sensor ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3935 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–22

3.8 Extension Housing Oil Seal, RWD

Replace

1 Raise the vehicle and support in a safe manner, refer to 0A General Information for the location of support points.

2 Remove the rear propeller shaft, refer to 4A Propeller Shaft.

3 Place a suitable size drip tray underneath rear of transmission.

Take care not to scratch the machined seal

recess in the extension housing as

transmission fluid may weep past the outer

diameter of the installed seal.

4 Using the seal remover, Tool No. E308 (1) or equivalent, prise the oil seal (2) from rear of the

extension housing (3) and discard the seal.

5 Thoroughly clean around the seal bore in the extension housing and ensure there are no burrs.

Figure 7C4 – 20

6 Use the seal installer, Tool No. J21426 (1) and a soft faced hammer to tap a new oil seal (2) into place in

the extension housing (3).

7 Install the rear propeller shaft, refer to 4A Propeller Shaft.

8 Lower the vehicle to the ground and check the fluid level, refer to 2.1 Transmission Fluid.

Figure 7C4 – 21

3.9 Extension Housing and Rear Bush, RWD

Remove

1 Raise the vehicle and support in a safe manner, refer to 0A General Information for the location of support points.

2 As required, remove the following components:

a Rear propeller shaft, refer to 4A Propeller Shaft.

b Transmission support and mount assembly, refer to 3.7 Transmission Support and Mount.

c Vehicle speed sensor, refer to 3.5 Vehicle Speed Sensor.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3956 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–43

If the verifier disc does not clip into place, the

quick-connect fitting is not engaged, rectify

as required.

10 As a security check, push and clip each verification disc into place over the quick-connect fittings. If difficulty is experienced, repeat the installation process until the verification disc can be clipped into place over the radiator

quick-connect fitting.

11 Snap the outlet cooler line (4) in the clip (5) of the radiator fan shroud.

12 Ensure the routeing of the cooler lines is correct and there is no fouling of the lines.

13 Tighten the screw attaching the cooler lines bracket to the correct torque specifications.

Transmission cooler lines bracket

attaching screw torque specification .................. 23.0 Nm

14 If required, top up the transmission fluid level (cold).

15 Start the engine and check for any fluid leak at the fittings. If a leak is found, stop the engine and rectify the leak.

16 Check and top up the transmission fluid to the correct level as required, refer to 2.1 Transmission Fluid.

3.18 Transmission Assembly

Remove

Disconnection of the battery affects certain

vehicle electronic systems. Refer to 6D1-3

Battery, before disconnecting the battery.

1 Disconnect the battery ground lead.

2 Raise the vehicle and support in a safe manner, refer to 0A General Information for the location of support points.

3 Remove the heat shield from the neutral start and back-up lamp switch, gently prise the selector cable from the transmission external manual shaft linkage and remove the selector cable from the bracket, refer to

3.3 Selector Cable Assembly.

4 Disconnect the harness connectors from the following:

a Vehicle speed sensor, refer to 3.5 Vehicle Speed Sensor.

b Neutral start and back-up switch, refer to 3.4 Neutral Start and Back-up Lamp Switch.

c For the following on four wheel drive vehicles (4W D), refer to 7D Transfer Case and Adaptor Housing:

• neutral switch,

• 2WD – 4WD shift actuator switch,

• speed sensor.

NOTE

If the battery is connected, avoid turning the

ignition switch to the ON position, as the transfer

case control module (TTCM) must first be

removed (memory to be cleared as Check 4W D

Indicator will light).

5 Remove the following components: a Front and centre exhaust assemblies, refer to 6F Exhaust System.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3960 of 6020

Automatic Transmission – 4L60E – On-vehicle Servicing Page 7C4–47

14 Reconnect the fuel and EVAP pipes three brackets and clips, refer to 6C Fuel System – V6.

15 Reinstall the following components:

a Starter motor, refer to 6D1-2 Starting System.

b Transmission support, refer to 3.7 Transmission Support and Mount.

c Front and centre exhaust assemblies, refer to 6F Exhaust System.

d Rear propeller shaft and for 4WD front propeller shaft, refer to 4A Propeller Shaft.

16 Reconnect the harness connectors to the following: a Vehicle speed sensor, refer to 3.5 Vehicle Speed Sensor.

b Neutral start and back-up switch, refer to 3.4 Neutral Start and Back-up Lamp Switch.

c For the following on 4W D vehicles, refer to 7D Transfer Case and Adaptor Housing:

• neutral switch,

• 2WD – 4WD shift actuator switch,

• speed sensor.

17 Reinstall the selector cable to the transmission external manual shaft linkage, secure the selector cable to the bracket and attach the heat shield to the neutral start and back-up lamp switch, refer to 3.3 Selector Cable

Assembly.

18 Perform a reverse flush of the cooler lines and a flow rate test, refer to 2.2 Reverse Flush and Flow Rate, if either of the following applies:

• the transmission fluid is contaminated,

• the transmission has been replaced,

• the torque converter has been replaced, or

• the transmission oil pump has been replaced.

19 Lower the vehicle to the ground.

20 If required, top up the transmission fluid level (cold).

21 Reconnect the battery ground lead.

22 Start the engine and check for any fluid leaking at the fittings. If a leak is found, stop the engine and rectify the leak.

23 Road test until the transmission has reached operating temperature. Re-check the fluid level and for any fluid leaks, refer to 2.1 Transmission Fluid.

3.19 Transmission Control Module

Remove

1 Ensure the ignition switch is in the OFF position.

2 Disconnect the connector (1) from the transmission control module (TCM) (2) as follows, refer to Figure 7C4 – 63: a remove the securing pin (3),

b press the locking tab and swing the lever (4) to free the connector,

c remove the connector.

3 Remove the four bolts (5) and nuts (6), then the TCM from the mounting bracket (7).

4 If required, remove the two nuts (8) and the mounting bracket from the firewall.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3968 of 6020

7A2-2 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

Service Precaution

WARNING: THIS VEHICLE HAS A SUPPLEMENTAL

RESTRAINT SYSTEM (SRS). REFER TO THE SRS

COMPONENT AND WIRING LOCATION VIEW IN

ORDER TO DETERMINE WHETHER YOU ARE

PERFORMING SERVICE ON OR NEAR THE SRS

COMPONENTS OR THE SRS WIRING. WHEN YOU

ARE PERFORMING SERVICE ON OR NEAR THE

SRS COMPONENTS OR THE SRS WIRING, REFER

TO THE SRS SERVICE INFORMATION. FAILURE TO

FOLLOW WARNINGS COULD RESULT IN

POSSIBLE AIR BAG DEPLOYMENT, PERSONAL

INJURY, OR OTHERWISE UNNEEDED SRS SYSTEM

REPAIRS.

CAUTION: Always use the correct fastener in the

proper location. When you replace a fastener, use

ONLY the exact part number for that application.

ISUZU will call out those fasteners that require a

replacement after removal. ISUZU will also call out

the fasteners that require thread lockers or thread

sealant. UNLESS OTHERWISE SPECIFIED, do not

use supplemental coatings (Paints, greases, o

r

other corrosion inhibitors) on threaded fasteners or

fastener joint interfaces. Generally, such coatings

adversely affect the fastener torque and the joint

clamping force, and may damage the fastener.

When you install fasteners, use the correct

tightening sequence and specifications. Following

these instructions can help you avoid damage to

parts and systems.

General Description

The AW 30-40LE is a 4–speed fully electronically

controlled automatic transmission. It uses a

microcomputer as a control unit to judge driving

conditions including throttle opening rate and vehicle

speed, then it sets the shifting point in the optimum

timing so that best driving performance can be

achieved.

In addition, the built–in driving mode select function can

select three driving modes according to the driver's

preference:

• Normal mode –Normal shift pattern.

• 3rd Start mode –Starts in 3rd gear to reduce slippage

on mud, ice or snow.

• Power mode –Delays upshift timing when more

powerful acceleration is required.

Also, the built–in fail–safe function (“emergency mode")

assures driving performance even if the vehicle speed

sensor, throttle signal or any solenoid fails.

Further, the self–diagnostic function conducts diagnosis

in a short time when the control system fails, thus

improving serviceability.

The major features of AW 30-40LE are as follows:

•

A compact structure consisting of 2 sets of planetary

gears and flat torque converter.

• Electronic control selects the optimum driving mode according to the driving conditions.

• Electronic control maintains the optimum hydraulic

pressure for clutch, band brake as well as

transmission so that shift feeling is improved.

• W ide gear ratio and high torque rate of torque

converter provide excellent starting performance.

• Optimum Lock-up control of each driving mode can

have it both ways driving performance and fuel

economy.

• Excellent shift quality can be achieved by the torque

management control through the CAN

communication with the engine.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3974 of 6020

7A2-8 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

TCM Point Table

RTW 77ASF000401

C-94 Connector

PIN No. SIGNAL NAME

A1 GND

A2 PRESSURE CONTROL SOLENOID GND

A3 —

A4 PRESSURE CONTROL SOLENOID

A5 L-up SOLENOID

A6 STARTER SW (IG1)

A7 CAN COMMUNICATION (-)

A8 —

A9 —

A10 —

A11 T/M OIL TEMPERATURE SENSOR

A12 T/M OIL TEMPERATURE SENSOR GND

A13 —

A14 —

A15 SHIFT SOLENOID (S2)

A16 SHIFT SOLENOID (S1)

A17 CAN COMMUNICATION (+)

A18 —

A19 —

A20 —

A21 —

A22 —

A23 GND

A24 BATTERY

C-95 Connector

PIN No. SIGNAL NAME

B1 NEUTRAL START SW (R)

B2 POW ER LAMP

B3 CHECK TRANS LAMP

B4 PATTERN SELECT SW (3rd START)

B5 SPEED SENSOR (+)

B6 INPUT REVOLUTION SENSOR (+)

B7 NEUTRAL START SW (D)

B8 NEUTRAL START SW (N)

B9 NEUTRAL START SW (3)

B10 3rd START LAMP

B11 OIL TEMPERATURE W ARNING LAMP

B12 DIAGNOSIS TERMINAL

B13 PATTERN SELECT SW (POW ER)

B14 SPEED SENSOR (-)

B15 —

B16 INPUT REVOLUTION SENSOR (+)

B17 —

B18 NEUTRAL START SW (L)

B19 NEUTRAL START SW (2)

B20 NEUTRAL START SW (P)

B21 TRANSMISFER LOW 4 SW

B22 BRAKE LAMP SW

B23 DIAGNOSIS OUT PUT

B24 —

B25 —

B26 —

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3975 of 6020

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-9

TCM Voltage & Resistance Check Sheet

CHECK ITEM PIN No. VALUE NOTE

VIGN C-94: 6–1 VIGN Key “ON”

Backup Power Supply C-94: 24–1 +B (Always) Key “ON”

Neutral Start Switch P “P” Position VIGN Key “ON”

Except “P” 0V

Neutral Start Switch R C-95: 1–C-94: 1 “R” Position VIGN Key “ON”

Except “R” 0V

Neutral Start Switch N C-95: 8–C-94: 1 “N” Position VIGN Key “ON”

Except “N” 0V

Neutral Start Switch D C95: 7–C-94: 1 “D” Position VIGN Key “ON”

Except “D” 0V

Neutral Start Switch 2 C-95: 19–C-94: 1 “2” Position VIGN Key “ON”

Except “2” 0V

Neutral Start Switch 1 C-95: 18–C-94: 1 “1” Position VIGN Key “ON”

Except “1” 0V

Neutral Start Switch 3 C-95: 9–C-94: 1 “3” Position VIGN Key “ON”

Except “3” 0V

Power SW C-95: 13–C-94: 1 “ON” 0V Key “ON”

“OFF” VIGN

3rd Start SW C-95: 4–C-94: 1 “ON” 0V Key “ON”

“OFF” VIGN

Brake SW C-95: 22–C-94: 1 “ON” VIGN Key “ON”

“OFF” 0V

AT Oil Temperature

Sensor C-94: 11–12 20

°C/68 °F 4.6V Engine run.

155°C/311 °F 1.1V

4L Signal C-95: 21–C-94: 1 4L 0V Key “ON”

2H/4H VIGN

Diag SW C-95: 12–C-94: 1 “ON” VIGN Key “ON”

“OFF” 0V

Shift Solenoid A (S1) C-94: 16–1 P VIGN Engine run.

R VIGN

N VIGN

D–1 VIGN

D–2 VIGN

D–3 0V

D–4 0V

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3976 of 6020

7A2-10 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

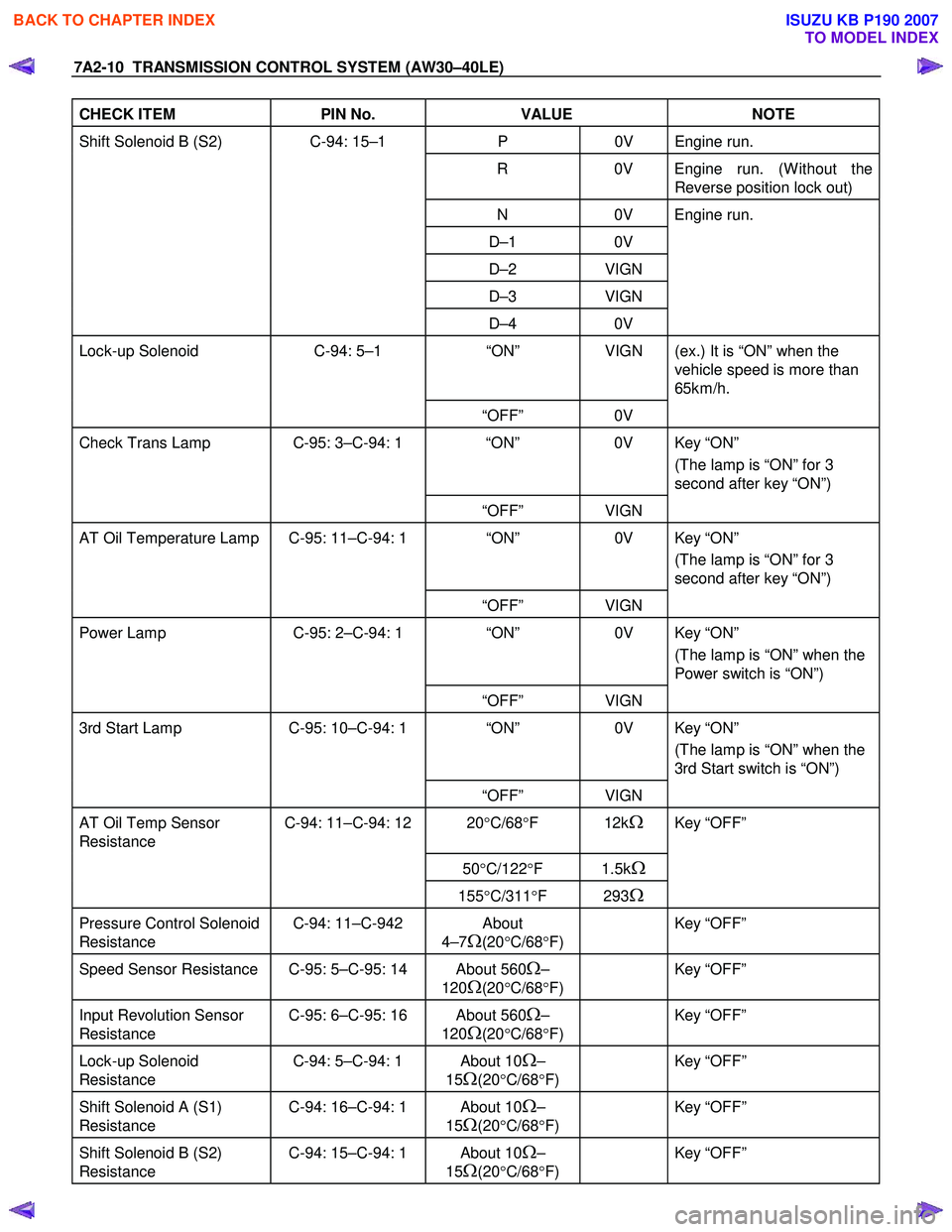

CHECK ITEM PIN No. VALUE NOTE

Shift Solenoid B (S2) C-94: 15–1 P 0V Engine run.

R 0V Engine run. (W ithout the

Reverse position lock out)

N 0V Engine run.

D–1 0V

D–2 VIGN

D–3 VIGN

D–4 0V

Lock-up Solenoid C-94: 5–1 “ON” VIGN (ex.) It is “ON” when the

vehicle speed is more than

65km/h.

“OFF” 0V

Check Trans Lamp C-95: 3–C-94: 1 “ON” 0V Key “ON”

(The lamp is “ON” for 3

second after key “ON”)

“OFF” VIGN

AT Oil Temperature Lamp C-95: 11–C-94: 1 “ON” 0V Key “ON”

(The lamp is “ON” for 3

second after key “ON”)

“OFF” VIGN

Power Lamp C-95: 2–C-94: 1 “ON” 0V Key “ON”

(The lamp is “ON” when the

Power switch is “ON”)

“OFF” VIGN

3rd Start Lamp C-95: 10–C-94: 1 “ON” 0V Key “ON”

(The lamp is “ON” when the

3rd Start switch is “ON”)

“OFF” VIGN

AT Oil Temp Sensor

Resistance C-94: 11–C-94: 12 20

°C/68 °F 12kΩ Key “OFF”

50°C/122 °F 1.5kΩ

155°C/311 °F 293Ω

Pressure Control Solenoid

Resistance C-94: 11–C-942 About

4–7

Ω(20 °C/68 °F)

Key “OFF”

Speed Sensor Resistance C-95: 5–C-95: 14 About 560Ω–

120

Ω(20 °C/68 °F)

Key “OFF”

Input Revolution Sensor

Resistance C-95: 6–C-95: 16 About 560Ω–

120

Ω(20 °C/68 °F)

Key “OFF”

Lock-up Solenoid

Resistance C-94: 5–C-94: 1 About 10Ω–

15

Ω(20 °C/68 °F)

Key “OFF”

Shift Solenoid A (S1)

Resistance C-94: 16–C-94: 1 About 10Ω–

15

Ω(20 °C/68 °F)

Key “OFF”

Shift Solenoid B (S2)

Resistance C-94: 15–C-94: 1 About 10Ω–

15

Ω(20 °C/68 °F)

Key “OFF”

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3979 of 6020

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-13

Item Description

Reverse lock out control If the select lever is moved to "R" position during forward driving, the TCM prohibits

reverse driving by turn off the S1 and turn on the S2 for prevention of danger and

protection of the automatic transmission.

1. Enable condition a) Vehicle speed is more than 11km/h (7mph).

2. Disable condition a) Vehicle speed is less than 9km/h (6mph).

b) W hen except "R" position is detected.

Auto cruise mode control If the auto cruise control can’t keep the setting speed like a uphill driving, the TCM selects the auto cruise mode shift pattern for downshifting, thus keeping the vehicle

speed.

W arm-up mode control TCM selects the warm-up mode shift pattern in engine cold condition for improvement of drivability and facilitation of warm-up.

Squat control W hen the TCM detects N→D garage shift, the TCM controls 1-3-1 shift by setting

timer, in order to improve the shift feel at N →D.

Coast down control The TCM switches to the coast down control at the coasting, in order to reduce the

roughness of shifting.

Uphill control W hen the TCM detected uphill, the TCM automatically switches to the uphill mode

in two-stage in proportion to inclination pitch to prevent the busy shifting and to

obtain an enough torque.

Downhill control W hen the TCM detected downhill, the TCM automatically switches to the downhill

mode, and shifts to the 3rd or keeps in the 3rd in order to prevent the vehicle

acceleration. Then, the brake load is reduced by a moderate engine brake and fuel

consumption is improved by the fuel cut.

Line pressure control The TCM controls the impressed current of the pressure control solenoid based on the throttle opening, and regulates suitable throttle pressure.

Engine truque management

control The TCM controls engine torque for improvement of shift quality or durability under

the following conditions.

• Upshift and downshift

• Garageshift

Indicate driving mode function The TCM indicates the following driving mode on instrument panel.

• Power mode

• 3rd start mode

Indicate oil temperature

warning function If the transmission oil temperature sensor senses that transmission oil temperature

is greater than 146 °C (295 °F) , the TCM turns on ATF warning lamp. (The warning

lamp is turned off, if oil temperature is less than 126 °C/ 259 °F .)

Fail-safe function W hen trouble occurs to vehicle sensor and each solenoid, TCM automatically exerts

fail-safe control not to spoil driveability.

• This control is exerted when sensor or actuator is in trouble, while TCM works

normally.

• The "CHECK TRANS" light flashes to alert the driver, and the transmission

must be manually shifted as follows.

Select lever position Gear position

D 4 (Fourth)

3 4 (Fourth)

2 3 (Third)

L 3 (Third)

R Reverse

Shift are firmer to prevent clutch slip and consequent wear. The fault should be

corrected as soon as possible.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3980 of 6020

7A2-14 TRANSMISSION CONTROL SYSTEM (AW30–40LE)

Item Description

Diagnosis function

• If there is an abnormality in vehicle sensors, each solenoid (S1, S2, SL, STH),

or throttle position sensor, "CHECK TRANS" lamp is actuated to warn the drive.

But when the abnormality items have been restored to normal, the light does

not blink.

• Faulty parts are memorized in TCM. If self-diagnosis start signal is inputted,

"CHECK TRANS" lamp is blinked and results of diagnosis are indicated. A

history of faults remains recorded even when IGN switch is off. If DG1 switch

signal is inputted, or by using F1: Clear DTC Information for TECH 2, the

records can be erased.

TECH 2

• Output of control data in the TCM

• Actuator (Solenoid) operation check

• Erasure of trouble code

• Output of DTC code

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3983 of 6020

TRANSMISSION CONTROL SYSTEM (AW30–40LE) 7A2-17

Normal

C07RY005-1

Abnormal

C07RY00042-1

On-Board Diagnostic (OBD) System Check

This test determines if the transmission or its input or

output connections or sensors are failing.

1. Connect the Tech 2: Go through Tech 2 Operating.

2. Turn on the ignition but not the engine.

3. Push “F0” on Tech 2 to see the Diagnostic Trouble Code (DTC):

4. Do you have a DTC? YES: write down all code numbers and do the DTC

CHECK

NO: the DTC can not help you find the problem.

1. Go through “Check Trans” Check

2. If it is flashing and the flash is 0.4 seconds “ON”

and 0.4 seconds “OFF”, this means that you

should have a DTC stored. Please recheck go

to On-Board Diagnostic (OBD) System Chec

k

and if you find the same problem, replace the

Transmission Control Module (TCM).

“Check Trans” Check

1. Indicator is “ON” during 3 seconds at ignition but it

is “OFF” after the engine starts. The indicator is

working normally go to On-Board Diagnostic

(OBD) System Check .

RTW 77ASH000101

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007