DATSUN 210 1979 Service Manual

Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 491 of 548

Body

Electrical

Sy

tem

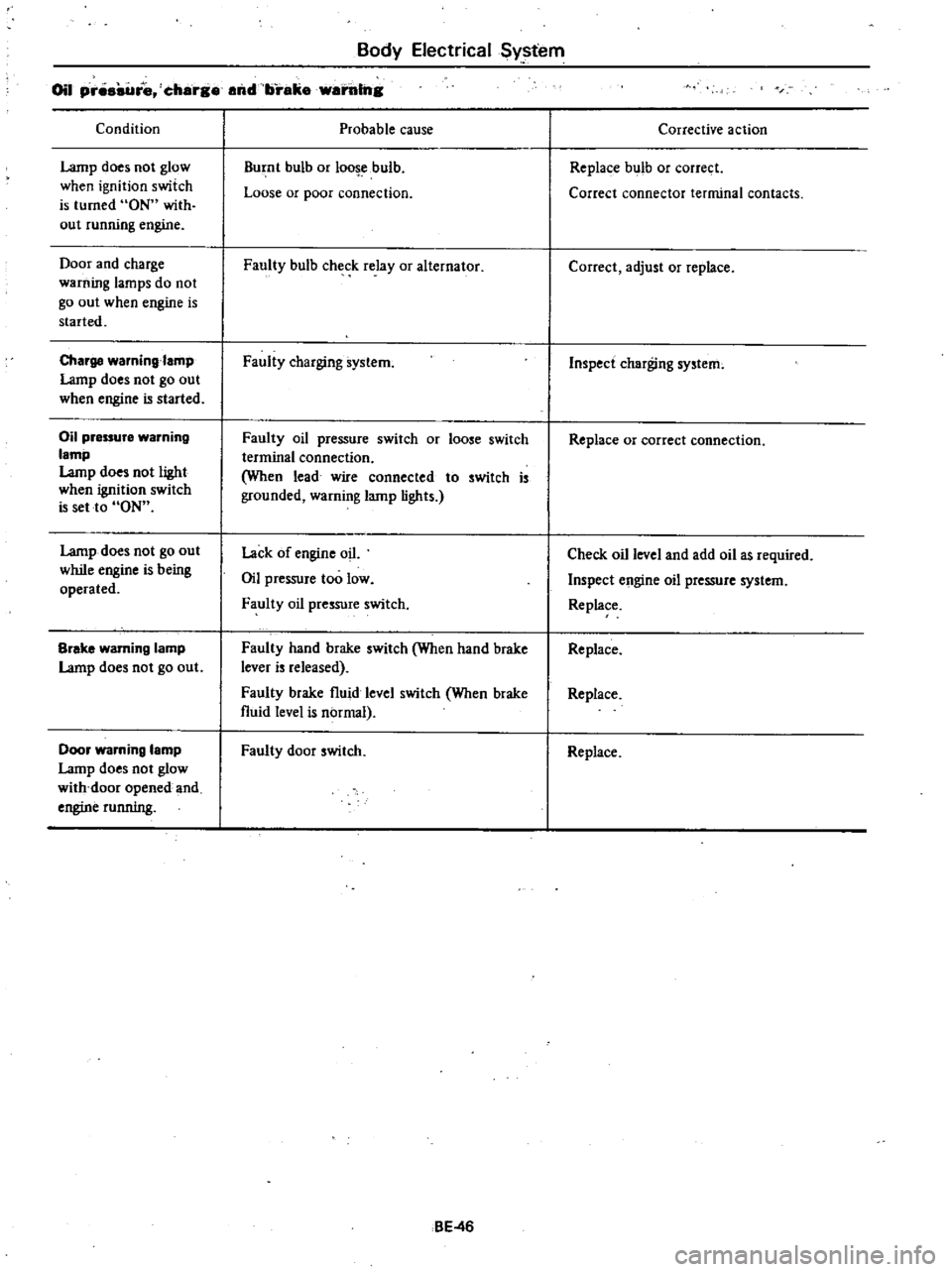

Oil

pr

re

charg

and

brake

warillng

Condition

Lamp

does

not

glow

when

ignition

switch

is

turned

ON

with

out

running

engine

Door

and

charge

warning

lamps

do

not

go

out

when

engine

is

started

Charge

waming

amp

Lamp

does

not

go

out

when

engine

is

started

Oil

pressure

warning

lamp

Lamp

does

not

light

when

ignition

switch

is

set

to

ON

Lamp

does

not

go

out

while

engine

is

being

operated

Brake

warning

lamp

Lamp

does

not

go

out

Door

warning

lamp

Lamp

does

not

glow

with

door

opened

and

engine

running

Probable

cause

Burnt

bulb

or

loo

ebulb

Loose

or

poor

connection

Faully

bulb

check

relay

or

alternator

Faully

charging

system

Faully

oil

pressure

switch

or

loose

switch

terminal

connection

When

lead

wire

connected

to

switch

is

grounded

warning

lamp

lights

Lack

of

engine

oil

Oil

pressure

too

low

Faully

oil

pressure

switch

Faulty

hand

brake

switch

When

hand

brake

lever

is

released

Faully

brake

fluid

level

switch

When

brake

fluid

level

is

normal

Faully

door

switch

BE

46

Corrective

action

Replace

bulb

or

correct

Correct

connector

terminal

contacts

Correct

adjust

or

replace

Inspect

charging

system

Replace

or

correct

connection

Check

oil

level

and

add

oil

as

required

Inspect

engine

oil

pressure

system

Replace

Replace

Replace

Replace

Page 492 of 548

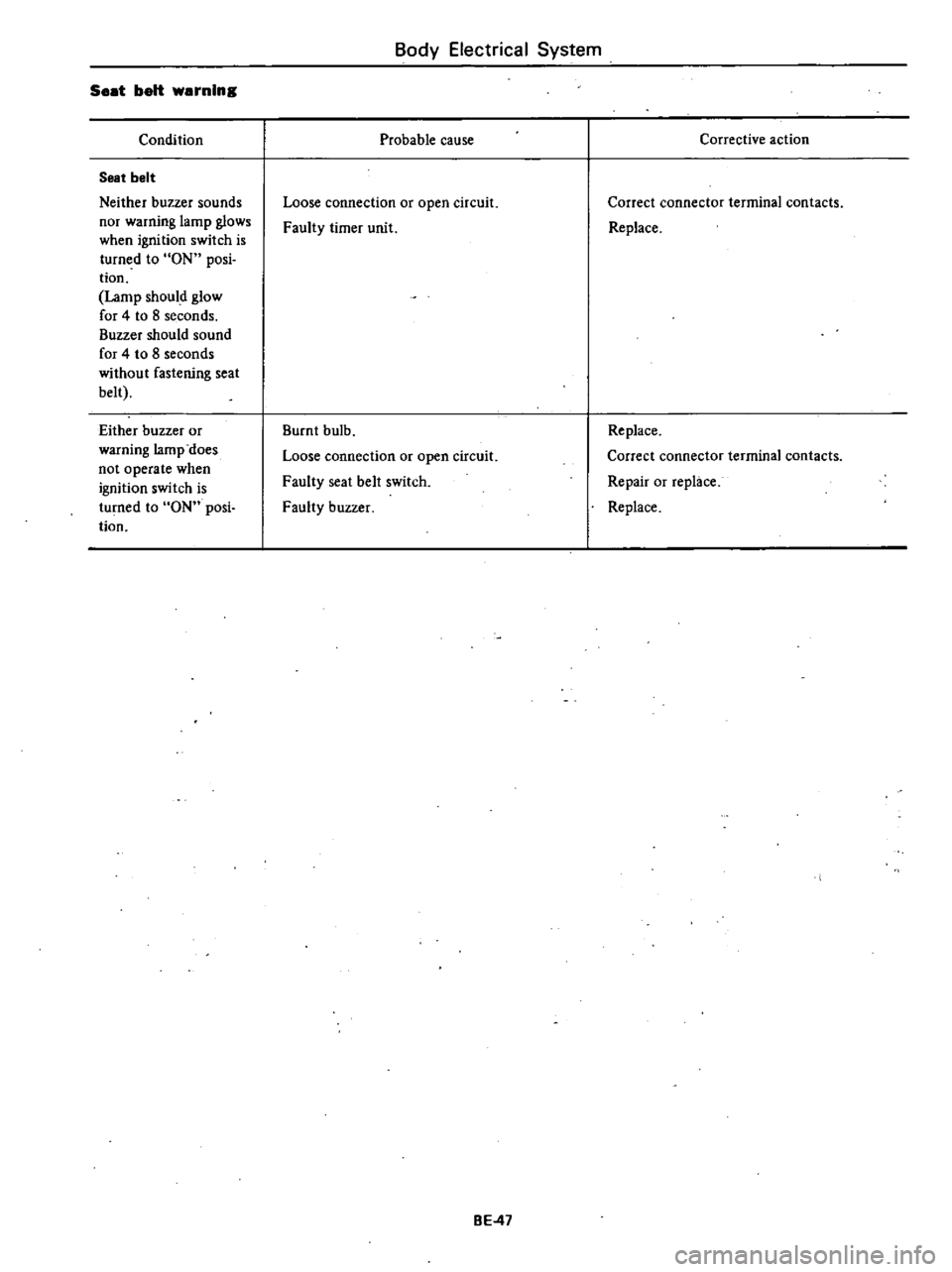

Seat

belt

warning

Condition

Seat

belt

Neither

buzzer

sounds

nor

warning

lamp

glows

when

ignition

switch

is

turned

to

ON

posi

tion

Lamp

should

glow

for

4

to

8

seconds

Buzzer

should

sound

for

4

to

8

seconds

without

fastening

seat

belt

Either

buzzer

or

warning

lamp

does

not

operate

when

ignition

switch

is

turned

to

ON

posi

tion

Body

Electrical

System

Probable

cause

Loose

connection

or

open

circuit

Faulty

timer

unit

Burnt

bulb

Loose

connection

or

open

circuit

Faulty

seat

belt

switch

Faulty

buzzer

BE

47

Corrective

action

Correct

connector

terminal

contacts

Replace

Replace

Correct

connector

terminal

contacts

Repair

or

replace

Replace

Page 493 of 548

m

J

Co

5

oil

tl

Cl

s

5

Q

0

0

WAS

ER

MOTOR

t

l

I

o

BATTERY

A

G

ll

J

wr

FUSIB

E

LINK

Off

UN

HI

WASH

11

J

BY

9

n

13

4d

1

o

14

J

I

Q

I

16

m

LW

2

0

u

J

WIPER

ANO

WASHER

SWITCH

I

lGCK

OfF

ACe

OM

Sf

2

0

OnOOB

m

iL

IG

i

I

0

S

00

A

II

WR

LB

IGNITION

SWITCH

Off

ON

WASHV

iW

REAR

WIPER

0

0

11

l

R

SWITCH

I

0

Q

I

2

I

B

HATCHBACK

0

I

I

3

o

II

LR

n

I

I

III

I

I

1

I

1

iI

Y

WIPER

MOTOR

LR

ti

BY

B

R

r

REAR

WASHER

MOTOR

IHATCHBACK

ANO

i

WAGON

Em

I

m

IIIn

zoot

a

11

1

I

a

E

lI

11

1

a

n

Jon

ZII

aen

i

III

a

io

OJ

a

It

8

0

It

m

l

l

In

l

CIl

l

3

HATCHBACK

LR

BOOYHARNESS

z

I

L

I

OO

B

iOl

c

TO

REAR

OEFOGGER

I

LR

rLB

1

I

3

0

i

BW

R

LRh

ftn

WAGON

0

0

r

o

REAR

WIPER

MOTOR

CRWl

T1

c

l

Rlif

1

I

mC

BilW

lJ

I

g

LR

Jj

i

1

FUSE

BLOCK

Page 494 of 548

Body

Electrical

System

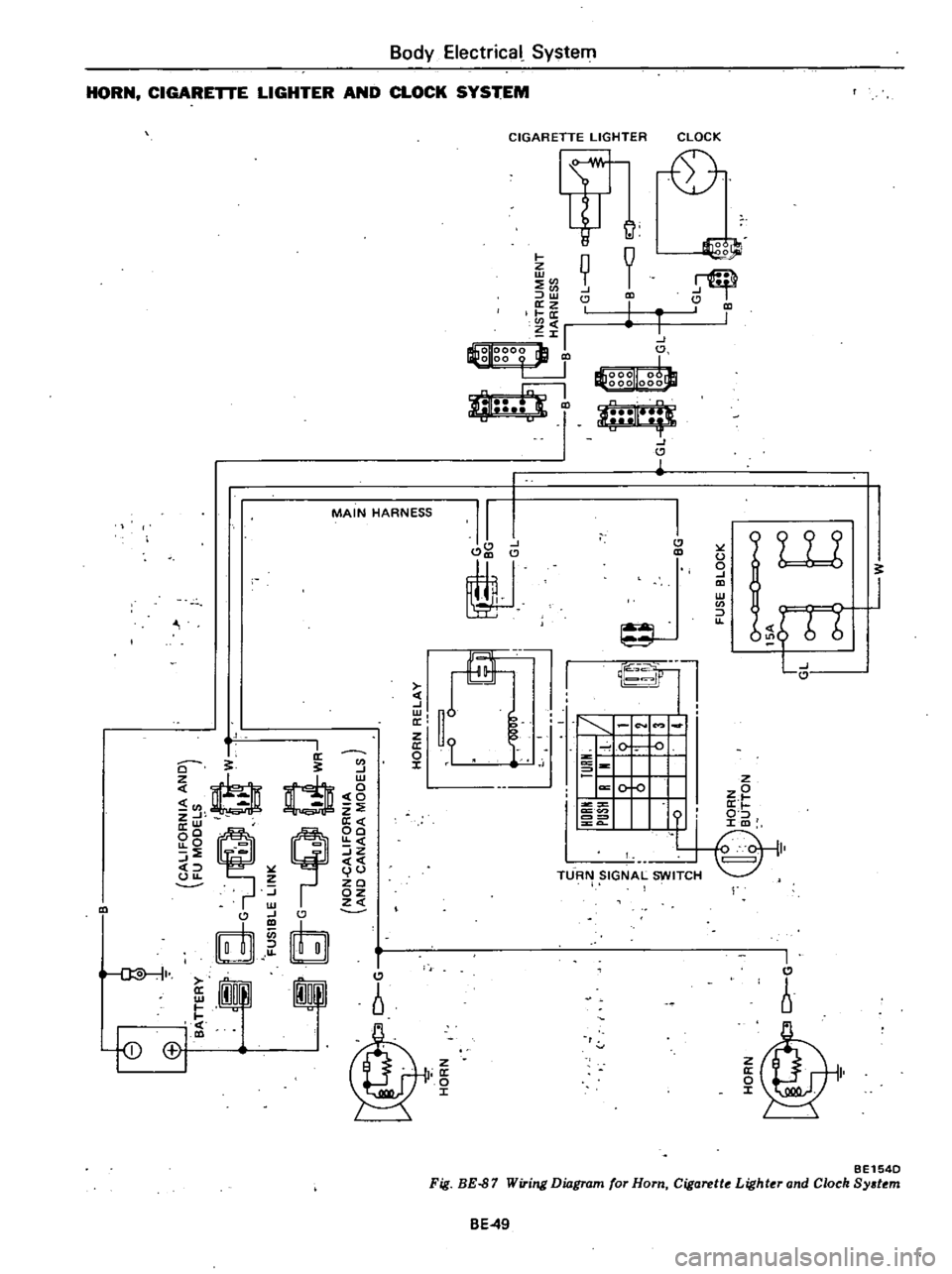

HORN

CIGARETTE

LIGHTER

AND

CLOCK

SYSTEM

I

I

0

W

l

I

fD

CCI

MAIN

HARNESS

I

I

0

en

srb

J

I

U

h

E

0

0

z

t

LL

Z

U

J

w

z

on

QlJ

J

w

0

Y

X

o

I

CIGARETTE

LIGHTER

Itt

9

J

J

I

Z

w

en

l

o

z

1

0

en

Zrl

I

O

tEl

g

r

J

i

I

J

al

I

J

ti

J

ti

1

1

J

J

8ho

f

J1

tf

J

P

II

J

J

1

I

I

e

o

TURN

SIGNAL

SWITCH

CLOCK

01

0

I

J

u

o

J

W

en

u

9W

tutJ

I

j

I

6

I

r

BE154D

Fig

BE

87

Wiring

Diagram

for

Horn

Cigarette

Lighter

and

Clock

System

BE49

Page 495 of 548

m

ii

lil

cIo

00

tl

i

3

Cl

0

m

0

g

fB

Jo

0

0

Ef1

CALIFORNIA

ANO

FU

MOOELS

t

f

G

W

g

dG

I

WR

FUSIBLE

LINK

8

G

uQ

t

WR

NON

cALIFORNIA

AND

CANAOA

MOOELS

J

TORQUE

CONVERTER

C

ao

GY

INOICATOR

LAMP

5

l

1

00

GW

I

BATTERY

CCOHST7

i

lOCK

Off

A

B

OO

C

I

ti

II

v

u

1

WITCH

IGNITION

S

2ND

Oil

lS1

B

C

C

AI8

C

I

5

A

8

I

QIQ

Q

Q

J1

0

0

I

0

6

B

6

0

7

Q

QIQIQ

8

0

0

0

9

O

I

LIGHTING

SWITCH

Z

1

D

Z

m

en

WR

LB

1lRG

GW

INSTRUMENT

HARNESS

j

lO

GW

I

oGW

GY

00

GY

LW

LW

I@o

00

og

B

0

u

B

LW

LB

I

I

0

0

J8

RG

w

1

0

r

O

FUSE

BLOCK

LW

ClO

LW

W

t

WB

1

r

GY

GW

RAOIO

ffi

i

n

In

U

L

J

UJ

J

U

WB

O

W

SPEAKER

OJ

o

Cl

m

CD

C

e

CIl

en

3

Page 496 of 548

m

ii

Co

0

i

tl

c

Cl

0

c

o

E

0

Cl

l

l

n

m

iO

t

B

i

BATTERY

A

G

FUSIBLE

LINK

I

I

lOCK

OfF

ACC

ON

S17

o

O

6

16

0

s

l

O

J

IA

IGN

ITION

SWITCH

FUSE

BLOCK

0

3

C

rT

l

WR

Q

BW

WR

I

BL

Z

J

Z

m

en

en

LG

l

LG

BOOY

HARNESS

6

J

1

nUl

I

OEFOGGER

l

C

ISEOAN

M

1R2

106

00

n

03

INSTRUMENT

B

I

II

8

HARNESS

f

i

G

0rF

to

LB

1

2

6

0

3

0

0

0

gg

REAR

WINOOW

OEFOGGER

SWITCH

l

0

II

11

1

Jo

II

E

z

a

11

1

II

o

8

11

1

II

OJ

o

Cl

m

CD

c

Ql

CIl

en

l

3

Page 497 of 548

Body

Electrical

System

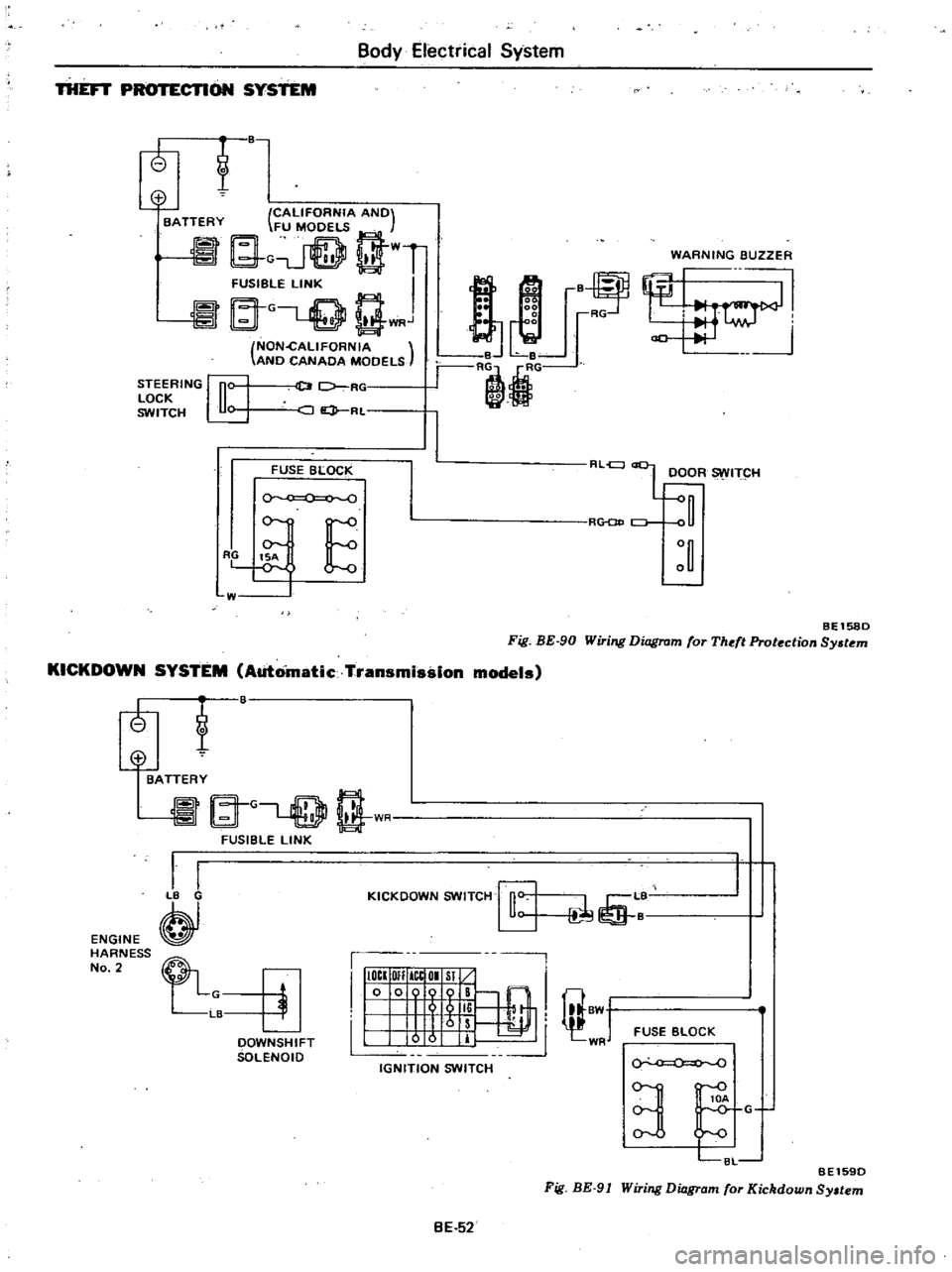

THEFT

CTlON

SYSTEM

t

o

CALIFORNIA

ANO

BATTERY

FU

MOOELS

G

t

WT

FUSIBGLE

LINK

I

at

L

Q

Q

WRJ

NON

cALlFORNIA

ANO

CANAOA

MOOELS

WARNING

BUZZER

STEERING

n

LOCK

u

SWITCH

U

D

7

RC

JQ

RL

2

2

00

i

r

B

Le

r

RljG

8

RG

FUSE

BLOCK

0

RLel

L

OOOR

ITCH

R

CJ

E

W

BEl580

Fig

BE

90

Wiring

Diagram

for

Theft

Protection

Sy

tem

KICKDOWN

SYSTEM

Automatic

Transmission

models

tf

ENGINE

HARNESS

No

2

@

BATTERY

A

G

rT

l

t

1

I

FUSIBLE

LINK

I

I

B

KICKOOWN

SWITCH

rfi

L

1

I

IIIOCI

OIl

ICtOI

Sl

10

009

B

@

I

I

5

li

I

8W

1

Irs

I

0

0

IT

WR

IGNITION

SWITCH

FUSE

BLOCK

OOWNSHIFT

SOLENOIO

0

0

BE1590

Fig

BE

91

Wiring

Diagram

for

Kickdown

Sy

tem

3

C8L

G

BE

52

Page 498 of 548

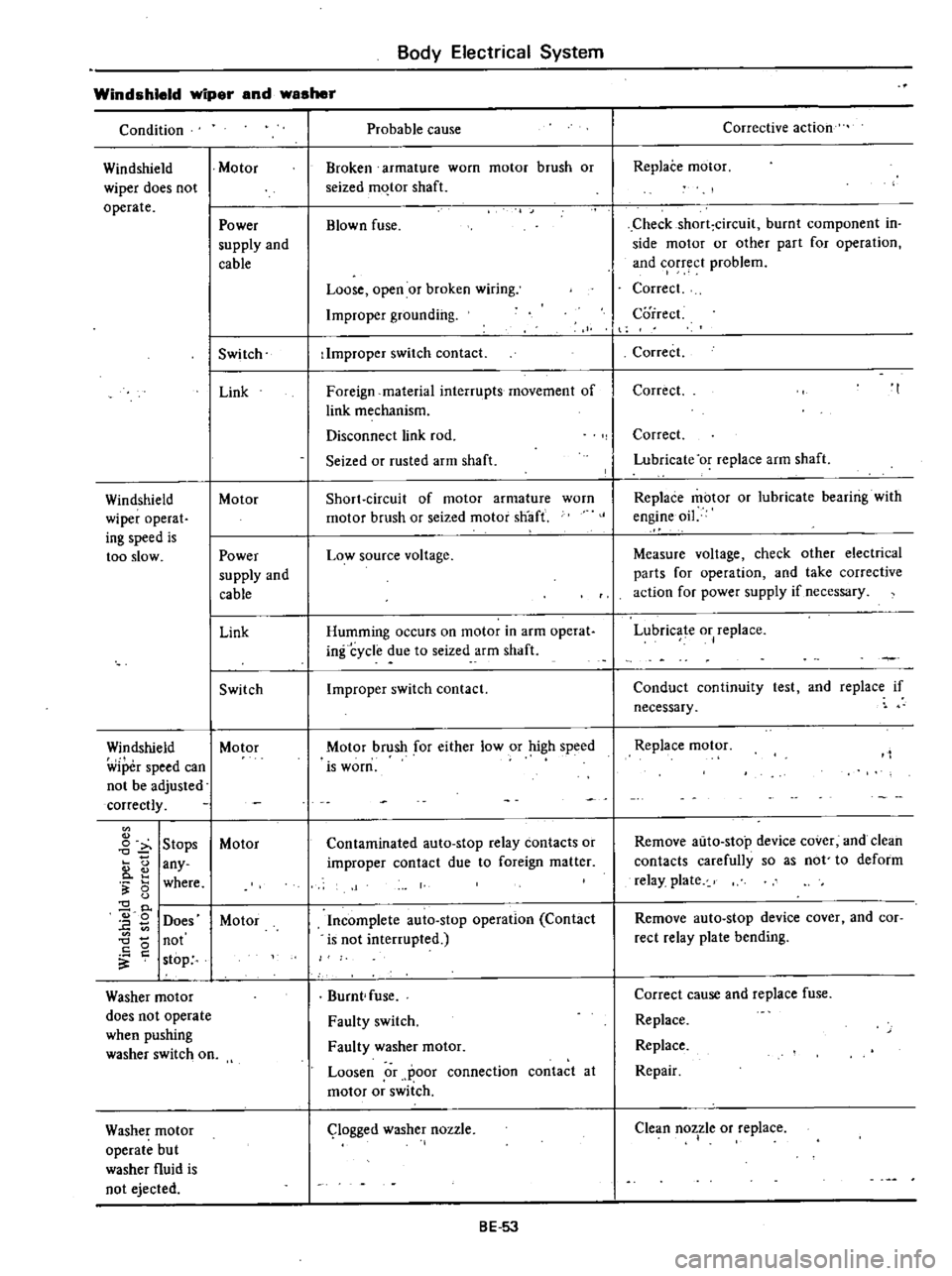

Body

Electrical

System

Condition

Windshield

wiper

and

washer

Probable

cause

Windshield

Motor

wiper

does

not

operate

Windshield

wiper

operat

ing

speed

is

too

slow

Power

supply

and

cable

Switch

Link

Motor

Power

supply

and

cable

Link

Switch

Windshield

Motor

wiper

speed

can

not

be

adjusted

correctly

o

o

fi

5

2

0

E

0

0

Stops

any

where

Does

not

stop

Washer

motor

does

not

operate

when

pushing

washer

switch

on

Washer

motor

operate

bu

t

washer

fluid

is

not

ejected

Motor

Motor

Broken

armature

worn

motor

brush

or

seized

m

tor

shaft

Blown

fuse

Loose

open

or

broken

wiring

Improper

grounding

Improper

switch

contact

Foreign

material

interrupts

movement

of

link

mechanism

Disconnect

link

rod

Seized

or

rusted

arm

shaft

Short

circuit

of

motor

armature

worn

motor

brush

or

seized

motor

snaft

Low

source

voltage

Humming

occurs

on

motor

in

arm

operat

infcycle

due

to

seized

arm

shaft

Improper

switch

contact

Motor

brush

for

either

low

or

high

speed

is

worn

Contaminated

auto

stop

relay

contacts

or

improper

contact

due

to

foreign

matter

Incomplete

auto

stop

operation

Contact

is

not

interrupted

Burnt

fuse

Faulty

switch

Faulty

washer

motor

Loosen

or

poor

connection

contact

at

motor

or

switch

logged

washer

nozzle

BE

53

Corrective

action

Replace

motor

Checkshort

circuit

burnt

component

in

side

motor

or

other

part

for

operation

and

corr

ct

problem

Correct

Correct

I

t

Correct

Correct

Correct

Lubricate

or

replace

arm

shaft

Replace

motor

or

lubricate

bearing

with

engine

oil

Measure

voltage

check

other

electrical

parts

for

operation

and

take

corrective

action

for

power

supply

if

necessary

Lubricate

or

replace

Conduct

continuity

test

and

replace

if

necessary

Replace

motor

Remove

auto

stop

device

cover

and

clean

contacts

carefully

so

as

not

to

deform

relay

plate

Remove

auto

stop

device

cover

and

cor

rect

relay

plate

bending

Correct

cause

and

replace

fuse

Replace

Replace

Repair

Clean

nozzle

or

replace

I

Page 499 of 548

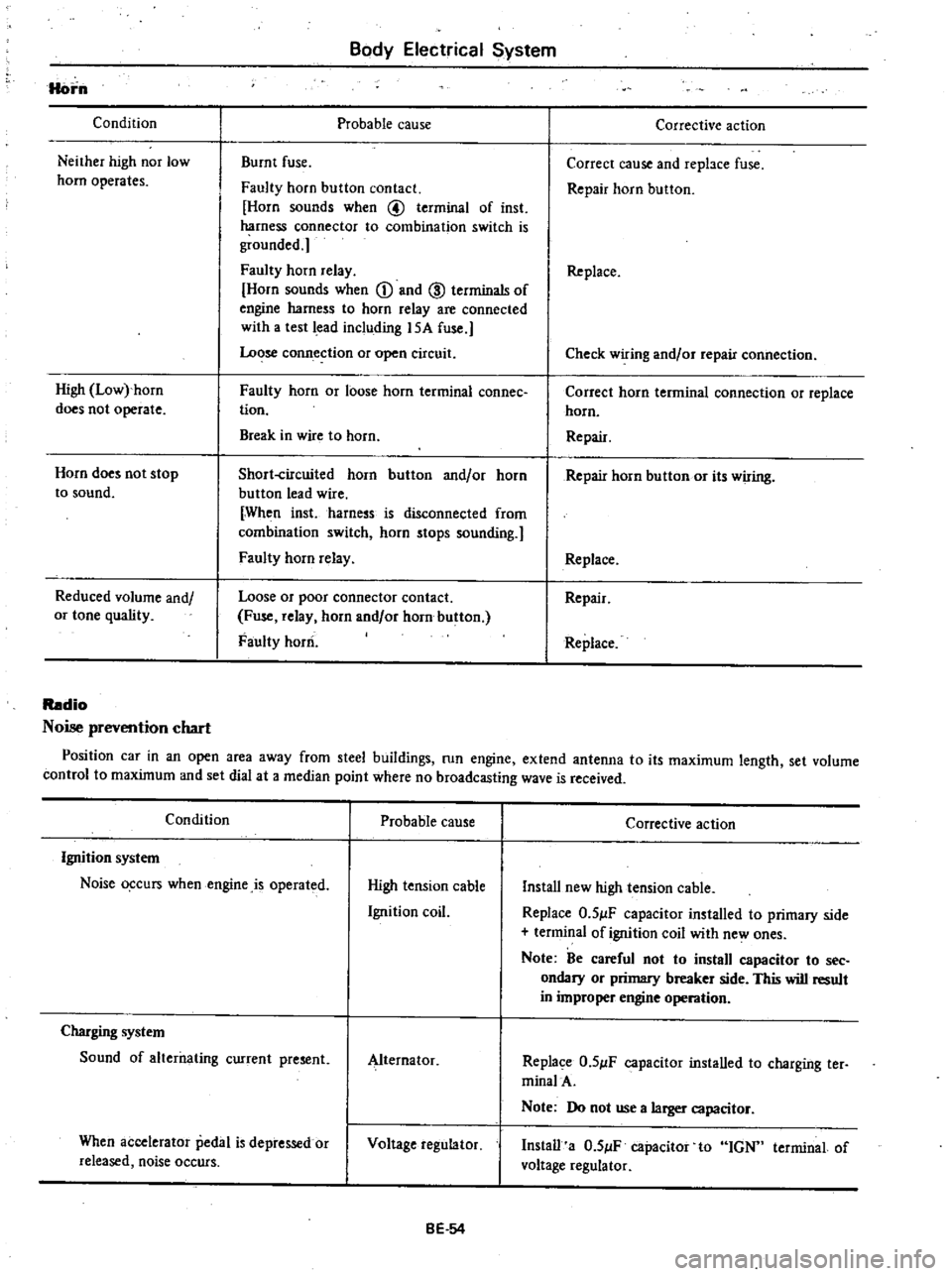

Horn

Condition

Neither

high

nor

low

horn

operates

High

Low

horn

does

not

operate

Horn

does

not

stop

to

sound

Reduced

volume

and

or

tone

quality

Body

Electrical

System

Probable

cause

Burnt

fuse

Faulty

horn

button

contact

Horn

sounds

when

@

terminal

of

inst

harness

connector

to

combination

switch

is

grounded

Faulty

horn

relay

Horn

sounds

when

CD

and

ID

terminals

of

engine

harness

to

horn

relay

are

connected

with

a

test

lead

including

15A

fuse

Lo

se

conn

ection

or

open

circuit

Faulty

horn

or

loose

horn

terminal

connee

tion

Break

in

wire

to

horn

Short

circuited

horn

button

and

or

horn

button

lead

wire

When

inst

harness

is

disconnected

from

combination

switch

horn

stops

sounding

Faulty

horn

relay

Loose

or

poor

connector

contact

Fuse

relay

horn

and

or

horn

button

Faulty

horn

Corrective

action

Correct

cause

and

repbce

fuse

Repair

horn

button

Replace

Check

wiring

and

or

repair

connection

Correct

horn

terminal

connection

or

replace

horn

Repair

Repair

horn

button

or

its

wiring

Replace

Repair

Replace

Radio

Noise

prevention

chart

Position

car

in

an

open

area

away

from

steel

buildings

run

engine

extend

antenna

to

its

maximum

length

set

volume

control

to

maximum

and

set

dial

at

a

median

point

where

no

broadcasting

wave

is

received

Condition

Probable

cause

Ignition

system

Noise

o

curs

when

engine

is

operated

High

tension

cable

Ignition

coil

Charging

system

Sound

of

alterilating

current

present

Alternator

When

accelerator

pedal

is

depressed

or

released

noise

occurs

Voltage

regulator

BE

54

Corrective

action

Install

new

high

tension

cable

Replace

O

5

lF

capacitor

installed

to

primary

side

terminal

of

ignition

coil

with

ne

ones

Note

Be

careful

not

to

install

capacitor

to

see

ondary

or

primary

breaker

side

This

will

result

in

improper

engine

operation

Replace

O

5

lF

capacitor

installed

to

charging

ter

minalA

Note

Do

not

use

a

larger

capacitor

Install

a

O

5

lF

capacitor

to

IGN

terminal

of

voltage

regulator

Page 500 of 548

m

ii

I

ll

ic

i

tl

Cl

Ul

0

is

B

w

ii

W

oa

LW

L

CALIFORNIA

ANO

I

d

S

R

FUSIBLE

LINK

o

BATTERY

S

JSt

wGLQ

gWR

NON

GALIFORNIA

ANO

CANAOA

MOOELS

LOC

Off

Ace

ON

Sf

o

0

i

IGNITION

SWITCH

L

B

LN

I

15A

0

0

0

0

o

v

E

FUSE

BLOCK

M

F

i

L

11L1

u

R

1

i

ri

1

w

RESISTOR

BW

Il

BLj

L

lljlj

U6

1

BWY

W

B

8

HEAVY

OUTY

TYPE

Standard

for

Canada

and

option

for

U

S

A

LW

HEATER

MOtOR

IOffl

I

2

3

Kro

lli

H

FAN

SWITCH

ST

ANOARO

TYPE

Z

II

II

a

OJ

o

Cl

m

CD

n

n

Ql

CIl

CJ

l

3