ACURA RL KA9 1996 Service Repair Manual

Manufacturer: ACURA, Model Year: 1996, Model line: RL KA9, Model: ACURA RL KA9 1996Pages: 1954, PDF Size: 61.44 MB

Page 361 of 1954

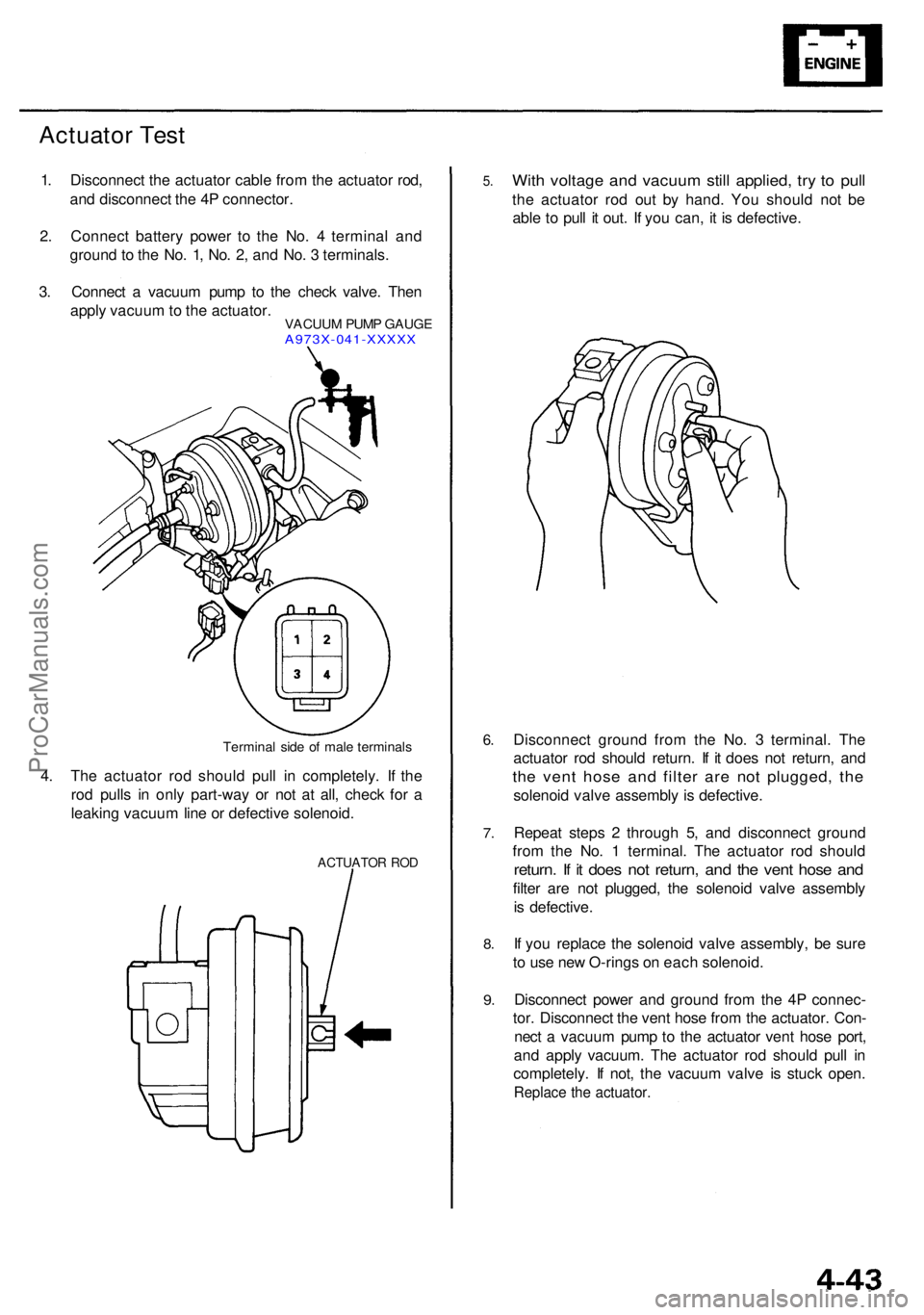

Actuator Tes t

1. Disconnec t th e actuato r cabl e fro m th e actuato r rod ,

an d disconnec t th e 4 P connector .

2 . Connec t batter y powe r t o th e No . 4 termina l an d

groun d to th e No . 1 , No . 2 , an d No . 3 terminals .

3 . Connec t a vacuu m pum p t o th e chec k valve . The n

appl y vacuu m to th e actuator .

VACUUM PUM P GAUG EA973X-041-XXXX X

Terminal sid e o f mal e terminal s

4. Th e actuato r ro d shoul d pul l i n completely . I f th e

ro d pull s i n onl y part-wa y o r no t a t all , chec k fo r a

leakin g vacuu m lin e o r defectiv e solenoid .

ACTUATO R RO D

5.

6.

7 .

8.

9 .

Wit h voltag e an d vacuu m stil l applied , tr y t o pul l

the actuato r ro d ou t b y hand . Yo u shoul d no t b e

abl e t o pul l i t out . I f yo u can , i t i s defective .

Disconnec t groun d fro m th e No . 3 terminal . Th e

actuato r ro d shoul d return . I f i t doe s no t return , an d

the ven t hos e an d filte r ar e no t plugged , th e

solenoi d valv e assembl y i s defective .

Repea t step s 2 throug h 5 , an d disconnec t groun d

fro m th e No . 1 terminal . Th e actuato r ro d shoul d

return. I f i t doe s no t return , an d th e ven t hos e an d

filte r ar e no t plugged , th e solenoi d valv e assembl y

i s defective .

I f yo u replac e th e solenoi d valv e assembly , b e sur e

t o us e ne w O-ring s o n eac h solenoid .

Disconnec t powe r an d groun d fro m th e 4 P connec -

tor . Disconnec t th e ven t hos e fro m th e actuator . Con -

nec t a vacuu m pum p t o th e actuato r ven t hos e port ,

an d appl y vacuum . Th e actuato r ro d shoul d pul l i n

completely . I f not , th e vacuu m valv e i s stuc k open .

Replac e th e actuator .

ProCarManuals.com

Page 362 of 1954

Cruise Contro l

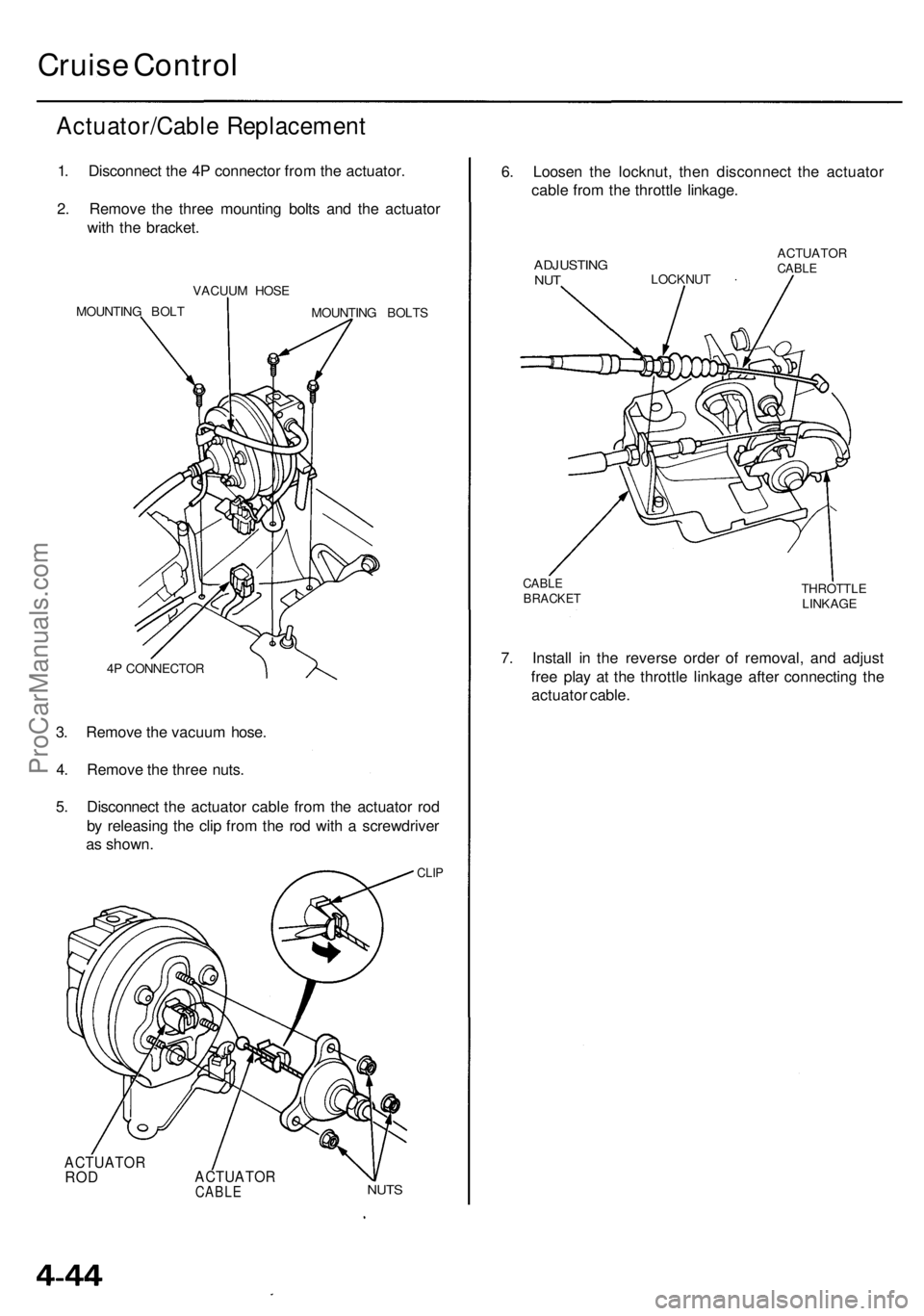

Actuator/Cabl e Replacemen t

1. Disconnec t th e 4 P connecto r fro m th e actuator .

2 . Remov e th e thre e mountin g bolt s an d th e actuato r

wit h th e bracket .

4P CONNECTO R

3. Remov e th e vacuu m hose .

4 . Remov e th e thre e nuts .

5 . Disconnec t th e actuato r cabl e fro m th e actuato r ro d

b y releasin g th e cli p fro m th e ro d wit h a screwdrive r

a s shown .

CLIP

ACTUATO RROD ACTUATO

RCABLE NUT S

6. Loose n th e locknut , the n disconnec t th e actuato r

cabl e fro m th e throttl e linkage .

ADJUSTIN GNUTLOCKNU T

ACTUATO RCABLE

CABL E

BRACKE TTHROTTL ELINKAGE

7. Instal l i n th e revers e orde r o f removal , an d adjus t

fre e pla y a t th e throttl e linkag e afte r connectin g th e

actuato r cable .

MOUNTIN G BOLT S

VACUU

M HOS E

MOUNTIN G BOL T

ProCarManuals.com

Page 363 of 1954

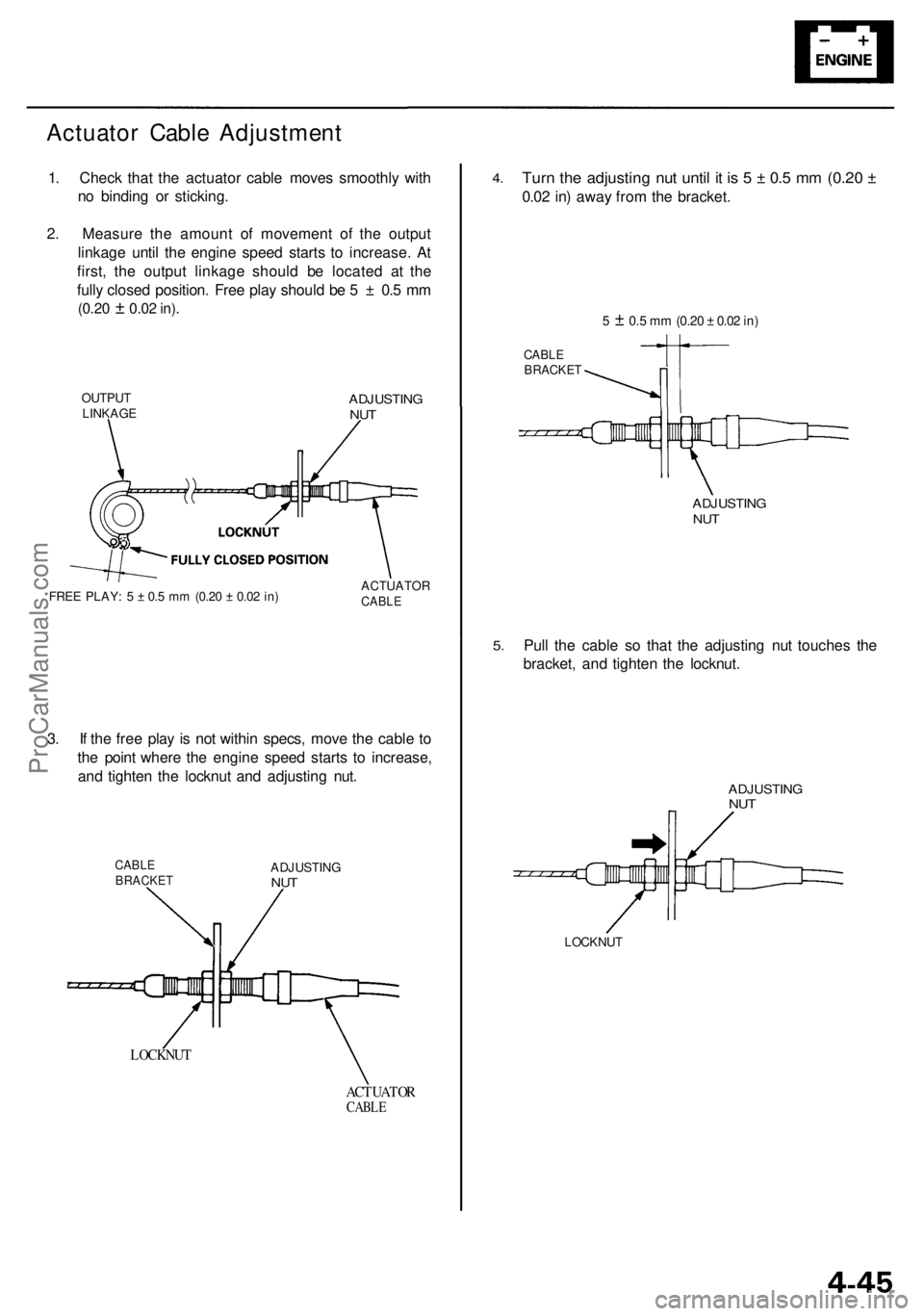

Actuator Cable Adjustment

1. Check that the actuator cable moves smoothly with

no binding or sticking.

2. Measure the amount of movement of the output

linkage until the engine speed starts to increase. At

first, the output linkage should be located at the

fully closed position. Free play should be 5 ± 0.5 mm

(0.20

±

0.02 in).

OUTPUT

LINKAGE

ADJUSTING

NUT

FREE PLAY: 5 ± 0.5 mm (0.20 ± 0.02 in)

ACTUATOR

CABLE

3. If the free play is not within specs, move the cable to

the point where the engine speed starts to increase,

and tighten the locknut and adjusting nut.

CABLE

BRACKET

ADJUSTING

NUT

LOCKNUT

ACTUATOR

CABLE

4.

Turn the adjusting nut until it is 5 ± 0.5 mm (0.20 ±

0.02 in) away from the bracket.

5 ± 0.5 mm

(0.20

±

0.02

in)

CABLE

BRACKET

ADJUSTING

NUT

5.

Pull the cable so that the adjusting nut touches the

bracket, and tighten the locknut.

ADJUSTING

NUT

LOCKNUTProCarManuals.com

Page 364 of 1954

Special Tool s

Ref. No.Too l Numbe r DescriptionQtyPag e Referenc e

A973 X - 04 1 - XXXX X

Vacuum Pump/Gauge , 0-3 0 in.Hg .

5-21 , 5-2 2

ProCarManuals.com

Page 365 of 1954

Engine Removal/Installatio n

Removal

Make sur e jack s an d safet y stand s ar e place d properl y

an d hois t bracket s ar e attache d to th e correc t position s

o n th e engine .

Mak e sur e th e vehicl e wil l no t rol l of f stand s an d fal l

whil e yo u ar e workin g unde r it .

CAUTION :

Us e fende r cover s t o avoi d damagin g painte d sur -

faces .

Unplu g th e wirin g connector s carefull y whil e holdin g

th e connecto r portio n to avoi d damage .

Mar k al l wirin g an d hose s t o avoi d misconnection .

Also , b e sur e tha t the y d o no t contac t othe r wirin g

o r hose s o r interfer e wit h othe r parts .

NOTE : D o th e PC M Memor y Settin g afte r reconnectin g

th e batter y (se e sectio n 11 ).

1 . Mov e th e fron t passenger' s sea t forward .

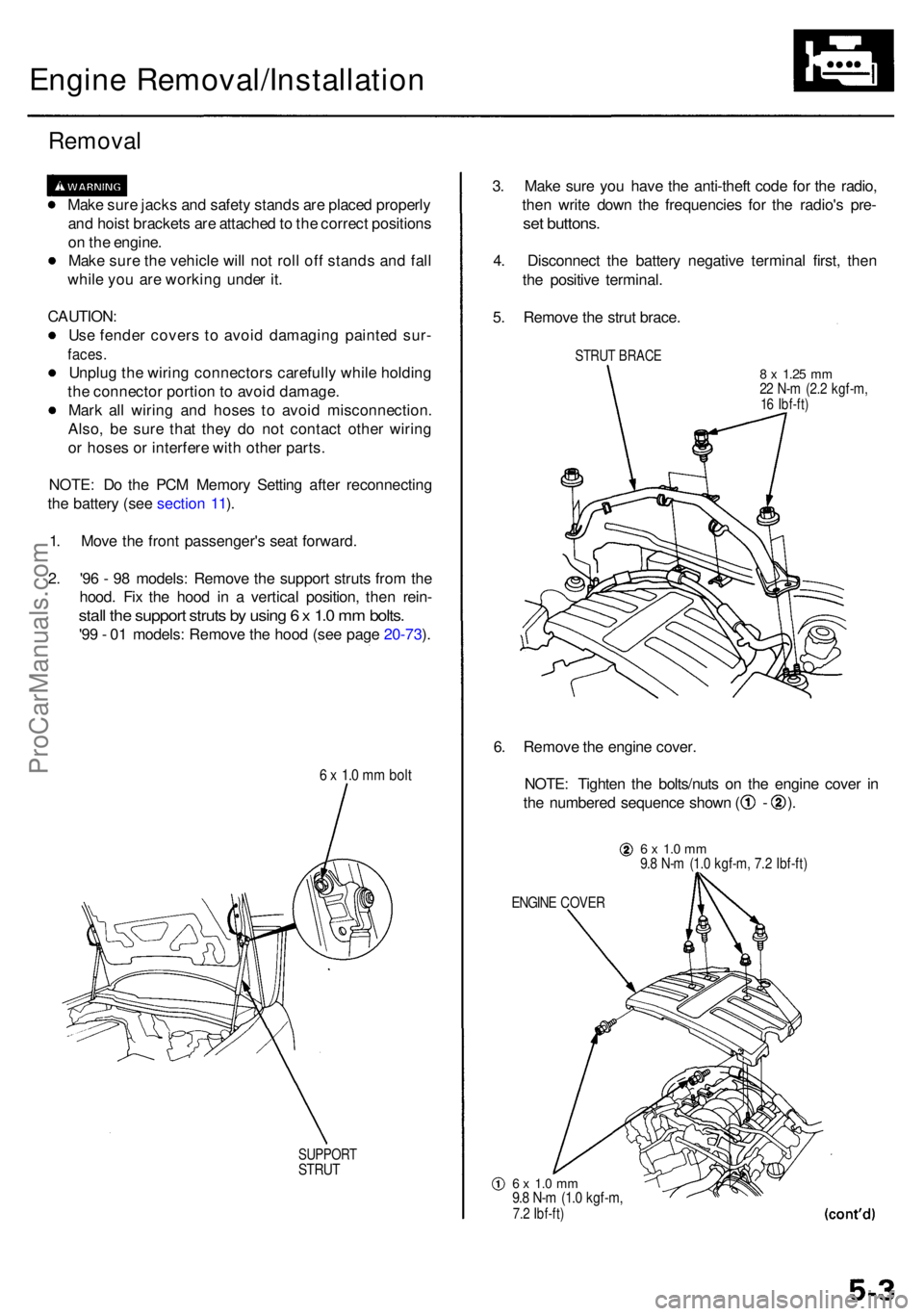

2 . '9 6 - 9 8 models : Remov e th e suppor t strut s fro m th e

hood . Fi x th e hoo d i n a vertica l position , the n rein -

stall th e suppor t strut s b y usin g 6 x 1. 0 m m bolts .

'99 - 0 1 models : Remov e th e hoo d (se e pag e 20-73 ).

6 x 1. 0 m m bol t

SUPPOR TSTRUT

3. Mak e sur e yo u hav e th e anti-thef t cod e fo r th e radio ,

the n writ e dow n th e frequencie s fo r th e radio' s pre -

set buttons .

4. Disconnec t th e batter y negativ e termina l first , the n

th e positiv e terminal .

5 . Remov e th e stru t brace .

STRUT BRAC E

8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,16 Ibf-ft )

6. Remov e th e engin e cover .

NOTE : Tighte n th e bolts/nut s o n th e engin e cove r i n

th e numbere d sequenc e show n ( - ).

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

ENGIN E COVE R

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,7.2 Ibf-ft )

ProCarManuals.com

Page 366 of 1954

Engine Removal/Installatio n

Removal (cont'd )

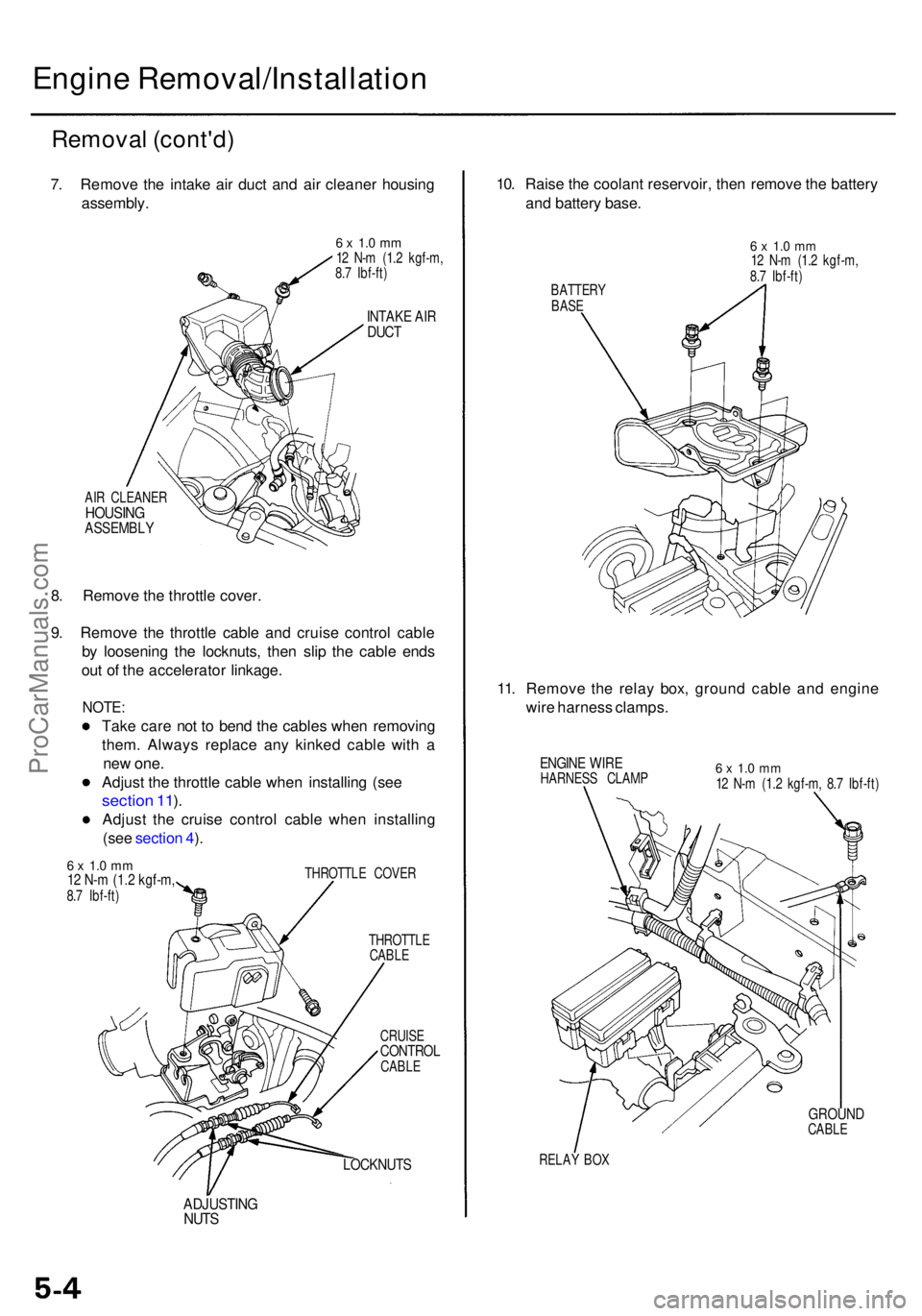

7. Remov e th e intak e ai r duc t an d ai r cleane r housin g

assembly .

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

INTAK E AI RDUC T

AIR CLEANE RHOUSINGASSEMBL Y

8. Remov e th e throttl e cover .

9 . Remov e th e throttl e cabl e an d cruis e contro l cabl e

b y loosenin g th e locknuts , the n sli p th e cabl e end s

ou t o f th e accelerato r linkage .

NOTE:

Take car e no t t o ben d th e cable s whe n removin g

them . Alway s replac e an y kinke d cabl e wit h a

ne w one .

Adjus t th e throttl e cabl e whe n installin g (se e

sectio n 11 ).

Adjus t th e cruis e contro l cabl e whe n installin g

(se e sectio n 4 ).

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,8.7 Ibf-ft ) THROTTL

E COVE R

THROTTL E

CABL E

CRUIS E

CONTRO LCABLE

LOCKNUT S

ADJUSTIN GNUTS

10. Rais e th e coolan t reservoir , the n remov e th e batter y

an d batter y base .

11 . Remov e th e rela y box , groun d cabl e an d engin e

wir e harnes s clamps .

ENGINE WIR EHARNES S CLAM P6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

GROUN DCABLE

RELA Y BO X

BATTER

Y

BAS E

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

ProCarManuals.com

Page 367 of 1954

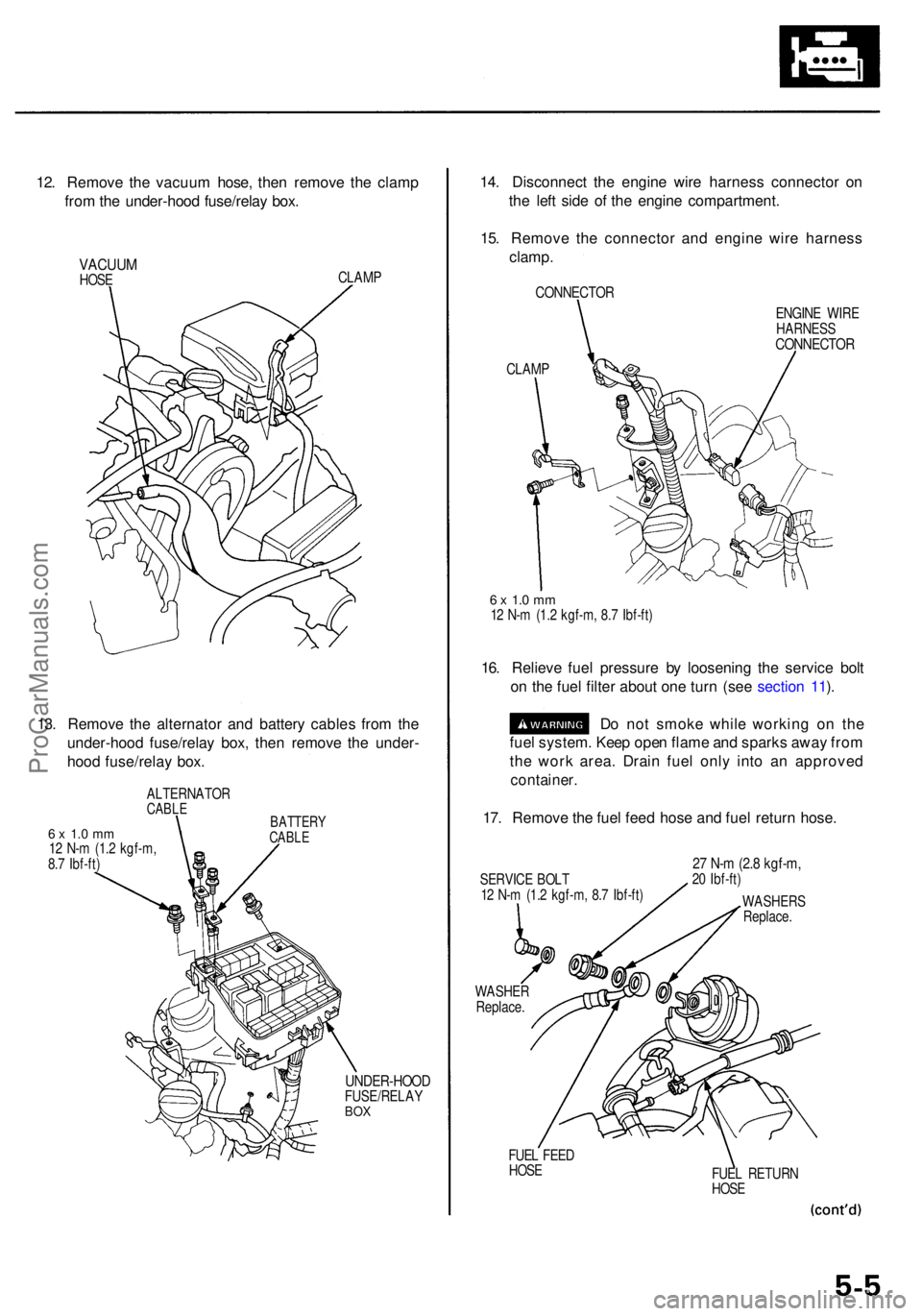

12. Remov e th e vacuu m hose , the n remov e th e clam p

fro m th e under-hoo d fuse/rela y box .

VACUU MHOSE CLAM

P

13. Remov e th e alternato r an d batter y cable s fro m th e

under-hoo d fuse/rela y box , the n remov e th e under -

hoo d fuse/rela y box .

ALTERNATO RCABLE

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

BATTER YCABLE

UNDER-HOO DFUSE/RELAYBOX

14. Disconnec t th e engin e wir e harnes s connecto r o n

th e lef t sid e o f th e engin e compartment .

15 . Remov e th e connecto r an d engin e wir e harnes s

clamp .

CONNECTO R

ENGINE WIR E

HARNES S

CONNECTO R

CLAMP

6 x 1. 0 m m12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

16. Reliev e fue l pressur e b y loosenin g th e servic e bol t

o n th e fue l filte r abou t on e tur n (se e sectio n 11 ).

D o no t smok e whil e workin g o n th e

fue l system . Kee p ope n flam e an d spark s awa y fro m

th e wor k area . Drai n fue l onl y int o a n approve d

container.

17. Remov e th e fue l fee d hos e an d fue l retur n hose .

SERVIC E BOL T

1 2 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

WASHE R

Replace .27 N- m (2. 8 kgf-m ,20 Ibf-ft )

WASHER S

Replace .

FUE L FEE D

HOS E

FUEL RETUR N

HOS E

ProCarManuals.com

Page 368 of 1954

Engine Removal/Installatio n

Removal (cont'd )

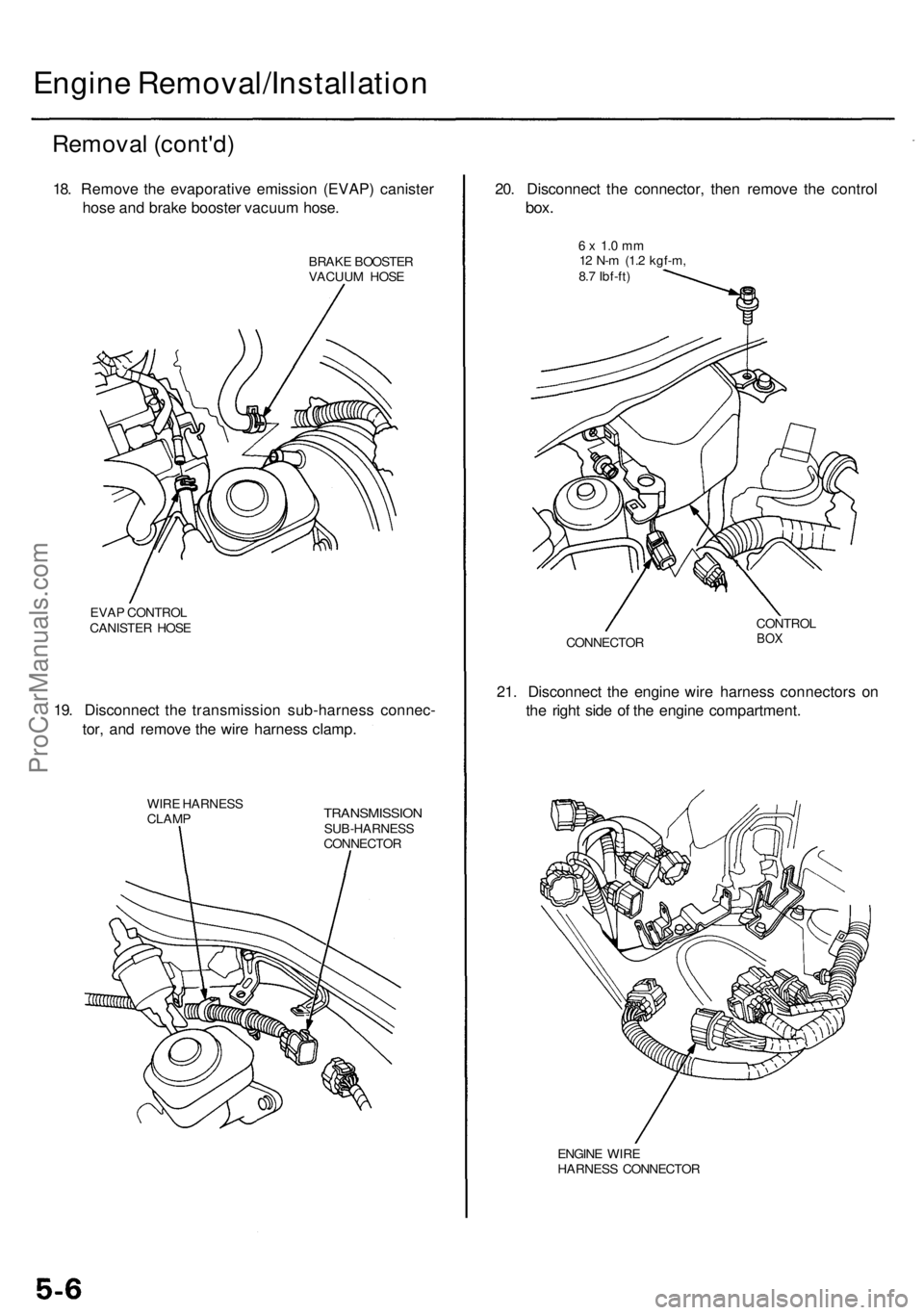

18. Remov e th e evaporativ e emissio n (EVAP ) caniste r

hos e an d brak e booste r vacuu m hose .

BRAK E BOOSTE R

VACUU M HOS E

EVA P CONTRO L

CANISTE R HOS E

19. Disconnec t th e transmissio n sub-harnes s connec -

tor , an d remov e th e wir e harnes s clamp .

WIRE HARNES SCLAMPTRANSMISSIO NSUB-HARNESS

CONNECTO R CONNECTO

R CONTRO

L

BOX

21. Disconnec t th e engin e wir e harnes s connector s o n

th e righ t sid e o f th e engin e compartment .

ENGINE WIR E

HARNES S CONNECTO R

20. Disconnec t th e connector , the n remov e th e contro l

box.

6 x 1. 0 m m12 N- m (1. 2 kgf-m ,

8. 7 Ibf-ft )

ProCarManuals.com

Page 369 of 1954

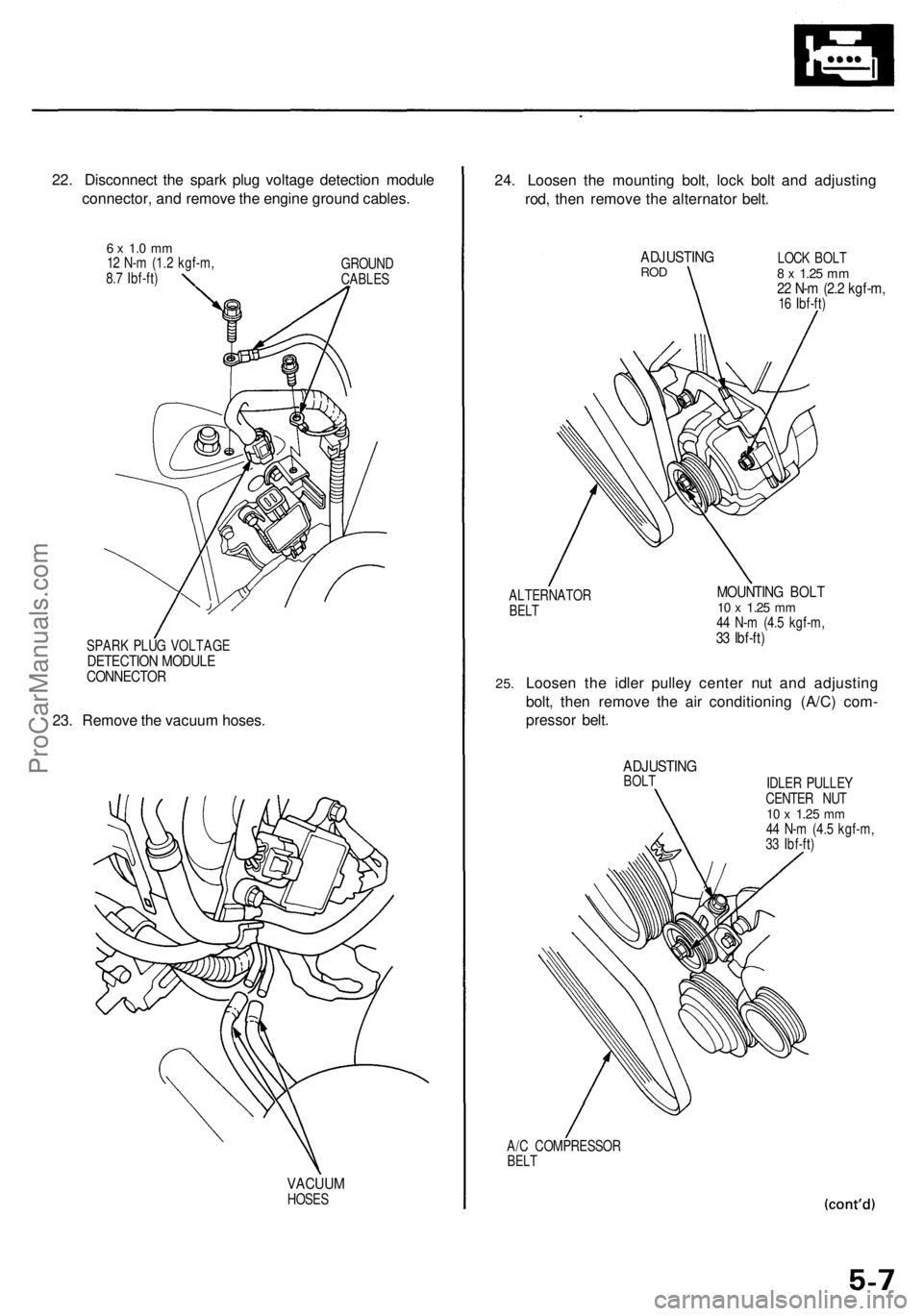

22. Disconnect the spark plug voltage detection module

connector, and remove the engine ground cables.

6 x 1.0 mm

12 N-m (1.2 kgf-m,

8.7 Ibf-ft)

GROUND

CABLES

SPARK PLUG VOLTAGE

DETECTION MODULE

CONNECTOR

23. Remove the vacuum hoses.

VACUUM

HOSES

24. Loosen the mounting bolt, lock bolt and adjusting

rod, then remove the alternator belt.

ADJUSTING

ROD

LOCK BOLT

8 x

1.25

mm

22 N-m (2.2 kgf-m,

16 Ibf-ft)

ALTERNATOR

BELT

MOUNTING BOLT

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

25.

Loosen the idler pulley center nut and adjusting

bolt, then remove the air conditioning (A/C) com-

pressor belt.

ADJUSTING

BOLT

IDLER PULLEY

CENTER NUT

10 x

1.25

mm

44 N-m (4.5 kgf-m,

33 Ibf-ft)

A/C COMPRESSOR

BELTProCarManuals.com

Page 370 of 1954

Engine Removal/Installatio n

Removal (cont'd )

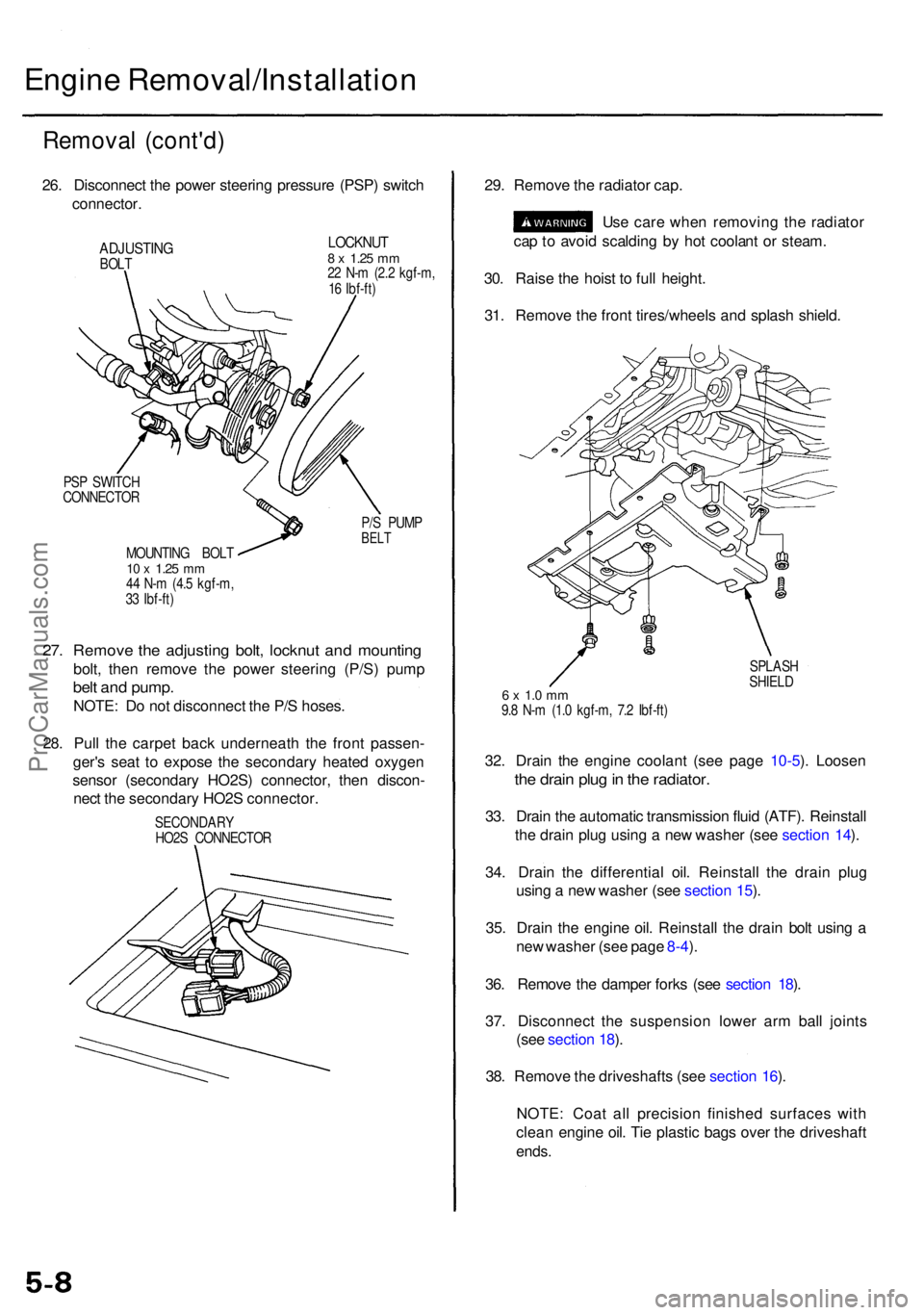

26. Disconnec t th e powe r steerin g pressur e (PSP ) switc h

connector .

ADJUSTIN GBOLT

LOCKNU T8 x 1.2 5 mm22 N- m (2. 2 kgf-m ,

1 6 Ibf-ft )

PS P SWITC H

CONNECTO R

P/S PUM P

BELTMOUNTIN G BOL T10 x 1.2 5 mm44 N- m (4. 5 kgf-m ,

3 3 Ibf-ft )

27. Remov e th e adjustin g bolt , locknu t an d mountin g

bolt, the n remov e th e powe r steerin g (P/S ) pum p

belt an d pump .

NOTE: D o no t disconnec t th e P/ S hoses .

28 . Pul l th e carpe t bac k underneat h th e fron t passen -

ger' s sea t t o expos e th e secondar y heate d oxyge n

senso r (secondar y HO2S ) connector , the n discon -

nec t th e secondar y HO2 S connector . 29

. Remov e th e radiato r cap .

Us e car e whe n removin g th e radiato r

ca p to avoi d scaldin g b y ho t coolan t o r steam .

30 . Rais e th e hois t t o ful l height .

31 . Remov e th e fron t tires/wheel s an d splas h shield .

SPLAS H

SHIEL D

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

32. Drai n th e engin e coolan t (se e pag e 10-5 ). Loose n

the drai n plu g in th e radiator .

33. Drai n th e automati c transmissio n flui d (ATF) . Reinstal l

th e drai n plu g usin g a ne w washe r (se e sectio n 14 ).

34 . Drai n th e differentia l oil . Reinstal l th e drai n plu g

usin g a ne w washer (see sectio n 15 ).

35 . Drai n th e engin e oil . Reinstal l th e drai n bol t usin g a

ne w washe r (se e pag e 8-4 ).

36 . Remov e th e dampe r fork s (se e sectio n 18 ).

37 . Disconnec t th e suspensio n lowe r ar m bal l joint s

(se e sectio n 18 ).

38 . Remov e th e driveshaft s (se e sectio n 16 ).

NOTE : Coa t al l precisio n finishe d surface s wit h

clea n engin e oil . Ti e plasti c bag s ove r th e driveshaf t

ends.

SECONDAR Y

HO2 S CONNECTO R

ProCarManuals.com