DATSUN 210 1979 Service Manual

Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 531 of 548

r

CYLINDER

HEAD

AND

VALVE

PLATE

Insufficient

refrigerant

v

p

sion

is

likely

to

be

caused

by

damaged

head

gasket

or

damaged

valves

Prior

to

servicing

the

head

and

valve

plate

both

service

valves

should

be

opened

to

free

any

gas

pressure

which

may

be

in

the

compressor

REMOVAL

I

Remove

cylinder

head

securing

bolts

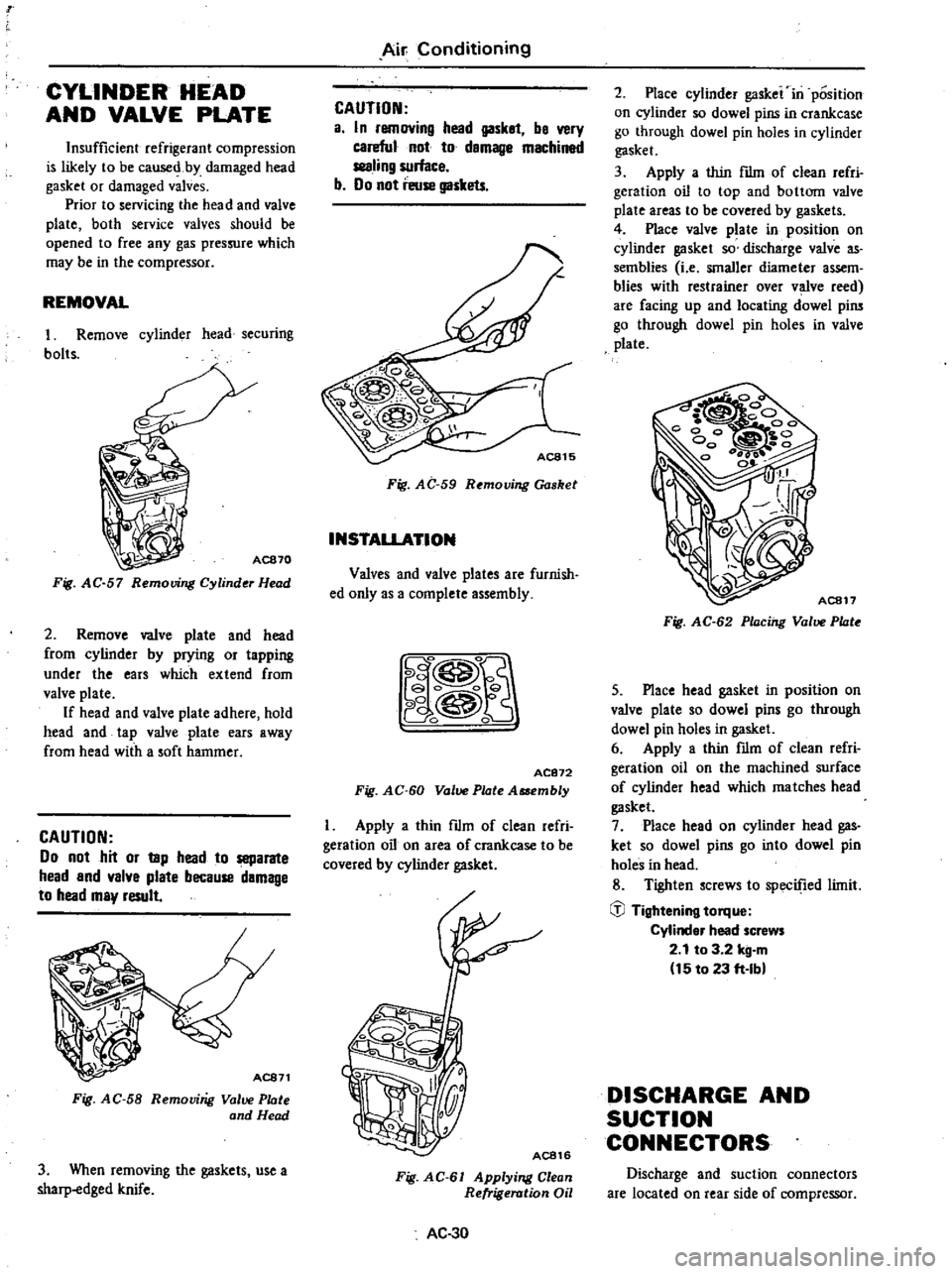

Fig

AC

57

Removing

Cylinder

Head

2

Remove

valve

plate

and

head

from

cylinder

by

prying

or

tapping

under

the

ears

which

extend

from

valve

plate

If

head

and

valve

plate

adhere

hold

head

and

tap

valve

plate

ears

away

from

head

with

a

soft

hammer

CAUTION

00

not

hit

or

llIp

head

to

separate

head

and

valve

plate

because

damage

to

head

may

result

AC871

Fig

AC

58

Removing

Volve

Plate

and

Head

3

When

removing

the

gaskets

use

a

sharp

edged

knife

Air

Conditioning

CAUTION

a

In

removing

head

gasket

be

very

careful

not

to

damage

machined

sealing

surface

b

00

not

reuse

gaskets

AC815

Fig

AC

59

Removing

Gasket

INSTALLATION

Valves

and

valve

plates

are

furnish

ed

only

as

a

complete

assembly

8

AC872

Fig

AC

60

Valve

Plate

Assembly

I

Apply

a

thin

mm

of

clean

refri

geration

oil

on

area

of

crankcase

to

be

covered

by

cylinder

gasket

Fig

AC

61

Applying

Clean

Refrigeration

Oil

AC

30

2

Place

cylinder

gasket

in

position

on

cylinder

so

dowel

pins

in

crankcase

go

through

dowel

pin

holes

in

cylinder

gasket

3

Apply

a

thin

flim

of

clean

refri

geralion

oil

to

top

and

bottom

valve

plate

areas

to

be

covered

by

gaskets

4

Place

valve

plate

in

position

on

cylinder

gasket

so

discharge

valve

as

semblies

I

e

smaller

diameter

assem

blies

with

restrainer

over

valve

reed

are

facing

up

and

locating

dowel

pins

go

through

dowel

pin

holes

in

valve

plate

AC817

Fig

AC

62

Placing

Valve

Plate

5

Place

head

gasket

in

position

on

valve

plate

so

dowel

pins

go

through

dowel

pin

holes

in

gasket

6

Apply

a

thin

mm

of

clean

refri

geration

oil

on

the

machined

surface

of

cylinder

head

which

matches

head

gasket

7

Place

head

on

cylinder

head

gas

ket

so

dowel

pins

go

into

dowel

pin

holes

in

head

8

Tighten

screws

to

specified

limit

iil

Tightening

torque

Cvlinder

head

screws

2

1

to

3

2

kg

m

15

to

23

ft

Ibl

DISCHARGE

AND

SUCTION

CONNECTORS

Discharge

and

suction

connectors

are

located

on

rear

side

of

compressor

Page 532 of 548

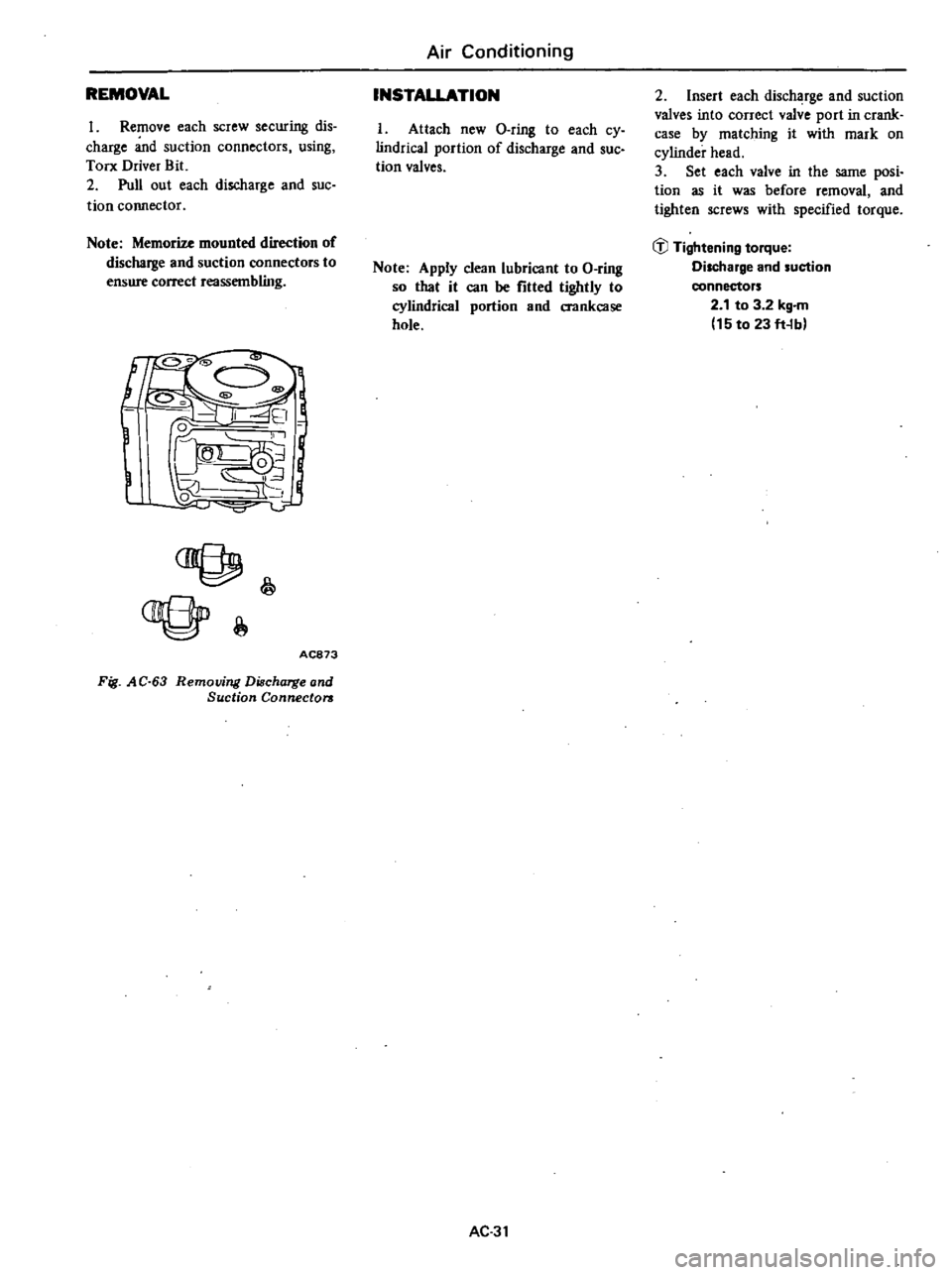

REMOVAL

1

Remove

each

screw

securing

dis

charge

and

suction

connectors

using

TOD

Driver

Bit

2

Pull

out

each

discharge

and

suc

tion

connector

Note

Memorize

mounted

direction

of

discharge

and

suction

connectors

to

ensure

correct

reassembling

a@

AC873

Fig

AC

63

Removing

Discharge

and

Suction

Connectors

Air

Conditioning

INSTALLATION

I

Attach

new

O

ring

to

each

cy

lindrical

portion

of

discharge

and

suc

tion

valves

Note

Apply

clean

lubricant

to

O

ring

so

that

it

can

be

fitted

tightly

to

cylindrical

portion

and

crankcase

hole

AC

31

2

Insert

each

discharge

and

suction

valves

into

correct

valve

port

in

crank

case

by

matching

it

with

mark

on

cylinder

head

3

Set

each

valve

in

the

same

posi

tion

as

it

was

before

removal

and

tighten

screws

with

specified

torque

cD

Tightening

torque

Discharge

and

suction

connectors

2

1

to

3

2

kg

m

15

to

23

ft

b

Page 533 of 548

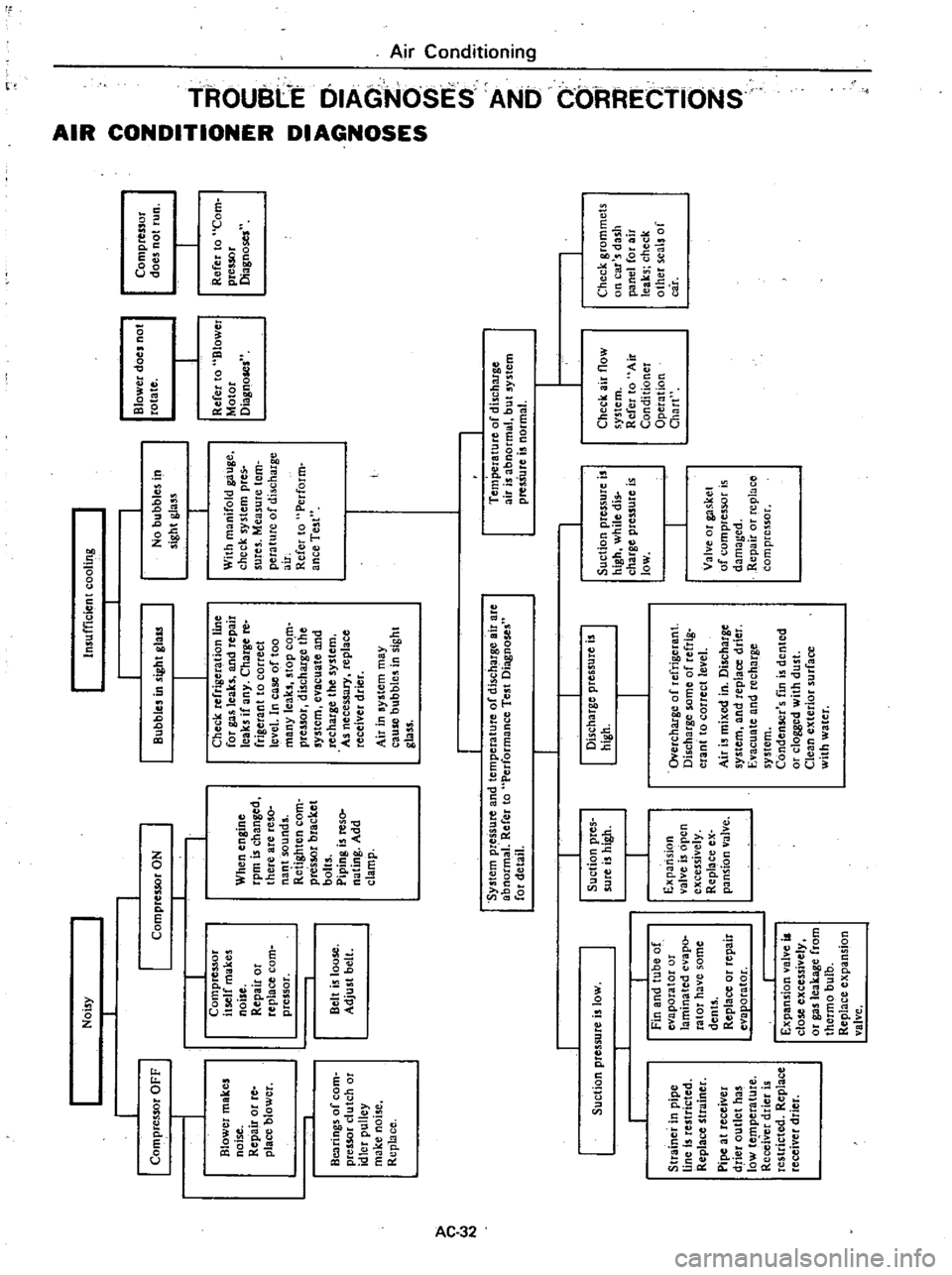

Com

pressor

OFF

I

I

Blower

makes

noise

Repair

or

re

place

blower

Bearings

of

com

pressor

clutch

or

idler

pulley

make

noise

Replace

C

l

W

Noisy

Compressor

itself

makes

noise

Repair

or

replace

com

pressor

Belt

is

loose

Adjust

belt

Suction

pressure

is

low

Strainer

in

pipe

Line

Is

restricted

Replace

strainer

Pipe

at

receiver

drier

outlet

has

low

temperature

Receiver

drier

is

restricted

Replace

receiver

drier

I

Fin

and

tube

of

evaporator

or

laminated

evapo

rator

have

some

dents

Replace

or

repair

evaporator

Expansion

valve

is

close

excessively

or

gas

leakage

from

thermo

bulb

Replace

expansion

valve

Compressor

ON

J

I

When

engine

rpm

is

changed

there

are

reso

nant

sounds

Retighten

com

pre

ssor

bracket

bolts

Piping

is

reso

nating

Add

clamp

Insufficient

cooling

Bubbles

in

sight

glaS

Check

refrigeration

line

for

gas

leaks

and

repair

leaks

if

any

Charge

re

frigerant

to

correct

level

In

case

of

too

many

leaks

stop

com

pressor

discharge

the

system

evaCUate

and

recharge

the

system

As

necessary

replace

receiver

drier

Air

in

system

may

cause

bubbles

in

sight

glass

System

pressure

and

temperature

of

discharge

air

llre

abnormal

Refer

to

Performance

Test

Diagnoses

for

detail

Suction

pres

sure

is

high

Expansion

valve

is

open

excessively

Replace

ex

pansion

valve

Discharge

pressure

is

high

Overcharge

of

refrigerant

Discharge

some

of

refrig

erani

to

correct

level

Air

is

mixed

in

Discharge

system

and

replace

drier

Evacuate

and

recharge

system

Condenser

s

fin

is

dented

or

clogged

with

dust

Clean

exterior

surface

with

water

No

bubbles

in

sight

glass

With

manifold

gauge

check

system

pres

sures

Measure

tem

perature

of

discharge

air

Refer

to

Perform

ance

Test

Blower

does

not

rotate

Refei

to

Blower

Motor

Diagnoses

Temperature

of

discharge

air

is

abnormal

but

system

pres5ure

is

normal

Suction

pressure

iJ

high

while

dis

charge

pressure

is

low

Valve

or

gasket

of

compressor

is

damaged

Repair

or

replace

compreuor

Check

air

flow

system

Refer

to

Air

Conditioner

Operation

Chart

Compressor

does

not

run

Refer

to

Com

pressor

Diagnoses

Check

grommets

on

car

s

dash

panel

for

air

leaks

check

other

seal

of

car

Page 534 of 548

Air

Conditioning

BLOWER

MOTOR

DIAGNOSES

I

Blower

motor

inoperative

I

Check

20

ampere

fuse

in

air

conditioner

harness

Fuse

blown

Fuse

OK

Locate

short

circuited

spot

and

repair

or

replace

faulty

parts

Ground

one

of

lead

wires

Black

blue

3

speed

Black

white

2

speed

Black

yellow

l

speed

1eading

to

fan

switch

Blower

runs

Blower

does

not

run

Check

ground

circuit

and

lead

wire

con

oeetion

When

no

problem

is

found

replace

blower

switch

Ground

black

wire

of

blower

motor

i

Blower

runs

Blower

does

not

run

Check

resistor

for

connection

When

no

problem

is

found

replace

resistor

Connect

12

volt

test

light

to

white

wire

leading

to

blower

motor

Light

ON

Light

OFF

Check

lead

wire

for

connection

When

no

problem

is

found

replace

blower

motor

Check

for

presence

of

voltage

at

main

relay

No

Yes

Check

for

presence

of

voltage

at

air

conditioner

harness

Check

lead

wire

for

connection

When

no

problem

is

found

replace

relay

AC

33

Page 535 of 548

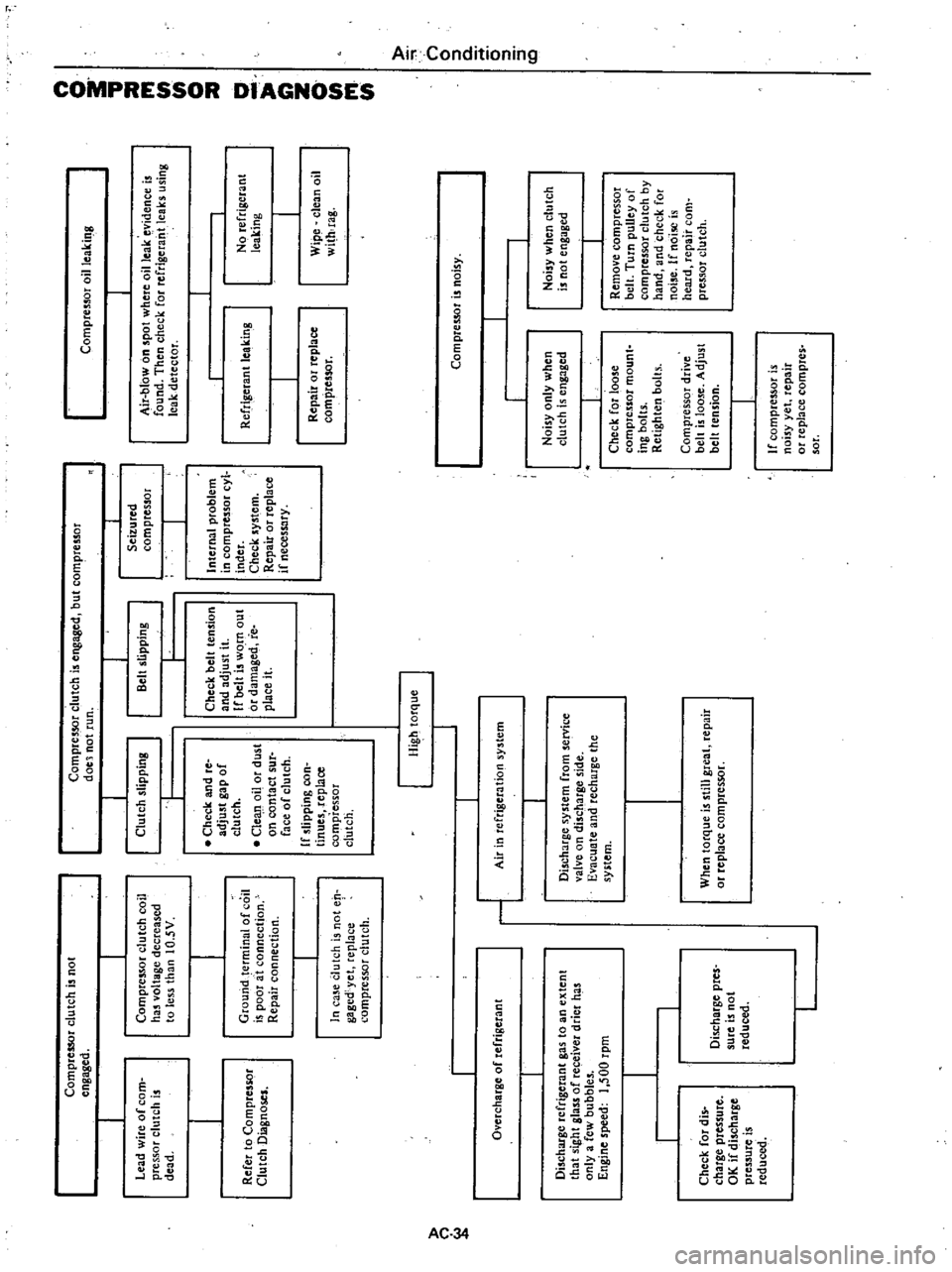

J

COnlp

reSSOI

clutch

is

not

J

engaged

c

00

ha

voltage

decreased

to

es

thall

lO

5V

Lead

wire

or

com

pressor

clutch

is

dead

I

Ground

terminal

of

coil

is

poor

a

t

connection

Repair

connection

Refer

to

CompreSior

Clutch

Diagnoses

J

J

r

In

c

e

Clutch

is

not

en

gaged

yet

replace

compressor

dutch

lr1

vetChatgO

of

Ief

ge1ant

I

I

e

refrigotant

gas

10

n

o

t

cnt

j

that

sight

gla

ss

of

receiver

drier

has

onlY

a

few

bubble

Engine5peed

l

OOrpm

i

l

r

Check

for

dis

charge

pressure

OK

if

dbcnarge

pres

ure

is

reduced

Discharge

pres

sure

is

not

reduced

l

Compressor

clutch

is

engaged

but

compre

sor

doe

not

IUn

Cbeck

and

re

adjust

gap

of

clutch

Clea

Il

oil

OJ

dust

on

contact

sur

face

of

clutch

if

slipping

con

ti

n

ues

rCPlaO

J

compressor

clutch

Check

belt

teMion

and

adjust

it

lfbelt

bwor

l

out

or

damaged

ie

pl

ce

iI

Air

in

refrigeration

System

J

Discharge

system

ftom

service

valve

on

discharge

side

Evacuate

a

nd

rech

arge

the

Lystem

J

When

torque

is

stm

grellt

repair

or

rtV1ace

compressor

j

T

son

rod

l

mp

teSSOI

j

Internal

problem

in

cornpre

sor

cyl

inder

Check

y

tem

Repau

or

replace

nece

tY

J

r

Compte

r

oille

ing

J

Air

blOW

on

spot

whcre

oil

leak

e

vidence

is

round

Then

check

for

refrigerant

leakS

us

n

leak

detectof

Refrigerant

leaking

Repau

01

replace

compttUOr

I

NO

teftig

lea

ing

Wipe

clean

oil

wi

h

Jag

L

Noisy

onlY

when

clutch

is

engaged

Check

for

oo

c

comprenor

mount

ing

Dolts

Retighten

bolts

Compressor

drive

belt

islOosc

Adjust

belt

ttM1on

If

cotTlpre

sor

is

noisY

yet

repair

or

replace

compres

sor

Noisy

when

clutch

is

not

engaged

Remove

cQm1JressOt

belL

Turn

pulley

of

compressot

clutch

by

hand

and

check

for

noise

If

noisC

is

MaId

repair

com

preM

or

clutCh

01

o

B

0

a

Ut

Ut

o

a

a

i

o

Ut

A

o

l

Cl

o

l

l

tC

Page 536 of 548

Air

Conditioning

COMPRESSOR

CLUTCH

DIAGNOSES

Compressor

clutch

is

not

engaged

Check

20

arnpere

fuse

in

air

conditioner

harness

Fuse

blown

Fuse

OK

Locate

short

circuited

spot

and

repair

or

replace

damaged

parts

Connect

12

volt

test

light

to

compressor

clutch

lead

wire

Ground

the

other

end

of

test

light

Set

air

control

lever

to

A

C

posi

tion

Light

ON

Light

OFF

I

Check

low

pressure

switch

for

continuity

L

H

drive

only

Check

lead

wire

and

ground

wire

of

compres

sor

clutch

for

connection

When

there

is

nothing

wrong

with

them

replace

compressor

clutch

No

I

Yes

Measure

pressure

in

system

If

there

is

a

leak

service

system

If

pressure

is

normal

check

low

pressure

switch

as

a

part

reo

place

if

necessary

Connect

12

volt

test

light

to

terminal

of

blue

green

wire

leading

to

thermostat

Ground

the

other

end

of

test

light

Light

ON

Light

OFF

Check

ground

circuit

and

make

sure

of

proper

connection

Further

check

lead

wire

connection

and

when

no

problem

is

found

replace

air

conditioner

harness

or

main

harness

Connect

12

volt

test

light

to

blue

white

wire

of

microswitch

Ground

the

other

end

of

test

light

I

Light

ON

I

Light

OFF

I

Check

lead

wire

connection

When

no

problem

is

found

replace

thermostat

Check

for

current

flow

in

lead

wire

to

main

relay

Yes

I

I

No

Check

lead

wire

for

connection

When

no

problem

is

found

replace

microswitch

or

main

relay

Check

power

supply

AC

35

Page 537 of 548

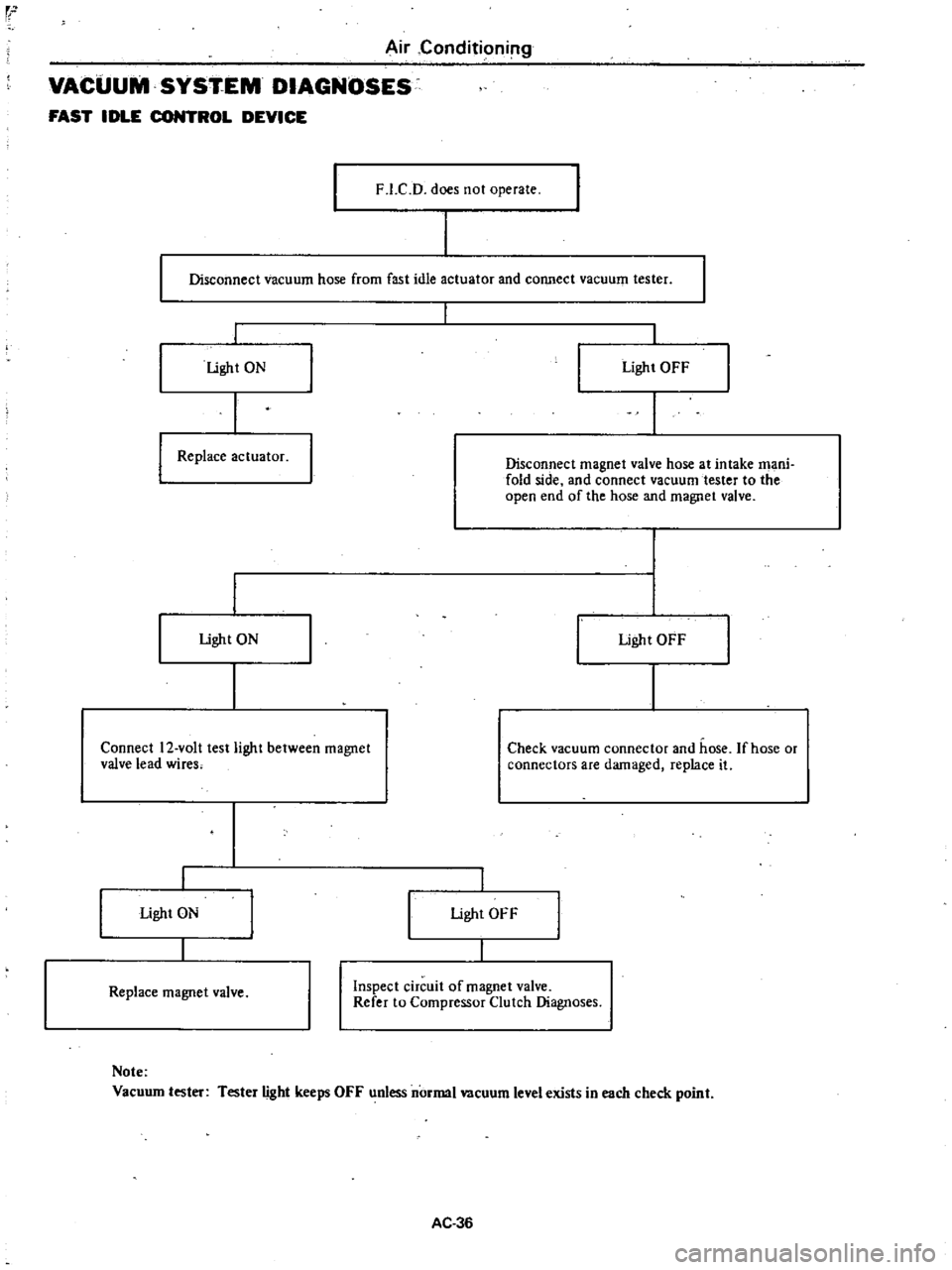

v

Air

Conditioning

VACUUM

SYSTEM

DIAGNOSES

FAST

IDLE

CONTROL

DEVICE

F

I

C

O

does

not

operate

Disconnect

vacuum

hose

from

fast

idle

actuator

and

connect

vacuum

tester

light

ON

Light

OFF

Replace

actuator

Disconnect

magnet

valve

hose

at

intake

mani

fold

side

and

connect

vacuum

tester

to

the

open

end

of

the

hose

and

magnet

valve

light

ON

I

light

OFF

Connect

12

volt

test

light

between

magnet

valve

lead

wires

Check

vacuum

connector

and

hose

If

hose

or

connectors

are

damaged

replace

it

light

ON

light

OFF

Replace

magnet

valve

Inspect

circuit

of

magnet

valve

Refer

to

Compressor

Clutch

Diagnoses

Note

Vacuum

lester

Tester

Iighl

keeps

OFF

unless

normal

wcuum

level

exists

in

each

check

point

AC

36

Page 538 of 548

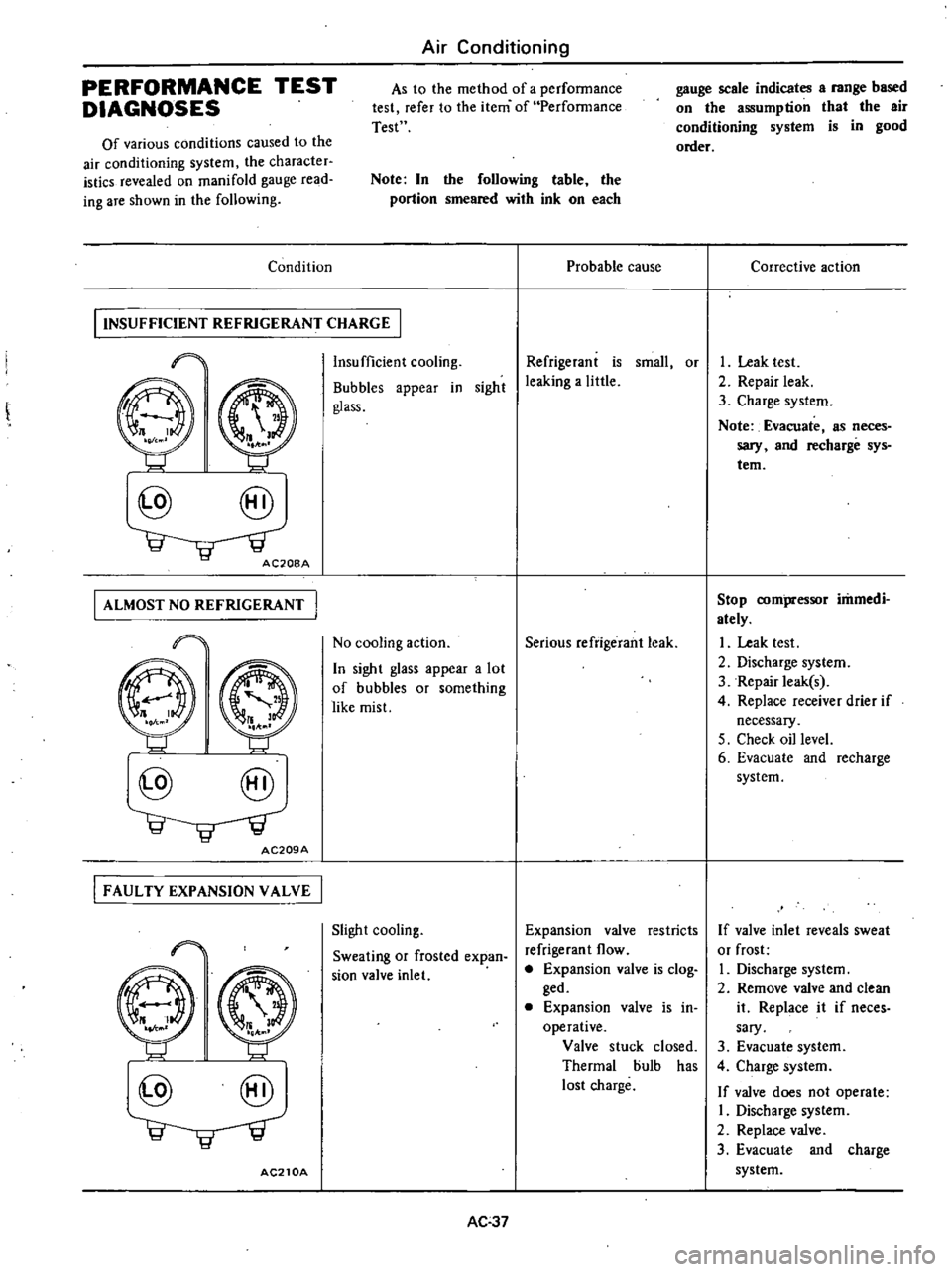

PERFORMANCE

TEST

DIAGNOSES

Of

various

conditions

caused

to

the

air

conditioning

system

the

character

istics

revealed

on

manifold

gauge

read

ing

are

shown

in

the

following

Condition

Air

Conditioning

As

to

the

method

of

a

perfonnance

test

refer

to

the

item

of

Perfonnance

Test

Note

In

the

following

table

the

portion

smeared

with

ink

on

each

I

INSUFFICIENT

REFRIGERANT

CHARGE

I

I

@

@

08A

I

ALMOST

NO

REFRIGERANT

i

@

@

AC209A

I

FAULTY

EXPANSION

VALVE

I

I

@

@

AC210A

Insufficient

cooling

Bubbles

appear

in

sight

glass

Probable

cause

Refrigerant

is

small

or

leaking

a

little

No

cooling

action

Serious

refrigerant

leak

In

sight

glass

appear

a

lot

of

bubbles

or

something

like

mist

Slight

cooling

Sweating

or

frosted

expan

sion

valve

inlet

AC37

Expansion

valve

restricts

refrigerant

flow

Expansion

valve

is

clog

ged

Expansion

valve

is

in

operative

Valve

stuck

closed

Thermal

bulb

has

lost

charge

gauge

scale

indicates

a

range

based

on

the

assumption

that

the

air

conditioning

system

is

in

good

order

Corrective

action

I

Leak

test

2

Repair

leak

3

Charge

system

Note

Evacuate

8S

neces

sary

and

recharge

sys

tem

Stop

rompressor

immedi

ately

I

Leak

test

2

Discharge

system

3

Repair

leak

s

4

Replace

receiver

drier

if

necessary

5

Check

oilleve

6

Evacuate

and

recharge

system

If

valve

inlet

reveals

sweat

or

frost

I

Discharge

system

2

Remove

valve

and

clean

it

Replace

it

if

neces

sary

3

Evacuate

system

4

Charge

system

If

valve

does

not

operate

I

Discharge

system

2

Replace

valve

3

Evacuate

and

charge

system

Page 539 of 548

r

l

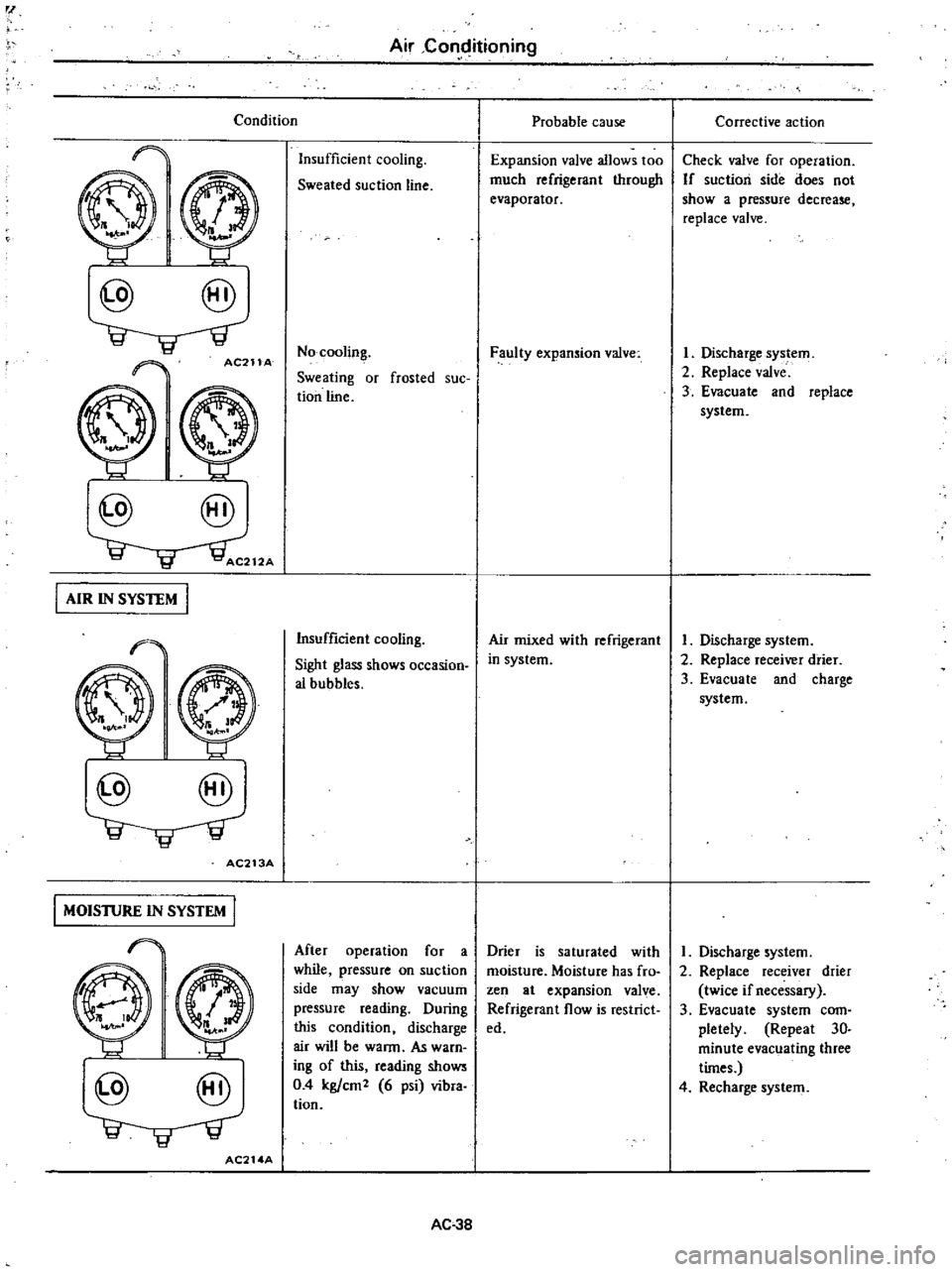

Condition

6

@

@

AC211

A

o

@

g

@

fj

212A

I

AIR

IN

SYSTEM

r

l

lI

IJI

I

J

ole

I

i

@

@

AC213A

I

MOISTIJRE

IN

SYSTEM

I

@

@

AC214A

Air

Co

itioning

Insufficient

cooling

Sweated

suction

line

No

cooling

Sweating

or

frosted

sue

tion

line

Insufficient

cooling

Sight

glass

shows

occasion

al

bubbles

After

operation

for

a

while

pressure

on

sllction

side

may

show

vacuum

pressure

reading

During

this

condition

discharge

air

will

be

wann

As

warn

ing

of

this

reading

shows

0

4

kg

cm2

6

psi

vibra

tion

AC

38

Probable

cause

Expansion

valve

allows

too

much

refrigerant

through

evaporator

F

aul

ty

expansion

valve

Air

mixed

with

refrigerant

in

system

Drier

is

saturated

with

moisture

Moisture

has

fro

zen

at

expansion

valve

Refrigerant

flow

is

restrict

ed

Corrective

action

Check

valve

for

operation

If

suction

side

does

not

show

a

pressure

decrease

replace

valve

I

Discharge

system

2

Replace

valve

3

Evacuate

and

replace

system

I

Discharge

system

2

Replace

receiver

drier

3

Evacuate

and

charge

system

I

Discharge

system

2

Replace

receiver

drier

twice

if

necessary

3

Evacuate

system

com

pletely

Repeat

30

minute

evacuating

three

times

4

Recharge

system

Page 540 of 548

Condition

I

FAULTY

CONDENSER

I

I

@

@

AC215A

I

HIGH

PRESSURE

liNE

BLOCKED

I

r

@

@

AC216A

I

FAULTY

COMPRESSOR

I

r

j

@

rg

AC217A

Air

Conditioning

o

cooling

action

engine

may

overheat

Bubbles

appear

in

sight

glass

of

drier

Suction

line

is

very

hot

Insufficient

cooling

Frosted

high

pressure

liquid

line

Insufficient

cooling

AC

39

Probable

cause

Condenser

is

often

found

not

functioning

well

Drier

clogged

or

restric

tion

in

high

pressure

line

Internal

problem

in

com

pressor

or

damaged

gasket

and

valve

Corrective

action

Check

fan

belt

and

fluid

coupling

Check

condenser

for

dirt

accumulation

Check

engine

coqling

system

for

overheat

Check

for

refrigerant

overcharge

Note

If

pressure

remains

high

in

spite

of

aU

above

actions

taken

re

move

and

inspect

the

condenser

for

possible

oil

clogging

I

Discharge

system

2

Remove

receiver

drier

or

strainer

and

replace

it

3

Evacuate

and

charge

system

I

Discharge

system

2

Remove

and

check

compressor

3

Repair

or

replace

com

pressor

4

Check

oil

level

5

Replace

receiver

drier

6

Evacuate

and

charge

system