DODGE NEON 1999 Service Repair Manual

Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 881 of 1200

VISUAL INSPECTIONÐDOHC

Before diagnosing or servicing the fuel injection

system, perform a visual inspection for loose, discon-

nected, or misrouted wires and hoses (Fig. 53). Athorough visual inspection that includes the following

checks saves unnecessary test and diagnostic time.

(1) Inspect the battery connections. Clean corroded

terminals (Fig. 31).

(2) Check the 2 PCM 40-way connector for

stretched wires on pushed out terminals (Fig. 54).

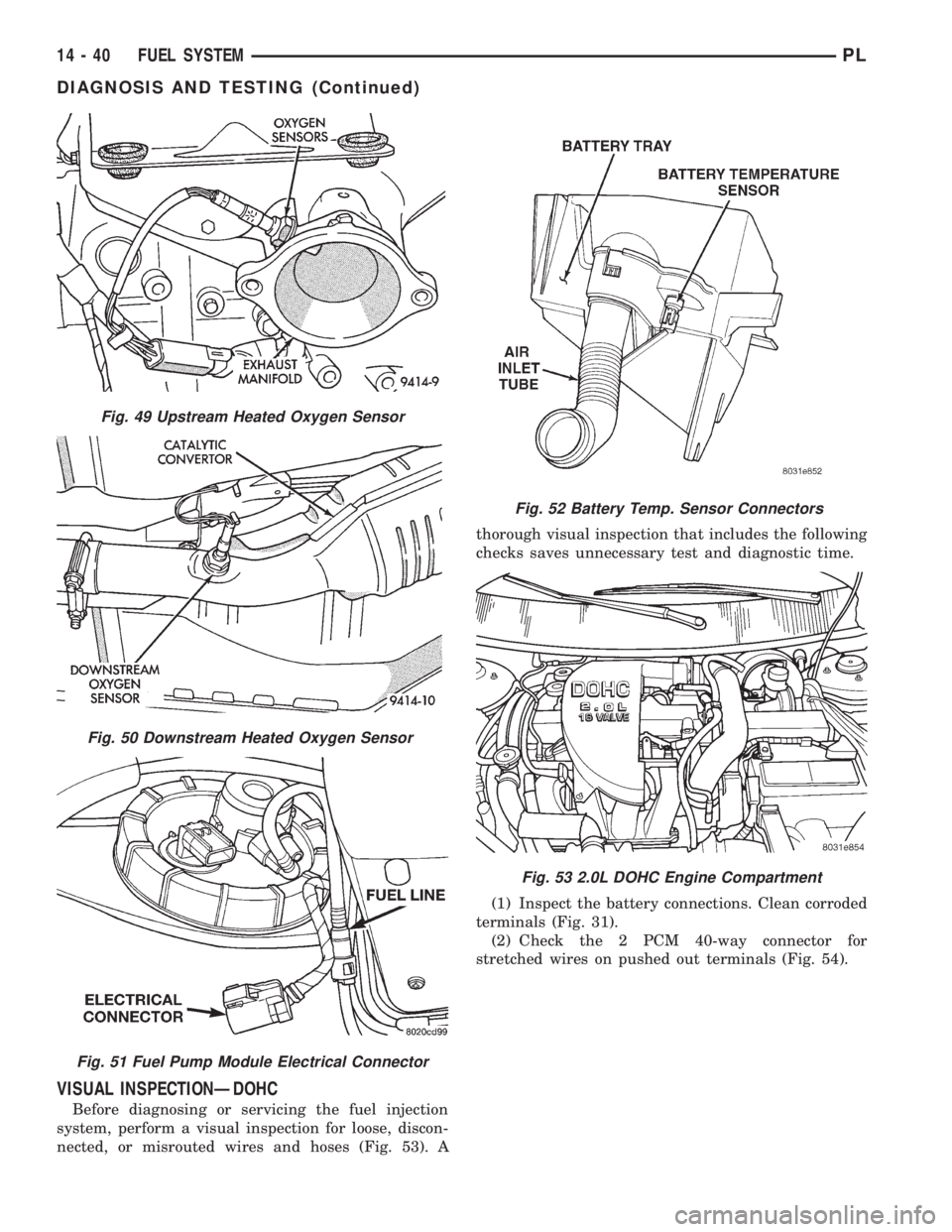

Fig. 49 Upstream Heated Oxygen Sensor

Fig. 50 Downstream Heated Oxygen Sensor

Fig. 51 Fuel Pump Module Electrical Connector

Fig. 52 Battery Temp. Sensor Connectors

Fig. 53 2.0L DOHC Engine Compartment

14 - 40 FUEL SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 882 of 1200

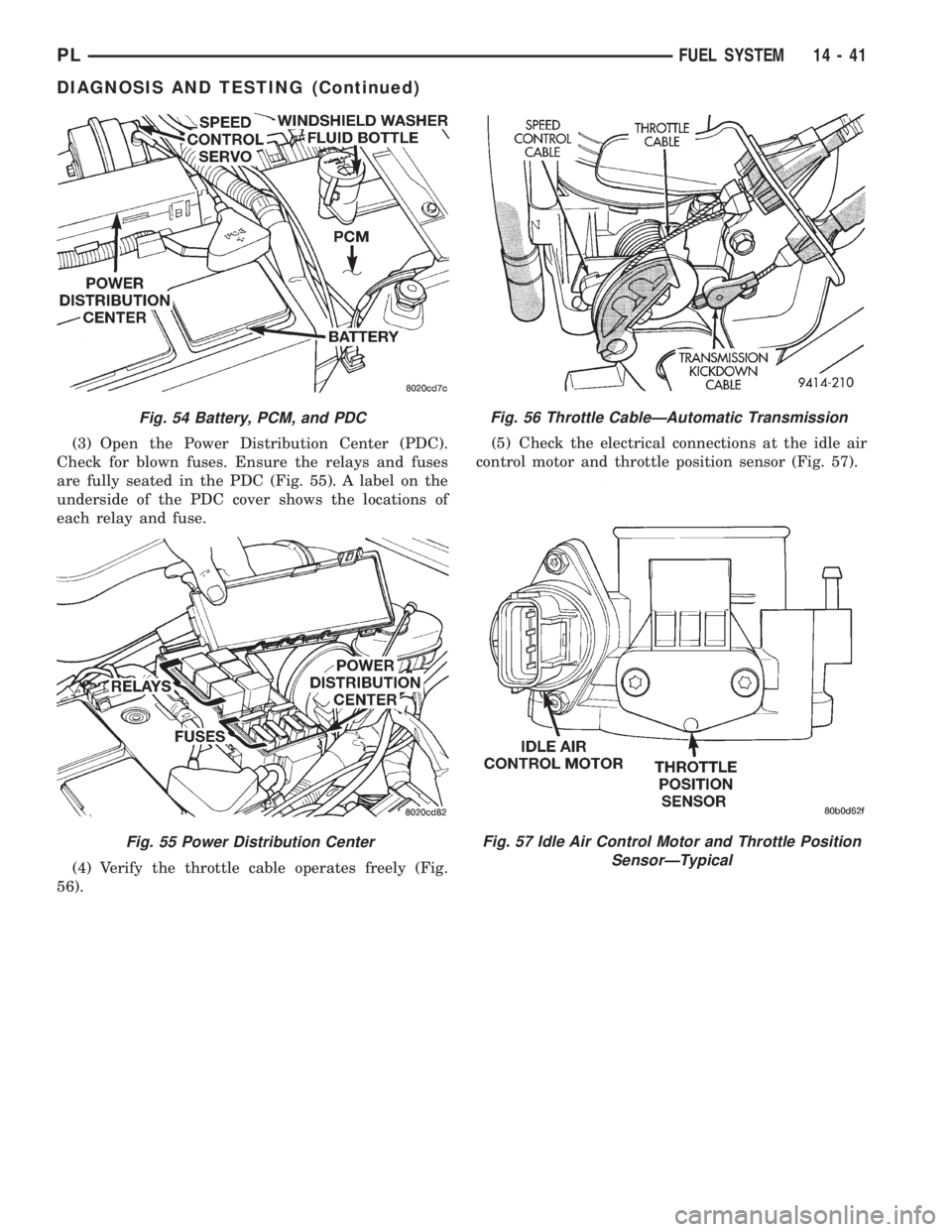

(3) Open the Power Distribution Center (PDC).

Check for blown fuses. Ensure the relays and fuses

are fully seated in the PDC (Fig. 55). A label on the

underside of the PDC cover shows the locations of

each relay and fuse.

(4) Verify the throttle cable operates freely (Fig.

56).(5) Check the electrical connections at the idle air

control motor and throttle position sensor (Fig. 57).

Fig. 54 Battery, PCM, and PDC

Fig. 55 Power Distribution Center

Fig. 56 Throttle CableÐAutomatic Transmission

Fig. 57 Idle Air Control Motor and Throttle Position

SensorÐTypical

PLFUEL SYSTEM 14 - 41

DIAGNOSIS AND TESTING (Continued)

Page 883 of 1200

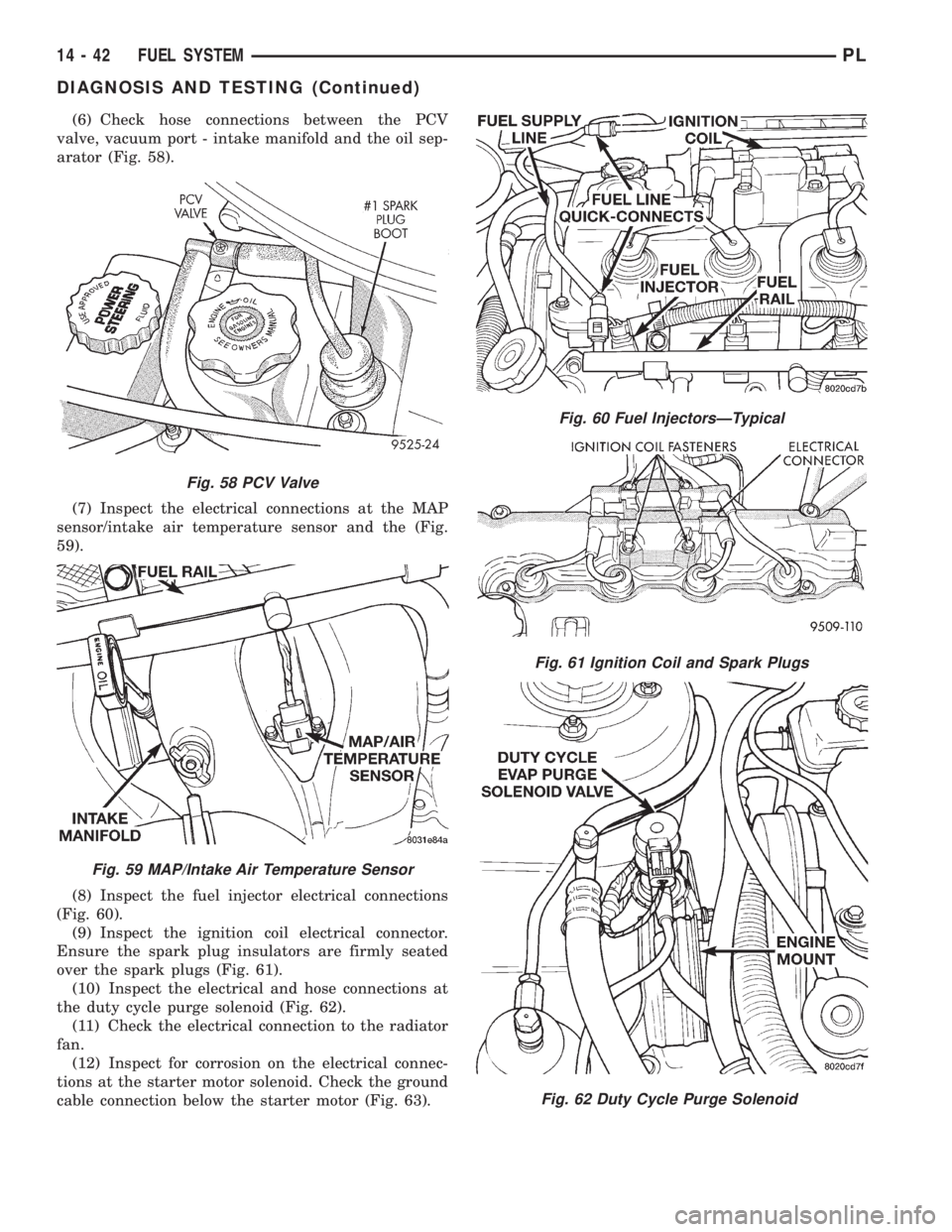

(6) Check hose connections between the PCV

valve, vacuum port - intake manifold and the oil sep-

arator (Fig. 58).

(7) Inspect the electrical connections at the MAP

sensor/intake air temperature sensor and the (Fig.

59).

(8) Inspect the fuel injector electrical connections

(Fig. 60).

(9) Inspect the ignition coil electrical connector.

Ensure the spark plug insulators are firmly seated

over the spark plugs (Fig. 61).

(10) Inspect the electrical and hose connections at

the duty cycle purge solenoid (Fig. 62).

(11) Check the electrical connection to the radiator

fan.

(12) Inspect for corrosion on the electrical connec-

tions at the starter motor solenoid. Check the ground

cable connection below the starter motor (Fig. 63).

Fig. 58 PCV Valve

Fig. 59 MAP/Intake Air Temperature Sensor

Fig. 60 Fuel InjectorsÐTypical

Fig. 61 Ignition Coil and Spark Plugs

Fig. 62 Duty Cycle Purge Solenoid

14 - 42 FUEL SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 884 of 1200

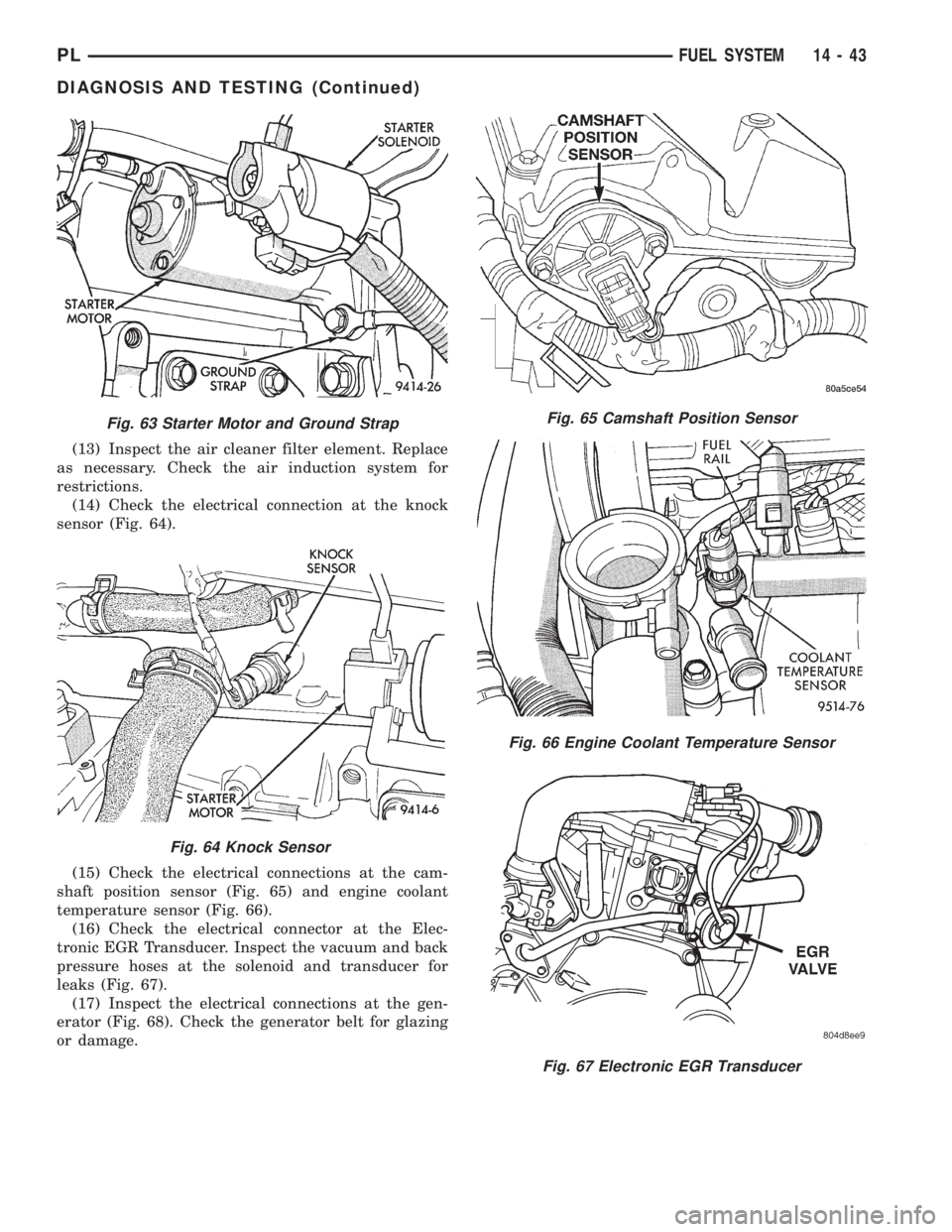

(13) Inspect the air cleaner filter element. Replace

as necessary. Check the air induction system for

restrictions.

(14) Check the electrical connection at the knock

sensor (Fig. 64).

(15) Check the electrical connections at the cam-

shaft position sensor (Fig. 65) and engine coolant

temperature sensor (Fig. 66).

(16) Check the electrical connector at the Elec-

tronic EGR Transducer. Inspect the vacuum and back

pressure hoses at the solenoid and transducer for

leaks (Fig. 67).

(17) Inspect the electrical connections at the gen-

erator (Fig. 68). Check the generator belt for glazing

or damage.

Fig. 63 Starter Motor and Ground Strap

Fig. 64 Knock Sensor

Fig. 65 Camshaft Position Sensor

Fig. 66 Engine Coolant Temperature Sensor

Fig. 67 Electronic EGR Transducer

PLFUEL SYSTEM 14 - 43

DIAGNOSIS AND TESTING (Continued)

Page 885 of 1200

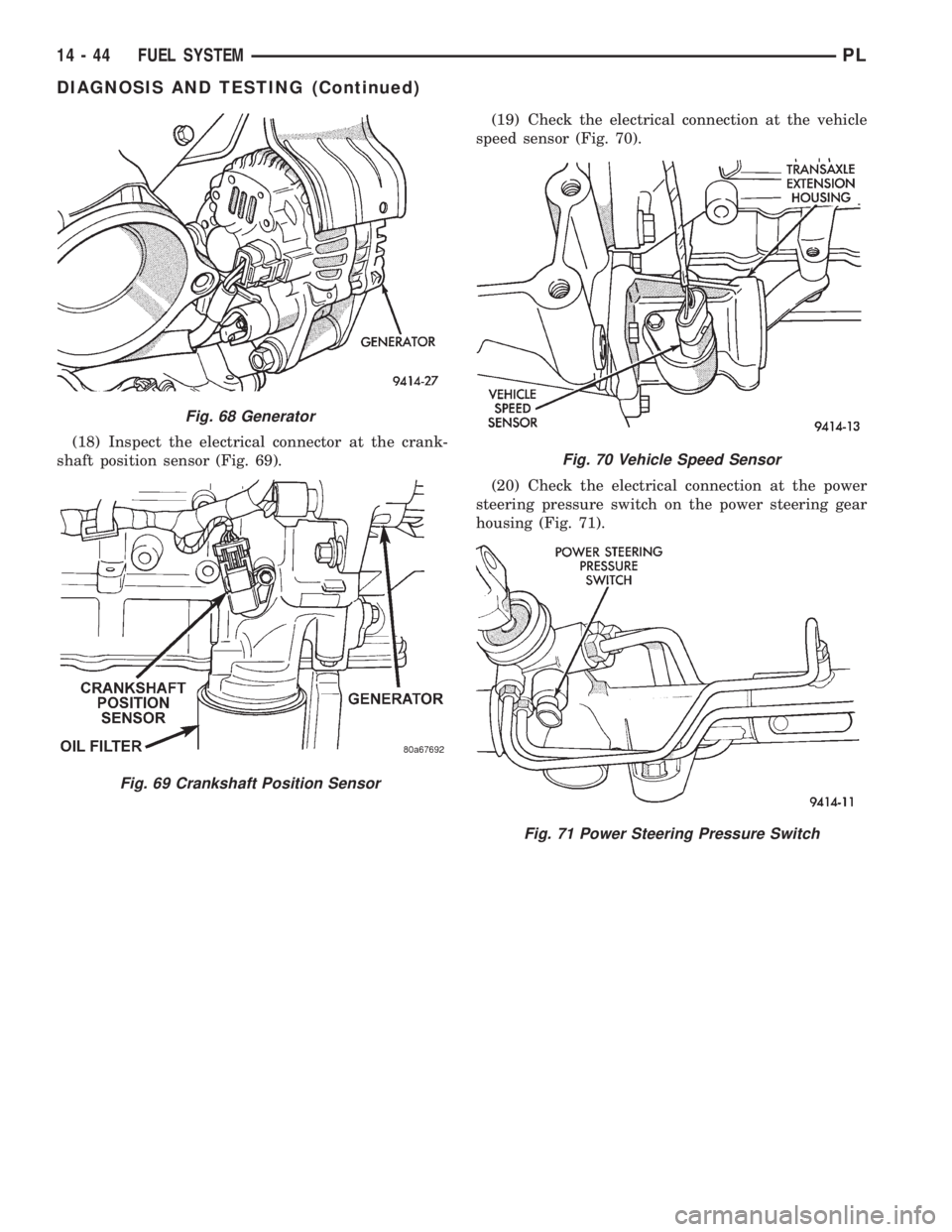

(18) Inspect the electrical connector at the crank-

shaft position sensor (Fig. 69).(19) Check the electrical connection at the vehicle

speed sensor (Fig. 70).

(20) Check the electrical connection at the power

steering pressure switch on the power steering gear

housing (Fig. 71).

Fig. 68 Generator

Fig. 69 Crankshaft Position Sensor

Fig. 70 Vehicle Speed Sensor

Fig. 71 Power Steering Pressure Switch

14 - 44 FUEL SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 886 of 1200

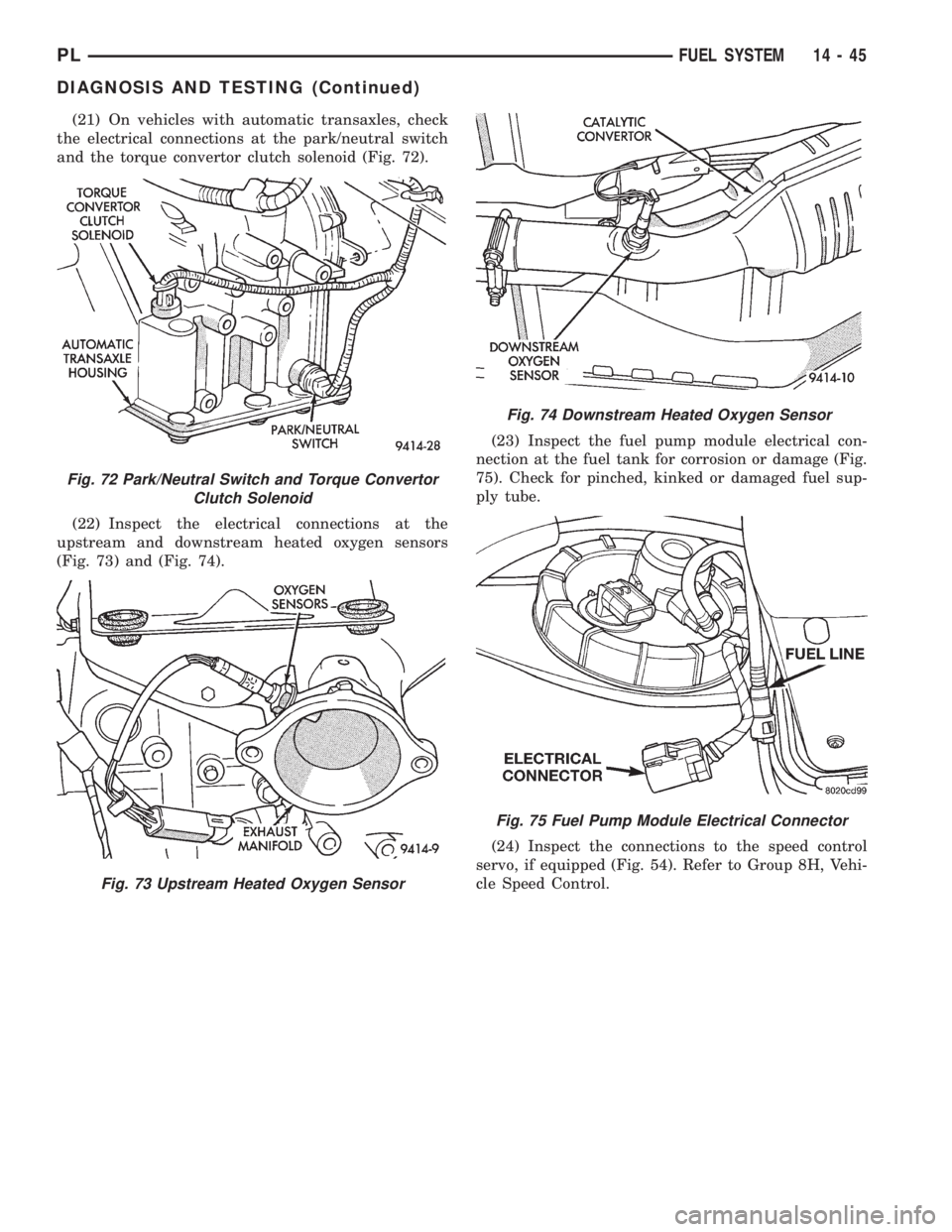

(21) On vehicles with automatic transaxles, check

the electrical connections at the park/neutral switch

and the torque convertor clutch solenoid (Fig. 72).

(22) Inspect the electrical connections at the

upstream and downstream heated oxygen sensors

(Fig. 73) and (Fig. 74).(23) Inspect the fuel pump module electrical con-

nection at the fuel tank for corrosion or damage (Fig.

75). Check for pinched, kinked or damaged fuel sup-

ply tube.

(24) Inspect the connections to the speed control

servo, if equipped (Fig. 54). Refer to Group 8H, Vehi-

cle Speed Control.

Fig. 72 Park/Neutral Switch and Torque Convertor

Clutch Solenoid

Fig. 73 Upstream Heated Oxygen Sensor

Fig. 74 Downstream Heated Oxygen Sensor

Fig. 75 Fuel Pump Module Electrical Connector

PLFUEL SYSTEM 14 - 45

DIAGNOSIS AND TESTING (Continued)

Page 887 of 1200

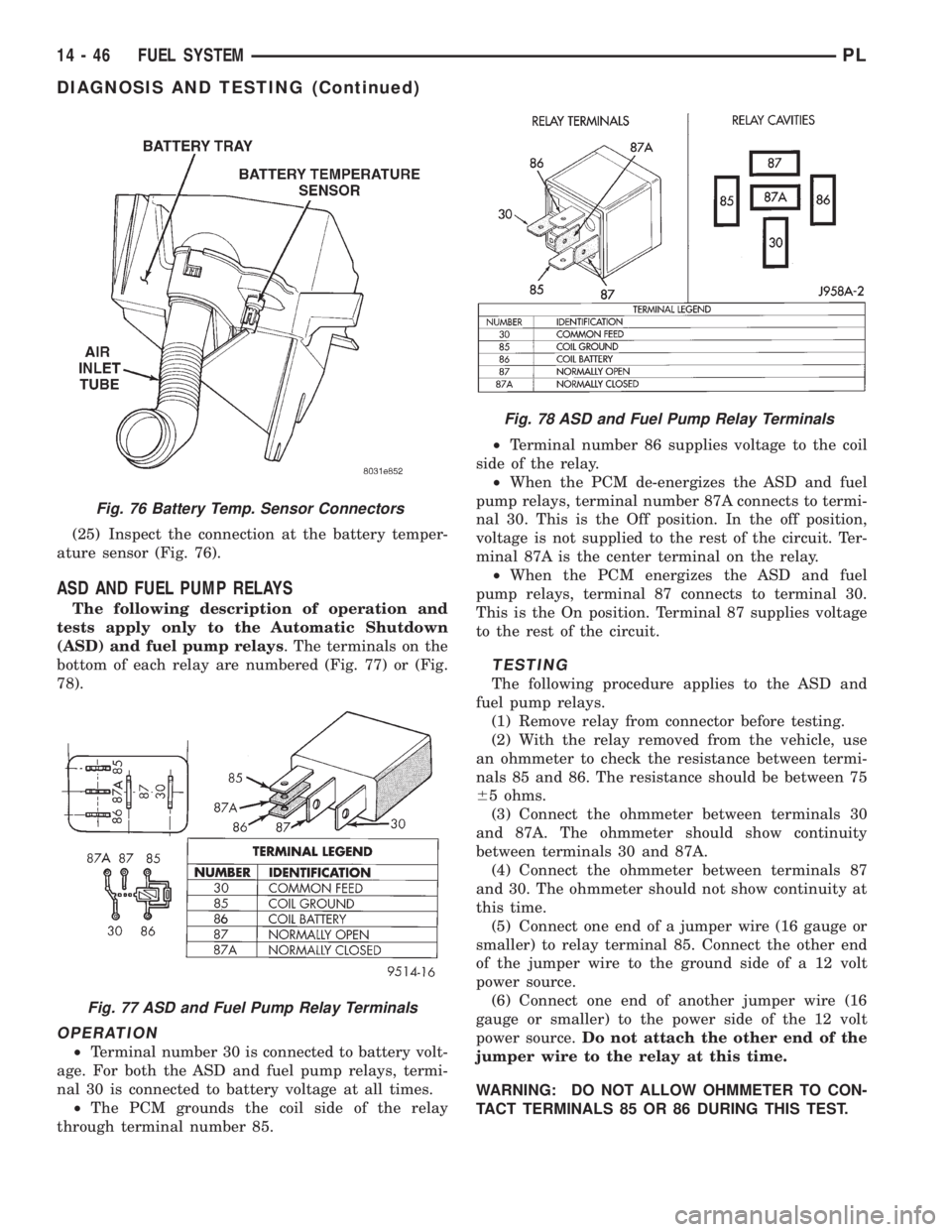

(25) Inspect the connection at the battery temper-

ature sensor (Fig. 76).

ASD AND FUEL PUMP RELAYS

The following description of operation and

tests apply only to the Automatic Shutdown

(ASD) and fuel pump relays. The terminals on the

bottom of each relay are numbered (Fig. 77) or (Fig.

78).

OPERATION

²Terminal number 30 is connected to battery volt-

age. For both the ASD and fuel pump relays, termi-

nal 30 is connected to battery voltage at all times.

²The PCM grounds the coil side of the relay

through terminal number 85.²Terminal number 86 supplies voltage to the coil

side of the relay.

²When the PCM de-energizes the ASD and fuel

pump relays, terminal number 87A connects to termi-

nal 30. This is the Off position. In the off position,

voltage is not supplied to the rest of the circuit. Ter-

minal 87A is the center terminal on the relay.

²When the PCM energizes the ASD and fuel

pump relays, terminal 87 connects to terminal 30.

This is the On position. Terminal 87 supplies voltage

to the rest of the circuit.

TESTING

The following procedure applies to the ASD and

fuel pump relays.

(1) Remove relay from connector before testing.

(2) With the relay removed from the vehicle, use

an ohmmeter to check the resistance between termi-

nals 85 and 86. The resistance should be between 75

65 ohms.

(3) Connect the ohmmeter between terminals 30

and 87A. The ohmmeter should show continuity

between terminals 30 and 87A.

(4) Connect the ohmmeter between terminals 87

and 30. The ohmmeter should not show continuity at

this time.

(5) Connect one end of a jumper wire (16 gauge or

smaller) to relay terminal 85. Connect the other end

of the jumper wire to the ground side of a 12 volt

power source.

(6) Connect one end of another jumper wire (16

gauge or smaller) to the power side of the 12 volt

power source.Do not attach the other end of the

jumper wire to the relay at this time.

WARNING: DO NOT ALLOW OHMMETER TO CON-

TACT TERMINALS 85 OR 86 DURING THIS TEST.

Fig. 76 Battery Temp. Sensor Connectors

Fig. 77 ASD and Fuel Pump Relay Terminals

Fig. 78 ASD and Fuel Pump Relay Terminals

14 - 46 FUEL SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 888 of 1200

(7) Attach the other end of the jumper wire to

relay terminal 86. This activates the relay. The ohm-

meter should now show continuity between relay ter-

minals 87 and 30. The ohmmeter should not show

continuity between relay terminals 87A and 30.

(8) Disconnect jumper wires.

(9) Replace the relay if it did not pass the continu-

ity and resistance tests. If the relay passed the tests,

it operates properly. Check the remainder of the ASD

and fuel pump relay circuits. Refer to group 8W, Wir-

ing Diagrams.

CAMSHAFT AND CRANKSHAFT POSITION SENSOR

Refer to Group 8D, Ignition for Diagnosis and Test-

ing of Camshaft and Crankshaft Sensors.

ENGINE COOLANT TEMPERATURE SENSOR

(1) With the key off, disconnect wire harness con-

nector from coolant temperature sensor (Fig. 79) or

(Fig. 80).(2) Connect a high input impedance (digital) volt-

ohmmeter to terminals A and B (Fig. 81). The ohm-

meter should read as follows:

²Engine/Sensor at normal operating temperature

around 200ÉF should read approximately 700 to

1,000 ohms.

²Engine/Sensor at room temperature around 70ÉF

ohmmeter should read approximately 7,000 to 13,000

ohms.

(3) T

est the resistance of the wire harness between

the PCM 60-way connector terminal 28 and the sensor

harness connector. Also check for continuity between

PCM 60-way connector terminal 51 and the sensor har-

ness connector. Refer to Group 8W, Wiring diagrams for

circuit information. If the resistance is greater than 1

ohm, repair the wire harness as necessary.

HEATED OXYGEN SENSOR

Use an ohmmeter to test the heating element of

the oxygen sensors. Disconnect the electrical connec-

tor from each oxygen sensor. The white wires in the

sensor connector are the power and ground circuits

for the heater. Connect the ohmmeter test leads to

terminals of the white wires in the heated oxygen

sensor connector. Replace the heated oxygen sensor if

the resistance is not between 4 and 7 ohms.

IDLE AIR CONTROL (IAC) MOTOR TEST

To preform a complete test of IAC motor and its

circuitry, refer to DRB scan tool and the appropriate

Powertrain Diagnostics Procedures manual.

KNOCK SENSOR

The engine knock sensor is affected by a number of

factors. A few of these are: ignition timing, cylinder

pressure, fuel octane, etc. The knock sensor generates

an AC voltage whose amplitude increases with the

increase of engine knock. The knock sensor can be

tested with a digital voltmeter. The RMS voltage starts

Fig. 79 Engine Coolant Temperature Sensor

LocationÐSOHC

Fig. 80 Engine Coolant Temperature Sensor

LocationÐDOHC

Fig. 81 Engine Coolant Temperature Sensor

PLFUEL SYSTEM 14 - 47

DIAGNOSIS AND TESTING (Continued)

Page 889 of 1200

at about 20mVac (at about 700 rpm) and increases to

approximately 600 mVac (5000 rpm). If the output falls

outside of this range a DTC will be set.

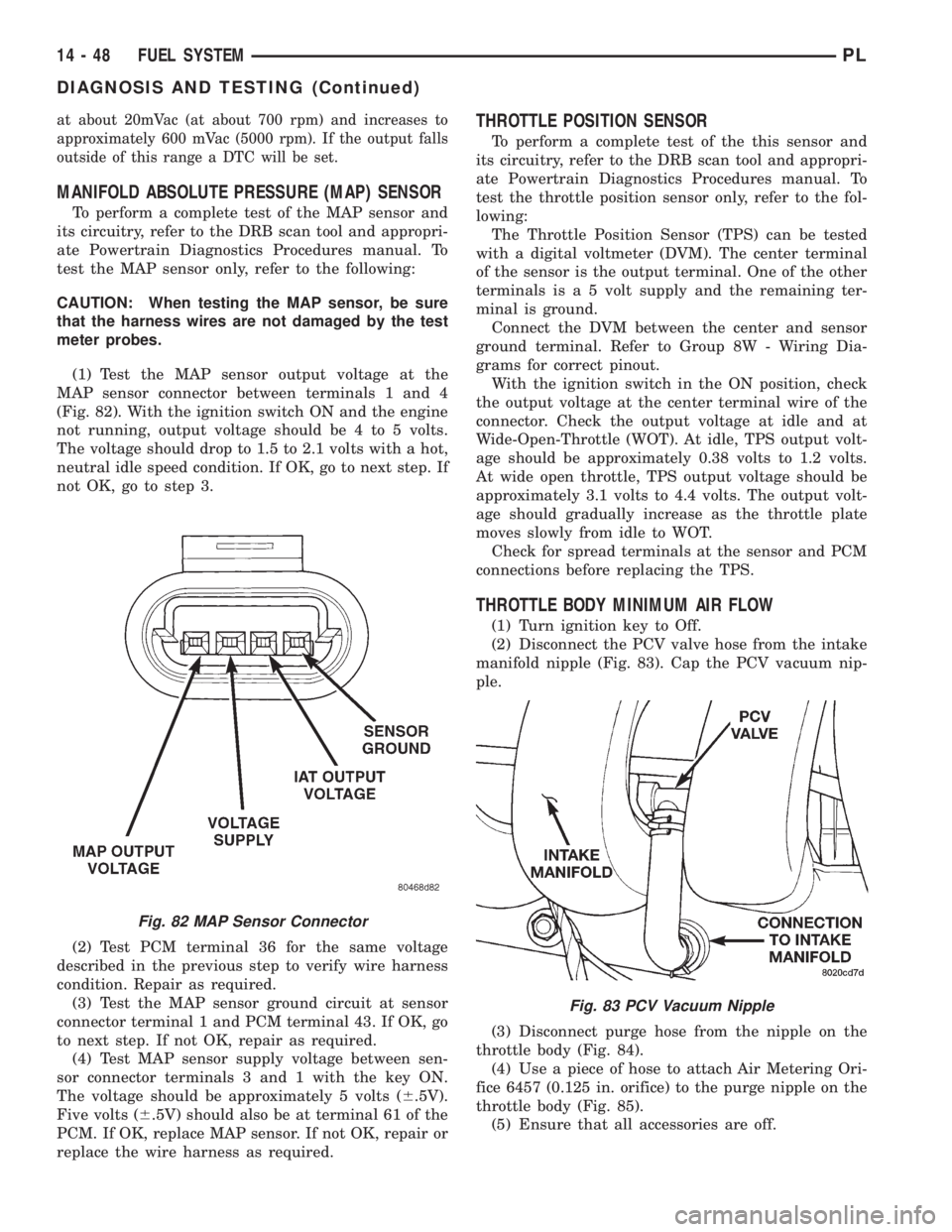

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

To perform a complete test of the MAP sensor and

its circuitry, refer to the DRB scan tool and appropri-

ate Powertrain Diagnostics Procedures manual. To

test the MAP sensor only, refer to the following:

CAUTION: When testing the MAP sensor, be sure

that the harness wires are not damaged by the test

meter probes.

(1) Test the MAP sensor output voltage at the

MAP sensor connector between terminals 1 and 4

(Fig. 82). With the ignition switch ON and the engine

not running, output voltage should be 4 to 5 volts.

The voltage should drop to 1.5 to 2.1 volts with a hot,

neutral idle speed condition. If OK, go to next step. If

not OK, go to step 3.

(2) Test PCM terminal 36 for the same voltage

described in the previous step to verify wire harness

condition. Repair as required.

(3) Test the MAP sensor ground circuit at sensor

connector terminal 1 and PCM terminal 43. If OK, go

to next step. If not OK, repair as required.

(4) Test MAP sensor supply voltage between sen-

sor connector terminals 3 and 1 with the key ON.

The voltage should be approximately 5 volts (6.5V).

Five volts (6.5V) should also be at terminal 61 of the

PCM. If OK, replace MAP sensor. If not OK, repair or

replace the wire harness as required.

THROTTLE POSITION SENSOR

To perform a complete test of the this sensor and

its circuitry, refer to the DRB scan tool and appropri-

ate Powertrain Diagnostics Procedures manual. To

test the throttle position sensor only, refer to the fol-

lowing:

The Throttle Position Sensor (TPS) can be tested

with a digital voltmeter (DVM). The center terminal

of the sensor is the output terminal. One of the other

terminals is a 5 volt supply and the remaining ter-

minal is ground.

Connect the DVM between the center and sensor

ground terminal. Refer to Group 8W - Wiring Dia-

grams for correct pinout.

With the ignition switch in the ON position, check

the output voltage at the center terminal wire of the

connector. Check the output voltage at idle and at

Wide-Open-Throttle (WOT). At idle, TPS output volt-

age should be approximately 0.38 volts to 1.2 volts.

At wide open throttle, TPS output voltage should be

approximately 3.1 volts to 4.4 volts. The output volt-

age should gradually increase as the throttle plate

moves slowly from idle to WOT.

Check for spread terminals at the sensor and PCM

connections before replacing the TPS.

THROTTLE BODY MINIMUM AIR FLOW

(1) Turn ignition key to Off.

(2) Disconnect the PCV valve hose from the intake

manifold nipple (Fig. 83). Cap the PCV vacuum nip-

ple.

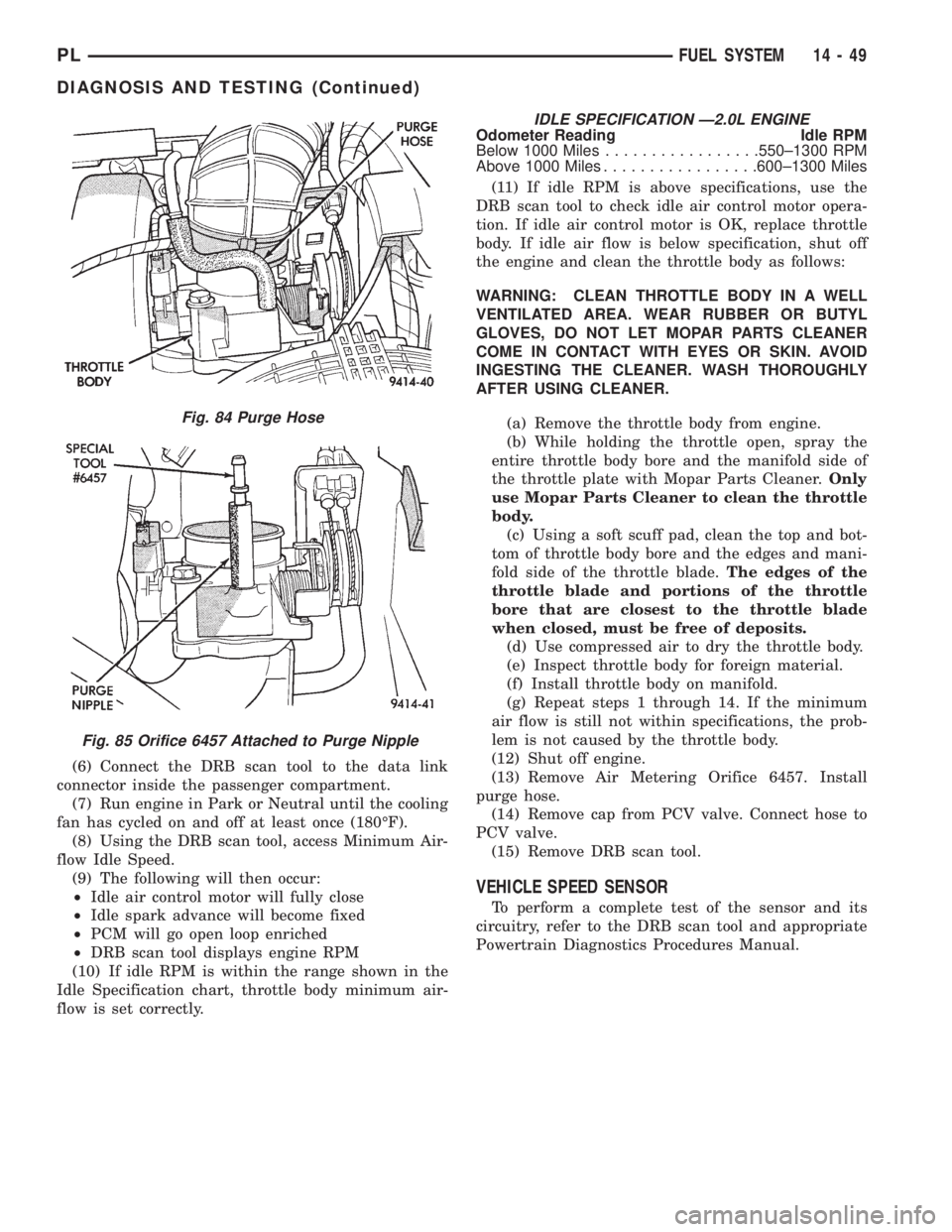

(3) Disconnect purge hose from the nipple on the

throttle body (Fig. 84).

(4) Use a piece of hose to attach Air Metering Ori-

fice 6457 (0.125 in. orifice) to the purge nipple on the

throttle body (Fig. 85).

(5) Ensure that all accessories are off.

Fig. 82 MAP Sensor Connector

Fig. 83 PCV Vacuum Nipple

14 - 48 FUEL SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 890 of 1200

(6) Connect the DRB scan tool to the data link

connector inside the passenger compartment.

(7) Run engine in Park or Neutral until the cooling

fan has cycled on and off at least once (180ÉF).

(8) Using the DRB scan tool, access Minimum Air-

flow Idle Speed.

(9) The following will then occur:

²Idle air control motor will fully close

²Idle spark advance will become fixed

²PCM will go open loop enriched

²DRB scan tool displays engine RPM

(10) If idle RPM is within the range shown in the

Idle Specification chart, throttle body minimum air-

flow is set correctly.

IDLE SPECIFICATION Ð2.0L ENGINEOdometer Reading Idle RPM

Below 1000 Miles.................550±1300 RPM

Above 1000 Miles.................600±1300 Miles

(11) If idle RPM is above specifications, use the

DRB scan tool to check idle air control motor opera-

tion. If idle air control motor is OK, replace throttle

body. If idle air flow is below specification, shut off

the engine and clean the throttle body as follows:

WARNING: CLEAN THROTTLE BODY IN A WELL

VENTILATED AREA. WEAR RUBBER OR BUTYL

GLOVES, DO NOT LET MOPAR PARTS CLEANER

COME IN CONTACT WITH EYES OR SKIN. AVOID

INGESTING THE CLEANER. WASH THOROUGHLY

AFTER USING CLEANER.

(a) Remove the throttle body from engine.

(b) While holding the throttle open, spray the

entire throttle body bore and the manifold side of

the throttle plate with Mopar Parts Cleaner.Only

use Mopar Parts Cleaner to clean the throttle

body.

(c) Using a soft scuff pad, clean the top and bot-

tom of throttle body bore and the edges and mani-

fold side of the throttle blade.The edges of the

throttle blade and portions of the throttle

bore that are closest to the throttle blade

when closed, must be free of deposits.

(d) Use compressed air to dry the throttle body.

(e) Inspect throttle body for foreign material.

(f) Install throttle body on manifold.

(g) Repeat steps 1 through 14. If the minimum

air flow is still not within specifications, the prob-

lem is not caused by the throttle body.

(12) Shut off engine.

(13) Remove Air Metering Orifice 6457. Install

purge hose.

(14) Remove cap from PCV valve. Connect hose to

PCV valve.

(15) Remove DRB scan tool.

VEHICLE SPEED SENSOR

To perform a complete test of the sensor and its

circuitry, refer to the DRB scan tool and appropriate

Powertrain Diagnostics Procedures Manual.

Fig. 84 Purge Hose

Fig. 85 Orifice 6457 Attached to Purge Nipple

PLFUEL SYSTEM 14 - 49

DIAGNOSIS AND TESTING (Continued)