HONDA INTEGRA 1998 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 871 of 1681

Windshield

Removal (cont'd)

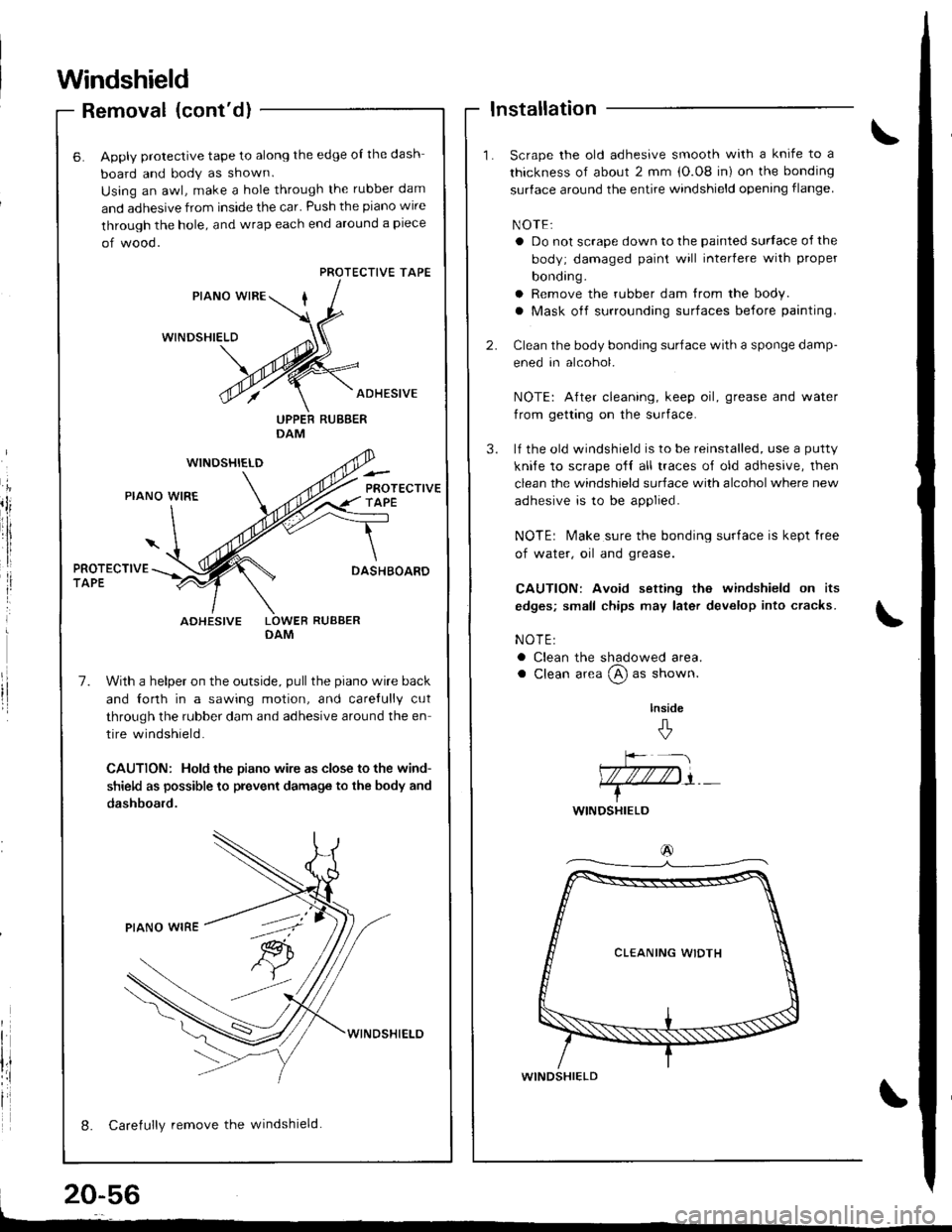

Apply protective tape to along the edge ol the dash

board and body as shown.

Using an awl, make a hole through the rubber dam

and adhesive from inside the car' Push the piano wire

through the hole, and wrap each end around a piece

of wood.

PROTECTIVE TAPE

WINDSHIELD

ADHESIVE

WINDSHIELD

PIANO WIRE

ADHESIVE

With a helper on the outside, pull the piano wire back

and forth in a sawing motion, and carelully cut

through the rubber dam and adhesive around the en

tire windshield.

CAUTION: Hold the oiano wire as close to the wind-

shield as possible to plevenl damage to the body and

dashboard.

8. Caretully remove the windshield

lnstallation

Scrape the old adhesive smooth with a knife to a

thickness of about 2 mm (O.08 in) on the bonding

surface around the entire windshield opening flange.

a Do not scrape down to the painted surtace oJ the

body; damaged paint will interfere with proper

bondang.

a Remove the rubber dam from the body.

a Mask off surrounding surfaces before painting.

Clean the body bonding sur,face with a sponge damp-

ened in alcohol.

NOTE: After cleaning, keep oil, grease and water

from getting on the surface.

lf the old windshield is to be reinstalled, use a putty

knile to scrape off all traces oI old adhesive, then

clean the windshield surface with alcohol where new

adhesive is to be applied.

NOTEr N4ake sure the bonding surface is kept free

of water, oil and grease.

CAUTION: Avoid setting the windshield on its

edges; small chips may later develop into cracks.

a Clean the shadowed area.

a Clean area @ as shown.

lnside

+

;

l!

i

1i

il

tl

WINDSHIELD

DAM

WINDSHIELD

,-----'---____/^_-___-/-------\

20-56

\-� ,,

Page 872 of 1681

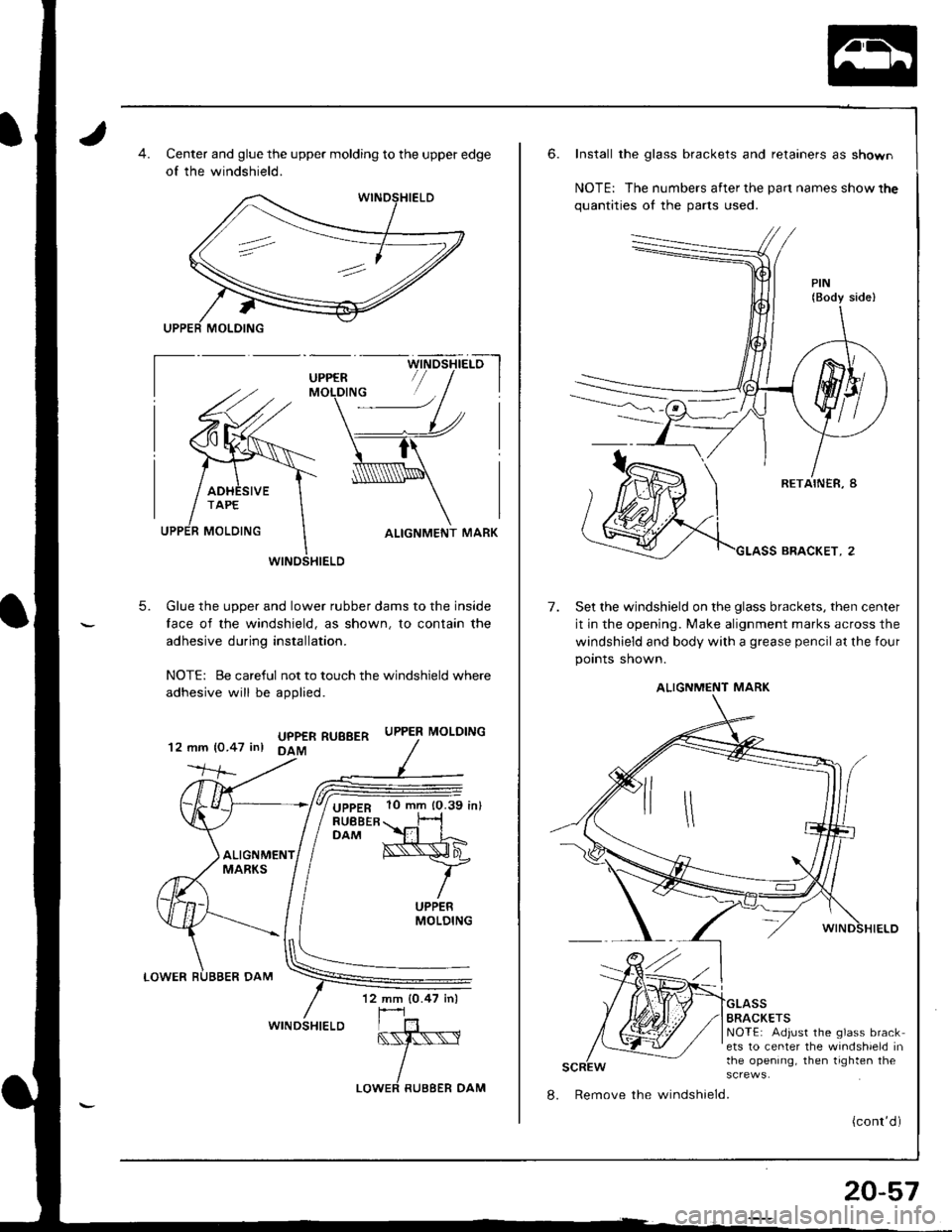

Center and glue the upper molding to the upper edge

of the windshield.

ALIGNMENT MARK

Glue the upper and lower rubber dams to the inside

lace of the windshield, as shown, to contain the

adhesive during installation.

NOTE: Be careful not to touch the windshield where

adhesive will be applied.

5.

UPPER RUBEER UPPER MOLDING

10 mm {0.39 in)

WINDSHIELD

LOWER RUBEER OAM8.

20-57

Install the glass brackets and retainers as shown

NOTE: The numbers after the part names show the

quantities of the parts used.

BRACKET,2

7. Set the windshield on the glass brackets, then center

it in the opening. Make alignment marks across the

windshield and body with a grease pencil at the four

potnrs snown.

6.

ERACKETSNOTE: Adjust the glass brackets to center the windshield inthe opening, then tighten thescrews.

Remove the windshield.

{cont'd )

ALIGNMENT MARK

Page 873 of 1681

Windshield

Installation (cont'dl

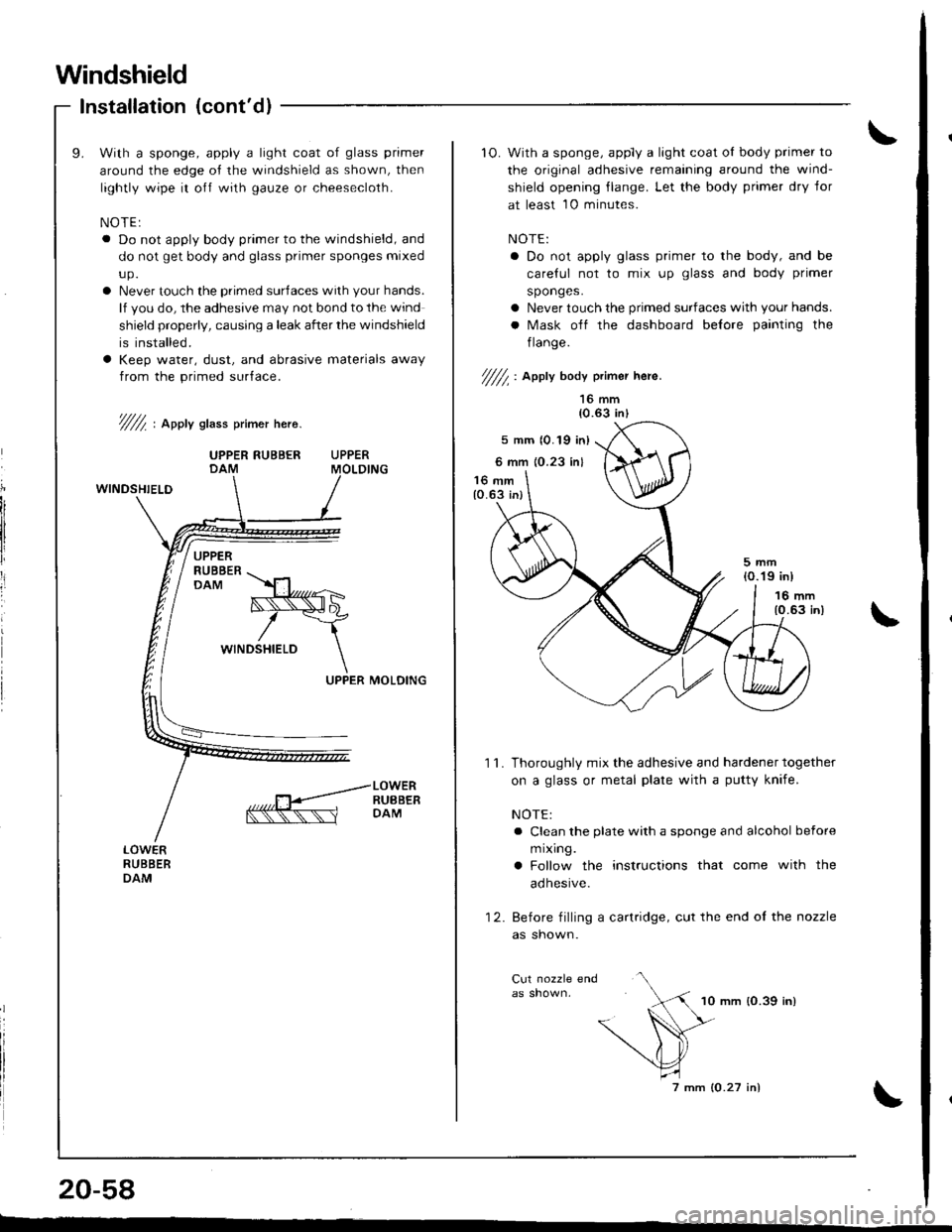

With a sponge, apply a light coat of glass primer

around the edge of the windshield as shown, then

lightly wipe it o{f with gauze or cheesecloth.

NOTE:a Do not apply body primer to the windshield, and

do not get body and glass primer sponges mixed

up.

a Never touch the primed surtaces with your hands.

lf you do, the adhesive may not bond to the wind

shield properly, causing a leak after the windshield

is installed.

a Keep water, dust, and abrasive materials away

from the primed sur{ace.

V///t t applv slass primer her6.

UPPER RUBBER UPPERDAM MOLDING

WINDSIIIELD

UPPER MOLOING

n------kBB''i+,

KKKxxl DAM

20-58

1O. With a sponge, apply a light coat oI body primer to

the original adhesive remaining around the wind-

shield opening llange. Let the body primer dry tor

at least 10 minutes.

NOTE:

a Do not apply glass primer to the body, and be

carelul not to mix up glass and body primer

sponges.

o Never touch the primed surfaces with your hands.

a Mask olf the dashboard be{ore painting the

flange.

/////,, epptv body p.imer here.

16 mm{0.63 inl

5 mm {0.19 in)

6 mm {0.23 inl'16 mm{0.63 in}

5mm(O.'19 inl

16 mm10.63 in)

1'1. Thoroughly mixthe adhesive and hardener together

on a glass or metal plate with a putty knife.

NOTE:

a Clean the plate with a sponge and alcohol before

mlxlng.

a Follow the instructions that come with the

adhesive.

12. Before filling a cartridge, cut the end of the nozzle

as shown.

10 mm {O.39 in}

Page 874 of 1681

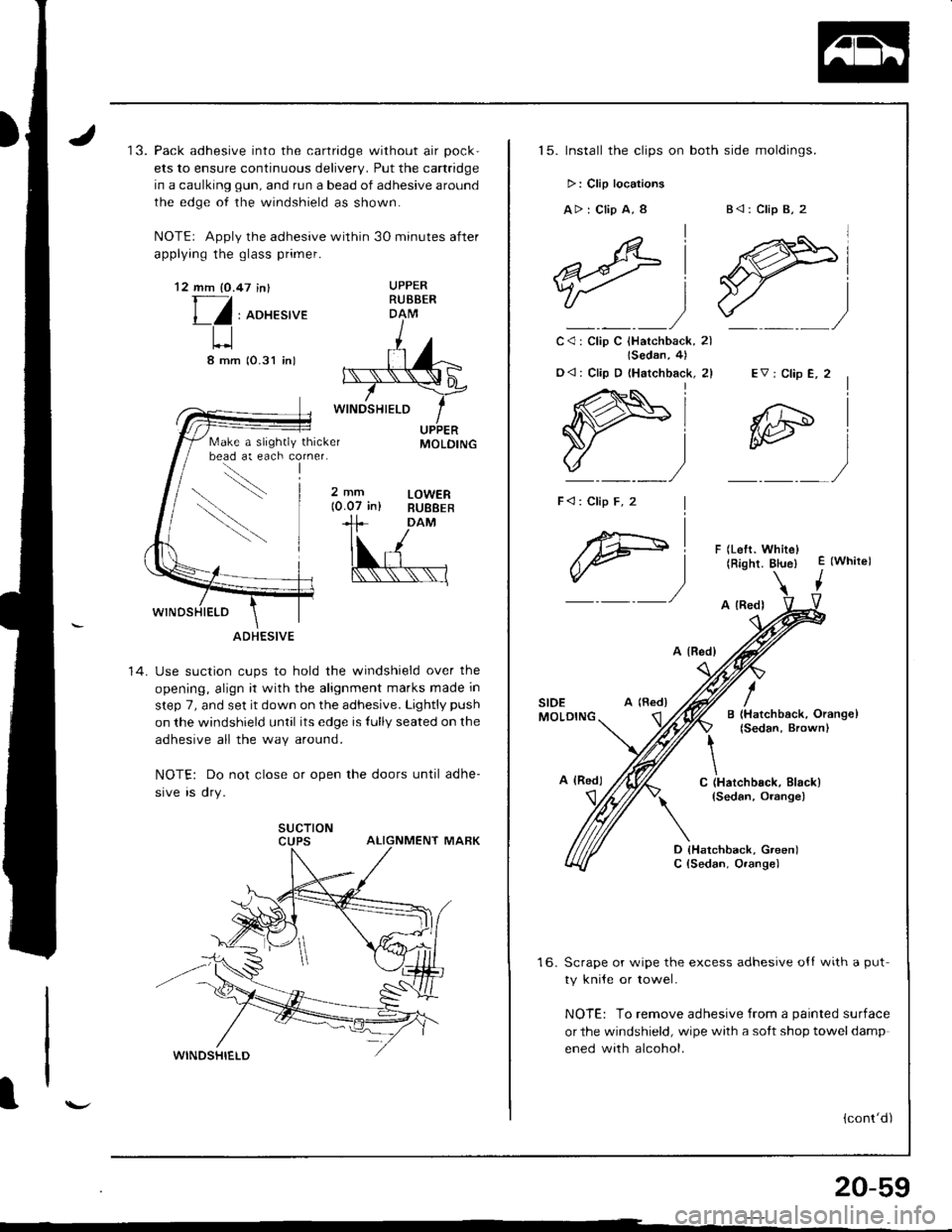

13. Pack adhesive into the cartridge without air pock-

ets to ensure continuous deliverv. Put the cartridge

in a caulking gun, and run a bead of adhesive around

the edge of the windshield as shown.

NOTEr Apply the adhesive within 30 minutes after

applying the glass primer.

12 mm 10.47 in)T-/

l 1l , ronesrvr

8 mm 10.31 in)

bead at each

'a\

'..\

\...

Make a slightly thickerMOLDING

LOWERBUBBEB

2mm

10.07 in)

DAM

WINDSIIIELD

14. Use suction cups to hold the windshield over the

opening, align it with the alignment marks made in

step 7, and set it down on the adhesive. Lightly push

on the windshield until its edge is tully seated on the

adhesive all the way around.

NOTE: Do not close or open the doors until adhe-

sive is dry.

SUCTIONCUPS ALIGNMENT MABK

t

ADHESIVE

'15. Install the clips on

> i Clip locations

A> : Clip A, a

both side moldings.

B<: Clip B, 2

_)_)

C<: Clip C lHatchback, 2llSedan,4l

D<: Clip D (Hatchback, 2lEV; Clip E, 2

\Yr i

P/l

Y___/

F<: Clip F, 2 |

_)

F:

F (Left. Whitel(Right. Blue)E (Whilel

I

A lRed)

A (Redl

stoEMOLDINGA (Red)/B (Hatchback, Orange)

{Sedan, Brownl

A lRedJ

I

\c (Hatchbsck. Elackllsedan, orange)

O {Hatchback, Green)C {sedan, Orange)

Scrape or wipe the excess adhesive of{ with a put

ty knite or towel.

NOTE: To remove adhesive from a painted surface

or the windshield, wipe with a soft shop towel damp

ened with alcohol.

{cont'd)

20-59

Page 875 of 1681

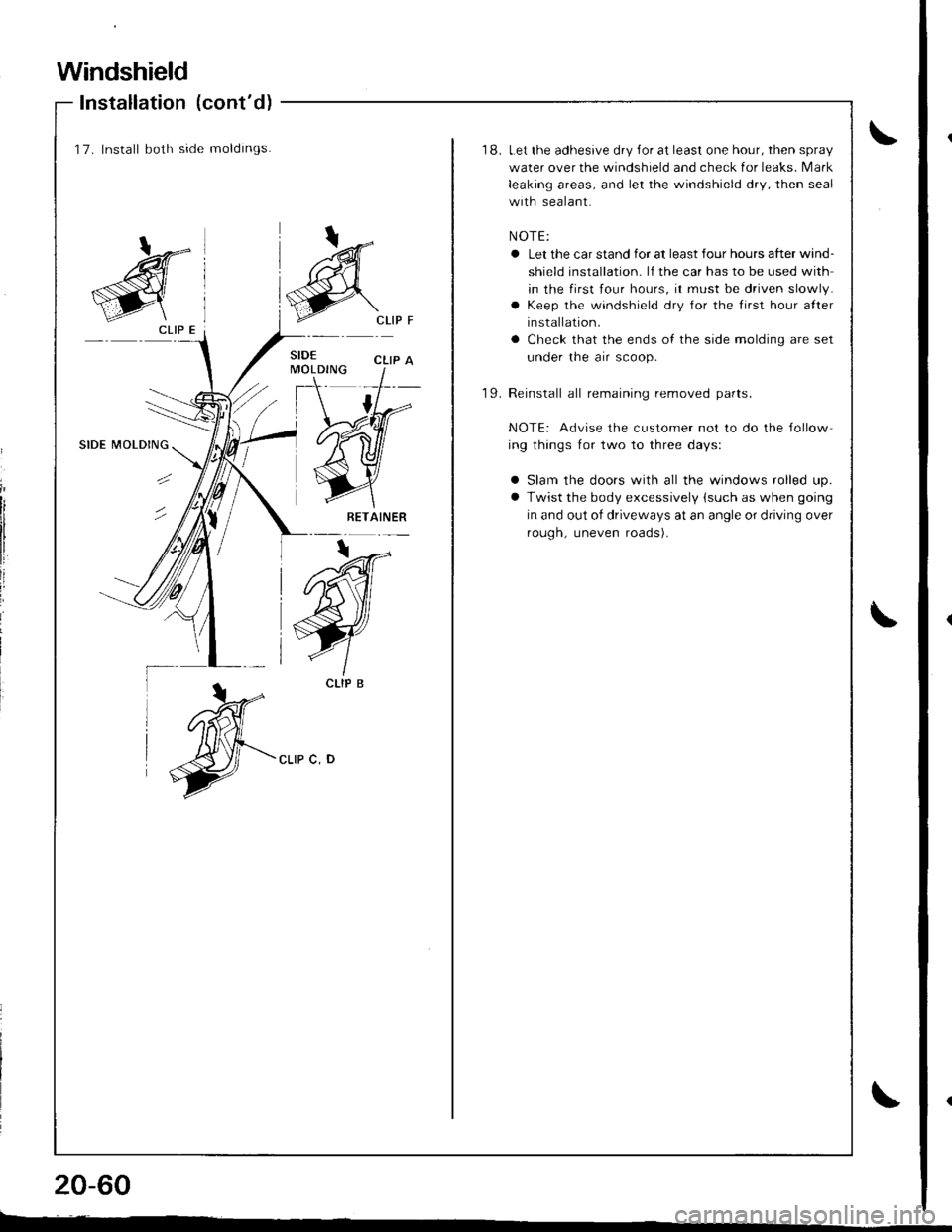

Windshield

Installation (cont'd)

20-60

L.--------: -

17. Install both side moldings.'18. Let the adhesive dry Jor at least one hour, then spray

water over the windshield and check for leaks. N4ark

leaking areas, and let the windshield dry, then seal

with sealant.

NOTE:

o Let the car stand for at least four hours after wind-

shield installation. lf the car has to be used with

in the first four hours, it must be driven slowly.

a Keep the windshield dry for the first hour after

installation.

a Check that the ends ol the side molding are set

under the air scoop.

g

CLIP E

19. Reinstall all remaining removed parts.

NOTE: Advise the customer not to do the Iollow

ing things for two to three days:

a Slam the doors with all the windows rolled up.

a Twist the body excessively (such as when going

in and out of driveways at an angle or driving over

rough, uneven roads).

I

CLIP C, D

Page 876 of 1681

Rear Window

Removal

5.

6.

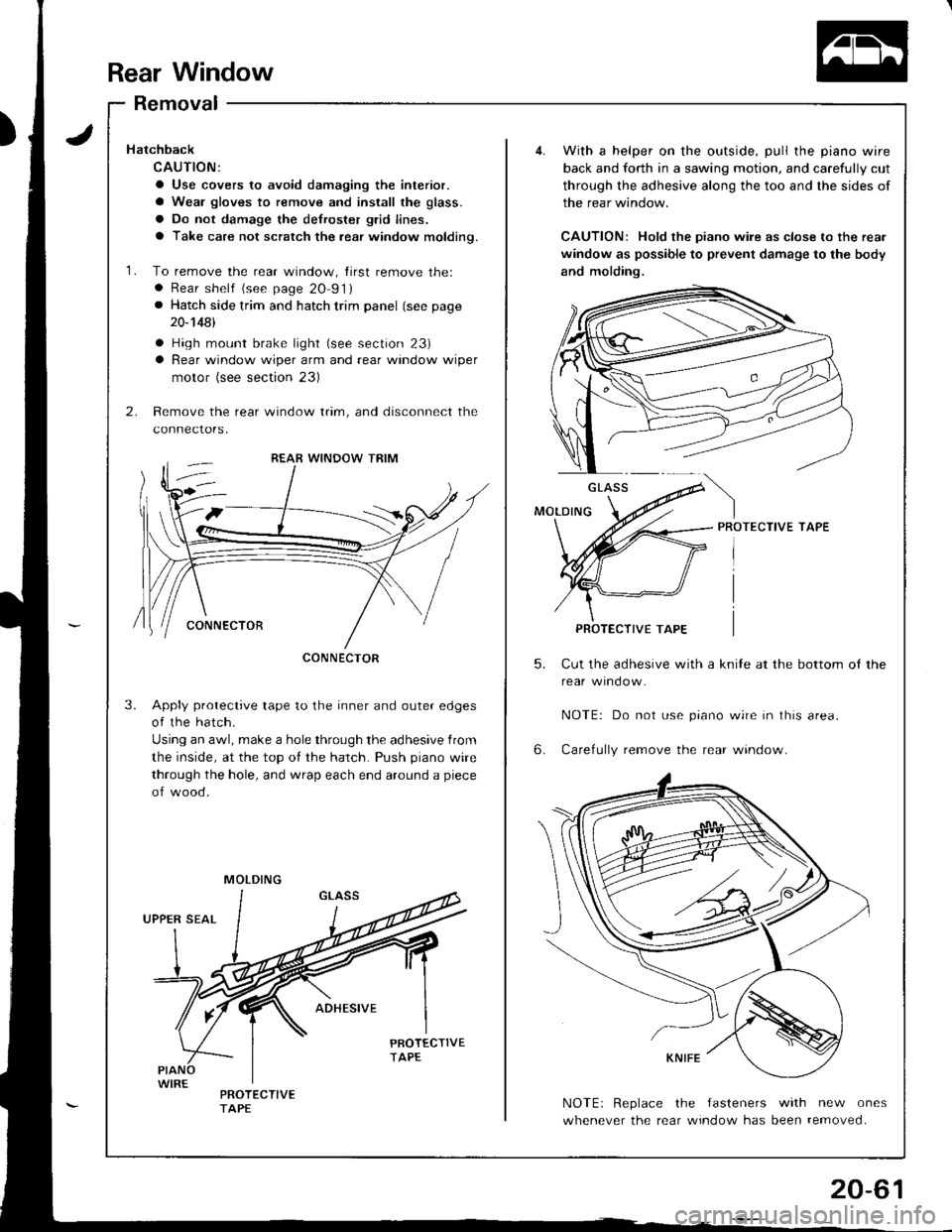

With a helper on the outside, pull the piano wire

back and forth in a sawing motion, and carefully cut

through the adhesive along the too and the sides of

the rear window.

CAUTION: Hold the piano wile as close to the rear

window as possible to prevent damage to the body

and molding.

PROTECTIVE TAPE

Cut the adhesive with a knile at the bottom ot the

NOTE| Do not use prano wrre In lhrs area.

Carefully remove the rear window.

NOTEr Replace the fasteners with new ones

whenever the rear window has been removed.

GLASS

PROTECTIVE TAPE

Hatchback

CAUTION:

a Use covers to avoid damaging the interior.

a Wear gloves to remove and install the glass.

a Do not damage the defroster glid lines.

a Take care not scratch the rear window moldino.

1. To remove the rear window, tirst remove the:. Rear shelf (see page 20 91). Hatch side trim and hatch trim panel (see page

20-14A1

a High mount brake light (see section 23)a Rear window wiper arm and rear window wiper

motor (see section 23)

2. Remove the rear window trim, and disconnect the

connectors,

Apply protective tape to the inner and outer edges

of the hatch.

Using an awl, make a hole through the adhesive from

the inside, at the top of the hatch. Push piano wire

through the hole, and wrap each end around a piece

of wood.

3.

CONNECTOR

MOLDING

Page 877 of 1681

Rear Window

{

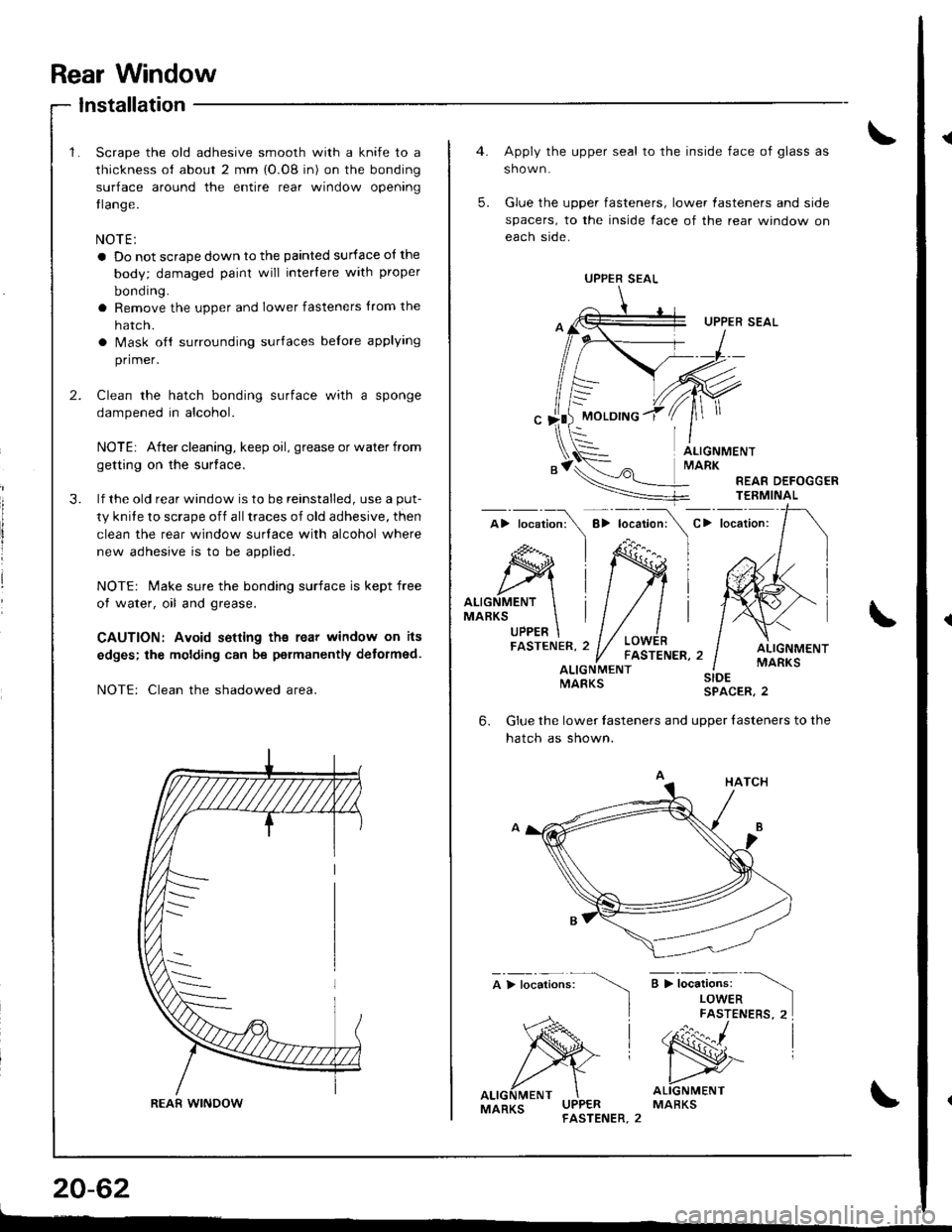

lnstallation

2.

3.

Scrape the old adhesive smooth with a knife to a

thickness of about 2 mm {O.08 in) on the bonding

surface around the entire rear window opening

tlange.

NOTE:

a Do not scrape down to the painted surface of the

body; damaged paint will interlere with proper

bonding.

a Remove the upper and lower fasteners trom the

hatc n.

a Mask oft surrounding surfaces belore applying

primer.

Clean the hatch bonding surface with a sponge

dampened in alcohol.

NOTEr After cleaning, keep oil, grease or water from

getting on the surface.

lf the old rear window is to be reinstalled, use a put-

ty knite to scrape off alltraces of old adhesive, then

clean the rear window surlace with alcohol where

new adhesive is to be applied.

NOTE: Make sure the bonding surface is kept free

of water, oil and grease.

CAUTION: Avoid setling ths rear window on its

edges; the molding can be permanently detormed.

NOTE: Clean the shadowed area.

REAfi WINDOW

20-62

Apply the upper seal to the inside face of glass as

shown.

Glue the upper fasteners, lower lasteners and side

spacers, to the inside face of the rear window on

each side.

UPPER SEAL

MOLDING

5.

ALIGNMENTMARK

REAR DEFOGGERTEEMINAL

C> locaiion:

ALIGNMENTMARKSUPPER

ALIGNMENTMARKSALIGNMENTMARKS

;>t";",i".",

)

SIDESPACER,2

6.Glue the lower lasteners and uooer {asteners to the

hatch as shown.

a > i*"ri".* -\

LOWERFASTENERS, 2I

'N^ |

ALIGNMENTMARKSMARKS

UPPER SEAL

Page 878 of 1681

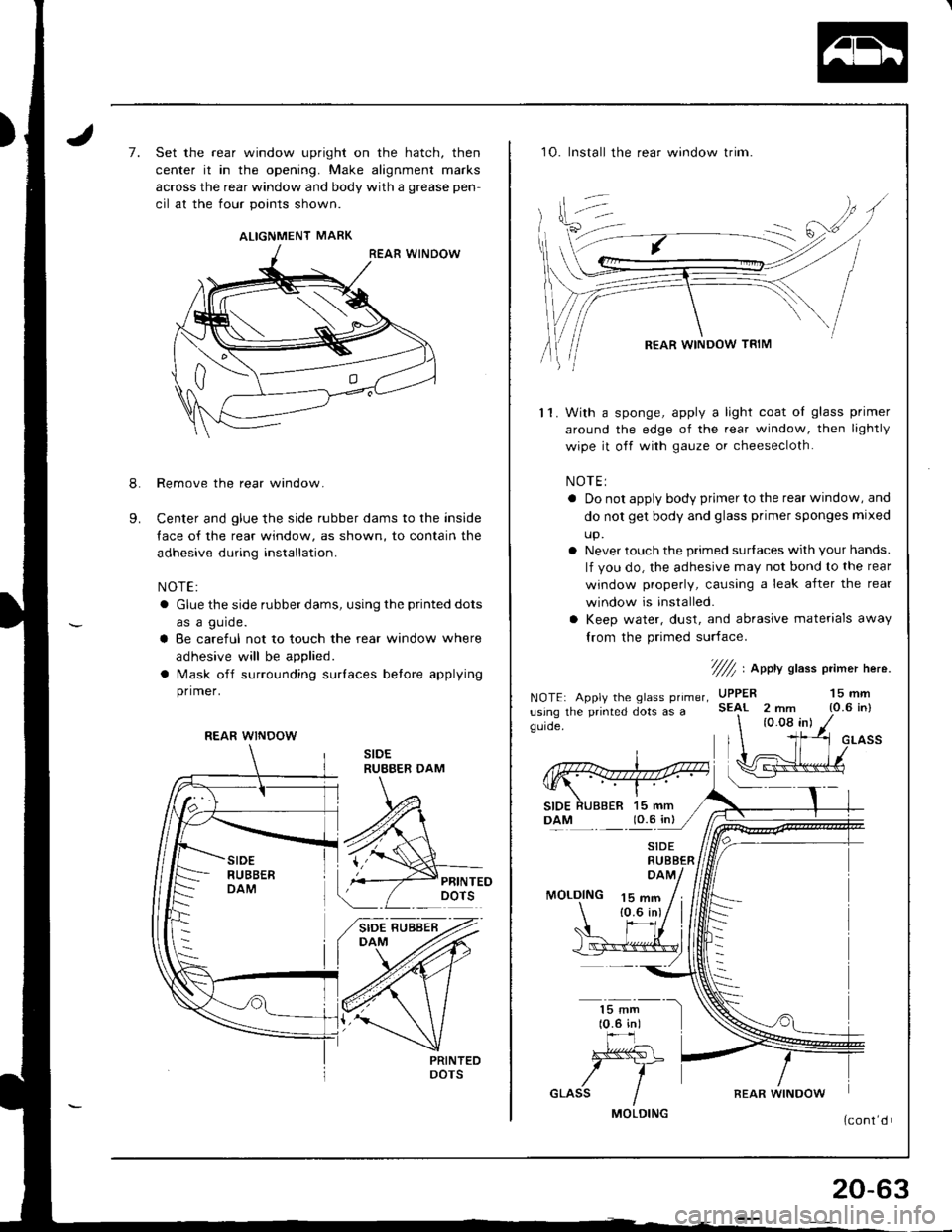

7.

9.

8.

Set the rear window upright on the hatch, then

center it in the opening. Make alignment marks

across the rear window and body with a grease pen-

cil at the four points shown.

Remove the rear window.

Center and glue the side rubber dams to the inside

Iace of the rear window, as shown, to contain the

adhesive during installation.

NOTE:

a Glue the side rubber dams, using the printed dots

as a gurde.

a Be careful not to touch the rear window where

adhesive will be applied.

a Mask off surrounding surlaces betore applying

primer.

ALIGNMENT MARK

REAR WINDOW

1O. Install the rear window trim.

With a sponge, apply a light coat oI glass primer

around the edge of the rear window, then lightly

wipe it off with gauze or cheesecloth.

NOTEI

a Do not apply body primer to the rear window, and

do not get body and glass primer sponges mlxed

up.

a Never touch the primed surlaces with Your hands.

lf you do, the adhesive may not bond to the rear

window properly, causing a leak after the rear

window is installed.

a Keep water, dust, and abrasive materials away

lrom the primed surface.

't1.

NOTE: Apply the glass primer,

usjng the printed dots as agLrde,

7///r1 , eppY slass p mer here.

MOLDING 15 661{0.6 inl

(0.08 in)

UPPERSEAI 2 mm15 mm{O.6 in}

GLASS

lO.5 in)

MOLDING

REAR WINDOW

20-63

Page 879 of 1681

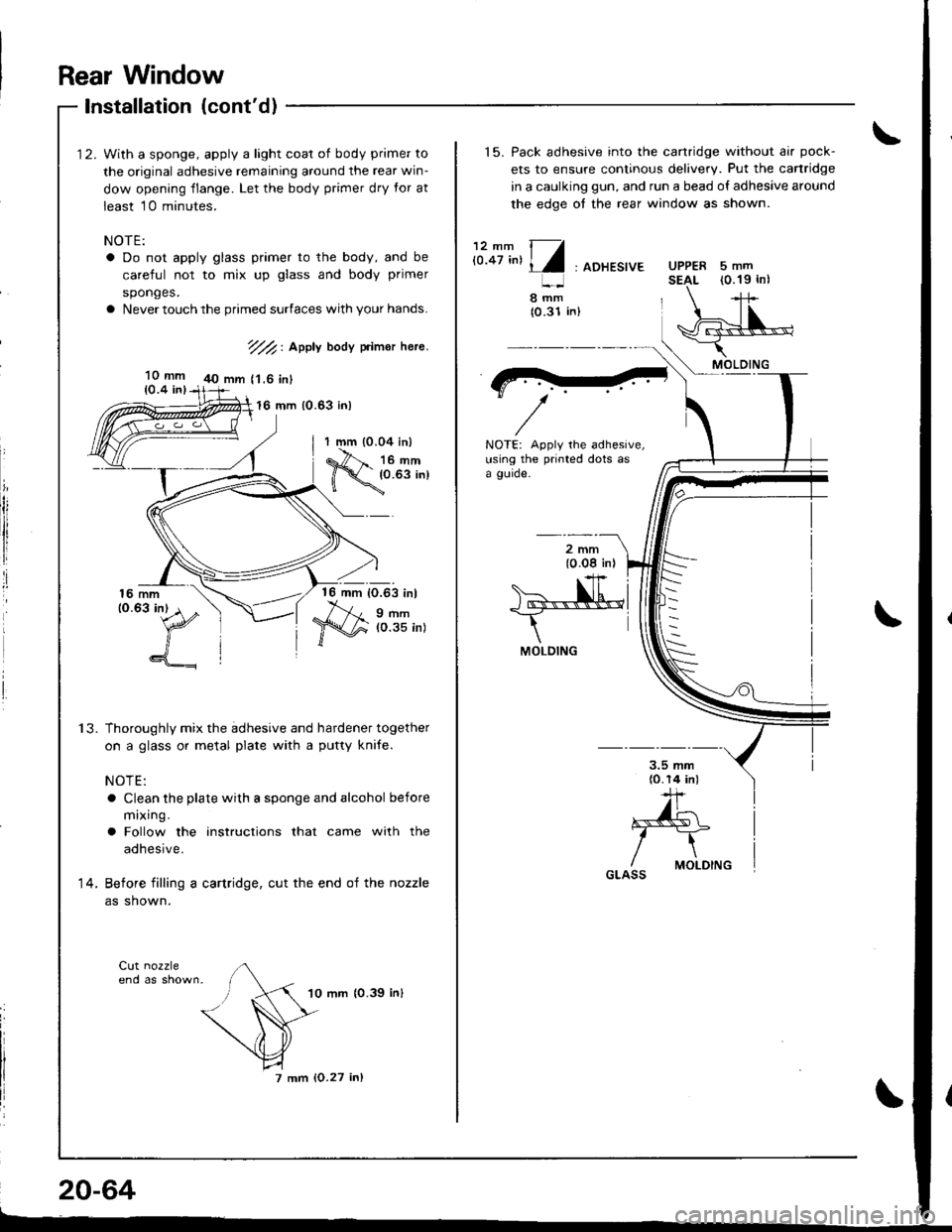

With a sponge, apply a light coat of body primer to

the original adhesive remaining around the rear win-

dow opening flange. Let the body primer dry for at

least 10 minutes.

NOTE:

a Do not apply glass primer to the body, and be

careful not to mix up glass and body primer

sponges.

a Never touch the primed surfaces with your hands.

7//2, Apply body primor here.

40 mm {'1.6 inl

16 mm (0.63 in)

ii

1 mm (0.04 inl

#;:;tT.,

1?

16 mm 10.63 inl

9 r'lm(O.35 in)

Thoroughly mix the adhesive and hardener together

on a glass or metal plate with a putty knife.

NOTE:

a Clean the plate with a sponge and alcohol before

mixing.

a Follow the instructions that came with the

adhesive.

Before filling a cartridge, cut the end of the nozzle

as shown.

10 mm 10.39 inl

7 mm {O.27 inl

14.

20-64

Rear Window

Installation (cont'd)

10 mm10.4 inl

L-

15. Pack adhesive into the cartridge without air pock-

ets to ensure continous delivery. Put the canridge

in a caulking gun, and run a bead of adhesive around

the edge of the rear window as shown.

i:.8r,^,4/: ADHE.,'E

NOTE: Apply the adhesive,using the printed dots asa gurde.

l0 Og in). +'F

>a--,N.h'*

IMOLDING

-r.]- |

^*{kL i

I "T^n i

5mm(0.19 inlUPPERSEAL

In,

!8(0

MOLDING

GLASS

Page 880 of 1681

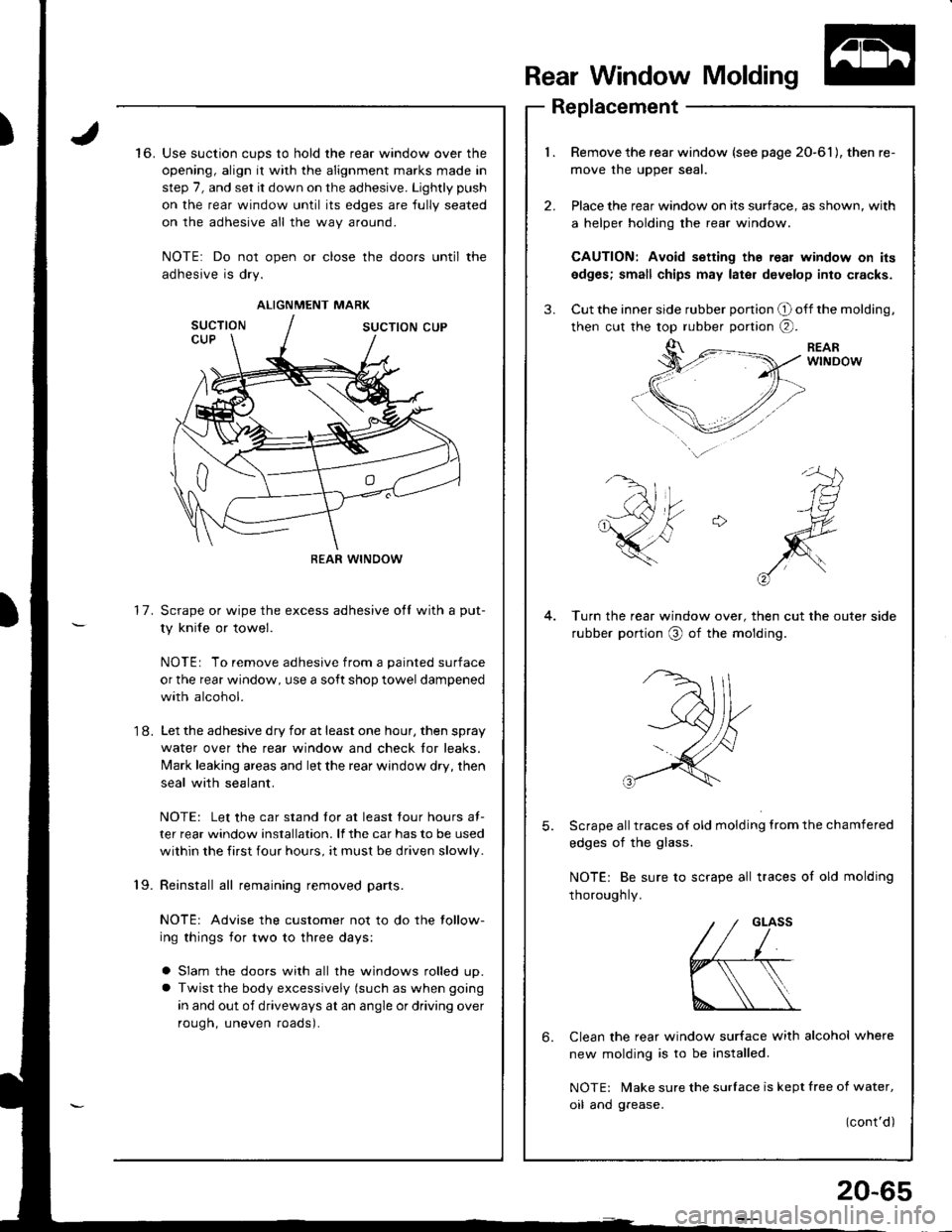

)Use suction cups to hold the rear window over the

opening, align it with the alignment marks made in

step 7, and set it down on the adhesive. Lightly push

on the rear window until its edges are fully seated

on the adhesive all the way around.

NOTE: Do not open or close the doors until the

adhesive is dry.

Scrape or wipe the excess adhesive ofl with a put-

ty knife or towel.

NOTE: To remove adhesive from a painted surface

or the rear window, use a soft shop towel dampened

with alcohol.

Let the adhesive dry for at least one hour, then spray

water over the rear window and check lor leaks.

Mark leaking areas and let the rear window dry, then

seal with sealant.

NOTE: Let the car stand tor at least four hours at-

ter rear window installation. lf the car has to be used

within the first four hours, it must be driven slowly.

all remaining removed parts.

NOTE: Advise the customer not to do the tollow-

ing things for two to three days:

a Slam the doors with all the windows rolled up.

a Twist the body excessively (such as when going

in and out of driveways at an angle or driving over

rough, uneven roads).

Rear Window Molding

2.

3.

6.

Replacement

Remove the rear window (see page 20-61), then

move the uoDer seal.

Place the rear window on its surface, as shown, v

a helper holding the rear window.

CAUTION: Avoid setting th6 real window on

edges; small chips may later develop into crac

Cut the inner side rubber ponion O off the moldi

then cut the top rubber portion @.

to.

Turn the rear window over, then cut the outer

rubber portion O of the molding.

17.

'1 8.

Scrape all traces of old molding from the cl

edges of the glass.

NOTE: Be sure to scrape all traces of old

thorough ly.

Clean the rear window surface with alcohol

new molding is to be installed.

NOTE: Make sure the surlace is kept free of

oil and grease.

mold19.

ALIGNMENT MARK

REAR WINDOW

w on ils

cracks.

molding,

side

chamfered

Ing

where

water,

)ont'd)

20-65