ACURA RL KA9 1996 Service Repair Manual

Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 381 of 1954

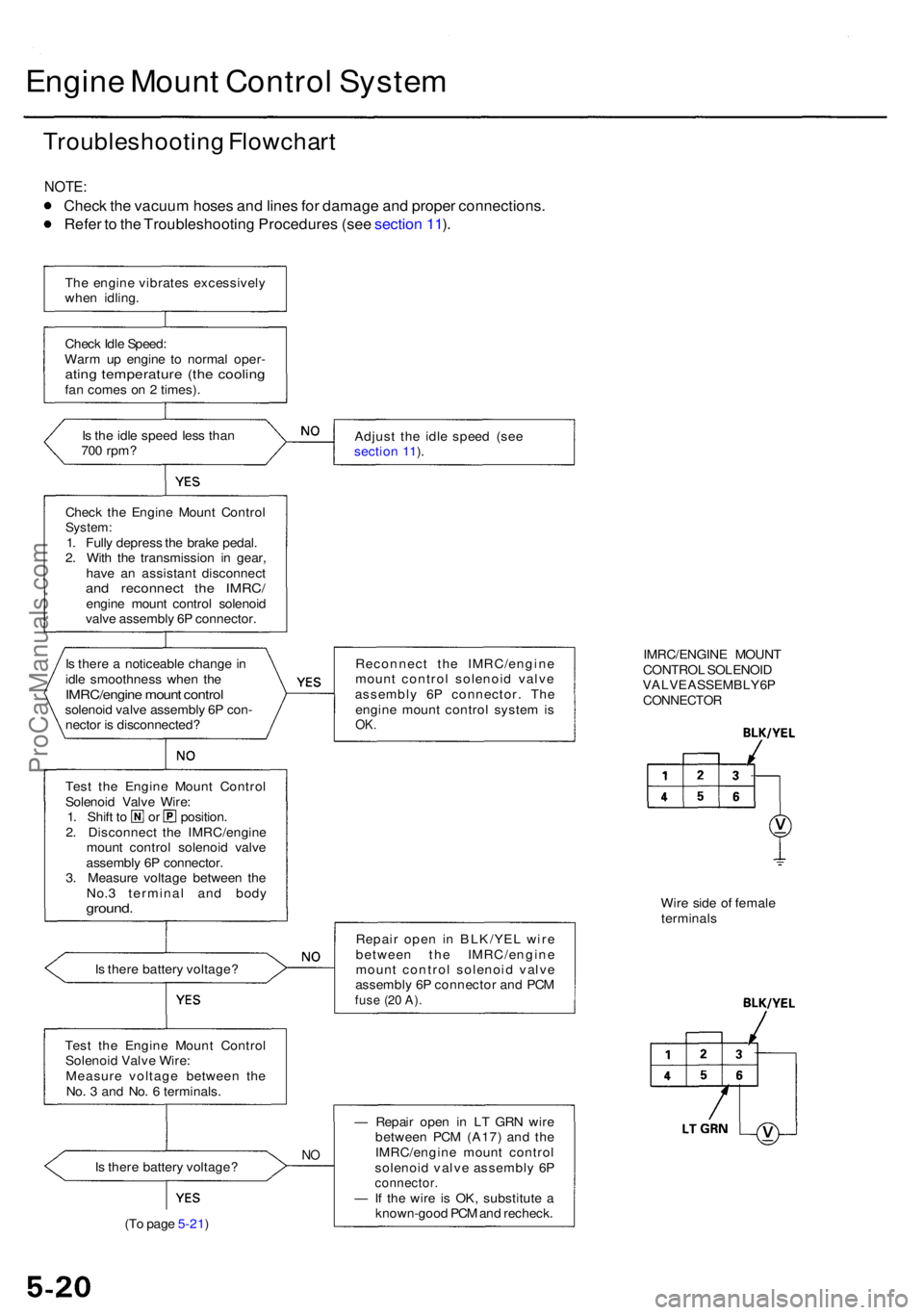

Engine Moun t Contro l Syste m

Troubleshootin g Flowchar t

NOTE:

Check th e vacuu m hose s an d line s fo r damag e an d prope r connections .

Refe r t o th e Troubleshootin g Procedure s (se e sectio n 11 ).

Th e engin e vibrate s excessivel y

whe n idling .

Chec k Idl e Speed :

War m u p engin e t o norma l oper -

ating temperatur e (th e coolin gfan come s o n 2 times) .

I s th e idl e spee d les s tha n

70 0 rpm ? Adjus

t th e idl e spee d (se e

sectio n 11 ).

Chec k th e Engin e Moun t Contro l

System:1. Full y depres s th e brak e pedal .

2 . Wit h th e transmissio n i n gear ,

hav e a n assistan t disconnec t

and reconnec t th e IMRC /engine moun t contro l solenoi d

valv e assembl y 6 P connector .

I s ther e a noticeabl e chang e in

idl e smoothnes s whe n th e

IMRC/engin e moun t contro lsolenoi d valv e assembl y 6 P con -

necto r i s disconnected ? Reconnec

t th e IMRC/engin e

moun t contro l solenoi d valv e

assembl y 6 P connector . Th e

engin e moun t contro l syste m isOK .

IMRC/ENGIN E MOUN T

CONTRO L SOLENOI D

VALV E ASSEMBL Y 6P

CONNECTO R

Test th e Engin e Moun t Contro l

Solenoi d Valv e Wire :

1. Shif t t o o r position .

2 . Disconnec t th e IMRC/engin e

moun t contro l solenoi d valv e

assembl y 6 P connector .

3 . Measur e voltag e betwee n th e

No. 3 termina l an d bod y

ground .

Is ther e batter y voltage ? Repai

r ope n i n BLK/YE L wir e

betwee n th e IMRC/engin e

moun t contro l solenoi d valv e

assembl y 6 P connecto r an d PC M

fuse (2 0 A) .

Wir e sid e o f femal e

terminal s

Tes t th e Engin e Moun t Contro l

Solenoi d Valv e Wire :

Measur e voltag e betwee n th e

No . 3 an d No . 6 terminals .

I s ther e batter y voltage ?

NO

(T o pag e 5-21 ) —

Repai r ope n i n L T GR N wir e

betwee n PC M (A17 ) an d th e

IMRC/engin e moun t contro l

solenoi d valv e assembl y 6 P

connector .— If th e wir e i s OK , substitut e a

known-goo d PC M an d recheck .

ProCarManuals.com

Page 382 of 1954

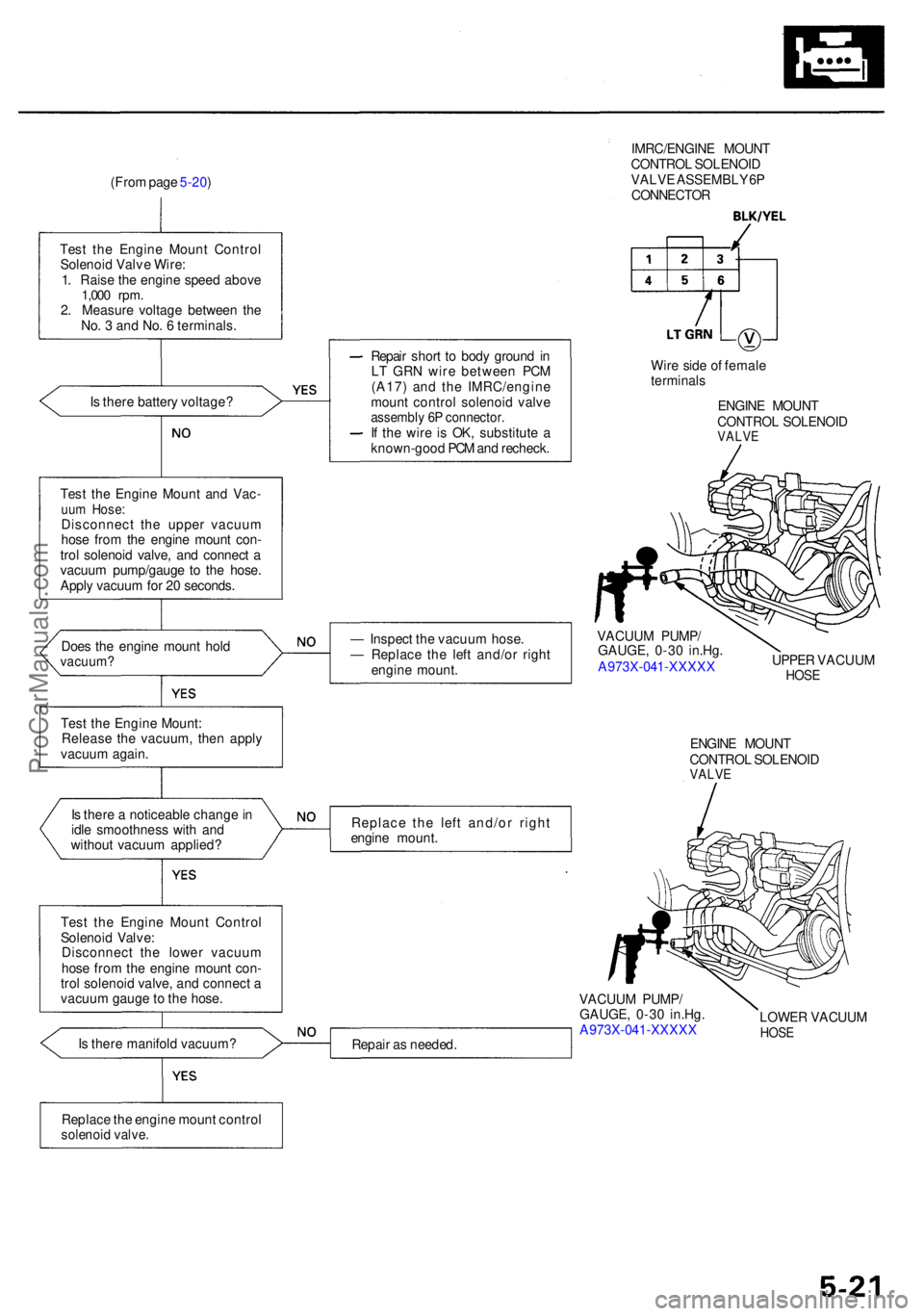

(From pag e 5-20 ) IMRC/ENGIN

E MOUN T

CONTRO L SOLENOI D

VALV E ASSEMBL Y 6PCONNECTO R

Test th e Engin e Moun t Contro l

Solenoi d Valv e Wire :

1 . Rais e th e engin e spee d abov e

1,000 rpm .2. Measur e voltag e betwee n th e

No . 3 an d No . 6 terminals .

I s ther e batter y voltage ? Repai

r shor t t o bod y groun d in

L T GR N wir e betwee n PC M

(A17 ) an d th e IMRC/engin e

moun t contro l solenoi d valv e

assembl y 6 P connector .If th e wir e i s OK , substitut e a

known-goo d PC M an d recheck . Wir

e sid e o f femal e

terminal s

ENGIN E MOUN TCONTRO L SOLENOI DVALVE

Test th e Engin e Moun t an d Vac -uum Hose :Disconnec t th e uppe r vacuu m

hos e fro m th e engin e moun t con -

tro l solenoi d valve , an d connec t a

vacuu m pump/gaug e t o th e hose .

Appl y vacuu m fo r 2 0 seconds .

Doe s th e engin e moun t hol d

vacuum ?

— Inspec t th e vacuu m hose .

— Replac e th e lef t and/o r righ t

engin e mount . VACUU

M PUMP /

GAUGE , 0-3 0 in.Hg .

A973 X-04 1-XXXX X UPPE

R VACUU M

HOSE

Test th e Engin e Mount :

Releas e th e vacuum , the n appl y

vacuu m again . ENGIN

E MOUN T

CONTRO L SOLENOI D

VALVE

Is ther e a noticeabl e chang e in

idl e smoothnes s wit h an d

withou t vacuu m applied ? Replac

e th e lef t and/o r righ t

engin e mount .

Tes t th e Engin e Moun t Contro l

Solenoi d Valve :

Disconnec t th e lowe r vacuu m

hos e fro m th e engin e moun t con -

tro l solenoi d valve , an d connec t a

vacuu m gaug e t o th e hose .

I s ther e manifol d vacuum ?

Repair a s needed . VACUU

M PUMP /

GAUGE , 0-3 0 in.Hg .

A973 X-04 1-XXXX X LOWE

R VACUU M

HOSE

Replac e th e engin e moun t contro lsolenoi d valve .

ProCarManuals.com

Page 383 of 1954

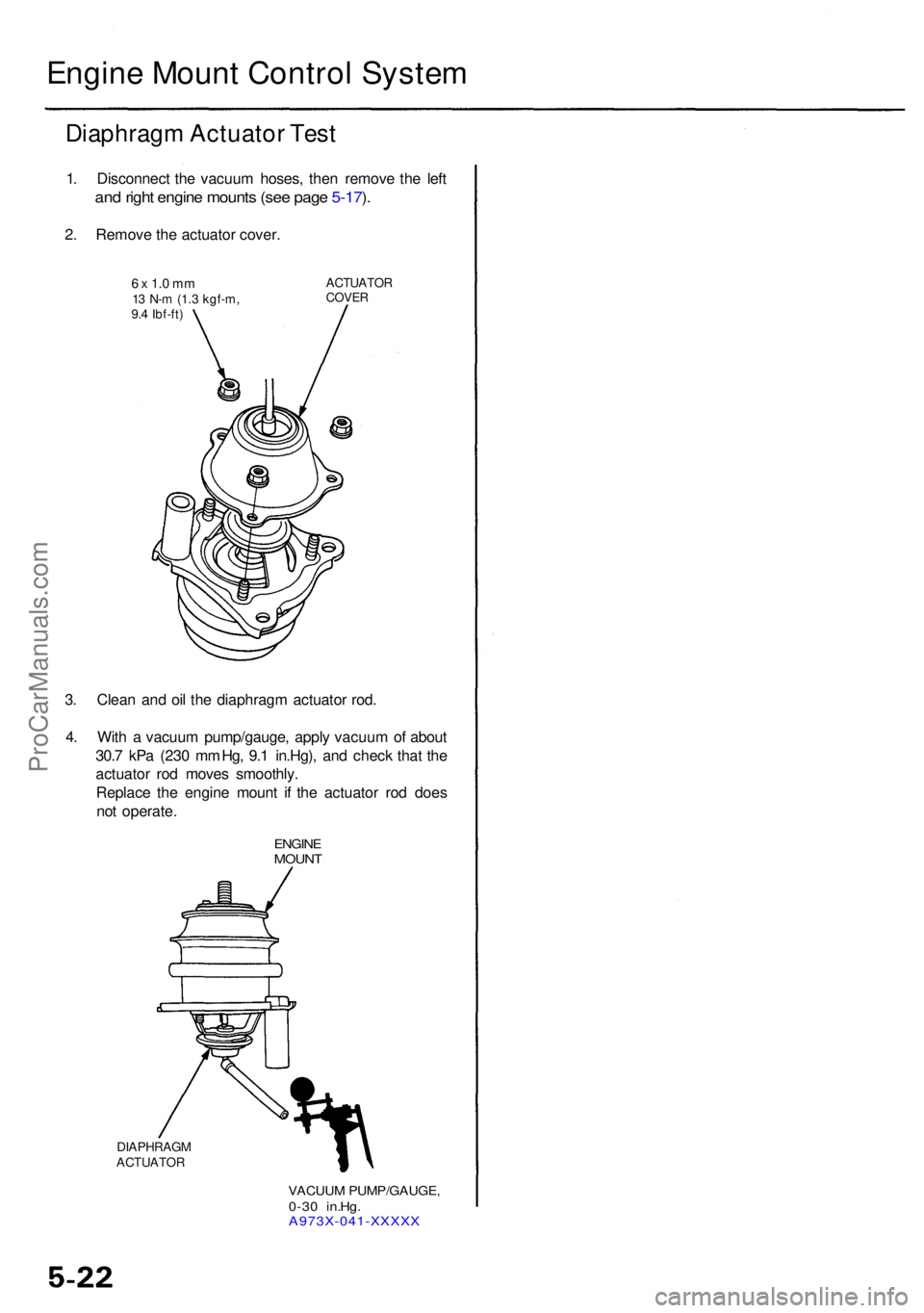

Engine Moun t Contro l Syste m

Diaphrag m Actuato r Tes t

1. Disconnec t th e vacuu m hoses , the n remov e th e lef t

and righ t engin e mount s (se e pag e 5-17 ).

2 . Remov e th e actuato r cover .

6 x 1. 0 m m13 N- m (1. 3 kgf-m ,

9. 4 Ibf-ft ) ACTUATO

RCOVER

3. Clea n an d oi l th e diaphrag m actuato r rod .

4 . Wit h a vacuu m pump/gauge , appl y vacuu m o f abou t

30. 7 kP a (23 0 m m Hg , 9. 1 in.Hg) , an d chec k tha t th e

actuato r ro d move s smoothly .

Replac e th e engin e moun t i f th e actuato r ro d doe s

no t operate .

DIAPHRAG M

ACTUATO R

VACUUM PUMP/GAUGE ,0-30 in.Hg .A973X-041-XXXX X

ENGINEMOUN T

ProCarManuals.com

Page 384 of 1954

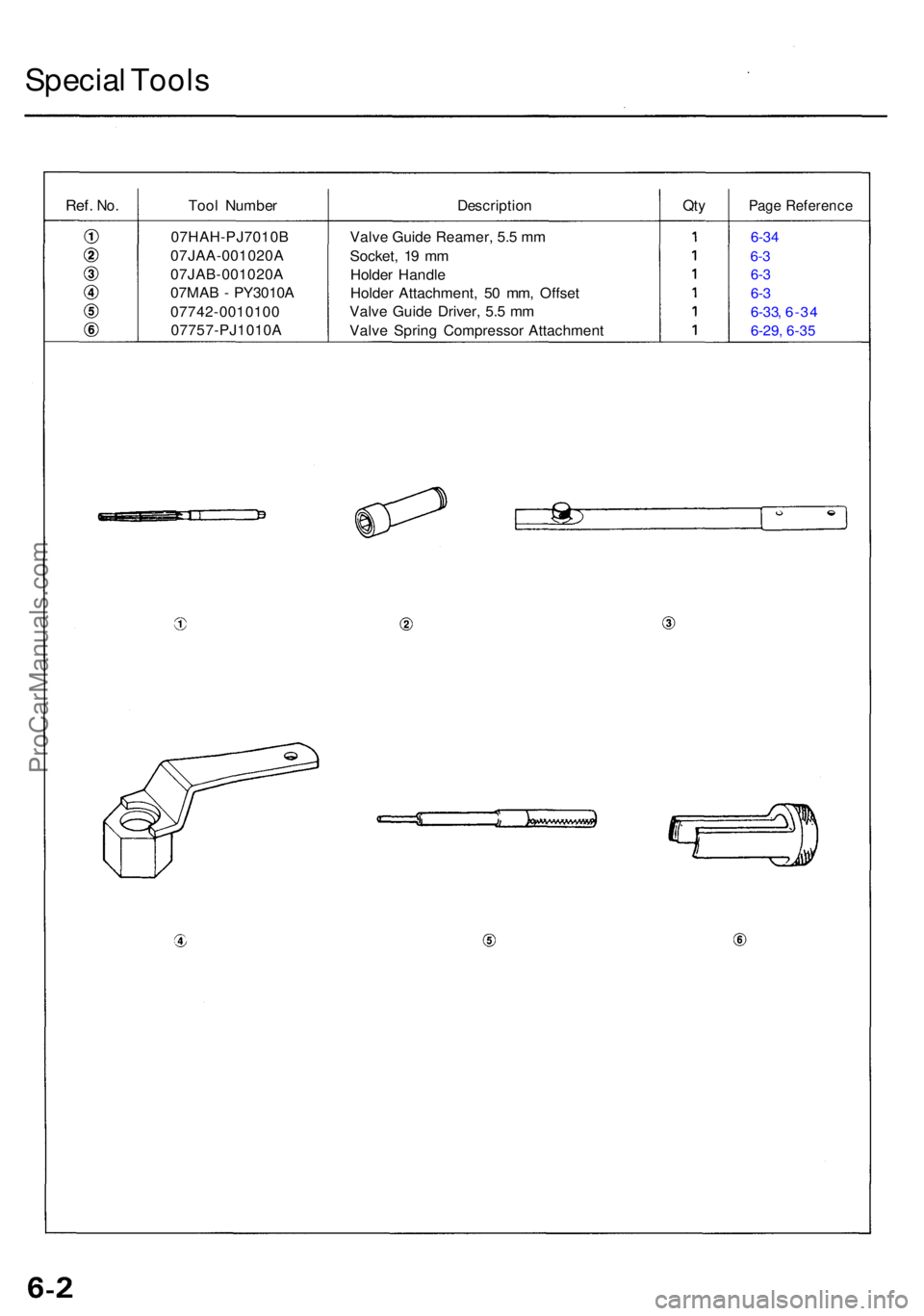

Special Tool s

Ref. No.Too l Numbe r DescriptionQtyPag e Referenc e

Valve Guid e Reamer , 5. 5 m m

Socket , 1 9 m m

Holde r Handl e

Holde r Attachment , 5 0 mm , Offse t

Valv e Guid e Driver , 5. 5 m m

Valv e Sprin g Compresso r Attachmen t6-34

6-3

6-3

6-3

6-3 3, 6- 34

6-29 , 6- 35

07HAH-PJ7010 B

07JAA-001020 A

07JAB-001020 A

07MA B - PY3010 A

07742-001010 0

07757-PJ1010 A

ProCarManuals.com

Page 385 of 1954

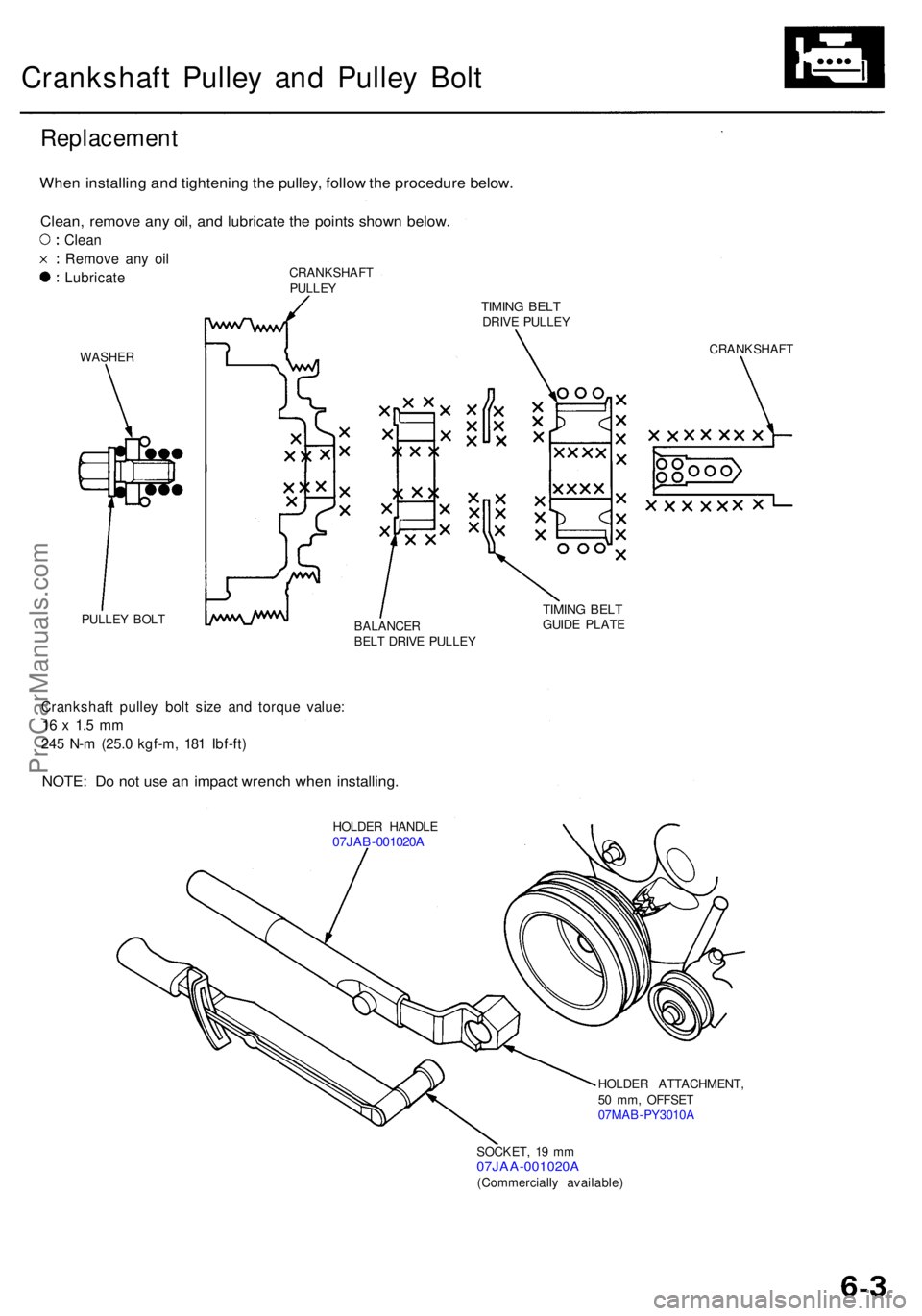

Crankshaft Pulle y an d Pulle y Bol t

Replacemen t

When installin g an d tightenin g th e pulley , follo w th e procedur e below .

Clean, remov e an y oil , an d lubricat e th e point s show n below .

Clean

Remov e an y oi l

Lubricat e

WASHER

PULLE Y BOL T CRANKSHAF

T

PULLE Y

TIMING BEL TDRIV E PULLE Y

CRANKSHAFT

BALANCE R

BEL T DRIV E PULLE Y

TIMING BEL TGUID E PLAT E

Crankshaf t pulle y bol t siz e an d torqu e value :

16 x 1. 5 m m

245 N- m (25. 0 kgf-m , 18 1 Ibf-ft )

HOLDE R HANDL E07JAB-001020 A

HOLDE R ATTACHMENT ,

5 0 mm , OFFSE T

07MA B-PY3010 A

SOCKET , 1 9 m m

07JAA-001020 A(Commercially available )

NOTE: D o no t us e a n impac t wrenc h whe n installing .

ProCarManuals.com

Page 386 of 1954

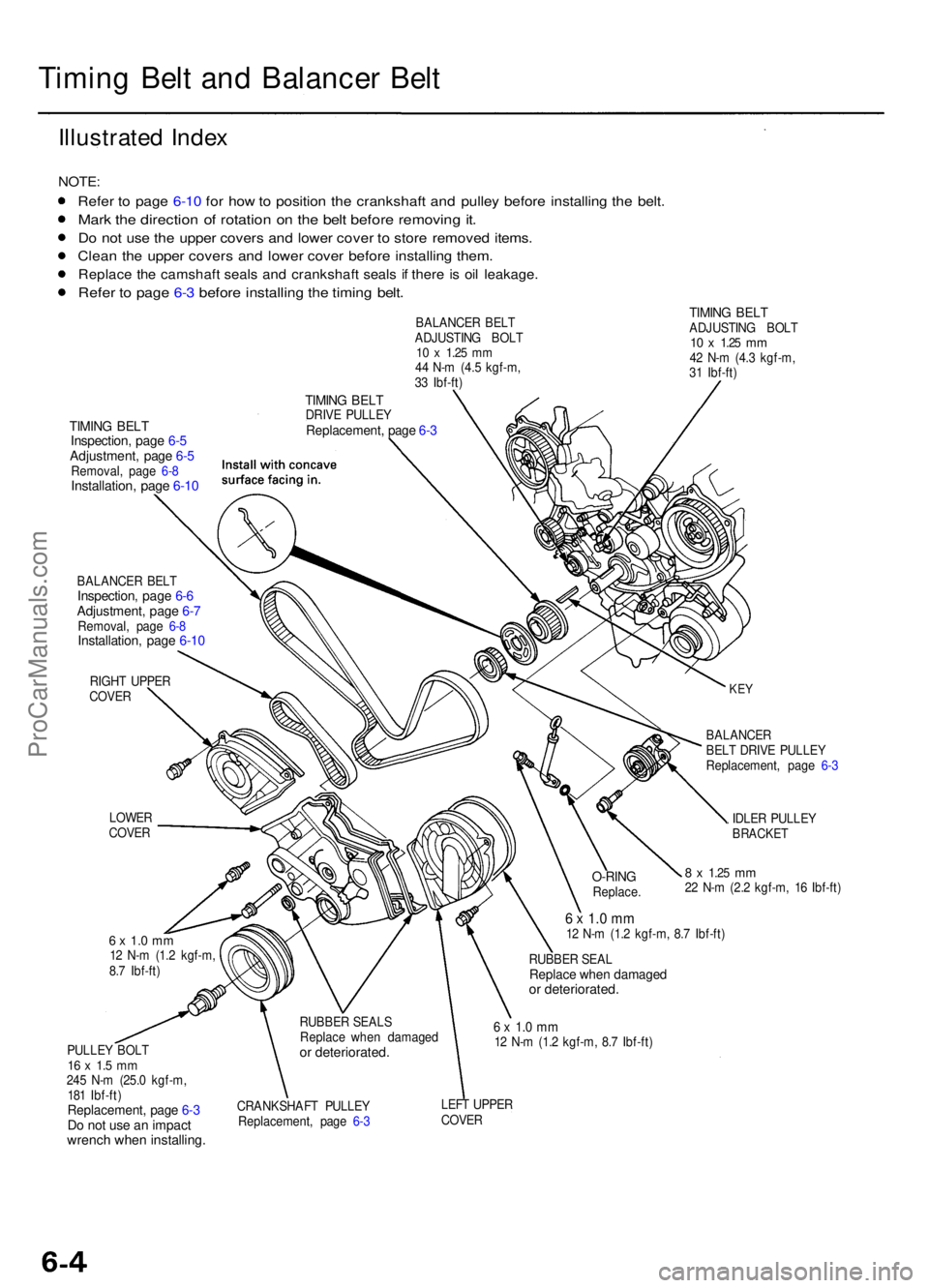

Timing Bel t an d Balance r Bel t

Illustrate d Inde x

NOTE :

Refer t o pag e 6-1 0 fo r ho w to positio n th e crankshaf t an d pulle y befor e installin g th e belt .

Mark th e directio n o f rotatio n o n th e bel t befor e removin g it .

Do no t us e th e uppe r cover s an d lowe r cove r t o stor e remove d items .

Clean th e uppe r cover s an d lowe r cove r befor e installin g them .

Replac e th e camshaf t seal s an d crankshaf t seal s i f ther e i s oi l leakage .

Refer t o pag e 6- 3 befor e installin g th e timin g belt .

TIMIN G BEL TADJUSTIN G BOL T10 x 1.2 5 mm42 N- m (4. 3 kgf-m ,

3 1 Ibf-ft )

TIMIN G BEL TInspection , pag e 6- 5Adjustment , pag e 6- 5Removal , pag e 6- 8Installation , pag e 6-1 0

BALANCE R BEL TInspection , pag e 6- 6Adjustment , pag e 6- 7Removal , pag e 6- 8Installation , pag e 6-1 0

RIGH T UPPE R

COVE R

TIMING BEL TDRIV E PULLE YReplacement , pag e 6- 3

LOWE R

COVE R BALANCE

R

BEL T DRIV E PULLE Y

Replacement , pag e 6- 3

IDLE R PULLE YBRACKE T

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

PULLE Y BOL T

16 x 1. 5 m m245 N- m (25. 0 kgf-m ,

18 1 Ibf-ft )

Replacement , pag e 6- 3Do no t us e a n impac twrench whe n installing .

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

RUBBE R SEA L

Replac e whe n damage dor deteriorated .

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

CRANKSHAF T PULLE Y

Replacement , pag e 6- 3 LEF

T UPPE R

COVE R

O-RINGReplace .

RUBBE R SEAL S

Replac e whe n damage d

or deteriorated .

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft ) BALANCE

R BEL T

ADJUSTIN G BOL T

10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

KEY

ProCarManuals.com

Page 387 of 1954

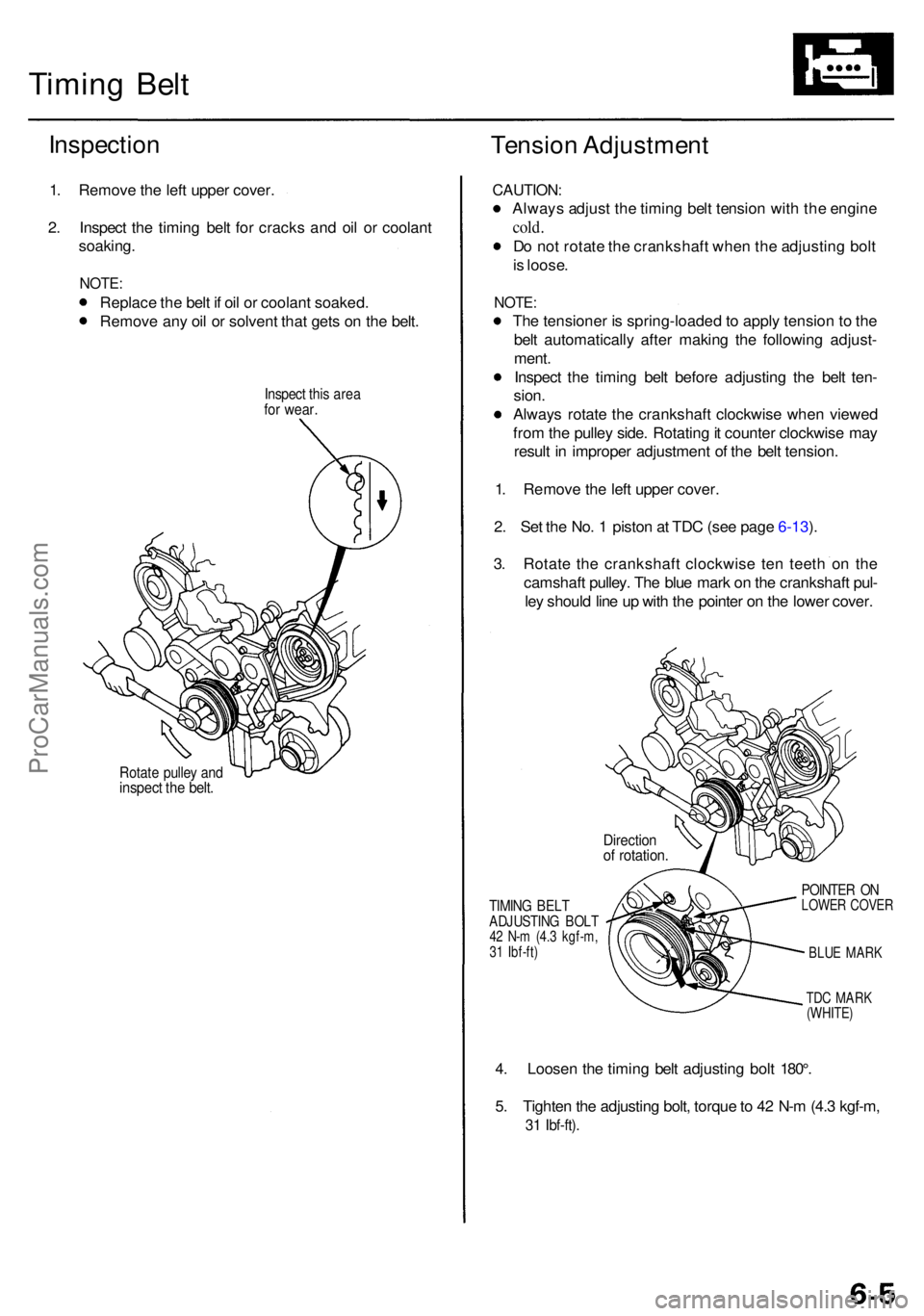

Timing Bel t

Inspectio n

1. Remov e th e lef t uppe r cover .

2 . Inspec t th e timin g bel t fo r crack s an d oi l o r coolan t

soaking .

NOTE:

Replac e th e bel t i f oi l o r coolan t soaked .

Remov e an y oi l o r solven t tha t get s o n th e belt .

Inspec t thi s are afor wear .

Tensio n Adjustmen t

Rotate pulle y an dinspec t th e belt .

CAUTION :

Always adjus t th e timin g bel t tensio n wit h th e engin e

cold.

Do no t rotat e th e crankshaf t whe n th e adjustin g bol t

i s loose .

NOTE :

The tensione r i s spring-loade d to appl y tensio n t o th e

bel t automaticall y afte r makin g th e followin g adjust -

ment .

Inspec t th e timin g bel t befor e adjustin g th e bel t ten -

sion .

Alway s rotat e th e crankshaf t clockwis e whe n viewe d

fro m th e pulle y side . Rotatin g it counte r clockwis e ma y

resul t i n imprope r adjustmen t o f th e bel t tension .

1 . Remov e th e lef t uppe r cover .

2 . Se t th e No . 1 pisto n a t TD C (se e pag e 6-13 ).

3 . Rotat e th e crankshaf t clockwis e te n teet h o n th e

camshaf t pulley . Th e blu e mar k o n th e crankshaf t pul -

le y shoul d lin e u p wit h th e pointe r o n th e lowe r cover .

TIMING BEL TADJUSTIN G BOL T42 N- m (4. 3 kgf-m ,

3 1 Ibf-ft )

POINTE R O NLOWE R COVE R

BLU E MAR K

TD C MAR K

(WHITE )

4. Loose n th e timin g bel t adjustin g bol t 180° .

5 . Tighte n th e adjustin g bolt , torqu e to 4 2 N- m (4. 3 kgf-m ,

31 Ibf-ft) .

Directio nof rotation .

ProCarManuals.com

Page 388 of 1954

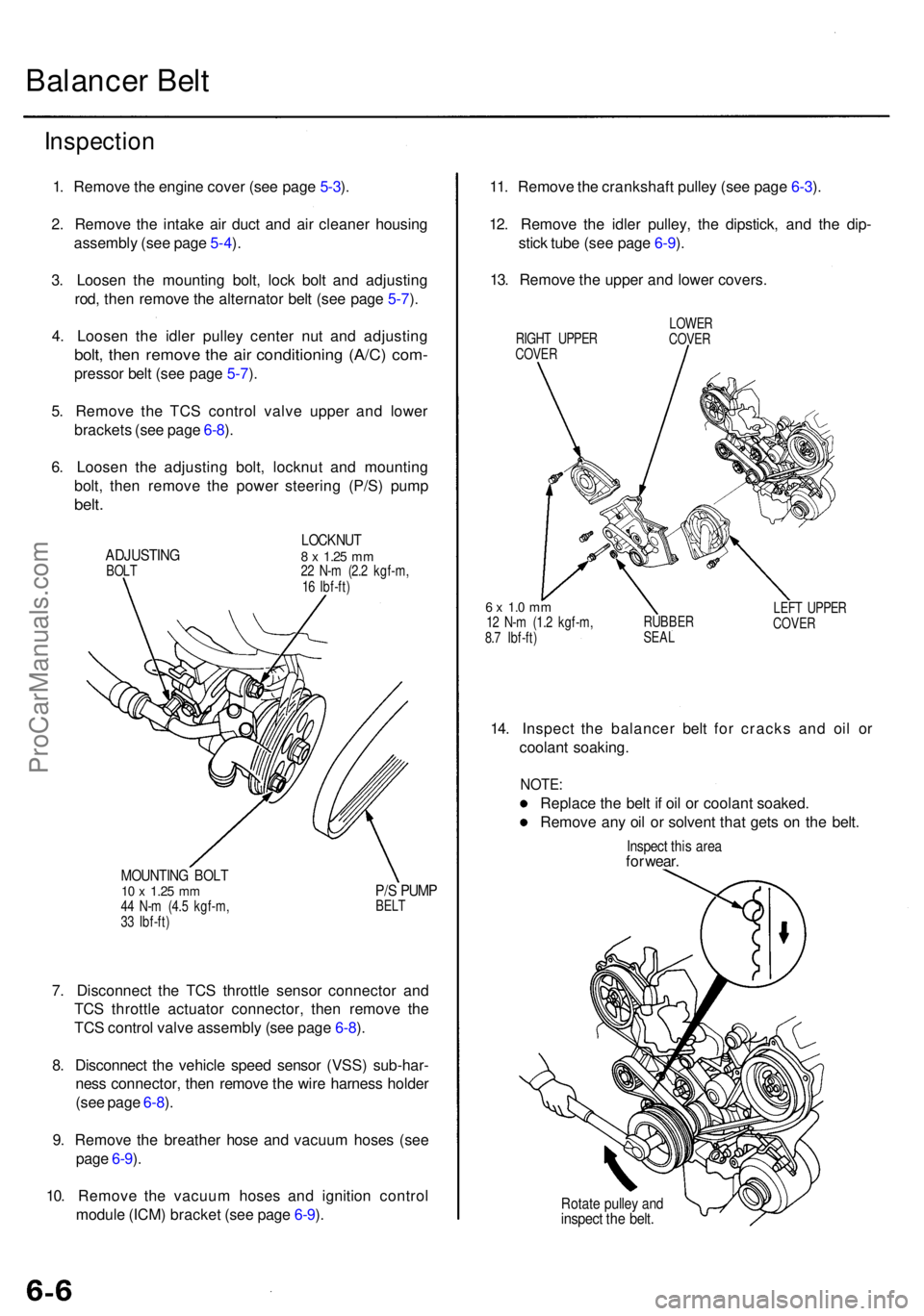

Balancer Bel t

Inspectio n

1. Remov e th e engin e cove r (se e pag e 5-3 ).

2 . Remov e th e intak e ai r duc t an d ai r cleane r housin g

assembl y (se e pag e 5-4 ).

3 . Loose n th e mountin g bolt , loc k bol t an d adjustin g

rod , the n remov e th e alternato r bel t (se e pag e 5-7 ).

4 . Loose n th e idle r pulle y cente r nu t an d adjustin g

bolt, the n remov e th e ai r conditionin g (A/C ) com -

presso r bel t (se e pag e 5-7 ).

5 . Remov e th e TC S contro l valv e uppe r an d lowe r

bracket s (se e pag e 6-8 ).

6 . Loose n th e adjustin g bolt , locknu t an d mountin g

bolt , the n remov e th e powe r steerin g (P/S ) pum p

belt.

ADJUSTIN GBOLT

LOCKNU T8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

MOUNTIN G BOL T10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )P/S PUM PBELT

7. Disconnec t th e TC S throttl e senso r connecto r an d

TC S throttl e actuato r connector , the n remov e th e

TC S contro l valv e assembl y (se e pag e 6-8 ).

8 . Disconnec t th e vehicl e spee d senso r (VSS ) sub-har -

nes s connector , the n remov e th e wir e harnes s holde r

(se e pag e 6-8 ).

9 . Remov e th e breathe r hos e an d vacuu m hose s (se e

pag e 6-9 ).

10 . Remov e th e vacuu m hose s an d ignitio n contro l

modul e (ICM ) bracke t (se e pag e 6-9 ). 11

. Remov e th e crankshaf t pulle y (se e pag e 6-3 ).

12 . Remov e th e idle r pulley , th e dipstick , an d th e dip -

stic k tub e (se e pag e 6-9 ).

13 . Remov e th e uppe r an d lowe r covers .

RIGHT UPPE R

COVE R LOWE

R

COVE R

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft ) RUBBE

R

SEA L LEF

T UPPE R

COVE R

14. Inspec t th e balance r bel t fo r crack s an d oi l o r

coolan t soaking .

NOTE:

Replac e th e bel t i f oi l o r coolan t soaked .

Remov e an y oi l o r solven t tha t get s o n th e belt .

Rotat e pulle y an dinspec t th e belt .

Inspec t thi s are afor wear .

ProCarManuals.com

Page 389 of 1954

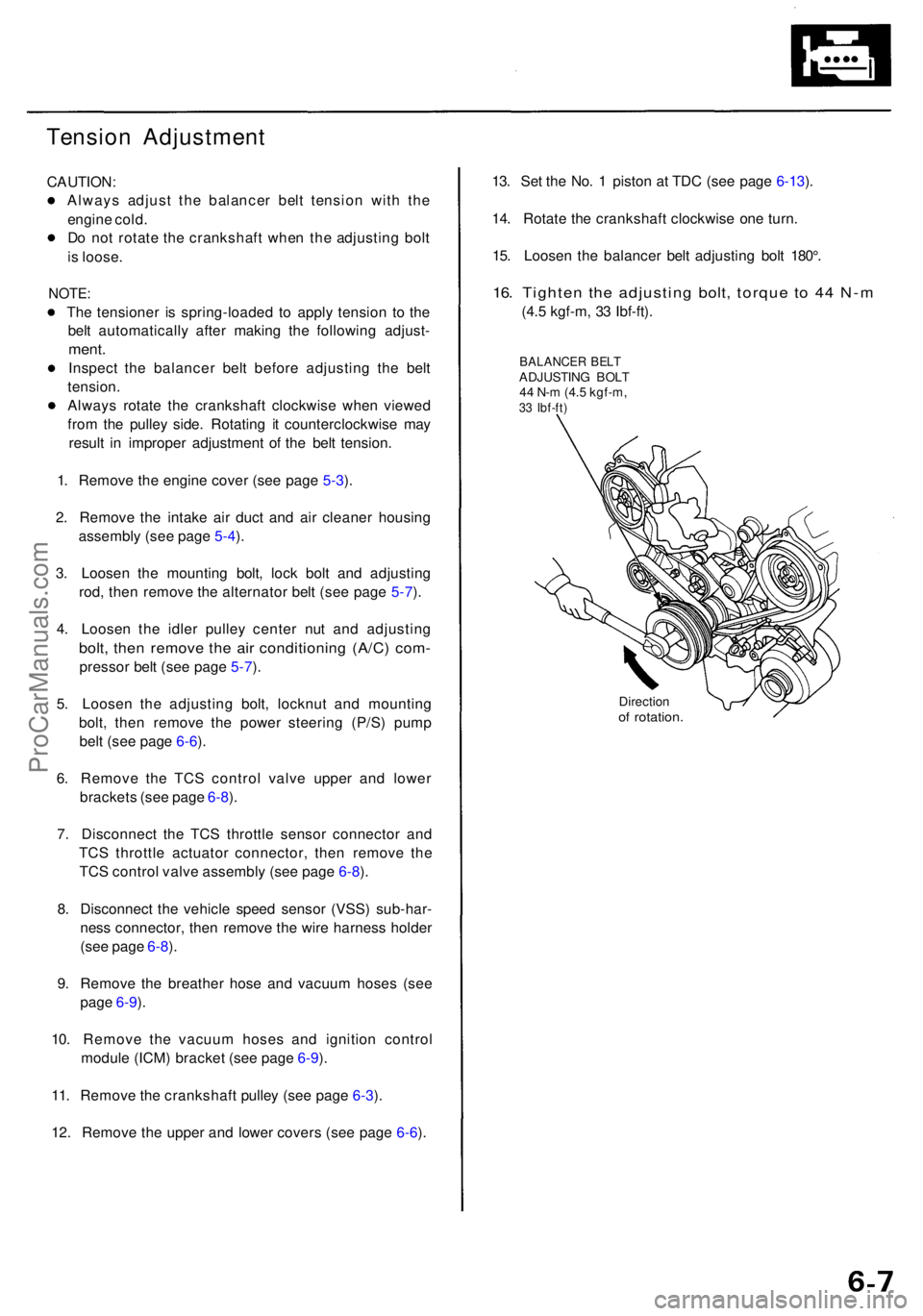

Tension Adjustmen t

CAUTION:

Always adjus t th e balance r bel t tensio n wit h th e

engin e cold .

D o no t rotat e th e crankshaf t whe n th e adjustin g bol t

i s loose .

NOTE :

The tensione r i s spring-loade d t o appl y tensio n t o th e

bel t automaticall y afte r makin g th e followin g adjust -

ment.

Inspec t th e balance r bel t befor e adjustin g th e bel t

tension .

Alway s rotat e th e crankshaf t clockwis e whe n viewe d

fro m th e pulle y side . Rotatin g i t counterclockwis e ma y

resul t i n imprope r adjustmen t o f th e bel t tension .

1 . Remov e th e engin e cove r (se e pag e 5-3 ).

2 . Remov e th e intak e ai r duc t an d ai r cleane r housin g

assembl y (se e pag e 5-4 ).

3 . Loose n th e mountin g bolt , loc k bol t an d adjustin g

rod , the n remov e th e alternato r bel t (se e pag e 5-7 ).

4 . Loose n th e idle r pulle y cente r nu t an d adjustin g

bolt, the n remov e th e ai r conditionin g (A/C ) com -

presso r bel t (se e pag e 5-7 ).

5 . Loose n th e adjustin g bolt , locknu t an d mountin g

bolt , the n remov e th e powe r steerin g (P/S ) pum p

bel t (se e pag e 6-6 ).

6 . Remov e th e TC S contro l valv e uppe r an d lowe r

bracket s (se e pag e 6-8 ).

7 . Disconnec t th e TC S throttl e senso r connecto r an d

TC S throttl e actuato r connector , the n remov e th e

TC S contro l valv e assembl y (se e pag e 6-8 ).

8 . Disconnec t th e vehicl e spee d senso r (VSS ) sub-har -

nes s connector , the n remov e th e wir e harnes s holde r

(se e pag e 6-8 ).

9 . Remov e th e breathe r hos e an d vacuu m hose s (se e

pag e 6-9 ).

10 . Remov e th e vacuu m hose s an d ignitio n contro l

modul e (ICM ) bracke t (se e pag e 6-9 ).

11 . Remov e th e crankshaf t pulle y (se e pag e 6-3 ).

12 . Remov e th e uppe r an d lowe r cover s (se e pag e 6-6 ). 13

. Se t th e No . 1 pisto n a t TD C (se e pag e 6-13 ).

14 . Rotat e th e crankshaf t clockwis e on e turn .

15 . Loose n th e balance r bel t adjustin g bol t 180° .

16. Tighte n th e adjustin g bolt , torqu e t o 4 4 N- m

(4.5 kgf-m , 3 3 Ibf-ft) .

BALANCE R BEL TADJUSTIN G BOL T

4 4 N- m (4. 5 kgf-m ,

33 Ibf-ft )

Directio nof rotation .

ProCarManuals.com

Page 390 of 1954

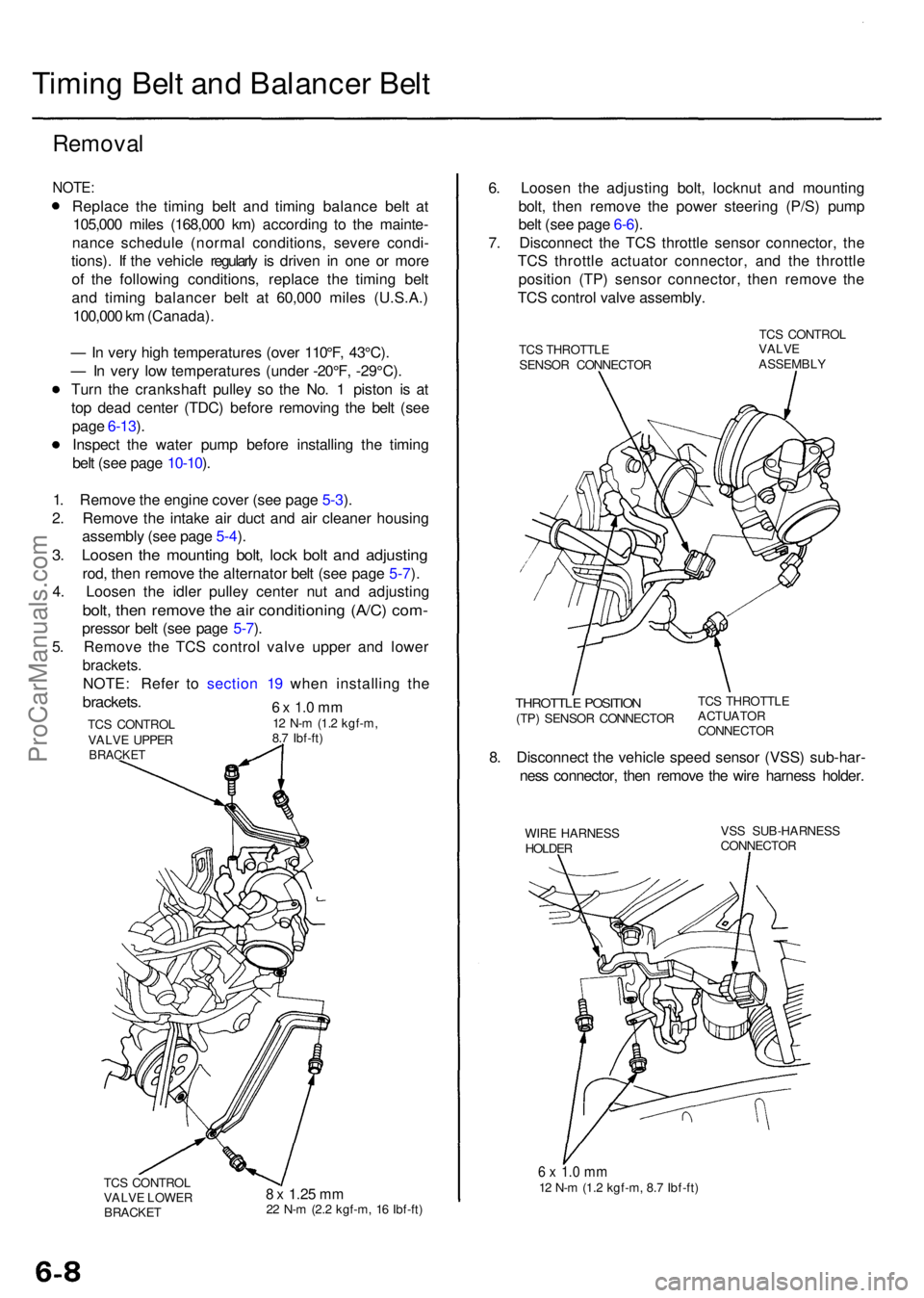

Timing Bel t an d Balance r Bel t

Remova l

NOTE:

Replac e th e timin g bel t an d timin g balanc e bel t a t

105,00 0 mile s (168,00 0 km ) accordin g t o th e mainte -

nanc e schedul e (norma l conditions , sever e condi -

tions) . I f th e vehicl e regularl y i s drive n i n on e o r mor e

o f th e followin g conditions , replac e th e timin g bel t

an d timin g balance r bel t a t 60,00 0 mile s (U.S.A. )

100,00 0 k m (Canada) .

— In ver y hig h temperature s (ove r 110°F , 43°C) .

— In ver y lo w temperature s (unde r -20°F , -29°C) .

Tur n th e crankshaf t pulle y s o th e No . 1 pisto n i s a t

to p dea d cente r (TDC ) befor e removin g th e bel t (se e

pag e 6-13 ).

Inspec t th e wate r pum p befor e installin g th e timin g

bel t (se e pag e 10-10 ).

1 . Remov e th e engin e cove r (se e pag e 5-3 ).

2 . Remov e th e intak e ai r duc t an d ai r cleane r housin g

assembl y (se e pag e 5-4 ).

3 . Loose n th e mountin g bolt , loc k bol t an d adjustin g

rod, the n remov e th e alternato r bel t (se e pag e 5-7 ).

4 . Loose n th e idle r pulle y cente r nu t an d adjustin g

bolt, the n remov e th e ai r conditionin g (A/C ) com -

presso r bel t (se e pag e 5-7 ).

5 . Remov e th e TC S contro l valv e uppe r an d lowe r

brackets .

NOTE: Refe r t o sectio n 1 9 whe n installin g th e

brackets .

TCS CONTRO L

VALV E LOWE R

BRACKE T8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

6. Loose n th e adjustin g bolt , locknu t an d mountin g

bolt , the n remov e th e powe r steerin g (P/S ) pum p

bel t (se e pag e 6-6 ).

7 . Disconnec t th e TC S throttl e senso r connector , th e

TC S throttl e actuato r connector , an d th e throttl e

positio n (TP ) senso r connector , the n remov e th e

TC S contro l valv e assembly .

TCS THROTTL E

SENSO R CONNECTO R TC

S CONTRO L

VALV E

ASSEMBL Y

THROTTLE POSITIO N(TP) SENSO R CONNECTO RTC

S THROTTL E

ACTUATO R

CONNECTO R

8. Disconnec t th e vehicl e spee d senso r (VSS ) sub-har -

nes s connector , the n remov e th e wir e harnes s holder .

WIRE HARNES S

HOLDE R VS

S SUB-HARNES S

CONNECTO R

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

TC

S CONTRO L

VALV E UPPE R

BRACKE T

ProCarManuals.com