DODGE NEON 1999 Service Repair Manual

Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 931 of 1200

but do not remove rear bolts from crossmem-

ber.(13) Using transmission jack, lower front suspen-

sion crossmember enough to allow steering gear to be

removed from crossmember (Fig. 14).When lower-

ing front suspension crossmember, do not let

crossmember hang from lower control arms

weight of crossmember should be supported by

transmission jack.

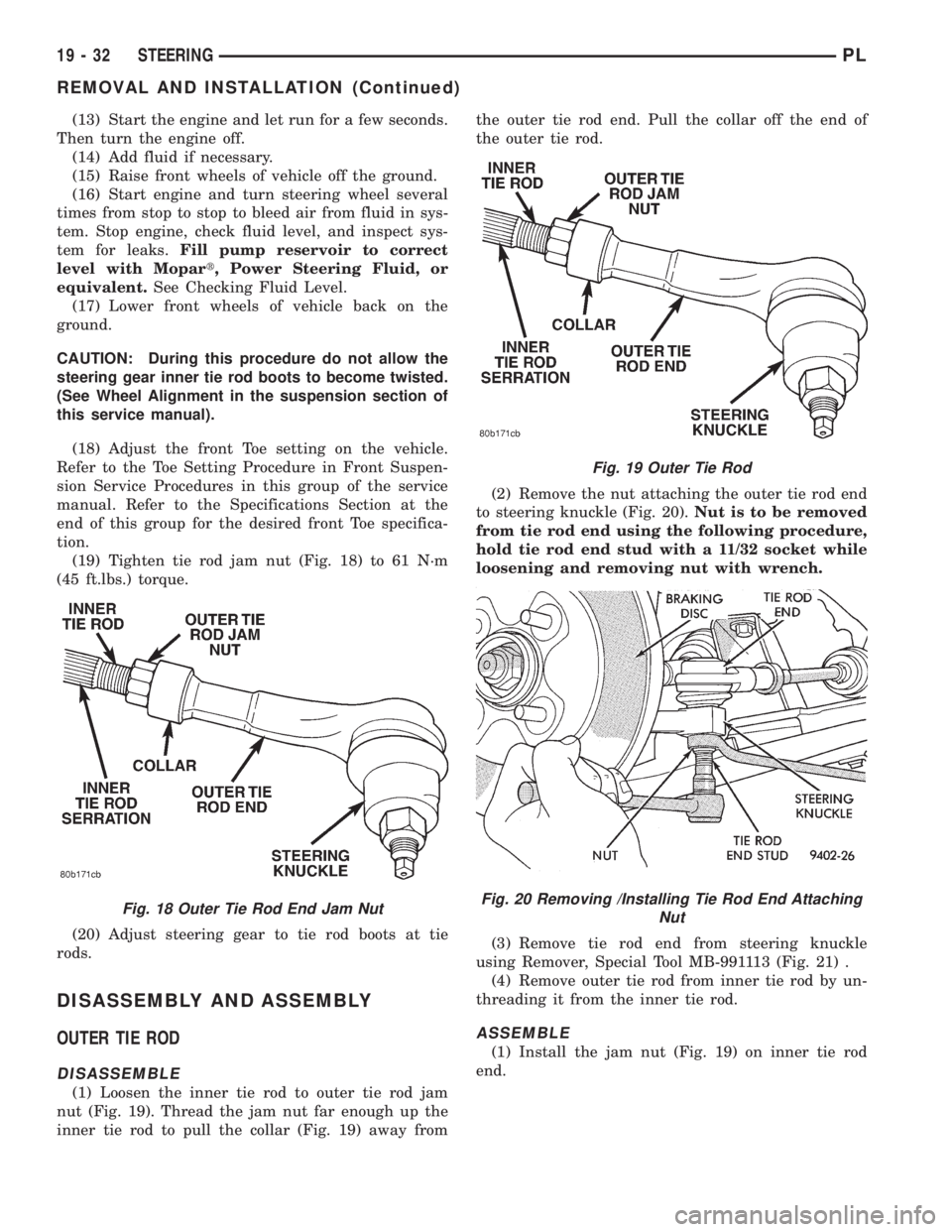

(14) Loosen and remove the 4 bolts (Fig. 15),

attaching steering assembly to front suspension

crossmember. Then remove the steering gear assem-

bly from the front suspension crossmember.

(15) Transfer required parts from removed steering

gear assembly to the replacement steering gear, if a

new steering gear is being installed.

INSTALL

(1) Install steering gear assembly on front suspen-

sion crossmember. Install the 4 steering gear assem-

bly to front crossmember mounting bolts (Fig. 15).

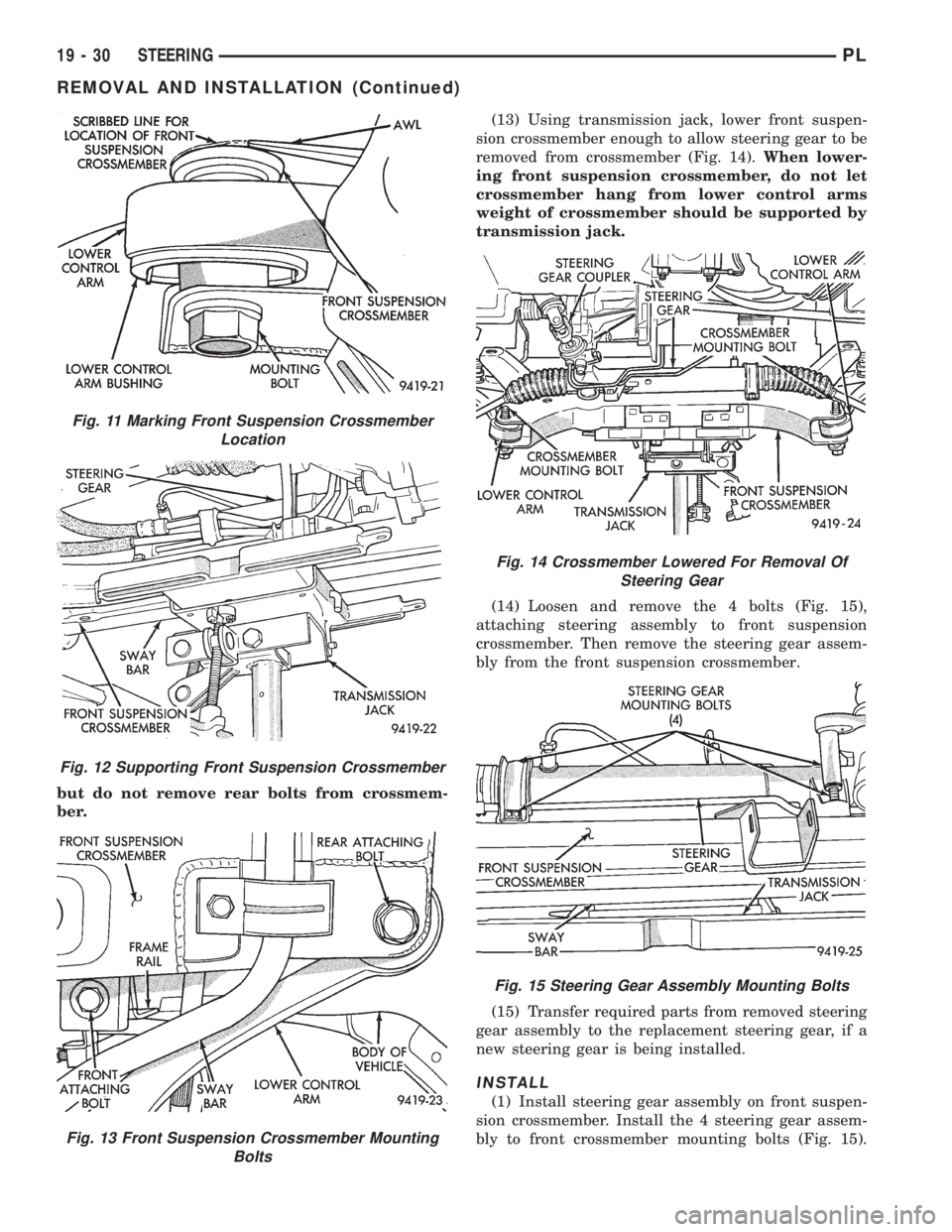

Fig. 11 Marking Front Suspension Crossmember

Location

Fig. 12 Supporting Front Suspension Crossmember

Fig. 13 Front Suspension Crossmember Mounting

Bolts

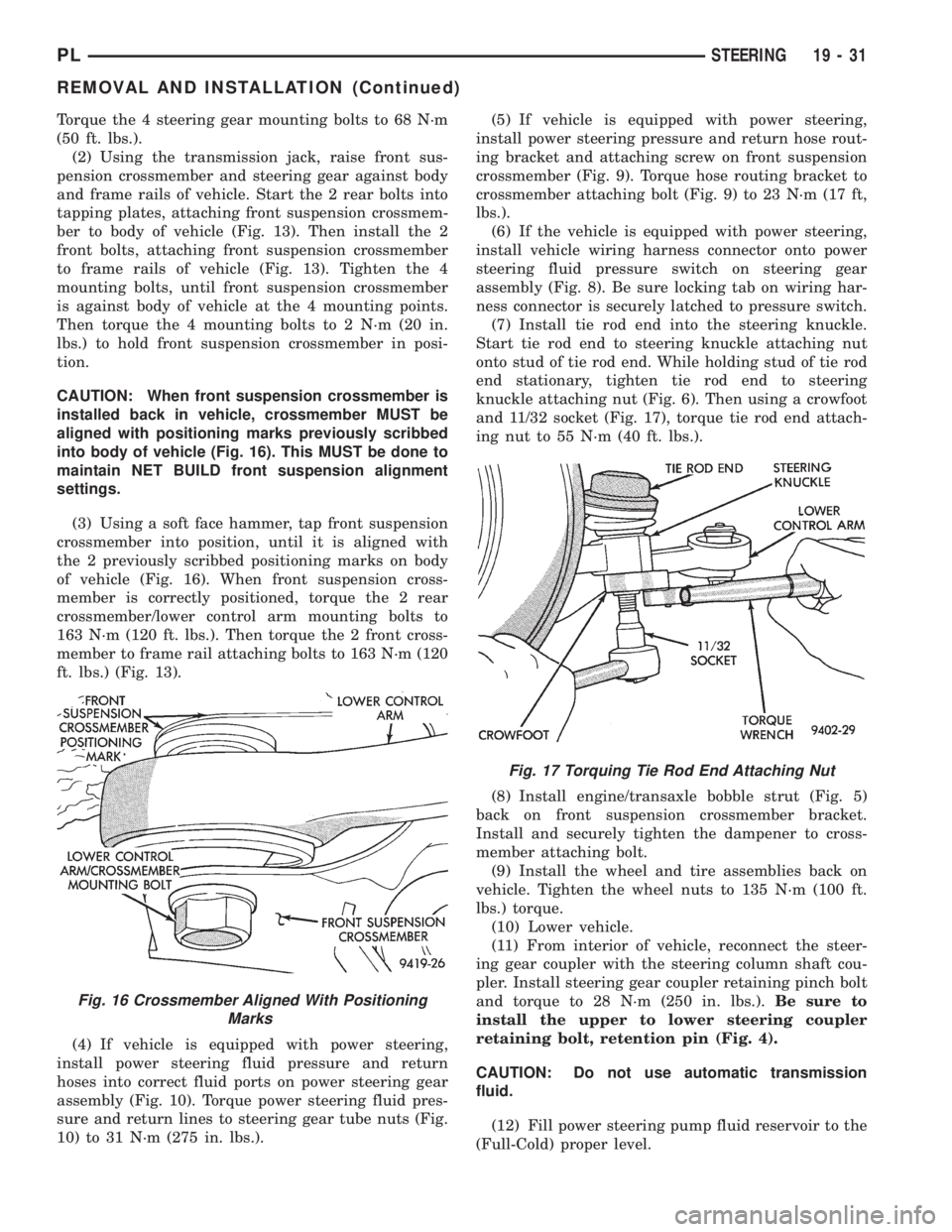

Fig. 14 Crossmember Lowered For Removal Of

Steering Gear

Fig. 15 Steering Gear Assembly Mounting Bolts

19 - 30 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 932 of 1200

Torque the 4 steering gear mounting bolts to 68 N´m

(50 ft. lbs.).

(2) Using the transmission jack, raise front sus-

pension crossmember and steering gear against body

and frame rails of vehicle. Start the 2 rear bolts into

tapping plates, attaching front suspension crossmem-

ber to body of vehicle (Fig. 13). Then install the 2

front bolts, attaching front suspension crossmember

to frame rails of vehicle (Fig. 13). Tighten the 4

mounting bolts, until front suspension crossmember

is against body of vehicle at the 4 mounting points.

Then torque the 4 mounting bolts to 2 N´m (20 in.

lbs.) to hold front suspension crossmember in posi-

tion.

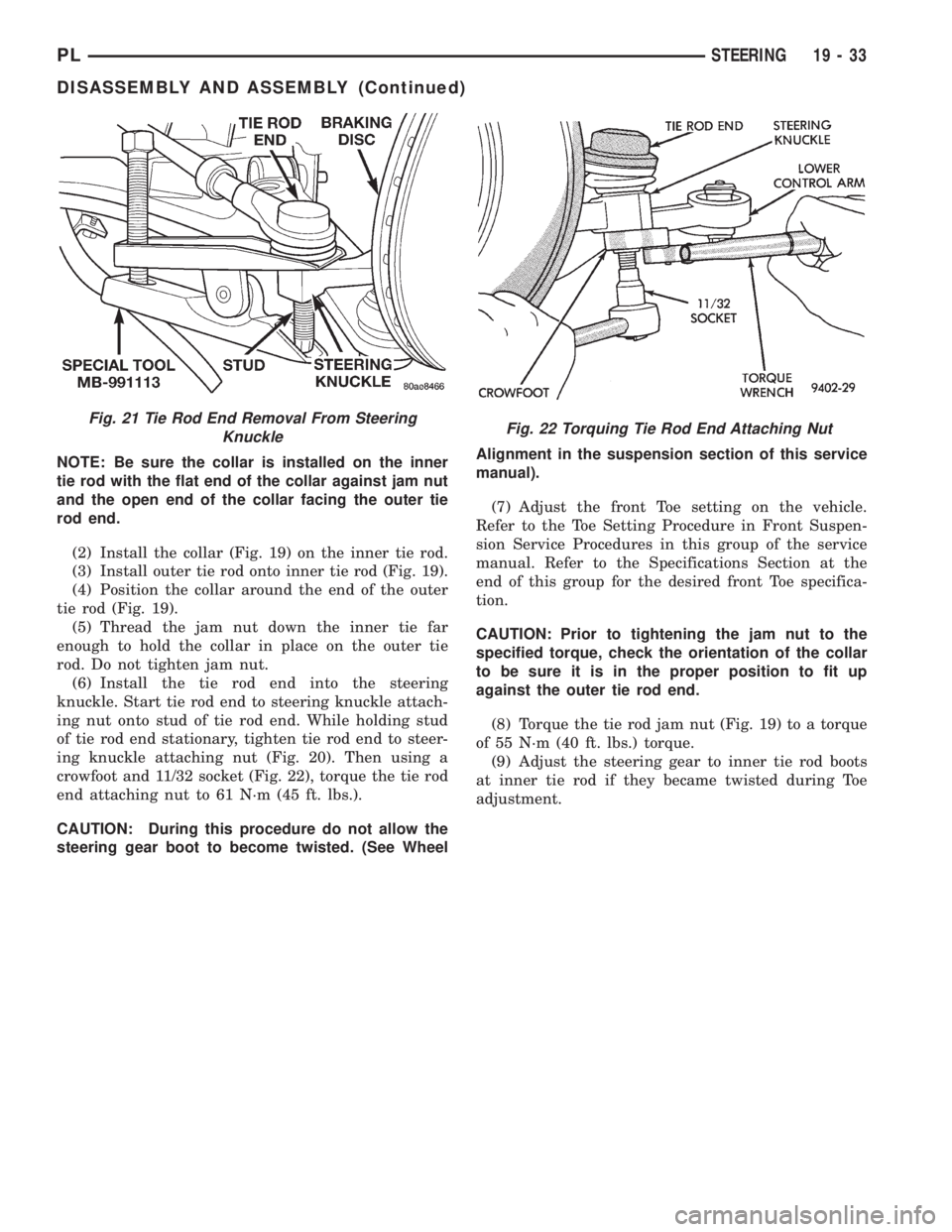

CAUTION: When front suspension crossmember is

installed back in vehicle, crossmember MUST be

aligned with positioning marks previously scribbed

into body of vehicle (Fig. 16). This MUST be done to

maintain NET BUILD front suspension alignment

settings.

(3) Using a soft face hammer, tap front suspension

crossmember into position, until it is aligned with

the 2 previously scribbed positioning marks on body

of vehicle (Fig. 16). When front suspension cross-

member is correctly positioned, torque the 2 rear

crossmember/lower control arm mounting bolts to

163 N´m (120 ft. lbs.). Then torque the 2 front cross-

member to frame rail attaching bolts to 163 N´m (120

ft. lbs.) (Fig. 13).

(4) If vehicle is equipped with power steering,

install power steering fluid pressure and return

hoses into correct fluid ports on power steering gear

assembly (Fig. 10). Torque power steering fluid pres-

sure and return lines to steering gear tube nuts (Fig.

10) to 31 N´m (275 in. lbs.).(5) If vehicle is equipped with power steering,

install power steering pressure and return hose rout-

ing bracket and attaching screw on front suspension

crossmember (Fig. 9). Torque hose routing bracket to

crossmember attaching bolt (Fig. 9) to 23 N´m (17 ft,

lbs.).

(6) If the vehicle is equipped with power steering,

install vehicle wiring harness connector onto power

steering fluid pressure switch on steering gear

assembly (Fig. 8). Be sure locking tab on wiring har-

ness connector is securely latched to pressure switch.

(7) Install tie rod end into the steering knuckle.

Start tie rod end to steering knuckle attaching nut

onto stud of tie rod end. While holding stud of tie rod

end stationary, tighten tie rod end to steering

knuckle attaching nut (Fig. 6). Then using a crowfoot

and 11/32 socket (Fig. 17), torque tie rod end attach-

ing nut to 55 N´m (40 ft. lbs.).

(8) Install engine/transaxle bobble strut (Fig. 5)

back on front suspension crossmember bracket.

Install and securely tighten the dampener to cross-

member attaching bolt.

(9) Install the wheel and tire assemblies back on

vehicle. Tighten the wheel nuts to 135 N´m (100 ft.

lbs.) torque.

(10) Lower vehicle.

(11) From interior of vehicle, reconnect the steer-

ing gear coupler with the steering column shaft cou-

pler. Install steering gear coupler retaining pinch bolt

and torque to 28 N´m (250 in. lbs.).Be sure to

install the upper to lower steering coupler

retaining bolt, retention pin (Fig. 4).

CAUTION: Do not use automatic transmission

fluid.

(12) Fill power steering pump fluid reservoir to the

(Full-Cold) proper level.

Fig. 16 Crossmember Aligned With Positioning

Marks

Fig. 17 Torquing Tie Rod End Attaching Nut

PLSTEERING 19 - 31

REMOVAL AND INSTALLATION (Continued)

Page 933 of 1200

(13) Start the engine and let run for a few seconds.

Then turn the engine off.

(14) Add fluid if necessary.

(15) Raise front wheels of vehicle off the ground.

(16) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks.Fill pump reservoir to correct

level with Mopart, Power Steering Fluid, or

equivalent.See Checking Fluid Level.

(17) Lower front wheels of vehicle back on the

ground.

CAUTION: During this procedure do not allow the

steering gear inner tie rod boots to become twisted.

(See Wheel Alignment in the suspension section of

this service manual).

(18) Adjust the front Toe setting on the vehicle.

Refer to the Toe Setting Procedure in Front Suspen-

sion Service Procedures in this group of the service

manual. Refer to the Specifications Section at the

end of this group for the desired front Toe specifica-

tion.

(19) Tighten tie rod jam nut (Fig. 18) to 61 N´m

(45 ft.lbs.) torque.

(20) Adjust steering gear to tie rod boots at tie

rods.

DISASSEMBLY AND ASSEMBLY

OUTER TIE ROD

DISASSEMBLE

(1) Loosen the inner tie rod to outer tie rod jam

nut (Fig. 19). Thread the jam nut far enough up the

inner tie rod to pull the collar (Fig. 19) away fromthe outer tie rod end. Pull the collar off the end of

the outer tie rod.

(2) Remove the nut attaching the outer tie rod end

to steering knuckle (Fig. 20).Nut is to be removed

from tie rod end using the following procedure,

hold tie rod end stud with a 11/32 socket while

loosening and removing nut with wrench.

(3) Remove tie rod end from steering knuckle

using Remover, Special Tool MB-991113 (Fig. 21) .

(4) Remove outer tie rod from inner tie rod by un-

threading it from the inner tie rod.

ASSEMBLE

(1) Install the jam nut (Fig. 19) on inner tie rod

end.

Fig. 18 Outer Tie Rod End Jam Nut

Fig. 19 Outer Tie Rod

Fig. 20 Removing /Installing Tie Rod End Attaching

Nut

19 - 32 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 934 of 1200

NOTE: Be sure the collar is installed on the inner

tie rod with the flat end of the collar against jam nut

and the open end of the collar facing the outer tie

rod end.

(2) Install the collar (Fig. 19) on the inner tie rod.

(3) Install outer tie rod onto inner tie rod (Fig. 19).

(4) Position the collar around the end of the outer

tie rod (Fig. 19).

(5) Thread the jam nut down the inner tie far

enough to hold the collar in place on the outer tie

rod. Do not tighten jam nut.

(6) Install the tie rod end into the steering

knuckle. Start tie rod end to steering knuckle attach-

ing nut onto stud of tie rod end. While holding stud

of tie rod end stationary, tighten tie rod end to steer-

ing knuckle attaching nut (Fig. 20). Then using a

crowfoot and 11/32 socket (Fig. 22), torque the tie rod

end attaching nut to 61 N´m (45 ft. lbs.).

CAUTION: During this procedure do not allow the

steering gear boot to become twisted. (See WheelAlignment in the suspension section of this service

manual).

(7) Adjust the front Toe setting on the vehicle.

Refer to the Toe Setting Procedure in Front Suspen-

sion Service Procedures in this group of the service

manual. Refer to the Specifications Section at the

end of this group for the desired front Toe specifica-

tion.

CAUTION: Prior to tightening the jam nut to the

specified torque, check the orientation of the collar

to be sure it is in the proper position to fit up

against the outer tie rod end.

(8) Torque the tie rod jam nut (Fig. 19) to a torque

of 55 N´m (40 ft. lbs.) torque.

(9) Adjust the steering gear to inner tie rod boots

at inner tie rod if they became twisted during Toe

adjustment.

Fig. 22 Torquing Tie Rod End Attaching NutFig. 21 Tie Rod End Removal From Steering

Knuckle

PLSTEERING 19 - 33

DISASSEMBLY AND ASSEMBLY (Continued)

Page 935 of 1200

SPECIFICATIONS

STEERING GEAR FASTENER TORQUE

SPECIFICATIONS

DESCRIPTION TORQUE

FRONT SUSPENSION CROSSMEMBER:

To Body Mounting Bolts......163 N´m (120 ft. lbs.)

STEERING GEAR:

To Crossmember Mounting Bolts .68 N´m (50 ft. lbs.)

OUTER TIE ROD:

To Steering Knuckle Nut.......55N´m(40ft.lbs.)

To Inner Tie Rod Jam Nut......61N´m(45ft.lbs.)

POWER STEERING HOSE:

Tube Nuts.................31N´m(275 in. lbs.)

Routing Bracket At Crossmember .23 N´m (17 ft. lbs.)

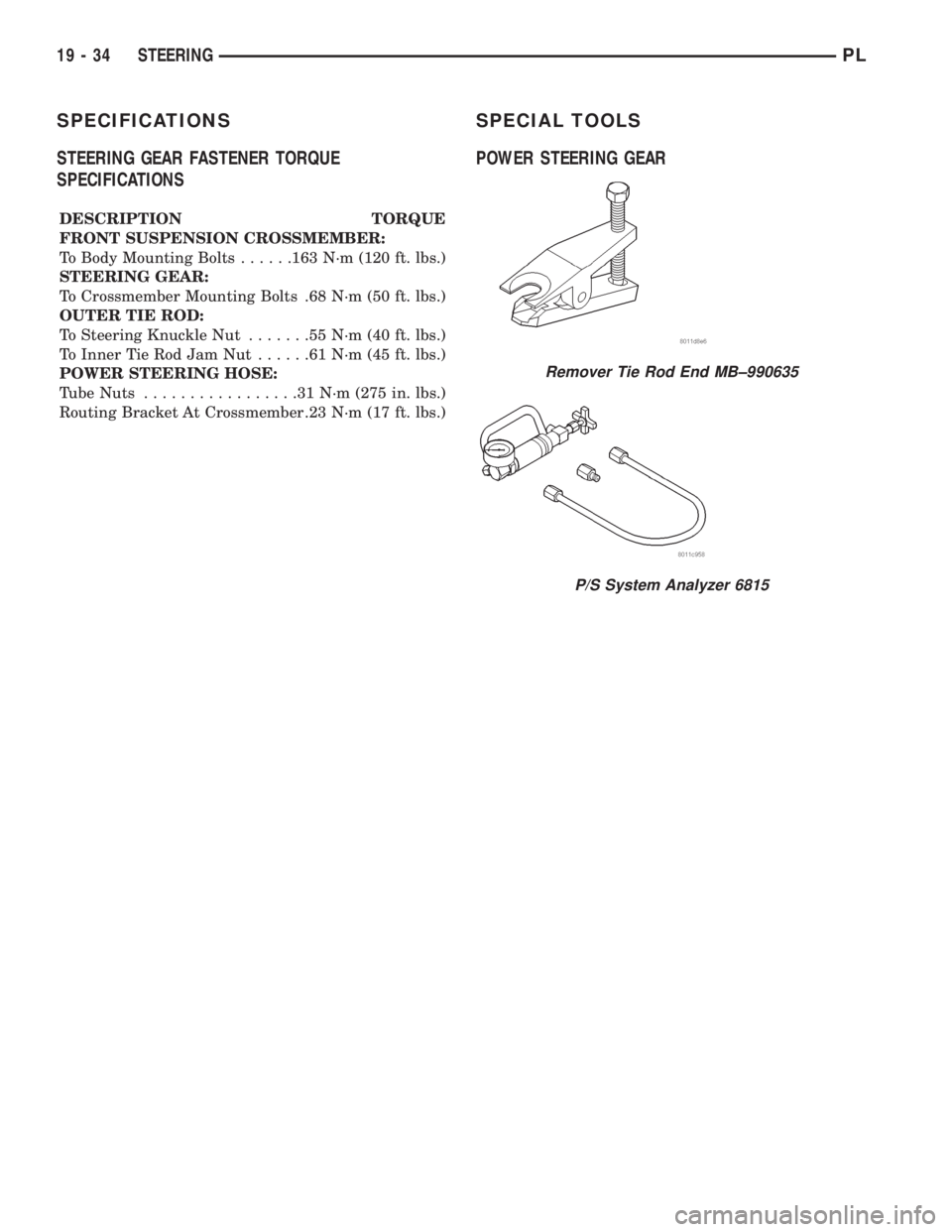

SPECIAL TOOLS

POWER STEERING GEAR

Remover Tie Rod End MB±990635

P/S System Analyzer 6815

19 - 34 STEERINGPL

Page 936 of 1200

STEERING COLUMN

INDEX

page page

DESCRIPTION AND OPERATION

STEERING COLUMN ASSEMBLY............ 35

STEERING GEAR TO STEERING

COLUMN COUPLING................... 36

DIAGNOSIS AND TESTING

STEERING COLUMN TO STEERING

GEAR COUPLING...................... 36

STEERING COLUMN..................... 36REMOVAL AND INSTALLATION

STEERING COLUMN SERVICE

PROCEDURE WARNINGS............... 37

STEERING COLUMN..................... 38

SPECIFICATIONS

STEERING COLUMN FASTEER

TORQUE SPECIFICATIONS.............. 42

DESCRIPTION AND OPERATION

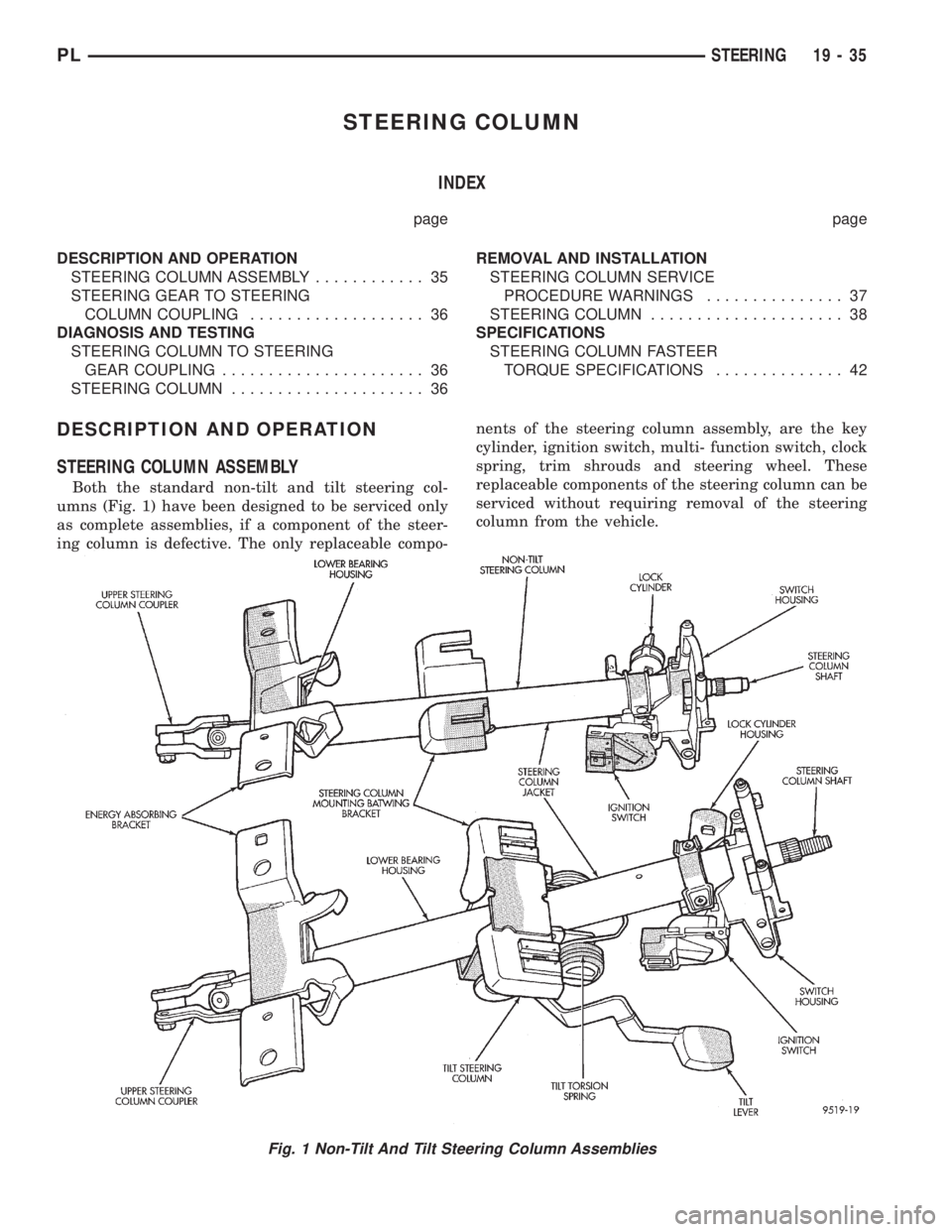

STEERING COLUMN ASSEMBLY

Both the standard non-tilt and tilt steering col-

umns (Fig. 1) have been designed to be serviced only

as complete assemblies, if a component of the steer-

ing column is defective. The only replaceable compo-nents of the steering column assembly, are the key

cylinder, ignition switch, multi- function switch, clock

spring, trim shrouds and steering wheel. These

replaceable components of the steering column can be

serviced without requiring removal of the steering

column from the vehicle.

Fig. 1 Non-Tilt And Tilt Steering Column Assemblies

PLSTEERING 19 - 35

Page 937 of 1200

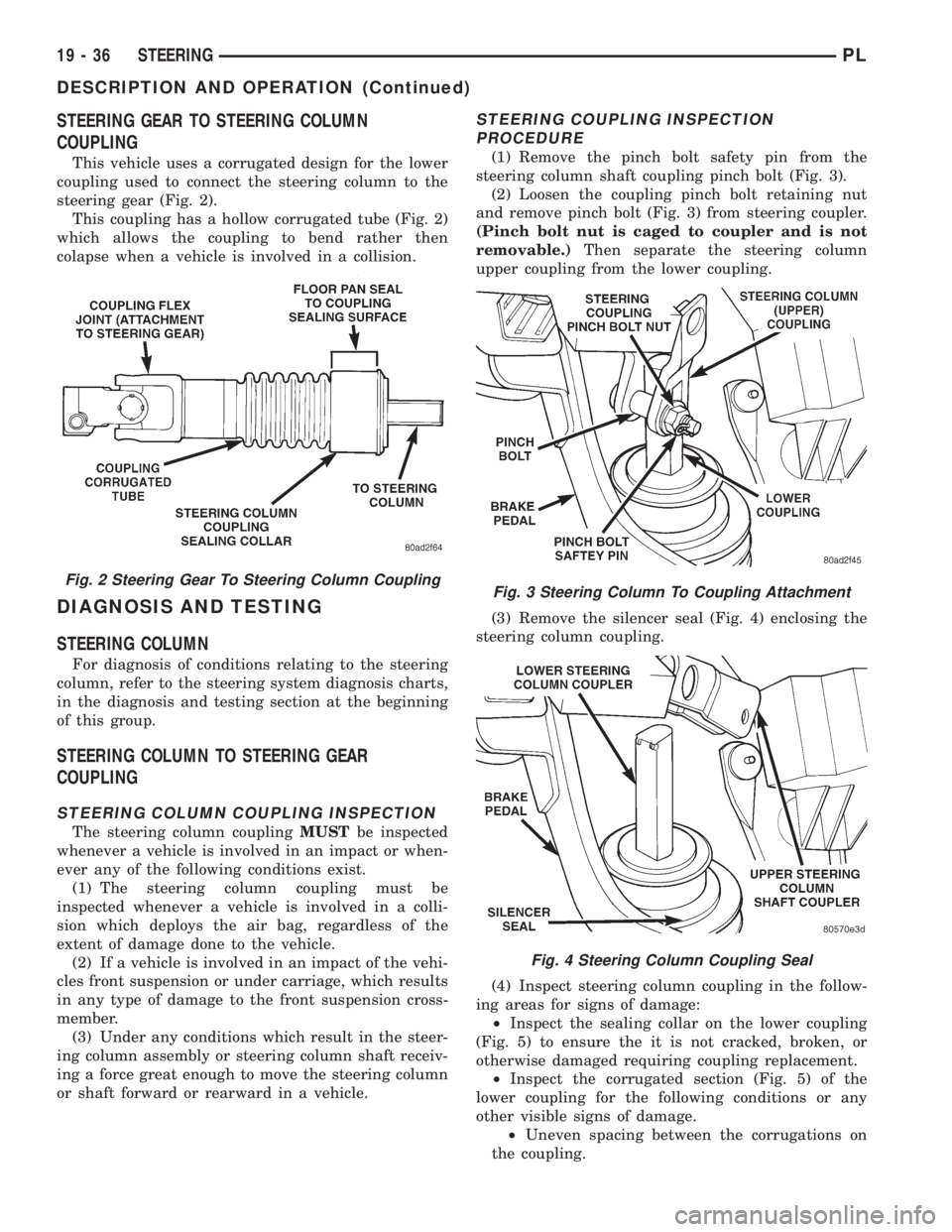

STEERING GEAR TO STEERING COLUMN

COUPLING

This vehicle uses a corrugated design for the lower

coupling used to connect the steering column to the

steering gear (Fig. 2).

This coupling has a hollow corrugated tube (Fig. 2)

which allows the coupling to bend rather then

colapse when a vehicle is involved in a collision.

DIAGNOSIS AND TESTING

STEERING COLUMN

For diagnosis of conditions relating to the steering

column, refer to the steering system diagnosis charts,

in the diagnosis and testing section at the beginning

of this group.

STEERING COLUMN TO STEERING GEAR

COUPLING

STEERING COLUMN COUPLING INSPECTION

The steering column couplingMUSTbe inspected

whenever a vehicle is involved in an impact or when-

ever any of the following conditions exist.

(1) The steering column coupling must be

inspected whenever a vehicle is involved in a colli-

sion which deploys the air bag, regardless of the

extent of damage done to the vehicle.

(2) If a vehicle is involved in an impact of the vehi-

cles front suspension or under carriage, which results

in any type of damage to the front suspension cross-

member.

(3) Under any conditions which result in the steer-

ing column assembly or steering column shaft receiv-

ing a force great enough to move the steering column

or shaft forward or rearward in a vehicle.

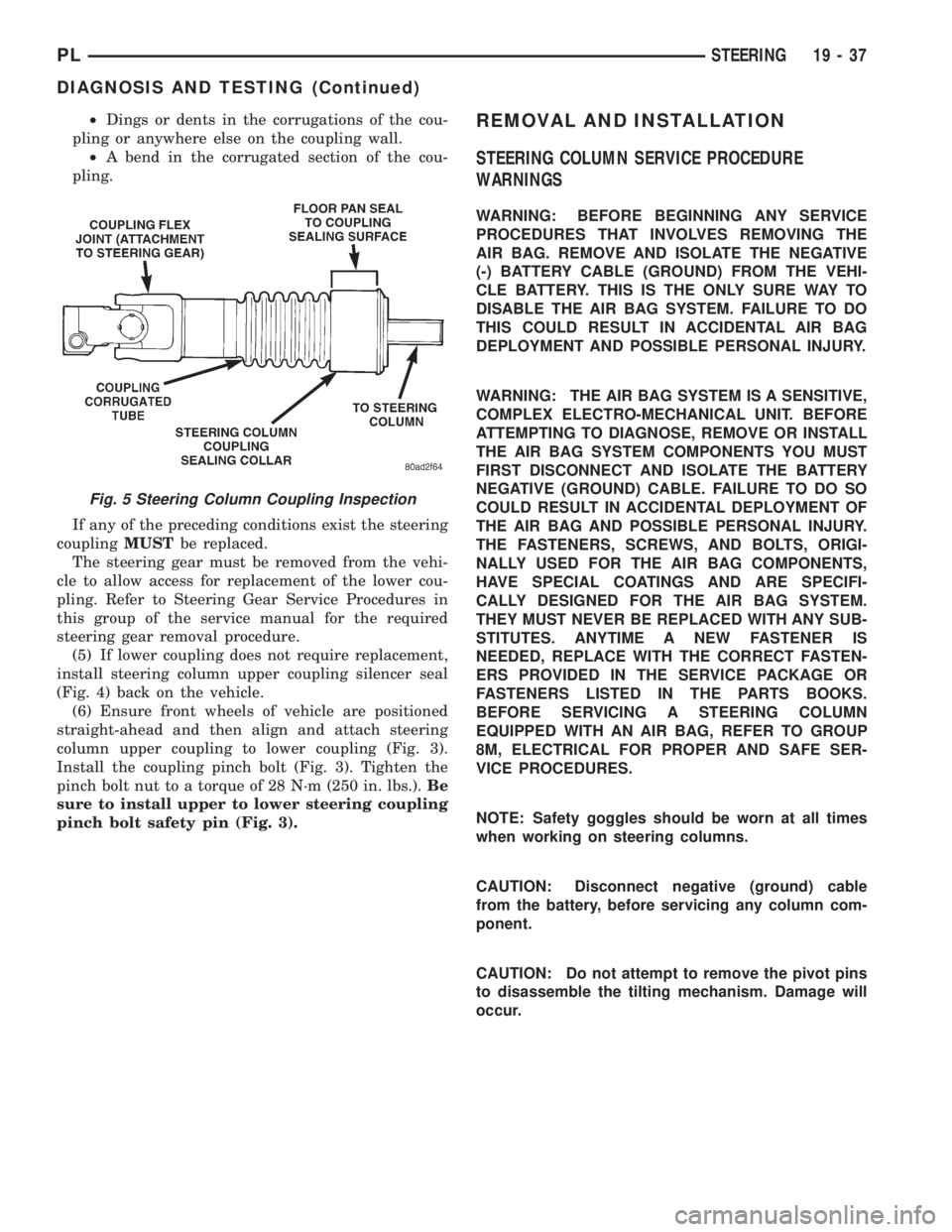

STEERING COUPLING INSPECTION

PROCEDURE

(1) Remove the pinch bolt safety pin from the

steering column shaft coupling pinch bolt (Fig. 3).

(2) Loosen the coupling pinch bolt retaining nut

and remove pinch bolt (Fig. 3) from steering coupler.

(Pinch bolt nut is caged to coupler and is not

removable.)Then separate the steering column

upper coupling from the lower coupling.

(3) Remove the silencer seal (Fig. 4) enclosing the

steering column coupling.

(4) Inspect steering column coupling in the follow-

ing areas for signs of damage:

²Inspect the sealing collar on the lower coupling

(Fig. 5) to ensure the it is not cracked, broken, or

otherwise damaged requiring coupling replacement.

²Inspect the corrugated section (Fig. 5) of the

lower coupling for the following conditions or any

other visible signs of damage.

²Uneven spacing between the corrugations on

the coupling.

Fig. 2 Steering Gear To Steering Column CouplingFig. 3 Steering Column To Coupling Attachment

Fig. 4 Steering Column Coupling Seal

19 - 36 STEERINGPL

DESCRIPTION AND OPERATION (Continued)

Page 938 of 1200

²Dings or dents in the corrugations of the cou-

pling or anywhere else on the coupling wall.

²A bend in the corrugated section of the cou-

pling.

If any of the preceding conditions exist the steering

couplingMUSTbe replaced.

The steering gear must be removed from the vehi-

cle to allow access for replacement of the lower cou-

pling. Refer to Steering Gear Service Procedures in

this group of the service manual for the required

steering gear removal procedure.

(5) If lower coupling does not require replacement,

install steering column upper coupling silencer seal

(Fig. 4) back on the vehicle.

(6) Ensure front wheels of vehicle are positioned

straight-ahead and then align and attach steering

column upper coupling to lower coupling (Fig. 3).

Install the coupling pinch bolt (Fig. 3). Tighten the

pinch bolt nut to a torque of 28 N´m (250 in. lbs.).Be

sure to install upper to lower steering coupling

pinch bolt safety pin (Fig. 3).REMOVAL AND INSTALLATION

STEERING COLUMN SERVICE PROCEDURE

WARNINGS

WARNING: BEFORE BEGINNING ANY SERVICE

PROCEDURES THAT INVOLVES REMOVING THE

AIR BAG. REMOVE AND ISOLATE THE NEGATIVE

(-) BATTERY CABLE (GROUND) FROM THE VEHI-

CLE BATTERY. THIS IS THE ONLY SURE WAY TO

DISABLE THE AIR BAG SYSTEM. FAILURE TO DO

THIS COULD RESULT IN ACCIDENTAL AIR BAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY.

WARNING: THE AIR BAG SYSTEM IS A SENSITIVE,

COMPLEX ELECTRO-MECHANICAL UNIT. BEFORE

ATTEMPTING TO DIAGNOSE, REMOVE OR INSTALL

THE AIR BAG SYSTEM COMPONENTS YOU MUST

FIRST DISCONNECT AND ISOLATE THE BATTERY

NEGATIVE (GROUND) CABLE. FAILURE TO DO SO

COULD RESULT IN ACCIDENTAL DEPLOYMENT OF

THE AIR BAG AND POSSIBLE PERSONAL INJURY.

THE FASTENERS, SCREWS, AND BOLTS, ORIGI-

NALLY USED FOR THE AIR BAG COMPONENTS,

HAVE SPECIAL COATINGS AND ARE SPECIFI-

CALLY DESIGNED FOR THE AIR BAG SYSTEM.

THEY MUST NEVER BE REPLACED WITH ANY SUB-

STITUTES. ANYTIME A NEW FASTENER IS

NEEDED, REPLACE WITH THE CORRECT FASTEN-

ERS PROVIDED IN THE SERVICE PACKAGE OR

FASTENERS LISTED IN THE PARTS BOOKS.

BEFORE SERVICING A STEERING COLUMN

EQUIPPED WITH AN AIR BAG, REFER TO GROUP

8M, ELECTRICAL FOR PROPER AND SAFE SER-

VICE PROCEDURES.

NOTE: Safety goggles should be worn at all times

when working on steering columns.

CAUTION: Disconnect negative (ground) cable

from the battery, before servicing any column com-

ponent.

CAUTION: Do not attempt to remove the pivot pins

to disassemble the tilting mechanism. Damage will

occur.

Fig. 5 Steering Column Coupling Inspection

PLSTEERING 19 - 37

DIAGNOSIS AND TESTING (Continued)

Page 939 of 1200

STEERING COLUMN

REMOVE

(1) Disconnect the negative (ground) cable from

the battery and isolate cable.

(2) Before beginning removal of steering column

assembly from vehicle, be sure front wheels of vehicle

are in thestraight aheadposition.

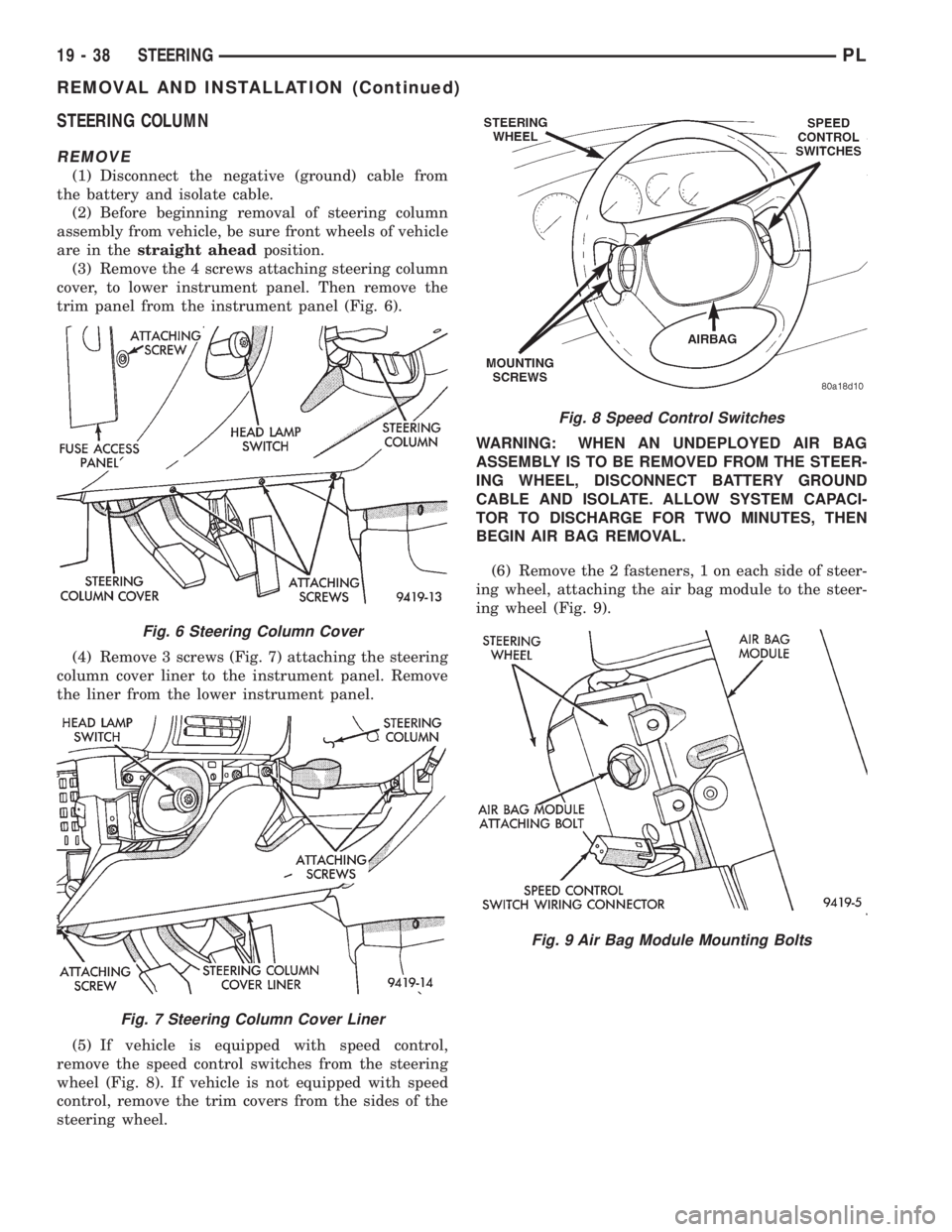

(3) Remove the 4 screws attaching steering column

cover, to lower instrument panel. Then remove the

trim panel from the instrument panel (Fig. 6).

(4) Remove 3 screws (Fig. 7) attaching the steering

column cover liner to the instrument panel. Remove

the liner from the lower instrument panel.

(5) If vehicle is equipped with speed control,

remove the speed control switches from the steering

wheel (Fig. 8). If vehicle is not equipped with speed

control, remove the trim covers from the sides of the

steering wheel.WARNING: WHEN AN UNDEPLOYED AIR BAG

ASSEMBLY IS TO BE REMOVED FROM THE STEER-

ING WHEEL, DISCONNECT BATTERY GROUND

CABLE AND ISOLATE. ALLOW SYSTEM CAPACI-

TOR TO DISCHARGE FOR TWO MINUTES, THEN

BEGIN AIR BAG REMOVAL.

(6) Remove the 2 fasteners, 1 on each side of steer-

ing wheel, attaching the air bag module to the steer-

ing wheel (Fig. 9).

Fig. 6 Steering Column Cover

Fig. 7 Steering Column Cover Liner

Fig. 8 Speed Control Switches

Fig. 9 Air Bag Module Mounting Bolts

19 - 38 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 940 of 1200

WARNING: WHEN HANDLING AN UNDEPLOYED

AIR BAG MODULE DURING SERVICING OF THE

STEERING COLUMN THE FOLLOWING PRECAU-

TIONS SHOULD BE OBSERVED. AT NO TIME

SHOULD ANY SOURCE OF ELECTRICITY BE PER-

MITTED NEAR THE INFLATOR ON THE BACK OF

THE AIR BAG MODULE. WHEN CARRYING A LIVE

MODULE, THE TRIM COVER SHOULD BE POINTED

AWAY FROM THE BODY TO MINIMIZE INJURY IF

MODULE ACCIDENTLY DEPLOYS. IF AIR BAG MOD-

ULE IS PLACED ON A BENCH OR OTHER SUR-

FACE, PLASTIC COVER SHOULD BE FACE UP TO

MINIMIZE MOVEMENT IN CASE OF ACCIDENTAL

DEPLOYMENT.

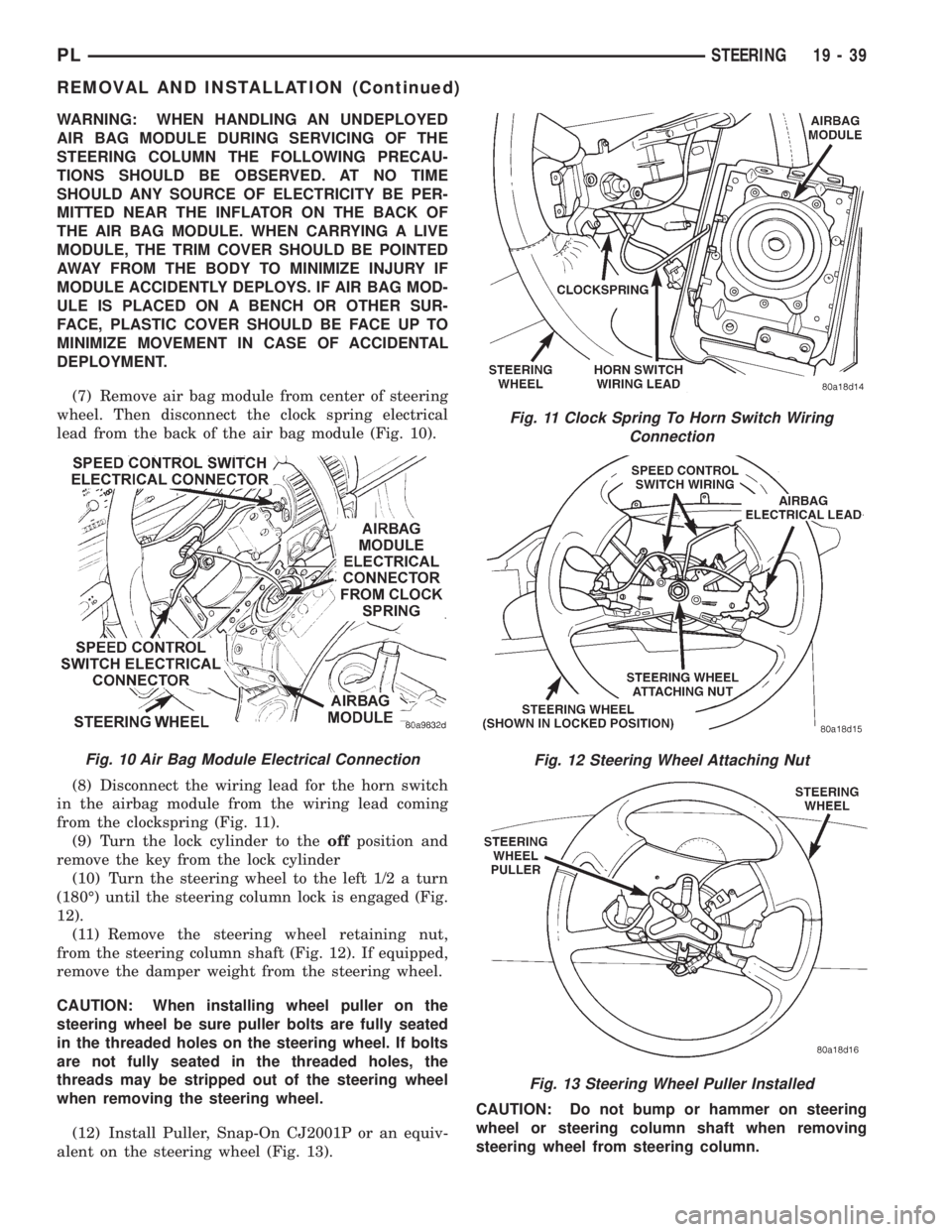

(7) Remove air bag module from center of steering

wheel. Then disconnect the clock spring electrical

lead from the back of the air bag module (Fig. 10).

(8) Disconnect the wiring lead for the horn switch

in the airbag module from the wiring lead coming

from the clockspring (Fig. 11).

(9) Turn the lock cylinder to theoffposition and

remove the key from the lock cylinder

(10) Turn the steering wheel to the left 1/2 a turn

(180É) until the steering column lock is engaged (Fig.

12).

(11) Remove the steering wheel retaining nut,

from the steering column shaft (Fig. 12). If equipped,

remove the damper weight from the steering wheel.

CAUTION: When installing wheel puller on the

steering wheel be sure puller bolts are fully seated

in the threaded holes on the steering wheel. If bolts

are not fully seated in the threaded holes, the

threads may be stripped out of the steering wheel

when removing the steering wheel.

(12) Install Puller, Snap-On CJ2001P or an equiv-

alent on the steering wheel (Fig. 13).CAUTION: Do not bump or hammer on steering

wheel or steering column shaft when removing

steering wheel from steering column.

Fig. 11 Clock Spring To Horn Switch Wiring

Connection

Fig. 12 Steering Wheel Attaching Nut

Fig. 13 Steering Wheel Puller Installed

Fig. 10 Air Bag Module Electrical Connection

PLSTEERING 19 - 39

REMOVAL AND INSTALLATION (Continued)