DODGE NEON 1999 Service Repair Manual

Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 251 of 1200

The major difference between the two engines is

component location which affects the ignition system

service procedures. There are various sensors that

are in different locations due to a different cylinder

head and intake manifold.

The 2.0L engines use a fixed ignition timing sys-

tem. The distributorless electronic ignition system is

referred to as the Direct Ignition System (DIS).

Basic ignition timing is not adjustable.The

Powertrain Control Module (PCM) determines spark

advance. The system's three main components are

the coil pack, crankshaft position sensor, and cam-

shaft position sensor.

POWERTRAIN CONTROL MODULE

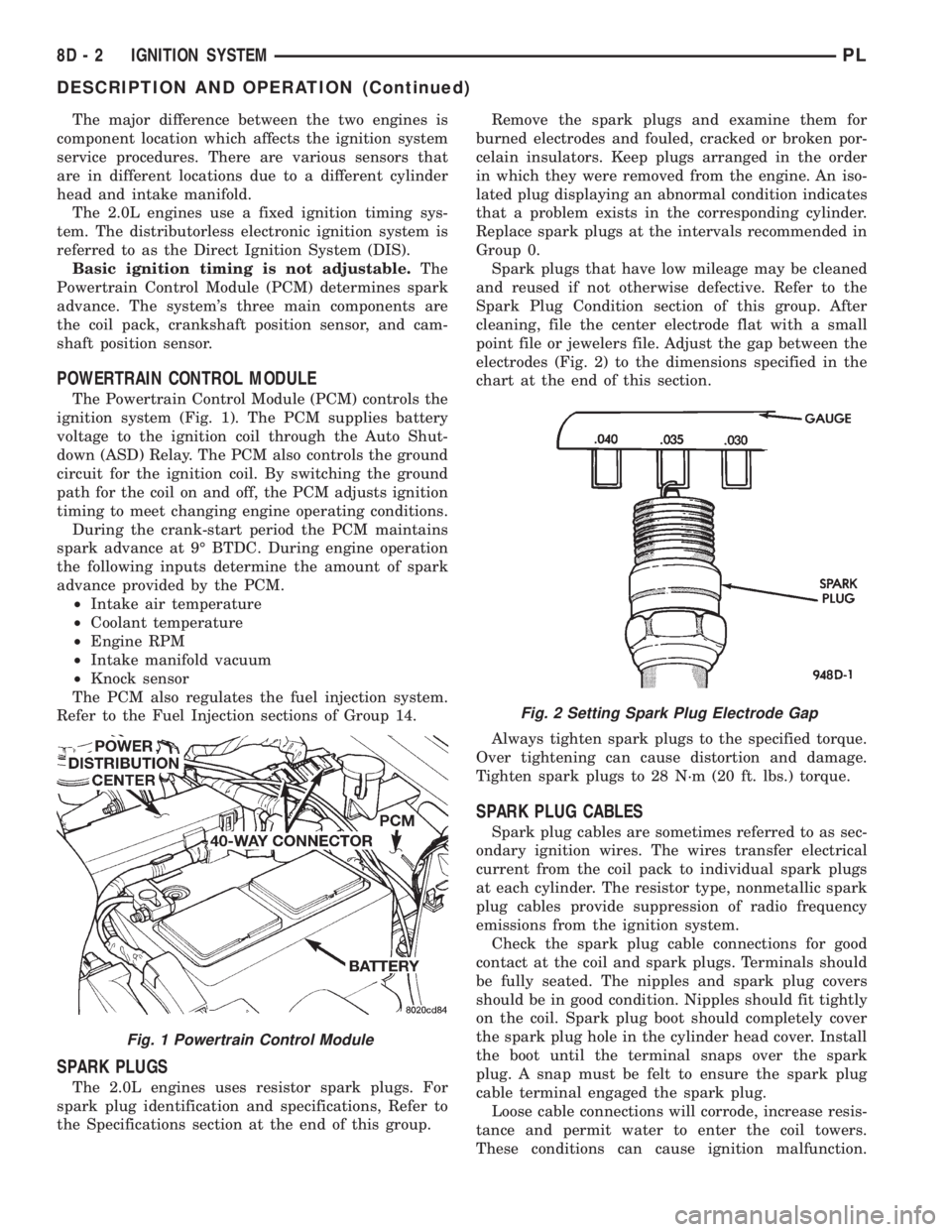

The Powertrain Control Module (PCM) controls the

ignition system (Fig. 1). The PCM supplies battery

voltage to the ignition coil through the Auto Shut-

down (ASD) Relay. The PCM also controls the ground

circuit for the ignition coil. By switching the ground

path for the coil on and off, the PCM adjusts ignition

timing to meet changing engine operating conditions.

During the crank-start period the PCM maintains

spark advance at 9É BTDC. During engine operation

the following inputs determine the amount of spark

advance provided by the PCM.

²Intake air temperature

²Coolant temperature

²Engine RPM

²Intake manifold vacuum

²Knock sensor

The PCM also regulates the fuel injection system.

Refer to the Fuel Injection sections of Group 14.

SPARK PLUGS

The 2.0L engines uses resistor spark plugs. For

spark plug identification and specifications, Refer to

the Specifications section at the end of this group.Remove the spark plugs and examine them for

burned electrodes and fouled, cracked or broken por-

celain insulators. Keep plugs arranged in the order

in which they were removed from the engine. An iso-

lated plug displaying an abnormal condition indicates

that a problem exists in the corresponding cylinder.

Replace spark plugs at the intervals recommended in

Group 0.

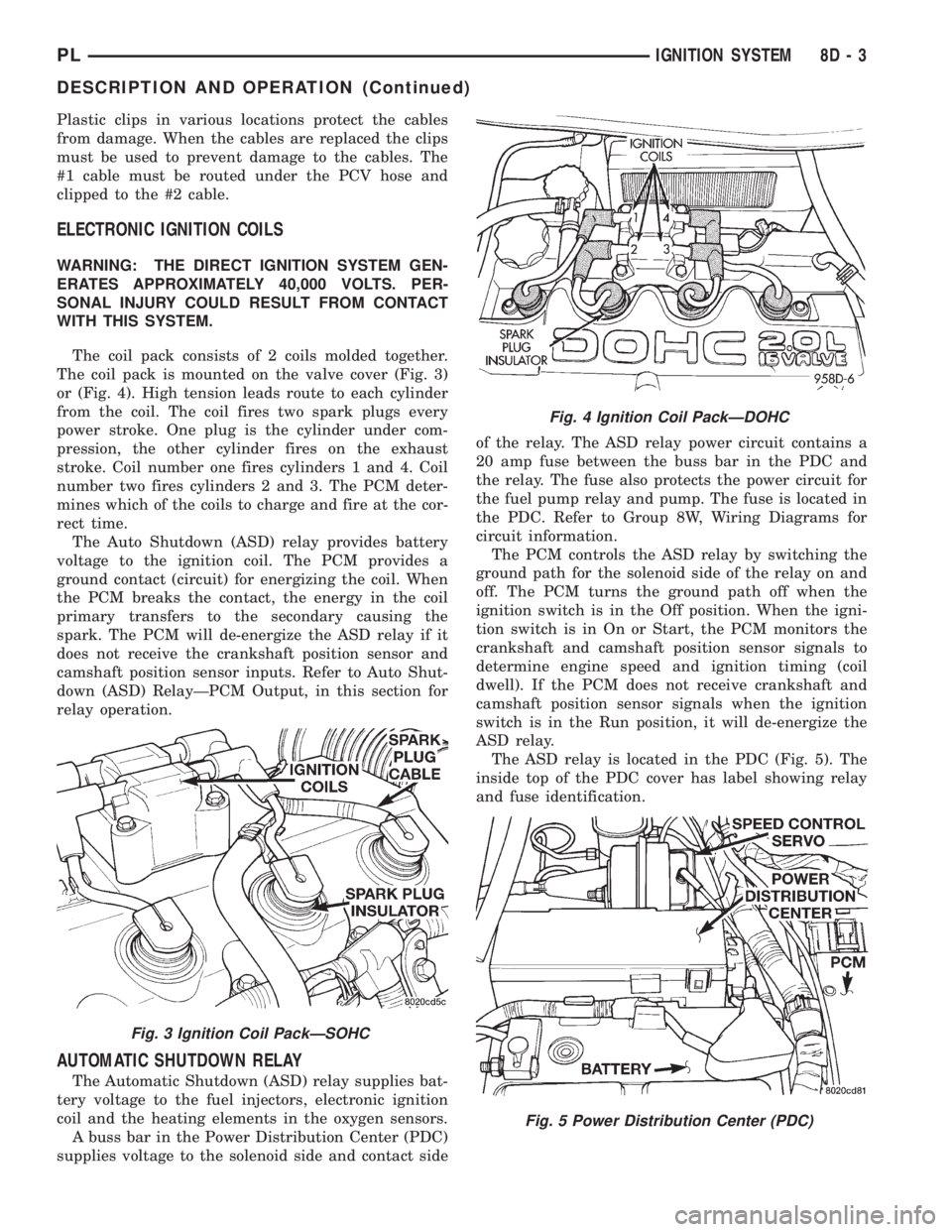

Spark plugs that have low mileage may be cleaned

and reused if not otherwise defective. Refer to the

Spark Plug Condition section of this group. After

cleaning, file the center electrode flat with a small

point file or jewelers file. Adjust the gap between the

electrodes (Fig. 2) to the dimensions specified in the

chart at the end of this section.

Always tighten spark plugs to the specified torque.

Over tightening can cause distortion and damage.

Tighten spark plugs to 28 N´m (20 ft. lbs.) torque.

SPARK PLUG CABLES

Spark plug cables are sometimes referred to as sec-

ondary ignition wires. The wires transfer electrical

current from the coil pack to individual spark plugs

at each cylinder. The resistor type, nonmetallic spark

plug cables provide suppression of radio frequency

emissions from the ignition system.

Check the spark plug cable connections for good

contact at the coil and spark plugs. Terminals should

be fully seated. The nipples and spark plug covers

should be in good condition. Nipples should fit tightly

on the coil. Spark plug boot should completely cover

the spark plug hole in the cylinder head cover. Install

the boot until the terminal snaps over the spark

plug. A snap must be felt to ensure the spark plug

cable terminal engaged the spark plug.

Loose cable connections will corrode, increase resis-

tance and permit water to enter the coil towers.

These conditions can cause ignition malfunction.

Fig. 1 Powertrain Control Module

Fig. 2 Setting Spark Plug Electrode Gap

8D - 2 IGNITION SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 252 of 1200

Plastic clips in various locations protect the cables

from damage. When the cables are replaced the clips

must be used to prevent damage to the cables. The

#1 cable must be routed under the PCV hose and

clipped to the #2 cable.

ELECTRONIC IGNITION COILS

WARNING: THE DIRECT IGNITION SYSTEM GEN-

ERATES APPROXIMATELY 40,000 VOLTS. PER-

SONAL INJURY COULD RESULT FROM CONTACT

WITH THIS SYSTEM.

The coil pack consists of 2 coils molded together.

The coil pack is mounted on the valve cover (Fig. 3)

or (Fig. 4). High tension leads route to each cylinder

from the coil. The coil fires two spark plugs every

power stroke. One plug is the cylinder under com-

pression, the other cylinder fires on the exhaust

stroke. Coil number one fires cylinders 1 and 4. Coil

number two fires cylinders 2 and 3. The PCM deter-

mines which of the coils to charge and fire at the cor-

rect time.

The Auto Shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When

the PCM breaks the contact, the energy in the coil

primary transfers to the secondary causing the

spark. The PCM will de-energize the ASD relay if it

does not receive the crankshaft position sensor and

camshaft position sensor inputs. Refer to Auto Shut-

down (ASD) RelayÐPCM Output, in this section for

relay operation.

AUTOMATIC SHUTDOWN RELAY

The Automatic Shutdown (ASD) relay supplies bat-

tery voltage to the fuel injectors, electronic ignition

coil and the heating elements in the oxygen sensors.

A buss bar in the Power Distribution Center (PDC)

supplies voltage to the solenoid side and contact sideof the relay. The ASD relay power circuit contains a

20 amp fuse between the buss bar in the PDC and

the relay. The fuse also protects the power circuit for

the fuel pump relay and pump. The fuse is located in

the PDC. Refer to Group 8W, Wiring Diagrams for

circuit information.

The PCM controls the ASD relay by switching the

ground path for the solenoid side of the relay on and

off. The PCM turns the ground path off when the

ignition switch is in the Off position. When the igni-

tion switch is in On or Start, the PCM monitors the

crankshaft and camshaft position sensor signals to

determine engine speed and ignition timing (coil

dwell). If the PCM does not receive crankshaft and

camshaft position sensor signals when the ignition

switch is in the Run position, it will de-energize the

ASD relay.

The ASD relay is located in the PDC (Fig. 5). The

inside top of the PDC cover has label showing relay

and fuse identification.

Fig. 3 Ignition Coil PackÐSOHC

Fig. 4 Ignition Coil PackÐDOHC

Fig. 5 Power Distribution Center (PDC)

PLIGNITION SYSTEM 8D - 3

DESCRIPTION AND OPERATION (Continued)

Page 253 of 1200

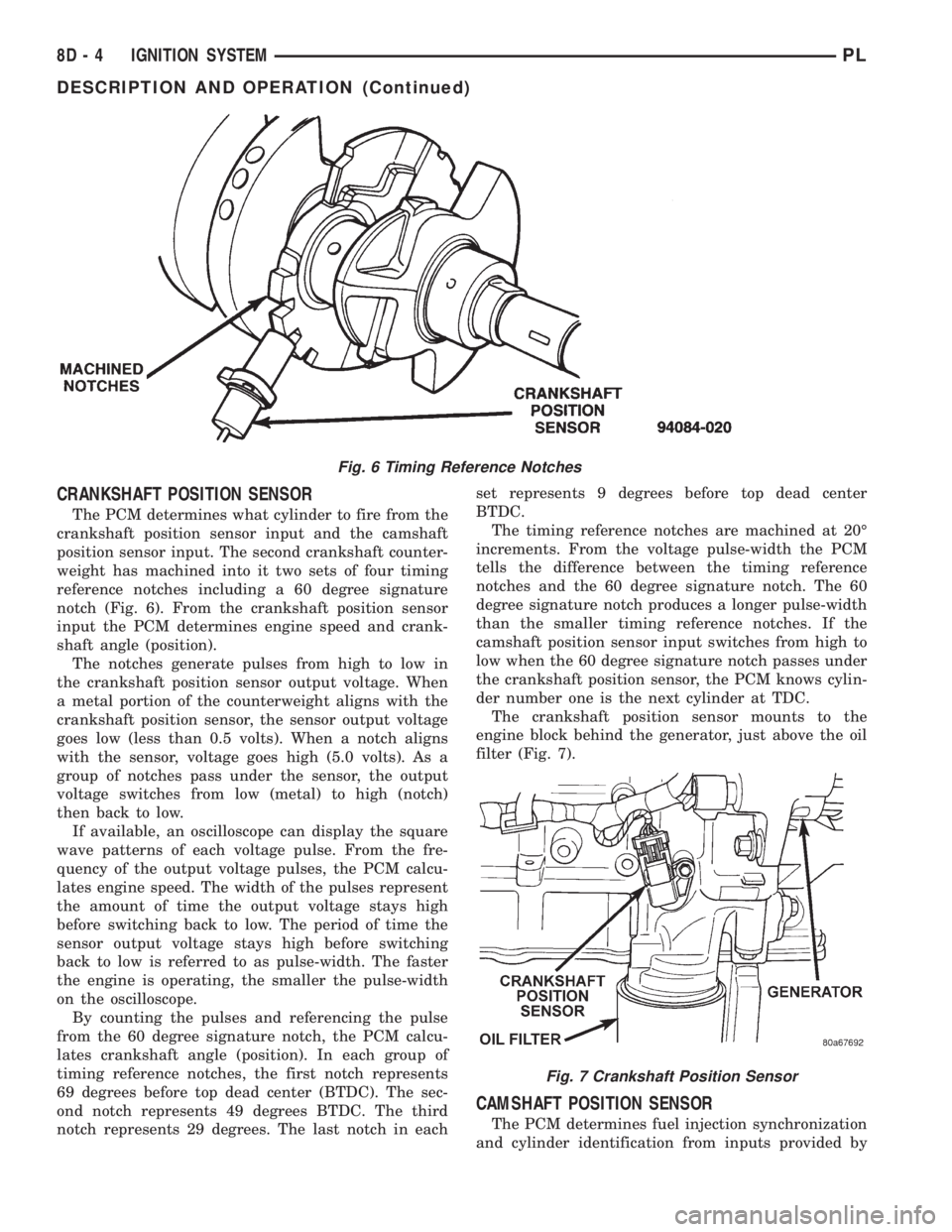

CRANKSHAFT POSITION SENSOR

The PCM determines what cylinder to fire from the

crankshaft position sensor input and the camshaft

position sensor input. The second crankshaft counter-

weight has machined into it two sets of four timing

reference notches including a 60 degree signature

notch (Fig. 6). From the crankshaft position sensor

input the PCM determines engine speed and crank-

shaft angle (position).

The notches generate pulses from high to low in

the crankshaft position sensor output voltage. When

a metal portion of the counterweight aligns with the

crankshaft position sensor, the sensor output voltage

goes low (less than 0.5 volts). When a notch aligns

with the sensor, voltage goes high (5.0 volts). As a

group of notches pass under the sensor, the output

voltage switches from low (metal) to high (notch)

then back to low.

If available, an oscilloscope can display the square

wave patterns of each voltage pulse. From the fre-

quency of the output voltage pulses, the PCM calcu-

lates engine speed. The width of the pulses represent

the amount of time the output voltage stays high

before switching back to low. The period of time the

sensor output voltage stays high before switching

back to low is referred to as pulse-width. The faster

the engine is operating, the smaller the pulse-width

on the oscilloscope.

By counting the pulses and referencing the pulse

from the 60 degree signature notch, the PCM calcu-

lates crankshaft angle (position). In each group of

timing reference notches, the first notch represents

69 degrees before top dead center (BTDC). The sec-

ond notch represents 49 degrees BTDC. The third

notch represents 29 degrees. The last notch in eachset represents 9 degrees before top dead center

BTDC.

The timing reference notches are machined at 20É

increments. From the voltage pulse-width the PCM

tells the difference between the timing reference

notches and the 60 degree signature notch. The 60

degree signature notch produces a longer pulse-width

than the smaller timing reference notches. If the

camshaft position sensor input switches from high to

low when the 60 degree signature notch passes under

the crankshaft position sensor, the PCM knows cylin-

der number one is the next cylinder at TDC.

The crankshaft position sensor mounts to the

engine block behind the generator, just above the oil

filter (Fig. 7).

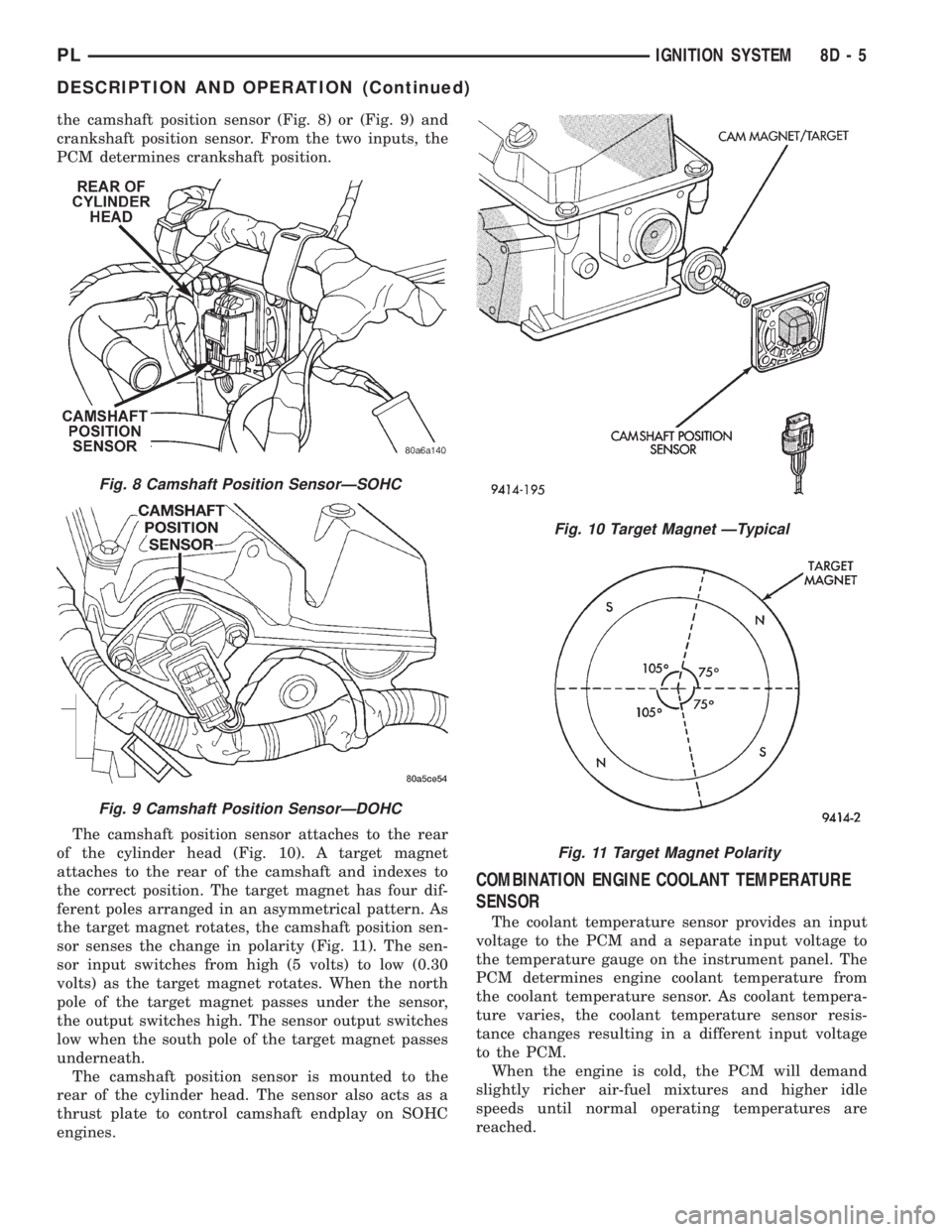

CAMSHAFT POSITION SENSOR

The PCM determines fuel injection synchronization

and cylinder identification from inputs provided by

Fig. 6 Timing Reference Notches

Fig. 7 Crankshaft Position Sensor

8D - 4 IGNITION SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 254 of 1200

the camshaft position sensor (Fig. 8) or (Fig. 9) and

crankshaft position sensor. From the two inputs, the

PCM determines crankshaft position.

The camshaft position sensor attaches to the rear

of the cylinder head (Fig. 10). A target magnet

attaches to the rear of the camshaft and indexes to

the correct position. The target magnet has four dif-

ferent poles arranged in an asymmetrical pattern. As

the target magnet rotates, the camshaft position sen-

sor senses the change in polarity (Fig. 11). The sen-

sor input switches from high (5 volts) to low (0.30

volts) as the target magnet rotates. When the north

pole of the target magnet passes under the sensor,

the output switches high. The sensor output switches

low when the south pole of the target magnet passes

underneath.

The camshaft position sensor is mounted to the

rear of the cylinder head. The sensor also acts as a

thrust plate to control camshaft endplay on SOHC

engines.

COMBINATION ENGINE COOLANT TEMPERATURE

SENSOR

The coolant temperature sensor provides an input

voltage to the PCM and a separate input voltage to

the temperature gauge on the instrument panel. The

PCM determines engine coolant temperature from

the coolant temperature sensor. As coolant tempera-

ture varies, the coolant temperature sensor resis-

tance changes resulting in a different input voltage

to the PCM.

When the engine is cold, the PCM will demand

slightly richer air-fuel mixtures and higher idle

speeds until normal operating temperatures are

reached.

Fig. 8 Camshaft Position SensorÐSOHC

Fig. 9 Camshaft Position SensorÐDOHC

Fig. 10 Target Magnet ÐTypical

Fig. 11 Target Magnet Polarity

PLIGNITION SYSTEM 8D - 5

DESCRIPTION AND OPERATION (Continued)

Page 255 of 1200

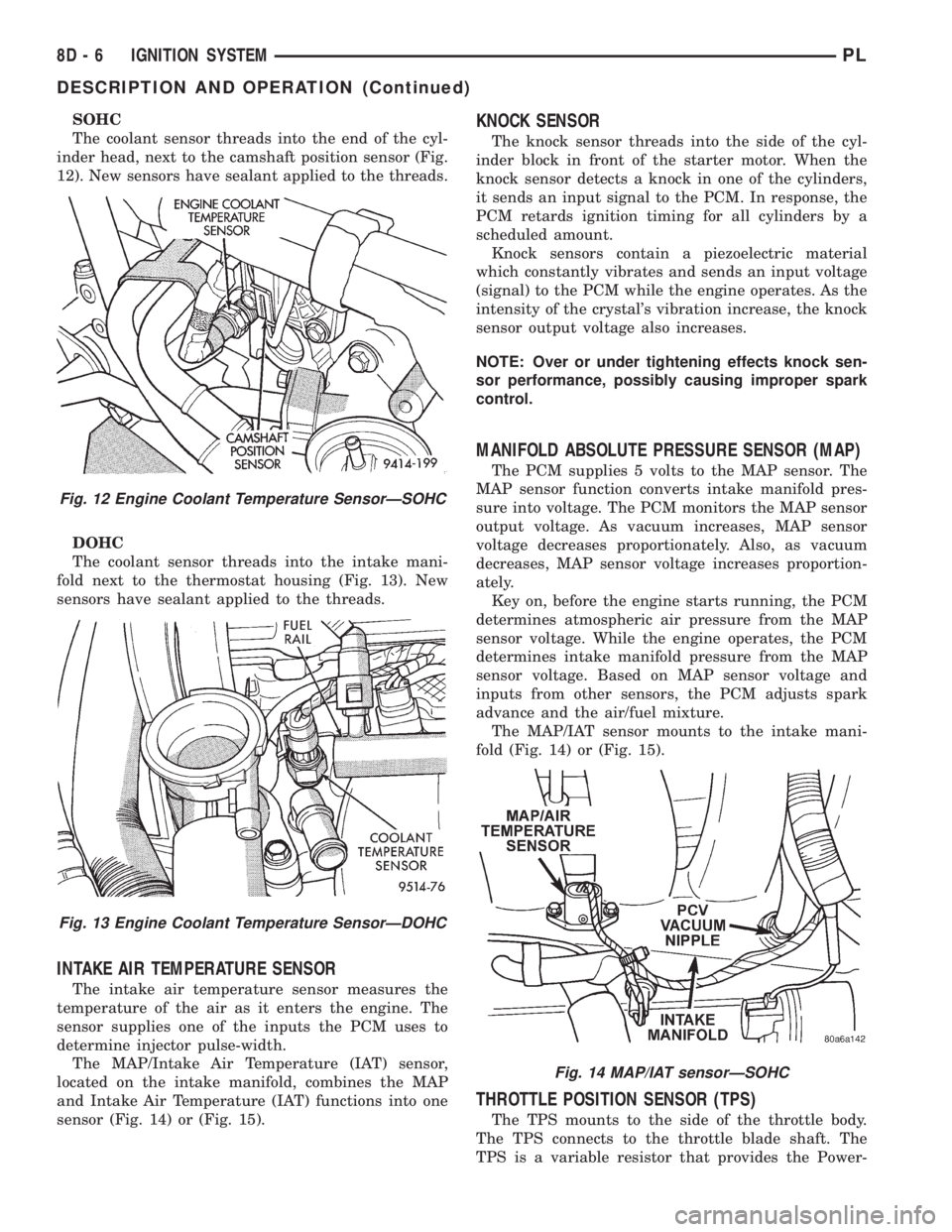

SOHC

The coolant sensor threads into the end of the cyl-

inder head, next to the camshaft position sensor (Fig.

12). New sensors have sealant applied to the threads.

DOHC

The coolant sensor threads into the intake mani-

fold next to the thermostat housing (Fig. 13). New

sensors have sealant applied to the threads.

INTAKE AIR TEMPERATURE SENSOR

The intake air temperature sensor measures the

temperature of the air as it enters the engine. The

sensor supplies one of the inputs the PCM uses to

determine injector pulse-width.

The MAP/Intake Air Temperature (IAT) sensor,

located on the intake manifold, combines the MAP

and Intake Air Temperature (IAT) functions into one

sensor (Fig. 14) or (Fig. 15).

KNOCK SENSOR

The knock sensor threads into the side of the cyl-

inder block in front of the starter motor. When the

knock sensor detects a knock in one of the cylinders,

it sends an input signal to the PCM. In response, the

PCM retards ignition timing for all cylinders by a

scheduled amount.

Knock sensors contain a piezoelectric material

which constantly vibrates and sends an input voltage

(signal) to the PCM while the engine operates. As the

intensity of the crystal's vibration increase, the knock

sensor output voltage also increases.

NOTE: Over or under tightening effects knock sen-

sor performance, possibly causing improper spark

control.

MANIFOLD ABSOLUTE PRESSURE SENSOR (MAP)

The PCM supplies 5 volts to the MAP sensor. The

MAP sensor function converts intake manifold pres-

sure into voltage. The PCM monitors the MAP sensor

output voltage. As vacuum increases, MAP sensor

voltage decreases proportionately. Also, as vacuum

decreases, MAP sensor voltage increases proportion-

ately.

Key on, before the engine starts running, the PCM

determines atmospheric air pressure from the MAP

sensor voltage. While the engine operates, the PCM

determines intake manifold pressure from the MAP

sensor voltage. Based on MAP sensor voltage and

inputs from other sensors, the PCM adjusts spark

advance and the air/fuel mixture.

The MAP/IAT sensor mounts to the intake mani-

fold (Fig. 14) or (Fig. 15).

THROTTLE POSITION SENSOR (TPS)

The TPS mounts to the side of the throttle body.

The TPS connects to the throttle blade shaft. The

TPS is a variable resistor that provides the Power-

Fig. 12 Engine Coolant Temperature SensorÐSOHC

Fig. 13 Engine Coolant Temperature SensorÐDOHC

Fig. 14 MAP/IAT sensorÐSOHC

8D - 6 IGNITION SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 256 of 1200

train Control Module (PCM) with an input signal

(voltage). The signal represents throttle blade posi-

tion. As the position of the throttle blade changes,

the resistance of the TPS changes.

The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

powertrain control module) represents throttle blade

position. The TPS output voltage to the PCM varies

from approximately 0.38 volts to 1.2 volts at mini-

mum throttle opening (idle) to a maximum of 3.1

volts to 4.4 volts at wide open throttle.

Along with inputs from other sensors, the PCM

uses the TPS input to determine current engine oper-

ating conditions. The PCM also adjusts fuel injector

pulse width and ignition timing based on these

inputs.

IGNITION SWITCH

In the RUN position, the ignition switch connects

power from the Power Distribution Center (PDC) to a

30 amp fuse in the fuse block, back to a bus bar in

the PDC. The bus bar feeds circuits for the Power-

train Control Module (PCM), duty cycle purge sole-

noid, EGR solenoid, and ABS system. The bus bar in

the PDC feeds the coil side of the radiator fan relay,

A/C compressor clutch relay, and the fuel pump relay.

It also feeds the Airbag Control Module (ACM)

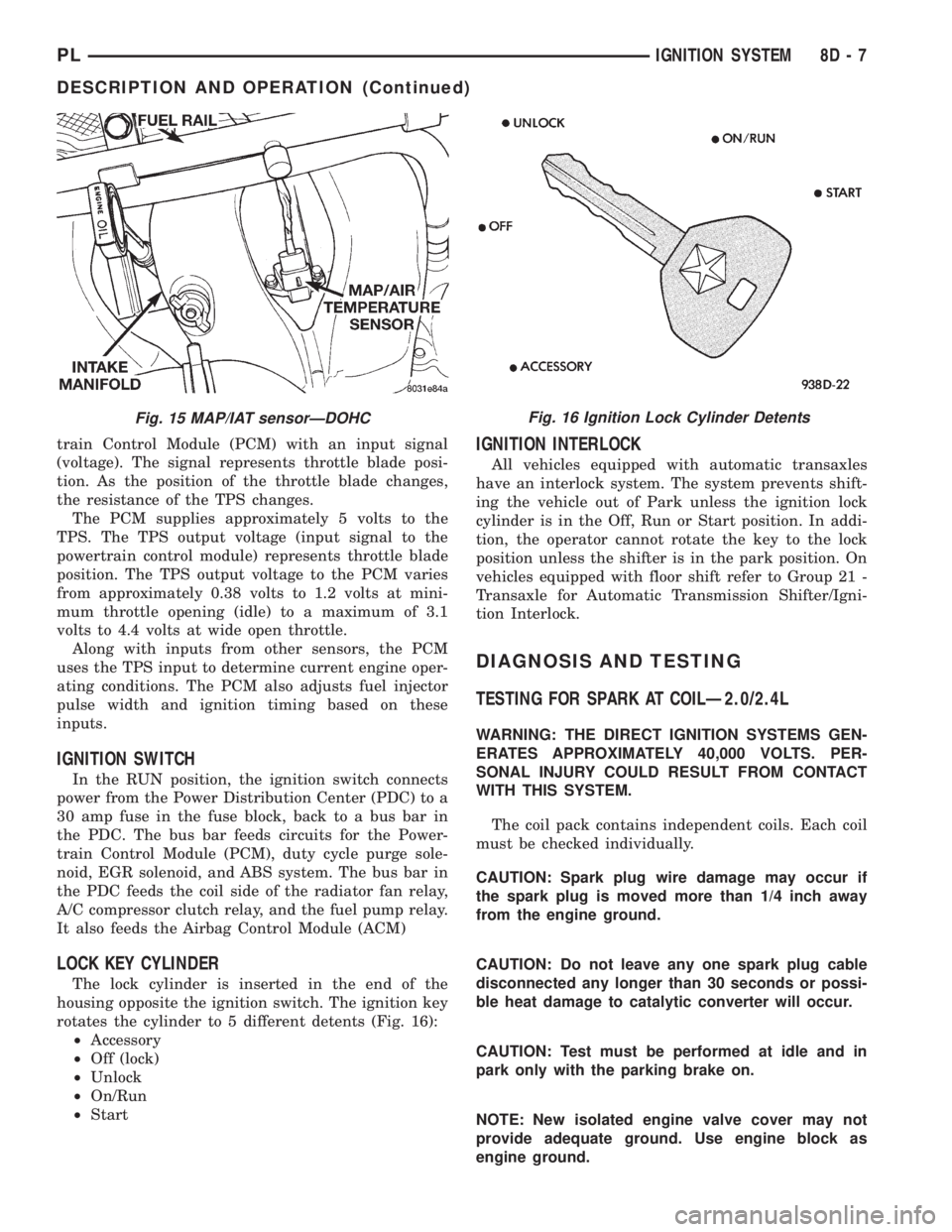

LOCK KEY CYLINDER

The lock cylinder is inserted in the end of the

housing opposite the ignition switch. The ignition key

rotates the cylinder to 5 different detents (Fig. 16):

²Accessory

²Off (lock)

²Unlock

²On/Run

²Start

IGNITION INTERLOCK

All vehicles equipped with automatic transaxles

have an interlock system. The system prevents shift-

ing the vehicle out of Park unless the ignition lock

cylinder is in the Off, Run or Start position. In addi-

tion, the operator cannot rotate the key to the lock

position unless the shifter is in the park position. On

vehicles equipped with floor shift refer to Group 21 -

Transaxle for Automatic Transmission Shifter/Igni-

tion Interlock.

DIAGNOSIS AND TESTING

TESTING FOR SPARK AT COILÐ2.0/2.4L

WARNING: THE DIRECT IGNITION SYSTEMS GEN-

ERATES APPROXIMATELY 40,000 VOLTS. PER-

SONAL INJURY COULD RESULT FROM CONTACT

WITH THIS SYSTEM.

The coil pack contains independent coils. Each coil

must be checked individually.

CAUTION: Spark plug wire damage may occur if

the spark plug is moved more than 1/4 inch away

from the engine ground.

CAUTION: Do not leave any one spark plug cable

disconnected any longer than 30 seconds or possi-

ble heat damage to catalytic converter will occur.

CAUTION: Test must be performed at idle and in

park only with the parking brake on.

NOTE: New isolated engine valve cover may not

provide adequate ground. Use engine block as

engine ground.

Fig. 15 MAP/IAT sensorÐDOHCFig. 16 Ignition Lock Cylinder Detents

PLIGNITION SYSTEM 8D - 7

DESCRIPTION AND OPERATION (Continued)

Page 257 of 1200

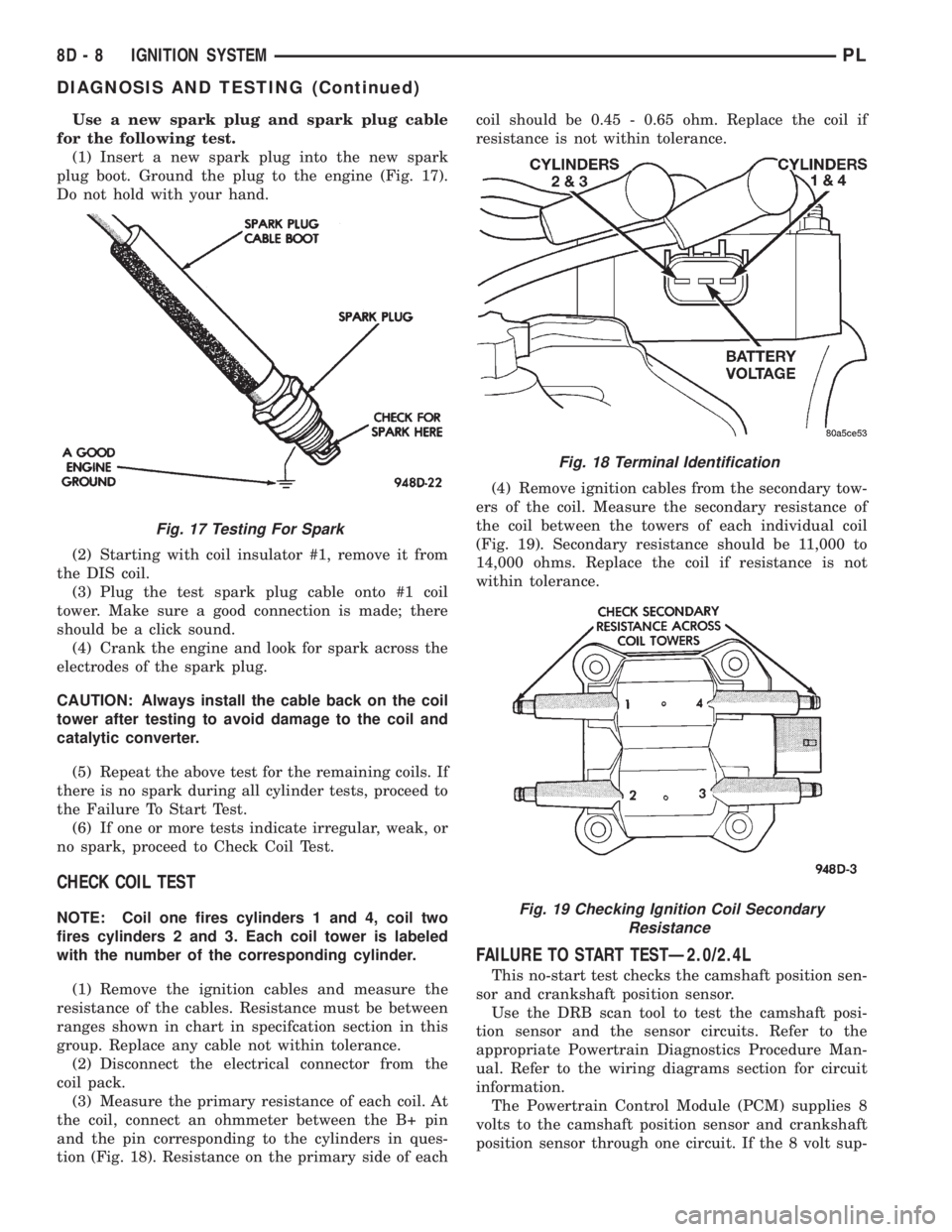

Use a new spark plug and spark plug cable

for the following test.

(1) Insert a new spark plug into the new spark

plug boot. Ground the plug to the engine (Fig. 17).

Do not hold with your hand.

(2) Starting with coil insulator #1, remove it from

the DIS coil.

(3) Plug the test spark plug cable onto #1 coil

tower. Make sure a good connection is made; there

should be a click sound.

(4) Crank the engine and look for spark across the

electrodes of the spark plug.

CAUTION: Always install the cable back on the coil

tower after testing to avoid damage to the coil and

catalytic converter.

(5) Repeat the above test for the remaining coils. If

there is no spark during all cylinder tests, proceed to

the Failure To Start Test.

(6) If one or more tests indicate irregular, weak, or

no spark, proceed to Check Coil Test.

CHECK COIL TEST

NOTE: Coil one fires cylinders 1 and 4, coil two

fires cylinders 2 and 3. Each coil tower is labeled

with the number of the corresponding cylinder.

(1) Remove the ignition cables and measure the

resistance of the cables. Resistance must be between

ranges shown in chart in specifcation section in this

group. Replace any cable not within tolerance.

(2) Disconnect the electrical connector from the

coil pack.

(3) Measure the primary resistance of each coil. At

the coil, connect an ohmmeter between the B+ pin

and the pin corresponding to the cylinders in ques-

tion (Fig. 18). Resistance on the primary side of eachcoil should be 0.45 - 0.65 ohm. Replace the coil if

resistance is not within tolerance.

(4) Remove ignition cables from the secondary tow-

ers of the coil. Measure the secondary resistance of

the coil between the towers of each individual coil

(Fig. 19). Secondary resistance should be 11,000 to

14,000 ohms. Replace the coil if resistance is not

within tolerance.

FAILURE TO START TESTÐ2.0/2.4L

This no-start test checks the camshaft position sen-

sor and crankshaft position sensor.

Use the DRB scan tool to test the camshaft posi-

tion sensor and the sensor circuits. Refer to the

appropriate Powertrain Diagnostics Procedure Man-

ual. Refer to the wiring diagrams section for circuit

information.

The Powertrain Control Module (PCM) supplies 8

volts to the camshaft position sensor and crankshaft

position sensor through one circuit. If the 8 volt sup-

Fig. 17 Testing For Spark

Fig. 18 Terminal Identification

Fig. 19 Checking Ignition Coil Secondary

Resistance

8D - 8 IGNITION SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 258 of 1200

ply circuit shorts to ground, neither sensor will pro-

duce a signal (output voltage to the PCM).

When the ignition key is turned and left in the On

position, the PCM automatically energizes the Auto

Shutdown (ASD) relay. However, the controller de-en-

ergizes the relay within one second because it has

not received a camshaft position sensor signal indi-

cating engine rotation.

During cranking, the ASD relay will not energize

until the PCM receives a camshaft position sensor

signal. Secondly, the ASD relay remains energized

only if the controller senses a crankshaft position

sensor signal immediately after detecting the cam-

shaft position sensor signal.

(1) Check battery voltage. Voltage should approxi-

mately 12.66 volts or higher to perform failure to

start test.

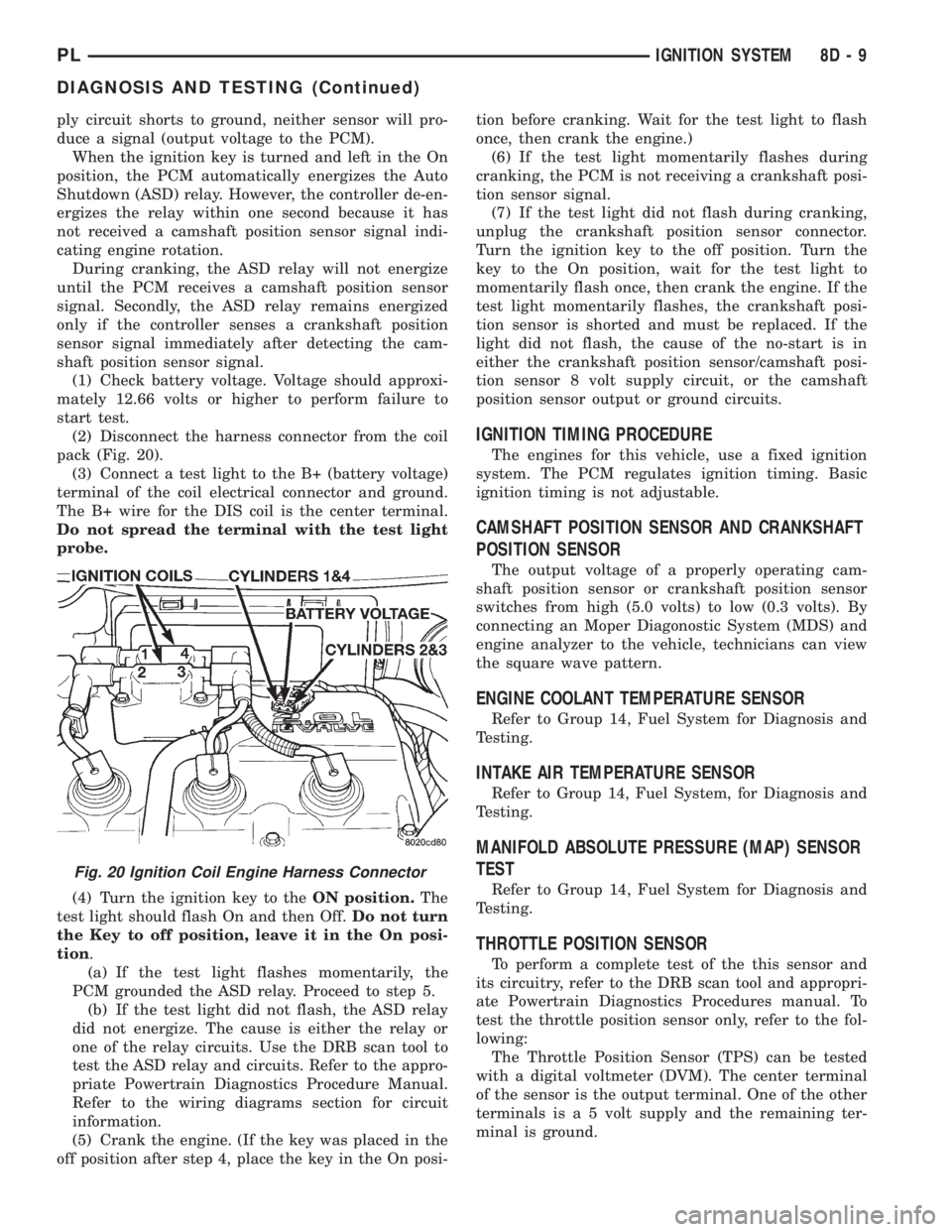

(2) Disconnect the harness connector from the coil

pack (Fig. 20).

(3) Connect a test light to the B+ (battery voltage)

terminal of the coil electrical connector and ground.

The B+ wire for the DIS coil is the center terminal.

Do not spread the terminal with the test light

probe.

(4) Turn the ignition key to theON position.The

test light should flash On and then Off.Do not turn

the Key to off position, leave it in the On posi-

tion.

(a) If the test light flashes momentarily, the

PCM grounded the ASD relay. Proceed to step 5.

(b) If the test light did not flash, the ASD relay

did not energize. The cause is either the relay or

one of the relay circuits. Use the DRB scan tool to

test the ASD relay and circuits. Refer to the appro-

priate Powertrain Diagnostics Procedure Manual.

Refer to the wiring diagrams section for circuit

information.

(5) Crank the engine. (If the key was placed in the

off position after step 4, place the key in the On posi-tion before cranking. Wait for the test light to flash

once, then crank the engine.)

(6) If the test light momentarily flashes during

cranking, the PCM is not receiving a crankshaft posi-

tion sensor signal.

(7) If the test light did not flash during cranking,

unplug the crankshaft position sensor connector.

Turn the ignition key to the off position. Turn the

key to the On position, wait for the test light to

momentarily flash once, then crank the engine. If the

test light momentarily flashes, the crankshaft posi-

tion sensor is shorted and must be replaced. If the

light did not flash, the cause of the no-start is in

either the crankshaft position sensor/camshaft posi-

tion sensor 8 volt supply circuit, or the camshaft

position sensor output or ground circuits.

IGNITION TIMING PROCEDURE

The engines for this vehicle, use a fixed ignition

system. The PCM regulates ignition timing. Basic

ignition timing is not adjustable.

CAMSHAFT POSITION SENSOR AND CRANKSHAFT

POSITION SENSOR

The output voltage of a properly operating cam-

shaft position sensor or crankshaft position sensor

switches from high (5.0 volts) to low (0.3 volts). By

connecting an Moper Diagonostic System (MDS) and

engine analyzer to the vehicle, technicians can view

the square wave pattern.

ENGINE COOLANT TEMPERATURE SENSOR

Refer to Group 14, Fuel System for Diagnosis and

Testing.

INTAKE AIR TEMPERATURE SENSOR

Refer to Group 14, Fuel System, for Diagnosis and

Testing.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

TEST

Refer to Group 14, Fuel System for Diagnosis and

Testing.

THROTTLE POSITION SENSOR

To perform a complete test of the this sensor and

its circuitry, refer to the DRB scan tool and appropri-

ate Powertrain Diagnostics Procedures manual. To

test the throttle position sensor only, refer to the fol-

lowing:

The Throttle Position Sensor (TPS) can be tested

with a digital voltmeter (DVM). The center terminal

of the sensor is the output terminal. One of the other

terminals is a 5 volt supply and the remaining ter-

minal is ground.

Fig. 20 Ignition Coil Engine Harness Connector

PLIGNITION SYSTEM 8D - 9

DIAGNOSIS AND TESTING (Continued)

Page 259 of 1200

Connect the DVM between the center and sensor

ground terminal. Refer to Group 8W - Wiring Dia-

grams for correct pinout.

With the ignition switch in the ON position, check

the output voltage at the center terminal wire of the

connector. Check the output voltage at idle and at

Wide-Open-Throttle (WOT). At idle, TPS output volt-

age should be approximately 0.38 volts to 1.2 volts.

At wide open throttle, TPS output voltage should be

approximately 3.1 volts to 4.4 volts. The output volt-

age should gradually increase as the throttle plate

moves slowly from idle to WOT.

Check for spread terminals at the sensor and PCM

connections before replacing the TPS.

SPARK PLUG CONDITION

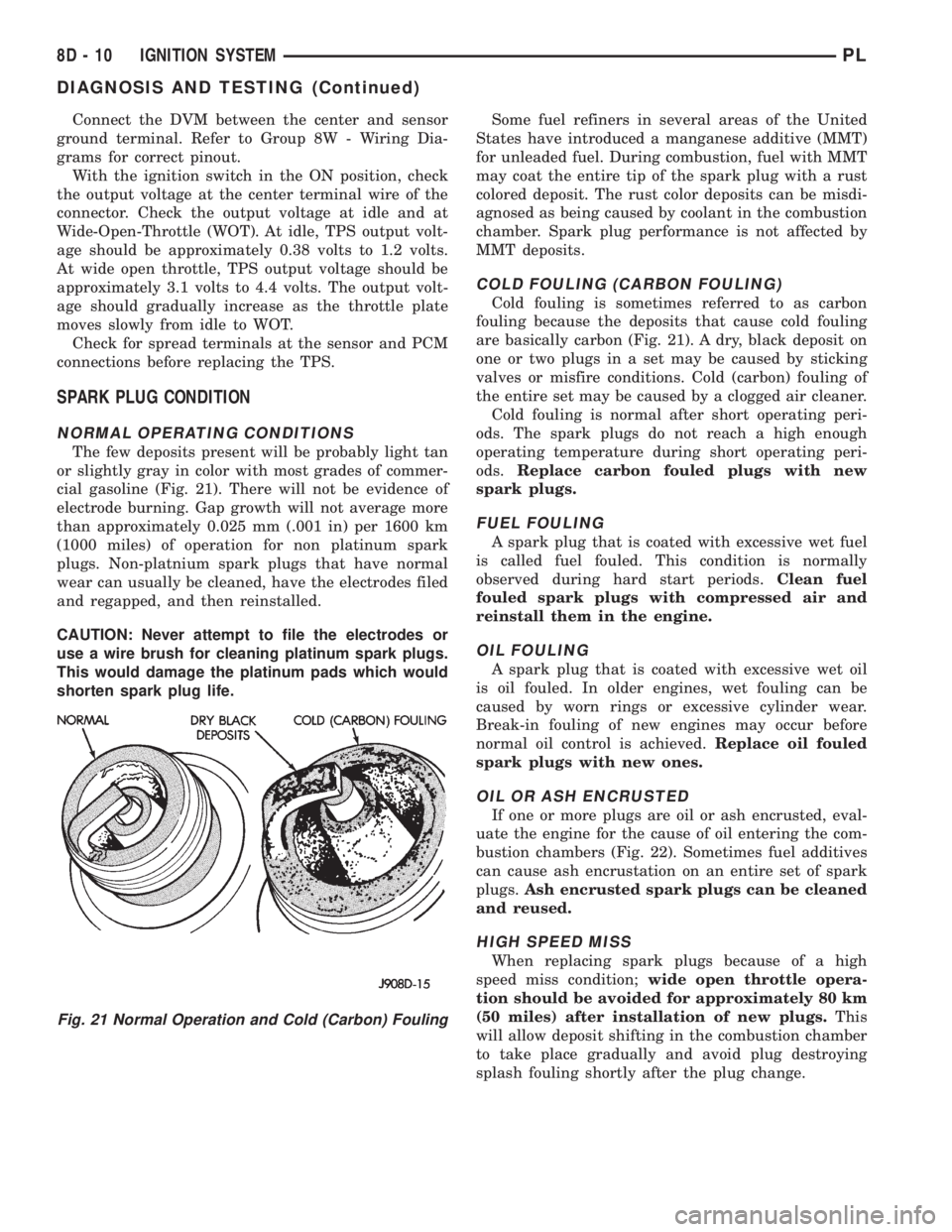

NORMAL OPERATING CONDITIONS

The few deposits present will be probably light tan

or slightly gray in color with most grades of commer-

cial gasoline (Fig. 21). There will not be evidence of

electrode burning. Gap growth will not average more

than approximately 0.025 mm (.001 in) per 1600 km

(1000 miles) of operation for non platinum spark

plugs. Non-platnium spark plugs that have normal

wear can usually be cleaned, have the electrodes filed

and regapped, and then reinstalled.

CAUTION: Never attempt to file the electrodes or

use a wire brush for cleaning platinum spark plugs.

This would damage the platinum pads which would

shorten spark plug life.Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

for unleaded fuel. During combustion, fuel with MMT

may coat the entire tip of the spark plug with a rust

colored deposit. The rust color deposits can be misdi-

agnosed as being caused by coolant in the combustion

chamber. Spark plug performance is not affected by

MMT deposits.

COLD FOULING (CARBON FOULING)

Cold fouling is sometimes referred to as carbon

fouling because the deposits that cause cold fouling

are basically carbon (Fig. 21). A dry, black deposit on

one or two plugs in a set may be caused by sticking

valves or misfire conditions. Cold (carbon) fouling of

the entire set may be caused by a clogged air cleaner.

Cold fouling is normal after short operating peri-

ods. The spark plugs do not reach a high enough

operating temperature during short operating peri-

ods.Replace carbon fouled plugs with new

spark plugs.

FUEL FOULING

A spark plug that is coated with excessive wet fuel

is called fuel fouled. This condition is normally

observed during hard start periods.Clean fuel

fouled spark plugs with compressed air and

reinstall them in the engine.

OIL FOULING

A spark plug that is coated with excessive wet oil

is oil fouled. In older engines, wet fouling can be

caused by worn rings or excessive cylinder wear.

Break-in fouling of new engines may occur before

normal oil control is achieved.Replace oil fouled

spark plugs with new ones.

OIL OR ASH ENCRUSTED

If one or more plugs are oil or ash encrusted, eval-

uate the engine for the cause of oil entering the com-

bustion chambers (Fig. 22). Sometimes fuel additives

can cause ash encrustation on an entire set of spark

plugs.Ash encrusted spark plugs can be cleaned

and reused.

HIGH SPEED MISS

When replacing spark plugs because of a high

speed miss condition;wide open throttle opera-

tion should be avoided for approximately 80 km

(50 miles) after installation of new plugs.This

will allow deposit shifting in the combustion chamber

to take place gradually and avoid plug destroying

splash fouling shortly after the plug change.

Fig. 21 Normal Operation and Cold (Carbon) Fouling

8D - 10 IGNITION SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 260 of 1200

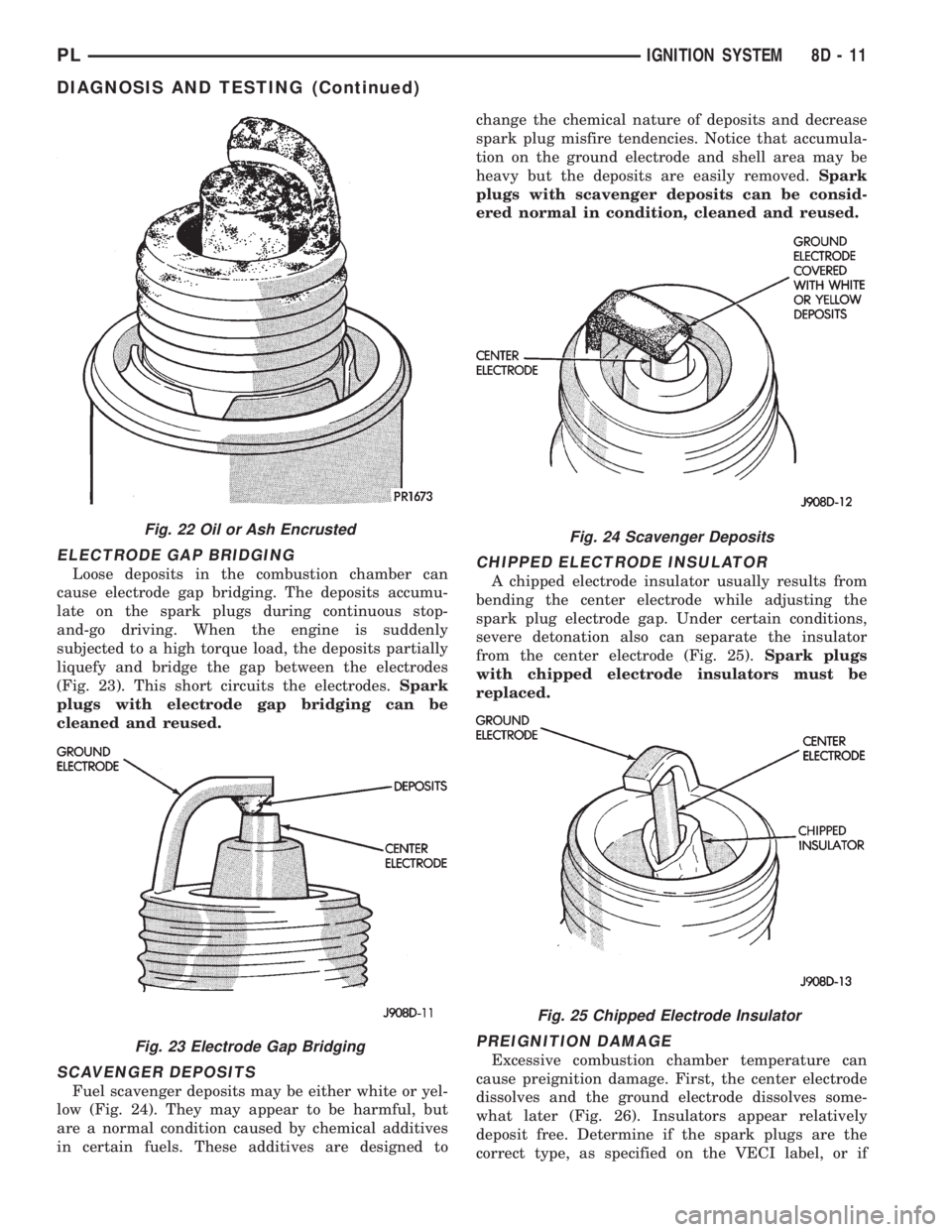

ELECTRODE GAP BRIDGING

Loose deposits in the combustion chamber can

cause electrode gap bridging. The deposits accumu-

late on the spark plugs during continuous stop-

and-go driving. When the engine is suddenly

subjected to a high torque load, the deposits partially

liquefy and bridge the gap between the electrodes

(Fig. 23). This short circuits the electrodes.Spark

plugs with electrode gap bridging can be

cleaned and reused.

SCAVENGER DEPOSITS

Fuel scavenger deposits may be either white or yel-

low (Fig. 24). They may appear to be harmful, but

are a normal condition caused by chemical additives

in certain fuels. These additives are designed tochange the chemical nature of deposits and decrease

spark plug misfire tendencies. Notice that accumula-

tion on the ground electrode and shell area may be

heavy but the deposits are easily removed.Spark

plugs with scavenger deposits can be consid-

ered normal in condition, cleaned and reused.

CHIPPED ELECTRODE INSULATOR

A chipped electrode insulator usually results from

bending the center electrode while adjusting the

spark plug electrode gap. Under certain conditions,

severe detonation also can separate the insulator

from the center electrode (Fig. 25).Spark plugs

with chipped electrode insulators must be

replaced.

PREIGNITION DAMAGE

Excessive combustion chamber temperature can

cause preignition damage. First, the center electrode

dissolves and the ground electrode dissolves some-

what later (Fig. 26). Insulators appear relatively

deposit free. Determine if the spark plugs are the

correct type, as specified on the VECI label, or if

Fig. 22 Oil or Ash Encrusted

Fig. 23 Electrode Gap Bridging

Fig. 24 Scavenger Deposits

Fig. 25 Chipped Electrode Insulator

PLIGNITION SYSTEM 8D - 11

DIAGNOSIS AND TESTING (Continued)