HONDA INTEGRA 1998 4.G Workshop Manual

Manufacturer: HONDA, Model Year: 1998, Model line: INTEGRA, Model: HONDA INTEGRA 1998 4.GPages: 1681, PDF Size: 54.22 MB

Page 881 of 1681

Rear Window Molding

Replacement (cont'd)

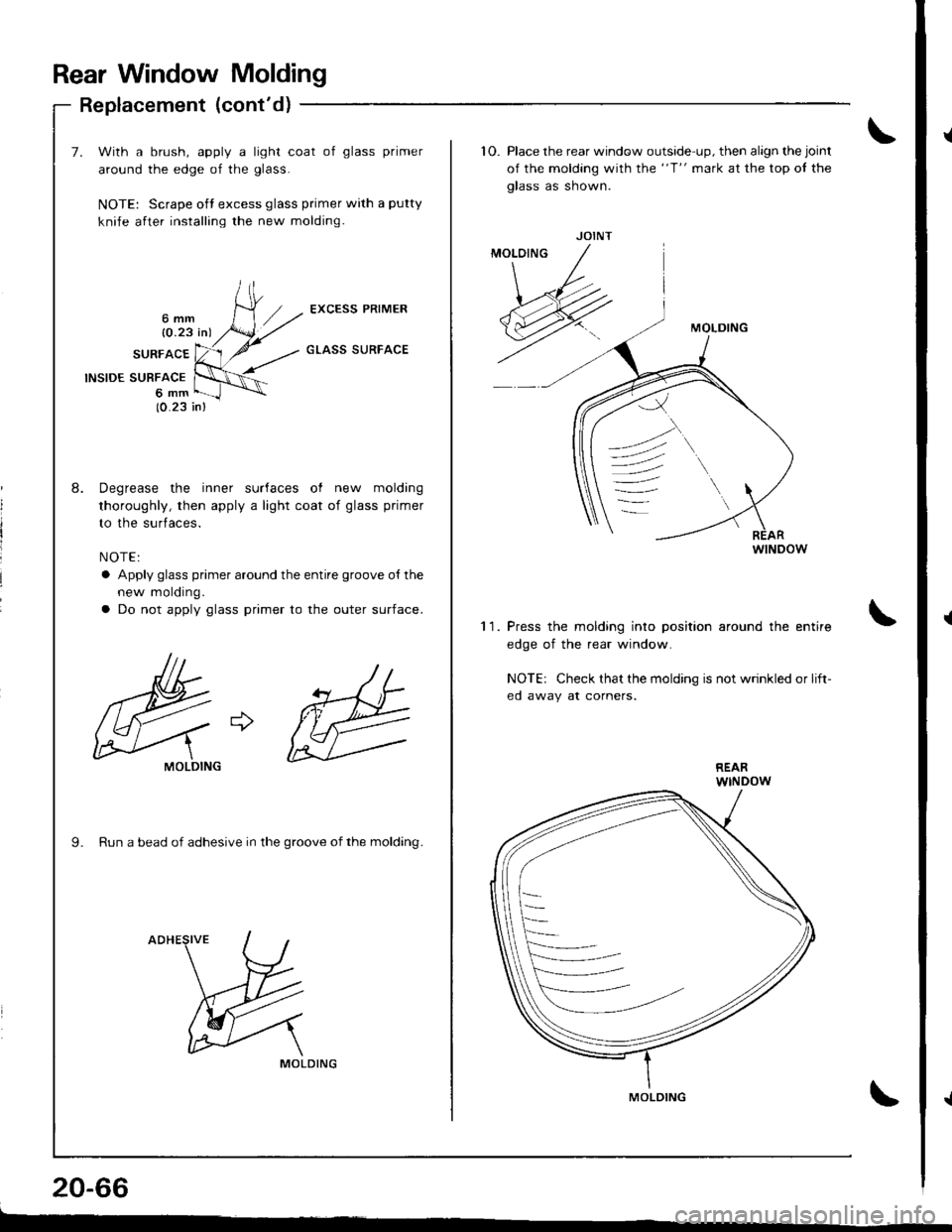

7. With a brush, apply a light coat of glass primer

around the edge of the 9lass.

NOTE: Scrape oft excess glass primer with a putty

knife after installing the new molding.

6mm{0.23 in)

SURFACE

INSIDE SURFACE

6mm(0.23 inl

8.Degrease the inner surfaces of new molding

thoroughly, then apply a light coat of glass primer

to the surfaces.

NOTE:

o Apply glass primer around the entire groove o{ the

new molding.

a Do not apply glass primer to the outer surface.

9. Run a bead of adhesive in the groove of the moldtng.

MOLDING

20-66

--�

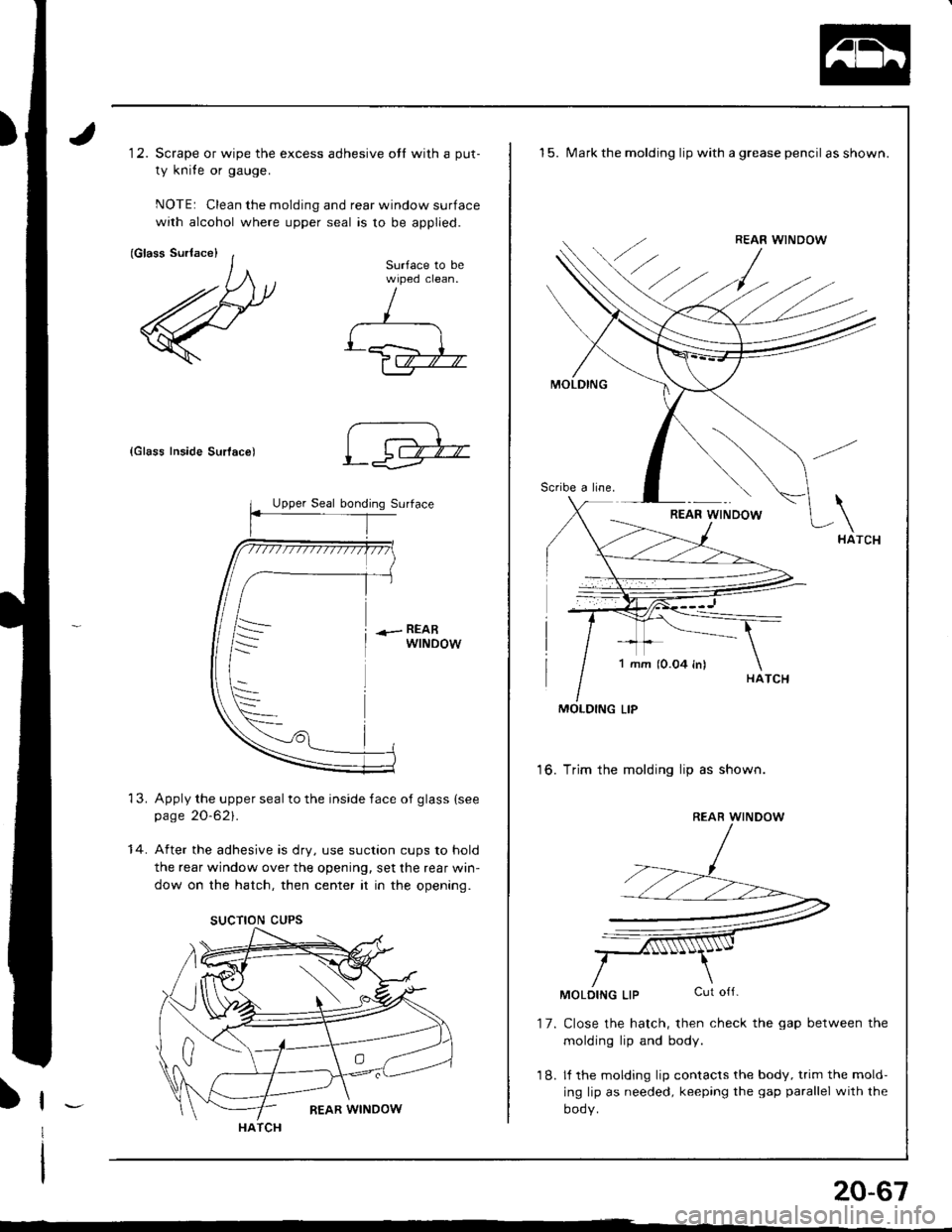

1O. Place the rear window outside-up, then align the joint

of the molding with the "T" mark at the top of the

gtass as snown.

MOLDING

\

-,-'/,-/ '\

:'-

11.

wtNDow

Press the molding into position around the entire

edge of the rear window.

NOTE: Check that the molding is not wrinkled or lift-

eo awaY aI corners.

REARwtNDow

JOINT

MOLDING

Page 882 of 1681

12. Scrape or wipe the excess adhesive otl with a put-

ty knife or gauge.

NOTE: Clean the molding and rear window surface

with alcohol where upper seal is to be applied.

{Glass Inside Surlac€)

Apply the upper seal to the inside face of glass (see

page 20-621.

After the adhesive is dry, use suction cups to hold

the rear window over the opening. set the rear win-

dow on the hatch, then center it in the opening.

(Glass Surrace) ,I surface to be

lA ! wrped clean.

/.n-v I-7...'/ ,/ |ar.-,/.---J

\sK L--=... ,

.g'_t-?,

14.

sucTroN cuPs

HATCH

1 5. Mark the molding lip with a grease pencil as shown.

MOLDING

'16. Trim the molding lip as shown.

MOLDING LIP UUI OII-

'17. Close the hatch, then check the gap between the

molding lip and body.

18. lf the molding lip contacts the body, trim the mold-

ing lip as needed, keeping the gap parallel with the

oooy.

20-67

REAR WINDOW

Page 883 of 1681

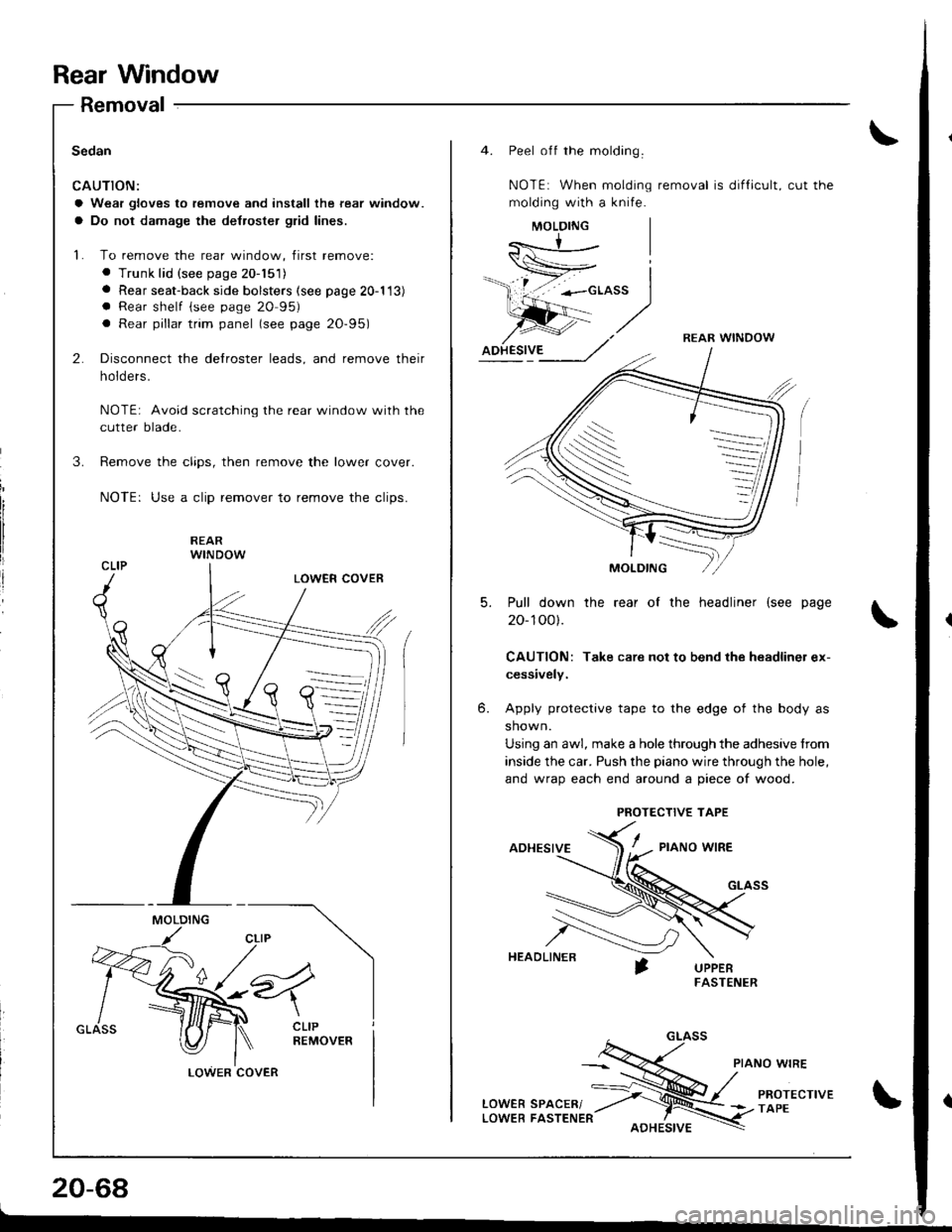

Rear Window

Removal

Sedan

CAUTION:

a Wear gloves to remove and install the rear window.

a Do not damage the de{roster glid lines.

L To remove the rear window, first remove:

. Trunk lid (see page 20-151)a Rear seat-back side bolsters (see page 20-113)a Rear shelf (see page 20 95)

a Rear pillar trim panel (see page 20-95)

2.

3.

Disconnect the delroster leads, and remove their

holders.

NOTE: Avoid scratching the rear window with the

cutter blade.

Remove the clips, then remove the lower cover.

NOTE: Use a clip remover to remove the clips.

_\--n _/i<.-,|

MOLDING

v"4

\CLIPREMOVER

LOWERCOVER

20-68

L

4. Peel off the molding.

NOTEi When molding removal is dif{icult, cut the

molding with a knife.

REAR WINDOW

S

-

5.Pull down

20- 100).

CAUTION:

cessively.

the rear of the headliner (see page

Take care not to bend the headliner ex-

6.Apply protective tape to the edge of the body as

shown.

Using an awl, make a hole through the adhesive from

inside the car. Push the piano wire through the hole,

and wrao each end around a oiece of wood.

ADHESIVE/ - ,,o"o *,aa

HEAOLINER

PROTECTIVE TAPE

Page 884 of 1681

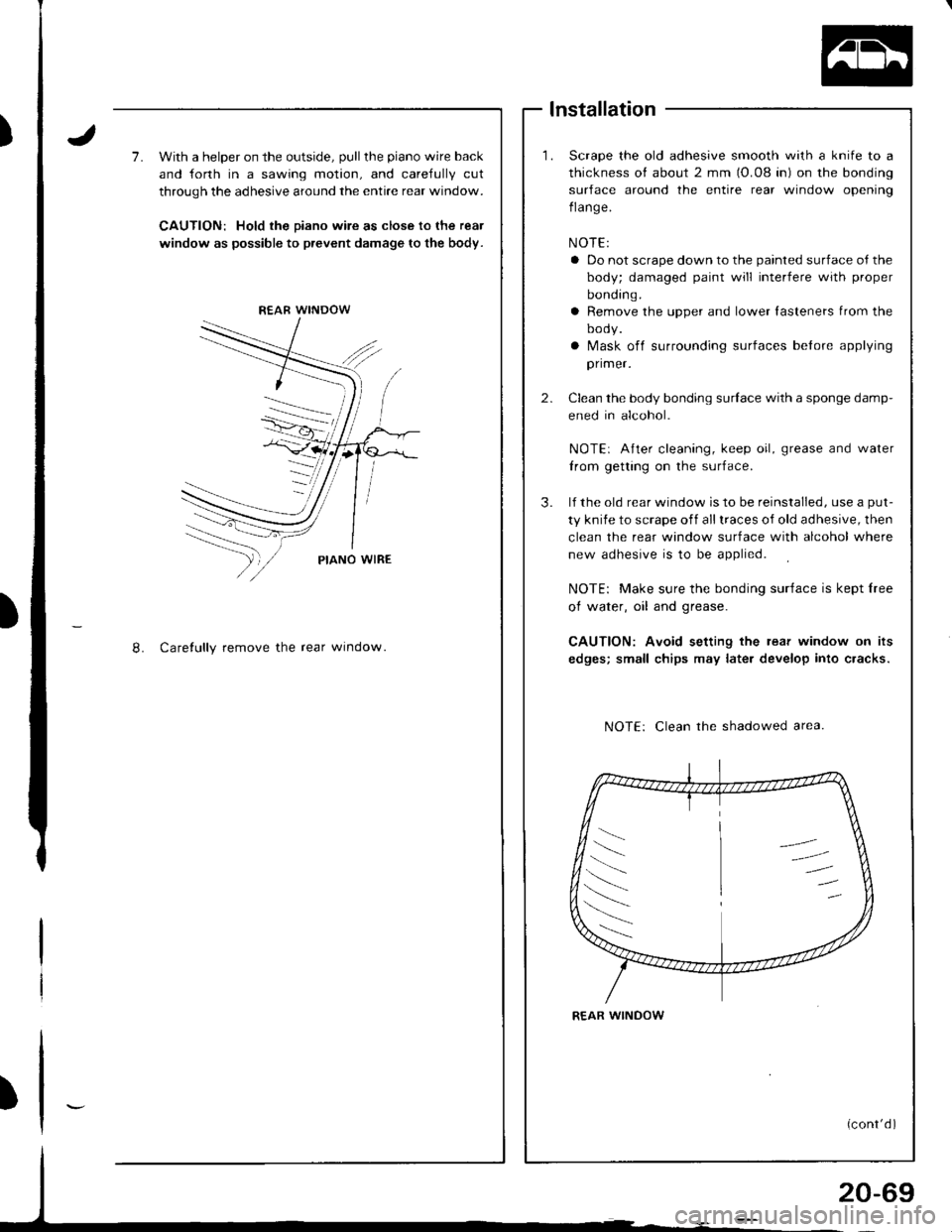

7.With a helper on the outside, pull the piano wire back

and forth in a sawing motion, and careJully cut

through the adhesive around the entire rear window.

CAUTION: Hold the eiano wire as close to the real

window as possible to p.event damage to the body.

REAB WINDOW

PIANO WIRE

8. Carefully remove the rear window.

lnstallation

Scrape the old adhesive smooth with a knife to a

thickness ol about 2 mm (O.08 in) on the bonding

surface around the entire rear window opening

flange.

a Do not scrape down to the painted surface ot the

body; damaged paint will interfere with proper

bonding.

a Remove the upper and lower fasteners from the

oooy.

a lvlask off surrounding surfaces belore applying

primer.

Clean the body bonding surlace with a sponge damp-

ened in alcohol.

NOTE: Ajter cleaning, keep oil, grease and waler

lrom getting on the surface.

lf the old rear window is to be reinstalled, use a put-

ty knife to scrape off alltraces oJ old adhesive, then

clean the rear window surface with alcohol where

new adhesive is to be applied.

NOTE: Make sure the bonding surlace is kept lree

of water, oil and grease.

CAUTION: Avoid setting the lear window on its

edges; small chips may later develop into cracks.

Clean the shadowed area.

(cont'd )

)

S

20-69

Page 885 of 1681

Rear Window

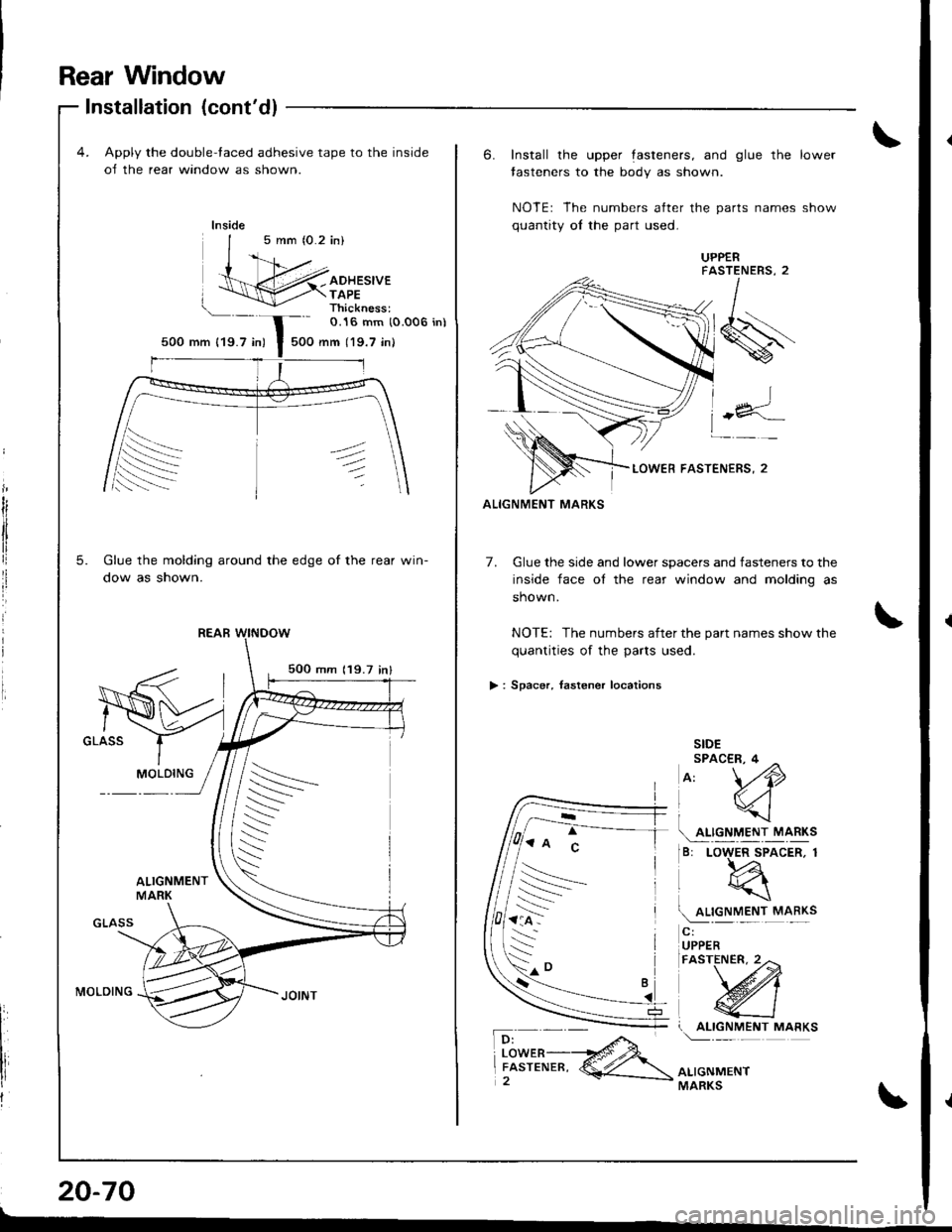

4. Apply the double-taced adhesive tape to the inside

oJ the rear window as shown.

5 mm (0.2 in)

Installation (cont'd)

500 mm {19.7 in)

ADHESIVETAPEThickness:O.16 mm (0.006 in)

500 mm (19.7 in)

l

i

I

Glue the molding around the edge of the rear win-

dow as shown.

500 mm 119.7 inl

MOLDING

20-70

I

6. Install the upper fasteners. and glue the lower

tasteners to the body as shown.

NOTE: The numbers after the parts names show

quantity ol the part used.

UPPERFASTENERS,2

7. Glue the side and lower spacers and fasteners to the

inside face of the rear window and molding as

shown.

NOTE: The numbers after the part names show the

quantities of the parts used.

> : Spacer, Iastener locations

s

SPAC€R, 4 .,^^,

r'P

K/]r'\

lr-rcrumerur nitanrs

lB: LOWER SPACER, 1

iq

(4rsryilr!ry'

c:UPPERFASTENER, 2/}

w ALIGNMENT MARKS

ALIGNMENTMARKS

lnside

MOLDING

ALIGNMENT MARKS

Page 886 of 1681

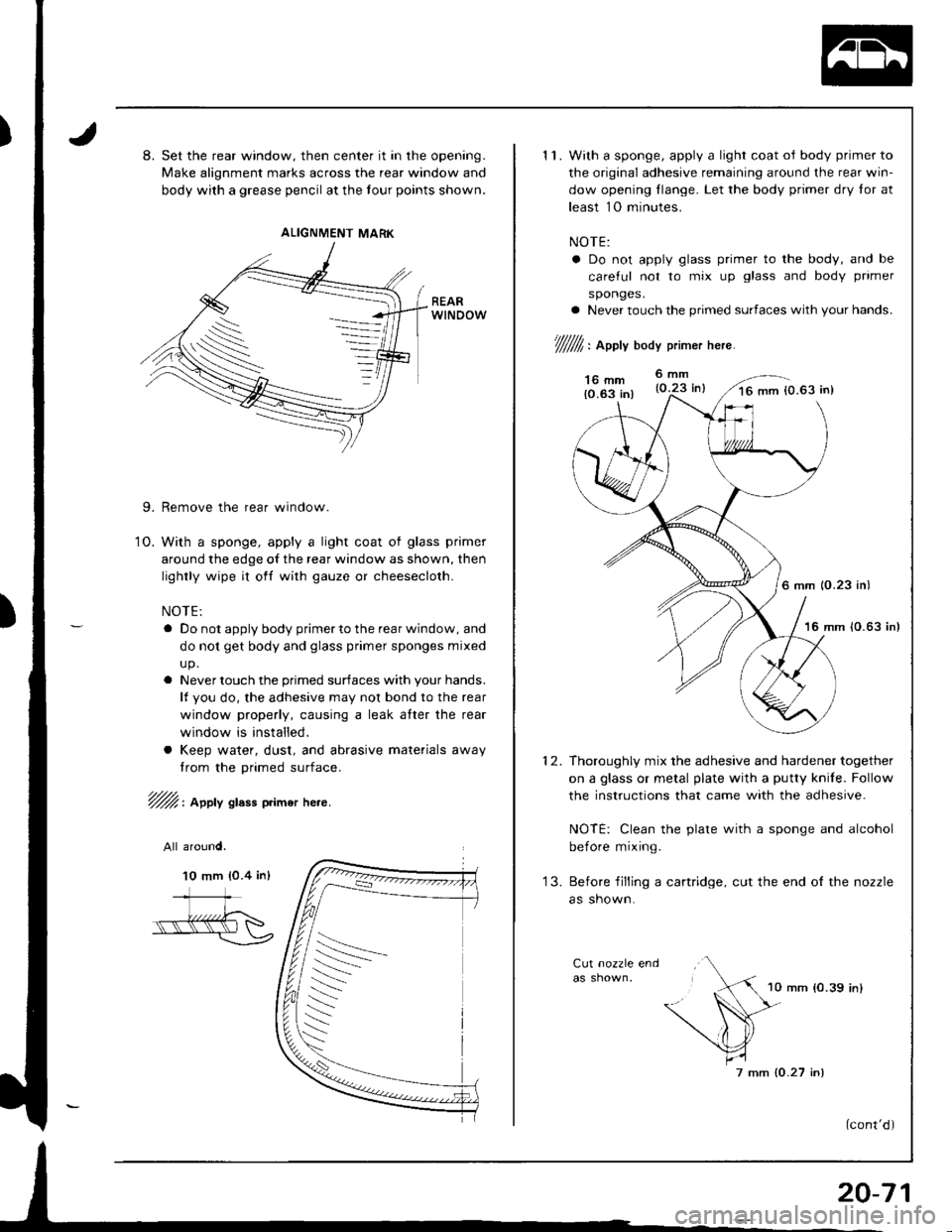

8. Set the rear window, then center it in the opening.

Make alignment marks across the rear window and

body with a grease pencil at the tour points shown.

9. Remove the rear window.

O. With a sponge, apply a light coat of glass primer

around the edge of the rear window as shown, then

lightly wipe it off with gauze or cheesecloth.

NOTE:

a Do not apply body primer to the rear window, and

do not get body and glass primer sponges mixed

up.

a Never touch the primed surfaces with your hands.

lf you do, the adhesive may not bond to the rear

window properly, causing a leak atter the rear

window is installed.

a Keep water, dust, and abrasive materials away

trom the primed surface.

'fu5 t appty gtass p.im€r he.e.

All around.

'10 mm {0.4 in)

ALIGNMENT MARK

...\

S;-1\-\

11. With a sponge, apply a light coat oJ body primer to

the original adhesive remaining around the rear win-

dow opening flange. Let the body primer dry tor at

least 1O minutes.

NOTE:

a Do not apply glass primer to the body, and be

carelul not to mix up glass and body primer

spon9es.

a Never touch the primed surfaces with your hands.

//ffi: Apgly body primer here.

'16 mm{O.63 in)

6mm{0.23 in}

6 mm 10.23 inl

16 mm 10.63 in)

Thoroughly mix the adhesive and hardener together

on a glass or metal plate with a putty knife. Follow

the instructions that came with the adhesive.

NOTE: Clean the plate with a sponge and alcohol

before mixing.

Before filling a cartridge, cut the end of the nozzle

as shown.

16 mm {0.63 in}

10 mm {0.39 in}

Cut nozzle end

Page 887 of 1681

Rear Window

Installation (cont'dl

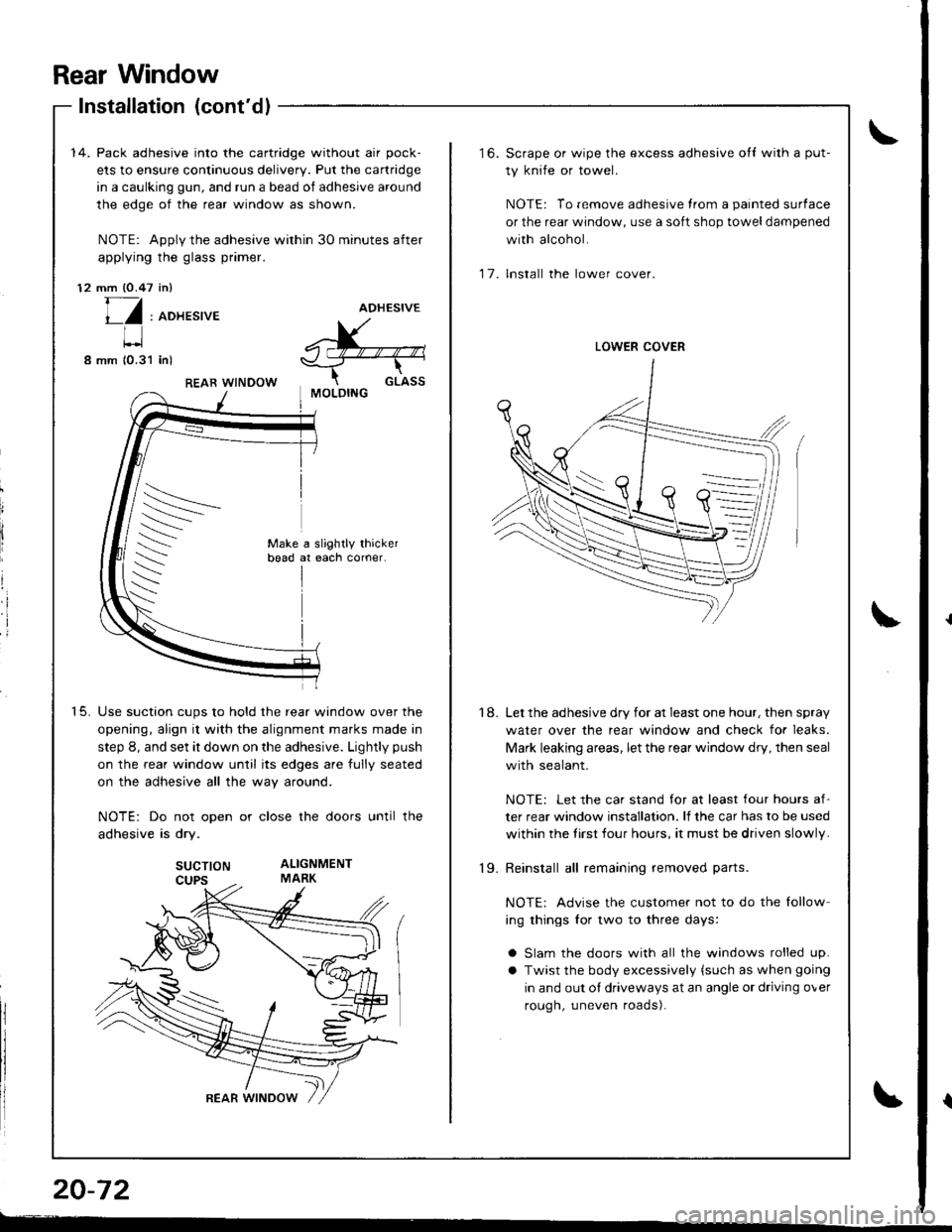

14. Pack adhesive into the cartridge without air pock-

ets to ensure continuous delivery. Put the cartridge

in a caulking gun, and run a bead of adhesive around

the edge of the rear window as shown.

NOTE: Apply the adhesive within 30 minutes after

applying the glass primer.

12 mm (O.47 in)

ADHESIVE

^X-*\..__-, I

i cr-issMOLDING

15.

[-/ , oo"r'u.

L-l

8 mm 10.31 in)

REAR WINDOW

Make a slightly thickerb6ad at each corner.

Use suction cups to hold the rear window over the

opening, align it with the alignment marks made in

step 8, and set it down on the adhesive. Lightly push

on the rear window unlil its edges are fully seated

on the adhesive all the way around.

NOTF: Do not open or close the doors until the

adhesive is dry.

ALIGNMENTMARK

'16. Scrape or wipe the excess adhesive ofl with a put-

ty knife or towel.

NOTE: To remove adhesive lrom a painted surface

or the rear window, use a soft shop towel dampened

with alcohol.

17. lnstall the lower cover.

18. Let the adhesive dry for at least one hour, then spray

water over the rear window and check for leaks.

Mark leaking areas, let the rear window dry, then seal

with sealant.

NOTE: Let the car stand for at least four hours af-

ter rear window installation. lf the car has to be used

within the first four hours, it must be driven slowly.

19. Reinstall all remaining removed parts.

NOTE: Advise the customer not to do the follow

ing things lor two to three days:

a Slam the doors with all the windows rolled up.

a Twist the body excessively {such as when going

in and out of driveways at an angle or driving o!er

rough, uneven roads).

LOWER COVER

\

I

I

I

20-72

!:e-

t

\

Page 888 of 1681

Ouarter Glass

Removallnstallation

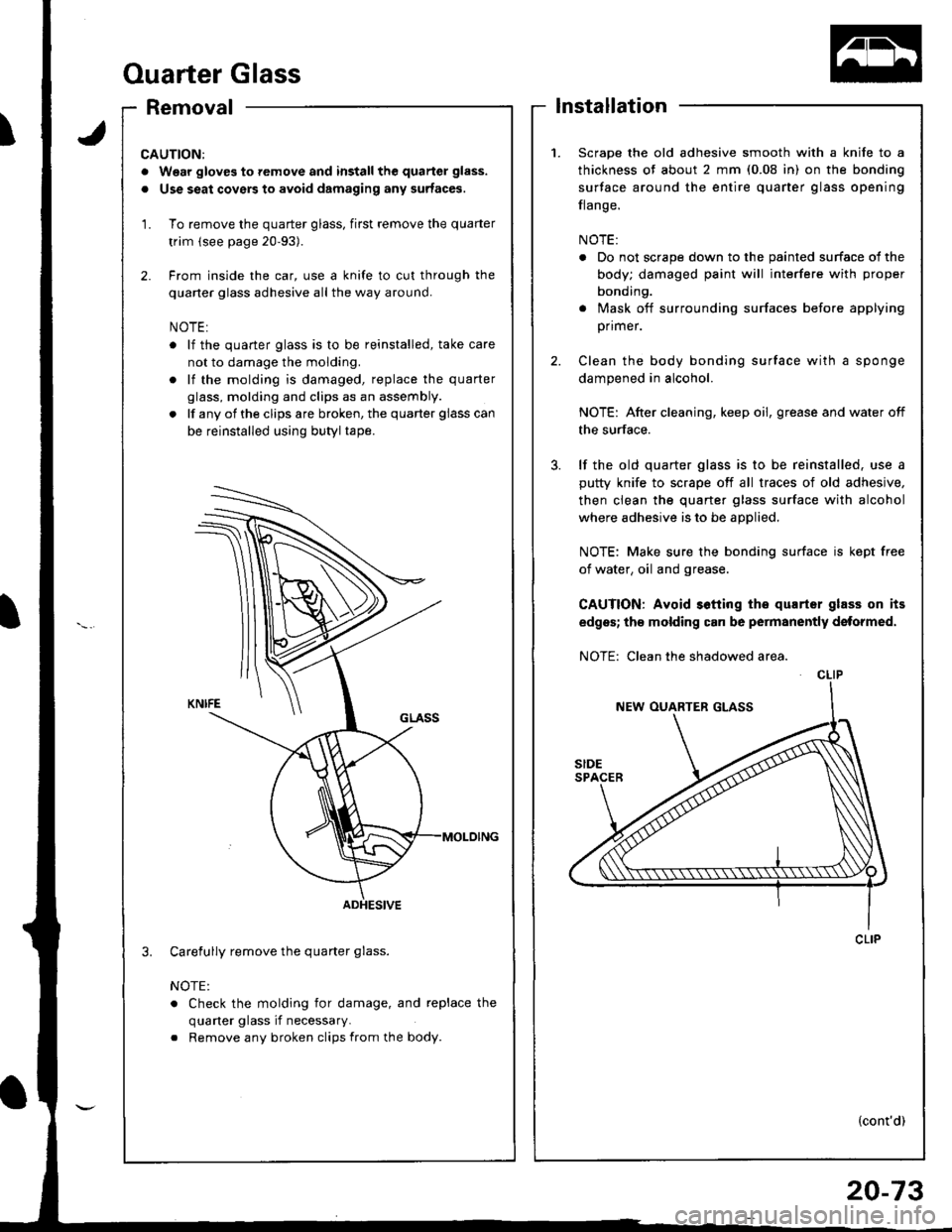

1.Scrape the old adhesive smooth with a knife to a

thickness of about 2 mm (0.08 in) on the bonding

surface around the entire quarter glass opening

flange.

NOTE:

. Do not scrape down to the painted surface ol the

body; damaged paint will interfere with proper

bonding.

. Mask off surrounding surfaces before applying

primer.

Clean the body bonding surface with a sponge

dampened in alcohol.

NOTE: After cleaning, keep oil, grease and water off

the surface.

lf the old quarter glass is to be reinstalled. use a

putty knife to scrape off all traces of old adhesive,

then clean the quarter glass surface with alcohol

where adhesive is to be applied.

NOTE: Make sure the bonding surface is kept free

of water, oil and grease.

CAUTION: Avoid s6tting tho qurrtsr glass on its

edges; th€ molding can be permanently dstormed.

NOTE: Clean the shadowed area.

3.

CLIP

(cont'd)

CAUTIONi

. Wear gloves to remove and install the quarter glass.

. Use seat covers to avoid dsmaging any surfaces.

1. To remove the quarter glass, first remove the quarter

trim (see page 20-93).

2. Frcm inside the car, use a knife to cut through the

quarter glass adhesive all the way around.

NOTE:

o lf the quarter glass is to be reinstalled, take care

not to damage the molding.

. lf the molding is damaged, replace the quarter

glass, molding and clips as an assembly.

. lf any of the clips are broken, the quarter glass can

be reinstalled using butyl tape.

Carefully remove the quarter glass.

NOTE:

. Check the molding for damage, and replace the

quaner glass if necessary.

. Remove any broken clips from the body.

3.

ADHESIVE

Page 889 of 1681

Ouarter Glass

Installation (cont'd)

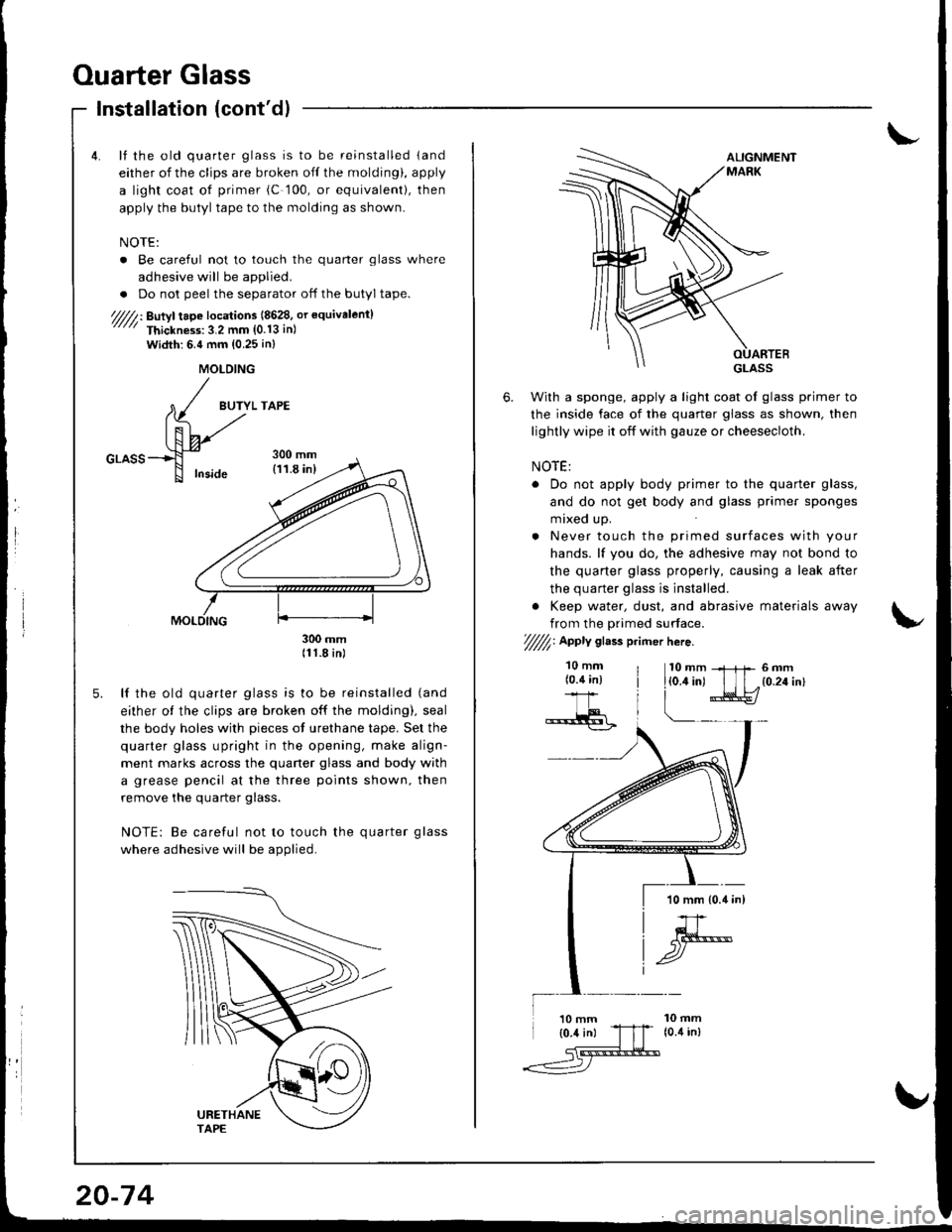

lf the old quarter glass is to be reinstalled land

either of the clips are broken off the molding), apply

a light coat ot primer (C 100, or equivalent|, then

apply the butyl tape to the molding as shown.

NOTE:

. Be careful not to touch the quarter glass where

adhesive will be applied.

. Do not peel the separator off the butyl tape.

//////.t Bulyl lape locations 18628, or equivalent)""' Thickness:3.2 mm {0.13 in)

Width: 6.4 mm (0.25 in)

BUTYL TAPE

300 mmn1.8 in)

lf the old quarter glass is to be reinstalled (and

either of the clips are broken off the molding), seal

the body holes with pieces of urethane tape. Set the

quarter glass upright in the opening, make align-

ment marks across the quaner glass and body with

a grease pencil at the three points shown, then

remove the quarter glass.

NOTE: Be careful not to touch the quarter glass

where adhesive will be applied.

6.With a sponge, apply a light coat of glass primer to

the inside face of the quarter glass as shown, then

lightly wipe it off with gauze or cheesecloth.

NOTE:

. Do not apply body primer to the quarter glass,

and do not get body and glass primer sponges

mixed up.

. Never touch the primed surfaces with your

hands. lf you do, the adhesive may not bond to

the quarter glass properly, causing a leak after

the quarter glass is installed.

. Keep water, dust, and abrasive materials away

from the primed surface.

/////1: Apotv slass oimer here.

6mm{0.24 in}

t

Page 890 of 1681

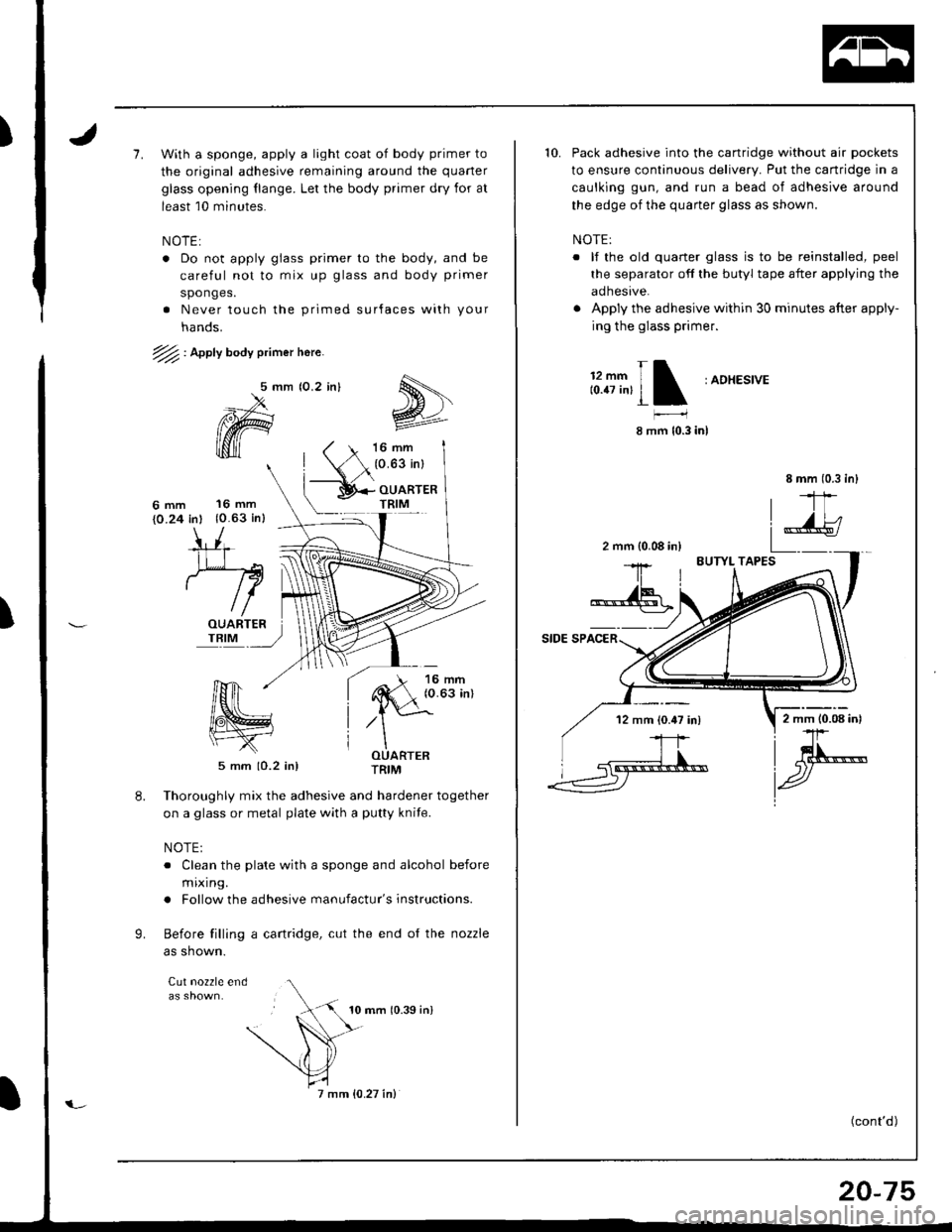

)7. With a sponge, apply a light coat of body primer to

the original adhesive remaining around the quaner

glass opening {lange. Let the body primer dry for at

least 10 minutes.

NOTE:

. Do not apply glass primer to the body, and be

careful not to mix up glass and body primer

sponges.

. Never touch the primed surfaces with your

na nos.

//;4: Aoely bodv Pimer hare

(0.2 inl5mm

ffi

16 mminl 10.63 inl

jrlr-

Il

)HI l(

OUARTERTRIM

16 rnm(0.63 in)

)

6mmlo.24

OUARTERTRIM

IP'--

8.

L

OUARTER5 mm lO.2 in) lRtM

Thoroughly mix the adhesive and hardener together

on a glass or metal plate with a putty knife.

NOTE:

. Clean the plate with a sponge and alcohol before

mrxrng.

. Follow the adhesive manufactur's instructions.

Before filling

as shown.

Cut nozzle end

a cartridge, cut the end of the nozzle

10 mm 10.39 in)

7 mm 10.27 in)

20-75

ffi;;[,] :AoHEs'�vE

8 mm 10.3 inl

2 mm (0.08 in)

in)

SIDE SPACER

10. Pack adhesive into the cartridge without air pockets

to ensure continuous delivery. Put the cartridge in a

caulking gun, and run a bead of adhesive around

the edge of the quarter glass as shown.

NOTE:

. lf the old quarter glass is to be reinstalled, peel

the separator off the butyl tape after applying the

adhesive.

. Apply the adhesive within 30 minutes after apply-

ing the glass primer.

8 mm (0.3

Tt

w

EUTYL TAPES

12 mm (0.47 in)2 mm 10.08 in)

(cont'd)