DODGE NEON 1999 Service Repair Manual

Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 131 of 1200

of the park brake lever. The park brake lever output

cable (Fig. 135) should never be attempted to be

repaired in any manner. Follow the require proce-

dures under park brake lever removal and replace-

ment when servicing a park brake lever output cable.

PARK BRAKE CABLES

NOTE: Note: Remove only one rear park brake

cable from rear brakes at a time. Failure to do so

will result in high efforts required to connect park

brake cables to equalizer or park brake lever at rear

wheel brakes.

For installation of the rear park brake cables fol-

low the procedure as listed below.

REMOVE

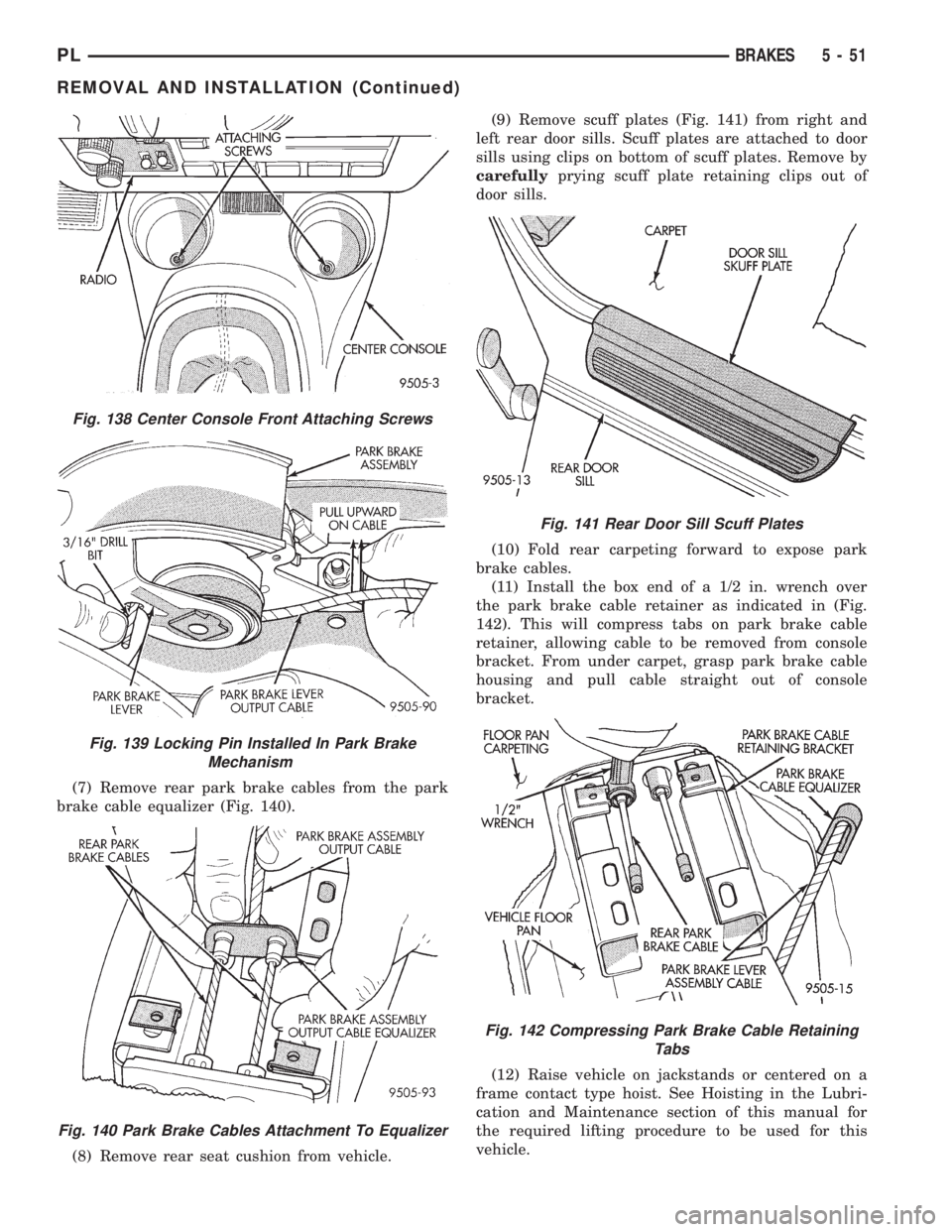

(1) Remove screws attaching rear of center console

assembly to floor pan of vehicle (Fig. 136) or (Fig.

137).(2) Remove the 2 screws located in cup holders

(Fig. 138) attaching front of center console to console

bracket.

(3) Raise park brake lever as high as it will go for

the clearance required to remove the center console.

(4) Remove center console assembly from vehicle.

WARNING: WHEN REPAIRS TO THE PARK BRAKE

HAND LEVER ASSEMBLY OR CABLES IS

REQUIRED, THE AUTO ADJUSTER MUST BE

RELOADED AND LOCKED OUT.

(5) Lower park brake lever handle.

(6) Grasp park lever output cable by hand and pull

rearward (Fig. 139). Continue pulling on cable until a

3/16 in. drill bit can be inserted into handle and sec-

tor gear of park brake mechanism (Fig. 139). This

will lock the park brake mechanism and take tension

off park brake cables.

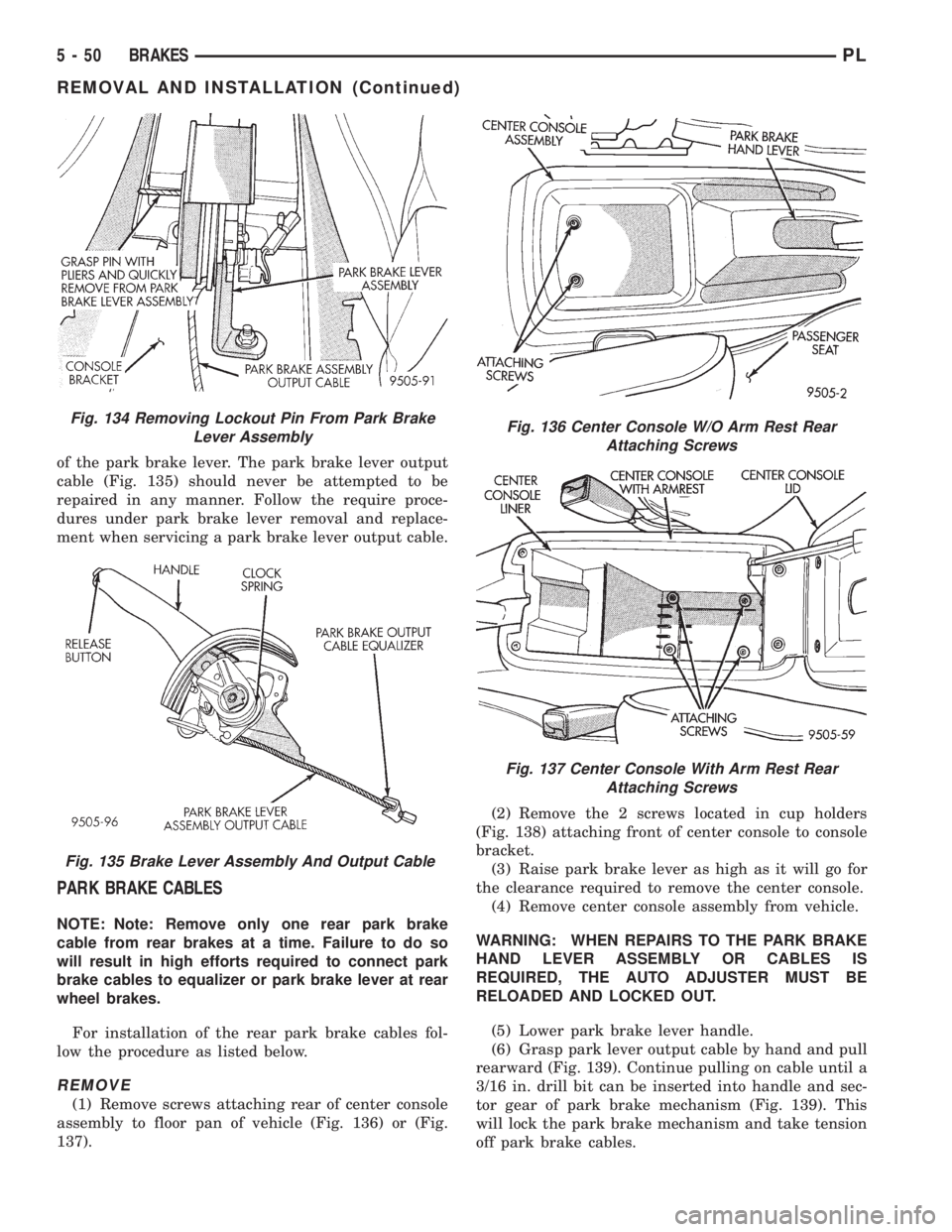

Fig. 134 Removing Lockout Pin From Park Brake

Lever Assembly

Fig. 135 Brake Lever Assembly And Output Cable

Fig. 136 Center Console W/O Arm Rest Rear

Attaching Screws

Fig. 137 Center Console With Arm Rest Rear

Attaching Screws

5 - 50 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 132 of 1200

(7) Remove rear park brake cables from the park

brake cable equalizer (Fig. 140).

(8) Remove rear seat cushion from vehicle.(9) Remove scuff plates (Fig. 141) from right and

left rear door sills. Scuff plates are attached to door

sills using clips on bottom of scuff plates. Remove by

carefullyprying scuff plate retaining clips out of

door sills.

(10) Fold rear carpeting forward to expose park

brake cables.

(11) Install the box end of a 1/2 in. wrench over

the park brake cable retainer as indicated in (Fig.

142). This will compress tabs on park brake cable

retainer, allowing cable to be removed from console

bracket. From under carpet, grasp park brake cable

housing and pull cable straight out of console

bracket.

(12) Raise vehicle on jackstands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual for

the required lifting procedure to be used for this

vehicle.

Fig. 138 Center Console Front Attaching Screws

Fig. 139 Locking Pin Installed In Park Brake

Mechanism

Fig. 140 Park Brake Cables Attachment To Equalizer

Fig. 141 Rear Door Sill Scuff Plates

Fig. 142 Compressing Park Brake Cable Retaining

Tabs

PLBRAKES 5 - 51

REMOVAL AND INSTALLATION (Continued)

Page 133 of 1200

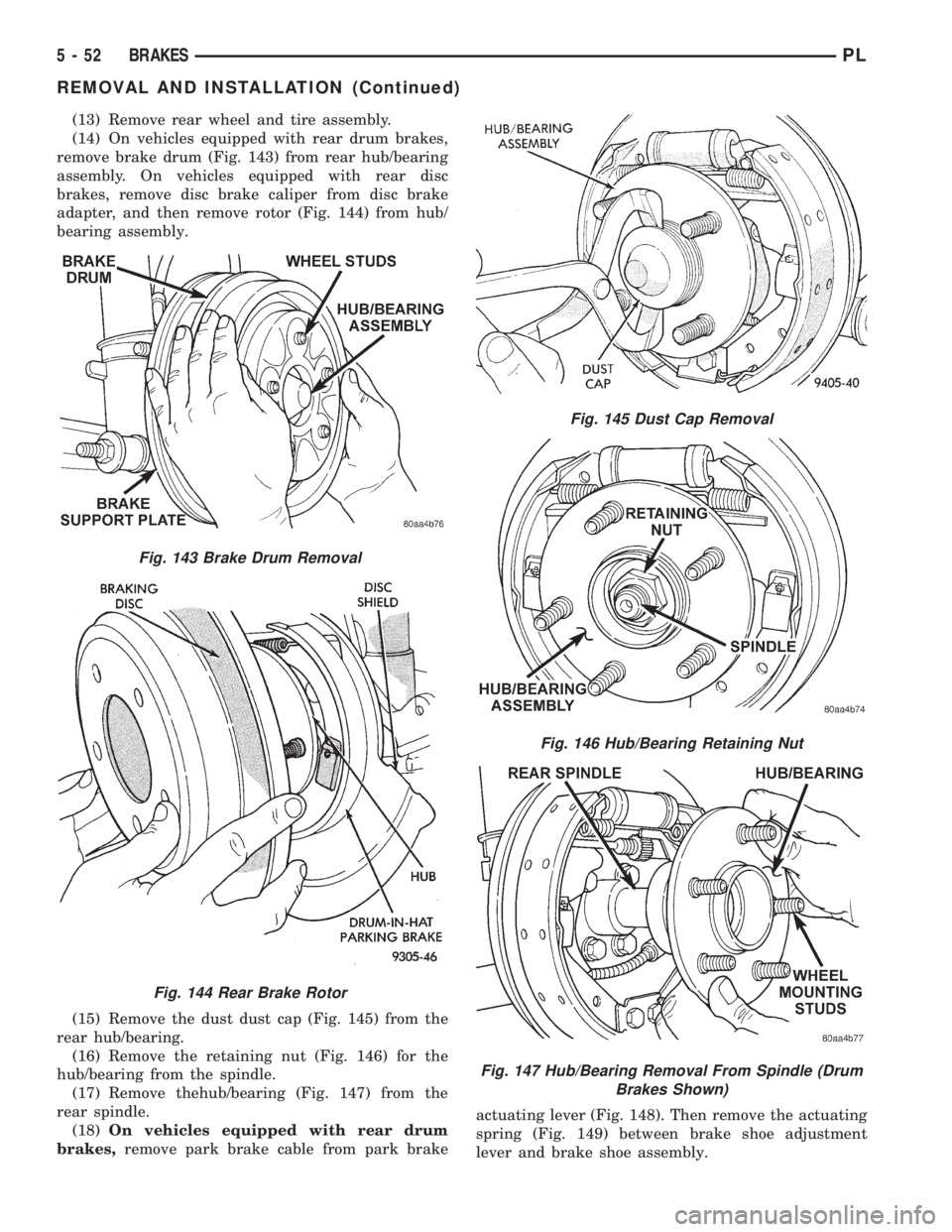

(13) Remove rear wheel and tire assembly.

(14) On vehicles equipped with rear drum brakes,

remove brake drum (Fig. 143) from rear hub/bearing

assembly. On vehicles equipped with rear disc

brakes, remove disc brake caliper from disc brake

adapter, and then remove rotor (Fig. 144) from hub/

bearing assembly.

(15) Remove the dust dust cap (Fig. 145) from the

rear hub/bearing.

(16) Remove the retaining nut (Fig. 146) for the

hub/bearing from the spindle.

(17) Remove thehub/bearing (Fig. 147) from the

rear spindle.

(18)On vehicles equipped with rear drum

brakes,remove park brake cable from park brakeactuating lever (Fig. 148). Then remove the actuating

spring (Fig. 149) between brake shoe adjustment

lever and brake shoe assembly.

Fig. 143 Brake Drum Removal

Fig. 144 Rear Brake Rotor

Fig. 145 Dust Cap Removal

Fig. 146 Hub/Bearing Retaining Nut

Fig. 147 Hub/Bearing Removal From Spindle (Drum

Brakes Shown)

5 - 52 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 134 of 1200

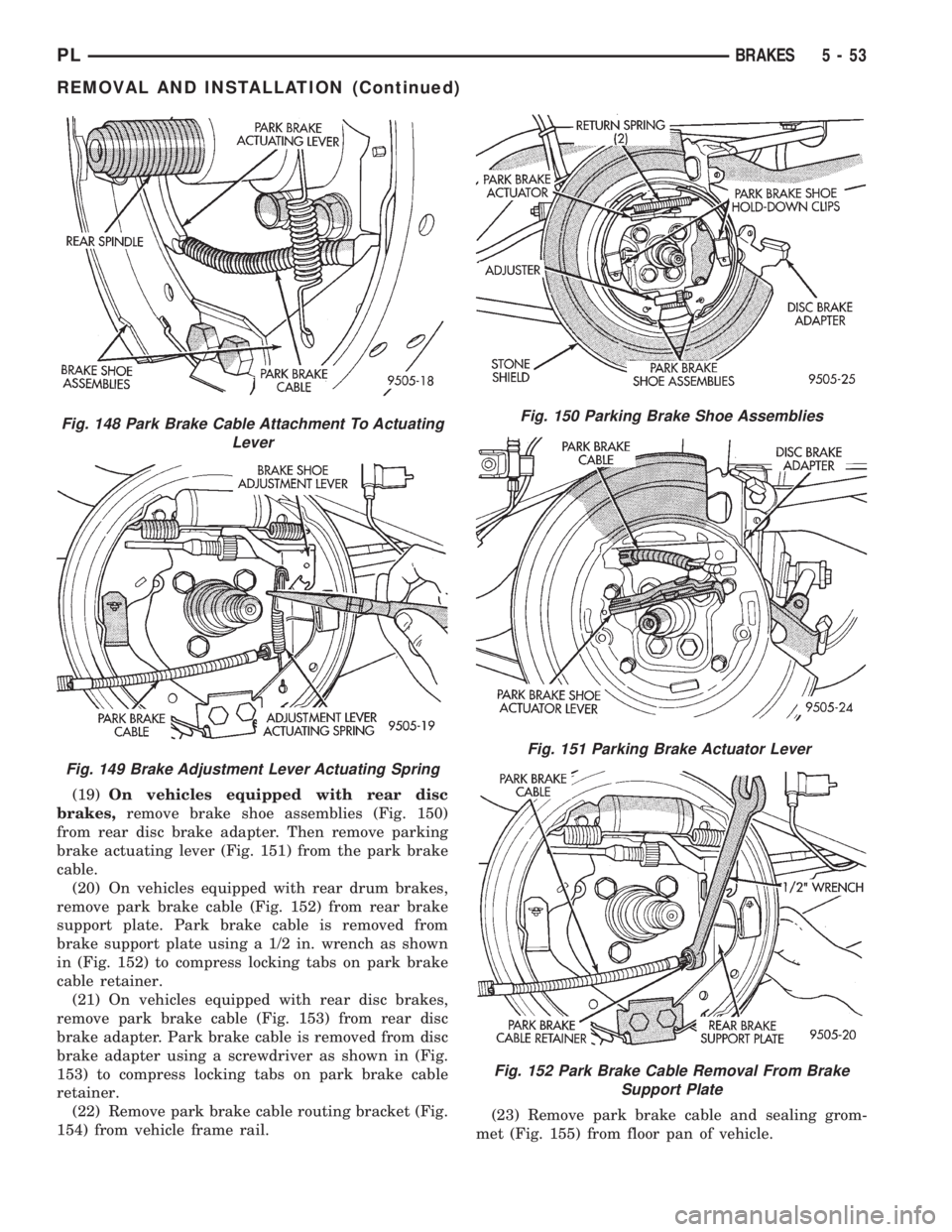

(19)On vehicles equipped with rear disc

brakes,remove brake shoe assemblies (Fig. 150)

from rear disc brake adapter. Then remove parking

brake actuating lever (Fig. 151) from the park brake

cable.

(20) On vehicles equipped with rear drum brakes,

remove park brake cable (Fig. 152) from rear brake

support plate. Park brake cable is removed from

brake support plate using a 1/2 in. wrench as shown

in (Fig. 152) to compress locking tabs on park brake

cable retainer.

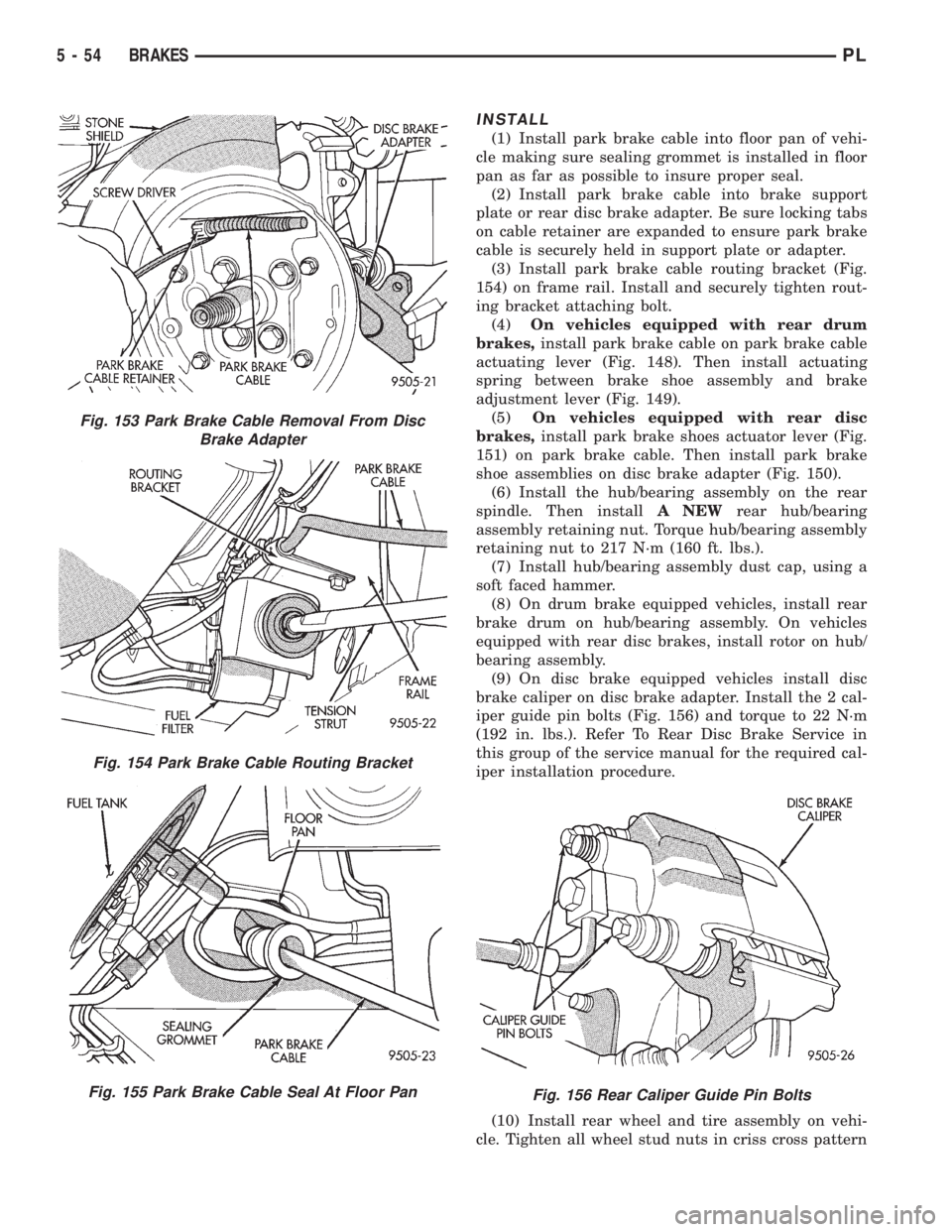

(21) On vehicles equipped with rear disc brakes,

remove park brake cable (Fig. 153) from rear disc

brake adapter. Park brake cable is removed from disc

brake adapter using a screwdriver as shown in (Fig.

153) to compress locking tabs on park brake cable

retainer.

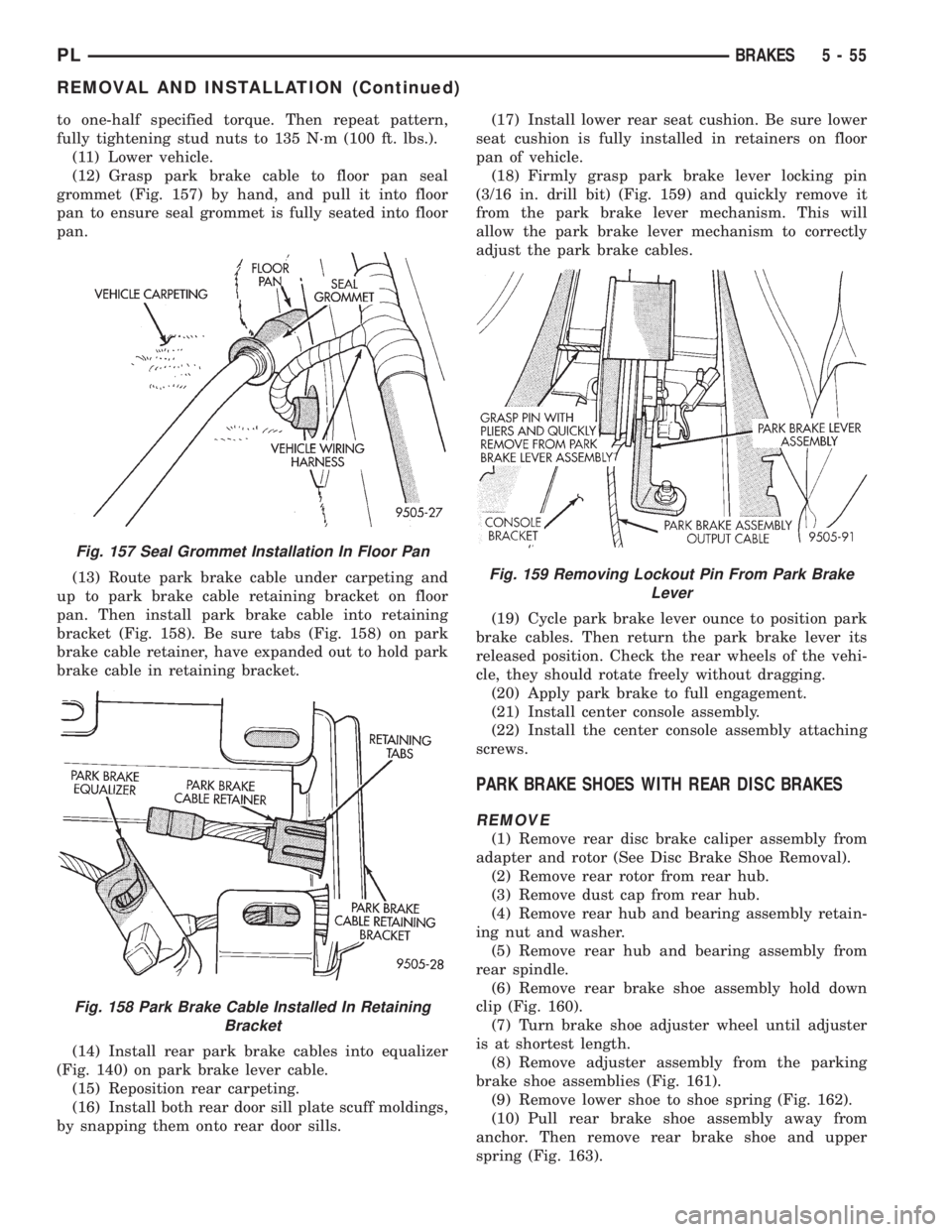

(22) Remove park brake cable routing bracket (Fig.

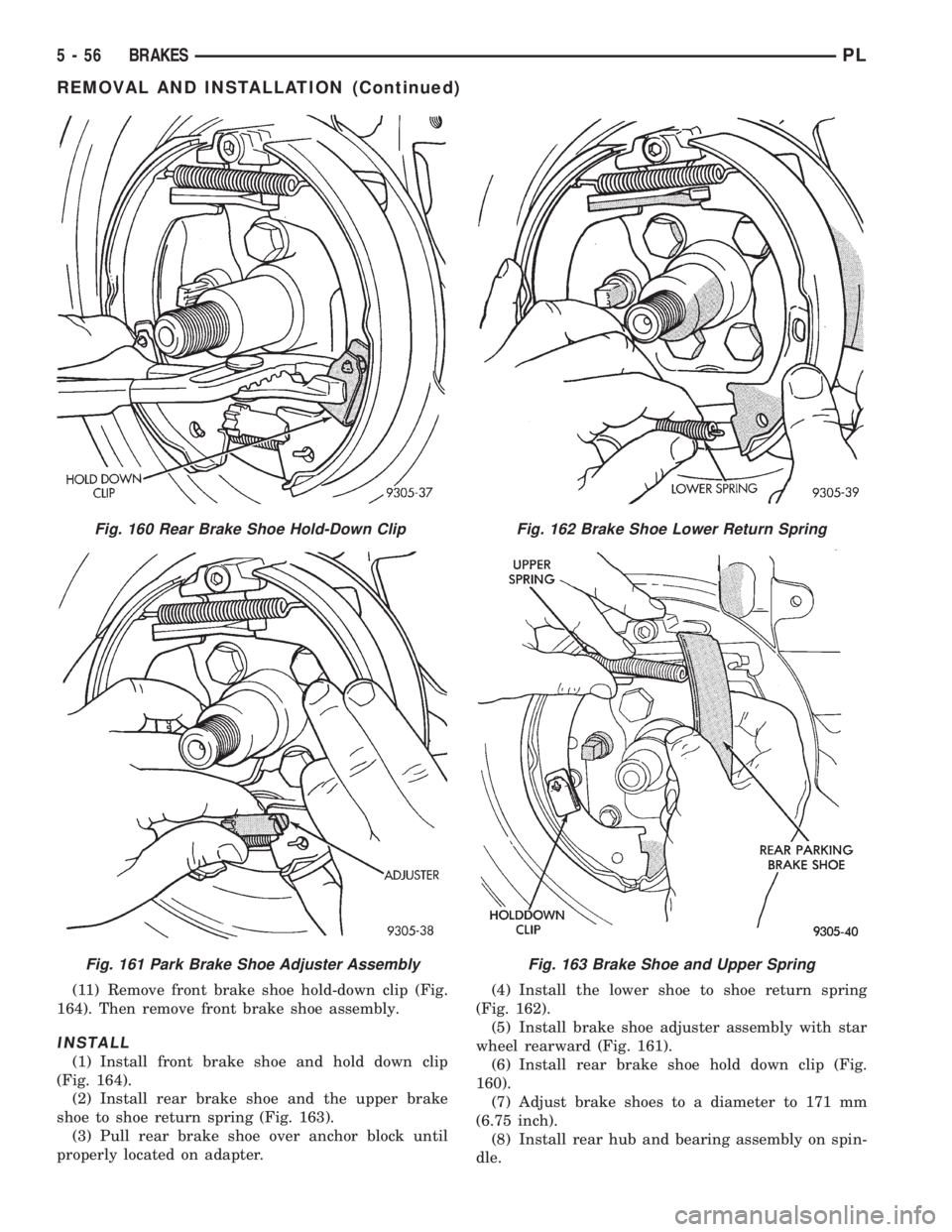

154) from vehicle frame rail.(23) Remove park brake cable and sealing grom-

met (Fig. 155) from floor pan of vehicle.

Fig. 148 Park Brake Cable Attachment To Actuating

Lever

Fig. 149 Brake Adjustment Lever Actuating Spring

Fig. 150 Parking Brake Shoe Assemblies

Fig. 151 Parking Brake Actuator Lever

Fig. 152 Park Brake Cable Removal From Brake

Support Plate

PLBRAKES 5 - 53

REMOVAL AND INSTALLATION (Continued)

Page 135 of 1200

INSTALL

(1) Install park brake cable into floor pan of vehi-

cle making sure sealing grommet is installed in floor

pan as far as possible to insure proper seal.

(2) Install park brake cable into brake support

plate or rear disc brake adapter. Be sure locking tabs

on cable retainer are expanded to ensure park brake

cable is securely held in support plate or adapter.

(3) Install park brake cable routing bracket (Fig.

154) on frame rail. Install and securely tighten rout-

ing bracket attaching bolt.

(4)On vehicles equipped with rear drum

brakes,install park brake cable on park brake cable

actuating lever (Fig. 148). Then install actuating

spring between brake shoe assembly and brake

adjustment lever (Fig. 149).

(5)On vehicles equipped with rear disc

brakes,install park brake shoes actuator lever (Fig.

151) on park brake cable. Then install park brake

shoe assemblies on disc brake adapter (Fig. 150).

(6) Install the hub/bearing assembly on the rear

spindle. Then installA NEWrear hub/bearing

assembly retaining nut. Torque hub/bearing assembly

retaining nut to 217 N´m (160 ft. lbs.).

(7) Install hub/bearing assembly dust cap, using a

soft faced hammer.

(8) On drum brake equipped vehicles, install rear

brake drum on hub/bearing assembly. On vehicles

equipped with rear disc brakes, install rotor on hub/

bearing assembly.

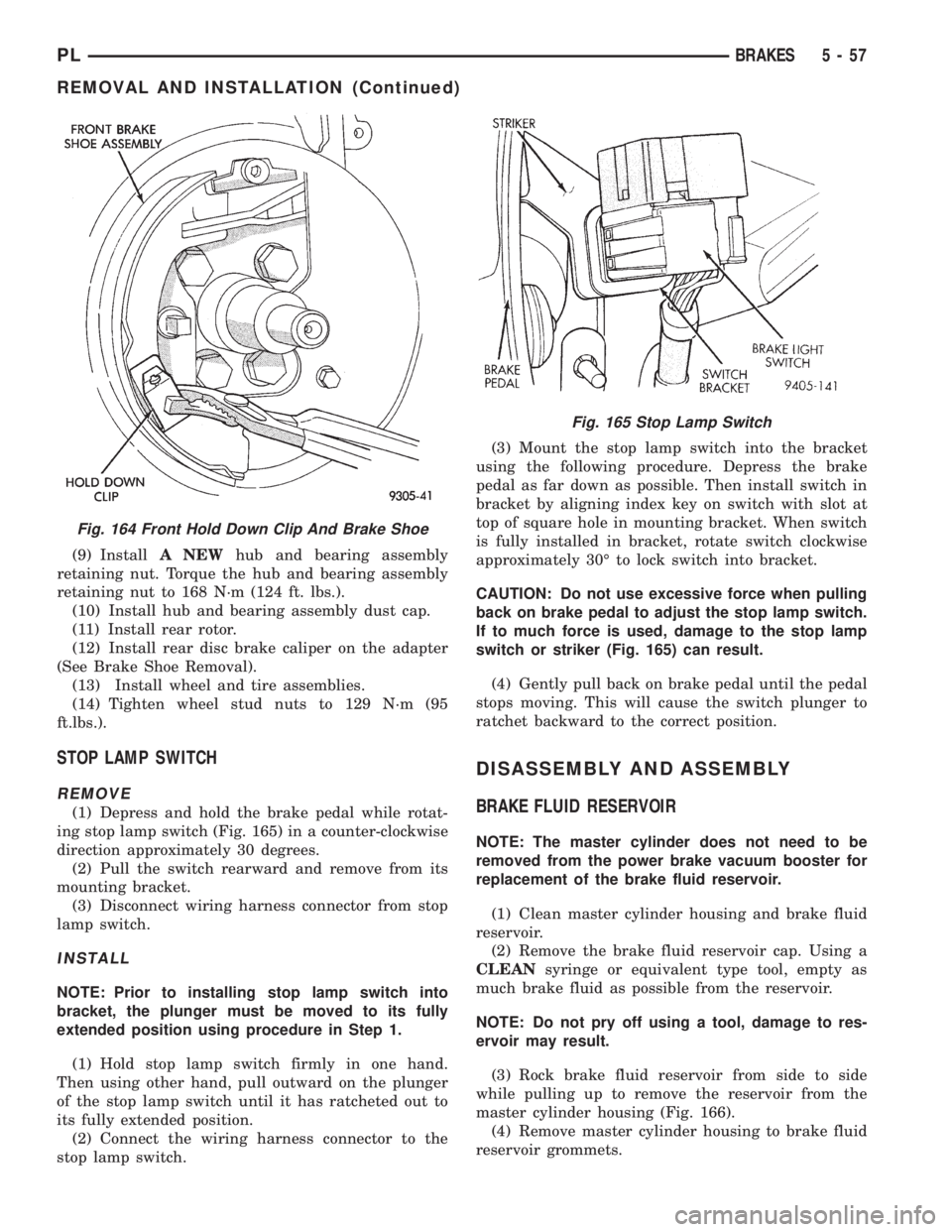

(9) On disc brake equipped vehicles install disc

brake caliper on disc brake adapter. Install the 2 cal-

iper guide pin bolts (Fig. 156) and torque to 22 N´m

(192 in. lbs.). Refer To Rear Disc Brake Service in

this group of the service manual for the required cal-

iper installation procedure.

(10) Install rear wheel and tire assembly on vehi-

cle. Tighten all wheel stud nuts in criss cross pattern

Fig. 153 Park Brake Cable Removal From Disc

Brake Adapter

Fig. 154 Park Brake Cable Routing Bracket

Fig. 155 Park Brake Cable Seal At Floor PanFig. 156 Rear Caliper Guide Pin Bolts

5 - 54 BRAKESPL

Page 136 of 1200

to one-half specified torque. Then repeat pattern,

fully tightening stud nuts to 135 N´m (100 ft. lbs.).

(11) Lower vehicle.

(12) Grasp park brake cable to floor pan seal

grommet (Fig. 157) by hand, and pull it into floor

pan to ensure seal grommet is fully seated into floor

pan.

(13) Route park brake cable under carpeting and

up to park brake cable retaining bracket on floor

pan. Then install park brake cable into retaining

bracket (Fig. 158). Be sure tabs (Fig. 158) on park

brake cable retainer, have expanded out to hold park

brake cable in retaining bracket.

(14) Install rear park brake cables into equalizer

(Fig. 140) on park brake lever cable.

(15) Reposition rear carpeting.

(16) Install both rear door sill plate scuff moldings,

by snapping them onto rear door sills.(17) Install lower rear seat cushion. Be sure lower

seat cushion is fully installed in retainers on floor

pan of vehicle.

(18) Firmly grasp park brake lever locking pin

(3/16 in. drill bit) (Fig. 159) and quickly remove it

from the park brake lever mechanism. This will

allow the park brake lever mechanism to correctly

adjust the park brake cables.

(19) Cycle park brake lever ounce to position park

brake cables. Then return the park brake lever its

released position. Check the rear wheels of the vehi-

cle, they should rotate freely without dragging.

(20) Apply park brake to full engagement.

(21) Install center console assembly.

(22) Install the center console assembly attaching

screws.

PARK BRAKE SHOES WITH REAR DISC BRAKES

REMOVE

(1) Remove rear disc brake caliper assembly from

adapter and rotor (See Disc Brake Shoe Removal).

(2) Remove rear rotor from rear hub.

(3) Remove dust cap from rear hub.

(4) Remove rear hub and bearing assembly retain-

ing nut and washer.

(5) Remove rear hub and bearing assembly from

rear spindle.

(6) Remove rear brake shoe assembly hold down

clip (Fig. 160).

(7) Turn brake shoe adjuster wheel until adjuster

is at shortest length.

(8) Remove adjuster assembly from the parking

brake shoe assemblies (Fig. 161).

(9) Remove lower shoe to shoe spring (Fig. 162).

(10) Pull rear brake shoe assembly away from

anchor. Then remove rear brake shoe and upper

spring (Fig. 163).

Fig. 157 Seal Grommet Installation In Floor Pan

Fig. 158 Park Brake Cable Installed In Retaining

Bracket

Fig. 159 Removing Lockout Pin From Park Brake

Lever

PLBRAKES 5 - 55

REMOVAL AND INSTALLATION (Continued)

Page 137 of 1200

(11) Remove front brake shoe hold-down clip (Fig.

164). Then remove front brake shoe assembly.

INSTALL

(1) Install front brake shoe and hold down clip

(Fig. 164).

(2) Install rear brake shoe and the upper brake

shoe to shoe return spring (Fig. 163).

(3) Pull rear brake shoe over anchor block until

properly located on adapter.(4) Install the lower shoe to shoe return spring

(Fig. 162).

(5) Install brake shoe adjuster assembly with star

wheel rearward (Fig. 161).

(6) Install rear brake shoe hold down clip (Fig.

160).

(7) Adjust brake shoes to a diameter to 171 mm

(6.75 inch).

(8) Install rear hub and bearing assembly on spin-

dle.

Fig. 160 Rear Brake Shoe Hold-Down Clip

Fig. 161 Park Brake Shoe Adjuster Assembly

Fig. 162 Brake Shoe Lower Return Spring

Fig. 163 Brake Shoe and Upper Spring

5 - 56 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 138 of 1200

(9) InstallA NEWhub and bearing assembly

retaining nut. Torque the hub and bearing assembly

retaining nut to 168 N´m (124 ft. lbs.).

(10) Install hub and bearing assembly dust cap.

(11) Install rear rotor.

(12) Install rear disc brake caliper on the adapter

(See Brake Shoe Removal).

(13) Install wheel and tire assemblies.

(14) Tighten wheel stud nuts to 129 N´m (95

ft.lbs.).

STOP LAMP SWITCH

REMOVE

(1) Depress and hold the brake pedal while rotat-

ing stop lamp switch (Fig. 165) in a counter-clockwise

direction approximately 30 degrees.

(2) Pull the switch rearward and remove from its

mounting bracket.

(3) Disconnect wiring harness connector from stop

lamp switch.

INSTALL

NOTE: Prior to installing stop lamp switch into

bracket, the plunger must be moved to its fully

extended position using procedure in Step 1.

(1) Hold stop lamp switch firmly in one hand.

Then using other hand, pull outward on the plunger

of the stop lamp switch until it has ratcheted out to

its fully extended position.

(2) Connect the wiring harness connector to the

stop lamp switch.(3) Mount the stop lamp switch into the bracket

using the following procedure. Depress the brake

pedal as far down as possible. Then install switch in

bracket by aligning index key on switch with slot at

top of square hole in mounting bracket. When switch

is fully installed in bracket, rotate switch clockwise

approximately 30É to lock switch into bracket.

CAUTION: Do not use excessive force when pulling

back on brake pedal to adjust the stop lamp switch.

If to much force is used, damage to the stop lamp

switch or striker (Fig. 165) can result.

(4) Gently pull back on brake pedal until the pedal

stops moving. This will cause the switch plunger to

ratchet backward to the correct position.

DISASSEMBLY AND ASSEMBLY

BRAKE FLUID RESERVOIR

NOTE: The master cylinder does not need to be

removed from the power brake vacuum booster for

replacement of the brake fluid reservoir.

(1) Clean master cylinder housing and brake fluid

reservoir.

(2) Remove the brake fluid reservoir cap. Using a

CLEANsyringe or equivalent type tool, empty as

much brake fluid as possible from the reservoir.

NOTE: Do not pry off using a tool, damage to res-

ervoir may result.

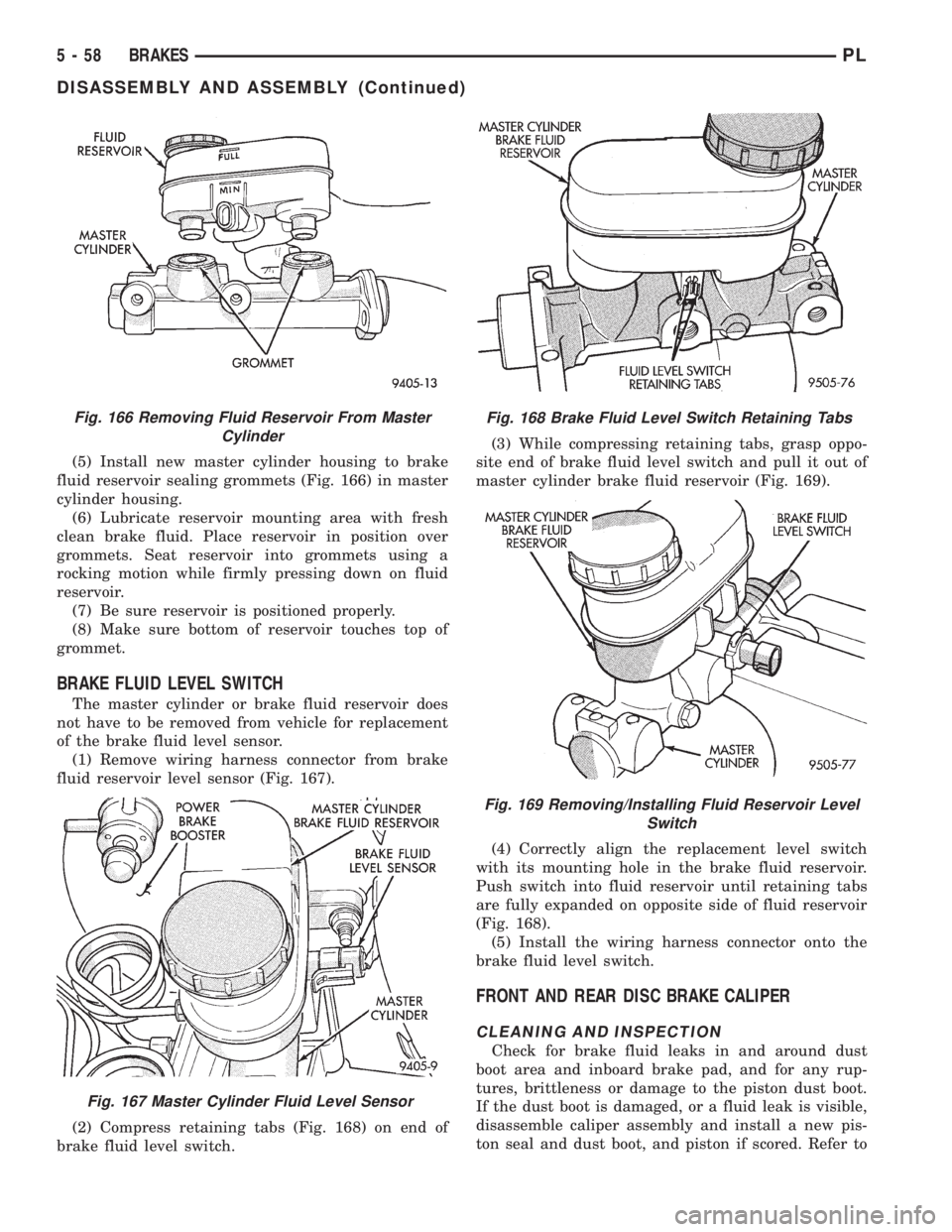

(3) Rock brake fluid reservoir from side to side

while pulling up to remove the reservoir from the

master cylinder housing (Fig. 166).

(4) Remove master cylinder housing to brake fluid

reservoir grommets.

Fig. 164 Front Hold Down Clip And Brake Shoe

Fig. 165 Stop Lamp Switch

PLBRAKES 5 - 57

REMOVAL AND INSTALLATION (Continued)

Page 139 of 1200

(5) Install new master cylinder housing to brake

fluid reservoir sealing grommets (Fig. 166) in master

cylinder housing.

(6) Lubricate reservoir mounting area with fresh

clean brake fluid. Place reservoir in position over

grommets. Seat reservoir into grommets using a

rocking motion while firmly pressing down on fluid

reservoir.

(7) Be sure reservoir is positioned properly.

(8) Make sure bottom of reservoir touches top of

grommet.

BRAKE FLUID LEVEL SWITCH

The master cylinder or brake fluid reservoir does

not have to be removed from vehicle for replacement

of the brake fluid level sensor.

(1) Remove wiring harness connector from brake

fluid reservoir level sensor (Fig. 167).

(2) Compress retaining tabs (Fig. 168) on end of

brake fluid level switch.(3) While compressing retaining tabs, grasp oppo-

site end of brake fluid level switch and pull it out of

master cylinder brake fluid reservoir (Fig. 169).

(4) Correctly align the replacement level switch

with its mounting hole in the brake fluid reservoir.

Push switch into fluid reservoir until retaining tabs

are fully expanded on opposite side of fluid reservoir

(Fig. 168).

(5) Install the wiring harness connector onto the

brake fluid level switch.

FRONT AND REAR DISC BRAKE CALIPER

CLEANING AND INSPECTION

Check for brake fluid leaks in and around dust

boot area and inboard brake pad, and for any rup-

tures, brittleness or damage to the piston dust boot.

If the dust boot is damaged, or a fluid leak is visible,

disassemble caliper assembly and install a new pis-

ton seal and dust boot, and piston if scored. Refer to

Fig. 166 Removing Fluid Reservoir From Master

Cylinder

Fig. 167 Master Cylinder Fluid Level Sensor

Fig. 168 Brake Fluid Level Switch Retaining Tabs

Fig. 169 Removing/Installing Fluid Reservoir Level

Switch

5 - 58 BRAKESPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 140 of 1200

Caliper Disassembly And Re-Assembly Procedures in

Disc Brake Caliper Service in this section of the ser-

vice manual.

Check the guide pin dust boots to determine if they

are in good condition. Replace if they are damaged,

dry, or found to be brittle. Refer to Guide Pin Bush-

ing Service in Disc Brake Caliper Service in this sec-

tion of the service manual.

CALIPER GUIDE PIN BUSHING SERVICE

The double pin caliper uses a sealed for life bush-

ing and sleeve assembly. If required this assembly

can be serviced using the following procedure.

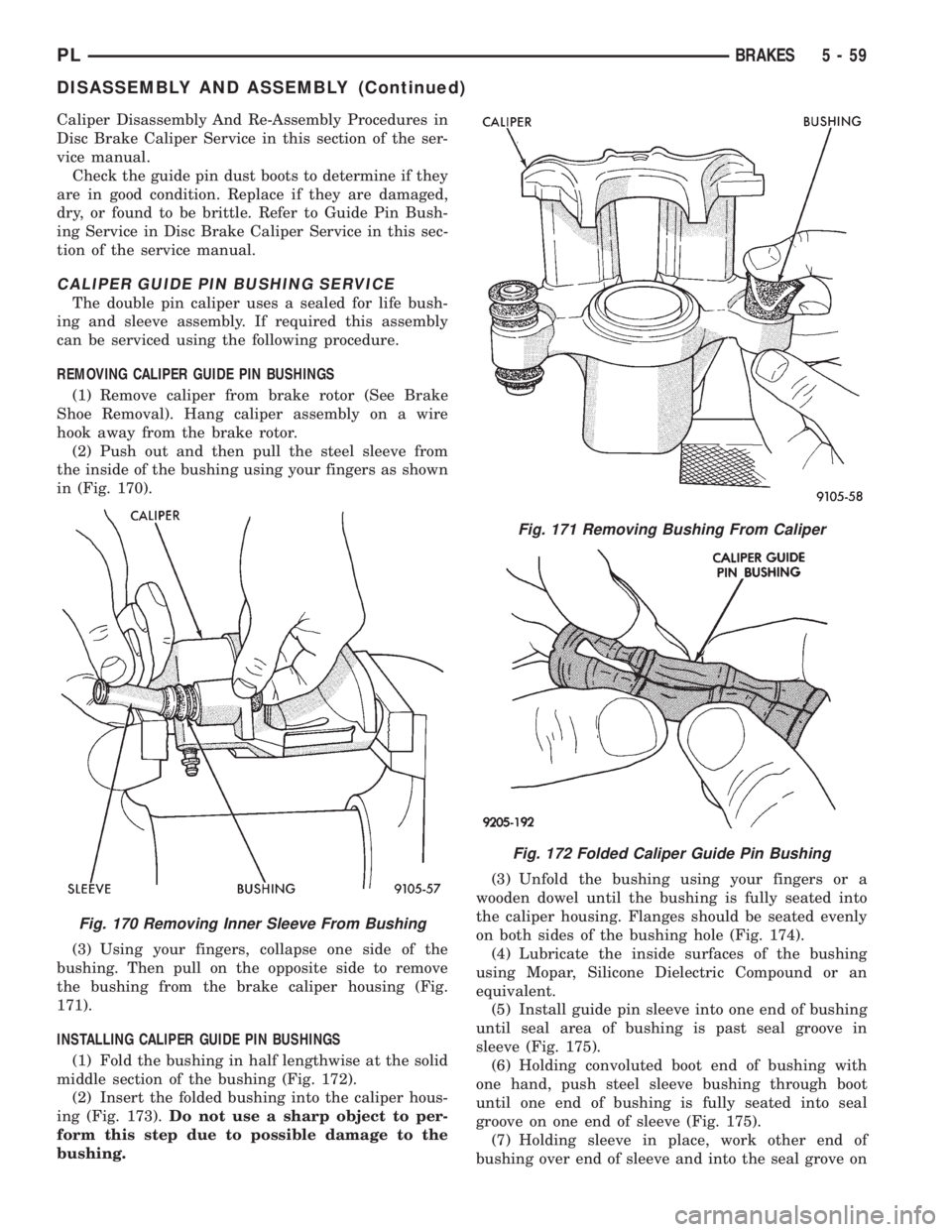

REMOVING CALIPER GUIDE PIN BUSHINGS

(1) Remove caliper from brake rotor (See Brake

Shoe Removal). Hang caliper assembly on a wire

hook away from the brake rotor.

(2) Push out and then pull the steel sleeve from

the inside of the bushing using your fingers as shown

in (Fig. 170).

(3) Using your fingers, collapse one side of the

bushing. Then pull on the opposite side to remove

the bushing from the brake caliper housing (Fig.

171).

INSTALLING CALIPER GUIDE PIN BUSHINGS

(1) Fold the bushing in half lengthwise at the solid

middle section of the bushing (Fig. 172).

(2) Insert the folded bushing into the caliper hous-

ing (Fig. 173).Do not use a sharp object to per-

form this step due to possible damage to the

bushing.(3) Unfold the bushing using your fingers or a

wooden dowel until the bushing is fully seated into

the caliper housing. Flanges should be seated evenly

on both sides of the bushing hole (Fig. 174).

(4) Lubricate the inside surfaces of the bushing

using Mopar, Silicone Dielectric Compound or an

equivalent.

(5) Install guide pin sleeve into one end of bushing

until seal area of bushing is past seal groove in

sleeve (Fig. 175).

(6) Holding convoluted boot end of bushing with

one hand, push steel sleeve bushing through boot

until one end of bushing is fully seated into seal

groove on one end of sleeve (Fig. 175).

(7) Holding sleeve in place, work other end of

bushing over end of sleeve and into the seal grove on

Fig. 170 Removing Inner Sleeve From Bushing

Fig. 171 Removing Bushing From Caliper

Fig. 172 Folded Caliper Guide Pin Bushing

PLBRAKES 5 - 59

DISASSEMBLY AND ASSEMBLY (Continued)