DODGE NEON 1999 Service Repair Manual

Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 401 of 1200

WARNING: BE SURE THAT THE IGNITION SWITCH

ALWAYS IS IN THE OFF POSITION, UNLESS THE

PROCEDURE REQUIRES IT TO BE ON.

WARNING: SET THE PARKING BRAKE WHEN

WORKING ON ANY VEHICLE. AN AUTOMATIC

TRANSMISSION SHOULD BE IN PARK. A MANUAL

TRANSMISSION SHOULD BE IN NEUTRAL.

WARNING: OPERATE THE ENGINE ONLY IN A

WELL-VENTILATED AREA.

WARNING: KEEP AWAY FROM MOVING PARTS

WHEN THE ENGINE IS RUNNING, ESPECIALLY THE

FAN AND BELTS.

WARNING: TO PREVENT SERIOUS BURNS, AVOID

CONTACT WITH HOT PARTS SUCH AS THE RADIA-

TOR, EXHAUST MANIFOLD(S), TAIL PIPE, CATA-

LYTIC CONVERTER, AND MUFFLER.

WARNING: DO NOT ALLOW FLAME OR SPARKS

NEAR THE BATTERY. GASES ARE ALWAYS

PRESENT IN AND AROUND THE BATTERY.

WARNING: ALWAYS REMOVE RINGS, WATCHES,

LOOSE HANGING JEWELRY, AND LOOSE CLOTH-

ING.

TAKE OUTS

The abbreviation T/O is used in the component

location section to indicate a point in which the wir-

ing harness branches out to a component.

ELECTROSTATIC DISCHARGE (ESD) SENSITIVE

DEVICES

All ESD sensitive components are solid state and a

symbol (Fig. 4) is used to indicate this. When han-

dling any component with this symbol comply with

the following procedures to reduce the possibility of

electrostatic charge build up on the body and inad-

vertent discharge into the component. If it is not

known whether the part is ESD sensitive, assume

that it is.

(1) Always touch a known good ground before han-

dling the part. This should be repeated while han-

dling the part and more frequently after sliding

across a seat, sitting down from a standing position,

or walking a distance.

(2) Avoid touching electrical terminals of the part,

unless instructed to do so by a written procedure.(3) When using a voltmeter, be sure to connect the

ground lead first.

(4) Do not remove the part from its protective

packing until it is time to install the part.

(5) Before removing the part from its package,

ground the package to a known good ground on the

vehicle.

DIAGNOSIS AND TESTING

TROUBLESHOOTING TOOLS

When diagnosing a problem in an electrical circuit

there are several common tools necessary. These tools

are listed and explained below.

²Jumper Wire - This is a test wire used to con-

nect two points of a circuit. It can be used to bypass

an open in a circuit.

WARNING: NEVER USE A JUMPER WIRE ACROSS

A LOAD, SUCH AS A MOTOR, CONNECTED

BETWEEN A BATTERY FEED AND GROUND.

²Voltmeter - Used to check for voltage on a cir-

cuit. Always connect the black lead to a known good

ground and the red lead to the positive side of the

circuit.

CAUTION: Most of the electrical components used

in today's vehicle are solid state. When checking

voltages in these circuits use a meter with a 10-me-

gohm or greater impedance rating.

²Ohmmeter - Used to check the resistance

between two points of a circuit. Low or no resistance

in a circuit means good continuity.

CAUTION: - Most of the electrical components used

in today's vehicle are Solid State. When checking

resistance in these circuits use a meter with a 10-

megohm or greater impedance rating. In addition,

make sure the power is disconnected from the cir-

cuit. Circuits that are powered up by the vehicle

electrical system can cause damage to the equip-

ment and provide false readings.

Fig. 4 Electrostatic Discharge Symbol

8W - 01 - 8 8W - 01 GENERAL INFORMATIONPL

DESCRIPTION AND OPERATION (Continued)

Page 402 of 1200

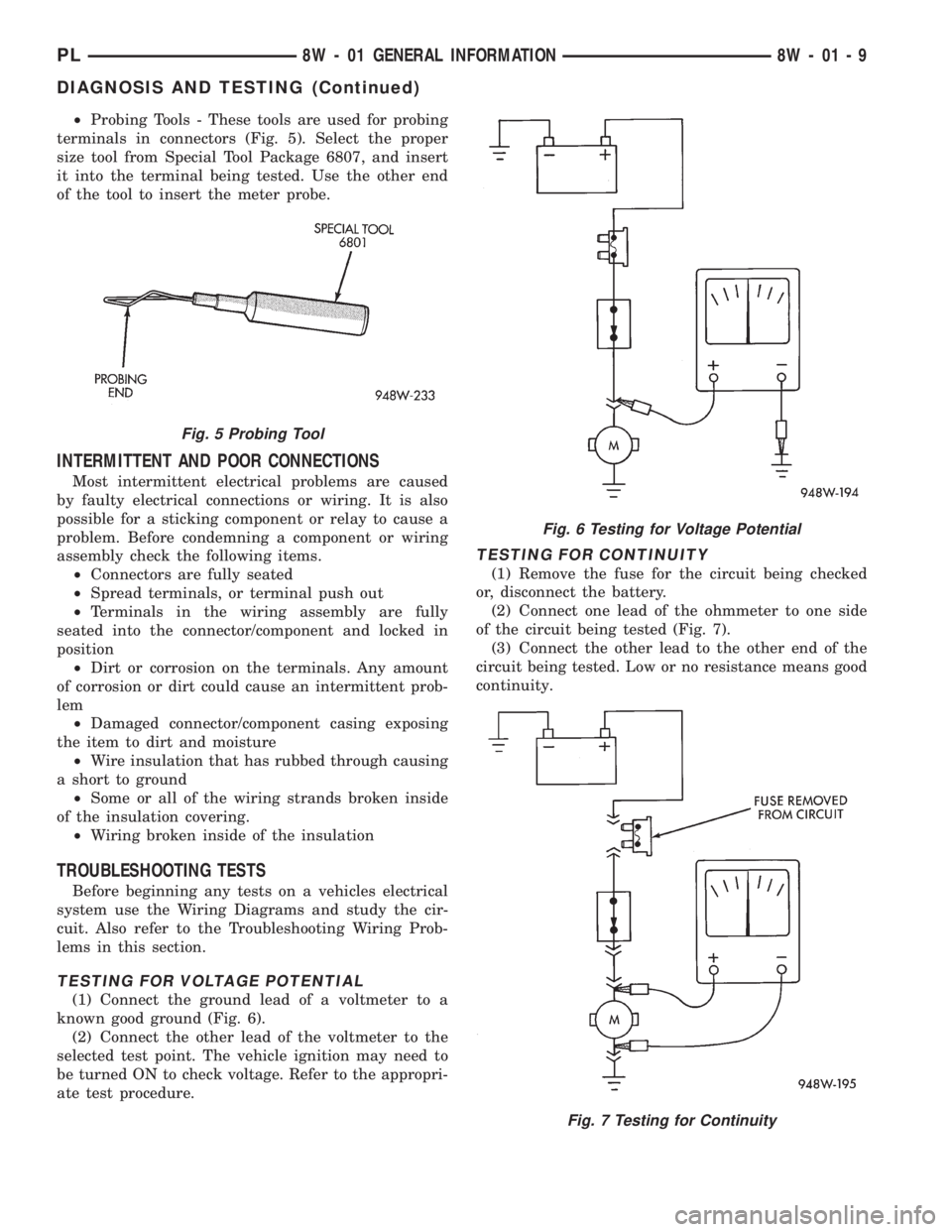

²Probing Tools - These tools are used for probing

terminals in connectors (Fig. 5). Select the proper

size tool from Special Tool Package 6807, and insert

it into the terminal being tested. Use the other end

of the tool to insert the meter probe.

INTERMITTENT AND POOR CONNECTIONS

Most intermittent electrical problems are caused

by faulty electrical connections or wiring. It is also

possible for a sticking component or relay to cause a

problem. Before condemning a component or wiring

assembly check the following items.

²Connectors are fully seated

²Spread terminals, or terminal push out

²Terminals in the wiring assembly are fully

seated into the connector/component and locked in

position

²Dirt or corrosion on the terminals. Any amount

of corrosion or dirt could cause an intermittent prob-

lem

²Damaged connector/component casing exposing

the item to dirt and moisture

²Wire insulation that has rubbed through causing

a short to ground

²Some or all of the wiring strands broken inside

of the insulation covering.

²Wiring broken inside of the insulation

TROUBLESHOOTING TESTS

Before beginning any tests on a vehicles electrical

system use the Wiring Diagrams and study the cir-

cuit. Also refer to the Troubleshooting Wiring Prob-

lems in this section.

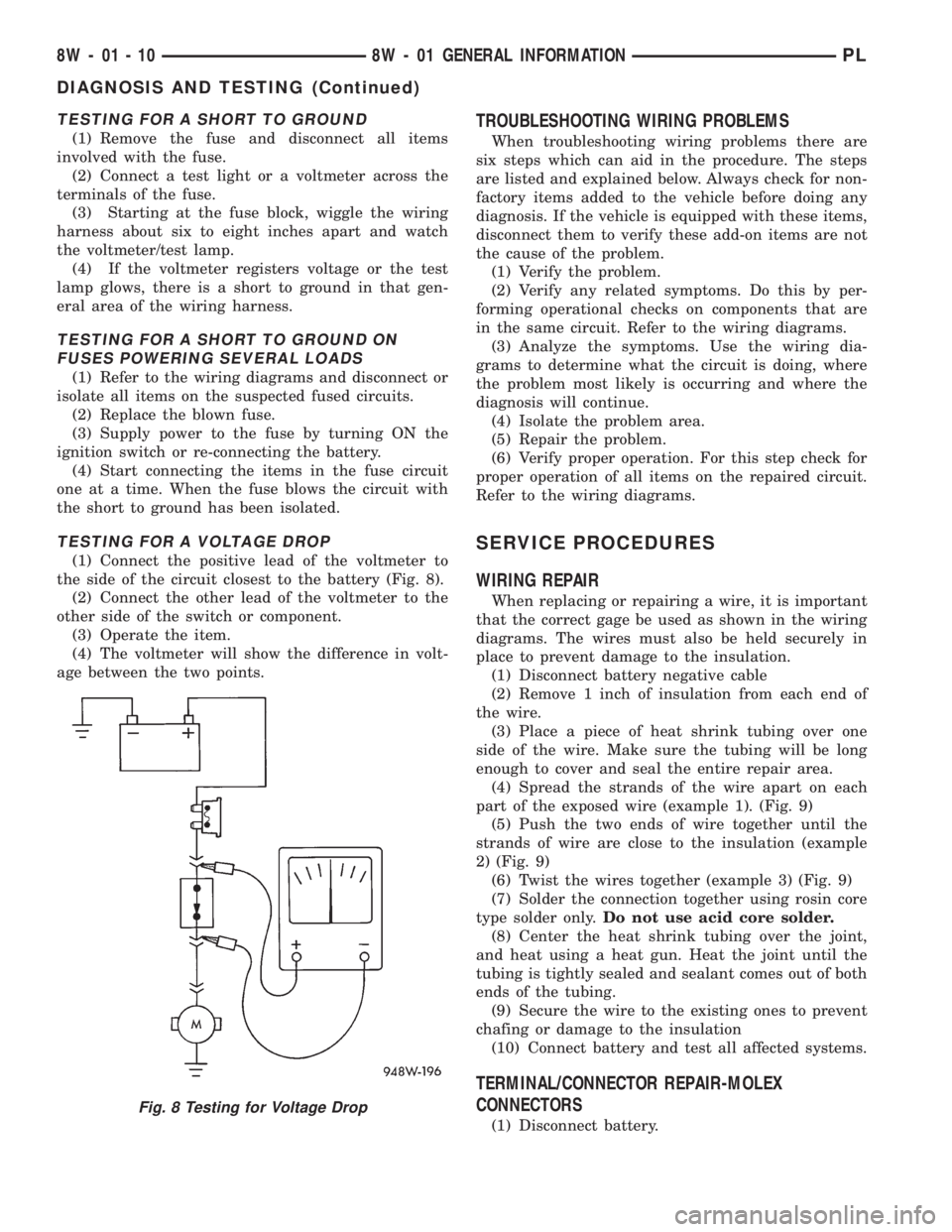

TESTING FOR VOLTAGE POTENTIAL

(1) Connect the ground lead of a voltmeter to a

known good ground (Fig. 6).

(2) Connect the other lead of the voltmeter to the

selected test point. The vehicle ignition may need to

be turned ON to check voltage. Refer to the appropri-

ate test procedure.

TESTING FOR CONTINUITY

(1) Remove the fuse for the circuit being checked

or, disconnect the battery.

(2) Connect one lead of the ohmmeter to one side

of the circuit being tested (Fig. 7).

(3) Connect the other lead to the other end of the

circuit being tested. Low or no resistance means good

continuity.

Fig. 5 Probing Tool

Fig. 6 Testing for Voltage Potential

Fig. 7 Testing for Continuity

PL8W - 01 GENERAL INFORMATION 8W - 01 - 9

DIAGNOSIS AND TESTING (Continued)

Page 403 of 1200

TESTING FOR A SHORT TO GROUND

(1) Remove the fuse and disconnect all items

involved with the fuse.

(2) Connect a test light or a voltmeter across the

terminals of the fuse.

(3) Starting at the fuse block, wiggle the wiring

harness about six to eight inches apart and watch

the voltmeter/test lamp.

(4) If the voltmeter registers voltage or the test

lamp glows, there is a short to ground in that gen-

eral area of the wiring harness.

TESTING FOR A SHORT TO GROUND ON

FUSES POWERING SEVERAL LOADS

(1) Refer to the wiring diagrams and disconnect or

isolate all items on the suspected fused circuits.

(2) Replace the blown fuse.

(3) Supply power to the fuse by turning ON the

ignition switch or re-connecting the battery.

(4) Start connecting the items in the fuse circuit

one at a time. When the fuse blows the circuit with

the short to ground has been isolated.

TESTING FOR A VOLTAGE DROP

(1) Connect the positive lead of the voltmeter to

the side of the circuit closest to the battery (Fig. 8).

(2) Connect the other lead of the voltmeter to the

other side of the switch or component.

(3) Operate the item.

(4) The voltmeter will show the difference in volt-

age between the two points.

TROUBLESHOOTING WIRING PROBLEMS

When troubleshooting wiring problems there are

six steps which can aid in the procedure. The steps

are listed and explained below. Always check for non-

factory items added to the vehicle before doing any

diagnosis. If the vehicle is equipped with these items,

disconnect them to verify these add-on items are not

the cause of the problem.

(1) Verify the problem.

(2) Verify any related symptoms. Do this by per-

forming operational checks on components that are

in the same circuit. Refer to the wiring diagrams.

(3) Analyze the symptoms. Use the wiring dia-

grams to determine what the circuit is doing, where

the problem most likely is occurring and where the

diagnosis will continue.

(4) Isolate the problem area.

(5) Repair the problem.

(6) Verify proper operation. For this step check for

proper operation of all items on the repaired circuit.

Refer to the wiring diagrams.

SERVICE PROCEDURES

WIRING REPAIR

When replacing or repairing a wire, it is important

that the correct gage be used as shown in the wiring

diagrams. The wires must also be held securely in

place to prevent damage to the insulation.

(1) Disconnect battery negative cable

(2) Remove 1 inch of insulation from each end of

the wire.

(3) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area.

(4) Spread the strands of the wire apart on each

part of the exposed wire (example 1). (Fig. 9)

(5) Push the two ends of wire together until the

strands of wire are close to the insulation (example

2) (Fig. 9)

(6) Twist the wires together (example 3) (Fig. 9)

(7) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(8) Center the heat shrink tubing over the joint,

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(9) Secure the wire to the existing ones to prevent

chafing or damage to the insulation

(10) Connect battery and test all affected systems.

TERMINAL/CONNECTOR REPAIR-MOLEX

CONNECTORS

(1) Disconnect battery.

Fig. 8 Testing for Voltage Drop

8W - 01 - 10 8W - 01 GENERAL INFORMATIONPL

DIAGNOSIS AND TESTING (Continued)

Page 404 of 1200

(2) Disconnect the connector from its mating half/

component.

(3) Insert the terminal releasing special tool 6742

into the terminal end of the connector (Fig. 10).(4) Using special tool 6742 release the locking fin-

gers on the terminal (Fig. 11).

(5) Pull on the wire to remove it from the connec-

tor.

(6) Repair or replace the connector or terminal, as

necessary.TERMINAL/CONNECTOR REPAIRÐTHOMAS AND

BETTS CONNECTORS

(1) Disconnect battery.

(2) Disconnect the connector from its mating half/

component.

(3) Push in the two lock tabs on the side of the

connector (Fig. 12).

Fig. 9 Wire Repair

Fig. 10 Molex Connector Repair

Fig. 11 Using Special Tool 6742

Fig. 12 Thomas and Betts Connector Lock Release

Tabs

PL8W - 01 GENERAL INFORMATION 8W - 01 - 11

SERVICE PROCEDURES (Continued)

Page 405 of 1200

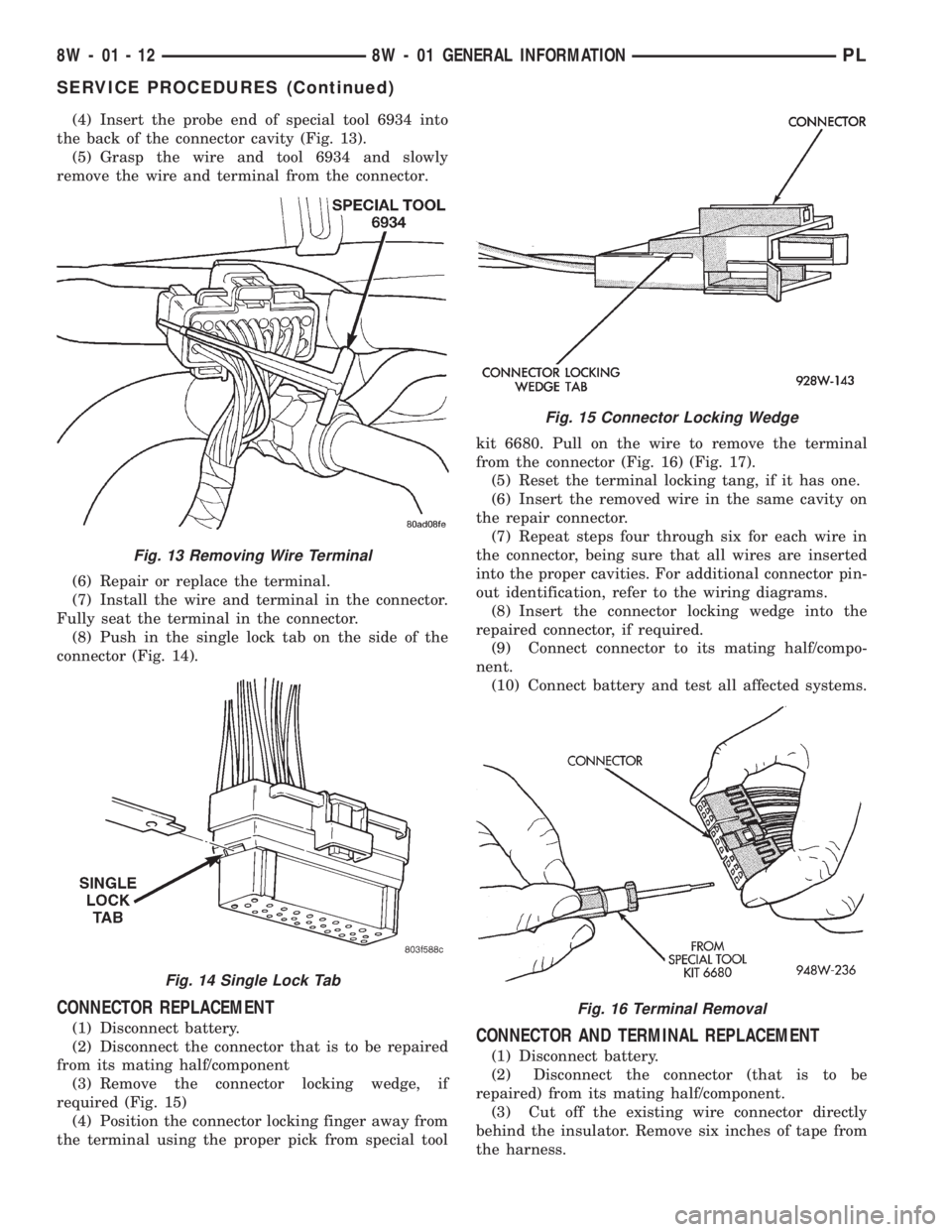

(4) Insert the probe end of special tool 6934 into

the back of the connector cavity (Fig. 13).

(5) Grasp the wire and tool 6934 and slowly

remove the wire and terminal from the connector.

(6) Repair or replace the terminal.

(7) Install the wire and terminal in the connector.

Fully seat the terminal in the connector.

(8) Push in the single lock tab on the side of the

connector (Fig. 14).

CONNECTOR REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector that is to be repaired

from its mating half/component

(3) Remove the connector locking wedge, if

required (Fig. 15)

(4) Position the connector locking finger away from

the terminal using the proper pick from special toolkit 6680. Pull on the wire to remove the terminal

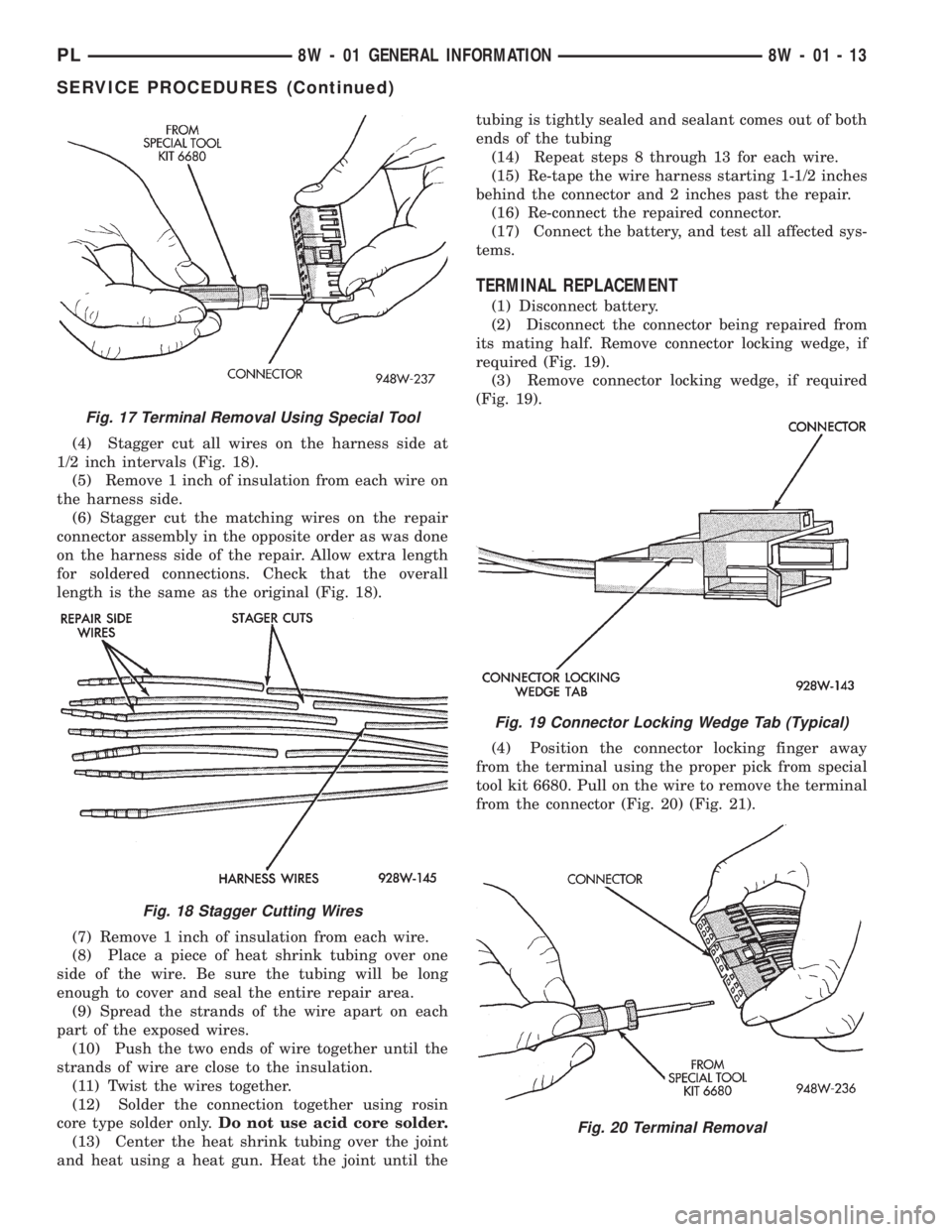

from the connector (Fig. 16) (Fig. 17).

(5) Reset the terminal locking tang, if it has one.

(6) Insert the removed wire in the same cavity on

the repair connector.

(7) Repeat steps four through six for each wire in

the connector, being sure that all wires are inserted

into the proper cavities. For additional connector pin-

out identification, refer to the wiring diagrams.

(8) Insert the connector locking wedge into the

repaired connector, if required.

(9) Connect connector to its mating half/compo-

nent.

(10) Connect battery and test all affected systems.CONNECTOR AND TERMINAL REPLACEMENT

(1) Disconnect battery.

(2) Disconnect the connector (that is to be

repaired) from its mating half/component.

(3) Cut off the existing wire connector directly

behind the insulator. Remove six inches of tape from

the harness.

Fig. 13 Removing Wire Terminal

Fig. 14 Single Lock Tab

Fig. 15 Connector Locking Wedge

Fig. 16 Terminal Removal

8W - 01 - 12 8W - 01 GENERAL INFORMATIONPL

SERVICE PROCEDURES (Continued)

Page 406 of 1200

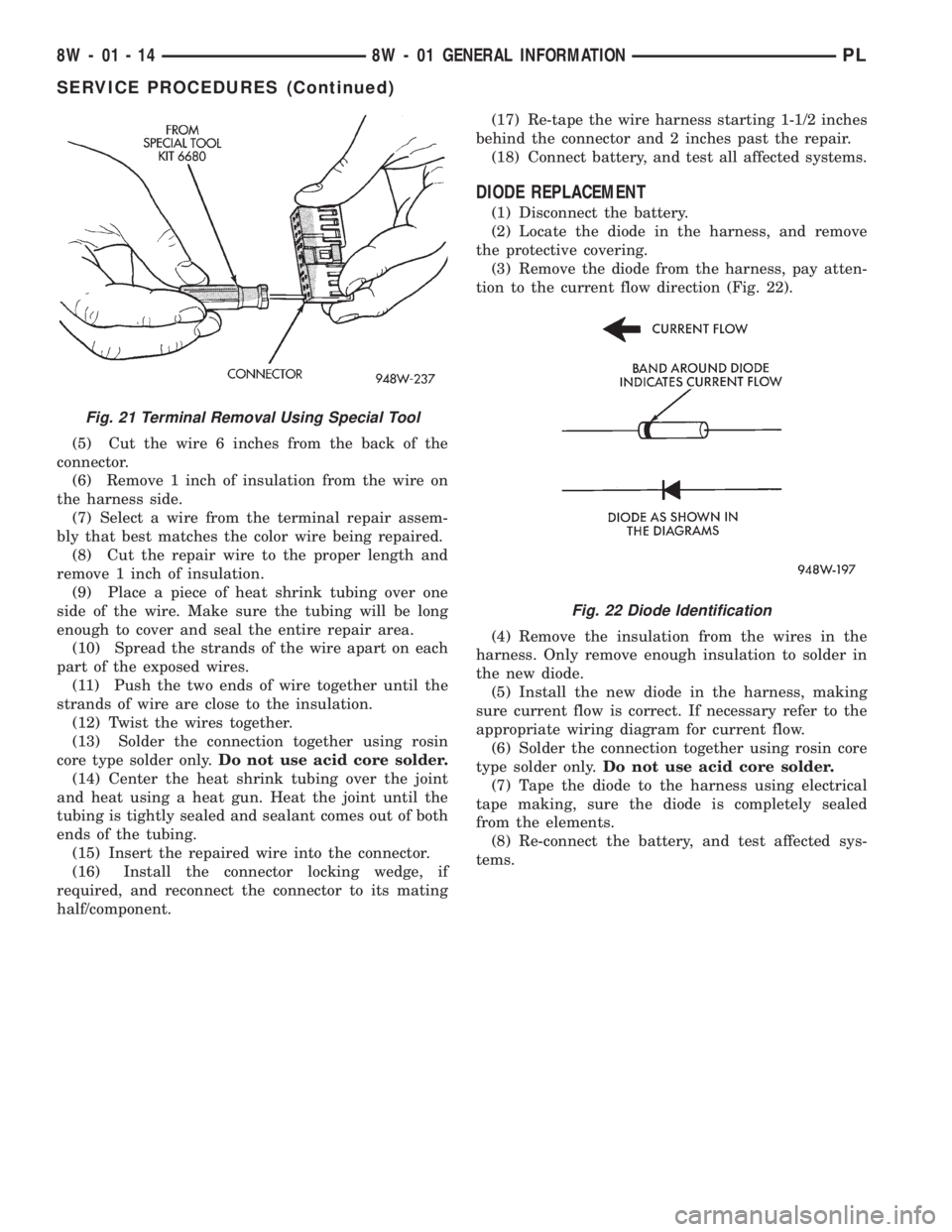

(4) Stagger cut all wires on the harness side at

1/2 inch intervals (Fig. 18).

(5) Remove 1 inch of insulation from each wire on

the harness side.

(6) Stagger cut the matching wires on the repair

connector assembly in the opposite order as was done

on the harness side of the repair. Allow extra length

for soldered connections. Check that the overall

length is the same as the original (Fig. 18).

(7) Remove 1 inch of insulation from each wire.

(8) Place a piece of heat shrink tubing over one

side of the wire. Be sure the tubing will be long

enough to cover and seal the entire repair area.

(9) Spread the strands of the wire apart on each

part of the exposed wires.

(10) Push the two ends of wire together until the

strands of wire are close to the insulation.

(11) Twist the wires together.

(12) Solder the connection together using rosin

core type solder only.Do not use acid core solder.

(13) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until thetubing is tightly sealed and sealant comes out of both

ends of the tubing

(14) Repeat steps 8 through 13 for each wire.

(15) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair.

(16) Re-connect the repaired connector.

(17) Connect the battery, and test all affected sys-

tems.

TERMINAL REPLACEMENT

(1) Disconnect battery.

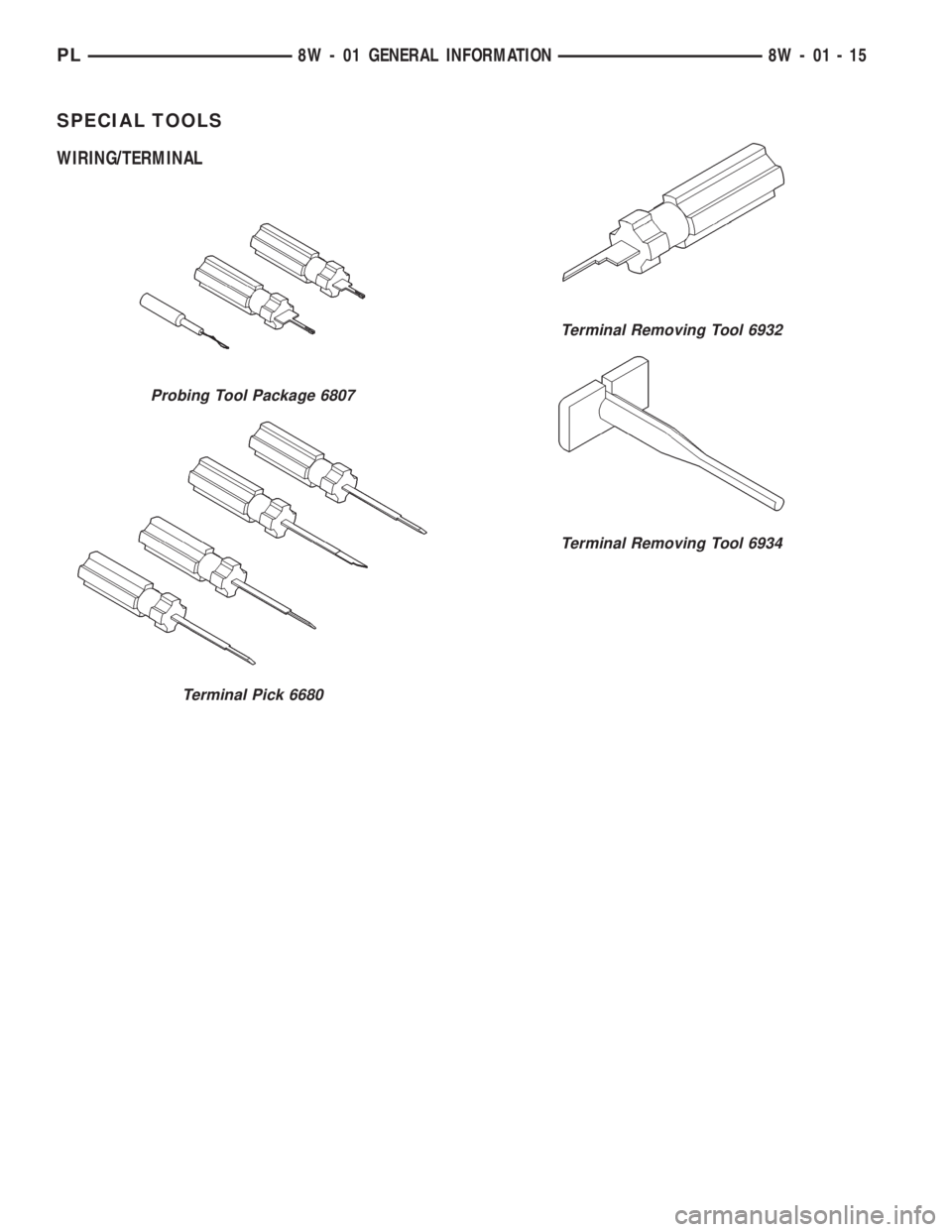

(2) Disconnect the connector being repaired from

its mating half. Remove connector locking wedge, if

required (Fig. 19).

(3) Remove connector locking wedge, if required

(Fig. 19).

(4) Position the connector locking finger away

from the terminal using the proper pick from special

tool kit 6680. Pull on the wire to remove the terminal

from the connector (Fig. 20) (Fig. 21).

Fig. 17 Terminal Removal Using Special Tool

Fig. 18 Stagger Cutting Wires

Fig. 19 Connector Locking Wedge Tab (Typical)

Fig. 20 Terminal Removal

PL8W - 01 GENERAL INFORMATION 8W - 01 - 13

SERVICE PROCEDURES (Continued)

Page 407 of 1200

(5) Cut the wire 6 inches from the back of the

connector.

(6) Remove 1 inch of insulation from the wire on

the harness side.

(7) Select a wire from the terminal repair assem-

bly that best matches the color wire being repaired.

(8) Cut the repair wire to the proper length and

remove 1 inch of insulation.

(9) Place a piece of heat shrink tubing over one

side of the wire. Make sure the tubing will be long

enough to cover and seal the entire repair area.

(10) Spread the strands of the wire apart on each

part of the exposed wires.

(11) Push the two ends of wire together until the

strands of wire are close to the insulation.

(12) Twist the wires together.

(13) Solder the connection together using rosin

core type solder only.Do not use acid core solder.

(14) Center the heat shrink tubing over the joint

and heat using a heat gun. Heat the joint until the

tubing is tightly sealed and sealant comes out of both

ends of the tubing.

(15) Insert the repaired wire into the connector.

(16) Install the connector locking wedge, if

required, and reconnect the connector to its mating

half/component.(17) Re-tape the wire harness starting 1-1/2 inches

behind the connector and 2 inches past the repair.

(18) Connect battery, and test all affected systems.

DIODE REPLACEMENT

(1) Disconnect the battery.

(2) Locate the diode in the harness, and remove

the protective covering.

(3) Remove the diode from the harness, pay atten-

tion to the current flow direction (Fig. 22).

(4) Remove the insulation from the wires in the

harness. Only remove enough insulation to solder in

the new diode.

(5) Install the new diode in the harness, making

sure current flow is correct. If necessary refer to the

appropriate wiring diagram for current flow.

(6) Solder the connection together using rosin core

type solder only.Do not use acid core solder.

(7) Tape the diode to the harness using electrical

tape making, sure the diode is completely sealed

from the elements.

(8) Re-connect the battery, and test affected sys-

tems.

Fig. 21 Terminal Removal Using Special Tool

Fig. 22 Diode Identification

8W - 01 - 14 8W - 01 GENERAL INFORMATIONPL

SERVICE PROCEDURES (Continued)

Page 408 of 1200

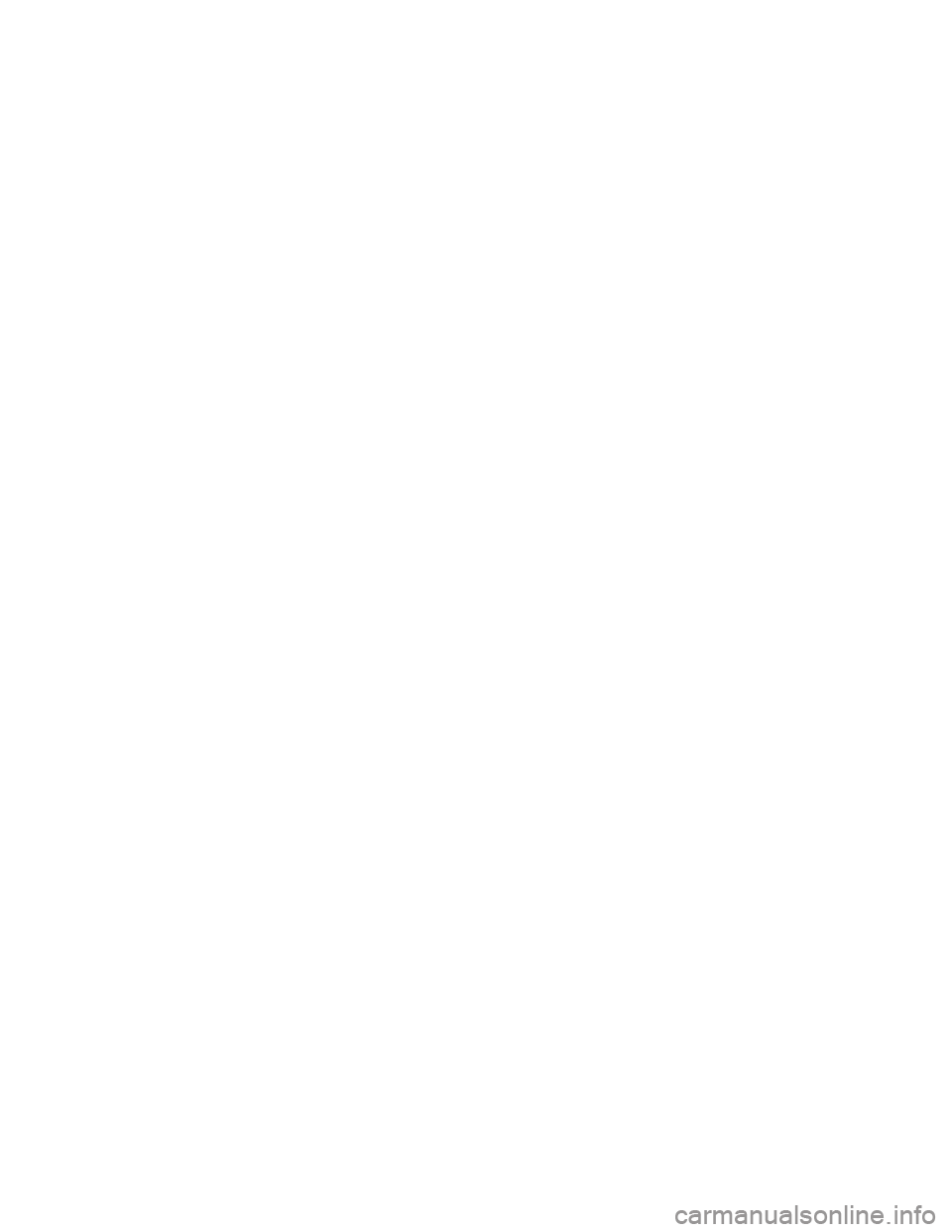

SPECIAL TOOLS

WIRING/TERMINAL

Probing Tool Package 6807

Terminal Pick 6680

Terminal Removing Tool 6932

Terminal Removing Tool 6934

PL8W - 01 GENERAL INFORMATION 8W - 01 - 15

Page 409 of 1200

Page 410 of 1200

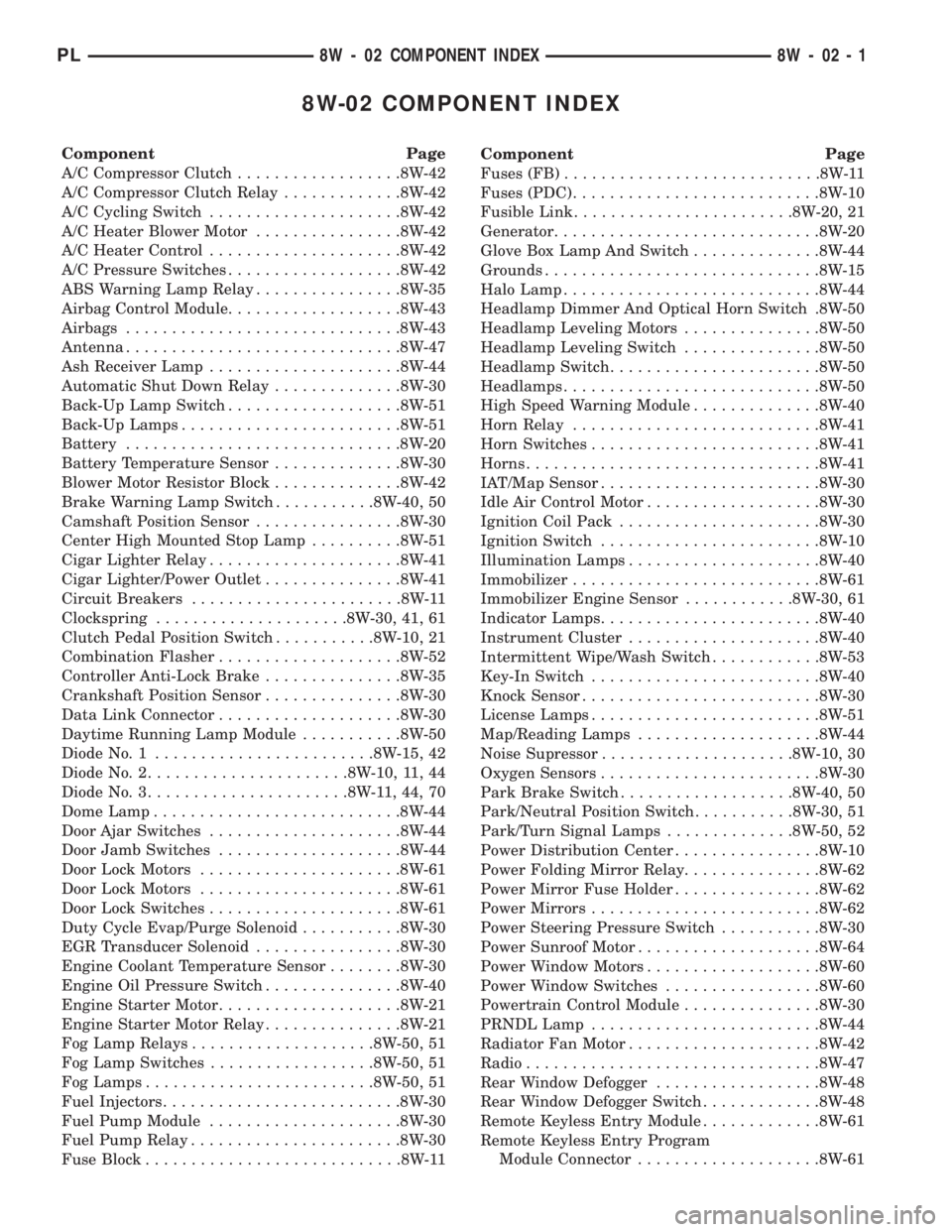

8W-02 COMPONENT INDEX

Component Page

A/C Compressor Clutch..................8W-42

A/C Compressor Clutch Relay.............8W-42

A/C Cycling Switch.....................8W-42

A/C Heater Blower Motor................8W-42

A/C Heater Control.....................8W-42

A/C Pressure Switches...................8W-42

ABS Warning Lamp Relay................8W-35

Airbag Control Module...................8W-43

Airbags..............................8W-43

Antenna..............................8W-47

Ash Receiver Lamp.....................8W-44

Automatic Shut Down Relay..............8W-30

Back-Up Lamp Switch...................8W-51

Back-Up Lamps........................8W-51

Battery..............................8W-20

Battery Temperature Sensor..............8W-30

Blower Motor Resistor Block..............8W-42

Brake Warning Lamp Switch...........8W-40, 50

Camshaft Position Sensor................8W-30

Center High Mounted Stop Lamp..........8W-51

Cigar Lighter Relay.....................8W-41

Cigar Lighter/Power Outlet...............8W-41

Circuit Breakers.......................8W-11

Clockspring.....................8W-30, 41, 61

Clutch Pedal Position Switch...........8W-10, 21

Combination Flasher....................8W-52

Controller Anti-Lock Brake...............8W-35

Crankshaft Position Sensor...............8W-30

Data Link Connector....................8W-30

Daytime Running Lamp Module...........8W-50

Diode No. 1........................8W-15, 42

Diode No. 2......................8W-10, 11, 44

Diode No. 3......................8W-11,44,70

Dome Lamp...........................8W-44

Door Ajar Switches.....................8W-44

Door Jamb Switches....................8W-44

Door Lock Motors......................8W-61

Door Lock Motors......................8W-61

Door Lock Switches.....................8W-61

Duty Cycle Evap/Purge Solenoid...........8W-30

EGR Transducer Solenoid................8W-30

Engine Coolant Temperature Sensor........8W-30

Engine Oil Pressure Switch...............8W-40

Engine Starter Motor....................8W-21

Engine Starter Motor Relay...............8W-21

Fog Lamp Relays....................8W-50, 51

Fog Lamp Switches..................8W-50, 51

Fog Lamps.........................8W-50, 51

Fuel Injectors..........................8W-30

Fuel Pump Module.....................8W-30

Fuel Pump Relay.......................8W-30

Fuse Block............................8W-11Component Page

Fuses (FB)............................8W-11

Fuses (PDC)...........................8W-10

Fusible Link........................8W-20, 21

Generator.............................8W-20

Glove Box Lamp And Switch..............8W-44

Grounds..............................8W-15

Halo Lamp............................8W-44

Headlamp Dimmer And Optical Horn Switch .8W-50

Headlamp Leveling Motors...............8W-50

Headlamp Leveling Switch...............8W-50

Headlamp Switch.......................8W-50

Headlamps............................8W-50

High Speed Warning Module..............8W-40

Horn Relay...........................8W-41

Horn Switches.........................8W-41

Horns................................8W-41

IAT/Map Sensor........................8W-30

Idle Air Control Motor...................8W-30

Ignition Coil Pack......................8W-30

Ignition Switch........................8W-10

Illumination Lamps.....................8W-40

Immobilizer...........................8W-61

Immobilizer Engine Sensor............8W-30, 61

Indicator Lamps........................8W-40

Instrument Cluster.....................8W-40

Intermittent Wipe/Wash Switch............8W-53

Key-In Switch.........................8W-40

Knock Sensor..........................8W-30

License Lamps.........................8W-51

Map/Reading Lamps....................8W-44

Noise Supressor.....................8W-10, 30

Oxygen Sensors........................8W-30

Park Brake Switch...................8W-40, 50

Park/Neutral Position Switch...........8W-30, 51

Park/Turn Signal Lamps..............8W-50, 52

Power Distribution Center................8W-10

Power Folding Mirror Relay...............8W-62

Power Mirror Fuse Holder................8W-62

Power Mirrors.........................8W-62

Power Steering Pressure Switch...........8W-30

Power Sunroof Motor....................8W-64

Power Window Motors...................8W-60

Power Window Switches.................8W-60

Powertrain Control Module...............8W-30

PRNDL Lamp.........................8W-44

Radiator Fan Motor.....................8W-42

Radio................................8W-47

Rear Window Defogger..................8W-48

Rear Window Defogger Switch.............8W-48

Remote Keyless Entry Module.............8W-61

Remote Keyless Entry Program

Module Connector....................8W-61

PL8W - 02 COMPONENT INDEX 8W - 02 - 1