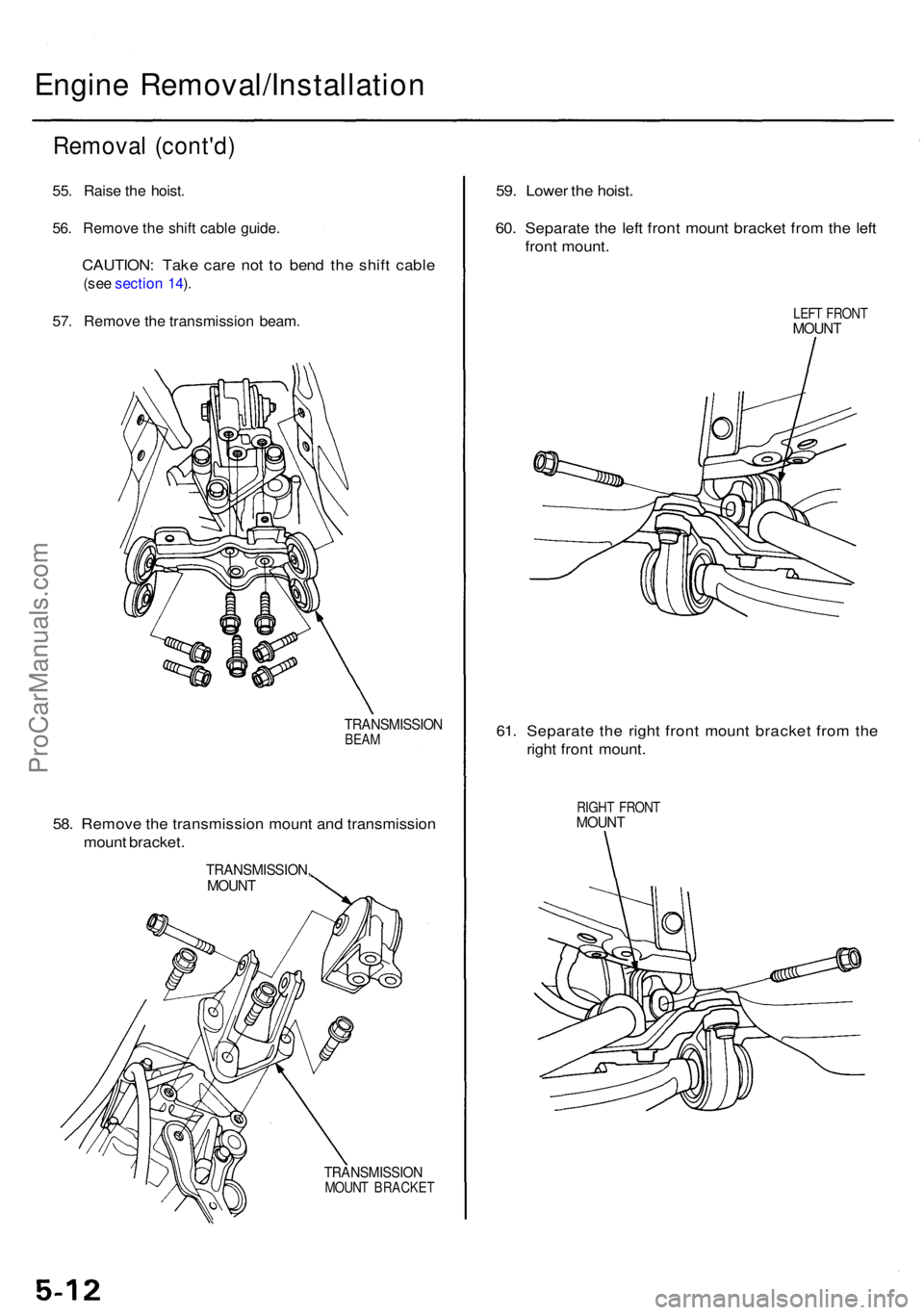

55. Rais e th e hoist .

56. Remov e th e shif t cabl e guide .

CAUTION : Tak e car e no t t o ben d th e shif t cabl e

(see sectio n 14 ).

57 . Remov e th e transmissio n beam .

TRANSMISSIO NBEAM

58. Remov e th e transmissio n moun t an d transmissio n

moun t bracket .

TRANSMISSION ,MOUNT

TRANSMISSIO NMOUNT BRACKE T

59. Lowe r th e hoist .

60 . Separat e th e lef t fron t moun t bracke t fro m th e lef t

fron t mount .

LEFT FRON TMOUNT

61. Separat e th e righ t fron t moun t bracke t fro m th e

righ t fron t mount .

RIGHT FRON TMOUNT

ProCarManuals.com

Page 375 of 1954

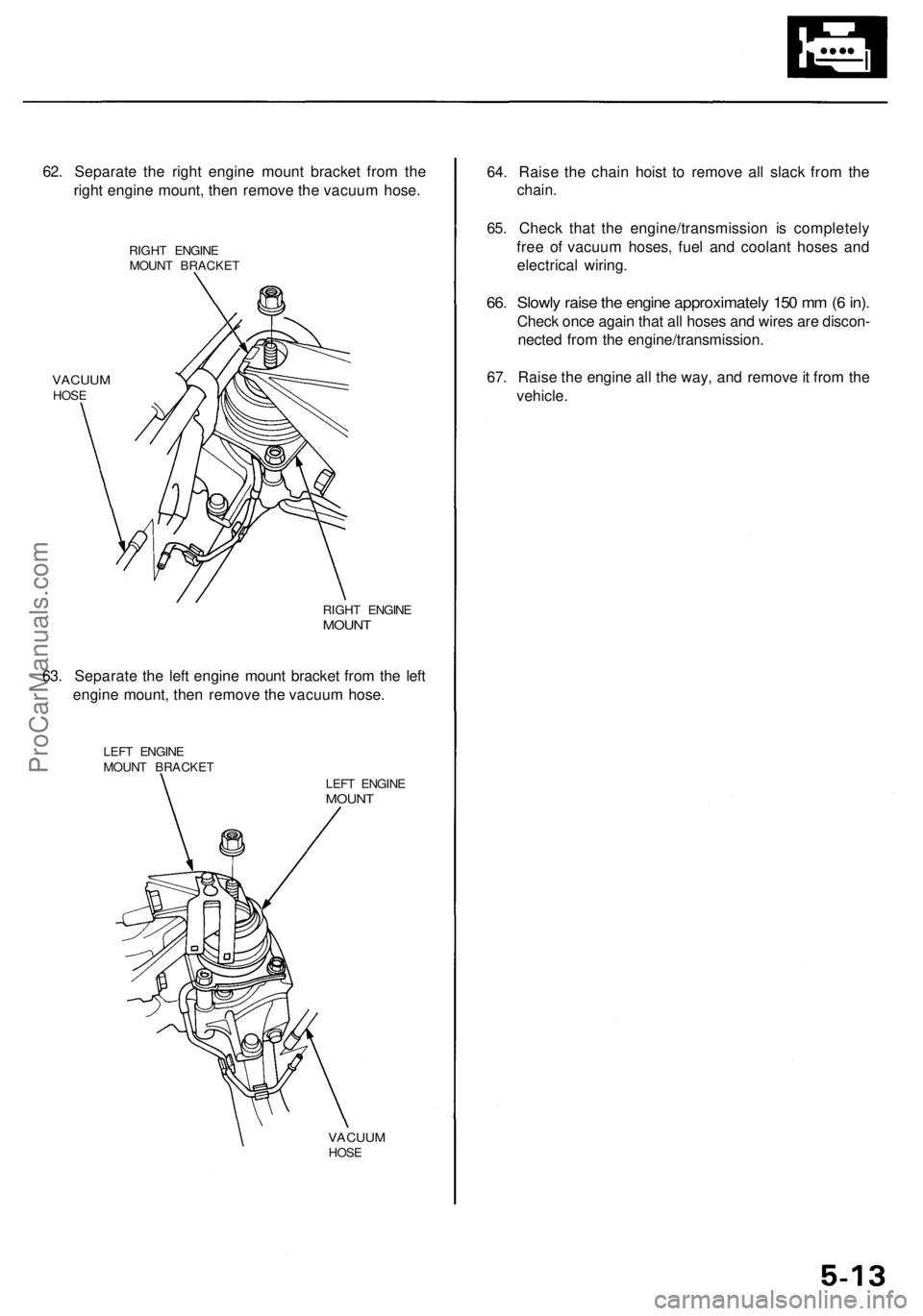

62. Separate the right engine mount bracket from the

right engine mount, then remove the vacuum hose.

RIGHT ENGINE

MOUNT BRACKET

VACUUM

HOSE

RIGHT ENGINE

MOUNT

63. Separate the left engine mount bracket from the left

engine mount, then remove the vacuum hose.

LEFT ENGINE

MOUNT BRACKET

LEFT ENGINE

MOUNT

VACUUM

HOSE

64. Raise the chain hoist to remove all slack from the

chain.

65. Check that the engine/transmission is completely

free of vacuum hoses, fuel and coolant hoses and

electrical wiring.

66. Slowly raise the engine approximately 150 mm (6 in).

Check once again that all hoses and wires are discon-

nected from the engine/transmission.

67. Raise the engine all the way, and remove it from the

vehicle.ProCarManuals.com

Page 376 of 1954

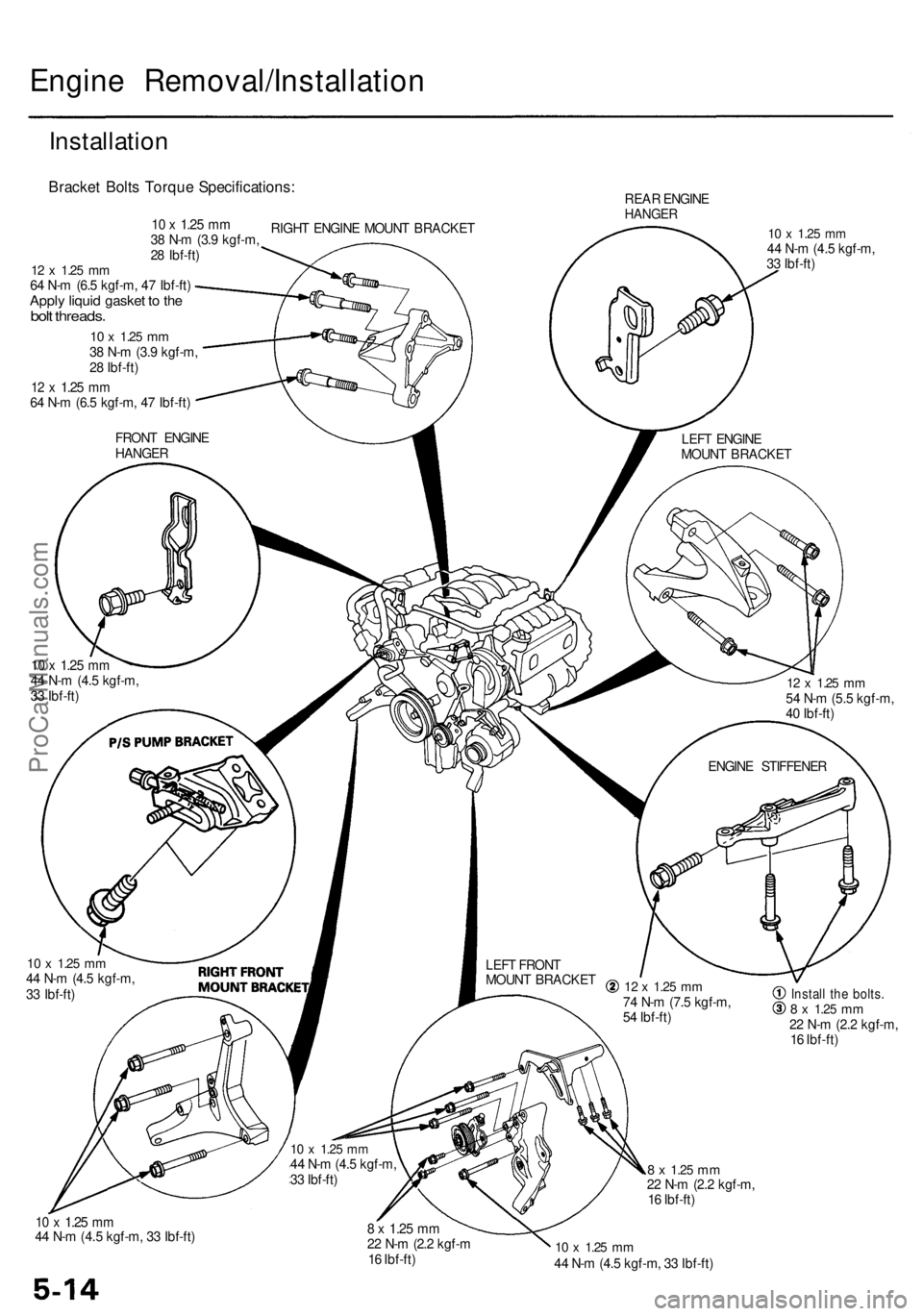

Engine Removal/Installatio n

Installation

Bracket Bolt s Torqu e Specifications :

RIGHT ENGIN E MOUN T BRACKE T REA

R ENGIN EHANGE R

10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )Instal l th e bolts .8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

10 x 1.2 5 mm44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )8 x 1.2 5 mm22 N- m (2. 2 kgf- m

1 6 Ibf-ft )10 x 1.2 5 mm44 N- m (4. 5 kgf-m , 3 3 Ibf-ft )

12 x 1.2 5 mm74 N- m (7. 5 kgf-m ,

5 4 Ibf-ft )

LEF

T FRON T

MOUN T BRACKE T ENGIN

E STIFFENE R

12 x 1.2 5 mm54 N- m (5. 5 kgf-m ,

4 0 Ibf-ft )

LEF

T ENGIN E

MOUN T BRACKE T

FRON

T ENGIN E

HANGE R

12 x 1.2 5 mm64 N- m (6. 5 kgf-m , 4 7 Ibf-ft )

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

12 x 1.2 5 mm64 N- m (6. 5 kgf-m , 4 7 Ibf-ft )Apply liqui d gaske t t o th ebol t threads .

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

10 x 1.2 5 m m44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

ProCarManuals.com

Page 377 of 1954

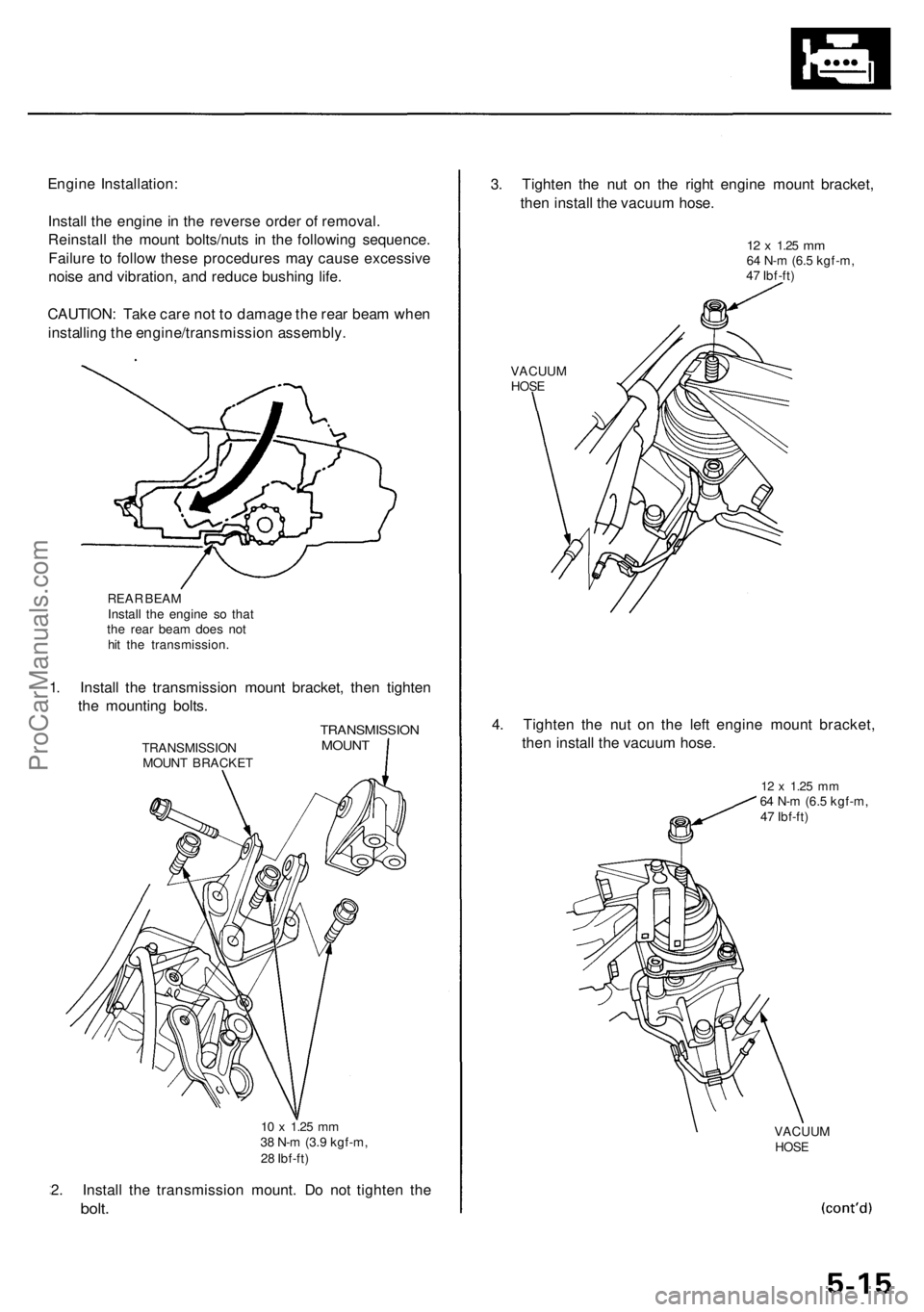

Engine Installation :

Instal l th e engin e in th e revers e orde r o f removal .

Reinstal l th e moun t bolts/nut s i n th e followin g sequence .

Failur e t o follo w thes e procedure s ma y caus e excessiv e

nois e an d vibration , an d reduc e bushin g life .

CAUTION : Tak e car e no t t o damag e th e rea r bea m whe n

installin g th e engine/transmissio n assembly .

REAR BEA M

Instal l th e engin e s o tha t

th e rea r bea m doe s no t

hi t th e transmission .

1. Instal l th e transmissio n moun t bracket , the n tighte n

th e mountin g bolts .

TRANSMISSIO N

MOUN T BRACKE T

TRANSMISSIO NMOUNT

2. Instal l th e transmissio n mount . D o no t tighte n th e

bolt .

3. Tighte n th e nu t o n th e righ t engin e moun t bracket ,

the n instal l th e vacuu m hose .

12 x 1.2 5 mm64 N- m (6. 5 kgf-m ,

4 7 Ibf-ft )

VACUU M

HOSE

4. Tighte n th e nu t o n th e lef t engin e moun t bracket ,

the n instal l th e vacuu m hose .

12 x 1.2 5 mm64 N- m (6. 5 kgf-m ,

4 7 Ibf-ft )

VACUU M

HOSE

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,

2 8 Ibf-ft )

ProCarManuals.com

Page 378 of 1954

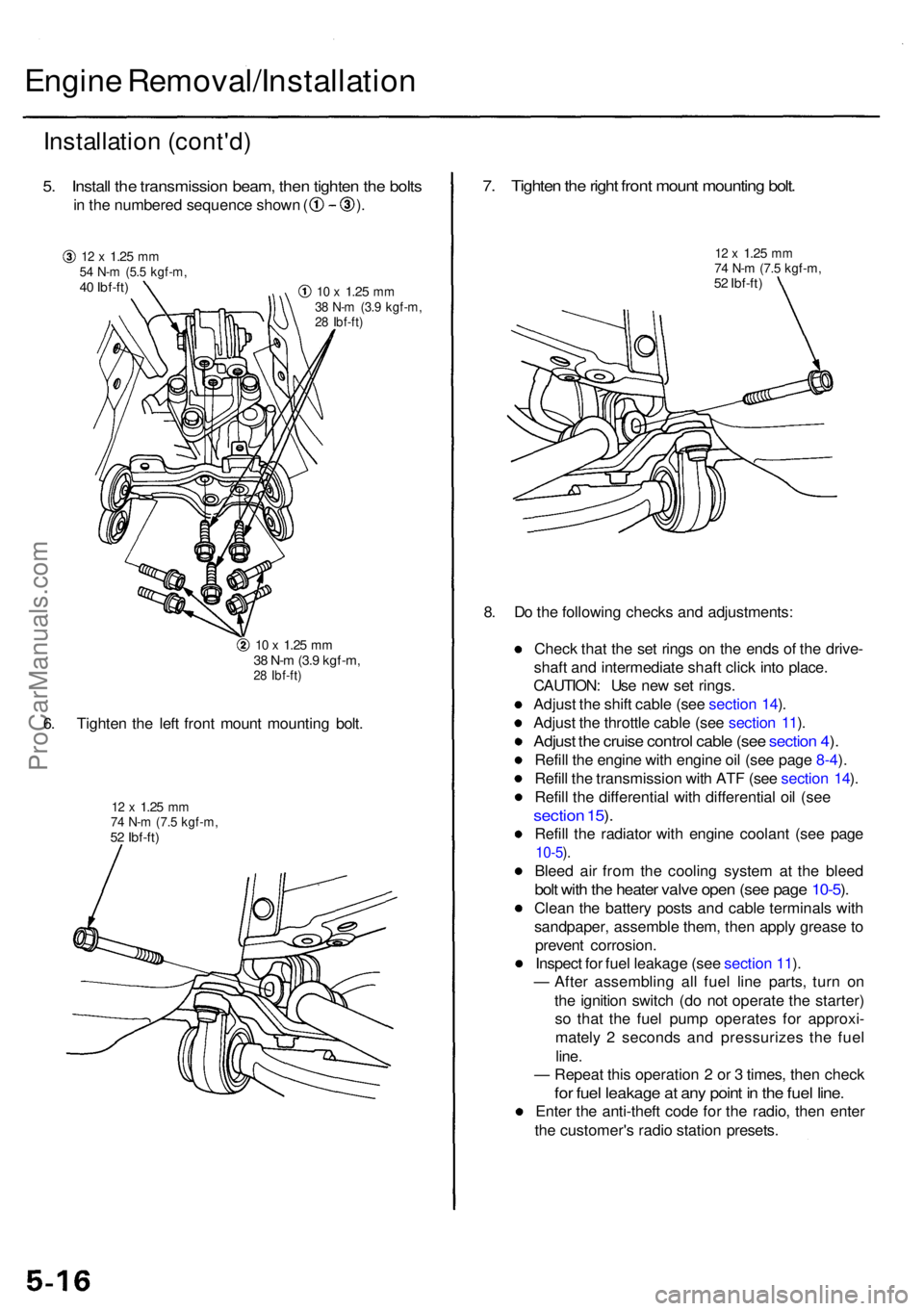

Engine Removal/Installatio n

Installation (cont'd )

5. Instal l th e transmissio n beam , the n tighte n th e bolt s

in th e numbere d sequenc e show n ( ) .

12 x 1.2 5 mm54 N- m (5. 5 kgf-m ,40 Ibf-ft )10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,28 Ibf-ft )

10 x 1.2 5 mm38 N- m (3. 9 kgf-m ,28 Ibf-ft )

6. Tighte n th e lef t fron t moun t mountin g bolt .

12 x 1.2 5 mm74 N- m (7. 5 kgf-m ,52 Ibf-ft )

7. Tighte n th e righ t fron t moun t mountin g bolt .

12 x 1.2 5 mm74 N- m (7. 5 kgf-m ,52 Ibf-ft )

8. D o th e followin g check s an d adjustments :

Chec k tha t th e se t ring s o n th e end s o f th e drive -

shaf t an d intermediat e shaf t clic k int o place .

CAUTION : Us e ne w se t rings .

Adjus t th e shif t cabl e (se e sectio n 14 ).

Adjus t th e throttl e cabl e (se e sectio n 11 ).

Adjus t th e cruis e contro l cabl e (se e sectio n 4 ).

Refil l th e engin e wit h engin e oi l (se e pag e 8-4 ).

Refil l th e transmissio n wit h AT F (se e sectio n 14 ).

Refil l th e differentia l wit h differentia l oi l (se e

sectio n 15 ).

Refil l th e radiato r wit h engin e coolan t (se e pag e

10-5).

Blee d ai r fro m th e coolin g syste m a t th e blee d

bolt wit h th e heate r valv e ope n (se e pag e 10-5 ).

Clea n th e batter y post s an d cabl e terminal s wit h

sandpaper , assembl e them , the n appl y greas e to

preven t corrosion .

Inspec t fo r fue l leakag e (se e sectio n 11 ).

— Afte r assemblin g al l fue l lin e parts , tur n o n

th e ignitio n switc h (d o no t operat e th e starter )

s o tha t th e fue l pum p operate s fo r approxi -

matel y 2 second s an d pressurize s th e fue l

line .

— Repea t thi s operatio n 2 or 3 times , the n chec k

for fue l leakag e a t an y poin t i n th e fue l line .

Ente r th e anti-thef t cod e fo r th e radio , the n ente r

th e customer' s radi o statio n presets .

ProCarManuals.com

Page 379 of 1954

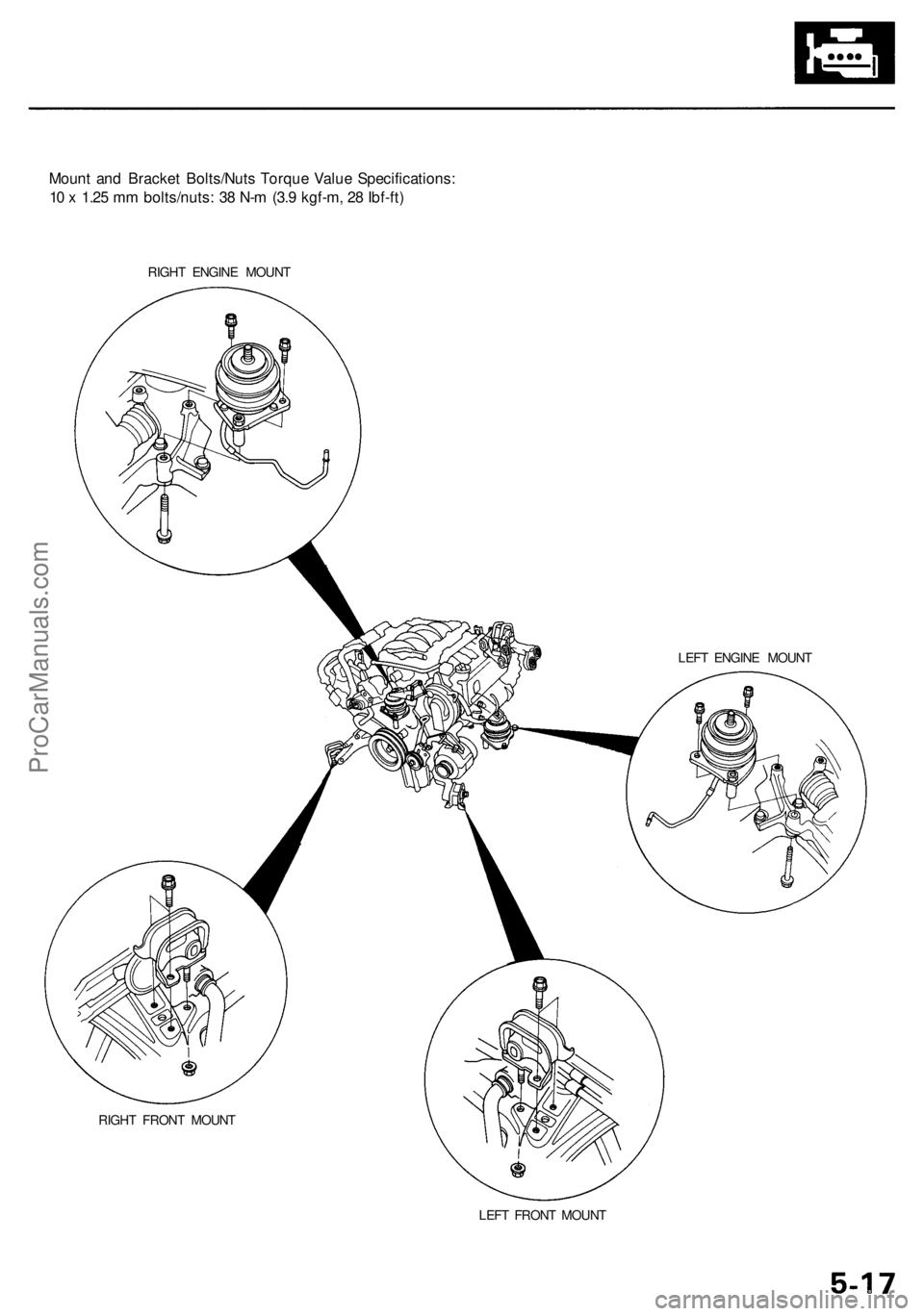

Mount and Bracket Bolts/Nuts Torque Value Specifications:

10 x 1.25 mm bolts/nuts: 38 N-m (3.9 kgf-m, 28 Ibf-ft)

RIGHT ENGINE MOUNT

LEFT ENGINE MOUNT

RIGHT FRONT MOUNT

LEFT FRONT MOUNTProCarManuals.com

Page 380 of 1954

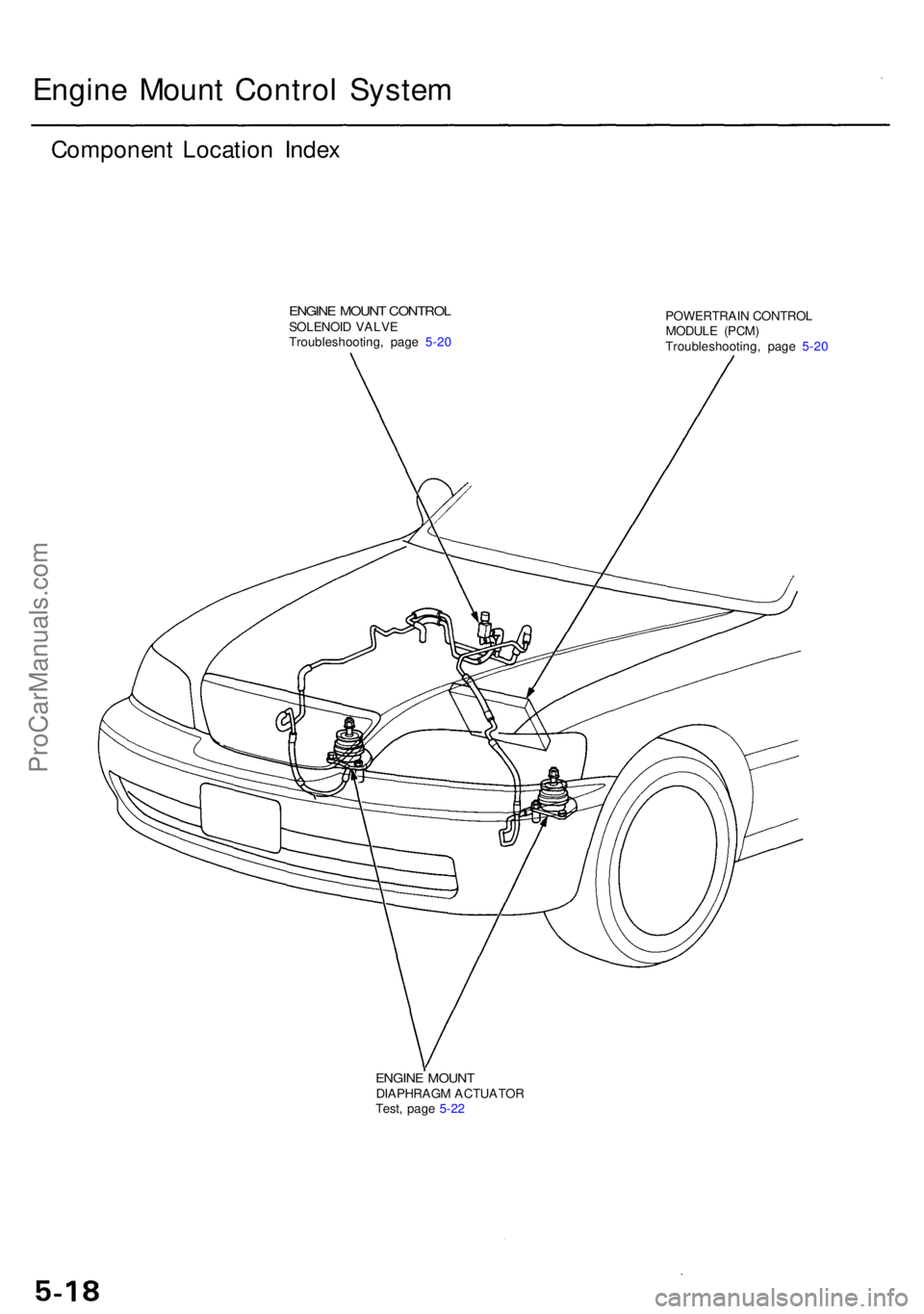

Engine Moun t Contro l Syste m

Componen t Locatio n Inde x

ENGIN E MOUN T CONTRO LSOLENOI D VALV E

Troubleshooting , pag e 5-2 0 POWERTRAI

N CONTRO L

MODUL E (PCM )

Troubleshooting , pag e 5-2 0

ENGIN E MOUN TDIAPHRAG M ACTUATO R

Test , pag e 5-2 2

ProCarManuals.com