DODGE NEON 1999 Service Repair Manual

Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 901 of 1200

Page 902 of 1200

STEERING

CONTENTS

page page

GENERAL INFORMATION................... 1

POWER STEERING PUMP.................. 9STEERING COLUMN...................... 35

STEERING GEAR........................ 26

GENERAL INFORMATION

INDEX

page page

GENERAL INFORMATION

STEERING SYSTEM AND COMPONENT

DESCRIPTION......................... 1DIAGNOSIS AND TESTING

STEERING SYSTEM DIAGNOSIS CHARTS..... 2

GENERAL INFORMATION

STEERING SYSTEM AND COMPONENT

DESCRIPTION

This vehicle comes with power steering as stan-

dard equipment and is the only steering system

available.

The power steering system consists of these six

major components. Power Steering Pump, Power

Steering Gear, Power Steering Reservoir, Power

Steering Supply and Pressure Hoses, and Power

Steering Fluid Return Hose. Turning of the steering

wheel is converted into linear travel through themeshing of the helical pinion teeth with the rack

teeth. Power assist steering is provided by an open

center, rotary type control valve. It is used to direct

oil from the power steering pump to either side of the

integral steering rack piston.

Road feel is controlled by the diameter of a torsion

bar which initially steers the vehicle. As steering

effort increases as in a turn, the torsion bar twists,

causing relative rotary motion between the rotary

valve body and valve spool. This movement directs

oil behind the integral rack piston, which in turn,

builds up hydraulic pressure and assists in the turn-

ing effort.

PLSTEERING 19 - 1

Page 903 of 1200

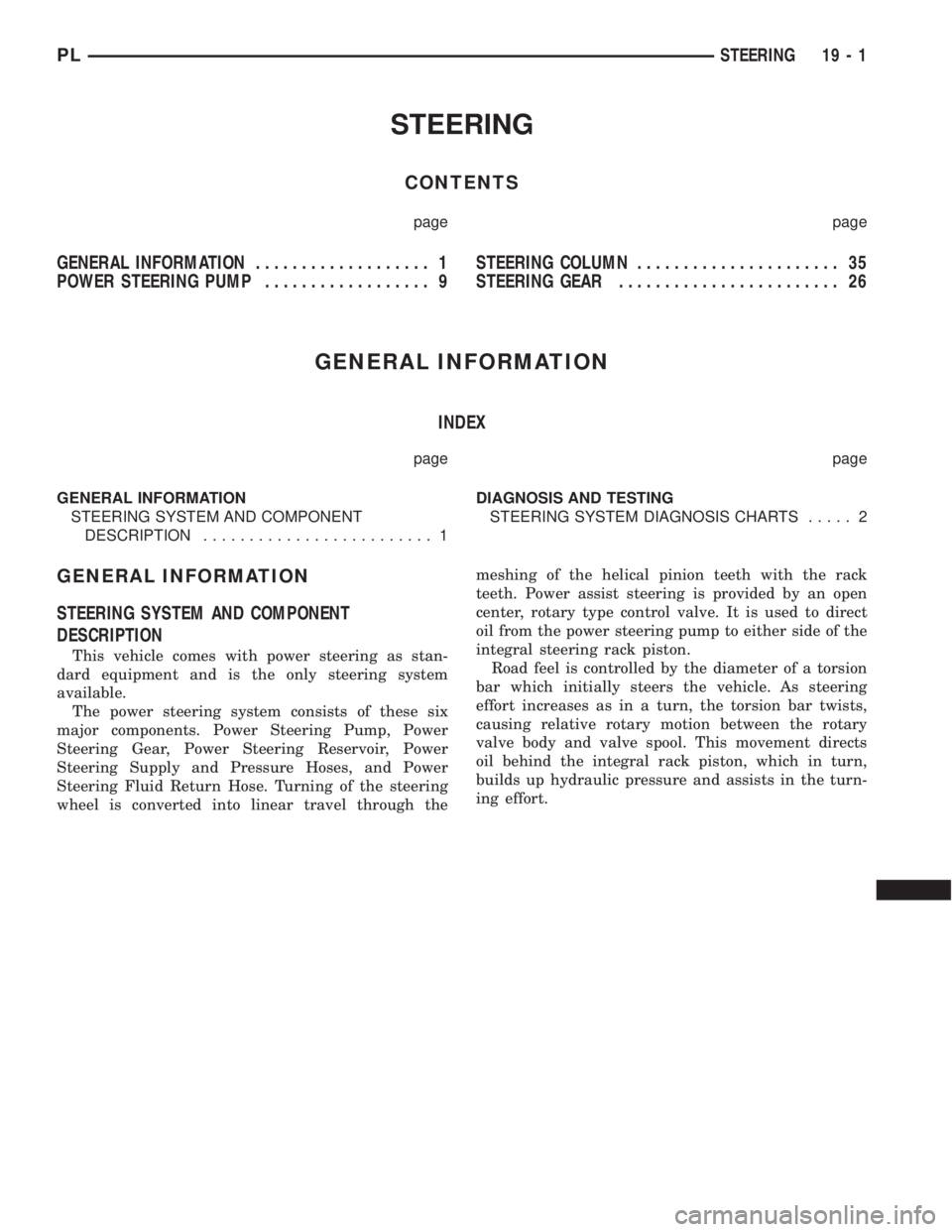

DIAGNOSIS AND TESTING

STEERING SYSTEM DIAGNOSIS CHARTS

STEERING NOISE

There is some noise in all power steering systems.

One of the most common is a hissing sound evidentat standstill parking. Hiss is a very high frequency

noise similar to that experienced while slowly closing

a water tap. The noise is present in every valve and

results in high velocity fluid passing valve orifice

edges. There is no relationship between this noise

and performance of the steering. Hiss may be

expected when steering wheel at end of travel or

slowly turning at standstill.

CONDITION POSSIBLE CAUSES CORRECTION

Objectionable Hiss Or Whistle 1. Damaged or mispositioned

steering column coupler to dash

panel seal.1. Check for proper seal between

steering column coupler and dash

seal.

2. Noisy valve in power steering

gear.2. Replace steering gear assembly.

Rattle Or Clunk 1. Steering gear loose on front

suspension crossmember.1. Check steering gear to front

suspension crossmember mounting

bolts. Tighten to the specified torque

if found to be loose.

2. Front suspension crossmember to

frame bolts or studs loose.2. Tighten the front suspension

crossmember attaching bolts or

studs to the specified torque.

3. Loose tie rod (outer or inner). 3. Check tie rod pivot points for

wear. Replace worn/loose parts as

required.

4. Loose lower control arm to front

suspension crossmember bolts.4. Tighten control arm mounting

bolts to the specified torques.

5. Loose strut assembly to body

attaching bolts or nuts.5. Check upper strut mount to body

attaching bolts or nuts for looseness.

If required, tighten to the specified

torques.

6. Power steering fluid pressure

hose touching the body of the

vehicle.6. Adjust hose to proper position by

loosening, repositioning, and

tightening fitting to specified torque.

Do not bend tubing.

7. Noise internal to power steering

gear.7. Replace steering gear assembly.

8. Damaged front suspension

crossmember.8. Replace front suspension

crossmember.

Chirp or squeal (in the area of the

power steering pump). Particularly

noticeable at full wheel travel and

during standstill parking.1. Loose power steering pump drive

belt.1. Adjust power steering pump drive

belt to specified tension.

19 - 2 STEERINGPL

Page 904 of 1200

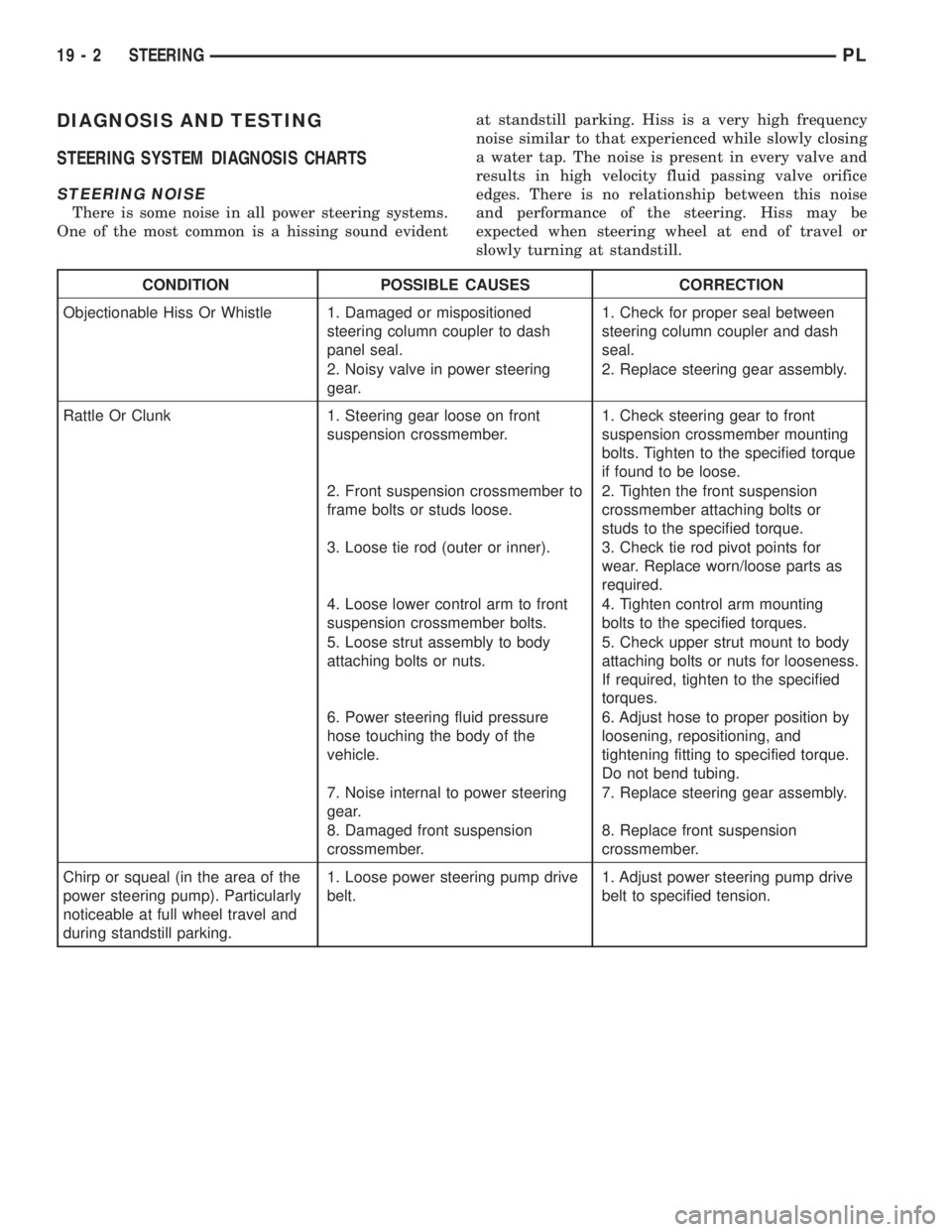

CONDITION POSSIBLE CAUSES CORRECTION

Power steering pump growl results from the development of high pressure fluid flow. Normally this noise should

not be high enough to be objectionable. Abnormal situations, such as a low oil level causing aeration or hose

touching the vehicle body, can create a noise level that could bring complaints.

Whine Or Growl (Pump Noise) 1. Low fluid level. 1. Fill power steering fluid reservoir

to proper level and perform leakage

diagnosis. (Recheck fluid level after

power steering fluid is free of air.)

2. Power steering hose touching

vehicle body or frame.2. Reposition power steering hose.

Replace hose if tube ends are bent.

3. Extreme wear of power steering

pump internal parts.3. Replace power steering pump and

flush system.

Sucking Air Sound 1. Loose clamp on power steering

fluid low pressure hose.1. Tighten or replace hose clamp.

2. Missing O-Ring on power steering

hose connection.2. Inspect connection and replace

O-Ring as required.

3. Low power steering fluid level 3. Fill power steering fluid reservoir

to proper level and perform leakage

diagnosis.

4. Air leak between power steering

fluid reservoir and power steering

pump.4. Inspect and or replace power

steering fluid reservoir as required.

SQUEAK OR RUBBING SOUND 1. Sound coming from steering

column.1.Check for squeak in steering

column. Inspect for contact between

shroud, intermediate shaft, column,

and steering wheel. Realign if

necessary.

2. Check for lack or grease on

steering column dash panel to lower

coupler seal.

2. Sound internal to steering gear. 1. Replace steering gear assembly.

SCRUBBING OR KNOCKING

SOUND1. Incorrect tire size. 1. Verify that tire size on vehicle is

the same as originally supplied.

2. Check clearance between tires

and other vehicle components,

through the full travel of the

suspension.2. Correct as necessary.

3. Check for interference between

steering gear and other

components.3.Correct as necessary.

4.Incorrect steering gear supplied. 4. Replace steering gear with correct

steering gear for specific vehicle.

PLSTEERING 19 - 3

DIAGNOSIS AND TESTING (Continued)

Page 905 of 1200

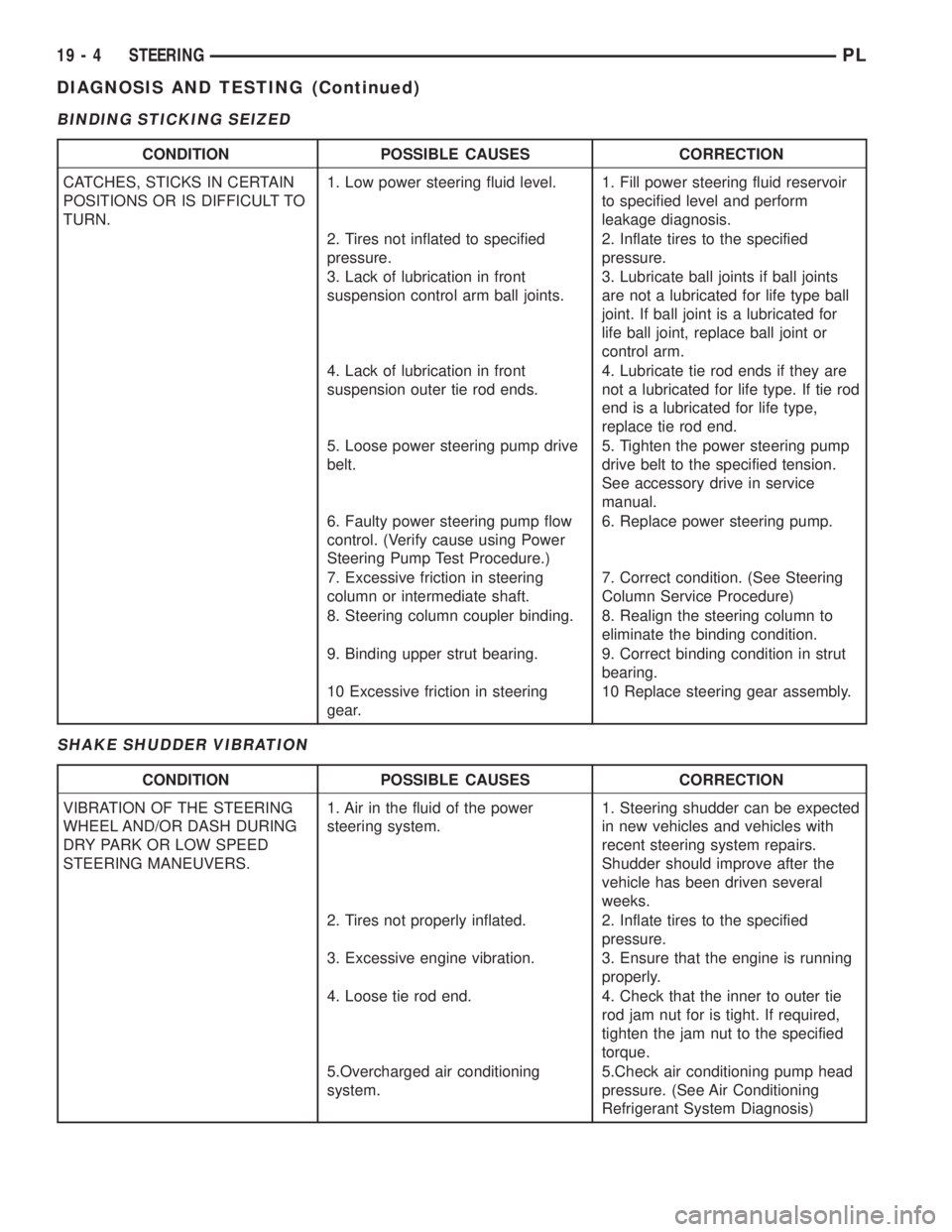

BINDING STICKING SEIZED

SHAKE SHUDDER VIBRATION

CONDITION POSSIBLE CAUSES CORRECTION

CATCHES, STICKS IN CERTAIN

POSITIONS OR IS DIFFICULT TO

TURN.1. Low power steering fluid level. 1. Fill power steering fluid reservoir

to specified level and perform

leakage diagnosis.

2. Tires not inflated to specified

pressure.2. Inflate tires to the specified

pressure.

3. Lack of lubrication in front

suspension control arm ball joints.3. Lubricate ball joints if ball joints

are not a lubricated for life type ball

joint. If ball joint is a lubricated for

life ball joint, replace ball joint or

control arm.

4. Lack of lubrication in front

suspension outer tie rod ends.4. Lubricate tie rod ends if they are

not a lubricated for life type. If tie rod

end is a lubricated for life type,

replace tie rod end.

5. Loose power steering pump drive

belt.5. Tighten the power steering pump

drive belt to the specified tension.

See accessory drive in service

manual.

6. Faulty power steering pump flow

control. (Verify cause using Power

Steering Pump Test Procedure.)6. Replace power steering pump.

7. Excessive friction in steering

column or intermediate shaft.7. Correct condition. (See Steering

Column Service Procedure)

8. Steering column coupler binding. 8. Realign the steering column to

eliminate the binding condition.

9. Binding upper strut bearing. 9. Correct binding condition in strut

bearing.

10 Excessive friction in steering

gear.10 Replace steering gear assembly.

CONDITION POSSIBLE CAUSES CORRECTION

VIBRATION OF THE STEERING

WHEEL AND/OR DASH DURING

DRY PARK OR LOW SPEED

STEERING MANEUVERS.1. Air in the fluid of the power

steering system.1. Steering shudder can be expected

in new vehicles and vehicles with

recent steering system repairs.

Shudder should improve after the

vehicle has been driven several

weeks.

2. Tires not properly inflated. 2. Inflate tires to the specified

pressure.

3. Excessive engine vibration. 3. Ensure that the engine is running

properly.

4. Loose tie rod end. 4. Check that the inner to outer tie

rod jam nut for is tight. If required,

tighten the jam nut to the specified

torque.

5.Overcharged air conditioning

system.5.Check air conditioning pump head

pressure. (See Air Conditioning

Refrigerant System Diagnosis)

19 - 4 STEERINGPL

DIAGNOSIS AND TESTING (Continued)

Page 906 of 1200

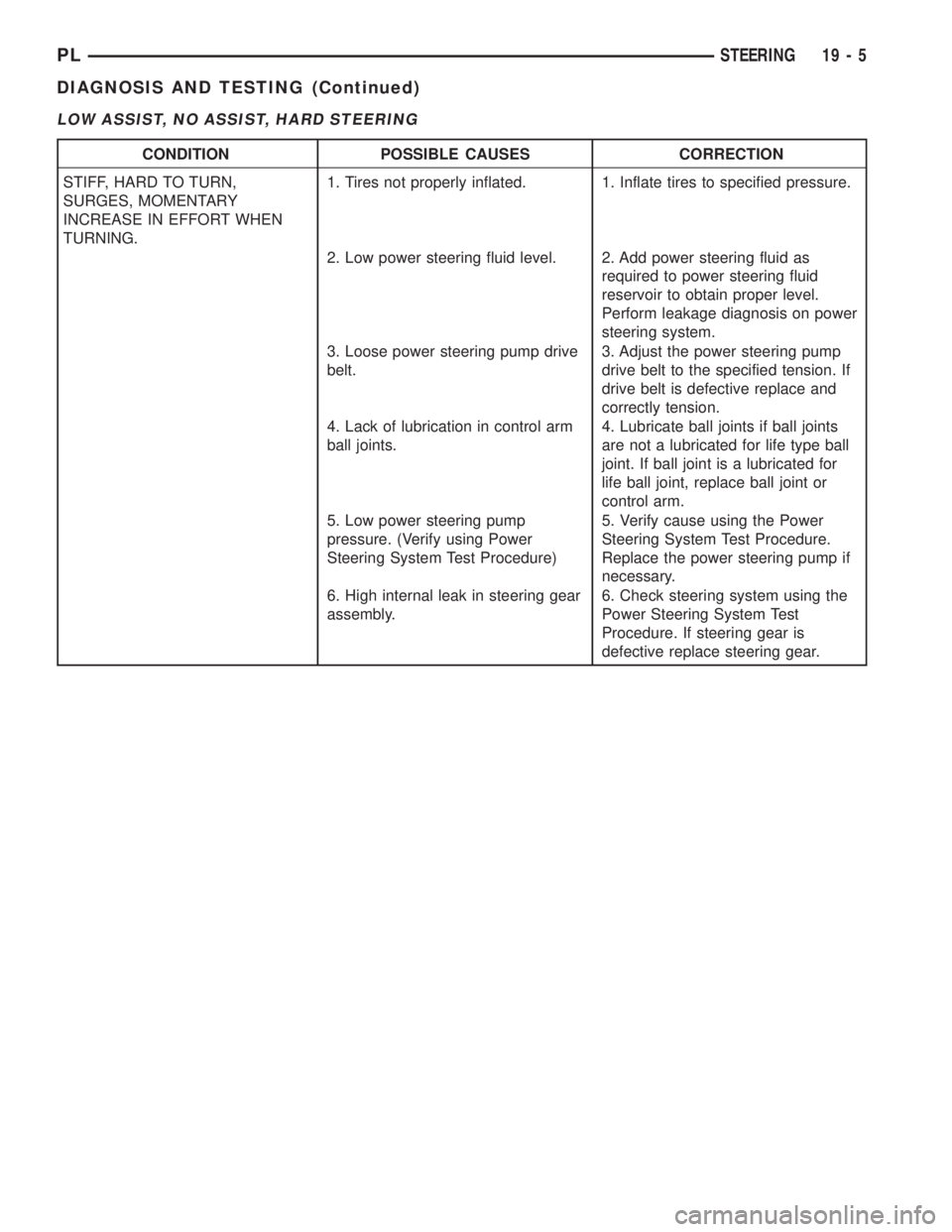

LOW ASSIST, NO ASSIST, HARD STEERING

CONDITION POSSIBLE CAUSES CORRECTION

STIFF, HARD TO TURN,

SURGES, MOMENTARY

INCREASE IN EFFORT WHEN

TURNING.1. Tires not properly inflated. 1. Inflate tires to specified pressure.

2. Low power steering fluid level. 2. Add power steering fluid as

required to power steering fluid

reservoir to obtain proper level.

Perform leakage diagnosis on power

steering system.

3. Loose power steering pump drive

belt.3. Adjust the power steering pump

drive belt to the specified tension. If

drive belt is defective replace and

correctly tension.

4. Lack of lubrication in control arm

ball joints.4. Lubricate ball joints if ball joints

are not a lubricated for life type ball

joint. If ball joint is a lubricated for

life ball joint, replace ball joint or

control arm.

5. Low power steering pump

pressure. (Verify using Power

Steering System Test Procedure)5. Verify cause using the Power

Steering System Test Procedure.

Replace the power steering pump if

necessary.

6. High internal leak in steering gear

assembly.6. Check steering system using the

Power Steering System Test

Procedure. If steering gear is

defective replace steering gear.

PLSTEERING 19 - 5

DIAGNOSIS AND TESTING (Continued)

Page 907 of 1200

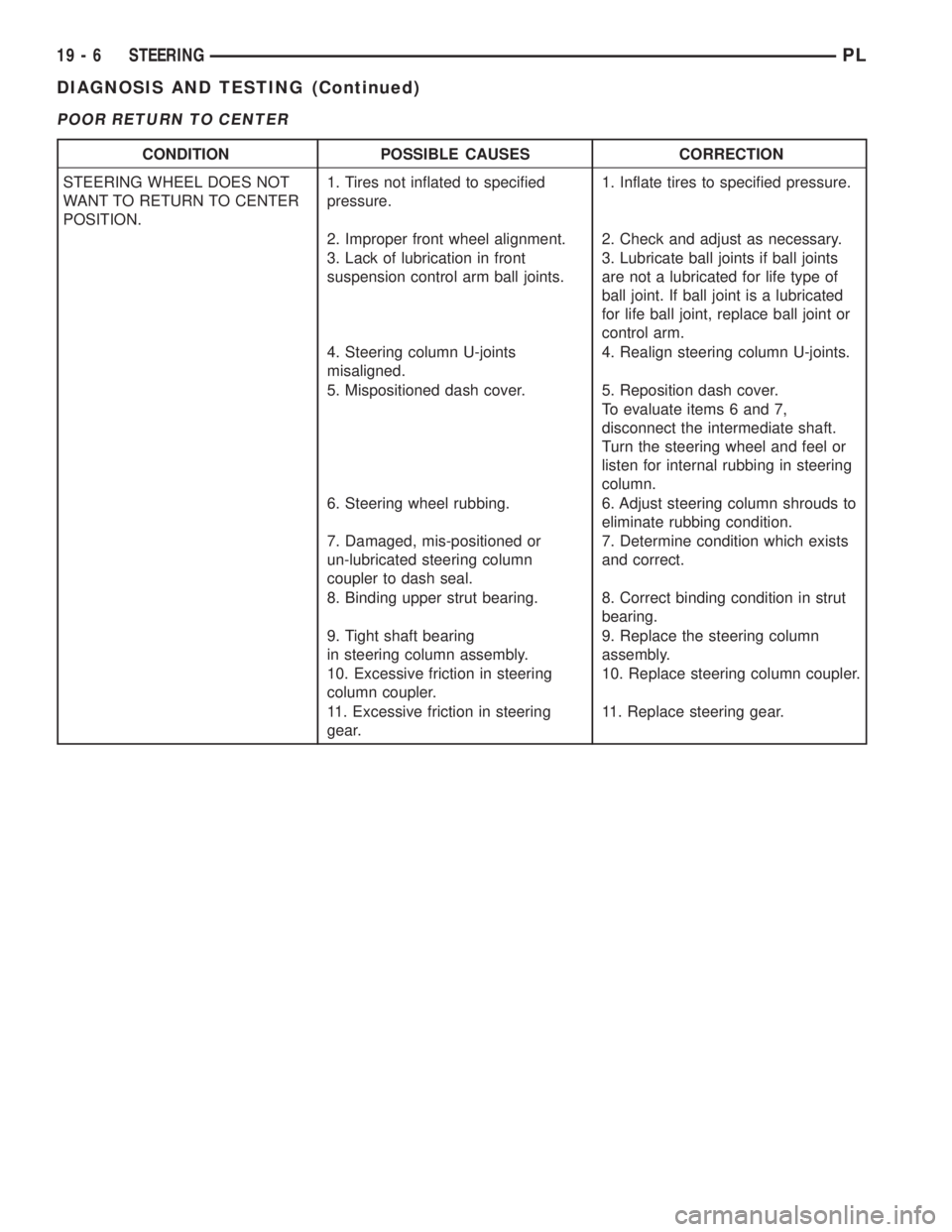

POOR RETURN TO CENTER

CONDITION POSSIBLE CAUSES CORRECTION

STEERING WHEEL DOES NOT

WANT TO RETURN TO CENTER

POSITION.1. Tires not inflated to specified

pressure.1. Inflate tires to specified pressure.

2. Improper front wheel alignment. 2. Check and adjust as necessary.

3. Lack of lubrication in front

suspension control arm ball joints.3. Lubricate ball joints if ball joints

are not a lubricated for life type of

ball joint. If ball joint is a lubricated

for life ball joint, replace ball joint or

control arm.

4. Steering column U-joints

misaligned.4. Realign steering column U-joints.

5. Mispositioned dash cover. 5. Reposition dash cover.

To evaluate items 6 and 7,

disconnect the intermediate shaft.

Turn the steering wheel and feel or

listen for internal rubbing in steering

column.

6. Steering wheel rubbing. 6. Adjust steering column shrouds to

eliminate rubbing condition.

7. Damaged, mis-positioned or

un-lubricated steering column

coupler to dash seal.7. Determine condition which exists

and correct.

8. Binding upper strut bearing. 8. Correct binding condition in strut

bearing.

9. Tight shaft bearing

in steering column assembly.9. Replace the steering column

assembly.

10. Excessive friction in steering

column coupler.10. Replace steering column coupler.

11. Excessive friction in steering

gear.11. Replace steering gear.

19 - 6 STEERINGPL

DIAGNOSIS AND TESTING (Continued)

Page 908 of 1200

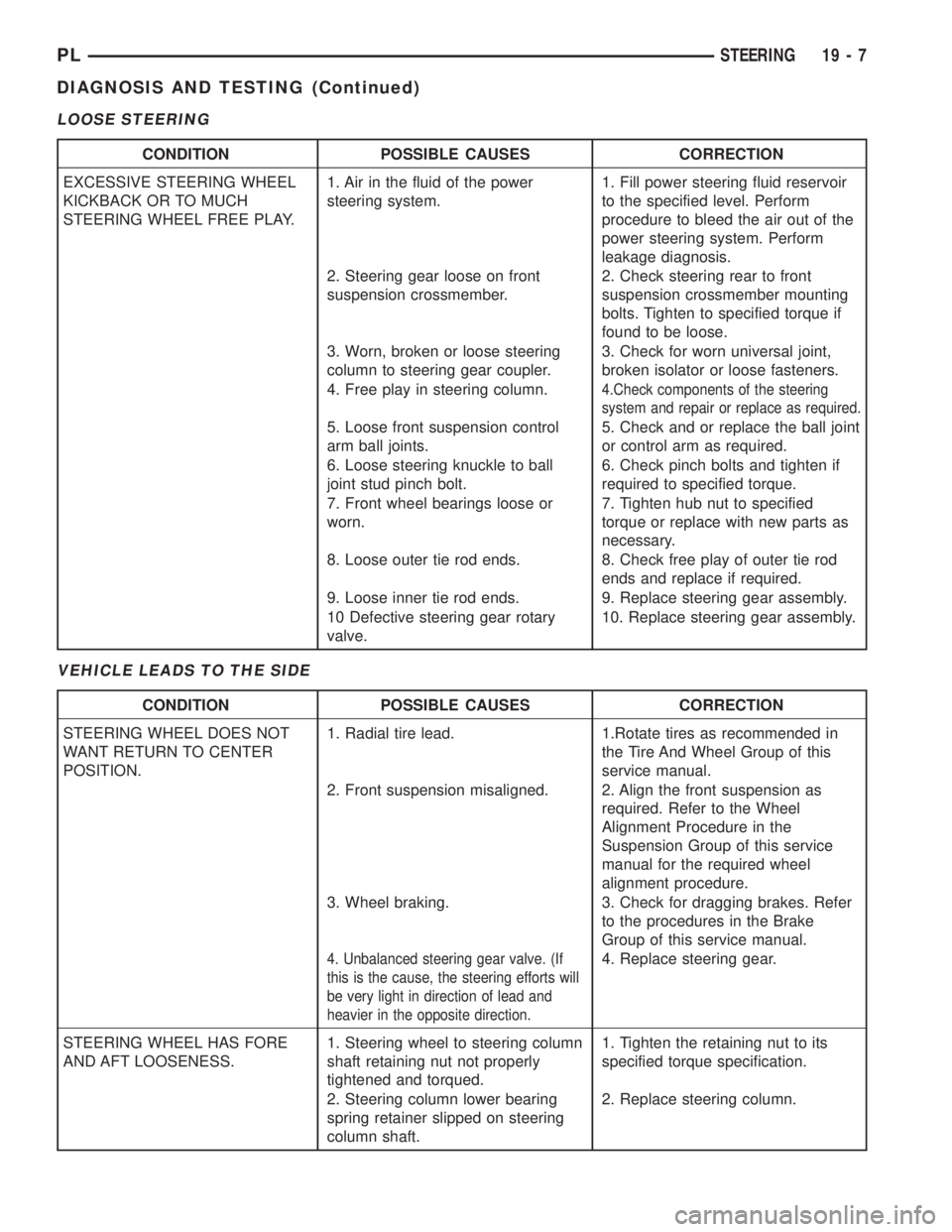

LOOSE STEERING

VEHICLE LEADS TO THE SIDE

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE STEERING WHEEL

KICKBACK OR TO MUCH

STEERING WHEEL FREE PLAY.1. Air in the fluid of the power

steering system.1. Fill power steering fluid reservoir

to the specified level. Perform

procedure to bleed the air out of the

power steering system. Perform

leakage diagnosis.

2. Steering gear loose on front

suspension crossmember.2. Check steering rear to front

suspension crossmember mounting

bolts. Tighten to specified torque if

found to be loose.

3. Worn, broken or loose steering

column to steering gear coupler.3. Check for worn universal joint,

broken isolator or loose fasteners.

4. Free play in steering column.

4.Check components of the steering

system and repair or replace as required.

5. Loose front suspension control

arm ball joints.5. Check and or replace the ball joint

or control arm as required.

6. Loose steering knuckle to ball

joint stud pinch bolt.6. Check pinch bolts and tighten if

required to specified torque.

7. Front wheel bearings loose or

worn.7. Tighten hub nut to specified

torque or replace with new parts as

necessary.

8. Loose outer tie rod ends. 8. Check free play of outer tie rod

ends and replace if required.

9. Loose inner tie rod ends. 9. Replace steering gear assembly.

10 Defective steering gear rotary

valve.10. Replace steering gear assembly.

CONDITION POSSIBLE CAUSES CORRECTION

STEERING WHEEL DOES NOT

WANT RETURN TO CENTER

POSITION.1. Radial tire lead. 1.Rotate tires as recommended in

the Tire And Wheel Group of this

service manual.

2. Front suspension misaligned. 2. Align the front suspension as

required. Refer to the Wheel

Alignment Procedure in the

Suspension Group of this service

manual for the required wheel

alignment procedure.

3. Wheel braking. 3. Check for dragging brakes. Refer

to the procedures in the Brake

Group of this service manual.

4. Unbalanced steering gear valve. (If

this is the cause, the steering efforts will

be very light in direction of lead and

heavier in the opposite direction.4. Replace steering gear.

STEERING WHEEL HAS FORE

AND AFT LOOSENESS.1. Steering wheel to steering column

shaft retaining nut not properly

tightened and torqued.1. Tighten the retaining nut to its

specified torque specification.

2. Steering column lower bearing

spring retainer slipped on steering

column shaft.2. Replace steering column.

PLSTEERING 19 - 7

DIAGNOSIS AND TESTING (Continued)

Page 909 of 1200

POWER STEERING FLUID LEAK

FOAMY OR MILKY POWER STEERING FLUID

CONDITION POSSIBLE CAUSES CORRECTION

LOW FLUID LEVEL WITH: NO

VISIBLE SIGNS OF A LEAK ON

THE STEERING GEAR, POWER

STEERING PUMP, FLOOR OR

ANYWHERE ELSE.1. Overfilled power steering pump

fluid reservoir.1. Adjust the power steering fluid fill

to the correct level.

LOW FLUID LEVEL WITH:

VISIBLE LEAK ON STEERING

GEAR, POWER STEERING

PUMP, FLOOR OR ANYWHERE

ELSE.2. Power steering hose connections

at the power steering pump or

steering gear.2. Check for loose fittings and if

found, tighten the fitting to its

specified torque. If fittings are tight

examine the fittings for damaged or

missing O-ring seals and replace as

required.

3. Power steering pump or power

steering gear leaking.3. Identify the location of the leak

and repair or replace the component

as required. Refer to Power Steering

Pump and/or Power Steering Gear in

this group of the service manual for

required procedures.

CONDITION POSSIBLE CAUSES CORRECTION

AERATION AND OVERFLOW OF

FLUID.1. Air leaks. 1. Check for an air leak into the

power steering system as described

under Sucking Air Diagnosis and

correct condition.

2. Low fluid level. 2. Extremely cold temperatures may

cause power steering fluid aeration if

the power steering fluid is low. Add

power steering fluid as required to

bring level up to specification.

3. Cracked power steering pump

housing.3. Remove power steering pump

from vehicle and inspect the power

steering pump housing for cracks. If

a defect in the housing is found,

replace the power steering pump.

4. Water contamination. 4. Drain the power steering fluid

from the system if there is evidence

of contamination. Then refill the

system with fresh clean power

steering fluid.

19 - 8 STEERINGPL

DIAGNOSIS AND TESTING (Continued)

Page 910 of 1200

POWER STEERING PUMP

INDEX

page page

DESCRIPTION AND OPERATION

POWER STEERING PUMP................. 9

DIAGNOSIS AND TESTING

POWER STEERING SYSTEM TEST

PROCEDURE......................... 10

SERVICE PROCEDURES

POWER STEERING PUMP

FLOW CONTROL VALVE SEAL............ 11

POWER STEERING PUMP

INITIAL OPERATION.................... 11

POWER STEERING PUMP

SUCTION PORT SEAL.................. 12

POWER STEERING SYSTEM

FLUID LEVEL CHECK................... 11

REMOVAL AND INSTALLATION

POWER STEERING FLUID PRESSURE HOSE . . 13

POWER STEERING FLUID RESERVOIR...... 21POWER STEERING FLUID RETURN HOSE.... 15

POWER STEERING FLUID SUPPLY HOSE

RESERVOIR TO POWER STEERING PUMP . . 17

POWER STEERING PRESSURE SWITCH..... 12

POWER STEERING PUMP (ALL ENGINES).... 18

DISASSEMBLY AND ASSEMBLY

POWER STEERING PUMP DRIVE PULLEY.... 22

POWER STEERING PUMP MOUNTING

BRACKET............................ 23

SPECIFICATIONS

POWER STEERING PUMP FASTENER

TORQUE SPECIFICATIONS.............. 25

POWER STEERING PUMP FLOW

SPECIFICATIONS...................... 25

SPECIAL TOOLS

POWER STEERING PUMP................. 25

DESCRIPTION AND OPERATION

POWER STEERING PUMP

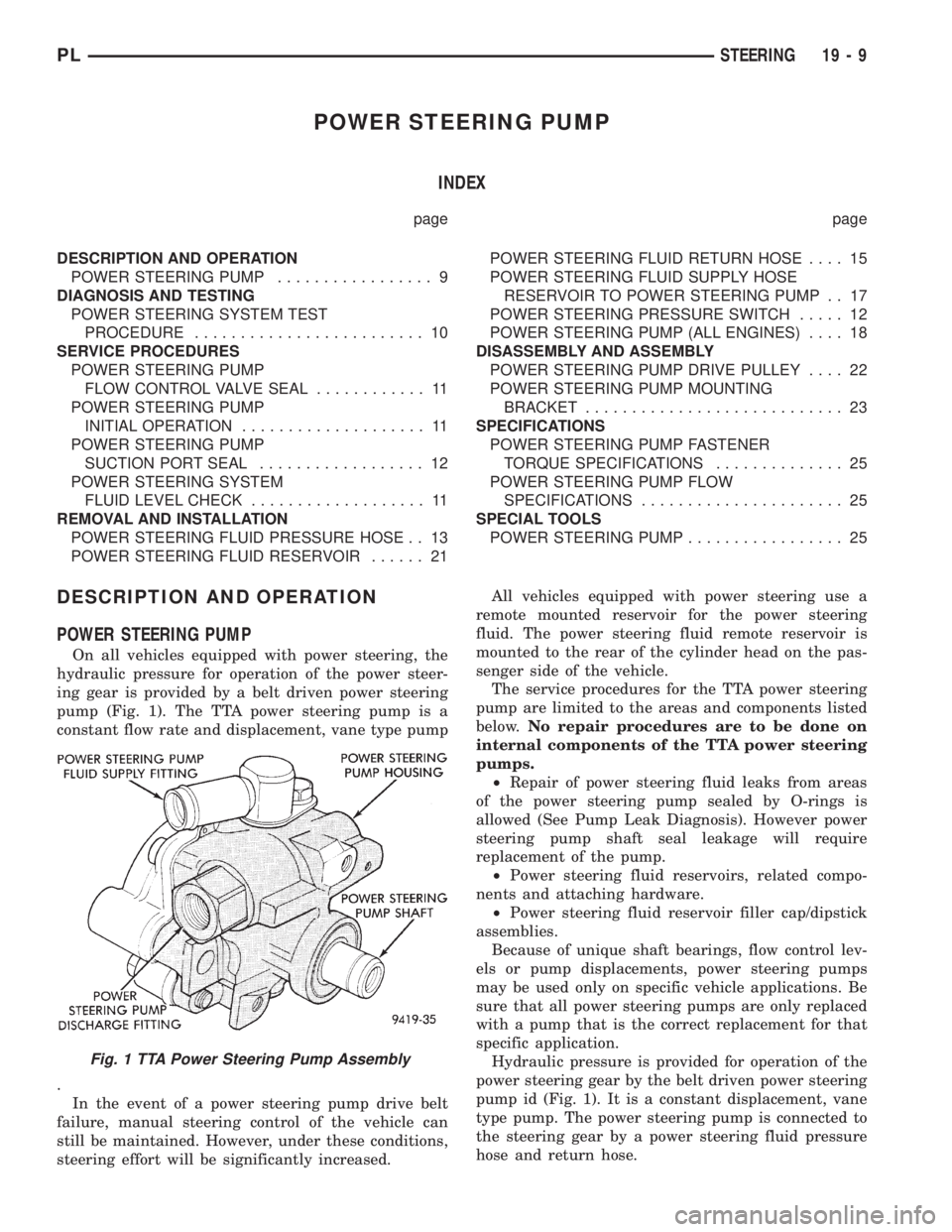

On all vehicles equipped with power steering, the

hydraulic pressure for operation of the power steer-

ing gear is provided by a belt driven power steering

pump (Fig. 1). The TTA power steering pump is a

constant flow rate and displacement, vane type pump

.

In the event of a power steering pump drive belt

failure, manual steering control of the vehicle can

still be maintained. However, under these conditions,

steering effort will be significantly increased.All vehicles equipped with power steering use a

remote mounted reservoir for the power steering

fluid. The power steering fluid remote reservoir is

mounted to the rear of the cylinder head on the pas-

senger side of the vehicle.

The service procedures for the TTA power steering

pump are limited to the areas and components listed

below.No repair procedures are to be done on

internal components of the TTA power steering

pumps.

²Repair of power steering fluid leaks from areas

of the power steering pump sealed by O-rings is

allowed (See Pump Leak Diagnosis). However power

steering pump shaft seal leakage will require

replacement of the pump.

²Power steering fluid reservoirs, related compo-

nents and attaching hardware.

²Power steering fluid reservoir filler cap/dipstick

assemblies.

Because of unique shaft bearings, flow control lev-

els or pump displacements, power steering pumps

may be used only on specific vehicle applications. Be

sure that all power steering pumps are only replaced

with a pump that is the correct replacement for that

specific application.

Hydraulic pressure is provided for operation of the

power steering gear by the belt driven power steering

pump id (Fig. 1). It is a constant displacement, vane

type pump. The power steering pump is connected to

the steering gear by a power steering fluid pressure

hose and return hose.

Fig. 1 TTA Power Steering Pump Assembly

PLSTEERING 19 - 9