FORD MUSTANG 1969 Volume One Chassis

Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 341 of 413

07-03-01

FMX Transmission

07-03-01

PART

7-3 FMX

Transmission

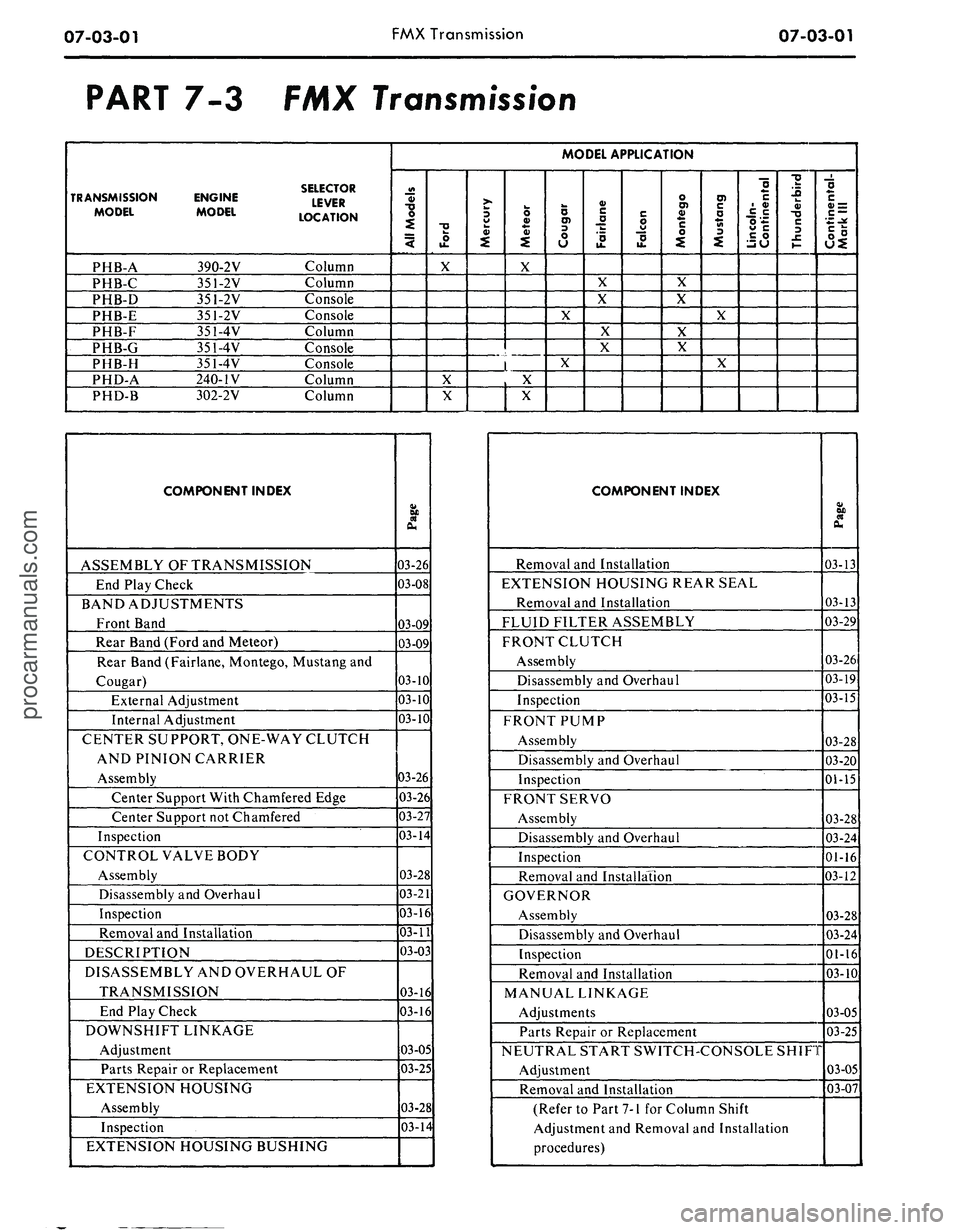

SELECTOR

TRANSMISSION ENGINE LEVER

MODEL MODEL LOCATION

PHB-A 390-2V Column

PHB-C 351-2V Column

PHB-D 351-2V Console

PHB-E 351-2V Console

PHB-F 351-4V Column

PHB-G 351-4V Console

PHB-H 351-4V Console

PHD-A 240-1V Column

PHD-B 302-2V Column

MODEL APPLICATION

All

Models

Ford

X

X

X

Mercury

Meteor

X

X

X

Cougar

X

X

Fairlane

X

X

X

X

Falcon

Montego

X

X

X

X

Mustang

X

X

Lincoln-

Continental

Thunderbird

Continental-

Mark III

COMPONENT INDEX

ASSEMBLY

OF

TRANSMISSION

End Play Check

BAND ADJUSTMENTS

Front Band

Rear Band (Ford

and

Meteor)

Rear Band (Fairlane, Montego, Mustang

and

Cougar)

External Adjustment

Internal Adjustment

CENTER SUPPORT, ONE-WAY CLUTCH

AND PINION CARRIER

Assembly

Center Support With Chamfered Edge

Center Support

not

Chamfered

Inspection

CONTROL VALVE BODY

Assembly

Disassembly

and

Overhaul

Inspection

Removal

and

Installation

DESCRIPTION

DISASSEMBLY

AND

OVERHAUL

OF

TRANSMISSION

End Play Check

DOWNSHIFT LINKAGE

Adjustment

Parts Repair

or

Replacement

EXTENSION HOUSING

Assembly

Inspection

EXTENSION HOUSING BUSHING

Page

03-26

03-08

03-09

03-09

03-10

03-10

03-10

03-26

03-26

03-27

03-14

03-28

03-21

03-16

03-11

03-03

03-16

03-16

03-05

03-25

03-28

03-14

COMPONENT INDEX

Removal

and

Installation

EXTENSION HOUSING REAR SEAL

Removal

and

Installation

FLUID FILTER ASSEMBLY

FRONT CLUTCH

Assembly

Disassembly

and

Overhaul

Inspection

FRONT PUMP

Assembly

Disassembly

and

Overhaul

Inspection

FRONT SERVO

Assembly

Disassembly

and

Overhaul

Inspection

Removal

and

Installation

GOVERNOR

Assembly

Disassembly

and

Overhaul

Inspection

Removal

and

Installation

MANUAL LINKAGE

Adjustments

Parts Repair

or

Replacement

NEUTRAL START SWITCH-CONSOLE SHIFT

Adjustment

Removal

and

Installation

(Refer

to

Part 7-1

for

Column Shift

Adjustment

and

Removal

and

Installation

procedures)

1

Page

03-13

03-13

03-29

03-26

03-19

03-15

03-28

03-20

01-15

03-28

03-24

01-16

03-12

03-28

03-24

01-16

03-10

03-05

03-25

03-05

03-07

procarmanuals.com

Page 342 of 413

07-03-02

FMX Transmission

07-03-02

COMPONENT INDEX

OIL PAN

Assembly

Removal and Installation

OUTPUT SHAFT

Assembly

Inspection

OUTPUT SHAFT BUSHING

Disassembly and Overhaul

PARKING PAWL

Removal and Installation

PRESSURE REGULATOR

Assembly

Disassembly and Overhaul

Inspection

Removal and Installation

PRIMARY SUN GEAR SHAFT

Disassembly and Overhaul

Inspection

REAR BRAKE DRUM SUPPORT BUSHING

Disassembly and Overhaul

REAR CLUTCH

Assembly

Disassembly and Overhaul

Inspection

Page

03-29

03-11

03-26

01-11

03-17

03-13

03-28

03-21

01-16

03-12

03-18

01-11

03-17

03-26

03-18

01-15

REAR SERVO

Assembly

Disassembly and Overhaul

Inspection

Removal and Installation

REAR SUPPORT

Assembly

Inspection

REAR SUPPORT BUSHING

Disassembly and Overhaul

SELECTOR LEVER-CONSOLE SHIFT

Removal and Installation

THROTTLE LINKAGE

Adjustment

Parts Repair or Replacement

TRANSMISSION (Complete)

Removal and Installation

TRANSMISSION CASE BUSHING

Parts Repair or Replacement

TRANSMISSION CASE LINKAGE

Parts Repair or Replacement

VACUUM DIAPHRAGM UNIT

Assembly

Adjustment

Checking

Page

03-28

03-24

01-16

03-12

03-28

03-15

03-21

03-08

03-05

03-05

03-14

03-26

03-25

03-29

01-07

01-04

DESCRIPTION

DESCRIPTION

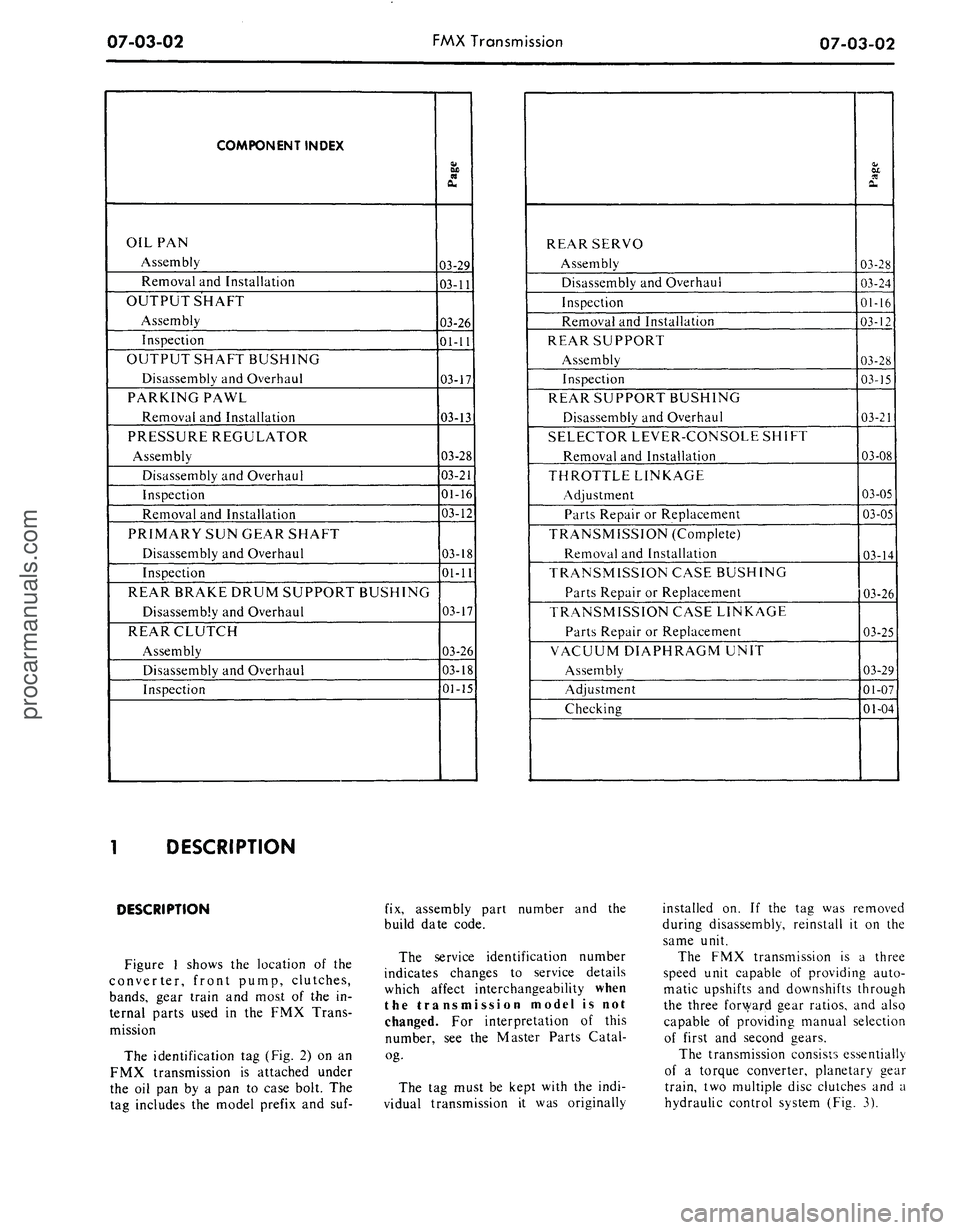

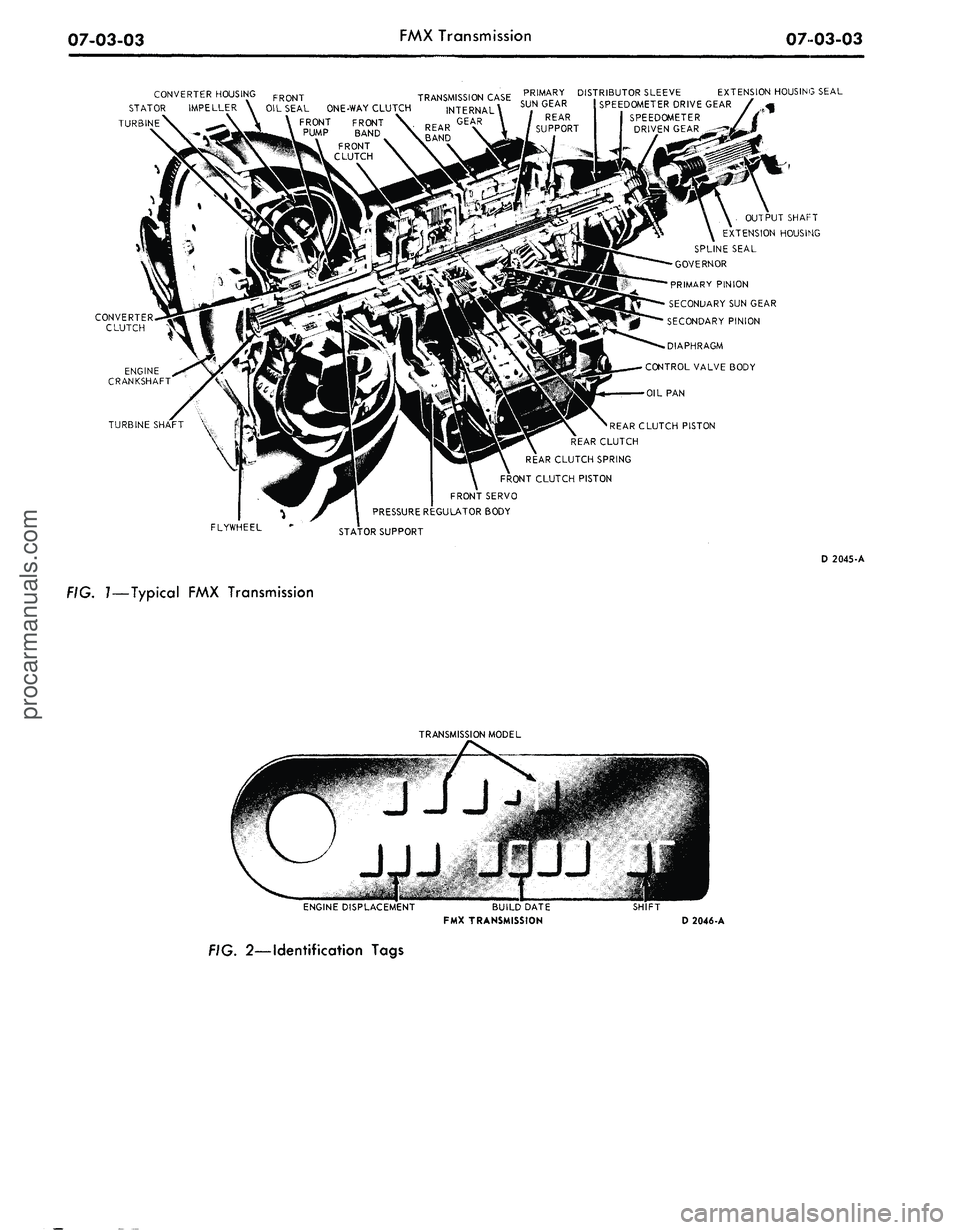

Figure 1 shows the location of the

converter, front pump, clutches,

bands,

gear train and most of the in-

ternal parts used in the FMX Trans-

mission

The identification tag (Fig. 2) on an

FMX transmission is attached under

the oil pan by a pan to case bolt. The

tag includes the model prefix and suf-

fix, assembly part number and the

build date code.

The service identification number

indicates changes to service details

which affect interchangeability when

the transmission model is not

changed. For interpretation of this

number, see the Master Parts Catal-

og-

The tag must be kept with the indi-

vidual transmission it was originally

installed on. If the tag was removed

during disassembly, reinstall it on the

same unit.

The FMX transmission is a three

speed unit capable of providing auto-

matic upshifts and downshifts through

the three forward gear ratios, and also

capable of providing manual selection

of first and second gears.

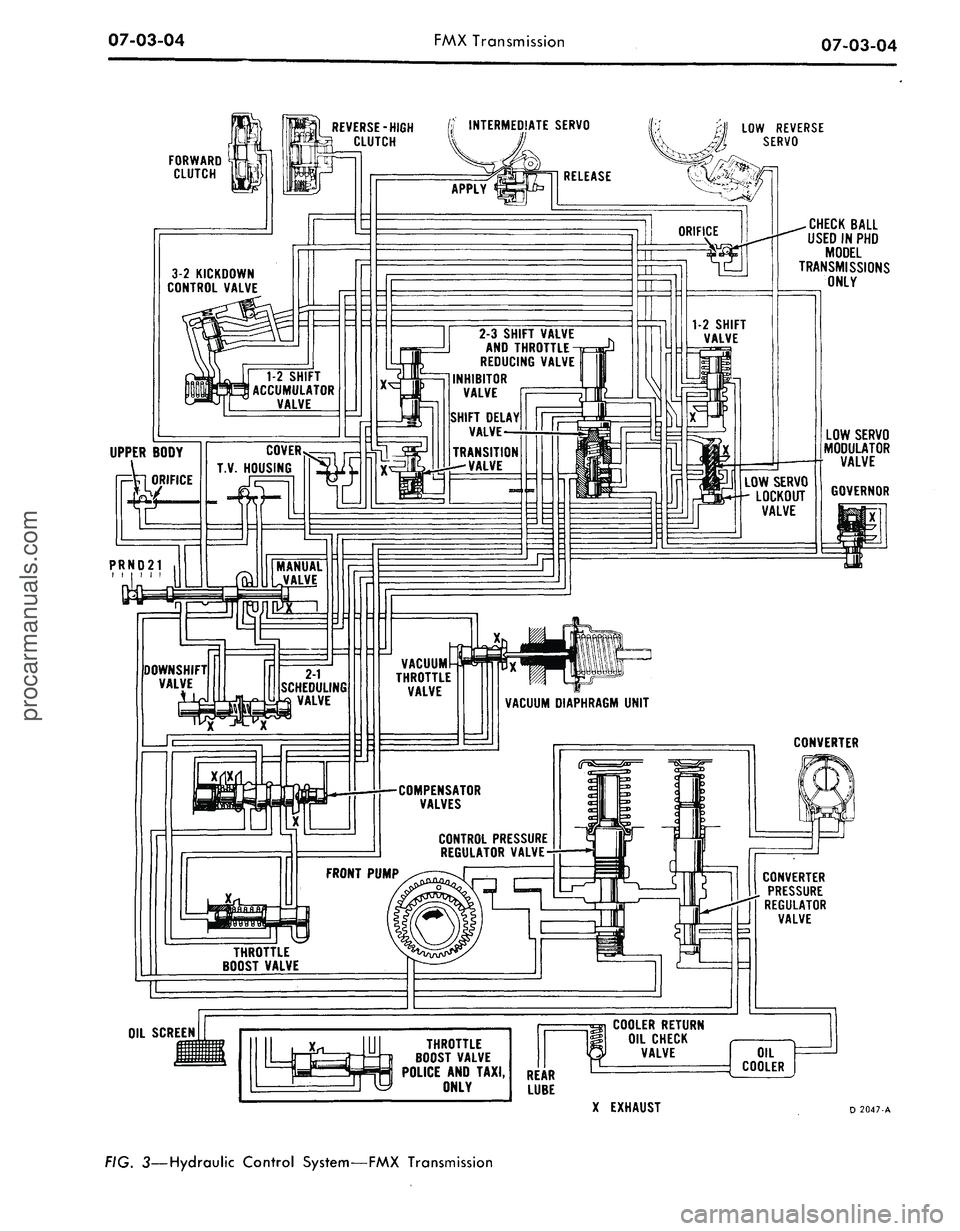

The transmission consists essentially

of a torque converter, planetary gear

train, two multiple disc clutches and a

hydraulic control system (Fig. 3).

procarmanuals.com

Page 343 of 413

07-03-03

FMX Transmission

0703-03

PRIMARY DISTRIBUTOR SLEEVE EXTENSION HOUSING SEAL

SUN GEAR ! SPEEDOMETER DRIVE GEAR /

OIL SEAL ONE-WAY CLUTCH

FRONT FRONT

PUMP BAND

FRONT

CLUTCH

OUTPUT SHAFT

EXTENSION HOUSING

SPLINE SEAL

GOVERNOR

PRIMARY PINION

SECONDARY SUN GEAR

SECONDARY PINION

DIAPHRAGM

CONTROL VALVE BODY

OIL PAN

TURBINE SHAFT

FLYWHEEL

'REAR CLUTCH PISTON

REAR CLUTCH

REAR CLUTCH SPRING

FRONT CLUTCH PISTON

FRONT SERVO

PRESSURE REGULATOR BODY

STATOR SUPPORT

D 2045-A

FIG. 7—Typical FMX Transmission

TRANSMISSION MODEL

ENGINE DISPLACEMENT

BUILD DATE

FMX TRANSMISSION

SHIFT

D 2046-A

FIG. 2—Identification Tagsprocarmanuals.com

Page 344 of 413

07-03-04

FMX Transmission

07-03-04

FORWARD

CLUTCH

REVERSE-HIGH

CLUTCH

' INTERMEDIATE SERVO

3-2 KICKDOWN

CONTROL VALVE

RELEASE

APPLY

LOW REVERSE

SERVO

ORIFICE

LOW SERVO

LOCKOUT

VALVE

2-3 SHIFT VALVE

AND THROTTLE

REDUCING VALVE

1-2 SHIFT

ACCUMULATOR

VALVE

CHECK BALL

USED IN PHD

MODEL

TRANSMISSIONS

ONLY

LOW SERVO

MODULATOR

VALVE

GOVERNOR

CONTROL PRESSURE

REGULATOR VALVE

FRONT PUMP

THROTTLE

BOOST VALVE

OIL

SCREEN

CONVERTER

CONVERTER

PRESSURE

REGULATOR

VALVE

THROTTLE

BOOST VALVE

POLICE

AND

TAXI,

ONLY

COOLER RETURN

OIL CHECK

VALVE

REAR

LUBE

OIL

COOLER

X EXHAUST

D 2047-A

FIG.

3—Hydraulic

Control System—FMX Transmissionprocarmanuals.com

Page 345 of 413

07-03-05

FMX Transmission

07-03-05

IN-VEHICLE ADJUSTMENTS AND REPAIRS

CONTROL LINKAGE

ADJUSTMENTS

The transmission control linkage

adjustments should be performed in

the order in which they appear in this

section of the manual.

THROTTLE AND

DOWNSHIFT LINKAGE

ADJUSTMENTS

Adjusting the throttle linkage is im-

portant to be certain the throttle and

kickdown systems are properly adjust-

ed. The kickdown system should come

in when the accelerator is pressed

through detent, and not before detent.

Refer to Group 10 for detailed

throttle and downshift linkage adjust-

ment procedures.

MANUAL LINKAGE

ADJUSTMENT

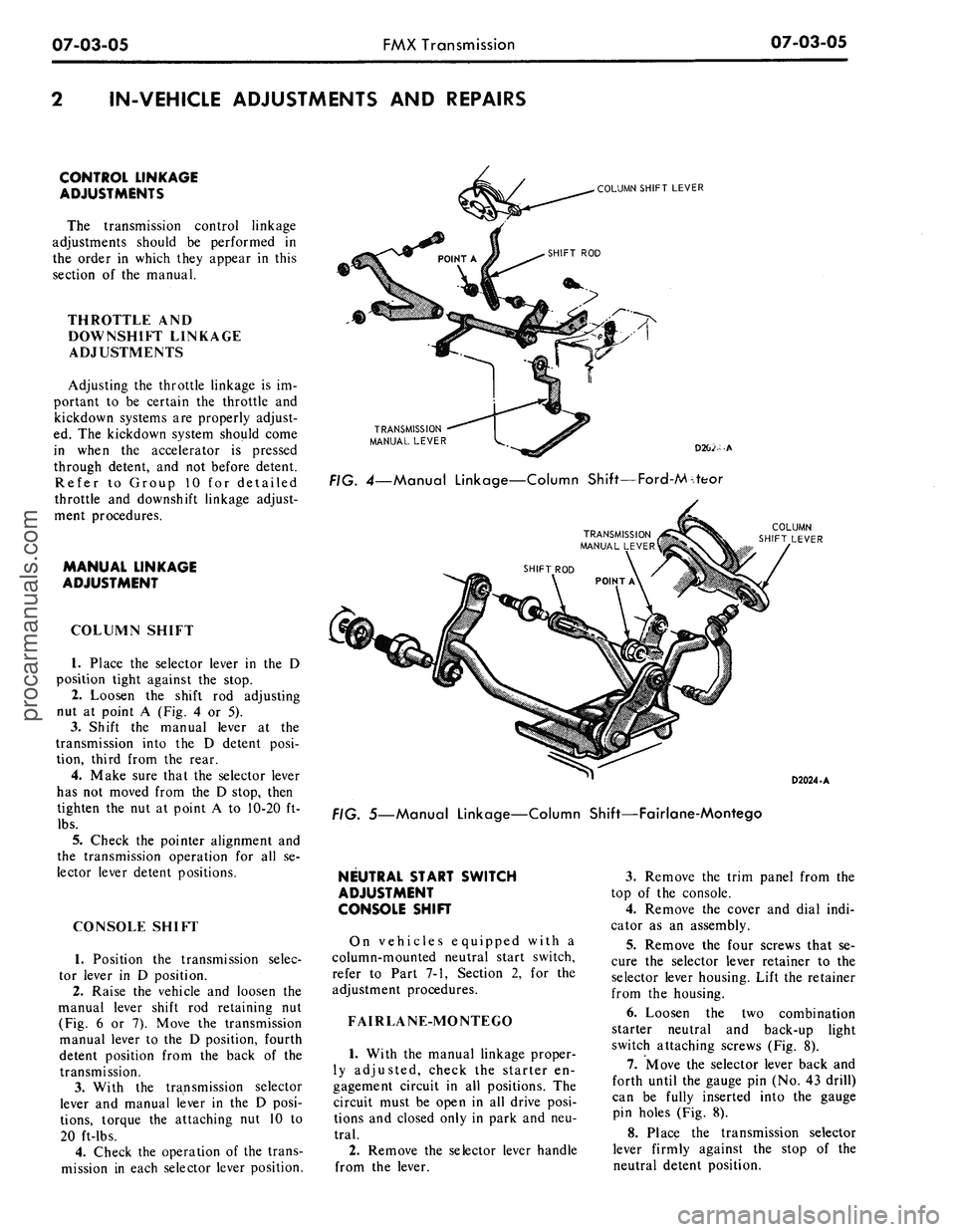

COLUMN SHIFT

1.

Place the selector lever in the D

position tight against the stop.

2.

Loosen the shift rod adjusting

nut at point A (Fig. 4 or 5).

3.

Shift the manual lever at the

transmission into the D detent posi-

tion, third from the rear.

4.

Make sure that the selector lever

has not moved from the D stop, then

tighten the nut at point A to 10-20 ft-

lbs.

5.

Check the pointer alignment and

the transmission operation for all se-

lector lever detent positions.

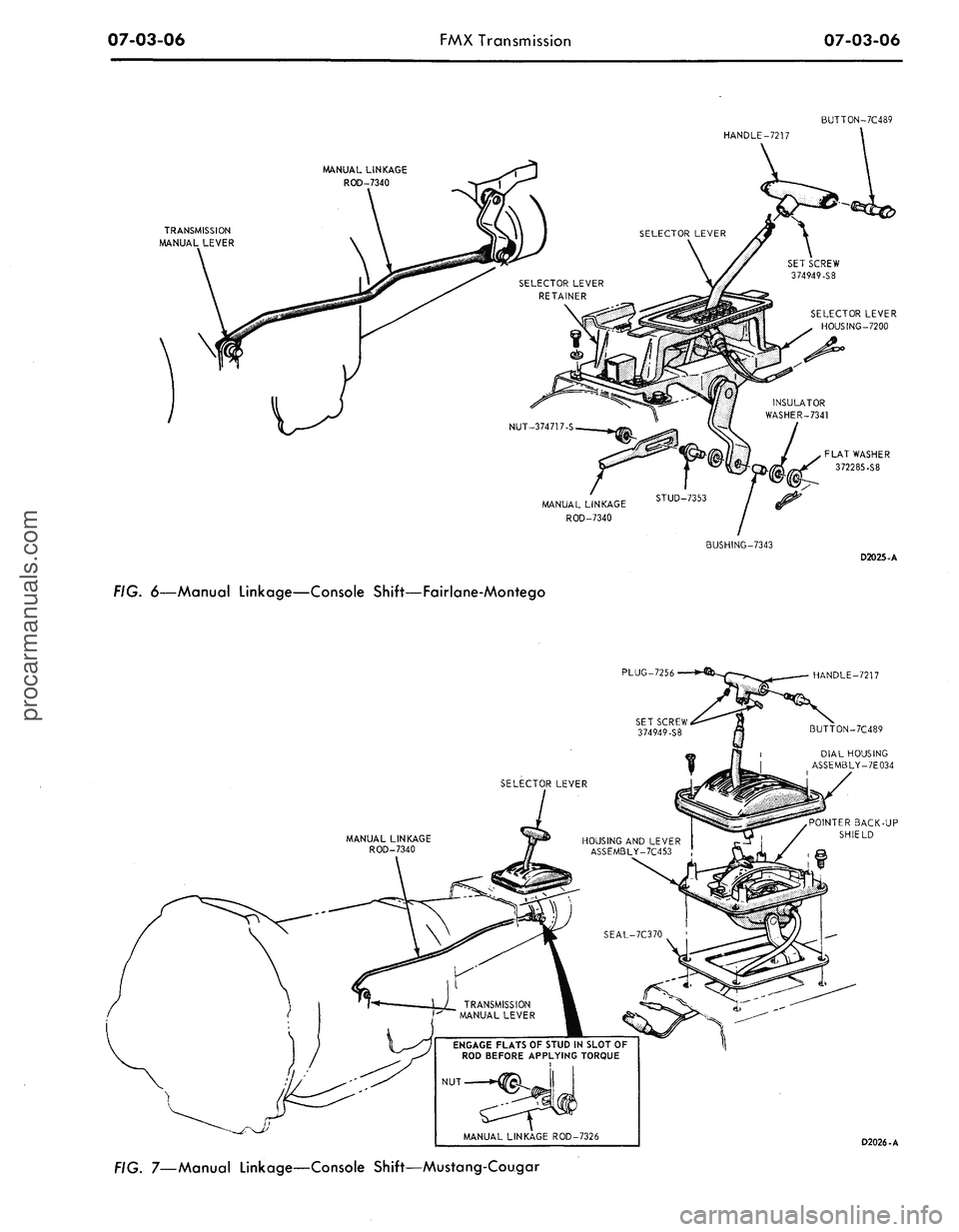

CONSOLE SHIFT

1.

Position the transmission selec-

tor lever in D position.

2.

Raise the vehicle and loosen the

manual lever shift rod retaining nut

(Fig. 6 or 7). Move the transmission

manual lever to the D position, fourth

detent position from the back of the

transmission.

3.

With the transmission selector

lever and manual lever in the D posi-

tions,

torque the attaching nut 10 to

20 ft-lbs.

4.

Check the operation of the trans-

mission in each selector lever position.

COLUMN SHIFT LEVER

€>

TRANSMISSION

MANUAL LEVER

FIG. 4—Manual Linkage—Column Shift—Ford-Mteor

D2024-A

FIG. 5—Manual Linkage—Column Shift—Fairlane-Montego

NEUTRAL START SWITCH

ADJUSTMENT

CONSOLE SHIFT

On vehicles equipped with a

column-mounted neutral start switch,

refer to Part 7-1, Section 2, for the

adjustment procedures.

FAIRLANE-MONTEGO

1.

With the manual linkage proper-

ly adjusted, check the starter en-

gagement circuit in all positions. The

circuit must be open in all drive posi-

tions and closed only in park and neu-

tral.

2.

Remove the selector lever handle

from the lever.

3.

Remove the trim panel from the

top of the console.

4.

Remove the cover and dial indi-

cator as an assembly.

5.

Remove the four screws that se-

cure the selector lever retainer to the

selector lever housing. Lift the retainer

from the housing.

6. Loosen the two combination

starter neutral and back-up light

switch attaching screws (Fig. 8).

7.

Move the selector lever back and

forth until the gauge pin (No. 43 drill)

can be fully inserted into the gauge

pin holes (Fig. 8).

8. Place the transmission selector

lever firmly against the stop of the

neutral detent position.procarmanuals.com

Page 346 of 413

07-03-06

FMX Transmission

07-03-06

BUTTON-7C489

TRANSMISSION

MANUAL LEVER

MANUAL LINKAGE

ROD-7340

HANDLE-7217

MANUAL LINKAGE

ROD-7340

BUSHING-7343

FIG.

6—Manual

Linkage—Console Shift—Fairlane-Montego

D2025-A

PLUG-7256

SELECTOR LEVER

HOUSING AND LEVER

ASSEM3LY-7C453

,'

SEAL-7C370

ENGAGE FLATS OF STUD

IN

SLOT

OF

ROD BEFORE APPLYING TORQUE

NUT

—^

MANUAL LINKAGE ROD-7326

HANDLE-7217

BUTTON-7C489

DIAL HOUSING

ASSEMBLY-7E034

POINTER 3ACK-UP

SHIELD

D2026-A

FIG.

7—Manual

Linkage—Console Shift—Mustang-Cougarprocarmanuals.com

Page 347 of 413

07-03-07

FMX Transmission

07-03-07

Gauge Pin

(No.

43 Drill)

NEUTRAL START

SWITCH

ADJUSTMENT

SCREWS

D 1759-A

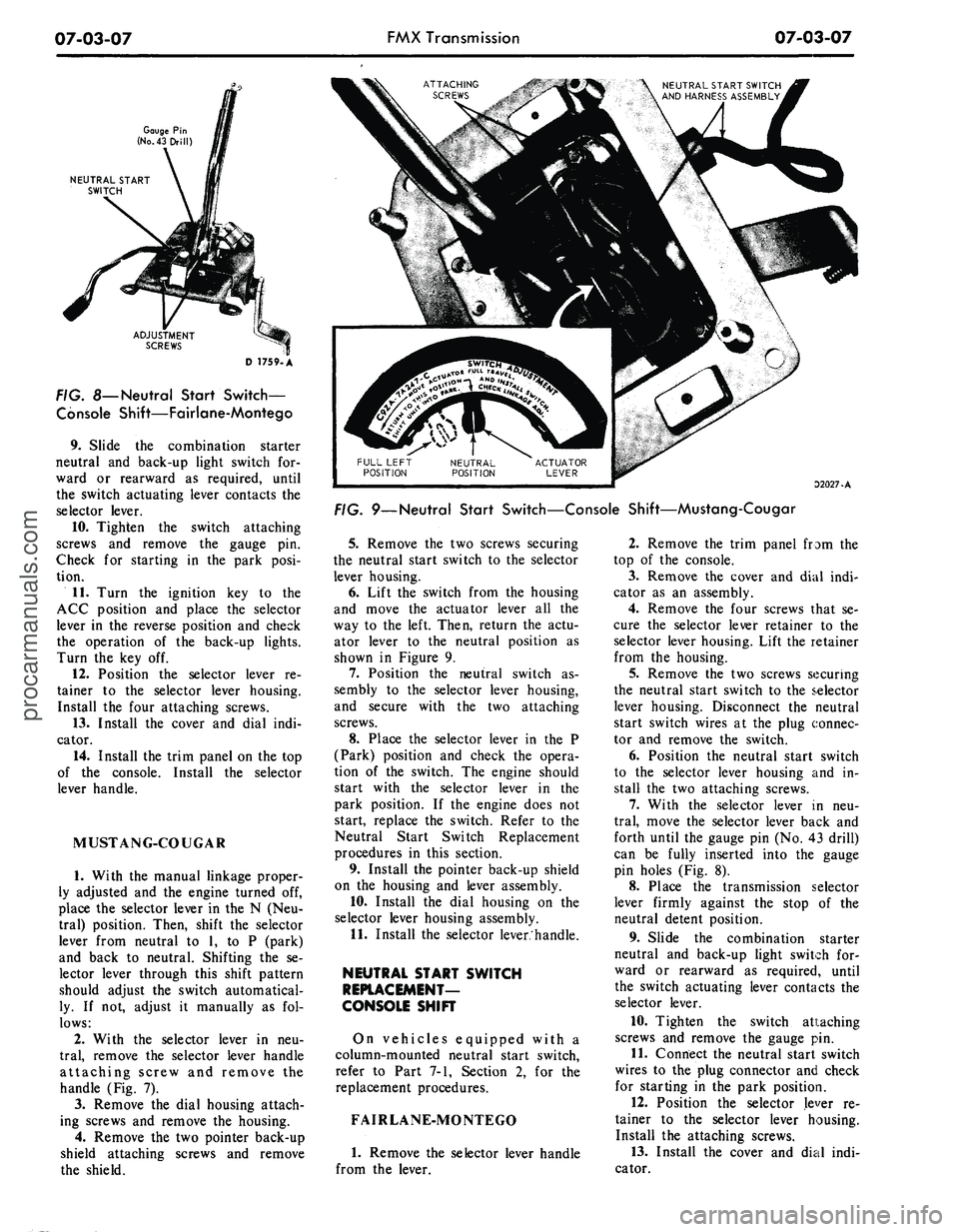

FIG. 8—

Neutral

Start Switch-

Console Shift—Fairlane-Montego

9. Slide the combination starter

neutral and back-up light switch for-

ward or rearward as required, until

the switch actuating lever contacts the

selector lever.

10.

Tighten the switch attaching

screws and remove the gauge pin.

Check for starting in the park posi-

tion.

11.

Turn the ignition key to the

ACC position and place the selector

lever in the reverse position and check

the operation of the back-up lights.

Turn the key off.

12.

Position the selector lever re-

tainer to the selector lever housing.

Install the four attaching screws.

13.

Install the cover and dial indi-

cator.

14.

Install the trim panel on the top

of the console. Install the selector

lever handle.

MUSTANG-COUGAR

1.

With the manual linkage proper-

ly adjusted and the engine turned off,

place the selector lever in the N (Neu-

tral) position. Then, shift the selector

lever from neutral to 1, to P (park)

and back to neutral. Shifting the se-

lector lever through this shift pattern

should adjust the switch automatical-

ly. If not, adjust it manually as fol-

lows:

2.

With the selector lever in neu-

tral,

remove the selector lever handle

attaching screw and remove the

handle (Fig. 7).

3.

Remove the dial housing attach-

ing screws and remove the housing.

4.

Remove the two pointer back-up

shield attaching screws and remove

the shield.

NEUTRAL START SWITCH

AND HARNESS ASSEMBLY

32027-A

FIG. 9—Neutral Start Switch—Console Shift—Mustang-Cougar

5.

Remove the two screws securing

the neutral start switch to the selector

lever housing.

6. Lift the switch from the housing

and move the actuator lever all the

way to the left. Then, return the actu-

ator lever to the neutral position as

shown in Figure 9.

7.

Position the neutral switch as-

sembly to the selector lever housing,

and secure with the two attaching

screws.

8. Place the selector lever in the P

(Park) position and check the opera-

tion of the switch. The engine should

start with the selector lever in the

park position. If the engine does not

start, replace the switch. Refer to the

Neutral Start Switch Replacement

procedures in this section.

9. Install the pointer back-up shield

on the housing and lever assembly.

10.

Install the dial housing on the

selector lever housing assembly.

11.

Install the selector lever.'handle.

NEUTRAL START SWITCH

REPLACEMENT-

CONSOLE SHIFT

On vehicles equipped with a

column-mounted neutral start switch,

refer to Part 7-1, Section 2, for the

replacement procedures.

FAIRLANE-MONTEGO

1.

Remove the selector lever handle

from the lever.

2.

Remove the trim panel from the

top of the console.

3.

Remove the cover and dial indi-

cator as an assembly.

4.

Remove the four screws that se-

cure the selector lever retainer to the

selector lever housing. Lift the retainer

from the housing.

5.

Remove the two screws securing

the neutral start switch to the selector

lever housing. Disconnect the neutral

start switch wires at the plug connec-

tor and remove the switch.

6. Position the neutral start switch

to the selector lever housing and in-

stall the two attaching screws.

7.

With the selector lever in neu-

tral,

move the selector lever back and

forth until the gauge pin (No. 43 drill)

can be fully inserted into the gauge

pin holes (Fig. 8).

8. Place the transmission selector

lever firmly against the stop of the

neutral detent position.

9. Slide the combination starter

neutral and back-up light switch for-

ward or rearward as required, until

the switch actuating lever contacts the

selector lever.

10.

Tighten the switch attaching

screws and remove the gauge pin.

11.

Connect the neutral start switch

wires to the plug connector and check

for starting in the park position.

12.

Position the selector lever re-

tainer to the selector lever housing.

Install the attaching screws.

13.

Install the cover and dial indi-

cator.procarmanuals.com

Page 348 of 413

07-03-08

FAAX Transmission

07-03-08

14.

Install the trim panel on the top

of the console. Install the selector

lever handle.

MUSTANG-COUGAR

1.

Place the transmission selector

lever in the N (Neutral) position.

2.

Raise the vehicle and remove the

manual lever control rod attaching nut

(Fig. 7).

3.

Lower the vehicle and remove

the selector lever handle attaching

screw and the handle.

4.

Remove the dial housing attach-

ing screws and the housing.

5.

Disconnect the dial indicator

light.

6. Disconnect the neutral start

switch and dial indicator light wires

from their connectors at the dash

panel.

7.

Remove the four selector housing

and lever assembly attaching bolts.

Remove the selector lever and housing

assembly.

8. Remove the two pointer back-up

shield attaching screws and remove

the shield.

9. Remove the two screws securing

the neutral start switch to the selector

lever housing. Push the neutral start

switch harness plug inward and re-

move the switch and harness assembly

(Fig. 9).

10.

Before installing the new

switch, hold it with the wires facing

downward and move the actuator

lever all the way to the left. Then, re-

turn the actuator lever to the neutral

position as shown in Figure 9.

11.

Position the harness and neutral

switch assembly in the selector lever

housing. Secure with the two attach-

ing screws.

12.

Install the pointer back-up

shield on the housing and lever assem-

bly.

13.

Position the selector lever and

housing assembly on the console and

install the attaching bolts.

14.

Connect the dial indicator light.

15.

Connect the neutral start switch

and dial indicator light wires to their

respective connectors at the dash

panel.

16.

Install the dial housing on the

selector lever housing assembly.

17.

Install the selector lever handle.

18.

Raise the vehicle and secure the

manual lever control rod to the selec-

tor lever arm.

19.

Lower the vehicle.

20.

Place the selector lever in the

park position and check the operation

of the switch.

DETENT PAWL

LOCK

NUT

DETENT PAWL

ADJUSTMENT SCREW

DETENT PLATE

D 1644-A

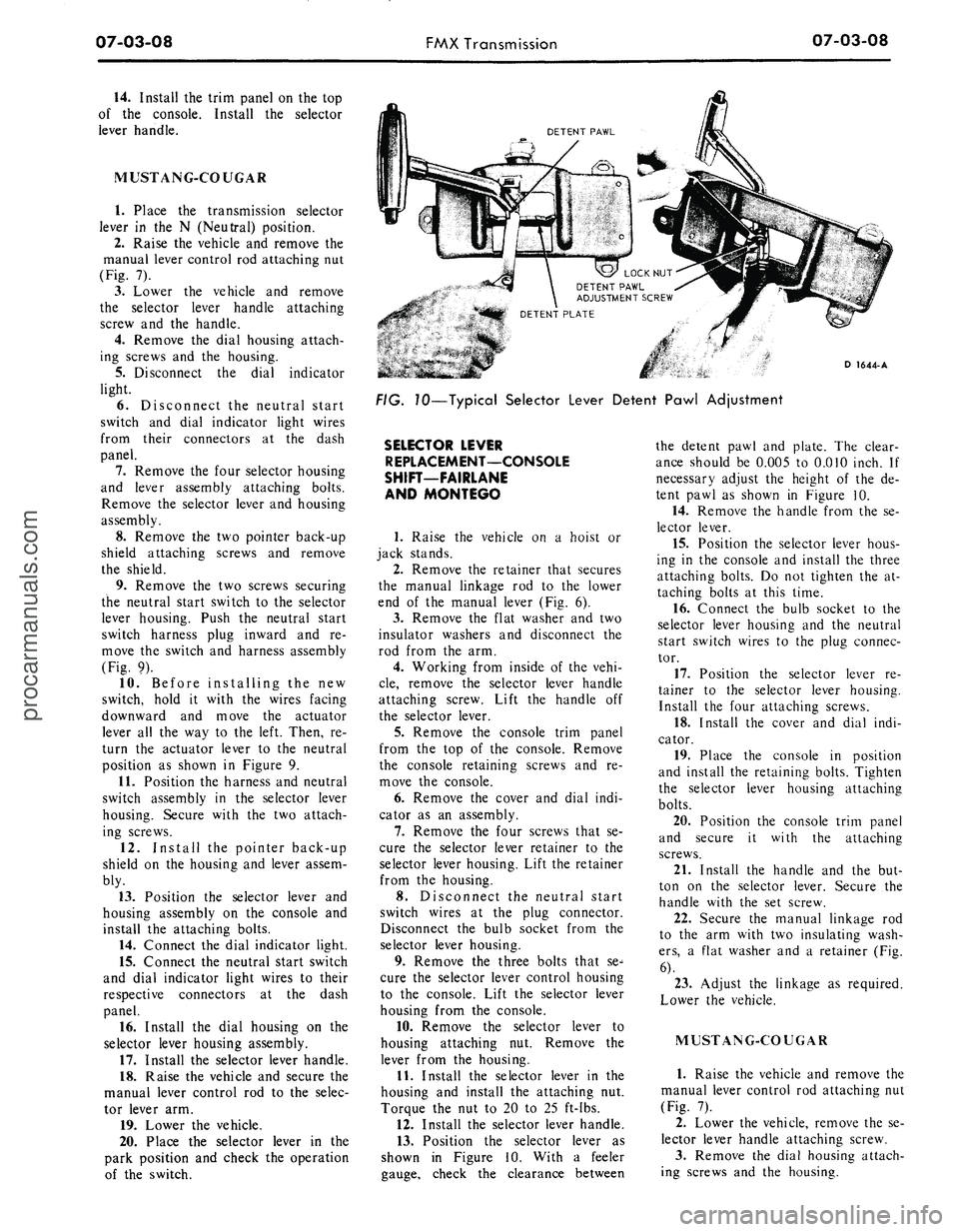

FIG.

10—Typical Selector Lever Detent Pawl Adjustment

SELECTOR LEVER

REPLACEMENT—CONSOLE

SHIFT—FAIRLANE

AND

MONTEGO

1.

Raise the vehicle on a hoist or

jack stands.

2.

Remove the retainer that secures

the manual linkage rod to the lower

end of the manual lever (Fig. 6).

3.

Remove the flat washer and two

insulator washers and disconnect the

rod from the arm.

4.

Working from inside of the vehi-

cle,

remove the selector lever handle

attaching screw. Lift the handle off

the selector lever.

5.

Remove the console trim panel

from the top of the console. Remove

the console retaining screws and re-

move the console.

6. Remove the cover and dial indi-

cator as an assembly.

7.

Remove the four screws that se-

cure the selector lever retainer to the

selector lever housing. Lift the retainer

from the housing.

8. Disconnect the neutral start

switch wires at the plug connector.

Disconnect the bulb socket from the

selector lever housing.

9. Remove the three bolts that se^

cure the selector lever control housing

to the console. Lift the selector lever

housing from the console.

10.

Remove the selector lever to

housing attaching nut. Remove the

lever from the housing.

11.

Install the selector lever in the

housing and install the attaching nut.

Torque the nut to 20 to 25 ft-lbs.

12.

Install the selector lever handle.

13.

Position the selector lever as

shown in Figure 10. With a feeler

gauge,

check the clearance between

the detent pawl and plate. The clear-

ance should be 0.005 to 0.010 inch. If

necessary adjust the height of the de-

tent pawl as shown in Figure 10.

14.

Remove the handle from the se-

lector lever.

15.

Position the selector lever hous-

ing in the console and install the three

attaching bolts. Do not tighten the at-

taching bolts at this time.

16.

Connect the bulb socket to the

selector lever housing and the neutral

start switch wires to the plug connec-

tor.

17.

Position the selector lever re-

tainer to the selector lever housing.

Install the four attaching screws.

18.

Install the cover and dial indi-

cator.

19.

Place the console in position

and install the retaining bolts. Tighten

the selector lever housing attaching

bolts.

20.

Position the console trim panel

and secure it with the attaching

screws.

21.

Install the handle and the but-

ton on the selector lever. Secure the

handle with the set screw.

22.

Secure the manual linkage rod

to the arm with two insulating wash-

ers,

a flat washer and a retainer (Fig.

6).

23.

Adjust the linkage as required.

Lower the vehicle.

MUSTANG-COUGAR

1.

Raise the vehicle and remove the

manual lever control rod attaching nut

(Fig. 7).

2.

Lower the vehicle, remove the se-

lector lever handle attaching screw.

3.

Remove the dial housing attach-

ing screws and the housing.procarmanuals.com

Page 349 of 413

07-03-09

FMX Transmission

07-03-09

4.

Remove the pointer back-up

shield attaching screws and the shield.

5.

Disconnect the dial indicator

light.

6. Disconnect the neutral start

switch and dial indicator light wires

from their connectors at the dash

panel.

7.

Remove the selector housing and

lever assembly attaching bolts. Re-

move the selector lever and housing.

8. Remove the selector lever to

housing attaching nut. Remove the

lever from the housing.

9. Install the selector lever in the

housing and install the attaching nut.

Torque the nut to 20 to 25 ft-lbs.

10.

Install the selector lever handle.

11.

Position the selector lever as

shown in Figure 10. With a feeler

gauge check the clearance between the

detent pawl and plate. The clearince

should be 0.005 to 0.010 inch. If nec-

essary, adjust the height of the detent

pawl as shown in Figure 10.

12.

Remo"~ the handle from tte se-

lector lever.

13.

Install the selector housing and

lever assembly as shown in Figure 4.

Torque the attaching bolts 4-6 ft-lbs.

14.

Connect the dial indicator light.

15.

Connect the neutral start switch

and dial indicator light wires to their

respective connectors at the dash

panel.

16.

Install the pointer back-up

shield and tighten the attaching

screws.

17.

Install the selector lever handle

and tighten the attaching screw.

18.

Position the selector lever in the

D position.

19.

Raise the vehicle. Install the

transmission manual lever rod to the

selector lever. Adjust the manual link-

age.

20.

Lower the vehicle and check the

transmission operation in each selec-

tor lever detent position.

BAND ADJUSTMENTS

FRONT BAND

ADJUSTMENT

1.

Drain the fluid from the trans-

mission by loosening the pan attach-

ing bolts starting at the rear of the

pan and working toward the front.

When most of the fluid has drained

from the pan, remove the remainder

of the attaching bolts. Use a clean

drain can equipped with a 100-mesh

screen if the fluid is to be reused.

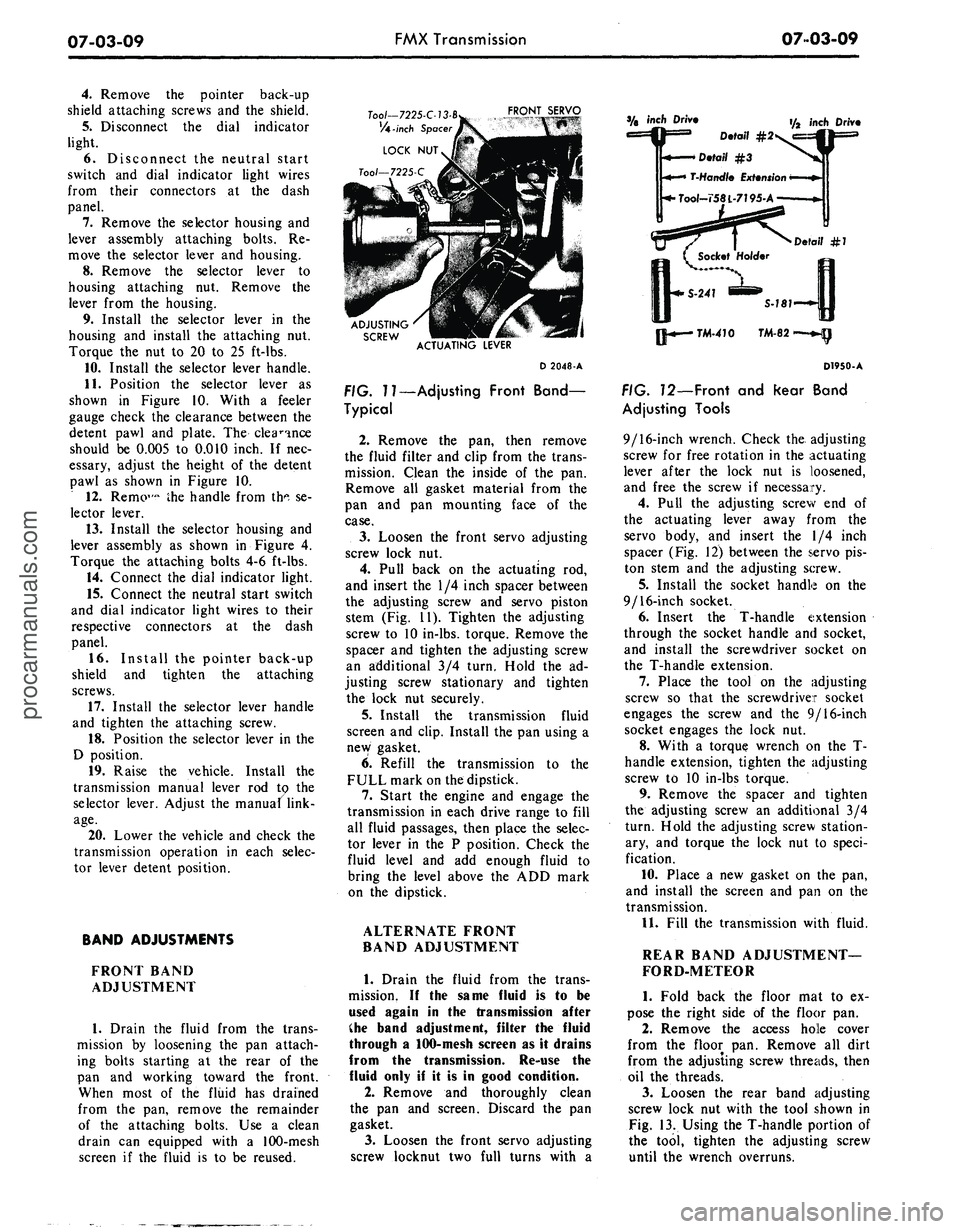

Too/—

7225-C-13B

/A

-inch

Spacer

FRONT SERVO

ACTUATING LEVER

D 2048-A

FIG.

7

7—Adjusting Front Band—

Typical

2.

Remove the pan, then remove

the fluid filter and clip from the trans-

mission. Clean the inside of the pan.

Remove all gasket material from the

pan and pan mounting face of the

case.

3.

Loosen the front servo adjusting

screw lock nut.

4.

Pull back on the actuating rod,

and insert the 1/4 inch spacer between

the adjusting screw and servo piston

stem (Fig. 11). Tighten the adjusting

screw to 10 in-lbs. torque. Remove the

spacer and tighten the adjusting screw

an additional 3/4 turn. Hold the ad-

justing screw stationary and tighten

the lock nut securely.

5.

Install the transmission fluid

screen and clip. Install the pan using a

new gasket.

6. Refill the transmission to the

FULL mark on the dipstick.

7.

Start the engine and engage the

transmission in each drive range to fill

all fluid passages, then place the selec-

tor lever in the P position. Check the

fluid level and add enough fluid to

bring the level above the ADD mark

on the dipstick.

ALTERNATE FRONT

BAND ADJUSTMENT

1.

Drain the fluid from the trans-

mission. If the same fluid is to be

used again in the transmission after

Che band adjustment, filter the fluid

through a 100-mesh screen as it drains

from the transmission. Re-use the

fluid only if it is in good condition.

2.

Remove and thoroughly clean

the pan and screen. Discard the pan

gasket.

3.

Loosen the front servo adjusting

screw locknut two full turns with a

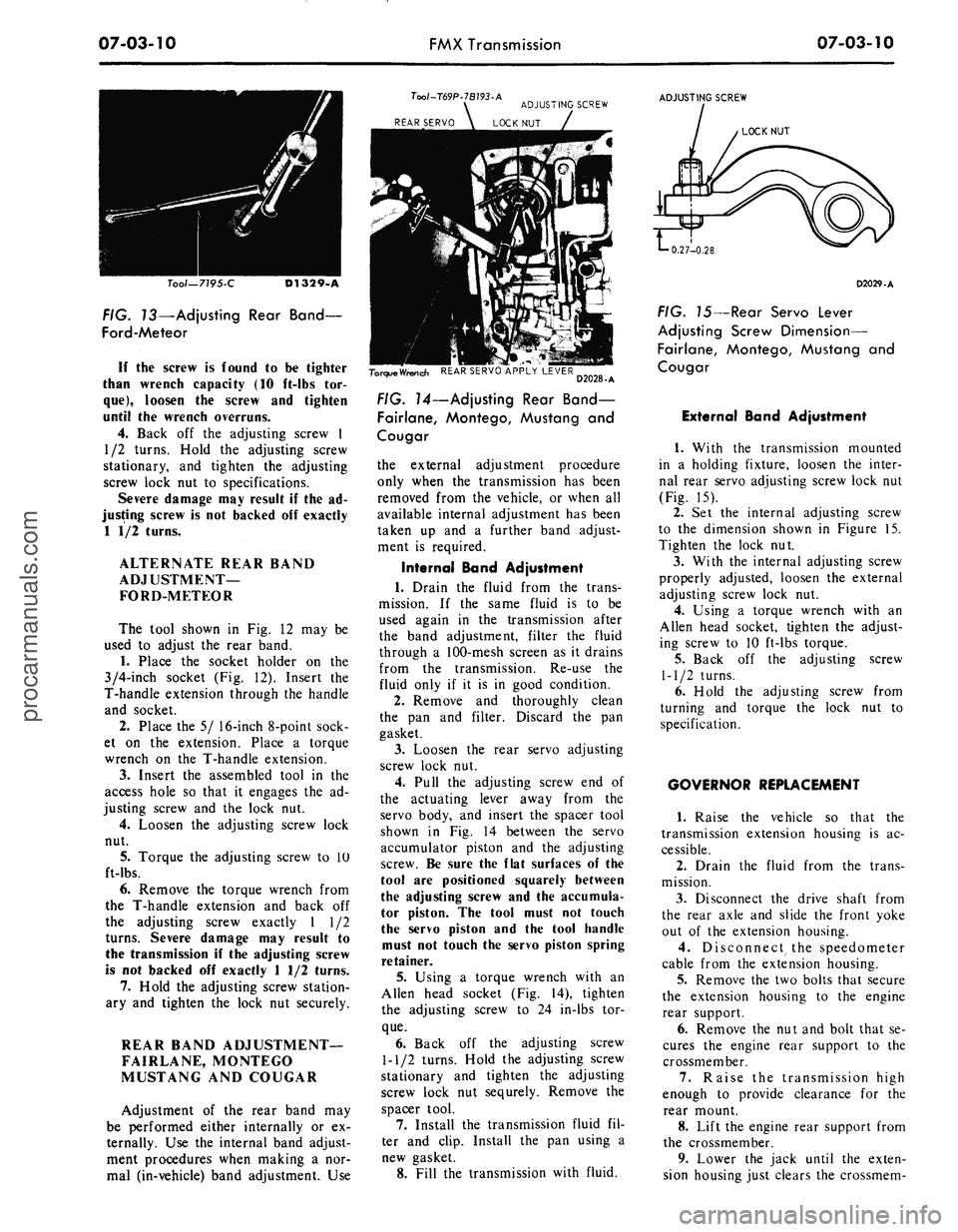

inch Driv

Detail #2

D.tai\

#3

T-Hond/e

Extension

Tool-758L-7195-A

f/2 inch Driv

Detail

#7

Qj-«—

TM-470 TM-82

D1950-A

FIG. 12—Front and Rear Band

Adjusting Tools

9/16-inch wrench. Check the. adjusting

screw for free rotation in the actuating

lever after the lock nut is loosened,

and free the screw if necessary.

4.

Pull the adjusting screw end of

the actuating lever away from the

servo body, and insert the 1/4 inch

spacer (Fig. 12) between the servo pis-

ton stem and the adjusting screw.

5.

Install the socket handle on the

9/16-inch socket.

6. Insert the T-handle extension

through the socket handle and socket,

and install the screwdriver socket on

the T-handle extension.

7.

Place the tool on the adjusting

screw so that the screwdriver socket

engages the screw and the 9/16-inch

socket engages the lock nut.

8. With a torque wrench on the T-

handle extension, tighten the adjusting

screw to 10 in-lbs torque.

9. Remove the spacer and tighten

the adjusting screw an additional 3/4

turn. Hold the adjusting screw station-

ary, and torque the lock nut to speci-

fication.

10.

Place a new gasket on the pan,

and install the screen and pan on the

transmission.

11.

Fill the transmission with fluid.

REAR BAND ADJUSTMENT—

FORD-METEOR

1.

Fold back the floor mat to ex-

pose the right side of the floor pan.

2.

Remove the access hole cover

from the floor pan. Remove all dirt

from the adjusting screw threads, then

oil the threads.

3.

Loosen the rear band adjusting

screw lock nut with the tool shown in

Fig. 13. Using the T-handle portion of

the tool, tighten the adjusting screw

until the wrench overruns.procarmanuals.com

Page 350 of 413

07-03-10

FMX Transmission

07-03-10

Too/-T69P-7B793-A

ADJUSTING SCREW

REAR SERVO \ LOCK NUT

Tool—7795-C

D1329-A

FIG. 13—Adjusting Rear Band—

Ford-Meteor

If

the

screw

is

found

to be

tighter

than

wrench

capacity

(10

ft-lbs

tor-

que),

loosen

the

screw

and

tighten

until

the

wrench

overruns.

4.

Back off the adjusting screw 1

1/2 turns. Hold the adjusting screw

stationary, and tighten the adjusting

screw lock nut to specifications.

Severe damage may result if the ad-

justing screw is not backed off exactly

1 1/2 turns.

ALTERNATE REAR BAND

ADJUSTMENT—

FORD-METEOR

The tool shown in Fig. 12 may be

used to adjust the rear band.

1.

Place the socket holder on the

3/4-inch socket (Fig. 12). Insert the

T-handle extension through the handle

and socket.

2.

Place the 5/ 16-inch 8-point sock-

et on the extension. Place a torque

wrench on the T-handle extension.

3.

Insert the assembled tool in the

access hole so that it engages the ad-

justing screw and the lock nut.

4.

Loosen the adjusting screw lock

nut.

5.

Torque the adjusting screw to 10

ft-lbs.

6. Remove the torque wrench from

the T-handle extension and back off

the adjusting screw exactly 1 1/2

turns.

Severe

damage

may

result

to

the

transmission

if the

adjusting

screw

is

not

backed

off

exactly

11/2

turns.

7.

Hold the adjusting screw station-

ary and tighten the lock nut securely.

REAR BAND ADJUSTMENT—

FAIRLANE, MONTEGO

MUSTANG AND COUGAR

Adjustment of the rear band may

be performed either internally or ex-

ternally. Use the internal band adjust-

ment procedures when making a nor-

mal (in-vehicle) band adjustment. Use

ADJUSTING SCREW

LOCK NUT

I

IN

TorqueWrench REAR SERVO APPLY LEVER

D2028-A

FIG. 14—Adjusting Rear Band—

Fairlane, Montego, Mustang and

Cougar

the external adjustment procedure

only when the transmission has been

removed from the vehicle, or when all

available internal adjustment has been

taken up and a further band adjust-

ment is required.

Internal Band Adjustment

1.

Drain the fluid from the trans-

mission. If the same fluid is to be

used again in the transmission after

the band adjustment, filter the fluid

through a 100-mesh screen as it drains

from the transmission. Re-use the

fluid only if it is in good condition.

2.

Remove and thoroughly clean

the pan and filter. Discard the pan

gasket.

3.

Loosen the rear servo adjusting

screw lock nut.

4.

Pull the adjusting screw end of

the actuating lever away from the

servo body, and insert the spacer tool

shown in Fig. 14 between the servo

accumulator piston and the adjusting

screw.

Be

sure

the

flat

surfaces

of the

tool

are

positioned

squarely

between

the

adjusting

screw

and the

accumula-

tor

piston.

The

tool must

not

touch

the servo

piston

and the

tool

handle

must

not

touch

the

servo

piston

spring

retainer.

5.

Using a torque wrench with an

Allen head socket (Fig. 14), tighten

the adjusting screw to 24 in-lbs tor-

que.

6. Back off the adjusting screw

1-1/2 turns. Hold the adjusting screw

stationary and tighten the adjusting

screw lock nut sequrely. Remove the

spacer tool.

7.

Install the transmission fluid fil-

ter and clip. Install the pan using a

new gasket.

8. Fill the transmission with fluid.

D2029-A

FIG. 15—Rear Servo Lever

Adjusting Screw Dimension—

Fairlane, Montego, Mustang and

Cougar

External Band Adjustment

1.

With the transmission mounted

in a holding fixture, loosen the inter-

nal rear servo adjusting screw lock nut

(Fig. 15).

2.

Set the internal adjusting screw

to the dimension shown in Figure 15.

Tighten the lock nut.

3.

With the internal adjusting screw

properly adjusted, loosen the external

adjusting screw lock nut.

4.

Using a torque wrench with an

Allen head socket, tighten the adjust-

ing screw to 10 ft-lbs torque.

5.

Back off the adjusting screw

1-1/2 turns.

6. Hold the adjusting screw from

turning and torque the lock nut to

specification.

GOVERNOR REPLACEMENT

1.

Raise the vehicle so that the

transmission extension housing is ac-

cessible.

2.

Drain the fluid from the trans-

mission.

3.

Disconnect the drive shaft from

the rear axle and slide the front yoke

out of the extension housing.

4.

Disconnect the speedometer

cable from the extension housing.

5.

Remove the two bolts that secure

the extension housing to the engine

rear support.

6. Remove the nut and bolt that se-

cures the engine rear support to the

crossmember.

7.

Raise the transmission high

enough to provide clearance for the

rear mount.

8. Lift the engine rear support from

the crossmember.

9. Lower the jack until the exten-

sion housing just clears the crossmem-procarmanuals.com