DODGE NEON 1999 Service Repair Manual

Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 281 of 1200

(6) Remove the screws attaching lens, dial and

gauge assembly to the housing. The bottom screws

attaching lens to the housing can be accessed without

removing the foam pad.

(7) Remove the lens, dial and gauge assembly from

housing.

(8) Remove the two screws holding the odometer to

dial and gauge assembly. When setting the dial/gauge

and/or cluster assembly down, it must be face up or

the gauge operation will be damaged.

INSTALLATION

For installation, reverse the above procedures.

Carefully place the dial and gauge assembly on the

cluster and ensure that the odometer connector is

placed through the board. Install with a slight rock-

ing motion to ensure the pins on gauges line up.

RADIO

For Radio removal procedures, Refer to Group 8F,

Audio Systems.

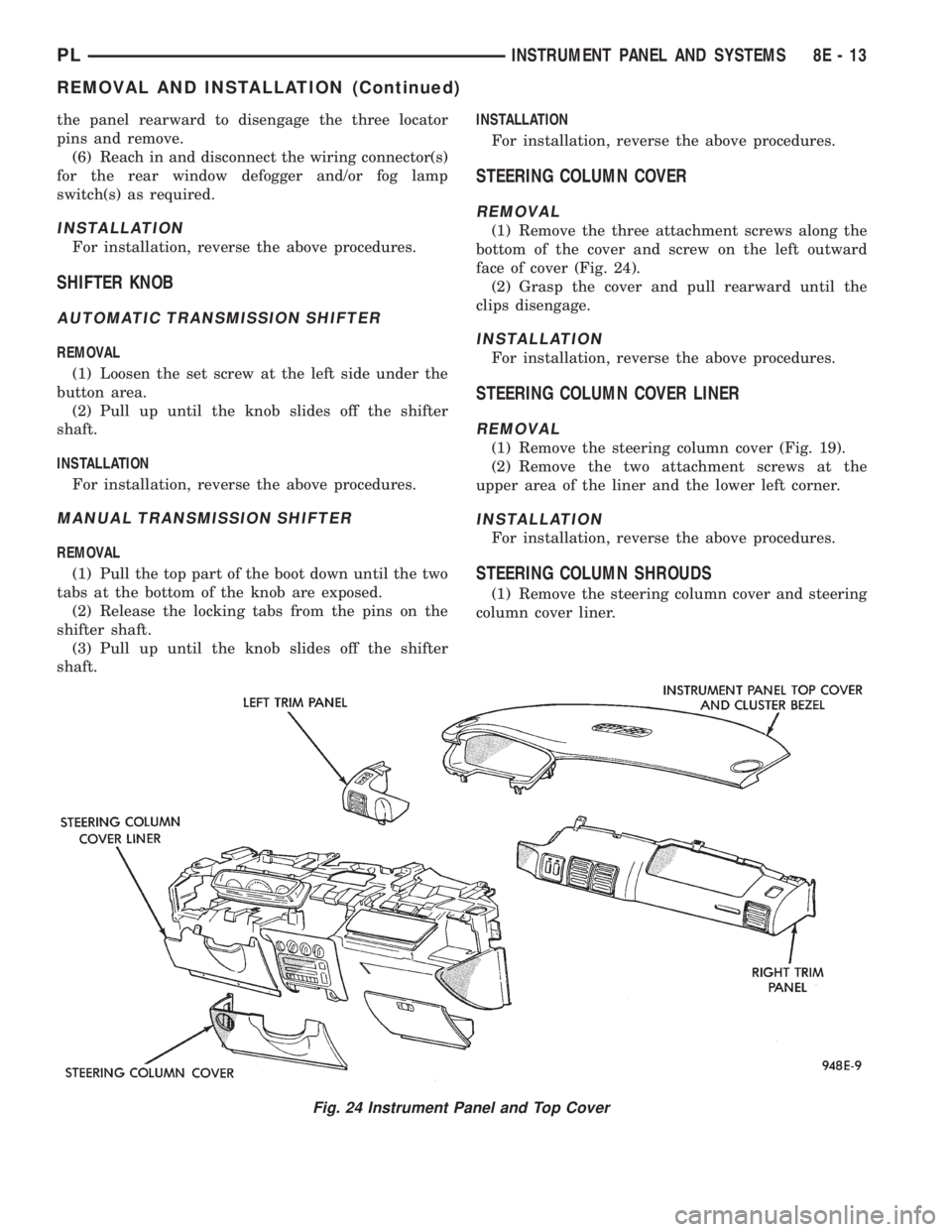

REAR WINDOW DEFOGGER AND/OR FOG LAMP

SWITCH

REMOVAL

(1) Remove the top cover and cluster bezel assem-

bly. Refer to the Top Cover and Cluster Bezel

Removal above.

(2) Reach in and disengage the bezel latches and

remove assembly (Fig. 23).

(3) Pull the bezel and switch(s) rearward from the

opening and disconnect the wire connector(s).

(4) Remove the switch from the bezel.

INSTALLATION

For installation, reverse the above procedures.

RIGHT TRIM PANEL

REMOVAL

(1) Disconnect and isolate the negative battery

cable.

(2) Using a trim stick (special tool #C-4755), gently

pry up on the top cover and cluster bezel to remove

(Fig. 19).

(3) Open the ash receiver.

(4) Using a trim stick (special tool #C-4755), gently

pry out on the center bezel and remove.

(5) Remove the six attaching screws across the for-

ward portion of the right upper trim panel. Then pull

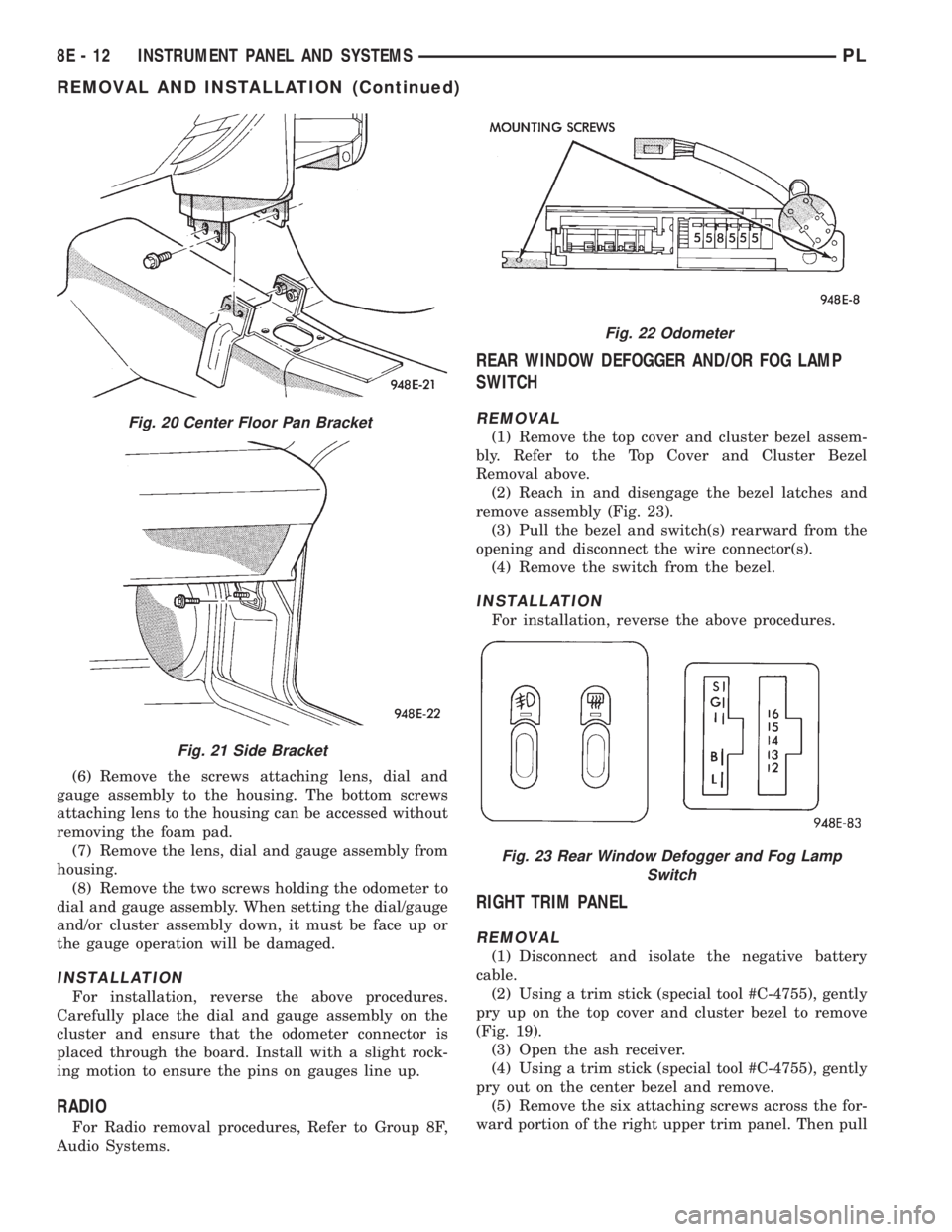

Fig. 20 Center Floor Pan Bracket

Fig. 21 Side Bracket

Fig. 22 Odometer

Fig. 23 Rear Window Defogger and Fog Lamp

Switch

8E - 12 INSTRUMENT PANEL AND SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 282 of 1200

the panel rearward to disengage the three locator

pins and remove.

(6) Reach in and disconnect the wiring connector(s)

for the rear window defogger and/or fog lamp

switch(s) as required.

INSTALLATION

For installation, reverse the above procedures.

SHIFTER KNOB

AUTOMATIC TRANSMISSION SHIFTER

REMOVAL

(1) Loosen the set screw at the left side under the

button area.

(2) Pull up until the knob slides off the shifter

shaft.

INSTALLATION

For installation, reverse the above procedures.

MANUAL TRANSMISSION SHIFTER

REMOVAL

(1) Pull the top part of the boot down until the two

tabs at the bottom of the knob are exposed.

(2) Release the locking tabs from the pins on the

shifter shaft.

(3) Pull up until the knob slides off the shifter

shaft.INSTALLATION

For installation, reverse the above procedures.

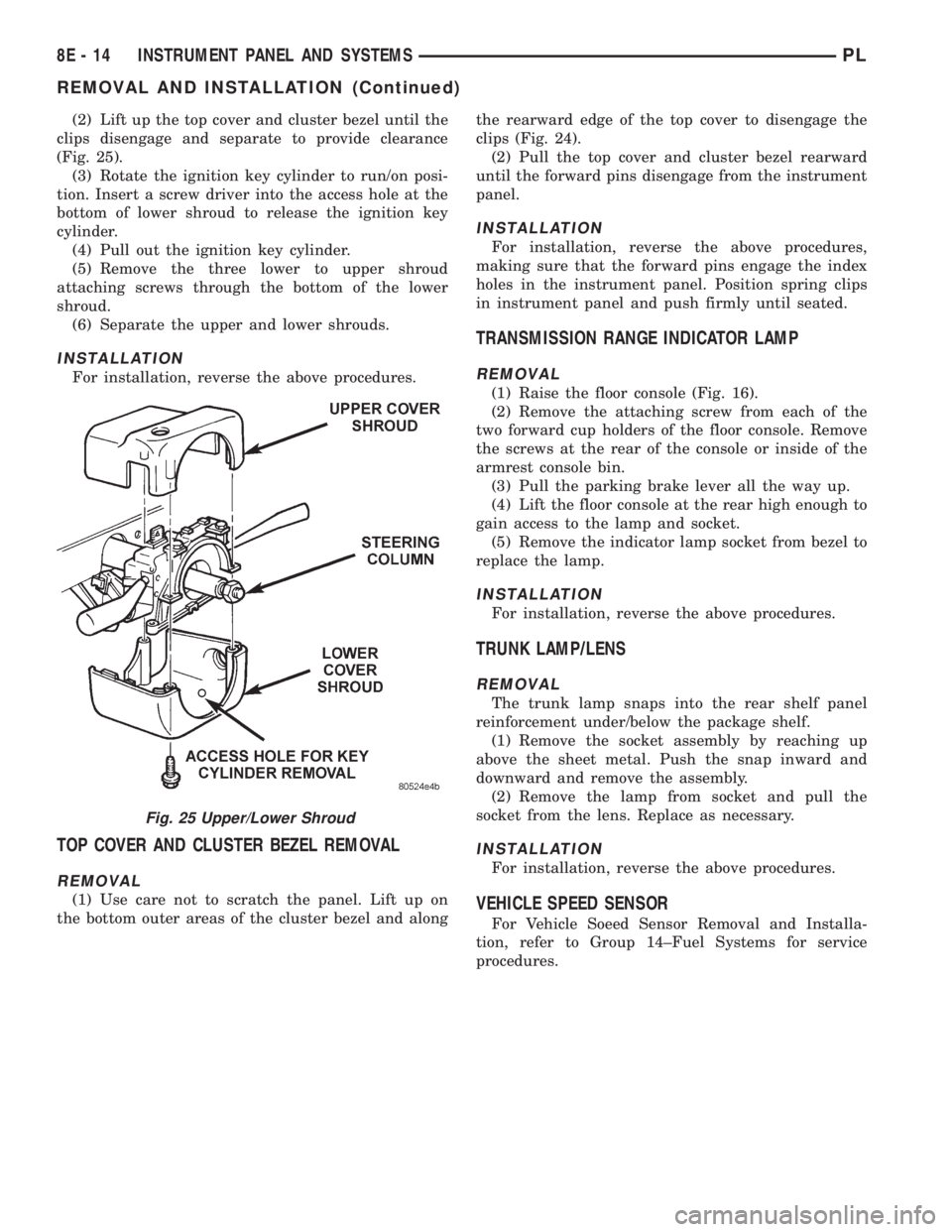

STEERING COLUMN COVER

REMOVAL

(1) Remove the three attachment screws along the

bottom of the cover and screw on the left outward

face of cover (Fig. 24).

(2) Grasp the cover and pull rearward until the

clips disengage.

INSTALLATION

For installation, reverse the above procedures.

STEERING COLUMN COVER LINER

REMOVAL

(1) Remove the steering column cover (Fig. 19).

(2) Remove the two attachment screws at the

upper area of the liner and the lower left corner.

INSTALLATION

For installation, reverse the above procedures.

STEERING COLUMN SHROUDS

(1) Remove the steering column cover and steering

column cover liner.

Fig. 24 Instrument Panel and Top Cover

PLINSTRUMENT PANEL AND SYSTEMS 8E - 13

REMOVAL AND INSTALLATION (Continued)

Page 283 of 1200

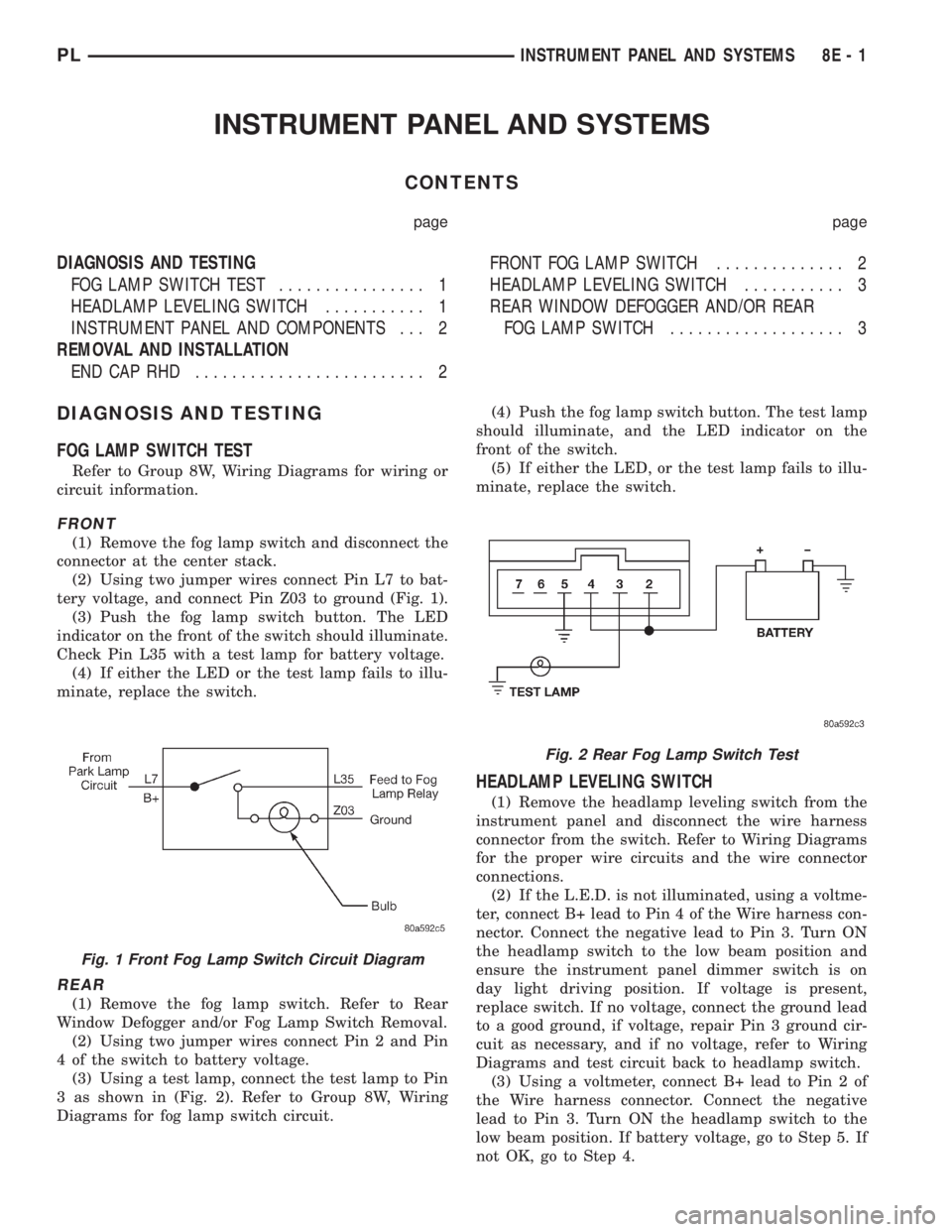

(2) Lift up the top cover and cluster bezel until the

clips disengage and separate to provide clearance

(Fig. 25).

(3) Rotate the ignition key cylinder to run/on posi-

tion. Insert a screw driver into the access hole at the

bottom of lower shroud to release the ignition key

cylinder.

(4) Pull out the ignition key cylinder.

(5) Remove the three lower to upper shroud

attaching screws through the bottom of the lower

shroud.

(6) Separate the upper and lower shrouds.

INSTALLATION

For installation, reverse the above procedures.

TOP COVER AND CLUSTER BEZEL REMOVAL

REMOVAL

(1) Use care not to scratch the panel. Lift up on

the bottom outer areas of the cluster bezel and alongthe rearward edge of the top cover to disengage the

clips (Fig. 24).

(2) Pull the top cover and cluster bezel rearward

until the forward pins disengage from the instrument

panel.

INSTALLATION

For installation, reverse the above procedures,

making sure that the forward pins engage the index

holes in the instrument panel. Position spring clips

in instrument panel and push firmly until seated.

TRANSMISSION RANGE INDICATOR LAMP

REMOVAL

(1) Raise the floor console (Fig. 16).

(2) Remove the attaching screw from each of the

two forward cup holders of the floor console. Remove

the screws at the rear of the console or inside of the

armrest console bin.

(3) Pull the parking brake lever all the way up.

(4) Lift the floor console at the rear high enough to

gain access to the lamp and socket.

(5) Remove the indicator lamp socket from bezel to

replace the lamp.

INSTALLATION

For installation, reverse the above procedures.

TRUNK LAMP/LENS

REMOVAL

The trunk lamp snaps into the rear shelf panel

reinforcement under/below the package shelf.

(1) Remove the socket assembly by reaching up

above the sheet metal. Push the snap inward and

downward and remove the assembly.

(2) Remove the lamp from socket and pull the

socket from the lens. Replace as necessary.

INSTALLATION

For installation, reverse the above procedures.

VEHICLE SPEED SENSOR

For Vehicle Soeed Sensor Removal and Installa-

tion, refer to Group 14±Fuel Systems for service

procedures.

Fig. 25 Upper/Lower Shroud

8E - 14 INSTRUMENT PANEL AND SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 284 of 1200

INSTRUMENT PANEL AND SYSTEMS

CONTENTS

page page

DIAGNOSIS AND TESTING

FOG LAMP SWITCH TEST................ 1

HEADLAMP LEVELING SWITCH........... 1

INSTRUMENT PANEL AND COMPONENTS . . . 2

REMOVAL AND INSTALLATION

END CAP RHD ......................... 2FRONT FOG LAMP SWITCH.............. 2

HEADLAMP LEVELING SWITCH........... 3

REAR WINDOW DEFOGGER AND/OR REAR

FOG LAMP SWITCH................... 3

DIAGNOSIS AND TESTING

FOG LAMP SWITCH TEST

Refer to Group 8W, Wiring Diagrams for wiring or

circuit information.

FRONT

(1) Remove the fog lamp switch and disconnect the

connector at the center stack.

(2) Using two jumper wires connect Pin L7 to bat-

tery voltage, and connect Pin Z03 to ground (Fig. 1).

(3) Push the fog lamp switch button. The LED

indicator on the front of the switch should illuminate.

Check Pin L35 with a test lamp for battery voltage.

(4) If either the LED or the test lamp fails to illu-

minate, replace the switch.

REAR

(1) Remove the fog lamp switch. Refer to Rear

Window Defogger and/or Fog Lamp Switch Removal.

(2) Using two jumper wires connect Pin 2 and Pin

4 of the switch to battery voltage.

(3) Using a test lamp, connect the test lamp to Pin

3 as shown in (Fig. 2). Refer to Group 8W, Wiring

Diagrams for fog lamp switch circuit.(4) Push the fog lamp switch button. The test lamp

should illuminate, and the LED indicator on the

front of the switch.

(5) If either the LED, or the test lamp fails to illu-

minate, replace the switch.

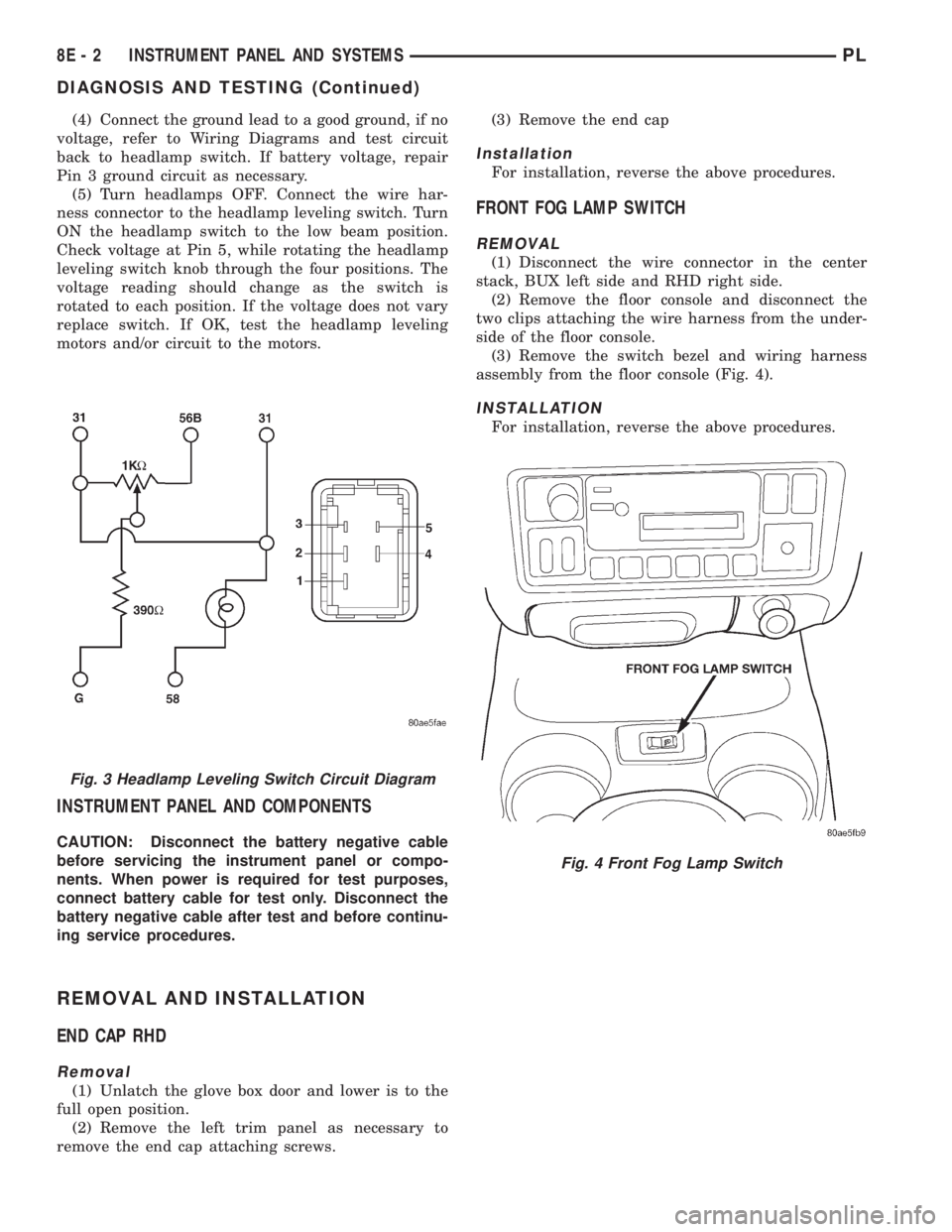

HEADLAMP LEVELING SWITCH

(1) Remove the headlamp leveling switch from the

instrument panel and disconnect the wire harness

connector from the switch. Refer to Wiring Diagrams

for the proper wire circuits and the wire connector

connections.

(2) If the L.E.D. is not illuminated, using a voltme-

ter, connect B+ lead to Pin 4 of the Wire harness con-

nector. Connect the negative lead to Pin 3. Turn ON

the headlamp switch to the low beam position and

ensure the instrument panel dimmer switch is on

day light driving position. If voltage is present,

replace switch. If no voltage, connect the ground lead

to a good ground, if voltage, repair Pin 3 ground cir-

cuit as necessary, and if no voltage, refer to Wiring

Diagrams and test circuit back to headlamp switch.

(3) Using a voltmeter, connect B+ lead to Pin 2 of

the Wire harness connector. Connect the negative

lead to Pin 3. Turn ON the headlamp switch to the

low beam position. If battery voltage, go to Step 5. If

not OK, go to Step 4.

Fig. 1 Front Fog Lamp Switch Circuit Diagram

Fig. 2 Rear Fog Lamp Switch Test

PLINSTRUMENT PANEL AND SYSTEMS 8E - 1

Page 285 of 1200

(4) Connect the ground lead to a good ground, if no

voltage, refer to Wiring Diagrams and test circuit

back to headlamp switch. If battery voltage, repair

Pin 3 ground circuit as necessary.

(5) Turn headlamps OFF. Connect the wire har-

ness connector to the headlamp leveling switch. Turn

ON the headlamp switch to the low beam position.

Check voltage at Pin 5, while rotating the headlamp

leveling switch knob through the four positions. The

voltage reading should change as the switch is

rotated to each position. If the voltage does not vary

replace switch. If OK, test the headlamp leveling

motors and/or circuit to the motors.

INSTRUMENT PANEL AND COMPONENTS

CAUTION: Disconnect the battery negative cable

before servicing the instrument panel or compo-

nents. When power is required for test purposes,

connect battery cable for test only. Disconnect the

battery negative cable after test and before continu-

ing service procedures.

REMOVAL AND INSTALLATION

END CAP RHD

Removal

(1) Unlatch the glove box door and lower is to the

full open position.

(2) Remove the left trim panel as necessary to

remove the end cap attaching screws.(3) Remove the end cap

Installation

For installation, reverse the above procedures.

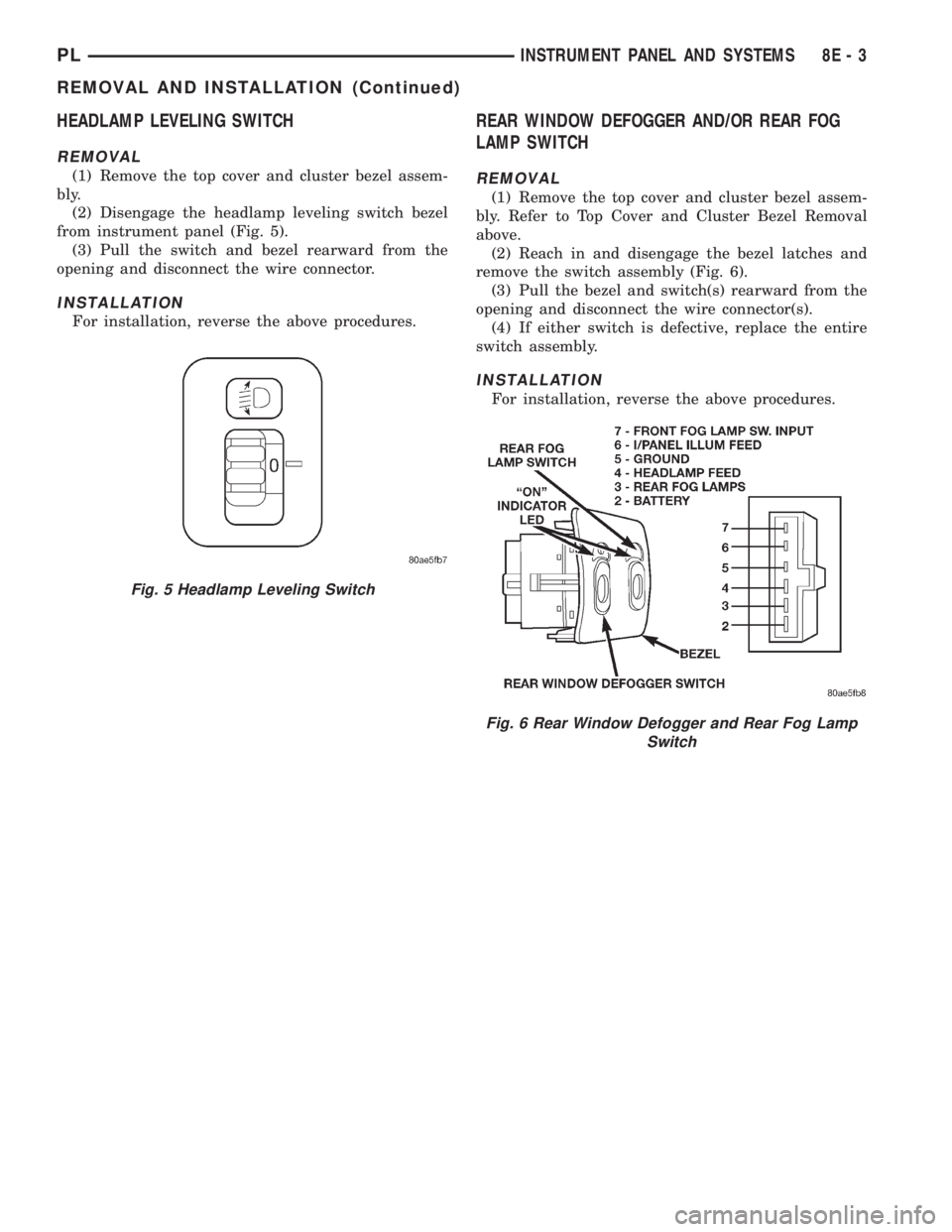

FRONT FOG LAMP SWITCH

REMOVAL

(1) Disconnect the wire connector in the center

stack, BUX left side and RHD right side.

(2) Remove the floor console and disconnect the

two clips attaching the wire harness from the under-

side of the floor console.

(3) Remove the switch bezel and wiring harness

assembly from the floor console (Fig. 4).

INSTALLATION

For installation, reverse the above procedures.

Fig. 3 Headlamp Leveling Switch Circuit Diagram

Fig. 4 Front Fog Lamp Switch

8E - 2 INSTRUMENT PANEL AND SYSTEMSPL

DIAGNOSIS AND TESTING (Continued)

Page 286 of 1200

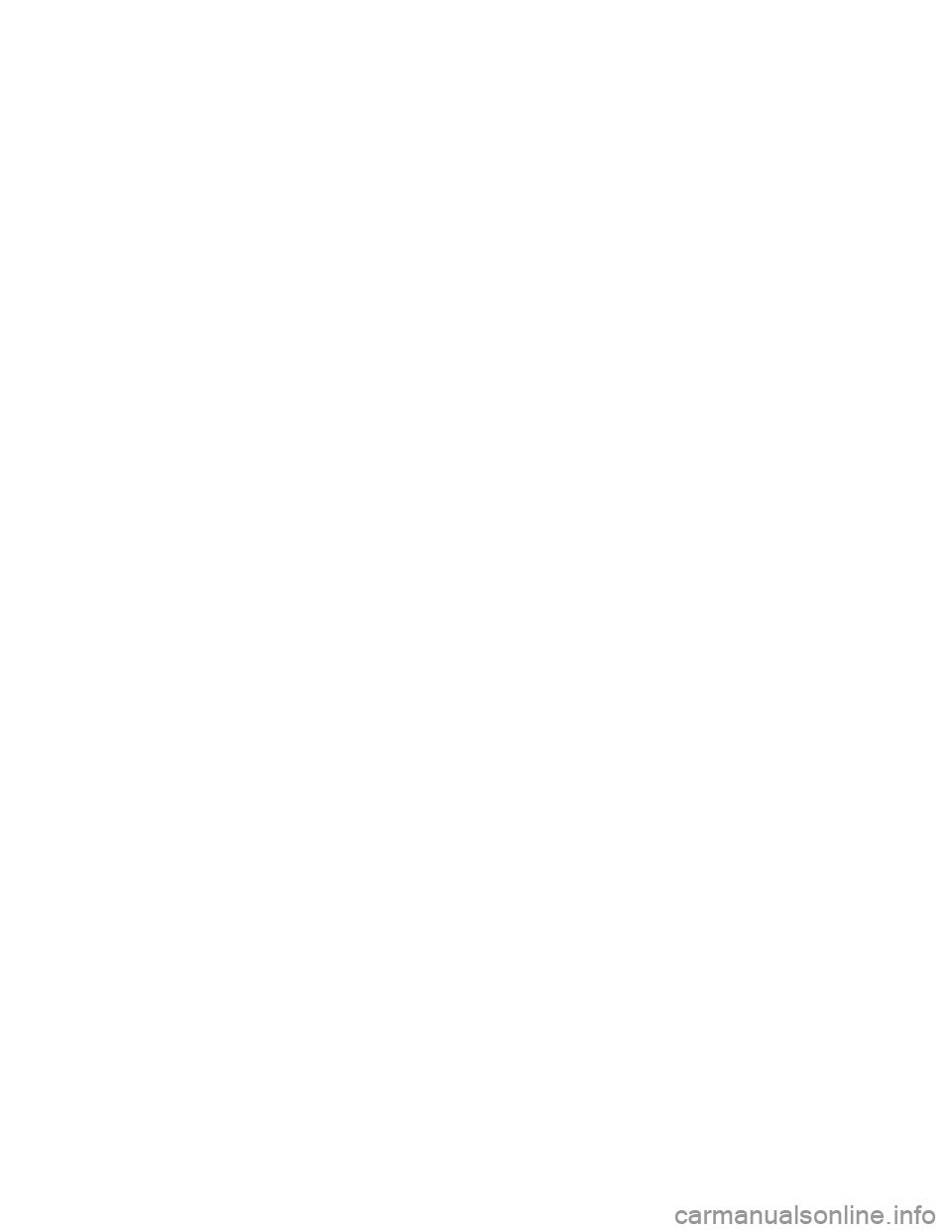

HEADLAMP LEVELING SWITCH

REMOVAL

(1) Remove the top cover and cluster bezel assem-

bly.

(2) Disengage the headlamp leveling switch bezel

from instrument panel (Fig. 5).

(3) Pull the switch and bezel rearward from the

opening and disconnect the wire connector.

INSTALLATION

For installation, reverse the above procedures.

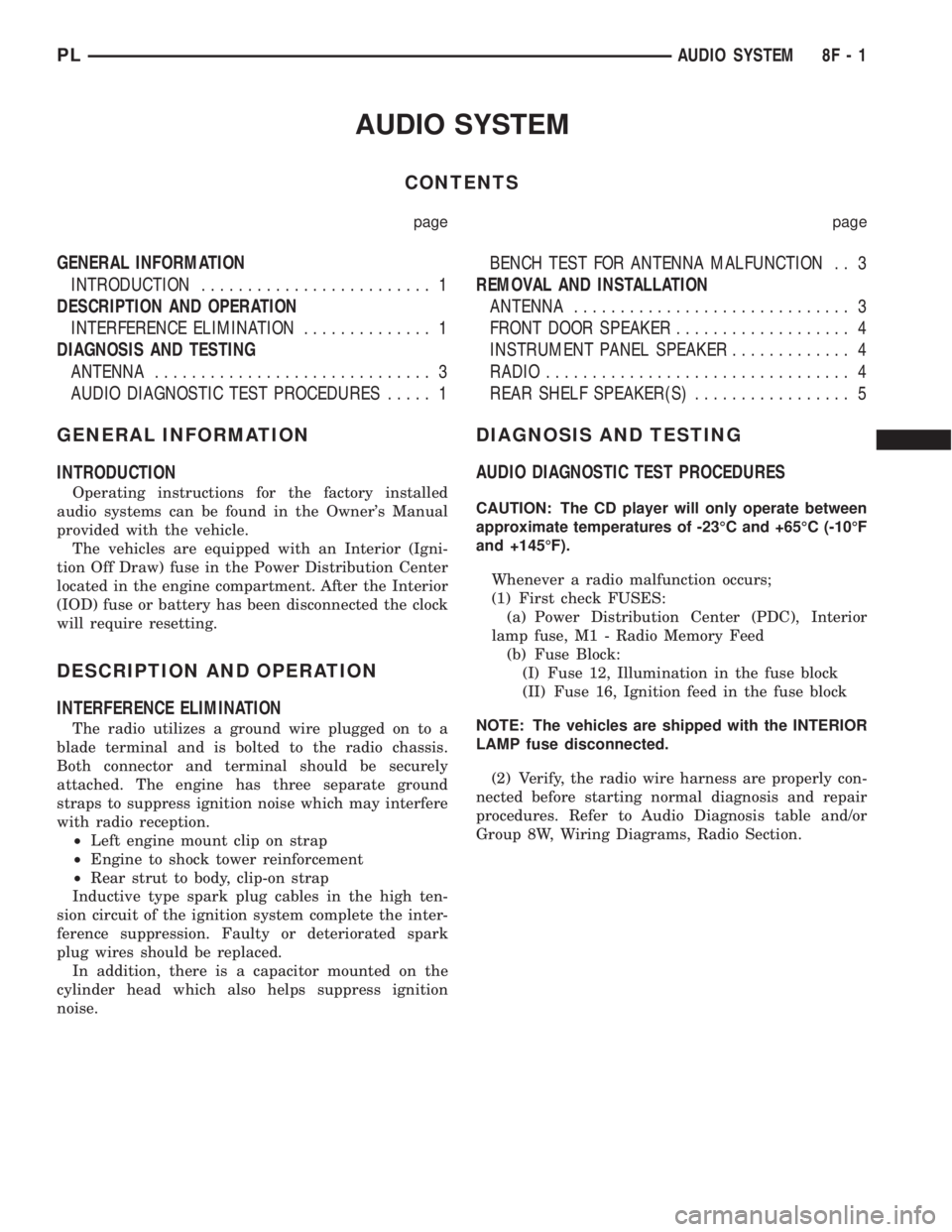

REAR WINDOW DEFOGGER AND/OR REAR FOG

LAMP SWITCH

REMOVAL

(1) Remove the top cover and cluster bezel assem-

bly. Refer to Top Cover and Cluster Bezel Removal

above.

(2) Reach in and disengage the bezel latches and

remove the switch assembly (Fig. 6).

(3) Pull the bezel and switch(s) rearward from the

opening and disconnect the wire connector(s).

(4) If either switch is defective, replace the entire

switch assembly.

INSTALLATION

For installation, reverse the above procedures.

Fig. 5 Headlamp Leveling Switch

Fig. 6 Rear Window Defogger and Rear Fog Lamp

Switch

PLINSTRUMENT PANEL AND SYSTEMS 8E - 3

REMOVAL AND INSTALLATION (Continued)

Page 287 of 1200

Page 288 of 1200

AUDIO SYSTEM

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

INTERFERENCE ELIMINATION.............. 1

DIAGNOSIS AND TESTING

ANTENNA.............................. 3

AUDIO DIAGNOSTIC TEST PROCEDURES..... 1BENCH TEST FOR ANTENNA MALFUNCTION . . 3

REMOVAL AND INSTALLATION

ANTENNA.............................. 3

FRONT DOOR SPEAKER................... 4

INSTRUMENT PANEL SPEAKER............. 4

RADIO................................. 4

REAR SHELF SPEAKER(S)................. 5

GENERAL INFORMATION

INTRODUCTION

Operating instructions for the factory installed

audio systems can be found in the Owner's Manual

provided with the vehicle.

The vehicles are equipped with an Interior (Igni-

tion Off Draw) fuse in the Power Distribution Center

located in the engine compartment. After the Interior

(IOD) fuse or battery has been disconnected the clock

will require resetting.

DESCRIPTION AND OPERATION

INTERFERENCE ELIMINATION

The radio utilizes a ground wire plugged on to a

blade terminal and is bolted to the radio chassis.

Both connector and terminal should be securely

attached. The engine has three separate ground

straps to suppress ignition noise which may interfere

with radio reception.

²Left engine mount clip on strap

²Engine to shock tower reinforcement

²Rear strut to body, clip-on strap

Inductive type spark plug cables in the high ten-

sion circuit of the ignition system complete the inter-

ference suppression. Faulty or deteriorated spark

plug wires should be replaced.

In addition, there is a capacitor mounted on the

cylinder head which also helps suppress ignition

noise.

DIAGNOSIS AND TESTING

AUDIO DIAGNOSTIC TEST PROCEDURES

CAUTION: The CD player will only operate between

approximate temperatures of -23ÉC and +65ÉC (-10ÉF

and +145ÉF).

Whenever a radio malfunction occurs;

(1) First check FUSES:

(a) Power Distribution Center (PDC), Interior

lamp fuse, M1 - Radio Memory Feed

(b) Fuse Block:

(I) Fuse 12, Illumination in the fuse block

(II) Fuse 16, Ignition feed in the fuse block

NOTE: The vehicles are shipped with the INTERIOR

LAMP fuse disconnected.

(2) Verify, the radio wire harness are properly con-

nected before starting normal diagnosis and repair

procedures. Refer to Audio Diagnosis table and/or

Group 8W, Wiring Diagrams, Radio Section.

PLAUDIO SYSTEM 8F - 1

Page 289 of 1200

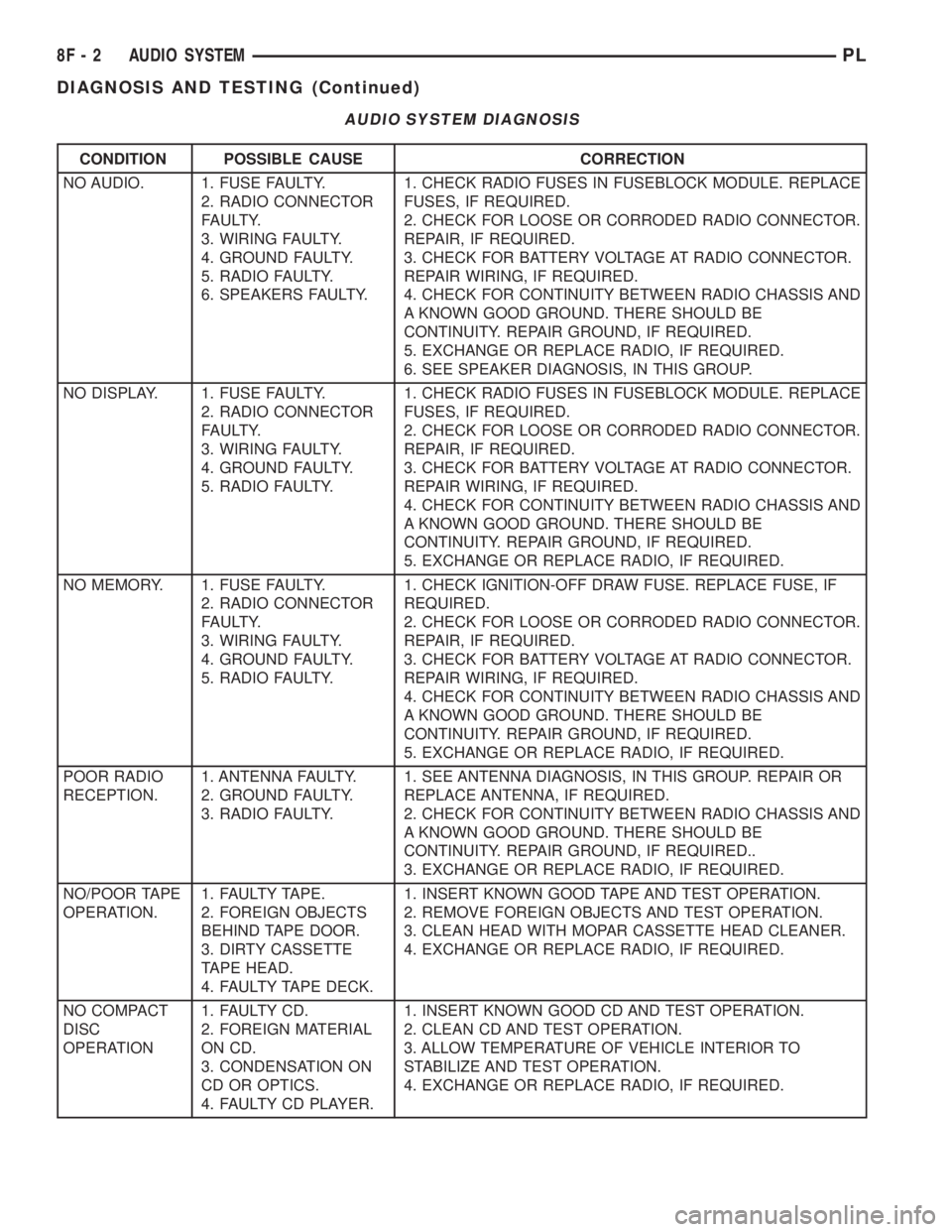

AUDIO SYSTEM DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

NO AUDIO. 1. FUSE FAULTY.

2. RADIO CONNECTOR

FAULTY.

3. WIRING FAULTY.

4. GROUND FAULTY.

5. RADIO FAULTY.

6. SPEAKERS FAULTY.1. CHECK RADIO FUSES IN FUSEBLOCK MODULE. REPLACE

FUSES, IF REQUIRED.

2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

6. SEE SPEAKER DIAGNOSIS, IN THIS GROUP.

NO DISPLAY. 1. FUSE FAULTY.

2. RADIO CONNECTOR

FAULTY.

3. WIRING FAULTY.

4. GROUND FAULTY.

5. RADIO FAULTY.1. CHECK RADIO FUSES IN FUSEBLOCK MODULE. REPLACE

FUSES, IF REQUIRED.

2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

NO MEMORY. 1. FUSE FAULTY.

2. RADIO CONNECTOR

FAULTY.

3. WIRING FAULTY.

4. GROUND FAULTY.

5. RADIO FAULTY.1. CHECK IGNITION-OFF DRAW FUSE. REPLACE FUSE, IF

REQUIRED.

2. CHECK FOR LOOSE OR CORRODED RADIO CONNECTOR.

REPAIR, IF REQUIRED.

3. CHECK FOR BATTERY VOLTAGE AT RADIO CONNECTOR.

REPAIR WIRING, IF REQUIRED.

4. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED.

5. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

POOR RADIO

RECEPTION.1. ANTENNA FAULTY.

2. GROUND FAULTY.

3. RADIO FAULTY.1. SEE ANTENNA DIAGNOSIS, IN THIS GROUP. REPAIR OR

REPLACE ANTENNA, IF REQUIRED.

2. CHECK FOR CONTINUITY BETWEEN RADIO CHASSIS AND

A KNOWN GOOD GROUND. THERE SHOULD BE

CONTINUITY. REPAIR GROUND, IF REQUIRED..

3. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

NO/POOR TAPE

OPERATION.1. FAULTY TAPE.

2. FOREIGN OBJECTS

BEHIND TAPE DOOR.

3. DIRTY CASSETTE

TAPE HEAD.

4. FAULTY TAPE DECK.1. INSERT KNOWN GOOD TAPE AND TEST OPERATION.

2. REMOVE FOREIGN OBJECTS AND TEST OPERATION.

3. CLEAN HEAD WITH MOPAR CASSETTE HEAD CLEANER.

4. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

NO COMPACT

DISC

OPERATION1. FAULTY CD.

2. FOREIGN MATERIAL

ON CD.

3. CONDENSATION ON

CD OR OPTICS.

4. FAULTY CD PLAYER.1. INSERT KNOWN GOOD CD AND TEST OPERATION.

2. CLEAN CD AND TEST OPERATION.

3. ALLOW TEMPERATURE OF VEHICLE INTERIOR TO

STABILIZE AND TEST OPERATION.

4. EXCHANGE OR REPLACE RADIO, IF REQUIRED.

8F - 2 AUDIO SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 290 of 1200

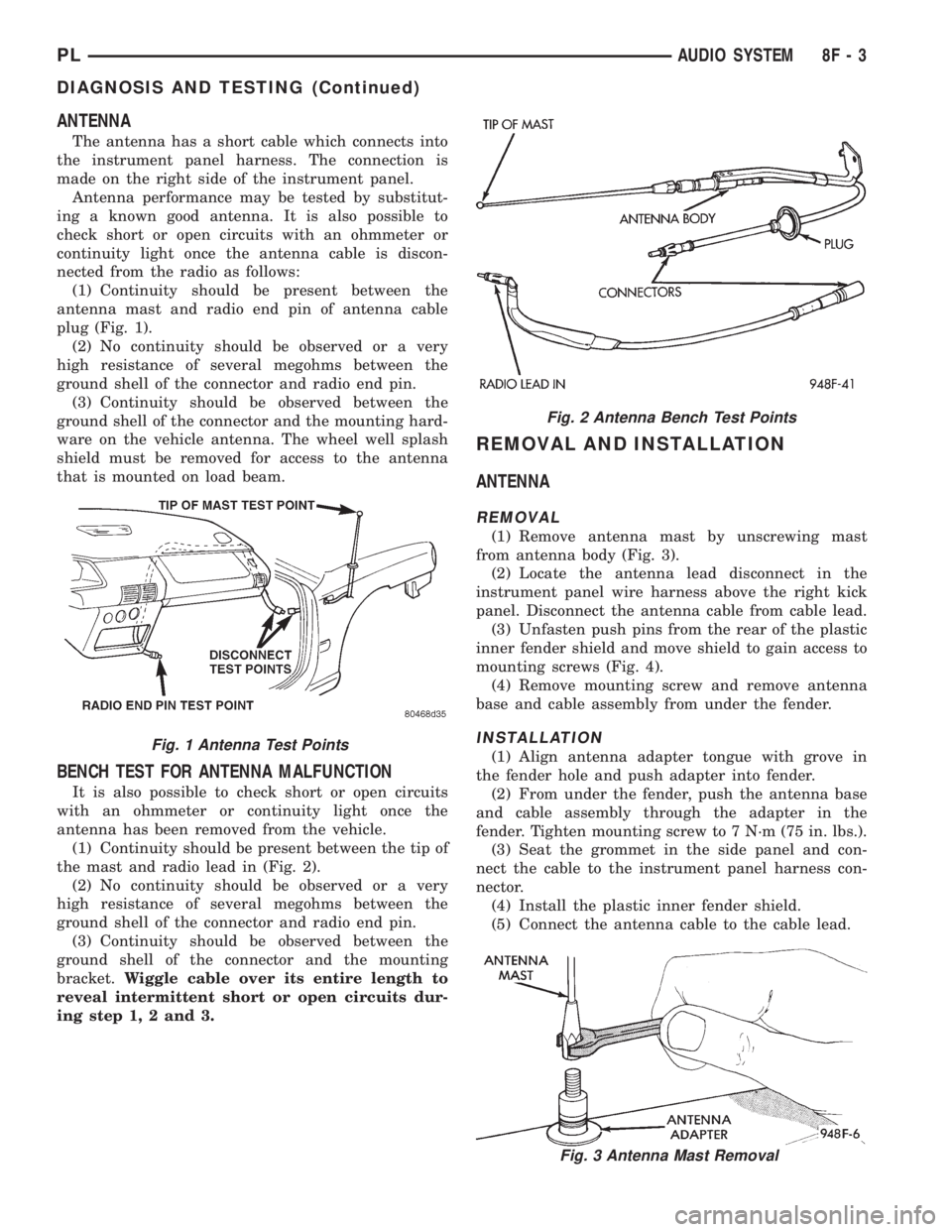

ANTENNA

The antenna has a short cable which connects into

the instrument panel harness. The connection is

made on the right side of the instrument panel.

Antenna performance may be tested by substitut-

ing a known good antenna. It is also possible to

check short or open circuits with an ohmmeter or

continuity light once the antenna cable is discon-

nected from the radio as follows:

(1) Continuity should be present between the

antenna mast and radio end pin of antenna cable

plug (Fig. 1).

(2) No continuity should be observed or a very

high resistance of several megohms between the

ground shell of the connector and radio end pin.

(3) Continuity should be observed between the

ground shell of the connector and the mounting hard-

ware on the vehicle antenna. The wheel well splash

shield must be removed for access to the antenna

that is mounted on load beam.

BENCH TEST FOR ANTENNA MALFUNCTION

It is also possible to check short or open circuits

with an ohmmeter or continuity light once the

antenna has been removed from the vehicle.

(1) Continuity should be present between the tip of

the mast and radio lead in (Fig. 2).

(2) No continuity should be observed or a very

high resistance of several megohms between the

ground shell of the connector and radio end pin.

(3) Continuity should be observed between the

ground shell of the connector and the mounting

bracket.Wiggle cable over its entire length to

reveal intermittent short or open circuits dur-

ing step 1, 2 and 3.

REMOVAL AND INSTALLATION

ANTENNA

REMOVAL

(1) Remove antenna mast by unscrewing mast

from antenna body (Fig. 3).

(2) Locate the antenna lead disconnect in the

instrument panel wire harness above the right kick

panel. Disconnect the antenna cable from cable lead.

(3) Unfasten push pins from the rear of the plastic

inner fender shield and move shield to gain access to

mounting screws (Fig. 4).

(4) Remove mounting screw and remove antenna

base and cable assembly from under the fender.

INSTALLATION

(1) Align antenna adapter tongue with grove in

the fender hole and push adapter into fender.

(2) From under the fender, push the antenna base

and cable assembly through the adapter in the

fender. Tighten mounting screw to 7 N´m (75 in. lbs.).

(3) Seat the grommet in the side panel and con-

nect the cable to the instrument panel harness con-

nector.

(4) Install the plastic inner fender shield.

(5) Connect the antenna cable to the cable lead.

Fig. 2 Antenna Bench Test Points

Fig. 3 Antenna Mast Removal

Fig. 1 Antenna Test Points

PLAUDIO SYSTEM 8F - 3

DIAGNOSIS AND TESTING (Continued)