ACURA RL KA9 1996 Service Repair Manual

Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 331 of 1954

Starting Syste m

Armatur e Inspectio n an d Tes t

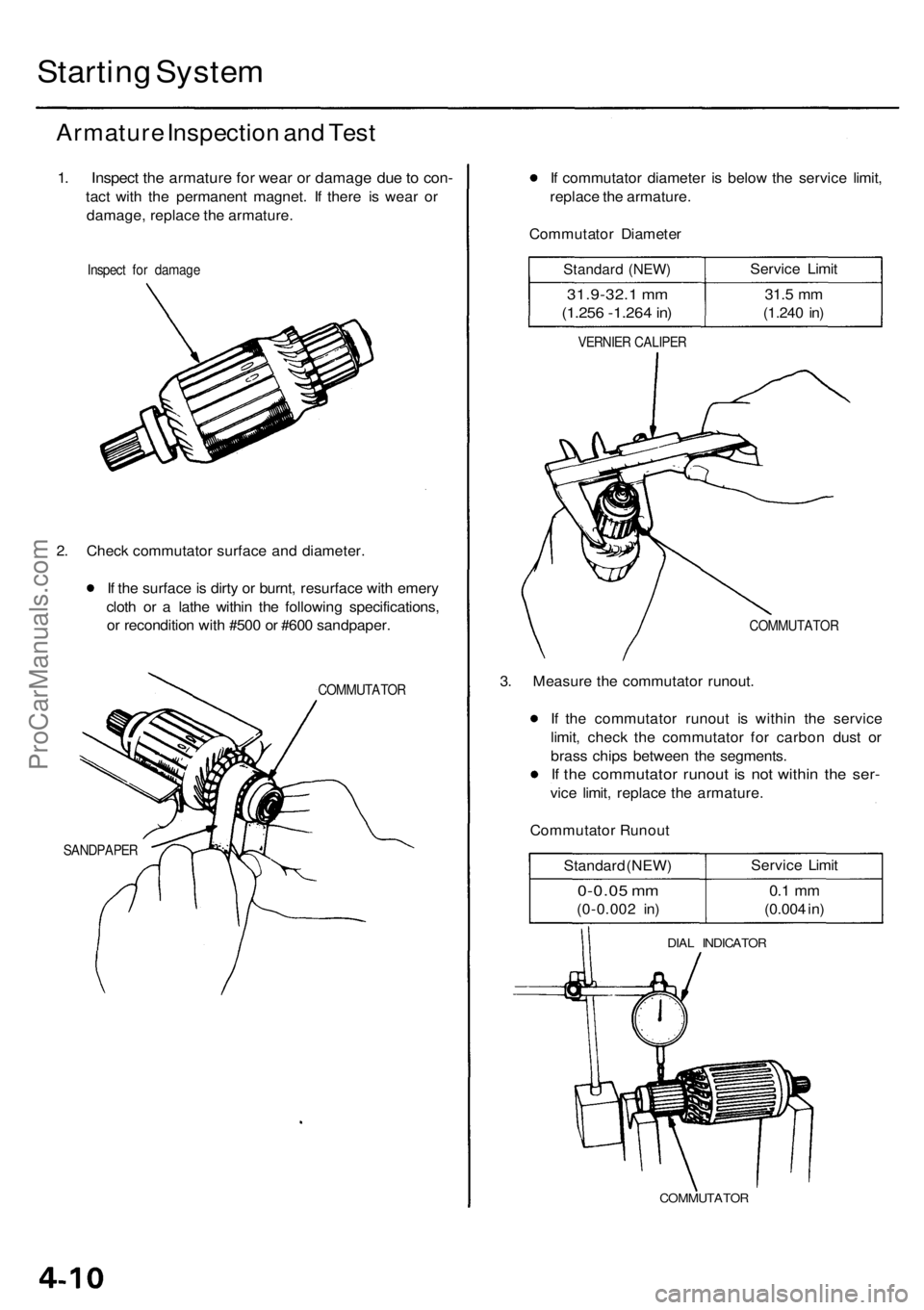

1. Inspec t th e armatur e fo r wea r o r damag e du e to con -

tact wit h th e permanen t magnet . I f ther e i s wea r o r

damage , replac e th e armature .

Inspect fo r damag e

2. Chec k commutato r surfac e an d diameter .

I f th e surfac e is dirt y o r burnt , resurfac e wit h emer y

clot h o r a lath e withi n th e followin g specifications ,

o r reconditio n wit h #50 0 o r #60 0 sandpaper .

COMMUTATO R

SANDPAPE R

If commutato r diamete r i s belo w th e servic e limit ,

replac e th e armature .

Commutato r Diamete r

Standard (NEW )

31.9-32. 1 m m

(1.25 6 -1.26 4 in )

Servic e Limi t

31.5 mm

(1.24 0 in )

VERNIE R CALIPE R

COMMUTATO R

3. Measur e th e commutato r runout .

I f th e commutato r runou t i s withi n th e servic e

limit , chec k th e commutato r fo r carbo n dus t o r

bras s chip s betwee n th e segments .

If th e commutato r runou t i s no t withi n th e ser -

vice limit , replac e th e armature .

Commutato r Runou t

Standar d (NEW )

0-0.05 m m

(0-0.00 2 in ) Servic

e Limi t

0.1 m m

(0.00 4 in )

DIA L INDICATO R

COMMUTATO R

ProCarManuals.com

Page 332 of 1954

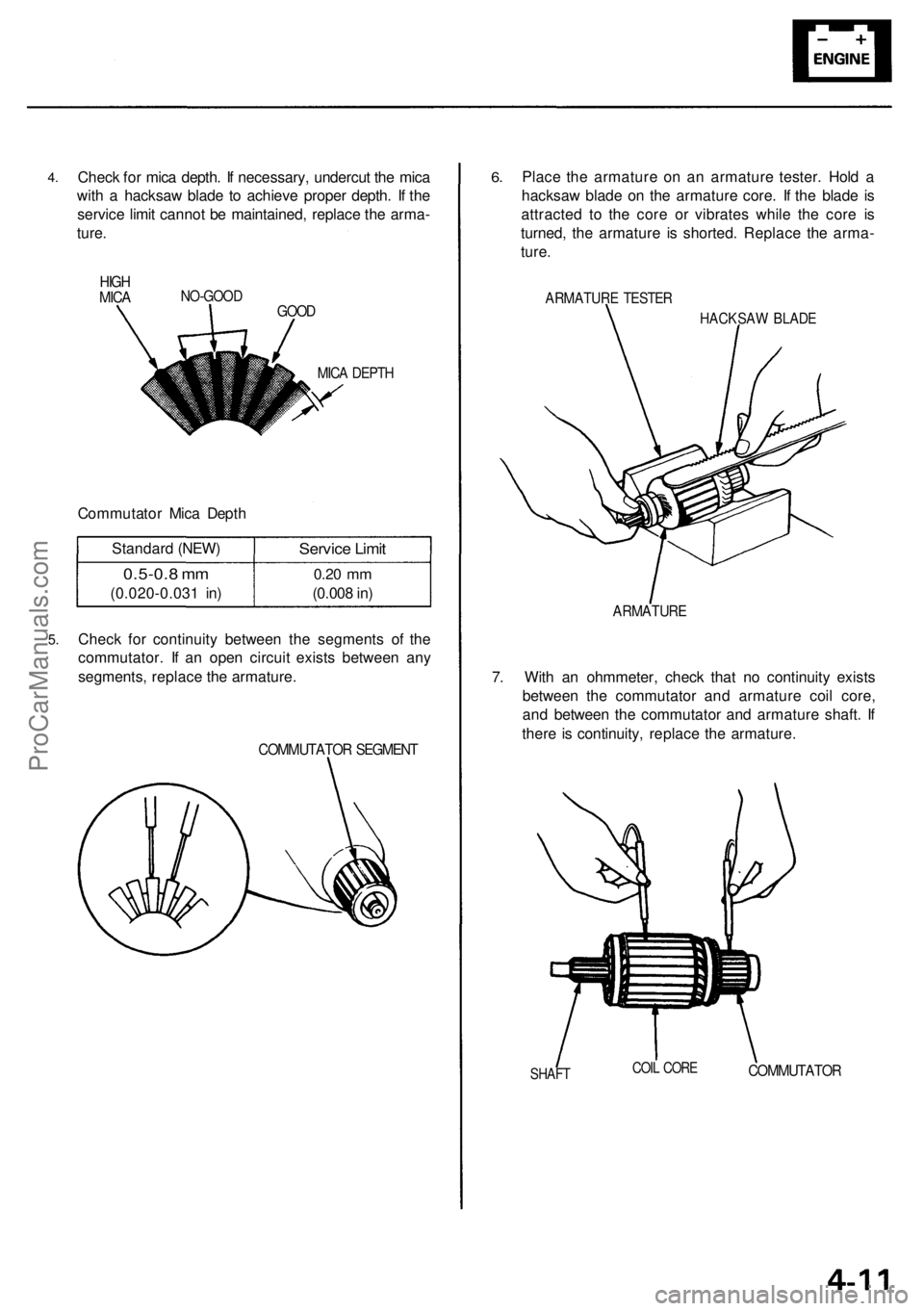

4.

Check for mica depth. If necessary, undercut the mica

with a hacksaw blade to achieve proper depth. If the

service limit cannot be maintained, replace the arma-

ture.

NO-GOOD

GOOD

MICA DEPTH

Commutator Mica Depth

Standard (NEW)

0.5-0.8 mm

(0.020-0.031 in)

Service Limit

0.20

mm

(0.008 in)

5.

Check for continuity between the segments of the

commutator. If an open circuit exists between any

segments, replace the armature.

COMMUTATOR SEGMENT

6.

Place the armature on an armature tester. Hold a

hacksaw blade on the armature core. If the blade is

attracted to the core or vibrates while the core is

turned, the armature is shorted. Replace the arma-

ture.

ARMATURE TESTER

HACKSAW BLADE

ARMATURE

7. With an ohmmeter, check that no continuity exists

between the commutator and armature coil core,

and between the commutator and armature shaft. If

there is continuity, replace the armature.

SHAFT

COIL CORE

COMMUTATOR

HIGH

MICAProCarManuals.com

Page 333 of 1954

Starting Syste m

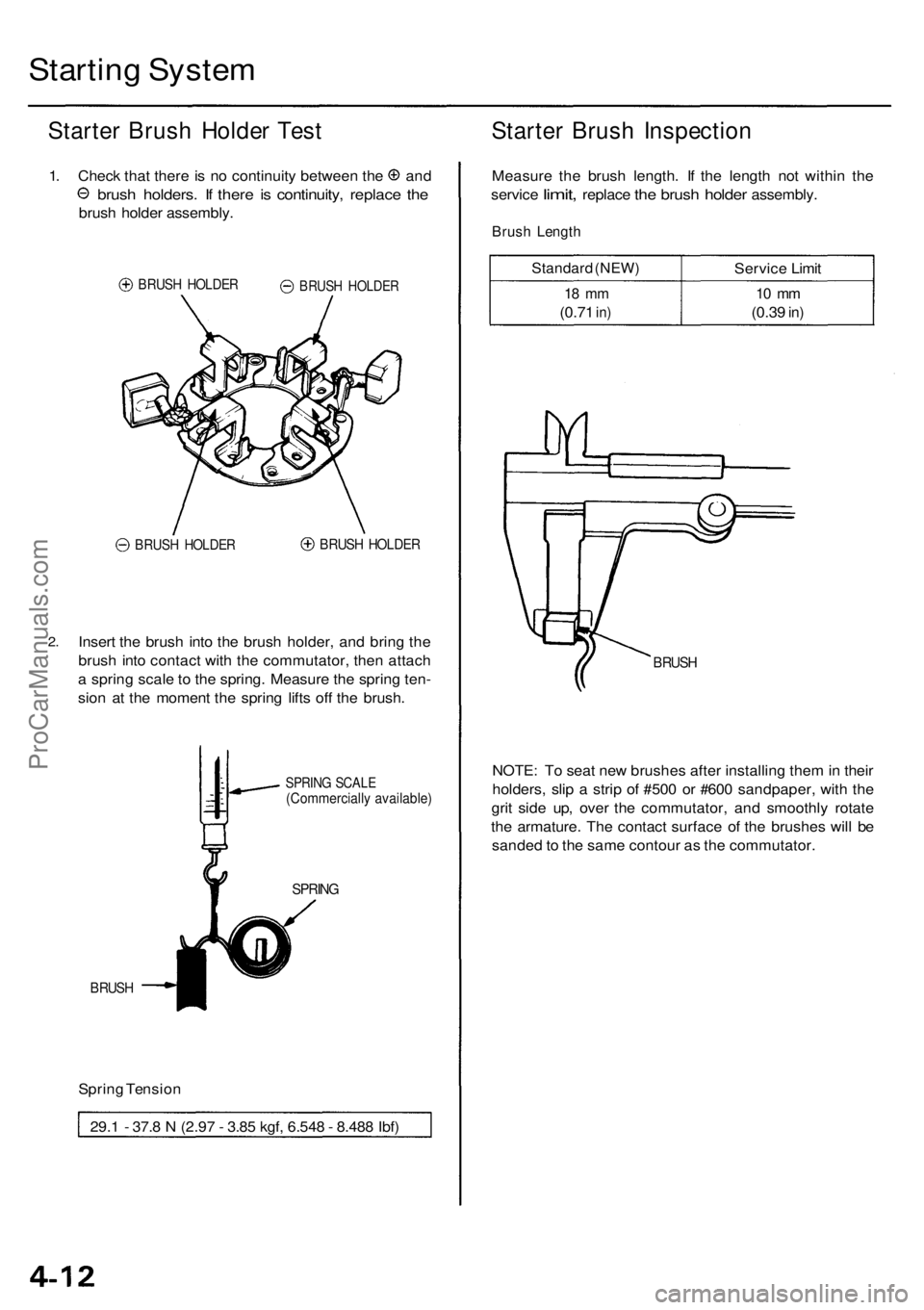

Starte r Brus h Holde r Tes t

1.Chec k tha t ther e is n o continuit y betwee n th e an d

brush holders . I f ther e i s continuity , replac e th e

brus h holde r assembly .

BRUSH HOLDE R

BRUSH HOLDE RBRUSH HOLDE R

2.Inser t th e brus h int o th e brus h holder , an d brin g th e

brus h int o contac t wit h th e commutator , the n attac h

a sprin g scal e to th e spring . Measur e th e sprin g ten -

sio n a t th e momen t th e sprin g lift s of f th e brush .

SPRIN G SCAL E(Commerciall y available )

SPRING

BRUSH

Spring Tensio n

29. 1 - 37. 8 N (2.9 7 - 3.8 5 kgf , 6.54 8 - 8.48 8 Ibf )

Starte r Brus h Inspectio n

Measure th e brus h length . I f th e lengt h no t withi n th e

servic e

limit, replac e the brus h holde r assembly .

Brush Lengt h

Standar d (NEW )

18 m m

(0.7 1 in)

Servic e Limi t

10 m m

(0.3 9 in)

BRUS H

NOTE : T o sea t ne w brushe s afte r installin g the m in thei r

holders , sli p a stri p o f #50 0 o r #60 0 sandpaper , wit h th e

gri t sid e up , ove r th e commutator , an d smoothl y rotat e

th e armature . Th e contac t surfac e o f th e brushe s wil l b e

sande d to th e sam e contou r a s th e commutator .

BRUSH HOLDE R

ProCarManuals.com

Page 334 of 1954

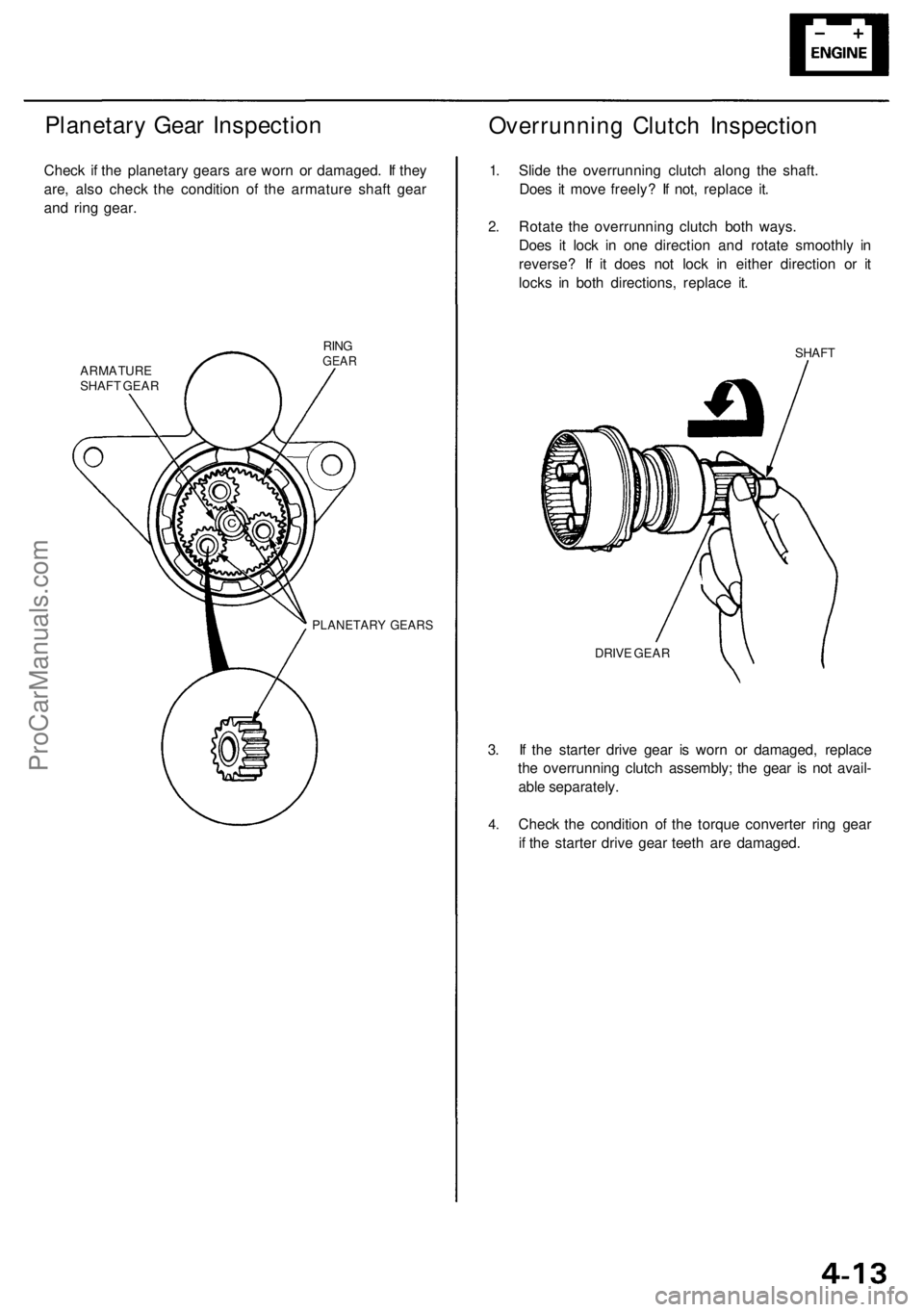

Planetary Gear Inspection

Check if the planetary gears are worn or damaged. If they

are, also check the condition of the armature shaft gear

and ring gear.

ARMATURE

SHAFT GEAR

RING

GEAR

PLANETARY GEARS

Overrunning Clutch Inspection

Slide the overrunning clutch along the shaft.

Does it move freely? If not, replace it.

1.

2.

Rotate the overrunning clutch both ways.

Does it lock in one direction and rotate smoothly in

reverse? If it does not lock in either direction or it

locks in both directions, replace it.

SHAFT

3.

4.

DRIVE GEAR

If the starter drive gear is worn or damaged, replace

the overrunning clutch assembly; the gear is not avail-

able separately.

Check the condition of the torque converter ring gear

if the starter drive gear teeth are damaged.ProCarManuals.com

Page 335 of 1954

Starting Syste m

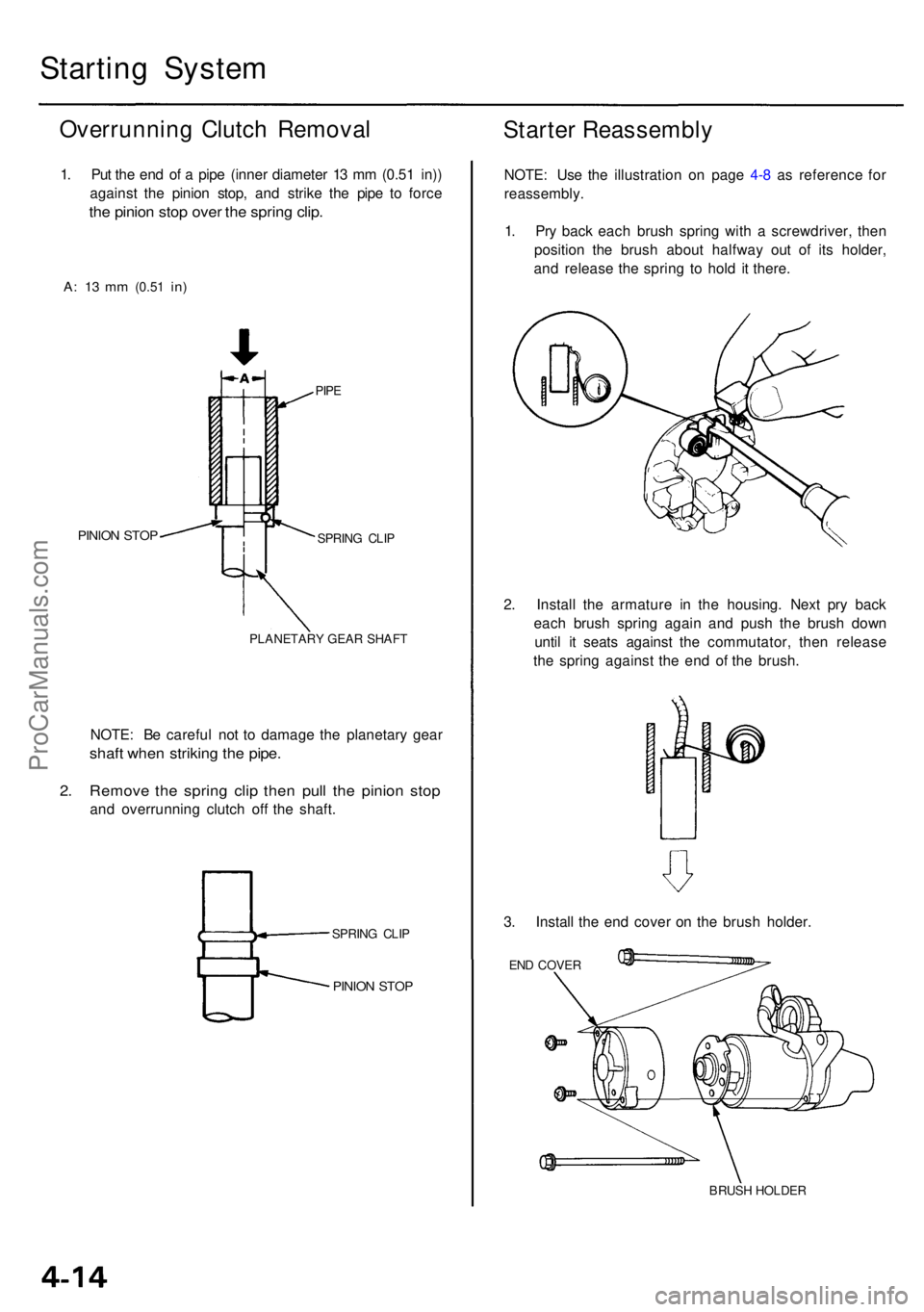

Overrunnin g Clutc h Remova l

1. Pu t th e en d o f a pip e (inne r diamete r 1 3 m m (0.5 1 in) )

agains t th e pinio n stop , an d strik e th e pip e t o forc e

the pinio n sto p ove r th e sprin g clip .

A: 1 3 m m (0.5 1 in)

PINIO N STO P

PIPE

SPRIN G CLI P

PLANETAR Y GEA R SHAF T

NOTE: B e carefu l no t t o damag e th e planetar y gea r

shaft whe n strikin g th e pipe .

2. Remov e th e sprin g cli p the n pul l th e pinio n sto p

and overrunnin g clutc h of f th e shaft .

SPRIN G CLI P

PINIO N STO P

Starte r Reassembl y

NOTE: Us e th e illustratio n o n pag e 4- 8 a s referenc e fo r

reassembly .

1 . Pr y bac k eac h brus h sprin g wit h a screwdriver , the n

positio n th e brus h abou t halfwa y ou t o f it s holder ,

an d releas e th e sprin g t o hol d i t there .

2 . Instal l th e armatur e i n th e housing . Nex t pr y bac k

eac h brus h sprin g agai n an d pus h th e brus h dow n

unti l i t seat s agains t th e commutator , the n releas e

th e sprin g agains t th e en d o f th e brush .

3 . Instal l th e en d cove r o n th e brus h holder .

END COVE R

BRUSH HOLDE R

ProCarManuals.com

Page 336 of 1954

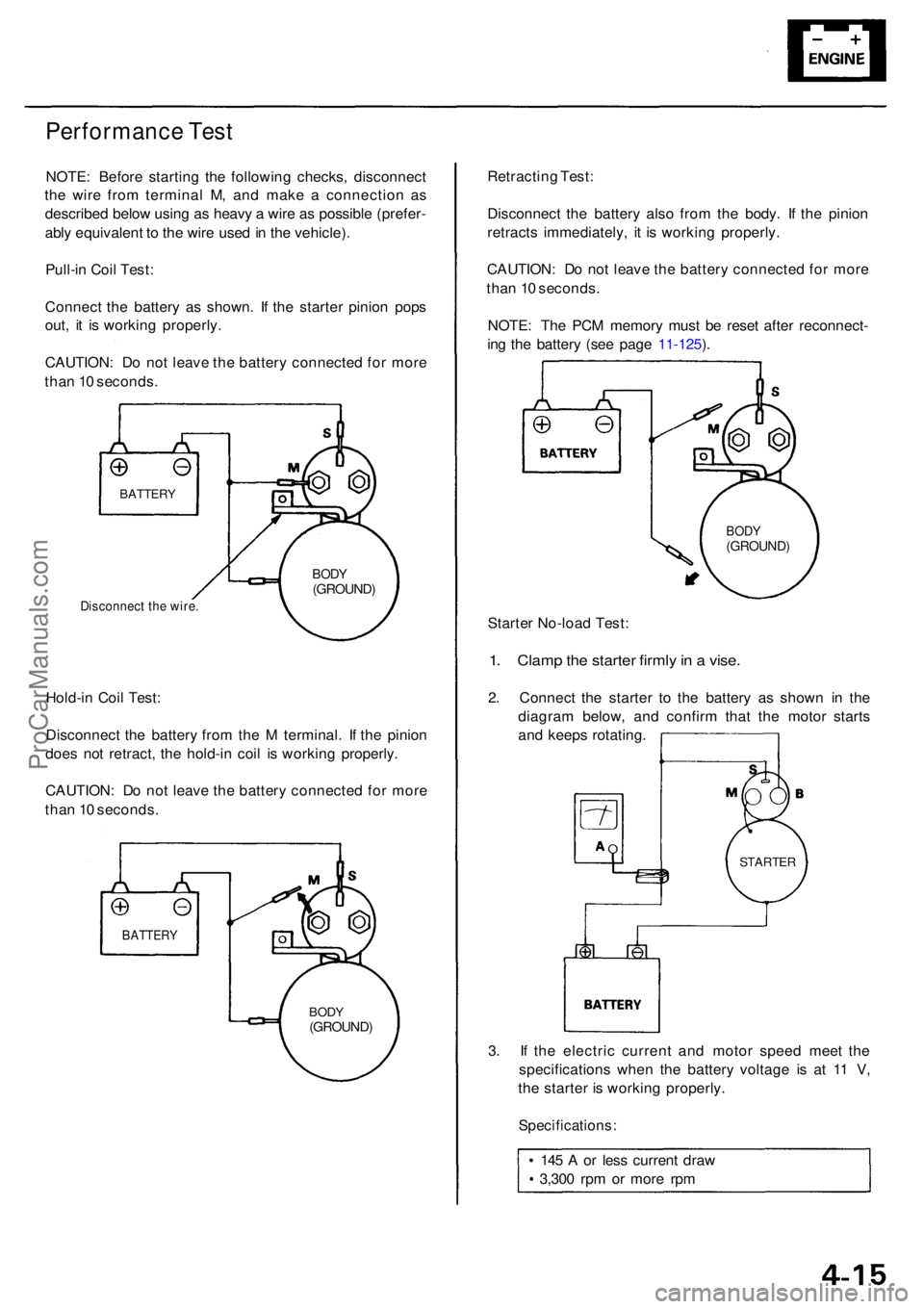

Performance Tes t

NOTE : Befor e startin g th e followin g checks , disconnec t

th e wir e fro m termina l M , an d mak e a connectio n a s

describe d belo w usin g a s heav y a wir e a s possibl e (prefer -

abl y equivalen t t o th e wir e use d in th e vehicle) .

Pull-i n Coi l Test :

Connec t th e batter y a s shown . I f th e starte r pinio n pop s

out , i t i s workin g properly .

CAUTION : D o no t leav e th e batter y connecte d fo r mor e

tha n 1 0 seconds .

Disconnec t th e wire .

Hold-i n Coi l Test :

Disconnec t th e batter y fro m th e M terminal . I f th e pinio n

doe s no t retract , th e hold-i n coi l i s workin g properly .

CAUTION : D o no t leav e th e batter y connecte d fo r mor e

tha n 1 0 seconds . Retractin

g Test :

Disconnec t th e batter y als o fro m th e body . I f th e pinio n

retract s immediately , i t i s workin g properly .

CAUTION : D o no t leav e th e batter y connecte d fo r mor e

tha n 1 0 seconds .

NOTE : Th e PC M memor y mus t b e rese t afte r reconnect -

in g th e batter y (se e pag e 11-125 ).

Starte r No-loa d Test :

1. Clam p th e starte r firml y in a vise .

2. Connec t th e starte r t o th e batter y a s show n i n th e

diagra m below , an d confir m tha t th e moto r start s

an d keep s rotating .

3 . I f th e electri c curren t an d moto r spee d mee t th e

specification s whe n th e batter y voltag e i s a t 1 1 V ,

th e starte r i s workin g properly .

Specifications :

145 A or les s curren t dra w

3,30 0 rp m o r mor e rp m

BOD Y(GROUND )

BODY(GROUND )

BATTERY

STARTER

BATTER Y

BODY(GROUND )

ProCarManuals.com

Page 337 of 1954

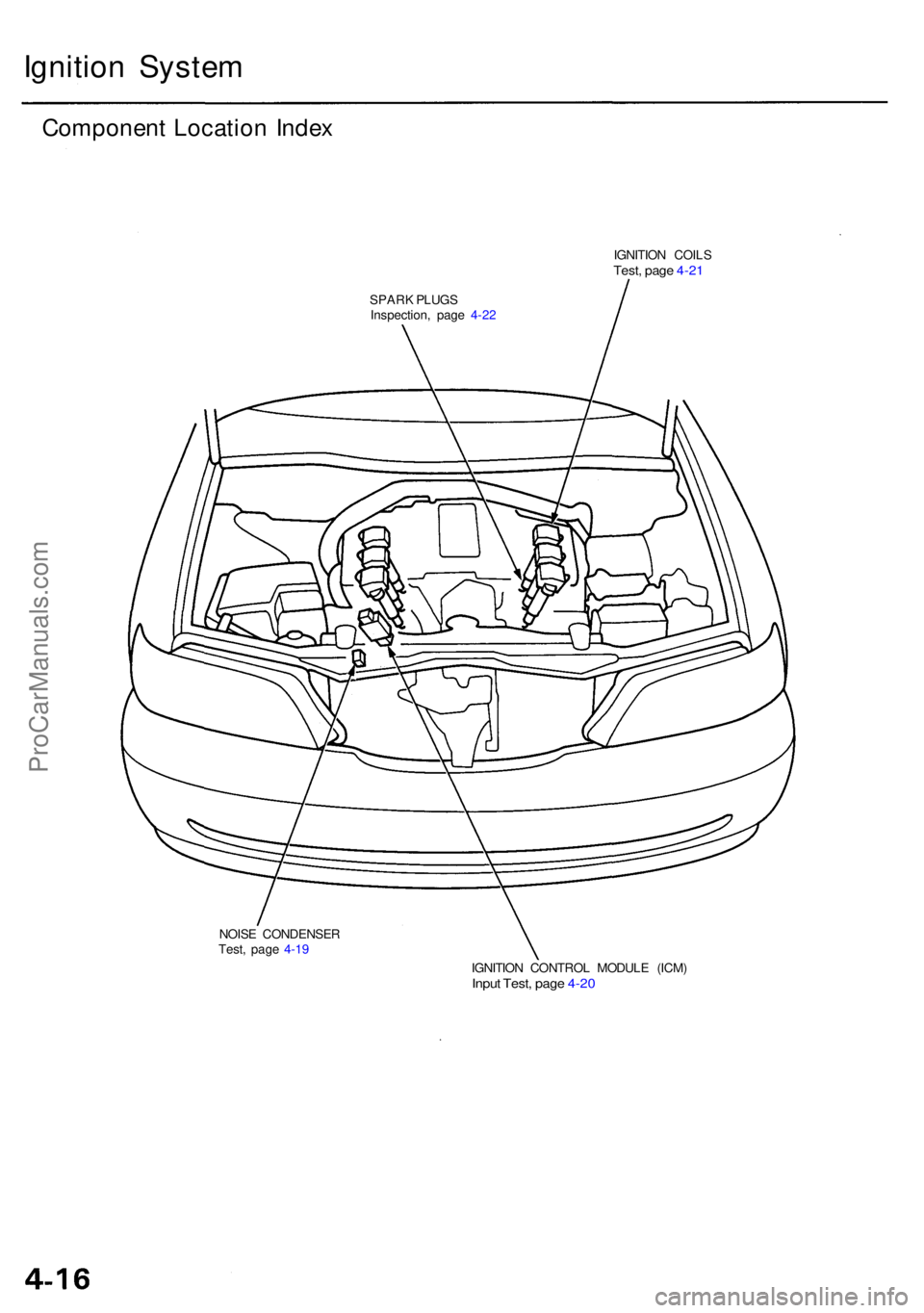

Ignition Syste m

Componen t Locatio n Inde x

IGNITIO N COIL STest, pag e 4-2 1

SPAR K PLUG S

Inspection , pag e 4-2 2

NOIS E CONDENSE R

Test , pag e 4-1 9

IGNITION CONTRO L MODUL E (ICM )

Input Test , pag e 4-2 0

ProCarManuals.com

Page 338 of 1954

Ignition Syste m

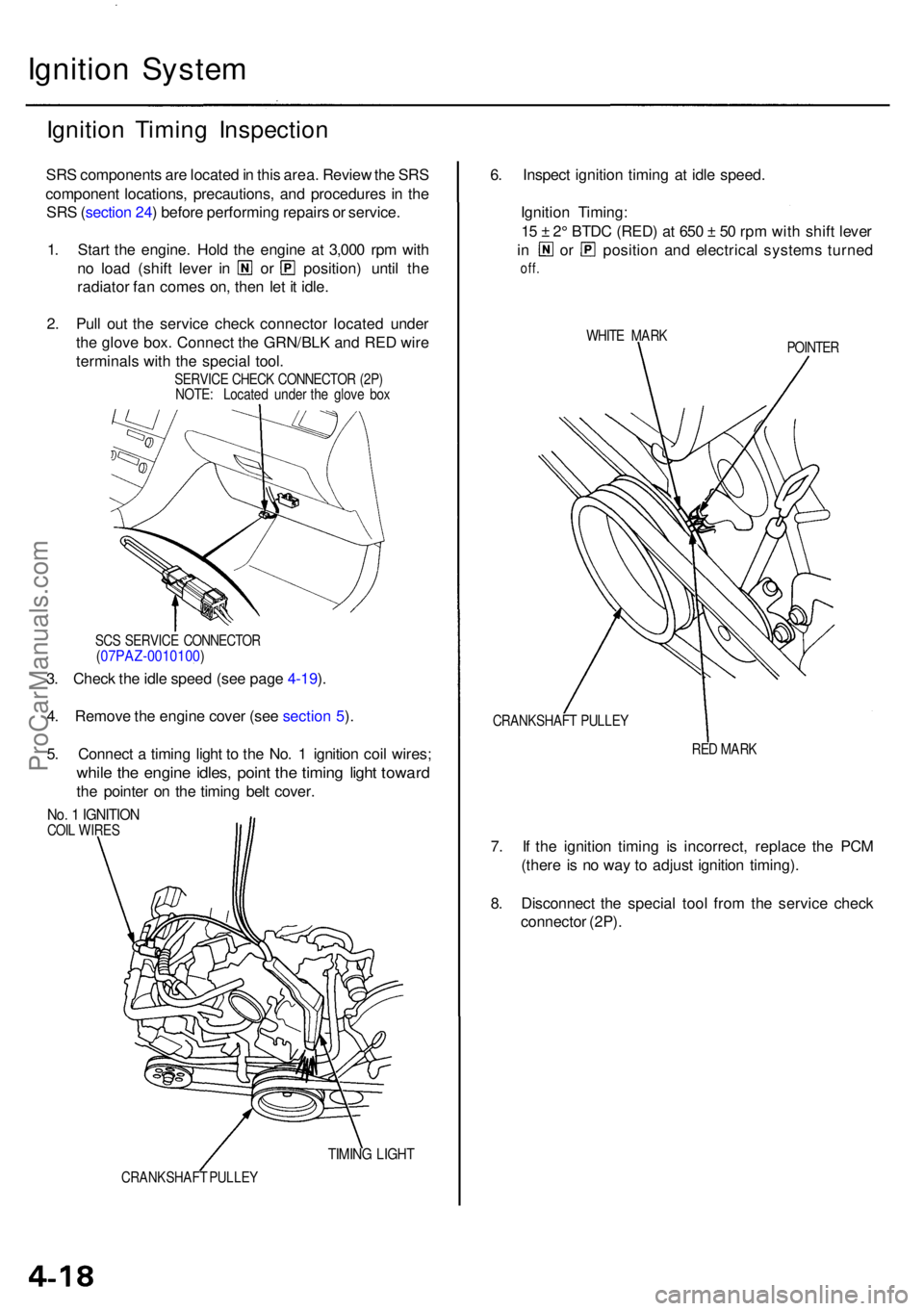

Ignition Timin g Inspectio n

SRS component s ar e locate d in thi s area . Revie w th e SR S

componen t locations , precautions , an d procedure s i n th e

SR S (sectio n 24 ) befor e performin g repair s o r service .

1 . Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (shif t leve r i n o r position ) unti l th e

radiato r fa n come s on , the n le t i t idle .

2 . Pul l ou t th e servic e chec k connecto r locate d unde r

th e glov e box . Connec t th e GRN/BL K an d RE D wir e

terminal s wit h th e specia l tool .

SERVIC E CHEC K CONNECTO R (2P )

NOTE : Locate d unde r th e glov e bo x

SC S SERVIC E CONNECTO R

(07PAZ-0010100 )

3. Chec k th e idl e spee d (se e pag e 4-19 ).

4 . Remov e th e engin e cove r (se e sectio n 5 ).

5 . Connec t a timin g ligh t t o th e No . 1 ignitio n coi l wires ;

while th e engin e idles , poin t th e timin g ligh t towar d

the pointe r o n th e timin g bel t cover .

No. 1 IGNITIO NCOIL WIRE S

TIMING LIGH T

CRANKSHAF T PULLE Y

6. Inspec t ignitio n timin g a t idl e speed .

Ignitio n Timing :

1 5 ± 2° BTD C (RED ) a t 65 0 ± 5 0 rp m wit h shif t leve r

in o r positio n an d electrica l system s turne d

off.

WHIT E MAR K

POINTER

CRANKSHAF T PULLE Y

RED MAR K

7. I f th e ignitio n timin g i s incorrect , replac e th e PC M

(ther e i s n o wa y t o adjus t ignitio n timing) .

8 . Disconnec t th e specia l too l fro m th e servic e chec k

connecto r (2P) .

ProCarManuals.com

Page 339 of 1954

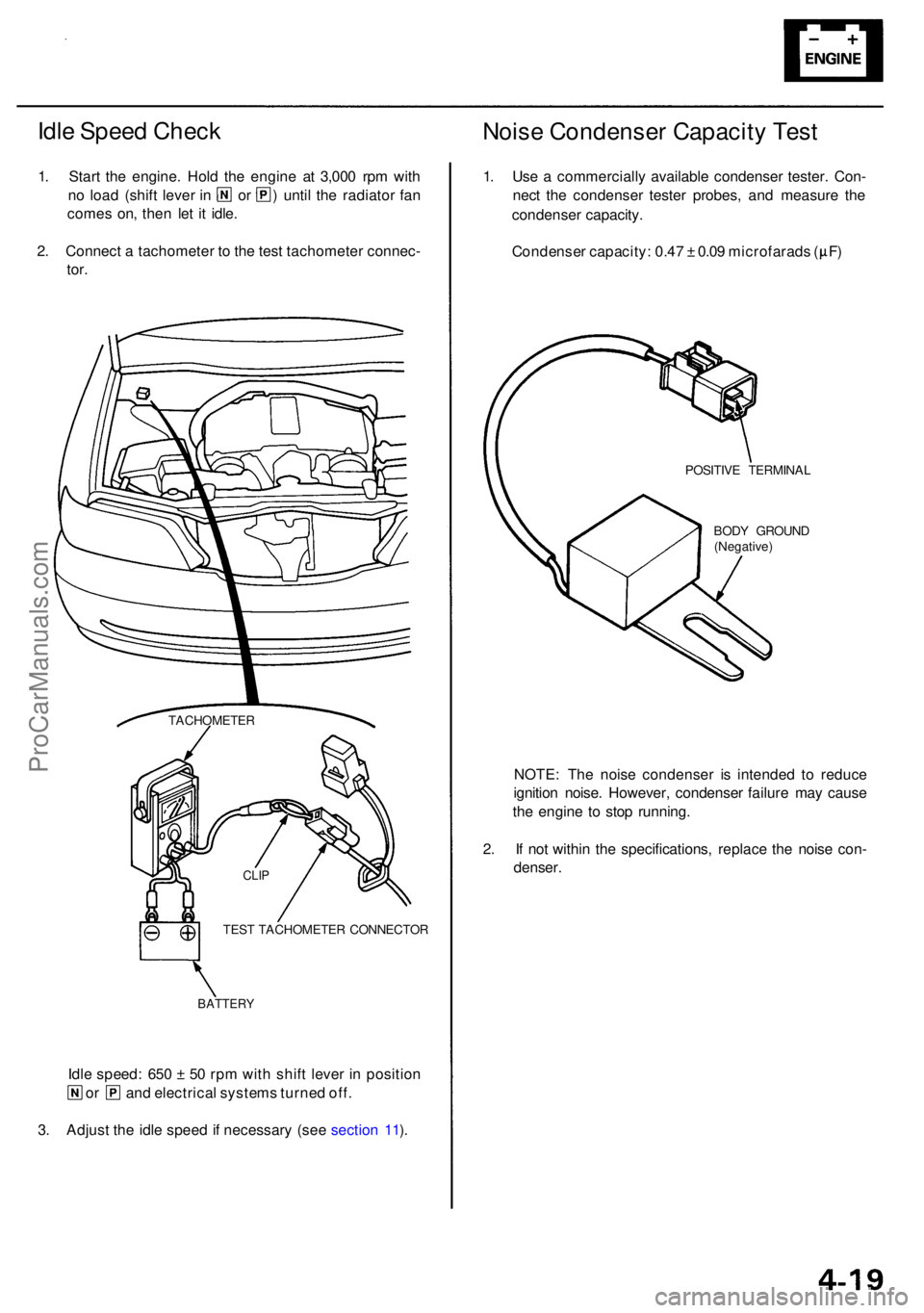

Idle Spee d Chec k

1. Star t th e engine . Hol d th e engin e a t 3,00 0 rp m wit h

no loa d (shif t leve r i n o r ) unti l th e radiato r fa n

come s on , the n le t i t idle .

2 . Connec t a tachomete r t o th e tes t tachomete r connec -

tor.

TES T TACHOMETE R CONNECTO R

BATTERY

Idle speed : 65 0 ± 50 rp m wit h shif t leve r i n positio n

or an d electrica l system s turne d off .

3 . Adjus t th e idl e spee d if necessar y (se e sectio n 11 ).

Nois e Condense r Capacit y Tes t

1. Us e a commerciall y availabl e condense r tester . Con -

nec t th e condense r teste r probes , an d measur e th e

condense r capacity .

Condense r capacity : 0.4 7 ± 0.0 9 microfarad s ( F )

POSITIV E TERMINA L

BOD Y GROUN D

(Negative )

NOTE: Th e nois e condense r i s intende d t o reduc e

ignitio n noise . However , condense r failur e ma y caus e

th e engin e t o sto p running .

2 . I f no t withi n th e specifications , replac e th e nois e con -

denser .CLIP

TACHOMETE R

ProCarManuals.com

Page 340 of 1954

Ignition Syste m

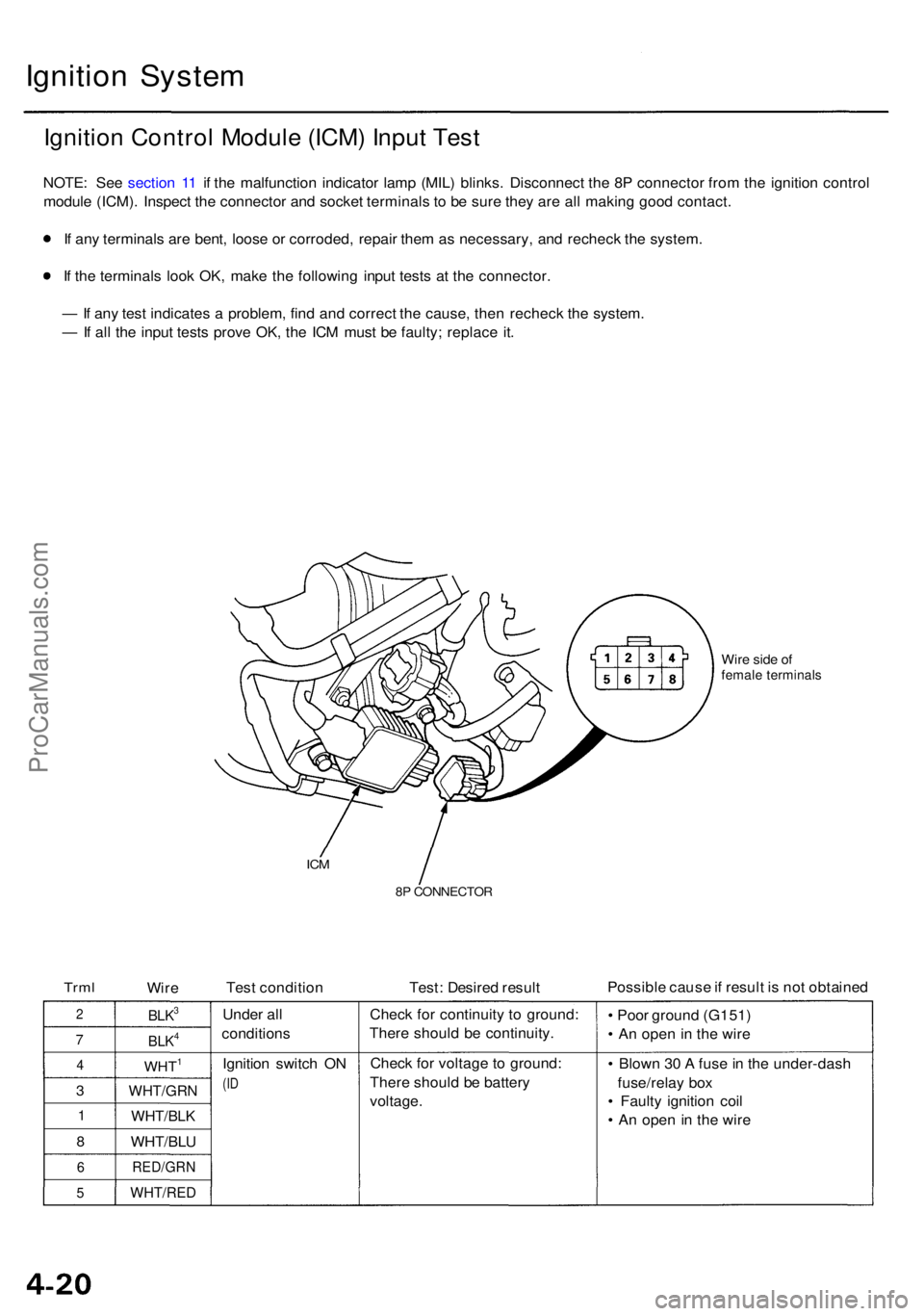

Ignition Contro l Modul e (ICM ) Inpu t Tes t

NOTE : Se e sectio n 1 1 i f th e malfunctio n indicator lamp (MIL ) blinks . Disconnec t th e 8 P connecto r fro m th e ignitio n contro l

modul e (ICM) . Inspec t th e connecto r an d socke t terminal s t o b e sur e the y ar e al l makin g goo d contact .

I f an y terminal s ar e bent , loos e o r corroded , repai r the m a s necessary , an d rechec k th e system .

I f th e terminal s loo k OK , mak e th e followin g inpu t test s a t th e connector .

— If an y tes t indicate s a problem , fin d an d correc t th e cause , the n rechec k th e system .

— If al l th e inpu t test s prov e OK , th e IC M mus t b e faulty ; replac e it .

Wir e sid e o ffemal e terminal s

ICM

8P CONNECTO R

TrmlWire Tes

t conditio n Test: Desire d resul t Possibl

e caus e if resul t i s no t obtaine d

2

7

4

3

1

8

6

5

BLK3

BLK4

WHT1

WHT/GR N

WHT/BLK

WHT/BLU

RED/GR N

WHT/RED

Under al l

condition s

Ignitio n switc h O N

(ID

Chec k fo r continuit y t o ground :

Ther e shoul d b e continuity .

Chec k fo r voltag e t o ground :

Ther e shoul d b e batter y

voltage . •

Poo r groun d (G151 )

• A n ope n in th e wir e

• Blow n 3 0 A fus e in th e under-das h

fuse/rela y bo x

• Fault y ignitio n coi l

• A n ope n i n th e wir e

ProCarManuals.com