stop start INFINITI QX56 2011 Factory Service Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 3123 of 5598

![INFINITI QX56 2011 Factory Service Manual

SYSTEMHAC-17

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

FRONT AUTOMATIC AIR CONDITIONIN G SYSTEM : Air Outlet ControlINFOID:0000000006275864

While air out INFINITI QX56 2011 Factory Service Manual

SYSTEMHAC-17

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

FRONT AUTOMATIC AIR CONDITIONIN G SYSTEM : Air Outlet ControlINFOID:0000000006275864

While air out](/img/42/57033/w960_57033-3122.png)

SYSTEMHAC-17

< SYSTEM DESCRIPTION > [AUTOMATIC AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

FRONT AUTOMATIC AIR CONDITIONIN G SYSTEM : Air Outlet ControlINFOID:0000000006275864

While air outlet is in automatic control, A/C auto amp. selects the

front mode door position depending on a target front air mix door

angle and outlet air temperature calculated from sunload.

If ambient temperature is excessively low, D/F is selected to pre- vent windshield fogging when air outlet is set to FOOT.

FRONT AUTOMATIC AIR CONDITIONIN G SYSTEM : Compressor Control

INFOID:0000000006275865

DESCRIPTION

When the compressor activation condition is satisfied while blower motor is activated, A/C auto amp. trans-

mits A/C ON signal and blower fan ON signal to ECM via CAN communication.

ECM judges that the compressor can be activated depending on each sensors state (refrigerant pressure sensor signal, and others). And transmits A/C compress or request signal to IPDM E/R via CAN communica-

tion.

IPDM E/R turns A/C relay ON and activates the compressor depending on request from ECM.

COMPRESSOR PROTECTION CONTROL AT PRESSURE MALFUNCTION

When high-pressure side value that is detected by refri gerant pressure sensor is as per the following state,

ECM requests IPDM E/R to turn A/C relay OFF and stops the compressor.

3.12 MPa (31.82 kg/cm

2, 452.4 psi) or more (When the engine speed is less than 1,500 rpm)

2.74 MPa (27.95 kg/cm

2, 397.3 psi) or more (When the engine speed is 1,500 rpm or more)

0.14 MPa (1.43 kg/cm

2, 20.3 psi) or less

COMPRESSOR OIL CIRCULATION CONTROL

When the engine starts while the engine coolant temperature is 56 °C (133 °F) or less, ECM activates the com-

pressor for approximately 6 seconds and circulates the compressor lubricant once.

LOW TEMPERATURE PROTECTION CONTROL

When intake sensor detects that front evaporator fin temperature is

2.5 °C (37 °F) or less, A/C auto amp. requests ECM to turn com-

pressor OFF, and stops the compressor.

When the front evaporator fin temperature returns to 5.0 °C (41 °F)

or more, the compressor is activated.

OPERATING RATE CONTROL

When set temperature is other than fully cold or air out let is “VENT”, “B/L” or “FOOT” A/C auto amp. controls

the compressor activation depending on ambient temperature.

AIR CONDITIONING CUT CONTROL

When set engine is running is excessively high load conditi on, ECM requests IPDM E/R to turn A/C relay OFF,

and stops the compressor. Refer to EC-47, "

AIR CONDITIONING CUT CONTRO L : System Description" for

details.

JMIIA0730GB

JMIIA0742GB

Revision: 2010 May2011 QX56

Page 3168 of 5598

![INFINITI QX56 2011 Factory Service Manual

HAC-62

< BASIC INSPECTION >[AUTOMATIC AIR CONDITIONING]

OPERATION INSPECTION

OPERATION INSPECTION

FRONT AUTOMATIC AIR CONDITIONING SYSTEM

FRONT AUTOMATIC AIR CONDITIONIN

G SYSTEM : Work ProcedureINFO INFINITI QX56 2011 Factory Service Manual

HAC-62

< BASIC INSPECTION >[AUTOMATIC AIR CONDITIONING]

OPERATION INSPECTION

OPERATION INSPECTION

FRONT AUTOMATIC AIR CONDITIONING SYSTEM

FRONT AUTOMATIC AIR CONDITIONIN

G SYSTEM : Work ProcedureINFO](/img/42/57033/w960_57033-3167.png)

HAC-62

< BASIC INSPECTION >[AUTOMATIC AIR CONDITIONING]

OPERATION INSPECTION

OPERATION INSPECTION

FRONT AUTOMATIC AIR CONDITIONING SYSTEM

FRONT AUTOMATIC AIR CONDITIONIN

G SYSTEM : Work ProcedureINFOID:0000000006275892

DESCRIPTION

The purpose of the operational check is to che ck that the individual system operates normally.

OPERATION INSPECTION

1.CHECK MEMORY FUNCTION

1. Set temperature control dial (driver side) to 32.0 °C (90 °F).

2. Press OFF switch.

3. Turn ignition switch OFF.

4. Turn ignition switch ON.

5. Press AUTO switch.

6. Check that set temperature is maintained.

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 12.

2.CHECK FRONT BLOWER MOTOR

1. Start engine.

2. Operate fan switch.

3. Check that fan speed changes. C heck operation for all fan speeds.

Is the inspection result normal?

YES >> GO TO 3.

NO >> GO TO 12.

3.CHECK DISCHARGE AIR (MOD E SWITCH AND DEF SWITCH)

1. Operate fan switch to set the fan speed to maximum speed.

2. Operate MODE switch and DEF switch.

3. Check that air outlets change according to each indica ted air outlet by placing a hand in front of the out-

lets. Refer to VTL-6, "

VENTILATION SYSTEM (FRONT AIR CO NDITIONING) : System Description".

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 12.

4.CHECK DISCHRGE AIR (UPPER VENTILATOR SWITCH)

1. Press MODE switch to set the air outlet to other than D/F or DEF.

2. Press upper ventilator switch. The upper ventilator switch indicator is turns ON.

3. Check that air flow blows from upper ventilator.

4. Press upper ventilator switch again. The upper ventilator switch indicator is turns OFF.

5. Check that air flow from upper ventilator stops.

Is the inspection result normal?

YES-1 >> With ACCS (advanced climate control system): GO TO 5.

YES-2 >> Without ACCS (advanced clim ate control system): GO TO 6.

NO >> GO TO 12.

5.CHECK INTAKE AIR [WITH ACCS (A DVANCED CLIMATE CONTROL SYSTEM)]

1. Press intake switch to set the air inlet to recirculation. The intake switch indicator turns ON.

2. Listen to intake sound and confirm air inlets change.

3. Press intake switch again to set the air inlet to fresh air intake. The intake switch indicator turns OFF.

4. Listen to intake sound and confirm air inlets change.

Is the inspection result normal?

Check condition : Engine running at normal operating temperature.

Revision: 2010 May2011 QX56

Page 3274 of 5598

SYSTEMINL-7

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K

M A

B

INL

N

O P

Interior Room Lamp Timer Basic Operation

NOTE:

A: Sets the interior room lamp gradual brightening and dimming time.

B: Gradually brightens from 0% to 100% and gradually dims from 100% to 0% in 1 second.

The interior room lamp turns ON and OFF (gradual brightening and dimming) by the interior room lamp

timer.

BCM judges the vehicle condition with the following items. It activates the interior room timer.

- Ignition switch status

- Door switch signal (except back door)

- Door lock/unlock signal (remote keyless entry receiv er, each door request switch, door key cylinder switch,

door lock/unlock switch)

NOTE:

Each function of interior room lamp ti mer can be set by CONSULT-III. Refer to INL-14, "

INT LAMP : CON-

SULT-III Function (BCM - INT LAMP)".

Interior Room Lamp ON Operation

BCM always turns the interior room lamp ON when any door opens excepting back door.

When all doors are closed, and any all door unlock operation is performed or ignition switch is turned OFF,

BCM brightens interior room lamp to 30% bri ghtness and maintains 30% brightness until any door opens.

BCM activates the interior room timer in any of the fo llowing conditions to turn the interior room lamp ON for

a period of time.

- Any door opens before all doors close excepting back door.

- Ignition switch is turned ON → OFF.

- Any door unlock signal is detected when all doors cl ose excepting back door with ignition switch OFF.

NOTE:

The timer restarts if new condition is input during the timer operating time.

Interior Room Lamp OFF Operation

BCM stops the timer and turns interior room lamp OF F, when any of the following conditions is satisfied.

The interior room lamp timer operating time is expired with all doors closed excepting back door.

Ignition switch position is other than O FF with all doors close excepting back door.

Any door lock signal is detected with all doors close excepting back door.

LUGGAGE ROOM LAMP CONTROL

BCM controls the luggage room lamp and automatic back door close switch illumination (ground-side) to turn

ON with back door switch ON.

When luggage room lamp switch is turned to the ON position, luggage room lamp turns ON.

When luggage room lamp switch is in the DOOR position and back door is opened, luggage room lamp turns ON.

When back door is opened, automatic back door close switch illumination turn ON.

STEP LAMP CONTROL

BCM controls the step lamp (ground-side) to turn ON with any door switch ON excepting back door.

PUDDLE LAMP TIMER CONTROL

Puddle Lamp Timer Basic Operation

BCM controls the ground to turn the puddle lamp ON.

JMLIA0961GB

Revision: 2010 May2011 QX56

Page 3275 of 5598

INL-8

< SYSTEM DESCRIPTION >

SYSTEM

The puddle lamp turns ON and OFF by the puddle lamp timer.

BCM judges the vehicle condition with the following items. It activates the puddle lamp timer.

- Ignition switch status

- Door switch signal (except back door)

- Door lock/unlock signal (remote keyless entry receiver, each door request switch)

- Driver side door lock status

Puddle Lamp ON Operation

BCM activates the puddle lamp timer in any of the following conditions to turn the puddle lamp ON for a period

of time.

Any door opens excepting back door.

Any door opens before all doors close excepting back door.

Ignition switch is turned ON → OFF.

Door unlock signal by remote keyless entry rece iver or each door request switch is detected.

Driver side door is locked*.

NOTE:

The timer restarts if new condition is input during the timer operating time.

Puddle Lamp OFF Operation

BCM stops the timer and turns puddle lamp OFF, when any of the following conditions are satisfied.

The puddle lamp timer operating time is expired.

The interior room lamp OFF conditions.

The interior room lamp timer operating time is expired.

PUSH-BUTTON IGNITION SWITCH ILLUMINATION CONTROL

Push-button Ignition Switch Illumination Basic Operation

BCM controls the ON/OFF status of push-button igni tion switch illumination according to vehicle status.

BCM provides the push-button ignition switch illumi nation control signal and the ground to turn the push-but-

ton ignition switch illumination ON.

BCM cuts the ground supply while each illumination (tai l lamp) is ON. BCM switches to the ground control

according to the meter illumination control function. Refer to MWI-16, "

METER ILLUMINATION CONTROL :

System Description".

Heart Beat Operation

BCM repeats brightening and dimming operation of push-button ignition switch illumination when any of the

following conditions are satisfied.

Welcome light function operates.

When ignition switch is OFF and any of the following conditions are satisfied.

- Driver side door changes from closed to open

- Driver side door changes from locked to unlocked

- Intelligent Key ID comparison is OK and driver side door changes from open to closed

- ID comparison by Intelligent Key transponder is OK

Illumination ON Operation

When ignition switch is not OFF or tail lamp turns ON, push-button ignition switch illumination turns ON.

Dimming Operation

When tail lamp turns OFF and ignition switch is turned OFF, push-button ignition switch illumination dims to

50% brightness.

Illumination OFF Operation

Push-button ignition switch illumination turns OFF when ignition switch turns OFF and tail lamp turns from ON

to OFF, while push-button ignition switch illumination is in ON status.

When push-button ignition switch illumination is at 50% brightness or in heartbeat status, and any of the fol-

lowing conditions are satisfied, push-butt on ignition switch illumination turns OFF.

15 seconds after start of heartbeat operation.

When welcome light function is not operating and any on the following conditions is satisfied.

- Driver side door is closed

- Driver side door is locked

- Intelligent Key ID comparison is NG

- Comparison of Intelligent Key ID by transponder is NG

INTERIOR ROOM LAMP BATTERY SAVER SYSTEM

Revision: 2010 May2011 QX56

Page 3358 of 5598

SQUEAK AND RATTLE TROUBLE DIAGNOSESINT-9

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

INT

N

O P

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.591 ×0.984 in) pad

68239-13E00: 5 mm (0.197 in) wide tape roll

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that is visible or does not fit. Only lasts a few months.

SILICONE SPRAY

Used when grease cannot be applied.

DUCT TAPE

Used to eliminate movement.

CONFIRM THE REPAIR

After repair is complete, test drive the vehicle to confi rm that the cause of noise is repaired by test driving the

vehicle. Operate the vehicle under the same conditions as when the noise originally occurred. Refer to the

notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000006220270

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by

applying felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate

wiring harness.

CAUTION:

Never use silicone spray to isolate a squeak or ra ttle. If the area is saturated with silicone, the

recheck of repair becomes impossible.

CENTER CONSOLE

Components to check include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Check the following items:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon connection to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping, moving the components, or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. The areas can usually be insula ted with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the customer.

In addition check for the following items:

Revision: 2010 May2011 QX56

Page 3399 of 5598

SQUEAK AND RATTLE TROUBLE DIAGNOSESIP-9

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

I

K L

M A

B

IP

N

O P

Used to insulate where movement does not occur. Ideal for instrument panel applications.

68370-4B000: 15 ×25 mm (0.591 ×0.984 in) pad

68239-13E00: 5 mm (0.197 in) wide tape roll

The following materials, not found in the kit, can also be used to repair squeaks and rattles.

UHMW (TEFLON) TAPE

Insulates where slight movement is present. Ideal for instrument panel applications.

SILICONE GREASE

Used in place of UHMW tape that is visible or does not fit. Only lasts a few months.

SILICONE SPRAY

Used when grease cannot be applied.

DUCT TAPE

Used to eliminate movement.

CONFIRM THE REPAIR

After repair is complete, test drive the vehicle to confi rm that the cause of noise is repaired by test driving the

vehicle. Operate the vehicle under the same conditions as when the noise originally occurred. Refer to the

notes on the Diagnostic Worksheet.

Inspection ProcedureINFOID:0000000006425524

Refer to Table of Contents for specific component removal and installation information.

INSTRUMENT PANEL

Most incidents are caused by contact and movement between:

1. The cluster lid A and instrument panel

2. Acrylic lens and combination meter housing

3. Instrument panel to front pillar garnish

4. Instrument panel to windshield

5. Instrument panel mounting pins

6. Wiring harnesses behind the combination meter

7. A/C defroster duct and duct joint

These incidents can usually be located by tapping or moving the components to duplicate the noise or by

pressing on the components while driving to stop the noise. Most of these incidents can be repaired by

applying felt cloth tape or silicon spray (in hard to reach areas). Urethane pads can be used to insulate

wiring harness.

CAUTION:

Never use silicone spray to isolate a squeak or ra ttle. If the area is saturated with silicone, the

recheck of repair becomes impossible.

CENTER CONSOLE

Components to check include:

1. Shifter assembly cover to finisher

2. A/C control unit and cluster lid C

3. Wiring harnesses behind audio and A/C control unit

The instrument panel repair and isolation pr ocedures also apply to the center console.

DOORS

Check the following items:

1. Finisher and inner panel making a slapping noise

2. Inside handle escutcheon connection to door finisher

3. Wiring harnesses tapping

4. Door striker out of alignment causing a popping noise on starts and stops

Tapping, moving the components, or pressing on them while driving to duplicate the conditions can isolate

many of these incidents. The areas can usually be insula ted with felt cloth tape or insulator foam blocks from

the NISSAN Squeak and Rattle Kit (J-43980) to repair the noise.

TRUNK

Trunk noises are often caused by a loose jack or loose items put into the trunk by the customer.

In addition check for the following items:

Revision: 2010 May2011 QX56

Page 3452 of 5598

![INFINITI QX56 2011 Factory Service Manual

LAN-32

< SYSTEM DESCRIPTION >[CAN]

SYSTEM

Steering calibration signal R T R

Hazard request signalRT

RT

Horn request signal R T

Low tire pressure warning

lamp signal RT

Tire pressure data signal R T

INFINITI QX56 2011 Factory Service Manual

LAN-32

< SYSTEM DESCRIPTION >[CAN]

SYSTEM

Steering calibration signal R T R

Hazard request signalRT

RT

Horn request signal R T

Low tire pressure warning

lamp signal RT

Tire pressure data signal R T](/img/42/57033/w960_57033-3451.png)

LAN-32

< SYSTEM DESCRIPTION >[CAN]

SYSTEM

Steering calibration signal R T R

Hazard request signalRT

RT

Horn request signal R T

Low tire pressure warning

lamp signal RT

Tire pressure data signal R T

A/C compresso r feedback

signal RRT

Detention switch signal R T R

Engine restart control sig-

nal RT

Front wiper stop position

signal RT

High beam status signal R T

Hood switch signal R T

Low beam status signal R R T

Push-button ignition switch

status signal RT

Starter control relay signal R T

Steering lock unit status

signal RT

CK SUSP indi cator lamp

signal RT

Brake fluid pressure control

signal R

T

BSW warning lamp signal R T

IBA OFF indicator lamp sig-

nal RT

IBA operation signal RT

ICC operation signal R T

ICC warning lamp signal R T

Lane departure warning

lamp signal RT

LDP ON indicator lamp sig-

nal RT

Target yaw moment signal R T

Signal name

ECM

4WD

ABS

TCM

A-BAG

AFSAV

BCM

CGW

HVAC

M&A

STRG

TPMS

IPDM-E ADP

PSB

E-SUS ICC

PWBD

Revision: 2010 May2011 QX56

Page 3660 of 5598

ENGINE OILLU-7

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M A

LU

NP

O

PERIODIC MAINTENANCE

ENGINE OIL

InspectionINFOID:0000000006289616

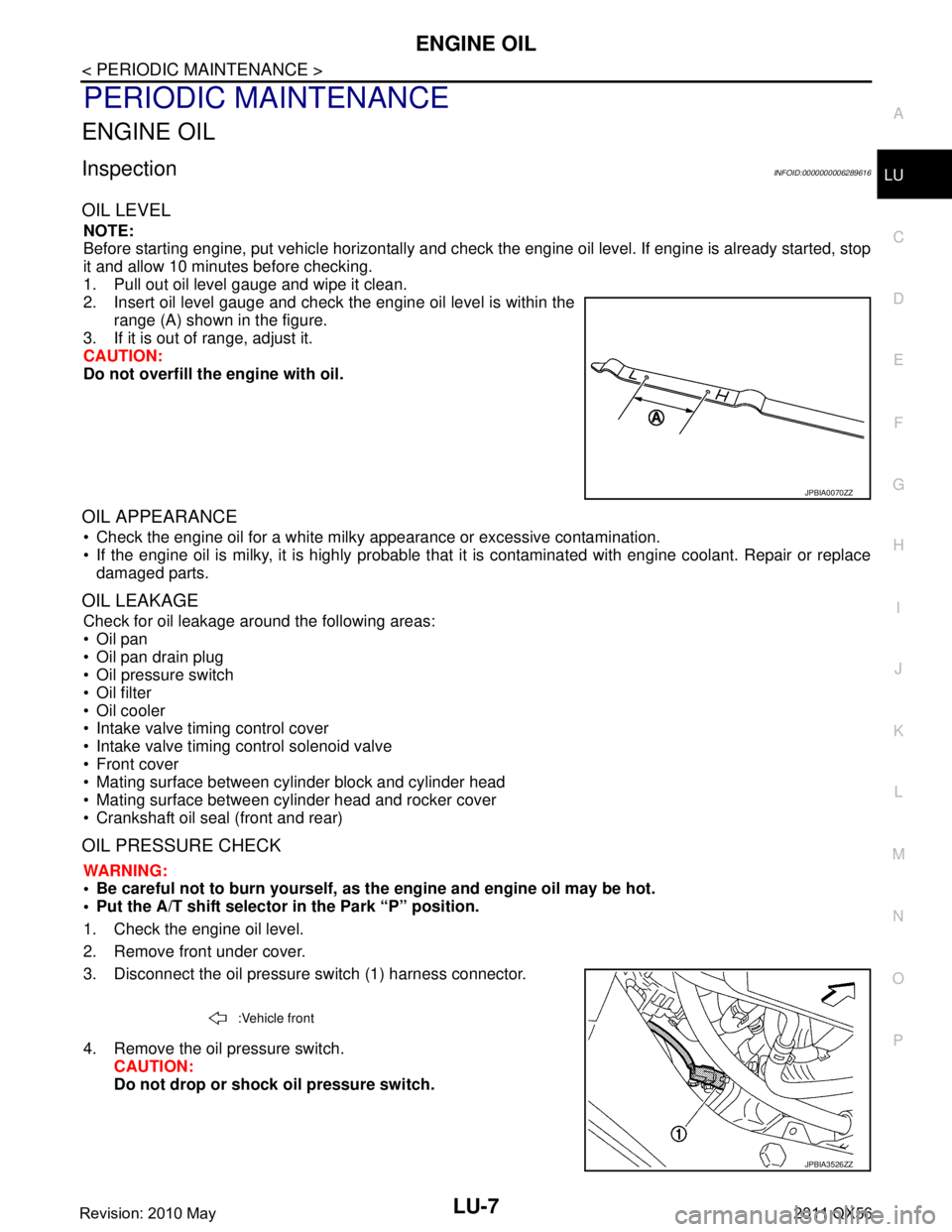

OIL LEVEL

NOTE:

Before starting engine, put vehicle horizontally and check

the engine oil level. If engine is already started, stop

it and allow 10 minutes before checking.

1. Pull out oil level gauge and wipe it clean.

2. Insert oil level gauge and check the engine oil level is within the range (A) shown in the figure.

3. If it is out of range, adjust it.

CAUTION:

Do not overfill the engine with oil.

OIL APPEARANCE

Check the engine oil for a white milky appearance or excessive contamination.

If the engine oil is milky, it is highly probable that it is contaminated with engine coolant. Repair or replace

damaged parts.

OIL LEAKAGE

Check for oil leakage around the following areas:

Oil pan

Oil pan drain plug

Oil pressure switch

Oil filter

Oil cooler

Intake valve timing control cover

Intake valve timing control solenoid valve

Front cover

Mating surface between cylinder block and cylinder head

Mating surface between cylinder head and rocker cover

Crankshaft oil seal (front and rear)

OIL PRESSURE CHECK

WARNING:

• Be careful not to burn yourself, as th e engine and engine oil may be hot.

Put the A/T shift selector in the Park “P” position.

1. Check the engine oil level.

2. Remove front under cover.

3. Disconnect the oil pressure switch (1) harness connector.

4. Remove the oil pressure switch. CAUTION:

Do not drop or shock oil pressure switch.

JPBIA0070ZZ

:Vehicle front

JPBIA3526ZZ

Revision: 2010 May2011 QX56

Page 3661 of 5598

![INFINITI QX56 2011 Factory Service Manual

LU-8

< PERIODIC MAINTENANCE >

ENGINE OIL

5. Install the oil pressure gauge [SST: ST25051001 (J25695-1)] (A)and hose [SST: ST25052000 (J25695-2)] (B).

6. Start the engine and warm it up to normal oper INFINITI QX56 2011 Factory Service Manual

LU-8

< PERIODIC MAINTENANCE >

ENGINE OIL

5. Install the oil pressure gauge [SST: ST25051001 (J25695-1)] (A)and hose [SST: ST25052000 (J25695-2)] (B).

6. Start the engine and warm it up to normal oper](/img/42/57033/w960_57033-3660.png)

LU-8

< PERIODIC MAINTENANCE >

ENGINE OIL

5. Install the oil pressure gauge [SST: ST25051001 (J25695-1)] (A)and hose [SST: ST25052000 (J25695-2)] (B).

6. Start the engine and warm it up to normal operating temperature.

7. Check the engine oil pressure with engine running under no-load. Refer to LU-17, "

EngineOilPressure".

CAUTION:

If the difference is extreme, check the oil passages and oil pump for leaks and blockages.

8. After the inspections, install oil pressure switch as follows:

a. Remove old liquid gasket adhering to oil pressure switch and engine.

b. Apply liquid gasket and tighten oil pressure switch to the specification. Use Genuine RTV Silicone Seal ant or equivalent. Refer to GI-22, "

Recommended Chemical Prod-

ucts and Sealants".

c. After warming up engine, make sure there is no leakage of engine oil with engine running.

DrainingINFOID:0000000006289617

WARNING:

Be careful not to burn yourself, as th e engine and engine oil may be hot.

Prolonged and repeated contact with used engine oil may cause skin cancer; try to avoid direct skin

contact with used oil. If skin contact is made, wash thoroughly with soap or hand cleaner as soon as

possible.

1. Warm up the engine, and check for any oil leaks.

2. Stop the engine and wait for at least 10 minutes.

3. Remove drain plug and oil filler cap to drain the old oil.

RefillingINFOID:0000000006289618

1. Install drain plug with new washer. CAUTION:

Be sure to clean drain plug and install with new washer.

2. Refill with new engine oil. Engine oil specification and viscosity:

Refer to MA-10, "

Fluids and Lubricants".

CAUTION:

The refill capacity depends on the engine oi l temperature and drain time. Use these specifica-

tions for reference only.

Always use oil level gauge to determine the proper amount of engine oil in engine.

3. Warm up the engine and check area around drain plug and oil filter for engine oil leakage.

4. Stop the engine and wait for 10 minutes.

5. Check the engine oil level. Refer to LU-7, "

Inspection".

JPBIA0074ZZ

Oil pressure switch torque : Refer to EM-57, "Exploded View".

Tightening torque : Refer to EM-54, "

Exploded View".

Engine oil capacity : Refer to LU-17, "

Periodical Maintenance Specification".

Revision: 2010 May2011 QX56

Page 3662 of 5598

OIL FILTERLU-9

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M A

LU

NP

O

OIL FILTER

Removal and InstallationINFOID:0000000006289619

REMOVAL

1. Remove front under cover.

2. Drain engine oil. Refer to

LU-8, "

Draining".

3. Remove oil filter using oil filter wrench [SST: KV10115801 (J- 38956)].

WARNING:

Be careful not to burn yourself, as the engine and engine oil

may be hot.

CAUTION:

The oil filter is equipped with a pressure relief valve.

Use Genuine NISSAN oil filter or equivalent.

When removing, prepare a s hop cloth to absorb any

engine oil leaks or spills.

Do not allow engine oil to adhere to the drive belts.

Completely wipe off any engine oil that adheres to the engine and the vehicle.

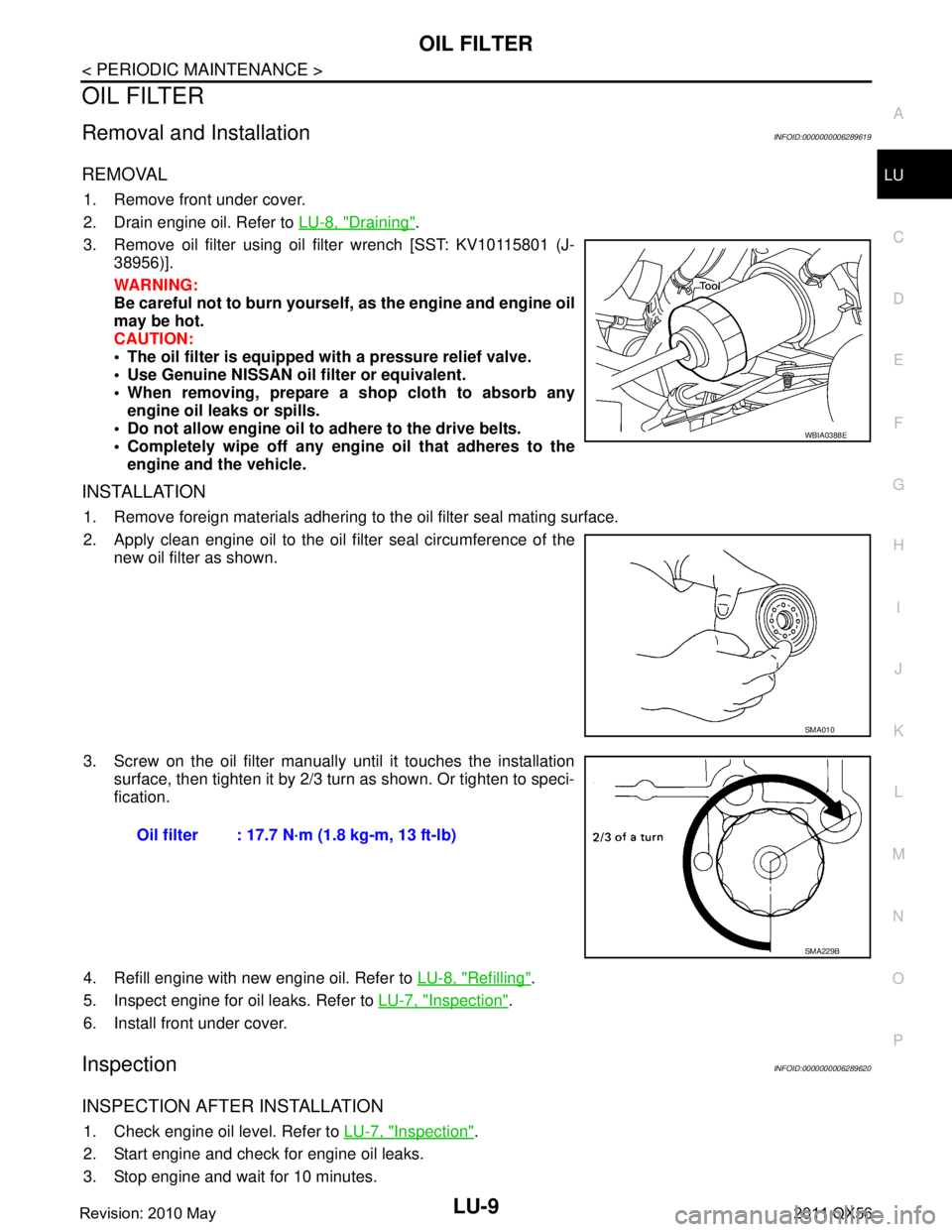

INSTALLATION

1. Remove foreign materials adhering to the oil filter seal mating surface.

2. Apply clean engine oil to the oil filter seal circumference of the

new oil filter as shown.

3. Screw on the oil filter manually until it touches the installation surface, then tighten it by 2/3 turn as shown. Or tighten to speci-

fication.

4. Refill engine with new engine oil. Refer to LU-8, "

Refilling".

5. Inspect engine for oil leaks. Refer to LU-7, "

Inspection".

6. Install front under cover.

InspectionINFOID:0000000006289620

INSPECTION AFTER INSTALLATION

1. Check engine oil level. Refer to LU-7, "Inspection".

2. Start engine and check for engine oil leaks.

3. Stop engine and wait for 10 minutes.

WBIA0388E

SMA010

Oil filter : 17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B

Revision: 2010 May2011 QX56