FORD MUSTANG 1969 Volume One Chassis

Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 381 of 413

07-04-12

C-6 Automatic Transmission

07-04-12

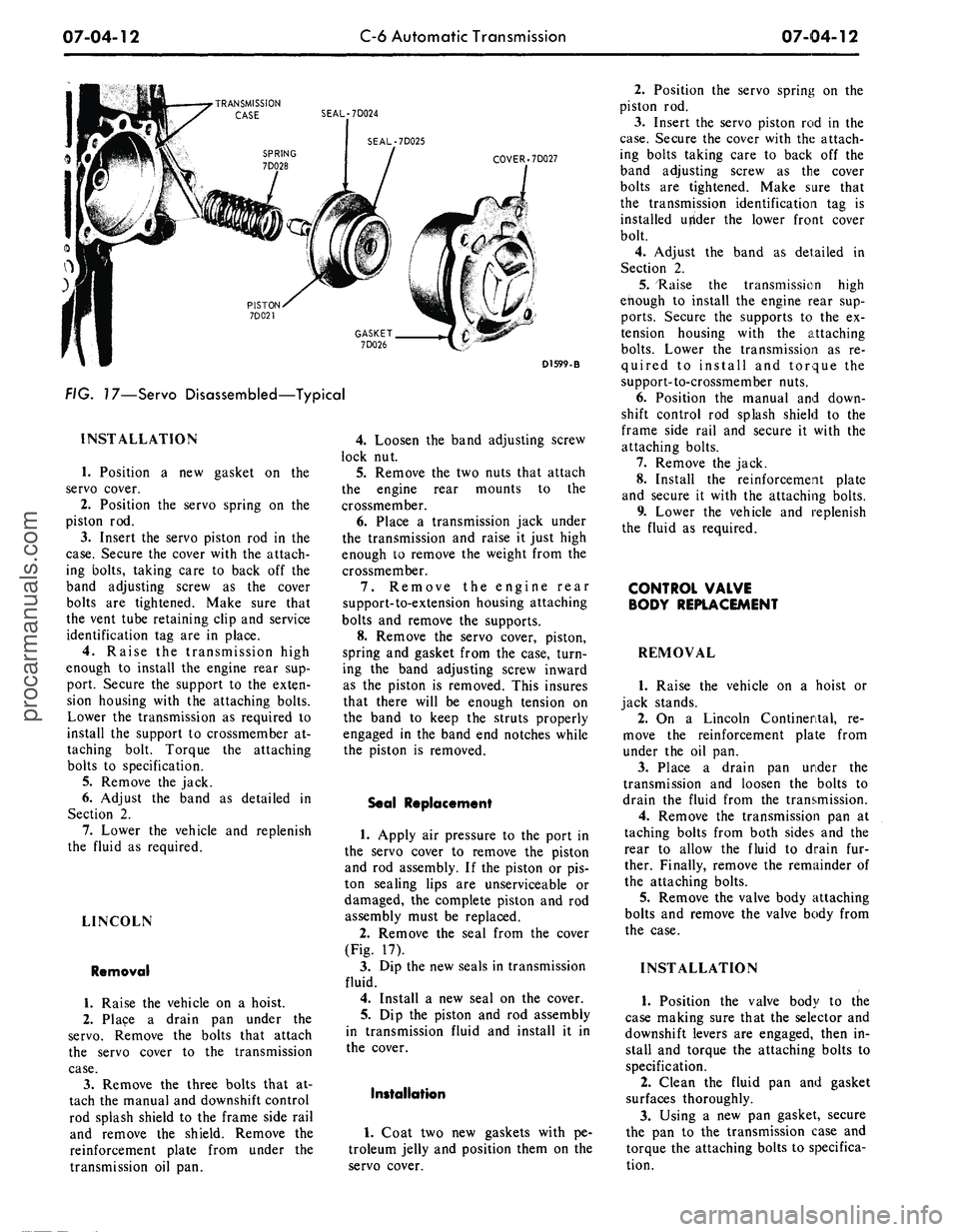

•TRANSMISSION

CASE SEAL-7D024

SEAL-7D025

COVER .7D027

D1599-B

FIG. 17—Servo Disassembled—Typical

INSTALLATION

1.

Position a new gasket on the

servo cover.

2.

Position the servo spring on the

piston rod.

3.

Insert the servo piston rod in the

case.

Secure the cover with the attach-

ing bolts, taking care to back off the

band adjusting screw as the cover

bolts are tightened. Make sure that

the vent tube retaining clip and service

identification tag are in place.

4.

Raise the transmission high

enough to install the engine rear sup-

port. Secure the support to the exten-

sion housing with the attaching bolts.

Lower the transmission as required to

install the support to crossmember at-

taching bolt. Torque the attaching

bolts to specification.

5.

Remove the jack.

6. Adjust the band as detailed in

Section 2.

7.

Lower the vehicle and replenish

the fluid as required.

LINCOLN

Removal

1.

Raise the vehicle on a hoist.

2.

Place a drain pan under the

servo.

Remove the bolts that attach

the servo cover to the transmission

case.

3.

Remove the three bolts that at-

tach the manual and downshift control

rod splash shield to the frame side rail

and remove the shield. Remove the

reinforcement plate from under the

transmission oil pan.

4.

Loosen the band adjusting screw

lock nut.

5.

Remove the two nuts that attach

the engine rear mounts to the

crossmember.

6. Place a transmission jack under

the transmission and raise it just high

enough to remove the weight from the

crossmember.

7.

Remove the engine rear

support-to-extension housing attaching

bolts and remove the supports.

8. Remove the servo cover, piston,

spring and gasket from the case, turn-

ing the band adjusting screw inward

as the piston is removed. This insures

that there will be enough tension on

the band to keep the struts properly

engaged in the band end notches while

the piston is removed.

Seal Replacement

1.

Apply air pressure to the port in

the servo cover to remove the piston

and rod assembly. If the piston or pis-

ton sealing lips are unserviceable or

damaged, the complete piston and rod

assembly must be replaced.

2.

Remove the seal from the cover

(Fig. 17).

3.

Dip the new seals in transmission

fluid.

4.

Install a new seal on the cover.

5.

Dip the piston and rod assembly

in transmission fluid and install it in

the cover.

Installation

1.

Coat two new gaskets with pe-

troleum jelly and position them on the

servo cover.

2.

Position the servo spring on the

piston rod.

3.

Insert the servo piston rod in the

case.

Secure the cover with the attach-

ing bolts taking care to back off the

band adjusting screw as the cover

bolts are tightened. Make sure that

the transmission identification tag is

installed utfider the lower front cover

bolt.

4.

Adjust the band as detailed in

Section 2.

5.

"Raise the transmission high

enough to install the engine rear sup-

ports.

Secure the supports to the ex-

tension housing with the attaching

bolts.

Lower the transmission as re-

quired to install and torque the

support-to-crossmember nuts.

6. Position the manual and down-

shift control rod splash shield to the

frame side rail and secure it with the

attaching bolts.

7.

Remove the jack.

8. Install the reinforcement plate

and secure it with the attaching bolts.

9. Lower the vehicle and replenish

the fluid as required.

CONTROL VALVE

BODY REPLACEMENT

REMOVAL

1.

Raise the vehicle on a hoist or

jack stands.

2.

On a Lincoln Continental, re-

move the reinforcement plate from

under the oil pan.

3.

Place a drain pan under the

transmission and loosen the bolts to

drain the fluid from the transmission.

4.

Remove the transmission pan at

taching bolts from both sides and the

rear to allow the fluid to drain fur-

ther. Finally, remove the remainder of

the attaching bolts.

5.

Remove the valve body attaching

bolts and remove the valve body from

the case.

INSTALLATION

1.

Position the valve body to the

case making sure that the selector and

downshift levers are engaged, then in-

stall and torque the attaching bolts to

specification.

2.

Clean the fluid pan and gasket

surfaces thoroughly.

3.

Using a new pan gasket, secure

the pan to the transmission case and

torque the attaching bolts to specifica-

tion.procarmanuals.com

Page 382 of 413

07-04-13

C-6 Automatic Transmission

07-04-13

On a Lincoln Continental, install

the reinforcement plate and secure it

with the attaching bolts.

4.

Lower the vehicle and fill the

transmission to the correct level with

the specified fluid.

EXTENSION HOUSING

BUSHING AND REAR

SEAL REPLACEMENT

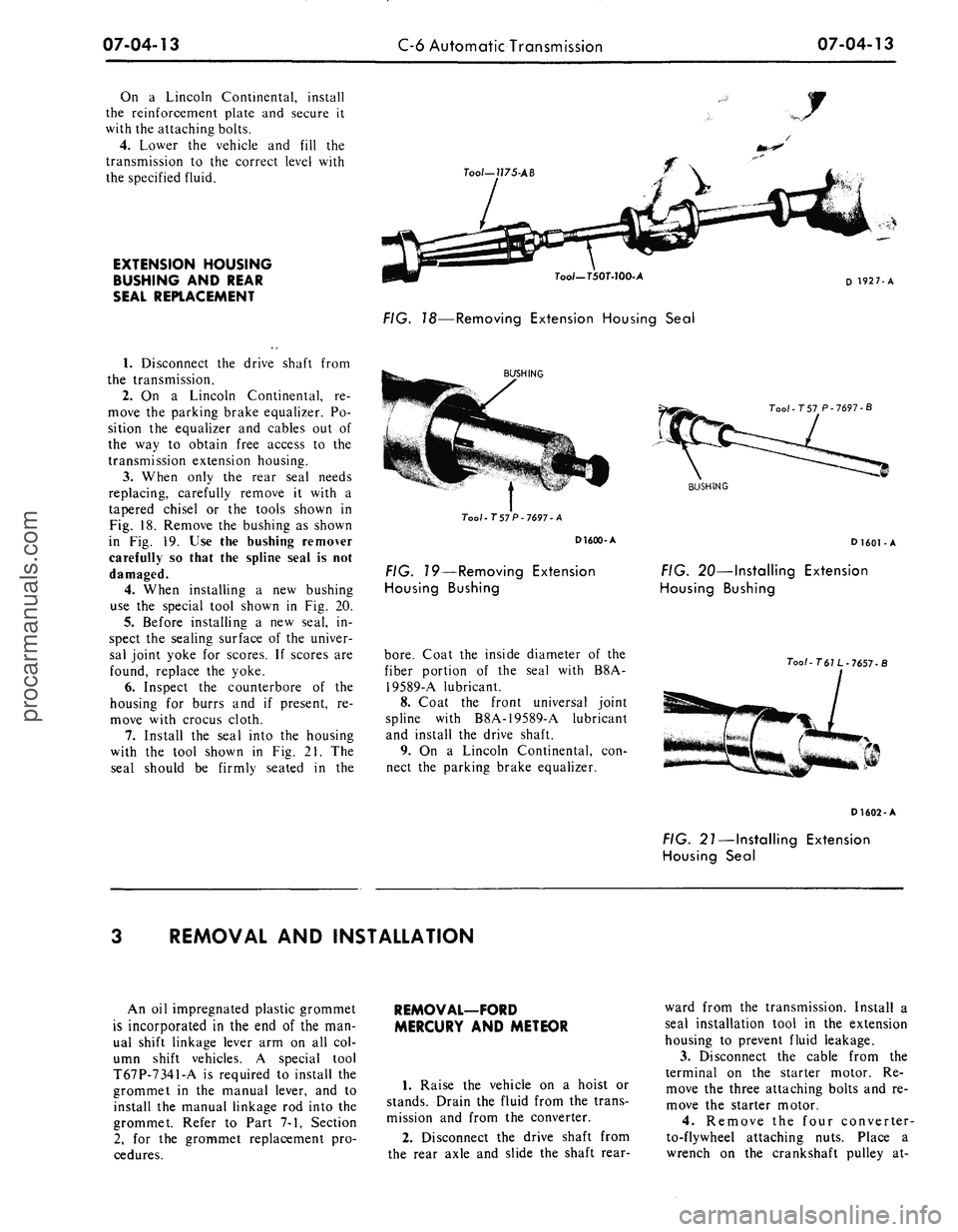

Too/—

1175-AB

Tool—750T-70O-A

D 1927-A

FIG. 18—Removing Extension Housing Seal

1.

Disconnect the drive shaft from

the transmission.

2.

On a Lincoln Continental, re-

move the parking brake equalizer. Po-

sition the equalizer and cables out of

the way to obtain free access to the

transmission extension housing.

3.

When only the rear seal needs

replacing, carefully remove it with a

tapered chisel or the tools shown in

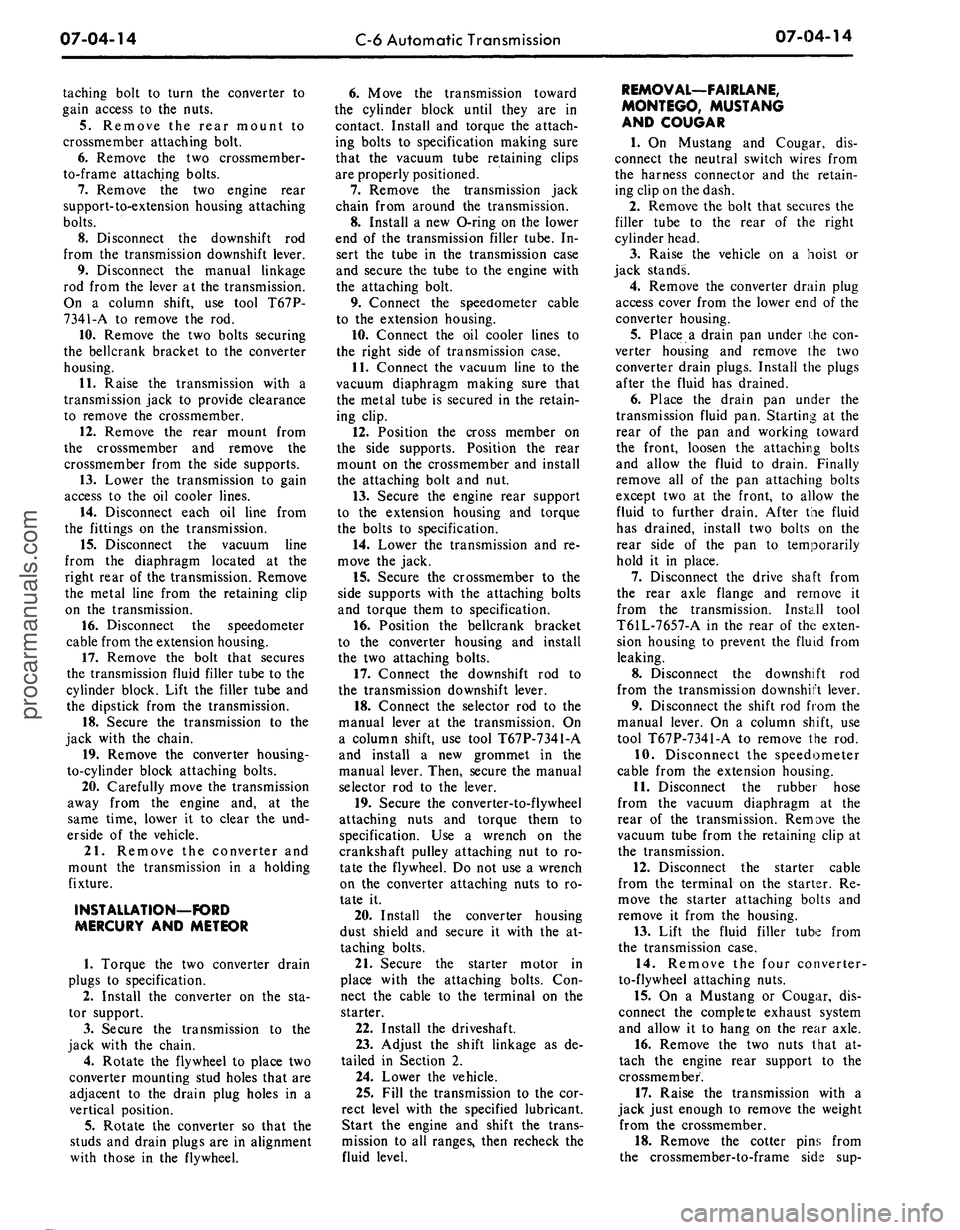

Fig. 18. Remove the bushing as shown

in Fig. 19. Use the bushing remover

carefully so that the spline seal is not

damaged.

4.

When installing a new bushing

use the special tool shown in Fig. 20.

5.

Before installing a new seal, in-

spect the sealing surface of the univer-

sal joint yoke for scores. If scores are

found, replace the yoke.

6. Inspect the counterbore of the

housing for burrs and if present, re-

move with crocus cloth.

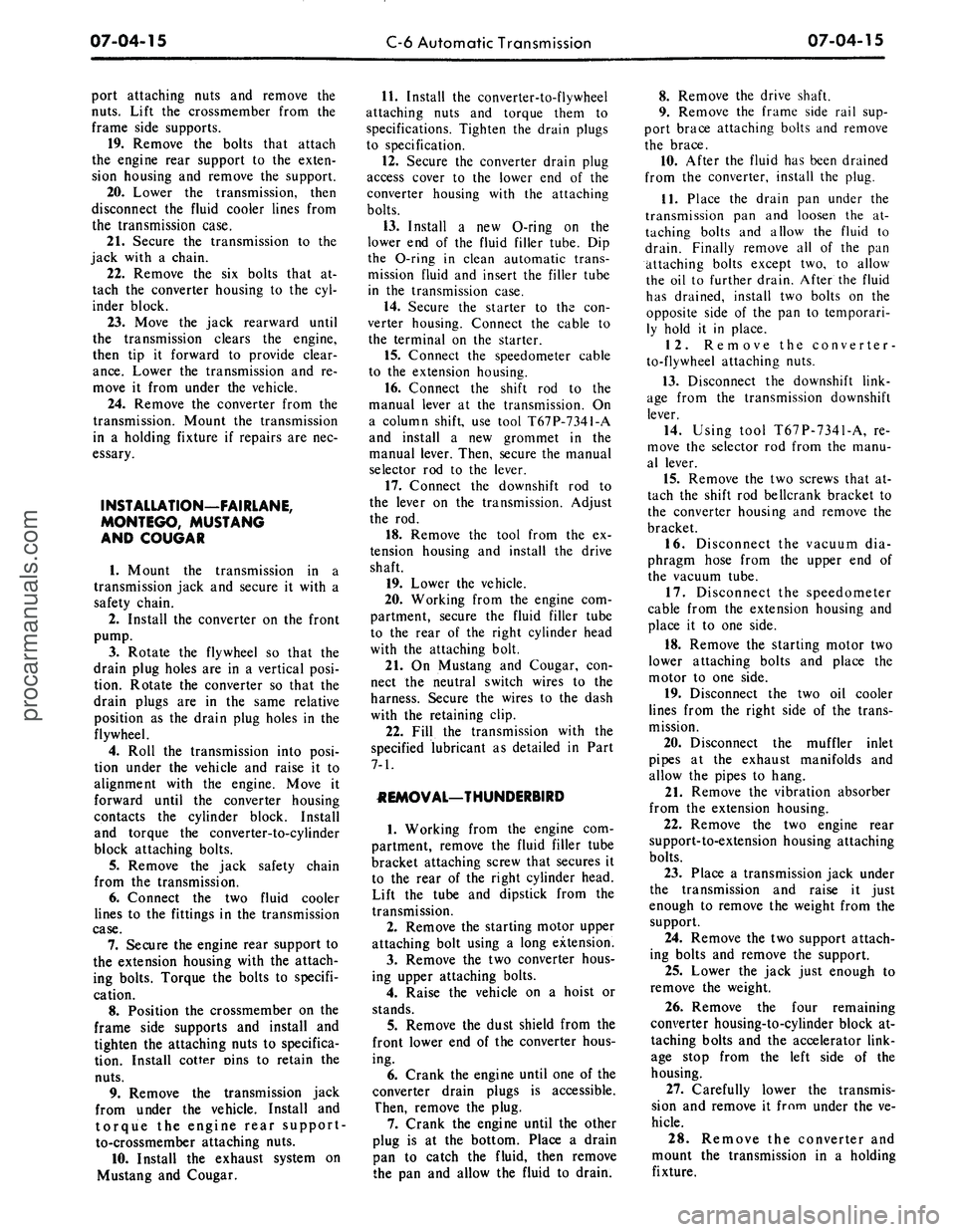

7.

Install the seal into the housing

with the tool shown in Fig. 21. The

seal should be firmly seated in the

BUSHING

Too/-757 P-7697-A

D1600-A

FIG. 19—Removing Extension

Housing Bushing

bore.

Coat the inside diameter of the

fiber portion of the seal with B8A-

19589-A lubricant.

8. Coat the front universal joint

spline with B8A-19589-A lubricant

and install the drive shaft.

9. On a Lincoln Continental, con-

nect the parking brake equalizer.

Tool-T 57 P-7697-B

BUSHING

D

1601

-A

FIG. 20—Installing Extension

Housing Bushing

Tool-

T61 L

-

7657-

B

D1602-A

FIG. 21—Installing Extension

Housing Seal

REMOVAL AND INSTALLATION

An oil impregnated plastic grommet

is incorporated in the end of the man-

ual shift linkage lever arm on all col-

umn shift vehicles. A special tool

T67P-7341-A is required to install the

grommet in the manual lever, and to

install the manual linkage rod into the

grommet. Refer to Part 7-1, Section

2,

for the grommet replacement pro-

cedures.

REMOVAL—FORD

MERCURY AND METEOR

1.

Raise the vehicle on a hoist or

stands. Drain the fluid from the trans-

mission and from the converter.

2.

Disconnect the drive shaft from

the rear axle and slide the shaft rear-

ward from the transmission. Install a

seal installation tool in the extension

housing to prevent fluid leakage.

3.

Disconnect the cable from the

terminal on the starter motor. Re-

move the three attaching bolts and re-

move the starter motor.

4.

Remove the four converter-

to-flywheel attaching nuts. Place a

wrench on the crankshaft pulley at-procarmanuals.com

Page 383 of 413

07-04-14

C-6 Automatic Transmission

07-04-14

taching bolt to turn the converter to

gain access to the nuts.

5.

Remove the rear mount to

crossmember attaching bolt.

6. Remove the two crossmember-

to-frame attaching bolts.

7.

Remove the two engine rear

support-to-extension housing attaching

bolts.

8. Disconnect the downshift rod

from the transmission downshift lever.

9. Disconnect the manual linkage

rod from the lever at the transmission.

On a column shift, use tool T67P-

7341-A to remove the rod.

10.

Remove the two bolts securing

the bellcrank bracket to the converter

housing.

11.

Raise the transmission with a

transmission jack to provide clearance

to remove the crossmember.

12.

Remove the rear mount from

the crossmember and remove the

crossmember from the side supports.

13.

Lower the transmission to gain

access to the oil cooler lines.

14.

Disconnect each oil line from

the fittings on the transmission.

15.

Disconnect the vacuum line

from the diaphragm located at the

right rear of the transmission. Remove

the metal line from the retaining clip

on the transmission.

16.

Disconnect the speedometer

cable from the extension housing.

17.

Remove the bolt that secures

the transmission fluid filler tube to the

cylinder block. Lift the filler tube and

the dipstick from the transmission.

18.

Secure the transmission to the

jack with the chain.

19.

Remove the converter housing-

to-cylinder block attaching bolts.

20.

Carefully move the transmission

away from the engine and, at the

same time, lower it to clear the und-

erside of the vehicle.

21.

Remove the converter and

mount the transmission in a holding

fixture.

INSTALLATION—FORD

MERCURY AND METEOR

1.

Torque the two converter drain

plugs to specification.

2.

Install the converter on the sta-

tor support.

3.

Secure the transmission to the

jack with the chain.

4.

Rotate the flywheel to place two

converter mounting stud holes that are

adjacent to the drain plug holes in a

vertical position.

5.

Rotate the converter so that the

studs and drain plugs are in alignment

with those in the flywheel.

6. Move the transmission toward

the cylinder block until they are in

contact. Install and torque the attach-

ing bolts to specification making sure

that the vacuum tube retaining clips

are properly positioned.

7.

Remove the transmission jack

chain from around the transmission.

8. Install a new Oring on the lower

end of the transmission filler tube. In-

sert the tube in the transmission case

and secure the tube to the engine with

the attaching bolt.

9. Connect the speedometer cable

to the extension housing.

10.

Connect the oil cooler lines to

the right side of transmission case.

11.

Connect the vacuum line to the

vacuum diaphragm making sure that

the metal tube is secured in the retain-

ing clip.

12.

Position the cross member on

the side supports. Position the rear

mount on the crossmember and install

the attaching bolt and nut.

13.

Secure the engine rear support

to the extension housing and torque

the bolts to specification.

14.

Lower the transmission and re-

move the jack.

15.

Secure the crossmember to the

side supports with the attaching bolts

and torque them to specification.

16.

Position the bellcrank bracket

to the converter housing and install

the two attaching bolts.

17.

Connect the downshift rod to

the transmission downshift lever.

18.

Connect the selector rod to the

manual lever at the transmission. On

a column shift, use tool T67P-7341-A

and install a new grommet in the

manual lever. Then, secure the manual

selector rod to the lever.

19.

Secure the converter-to-flywheel

attaching nuts and torque them to

specification. Use a wrench on the

crankshaft pulley attaching nut to ro-

tate the flywheel. Do not use a wrench

on the converter attaching nuts to ro-

tate it.

20.

Install the converter housing

dust shield and secure it with the at-

taching bolts.

21.

Secure the starter motor in

place with the attaching bolts. Con-

nect the cable to the terminal on the

starter.

22.

Install the driveshaft.

23.

Adjust the shift linkage as de-

tailed in Section 2.

24.

Lower the vehicle.

25.

Fill the transmission to the cor-

rect level with the specified lubricant.

Start the engine and shift the trans-

mission to all ranges, then recheck the

fluid level.

REMOVAL—FAIRLANE,

MONTEGO, MUSTANG

AND COUGAR

1.

On Mustang and Cougar, dis-

connect the neutral switch wires from

the harness connector and the retain-

ing clip on the dash.

2.

Remove the bolt that secures the

filler tube to the rear of the right

cylinder head.

3.

Raise the vehicle on a hoist or

jack stands.

4.

Remove the converter drain plug

access cover from the lower end of the

converter housing.

5.

Place a drain pan under nhe con-

verter housing and remove the two

converter drain plugs. Install the plugs

after the fluid has drained.

6. Place the drain pan under the

transmission fluid pan. Starting at the

rear of the pan and working toward

the front, loosen the attaching bolts

and allow the fluid to drain. Finally

remove all of the pan attaching bolts

except two at the front, to allow the

fluid to further drain. After the fluid

has drained, install two bolts on the

rear side of the pan to temporarily

hold it in place.

7.

Disconnect the drive shaft from

the rear axle flange and remove it

from the transmission. Install tool

T61L-7657-A in the rear of the exten-

sion housing to prevent the fluid from

leaking.

8. Disconnect the downshift rod

from the transmission downshift lever.

9. Disconnect the shift rod from the

manual lever. On a column shift, use

tool T67P-7341-A to remove the rod.

10.

Disconnect the speedometer

cable from the extension housing.

11.

Disconnect the rubber hose

from the vacuum diaphragm at the

rear of the transmission. Remove the

vacuum tube from the retaining clip at

the transmission.

12.

Disconnect the starter cable

from the terminal on the starter. Re-

move the starter attaching bolts and

remove it from the housing.

13.

Lift the fluid filler tube from

the transmission case.

14.

Remove the four converter-

to-flywheel attaching nuts.

15.

On a Mustang or Cougar, dis-

connect the complete exhaust system

and allow it to hang on the rear axle.

16.

Remove the two nuts that at-

tach the engine rear support to the

crossmember.

17.

Raise the transmission with a

jack just enough to remove the weight

from the crossmember.

18.

Remove the cotter pins from

the crossmember-to-frame side sup-procarmanuals.com

Page 384 of 413

07-04-15

C-6

Automatic Transmission

07-04-15

port attaching nuts and remove the

nuts.

Lift the crossmember from the

frame side supports.

19.

Remove the bolts that attach

the engine rear support to the exten-

sion housing and remove the support.

20.

Lower the transmission, then

disconnect the fluid cooler lines from

the transmission case.

21.

Secure the transmission to the

jack with a chain.

22.

Remove the six bolts that at-

tach the converter housing to the cyl-

inder block.

23.

Move the jack rearward until

the transmission clears the engine,

then tip it forward to provide clear-

ance. Lower the transmission and re-

move it from under the vehicle.

24.

Remove the converter from the

transmission. Mount the transmission

in a holding fixture if repairs are nec-

essary.

INSTALLATION—FAIRLANE,

MONTEGO,

MUSTANG

AND COUGAR

1. Mount the transmission in a

transmission jack and secure it with a

safety chain.

2.

Install the converter on the front

pump.

3.

Rotate the flywheel so that the

drain plug holes are in a vertical posi-

tion. Rotate the converter so that the

drain plugs are in the same relative

position as the drain plug holes in the

flywheel.

4.

Roll the transmission into posi-

tion under the vehicle and raise it to

alignment with the engine. Move it

forward until the converter housing

contacts the cylinder block. Install

and torque the converter-to-cylinder

block attaching bolts.

5.

Remove the jack safety chain

from the transmission.

6. Connect the two fluid cooler

lines to the fittings in the transmission

case.

7.

Secure the engine rear support to

the extension housing with the attach-

ing bolts. Torque the bolts to specifi-

cation.

8. Position the crossmember on the

frame side supports and install and

tighten the attaching nuts to specifica-

tion. Install cotter Dins to retain the

nuts.

9. Remove the transmission jack

from under the vehicle. Install and

torque the engine rear support-

to-crossmember attaching nuts.

10.

Install the exhaust system on

Mustang and Cougar.

11.

Install the converter-to-flywheel

attaching nuts and torque them to

specifications. Tighten the drain plugs

to specification.

12.

Secure the converter drain plug

access cover to the lower end of the

converter housing with the attaching

bolts.

13.

Install a new O-ring on the

lower end of the fluid filler tube. Dip

the O-ring in clean automatic trans-

mission fluid and insert the filler tube

in the transmission case.

14.

Secure the starter to the con-

verter housing. Connect the cable to

the terminal on the starter.

15.

Connect the speedometer cable

to the extension housing.

16.

Connect the shift rod to the

manual lever at the transmission. On

a column shift, use tool T67P-7341-A

and install a new grommet in the

manual lever. Then, secure the manual

selector rod to the lever.

17.

Connect the downshift rod to

the lever on the transmission. Adjust

the rod.

18.

Remove the tool from the ex-

tension housing and install the drive

shaft.

19.

Lower the vehicle.

20.

Working from the engine com-

partment, secure the fluid filler tube

to the rear of the right cylinder head

with the attaching bolt.

21.

On Mustang and Cougar, con-

nect the neutral switch wires to the

harness. Secure the wires to the dash

with the retaining clip.

22.

Fill the transmission with the

specified lubricant as detailed in Part

7-1.

REMOVAL—THUNDERBIRD

1. Working from the engine com-

partment, remove the fluid filler tube

bracket attaching screw that secures it

to the rear of the right cylinder head.

Lift the tube and dipstick from the

transmission.

2.

Remove the starting motor upper

attaching bolt using a long extension.

3.

Remove the two converter hous-

ing upper attaching bolts.

4.

Raise the vehicle on a hoist or

stands.

5.

Remove the dust shield from the

front lower end of the converter hous-

ing.

6. Crank the engine until one of the

converter drain plugs is accessible.

Then, remove the plug.

7.

Crank the engine until the other

plug is at the bottom. Place a drain

pan to catch the fluid, then remove

the pan and allow the fluid to drain.

8. Remove the drive shaft.

9. Remove the frame side rail sup-

port brace attaching bolts and remove

the brace.

10.

After the fluid has been drained

from the converter, install the plug.

11.

Place the drain pan under the

transmission pan and loosen the at-

taching bolts and allow the fluid to

drain. Finally remove all of the pan

attaching bolts except two, to allow

the oil to further drain. After the fluid

has drained, install two bolts on the

opposite side of the pan to temporari-

ly hold it in place.

12.

Remove the converter-

to-flywheel attaching nuts.

13.

Disconnect the downshift link-

age from the transmission downshift

lever.

14.

Using tool T67P-7341-A, re-

move the selector rod from the manu-

al lever.

15.

Remove the two screws that at-

tach the shift rod bellcrank bracket to

the converter housing and remove the

bracket.

16.

Disconnect the vacuum dia-

phragm hose from the upper end of

the vacuum tube.

17.

Disconnect the speedometer

cable from the extension housing and

place it to one side.

18.

Remove the starting motor two

lower attaching bolts and place the

motor to one side.

19.

Disconnect the two oil cooler

lines from the right side of the trans-

mission.

20.

Disconnect the muffler inlet

pipes at the exhaust manifolds and

allow the pipes to hang.

21.

Remove the vibration absorber

from the extension housing.

22.

Remove the two engine rear

support-to-extension housing attaching

bolts.

23.

Place a transmission jack under

the transmission and raise it just

enough to remove the weight from the

support.

24.

Remove the two support attach-

ing bolts and remove the support.

25.

Lower the jack just enough to

remove the weight.

26.

Remove the four remaining

converter housing-to-cylinder block at-

taching bolts and the accelerator link-

age stop from the left side of the

housing.

27.

Carefully lower the transmis-

sion and remove it from under the ve-

hicle.

28.

Remove the converter and

mount the transmission in a holding

fixture.procarmanuals.com

Page 385 of 413

07-04-16

C-6 Automatic Transmission

07-04-16

INSTALLATION—

THUNDERBIRD

1.

Torque the two converter drain

plugs to specification.

2.

Install the converter on the sta-

tor support.

3.

Secure the transmission on a

transmission jack.

4.

Rotate the converter so that the

studs and drain plugs are in alignment

with their holes in the flywheel.

5.

Move the transmission toward

the cylinder block until they contact

each other. Install and torque the at-

taching bolts to specification. Before

tightening the center bolt on the left

side,

make sure that the accelerator

linkage stop bracket is properly posi-

tioned so that the left upper bolt may

be installed later.

6. Connect the fluid cooler lines to

their fittings on the right side of the

transmission.

7.

Raise the transmission and in-

stall the engine rear support and tor-

que the bolts to specification. Make

sure that the hand brake equalizer is

positioned properly.

8. Lower the transmission and re-

move the jack.

9. Install the engine rear support-

to-extension housing attaching bolts.

10.

Install the drive shaft.

11.

Connect the speedometer cable

to the extension housing.

12.

Position the starting motor on

the converter housing and secure it

with the two lower bolts.

13.

Install the torque converter-

to-flywheel attaching nuts and torque

them to specification.

14.

Install the converter housing

dust shield.

15.

Secure the frame side rail sup-

port brace with the attaching bolts

and lock washers. Torque the bolts to

specification.

16.

Connect the downshift rod to

the transmission downshift lever.

17.

Connect the vacuum diaphragm

hose to the upper end of the vacuum

tube.

18.

Using Tool T67P-7341-A, in-

stall a new grommet in the manual

lever. Then, secure the manual selec-

tor rod to the lever.

19.

Position the vibration absorber

to the transmission extension housing

and secure it with the three attaching

bolts.

20.

Connect the muffler inlet pipes

to the exhaust manifolds.

21.

Lower the vehicle and install

the two converter housing upper bolts

and torque them to specification.

22.

Install the starting motor upper

bolt.

23.

Place a new O-ring on the end

of the fluid filler tube and insert it in

the transmission case. Secure the tube

to the rear of the right cylinder head

with the attaching screw and lock

washer.

24.

Fill the transmission to the

proper level with the specified fluids.

25.

Adjust the manual and throttle

linkage as required.

REMOVAL-

CONTINENTAL MARK III

1.

Working from the engine com-

partment, lift the fluid filler tube dio-

stick from the transmission.

2.

Raise the vehicle on a hoist or

stands.

3.

Remove the dust shield from the

front lower end of the converter hous-

ing.

4.

Crank the engine until one of the

converter drain plugs is accessible.

Then, remove the plug.

5.

Crank the engine until the other

plug is at the bottom. Place a drain

pan to catch the fluid, then remove

the pan and allow the fluid to drain.

6. Remove the driveshaft.

7.

Remove the frame side rail sup-

port brace attaching bolts and remove

the brace.

8. After the fluid has been drained

from the converter, install the plug.

9. Place the drain pan under the

transmission pan and loosen the at-

taching bolts and allow the fluid to

drain. Finally remove all of the pan

attaching bolts except two, to allow

the oil to further drain. After the fluid

has drained, install two bolts on the

opposite side of the pan to temporari-

ly hold it in place.

10.

Remove the. converter-

to-flywheel attaching nuts.

11.

Disconnect the downshift link-

age from the transmission downshift

lever.

12.

Using tool T67P-7341-A, re-

move the selector rod from the manu-

al lever.

13.

Remove the two screws that at-

tach the shift rod bellcrank bracket to

the converter housing and remove the

bracket.

14.

Disconnect the vacuum dia-

phragm hose at the transmission.

15.

Disconnect the speedometer

cable from the extension housing and

place it to one side.

16.

Remove the two idler arm

bracket retaining bolts at the frame

side rail and allow the linkage to

hang.

17.

Disconnect the starter cable

from the terminal on the starter. Re-

move the starter attaching bolts and

remove it from the housing.

18.

Remove the clip securing the oil

cooler lines to the support bracket.

19.

Disconnect the two oil cooler

lines from the right side of the trans-

mission.

20.

Disconnect the muffler inlet

pipes at the exhaust manifolds and

allow the pipes to hang.

21.

Remove the vibration absorber

from the extension housing.

22.

Remove the engine rear support

to extension housing attaching bolts.

23.

Place a transmission jack under

the transmission and raise it just

enough to remove the weight from the

support.

24.

Remove the two support attach-

ing bolts and remove the support.

25.

Lower the jack and secure the

transmission to the jack with a safety

chain.

26.

Remove the bolt that secures

the filler tube to the rear of the right

cylinder head and lift the tube from

the transmission case.

27.

Remove the six converter

housing-to-cylinder block attaching

bolts.

28.

Carefully lower the transmis-

sion and remove it from under the ve-

hicle.

29.

Remove the converter and

mount the transmission in a holding

fixture.

INSTALLATION—

CONTINENTAL MARK III

1.

Torque the two converter drain

plugs to specification.

2.

Install the converter on the sta-

tor support.

3.

Secure the transmission on a

transmission jack.

4.

Rotate the converter so that the

studs and drain plugs are in alignment

with their holes in the flywheel.

5.

Move the transmission toward

the cylinder block until they contact

each other. Install and torque the at-

taching bolts to specification

6. Remove the jack safety chain

from the transmission.

7.

Connect the fluid cooler lines to

their fittings on the right side of the

transmission.

8. Install a new O-ring on the lower

end of the fluid filler tube. Dip the

O-ring in clean automatic transmis-

sion fluid and insert the tube in the

transmission case. Install the attach-

ing bolt.procarmanuals.com

Page 386 of 413

07-04-17

C-6 Automatic Transmission

07-04-17

9. Raise the transmission and in-

stall the engine rear support and tor-

que the bolts to specification.

10.

Lower the transmission and re-

move the jack.

11.

Install the engine rear support-

to-extension housing attaching bolts.

12.

Install the drive shaft.

13.

Connect the speedometer cable

to the extension housing.

14.

Connect the muffler inlet pipes

to the exhaust manifolds.

15.

Position the starting motor on

the converter housing and secure it

with the attaching bolts. Connect the

cable to the terminal on the starter.

16.

Position the idler arm bracket

to the frame side rail and install the

attaching bolts.

17.

Install the torque converter-

to-flywheel attaching nuts and torque

them to specification.

18.

Install the converter housing

dust shield.

19.

Secure the frame side rail sup-

port brace with the attaching bolts

and lock washers. Torque the bolts to

specification.

20.

Connect the downshift rod to

the transmission downshift lever.

21.

Using Tool T67P-7341-A, in-

stall a new grommet in the manual

lever. Then, secure the manual selec-

tor rod to the lever.

22.

Connect the vacuum hose to the

vacuum diaphragm.

23.

Install the oil cooler line retain-

ing clip at the transmission support.

24.

Position the vibration absorber

to the transmission extension housing

and secure it with the three attaching

bolts.

25.

Lower the vehicle.

26.

Fill the transmission to the

proper level with the specified fluids.

27.

Adjust the manual and throttle

linkage as required.

REMOVAL-

LINCOLN CONTINENTAL

1.

Raise the hood and remove the

transmission dipstick.

2.

Raise the vehicle on a hoist. Re-

move the bolt that secures the trans-

mission filler tube to the cylinder

head.

3.

Remove the bolts that attach the

reinforcement plate at the rear of the

transmission oil pan and remove the

plate.

4.

Remove the three bolts that at-

tach the manual and downshift control

rod splash shield to the side rail and

remove the shield.

5.

Place a drain pan under the

transmission. Loosen all transmission

pan attaching bolts and allow the fluid

to drain. Remove the bolts from the

rear and both sides of the pan to

allow further drainage; then, finally

remove the pan. After all fluid has

been drained, install the pan using

four attaching bolts.

6. Remove the two bolts that attach

the cover to the lower end of the con-

verter housing.

7.

Remove the two front support

bracket bolts at the converter housing.

8. Remove the two drain plugs

from the converter and allow it to

drain.

9. Remove the four nuts that attach

the converter to the flywheel.

10.

Lift the fluid filler tube from

the transmission case.

11.

Remove the two idler arm

bracket bolts from the frame side rail

and allow the idler arm to hang free.

12.

Disconnect the starter cable

from the starter. Remove the starter

attaching bolts and remove the starter.

13.

Disconnect the oil cooler lines

from the transmission.

14.

Disconnect the vacuum hose

from the diaphragm.

15.

Loosen the parking brake ad-

justing nut at the equalizer and re-

move the retracting spring. Disconnect

the rear brake cables and remove the

equalizer from the bracket.

16.

Disconnect the speedometer

cable from the extension housing.

17.

Disconnect the drive shaft from

the transmission flange and position

the shaft out of the way.

18.

Disconnect the downshift rod

from the transmission downshift lever.

19.

Using tool T67P-7341-A, re-

move the manual selector rod from

the manual lever.

20.

Remove the lower bellcrank at-

taching bolts and remove the bell-

crank.

21.

Pry the upper bellcrank out of

the converter housing and allow it to

hang free.

22.

Remove the cooler lines from

the clip at the cylinder head.

23.

Remove the converter housing-

to-cylinder block lower attaching

bolts.

24.

Remove the two nuts that at-

tach the engine rear mounts to the

crossmember.

25.

Place a transmission jack under

the transmission and raise it just high

enough to remove the weight from the

crossmember.

26.

Remove the engine rear

support-to-extension housing attaching

bolts and remove the supports.

27.

Remove the crossmember-

to-frame attaching nuts and remove

the crossmember.

28.

Secure the transmission to the

jack with the safety chain. Lower the

transmission and remove the upper

converter housing-to-cylinder block at-

taching bolts.

29.

Move the transmission away

from the cylinder block.

30.

Carefully lower the transmis-

sion and remove it from under the ve-

hicle.

31.

Remove the converter and mount

the transmission in a holding fixture.

INSTALLATION-

LINCOLN CONTINENTAL

1.

Torque the two converter drain

plugs to specification.

2.

Install the converter on the sta-

tor support.

3.

Secure the transmission on a

transmission jack.

4.

Rotate the converter so that the

studs and drain plugs are in alignment

with those in the flywheel.

5.

Move the transmission toward the

cylinder block until they contact each

other. Install and torque the attaching

bolts to specification.

6. Secure the converter to the fly-

wheel with the four attaching nuts.

Torque the nuts to specification.

7.

Secure the converter access cover

to the converter housing with the at-

taching bolts.

8. Secure the two front support

brackets to the converter housing with

the attaching bolts.

9. Raise the transmission high en-

ough to position the crossmember. In-

stall the bolts, but do not tighten at

this time.

10.

Secure the engine rear support

to the extension housing and torque

the bolts to specification. At this time,

install and torque the crossmember-

to-frame attaching nuts to specifica-

tion.

11.

Lower the transmission and in-

stall the engine rear support-

to-crossmember attaching nuts and

plates.

Torque the •"its to specifica-

tion. Remove the transmission jack.

12.

Install the upper bellcrank in

the left side of the converter housing.

13.

Position the lower bellcrank to

the transmission and floor pan and se-

cure it with the two attaching bolts.

14.

Connect the downshift rod to

transmission downshift lever.

15.

Using tool T67P-7341-A, install

a new grommet in the manual lever.

Then, secure the manual selector rod

to the lever.procarmanuals.com

Page 387 of 413

07-04-18

C-6 Automatic Transmission

07-04-18

16.

Position the manual and down-

shift control rod splash shield to the

frame side rail and secure it with the

attaching bolts.

17.

Connect the speedometer cable

to the extension housing.

18.

Connect the vacuum hose to the

vacuum diaphragm and secure with a

clamp.

19.

Connect the two oil cooler lines

to the fittings on the right side of the

case.

20.

Install the cooler lines under

the clip at the cylinder head.

21.

Position the reinforcement plate

and torque the attaching bolts.

22.

Install the equalizer and park-

ing brake cables. Install the equalizer

lever retracting spring.

23.

Install the drive shaft.

24.

Install a new seal on the filler

tube and install it in the transmission

case.

Secure the filler tube to the cyl-

inder head.

25.

Install the starting motor and

connect the cable.

26.

Install the idler arm bracket-

to-frame side rail.

27.

Lower the vehicle.

28.

Fill the transmission to the cor-

rect level with the specified fluid.

29.

Adjust the manual and throttle

linkage as required.

MAJOR REPAIR OPERATIONS

DISASSEMBLY OF

TRANSMISSION

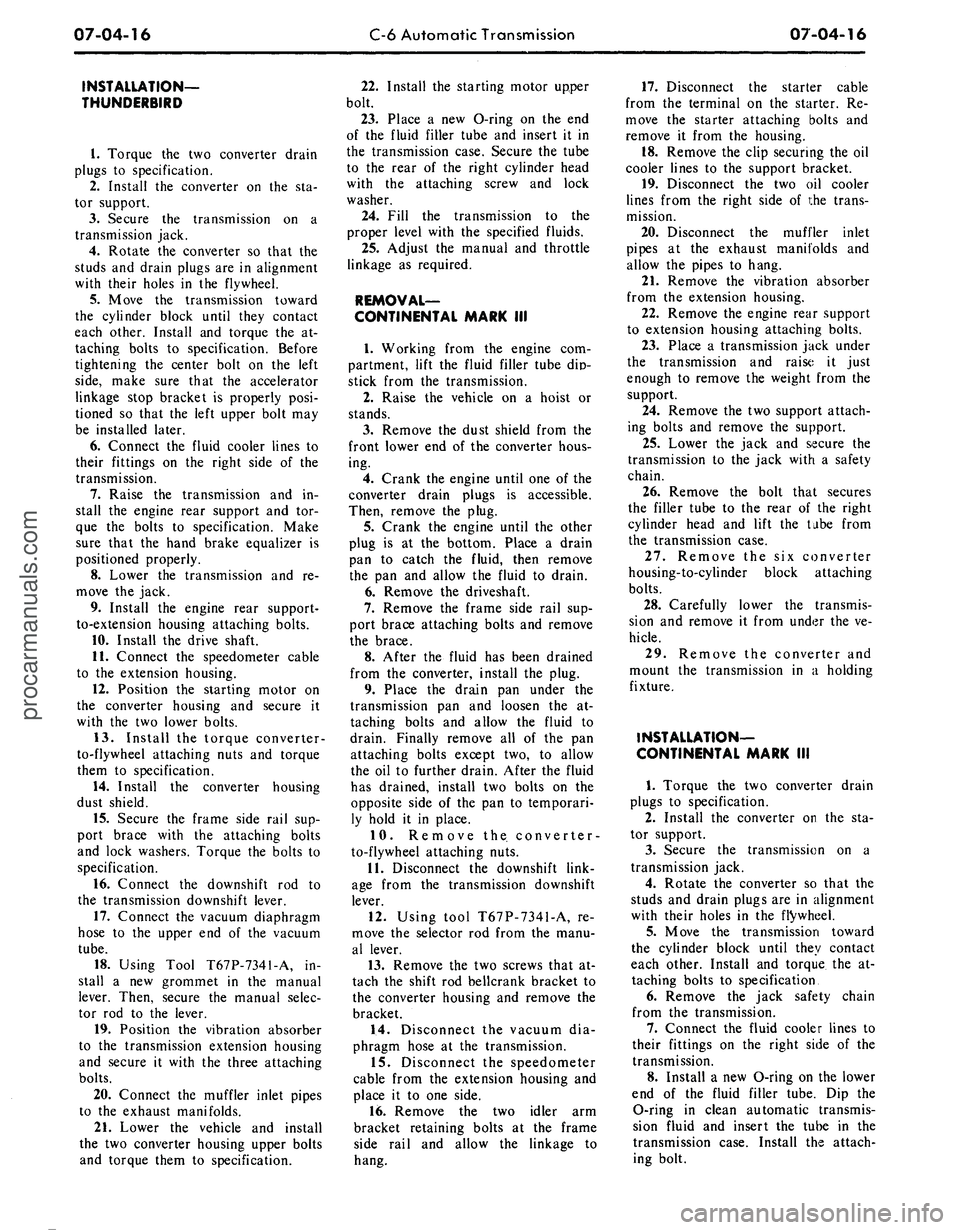

1.

Mount the transmission in hold-

ing fixture T64L-6001-A (Fig. 22).

2.

Remove the 17 fluid pan attach-

ing bolts. Remove pan and gasket.

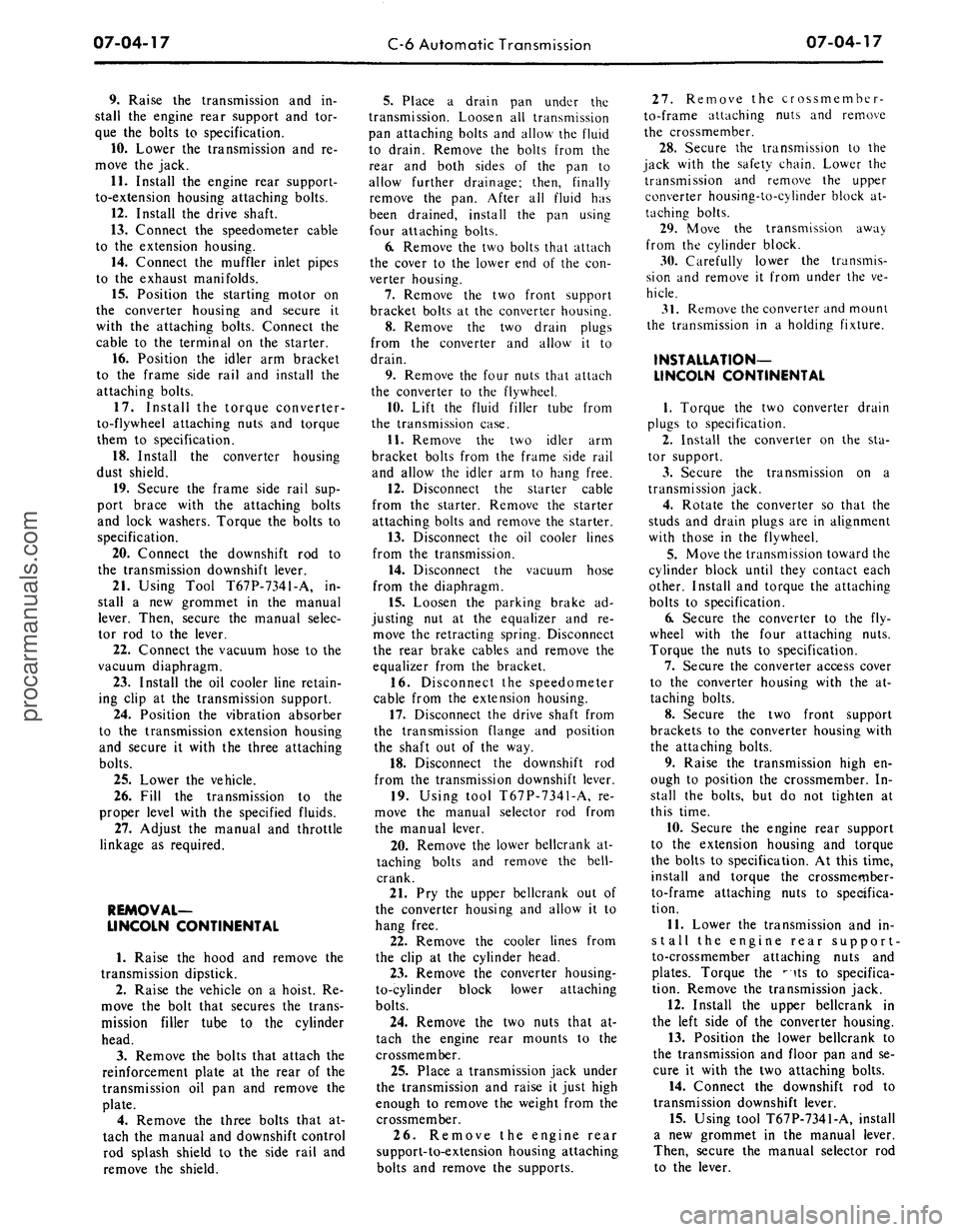

3.

Remove the 8 valve body attach-

ing bolts (Fig. 23). Lift the valve body

from the transmission case.

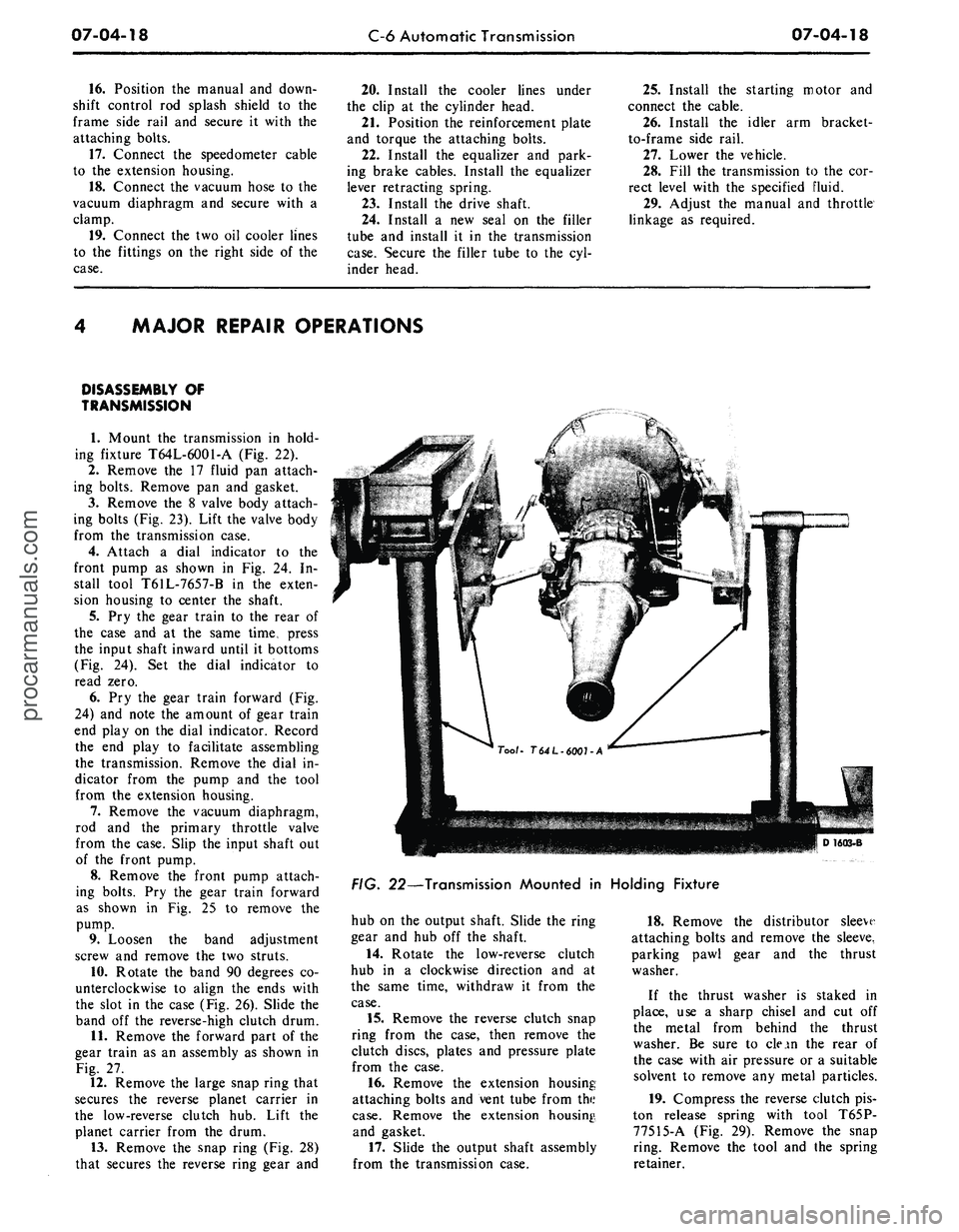

4.

Attach a dial indicator to the

front pump as shown in Fig. 24. In-

stall tool T61L-7657-B in the exten-

sion housing to center the shaft.

5.

Pry the gear train to the rear of

the case and at the same time, press

the input shaft inward until it bottoms

(Fig. 24). Set the dial indicator to

read zero.

6. Pry the gear train forward (Fig.

24) and note the amount of gear train

end play on the dial indicator. Record

the end play to facilitate assembling

the transmission. Remove the dial in-

dicator from the pump and the tool

from the extension housing.

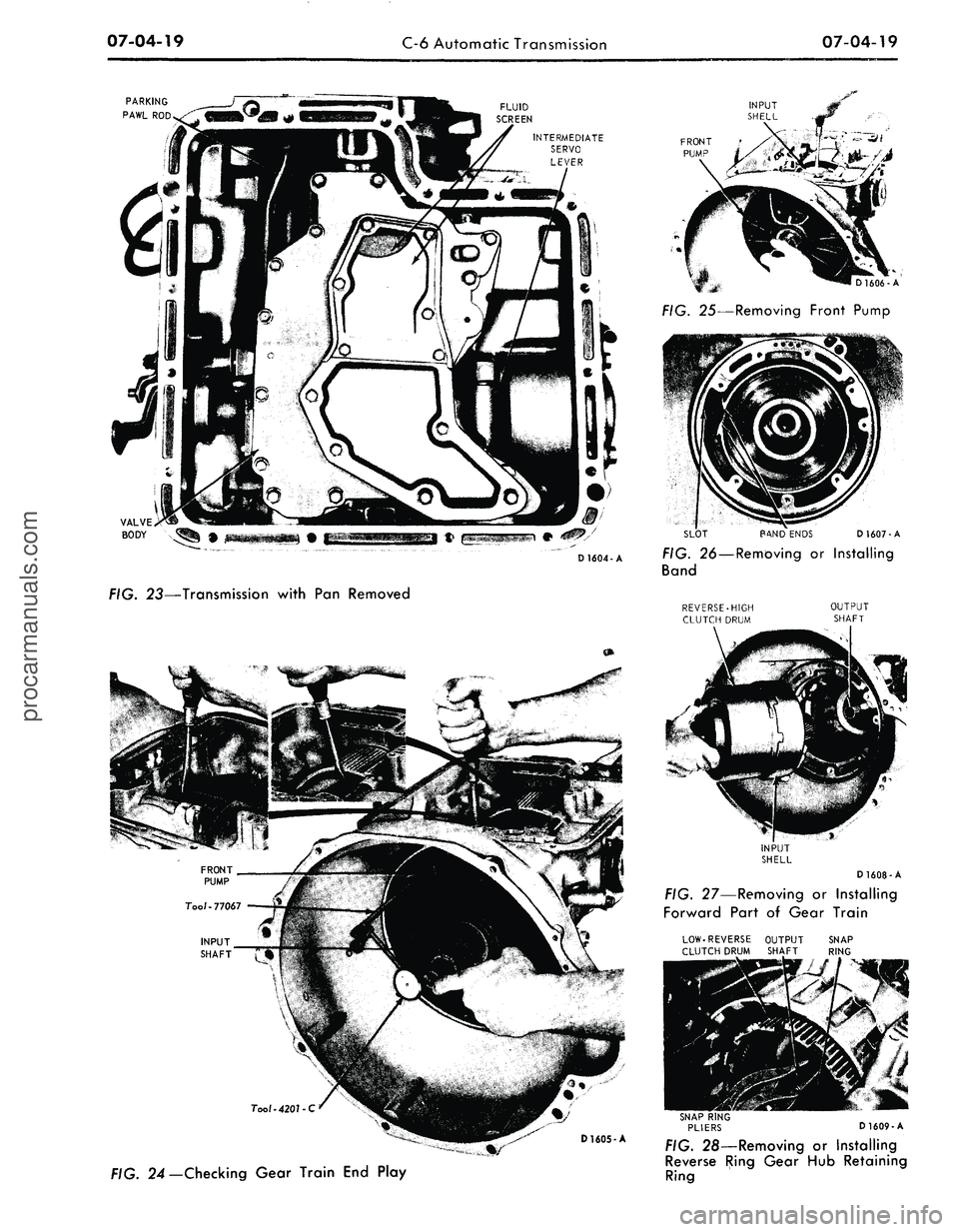

7.

Remove the vacuum diaphragm,

rod and the primary throttle valve

from the case. Slip the input shaft out

of the front pump.

8. Remove the front pump attach-

ing bolts. Pry the gear train forward

as shown in Fig. 25 to remove the

pump.

9. Loosen the band adjustment

screw and remove the two struts.

10.

Rotate the band 90 degrees co-

unterclockwise to align the ends with

the slot in the case (Fig. 26). Slide the

band off the reverse-high clutch drum.

11.

Remove the forward part of the

gear train as an assembly as shown in

Fig. 27.

12.

Remove the large snap ring that

secures the reverse planet carrier in

the low-reverse clutch hub. Lift the

planet carrier from the drum.

13.

Remove the snap ring (Fig. 28)

that secures the reverse ring gear and

D16Q3-B

FIG. 22—Transmission Mounted in Holding Fixture

hub on the output shaft. Slide the ring

gear and hub off the shaft.

14.

Rotate the low-reverse clutch

hub in a clockwise direction and at

the same time, withdraw it from the

case.

15.

Remove the reverse clutch snap

ring from the case, then remove the

clutch discs, plates and pressure plate

from the case.

16.

Remove the extension housing

attaching bolts and vent tube from the

case.

Remove the extension housing,

and gasket.

17.

Slide the output shaft assembly

from the transmission case.

18.

Remove the distributor sleeve

attaching bolts and remove the sleeve,

parking pawl gear and the thrust

washer.

If the thrust washer is staked in

place, use a sharp chisel and cut off

the metal from behind the thrust

washer. Be sure to clean the rear of

the case with air pressure or a suitable

solvent to remove any metal particles.

19.

Compress the reverse clutch pis-

ton release spring with tool T65P-

77515-A (Fig. 29). Remove the snap

ring. Remove the tool and the spring

retainer.procarmanuals.com

Page 388 of 413

07-04-19

C-6 Automatic Transmission

07-04-19

PARKING

PAWL

ROD

FLUID

SCREEN

INTERMEDIATE

SERVO

LEVER

FIG. 23—Transmission with Pan Removed

Tool-4201-C

D1605-A

D 1606-A

FIG. 25—Removing Front Pump

SLOT

BAND ENDS

D 1607-A

FIG. 26—Rembving or Installing

Band

REVERSE-HIGH OUTPUT

CLUTCH DRUM SHAFT

D 1608 -A

FIG. 27—Removing or Installing

Forward Part of Gear Train

LOW-REVERSE OUTPUT SNAP

CLUTCH DRUM SHAFT RING

D1609-A

FIG. 24— Checking Gear Train End Play

FIG. 28—Removing or Installing

Reverse Ring Gear Hub Retaining

Ringprocarmanuals.com

Page 389 of 413

07-04-20

C-6 Automatic Transmission

07-04-20

SNAP RING

LOW-REVERSE

CLUTCH PISTON

Tool -

T6SL-77515-A

RETAINER Toof - T65L- 77575- A

D1610-A

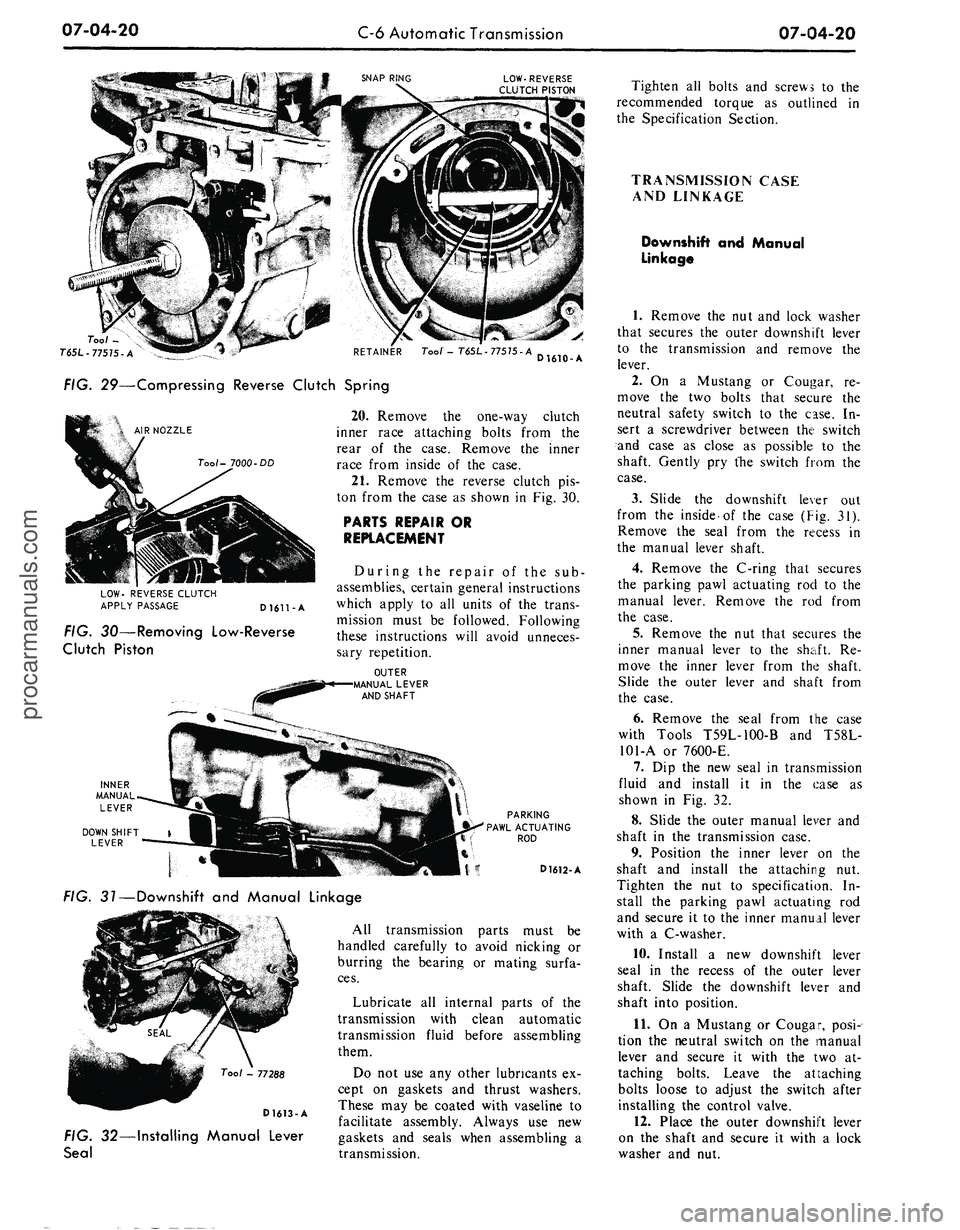

FIG. 29—Compressing Reverse Clutch Spring

AIR NOZZLE

Tool- 7000- DD

LOW- REVERSE CLUTCH

APPLY PASSAGE

D1611-A

FIG. 30—Removing Low-Reverse

Clutch Piston

20.

Remove the one-way clutch

inner race attaching bolts from the

rear of the case. Remove the inner

race from inside of the case.

21.

Remove the reverse clutch pis-

ton from the case as shown in Fig. 30.

PARTS REPAIR OR

REPLACEMENT

During the repair of the sub-

assemblies, certain general instructions

which apply to all units of the trans-

mission must be followed. Following

these instructions will avoid unneces-

sary repetition.

OUTER

MANUAL LEVER

AND SHAFT

PARKING

PAWL ACTUATING

ROD

D1612-A

FIG. 31—Downshift and Manual Linkage

7"oo/ - 77288

D1613-A

FIG. 32—Installing Manual Lever

Seal

All transmission parts must be

handled carefully to avoid nicking or

burring the bearing or mating surfa-

ces.

Lubricate all internal parts of the

transmission with clean automatic

transmission fluid before assembling

them.

Do not use any other lubricants ex-

cept on gaskets and thrust washers.

These may be coated with vaseline to

facilitate assembly. Always use new

gaskets and seals when assembling a

transmission.

Tighten all bolts and screws to the

recommended torque as outlined in

the Specification Section.

TRANSMISSION CASE

AND LINKAGE

Downshift and Manual

Linkage

1.

Remove the nut and lock washer

that secures the outer downshift lever

to the transmission and remove the

lever.

2.

On a Mustang or Cougar, re-

move the two bolts that secure the

neutral safety switch to the case. In-

sert a screwdriver between the switch

and case as close as possible to the

shaft. Gently pry the switch from the

case.

3.

Slide the downshift lever out

from the inside-of the case (Fig. 31).

Remove the seal from the recess in

the manual lever shaft.

4.

Remove the C-ring that secures

the parking pawl actuating rod to the

manual lever. Remove the rod from

the case.

5.

Remove the nut that secures the

inner manual lever to the shaft. Re-

move the inner lever from the shaft.

Slide the outer lever and shaft from

the case.

6. Remove the seal from the case

with Tools T59L-1OO-B and T58L-

101-A or 7600-E.

7.

Dip the new seal in transmission

fluid and install it in the case as

shown in Fig. 32.

8. Slide the outer manual lever and

shaft in the transmission case.

9. Position the inner lever on the

shaft and install the attaching nut.

Tighten the nut to specification. In-

stall the parking pawl actuating rod

and secure it to the inner manual lever

with a C-washer.

10.

Install a new downshift lever

seal in the recess of the outer lever

shaft. Slide the downshift lever and

shaft into position.

11.

On a Mustang or Cougar, posi-

tion the neutral switch on the manual

lever and secure it with the two at-

taching bolts. Leave the attaching

bolts loose to adjust the switch after

installing the control valve.

12.

Place the outer downshift lever

on the shaft and secure it with a lock

washer and nut.procarmanuals.com

Page 390 of 413

07-04-21

C-6 Automatic Transmission

07-04-21

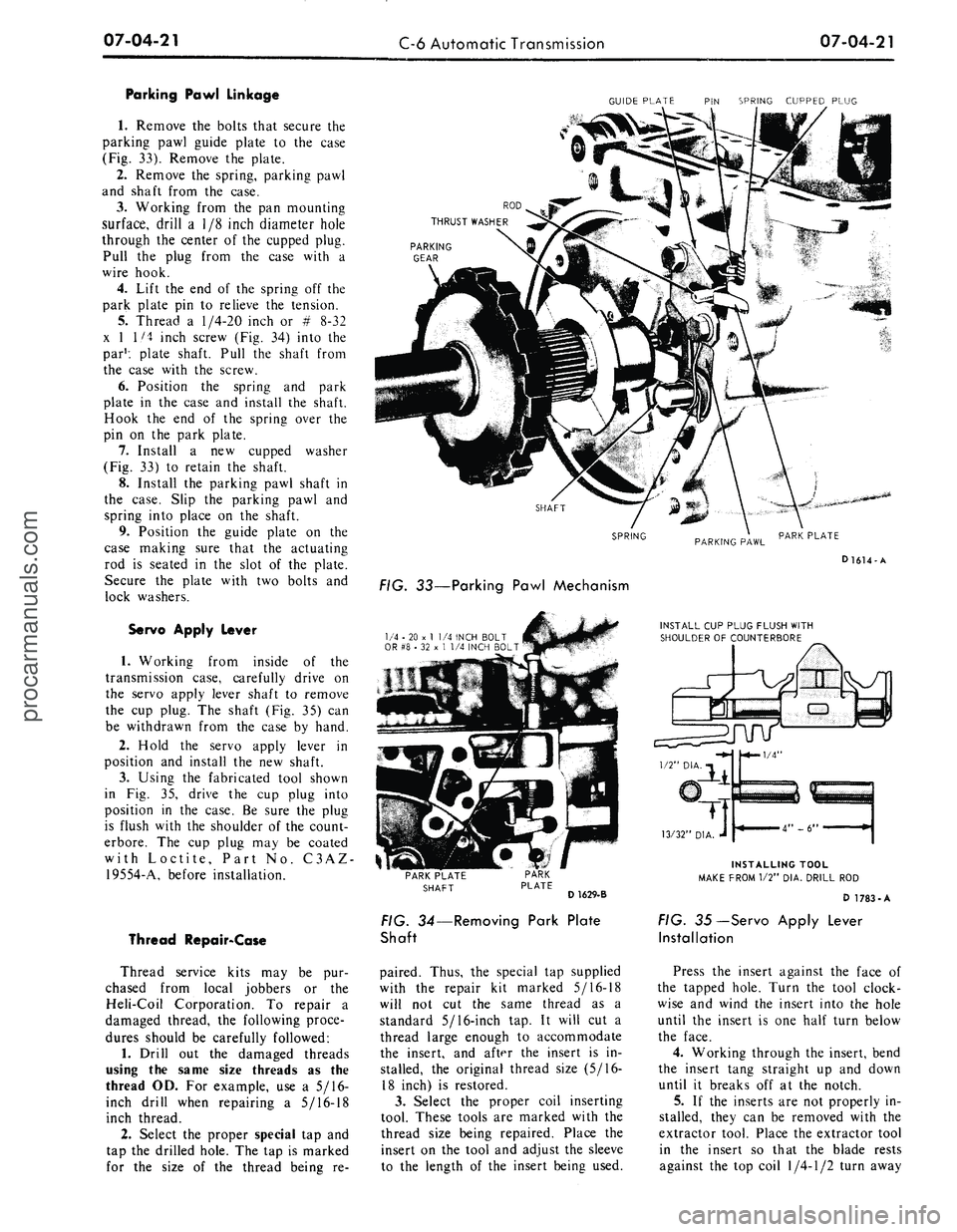

Parking Pawl Linkage

1.

Remove the bolts that secure the

parking pawl guide plate to the case

(Fig. 33). Remove the plate.

2.

Remove the spring, parking pawl

and shaft from the case.

3.

Working from the pan mounting

surface, drill a 1/8 inch diameter hole

through the center of the cupped plug.

Pull the plug from the case with a

wire hook.

4.

Lift the end of the spring off the

park plate pin to relieve the tension.

5.

Thread a

1/4-20

inch or # 8-32

x 1 1/4 inch screw (Fig. 34) into the

par1: plate shaft. Pull the shaft from

the case with the screw.

6. Position the spring and park

plate in the case and install the shaft.

Hook the end of the spring over the

pin on the park plate.

7.

Install a new cupped washer

(Fig. 33) to retain the shaft.

8. Install the parking pawl shaft in

the case. Slip the parking pawl and

spring into place on the shaft.

9. Position the guide plate on the

case making sure that the actuating

rod is seated in the slot of the plate.

Secure the plate with two bolts and

lock washers.

Servo Apply Lever

1.

Working from inside of the

transmission case, carefully drive on

the servo apply lever shaft to remove

the cup plug. The shaft (Fig. 35) can

be withdrawn from the case by hand.

2.

Hold the servo apply lever in

position and install the new shaft.

3.

Using the fabricated tool shown

in Fig. 35, drive the cup plug into

position in the case. Be sure the plug

is flush with the shoulder of the count-

erbore. The cup plug may be coated

with Loctite, Part No. C3AZ-

19554-A, before installation.

Thread Repair-Case

Thread service kits may be pur-

chased from local jobbers or the

Heli-Coil Corporation. To repair a

damaged thread, the following proce-

dures should be carefully followed:

1.

Drill out the damaged threads

using the same size threads as the

thread OD. For example, use a 5/16-

inch drill when repairing a 5/16-18

inch thread.

2.

Select the proper special tap and

tap the drilled hole. The tap is marked

for the size of the thread being re-

GUIDE PLATE PIN SPRING CUPPED PLUG

PARKING

GEAR

SHAFT

SPRING

PARKING PAWL

PARK PLATE

D1614-A

FIG. 33—Parking Pawl Mechanism

1/4 - 20 x

1

1/4 INCH BOLT

OR #8 • 32 x 1 1/4 INCH BOLT

INSTALL CUP PLUG FLUSH WITH

SHOULDER OF COUNTERBORE

PARK PLATE

SHAFT

D 1629-B

FIG. 34—Removing Park Plate

Shaft

paired. Thus, the special tap supplied

with the repair kit marked 5/16-18

will not cut the same thread as a

standard 5/16-inch tap. It will cut a

thread large enough to accommodate

the insert, and after the insert is in-

stalled, the original thread size (5/16-

18 inch) is restored.

3.

Select the proper coil inserting

tool. These tools are marked with the

thread size being repaired. Place the

insert on the tool and adjust the sleeve

to the length of the insert being used.

INSTALLING TOOL

MAKE FROM 1/2" DIA. DRILL ROD

D 1783-A

FIG. 35—Servo Apply Lever

Installation

Press the insert against the face of

the tapped hole. Turn the tool clock-

wise and wind the insert into the hole

until the insert is one half turn below

the face.

4.

Working through the insert, bend

the insert tang straight up and down

until it breaks off at the notch.

5.

If the inserts are not properly in-

stalled, they can be removed with the

extractor tool. Place the extractor tool

in the insert so that the blade rests

against the top coil

1/4-1/2

turn awayprocarmanuals.com