sensor ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3815 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–29

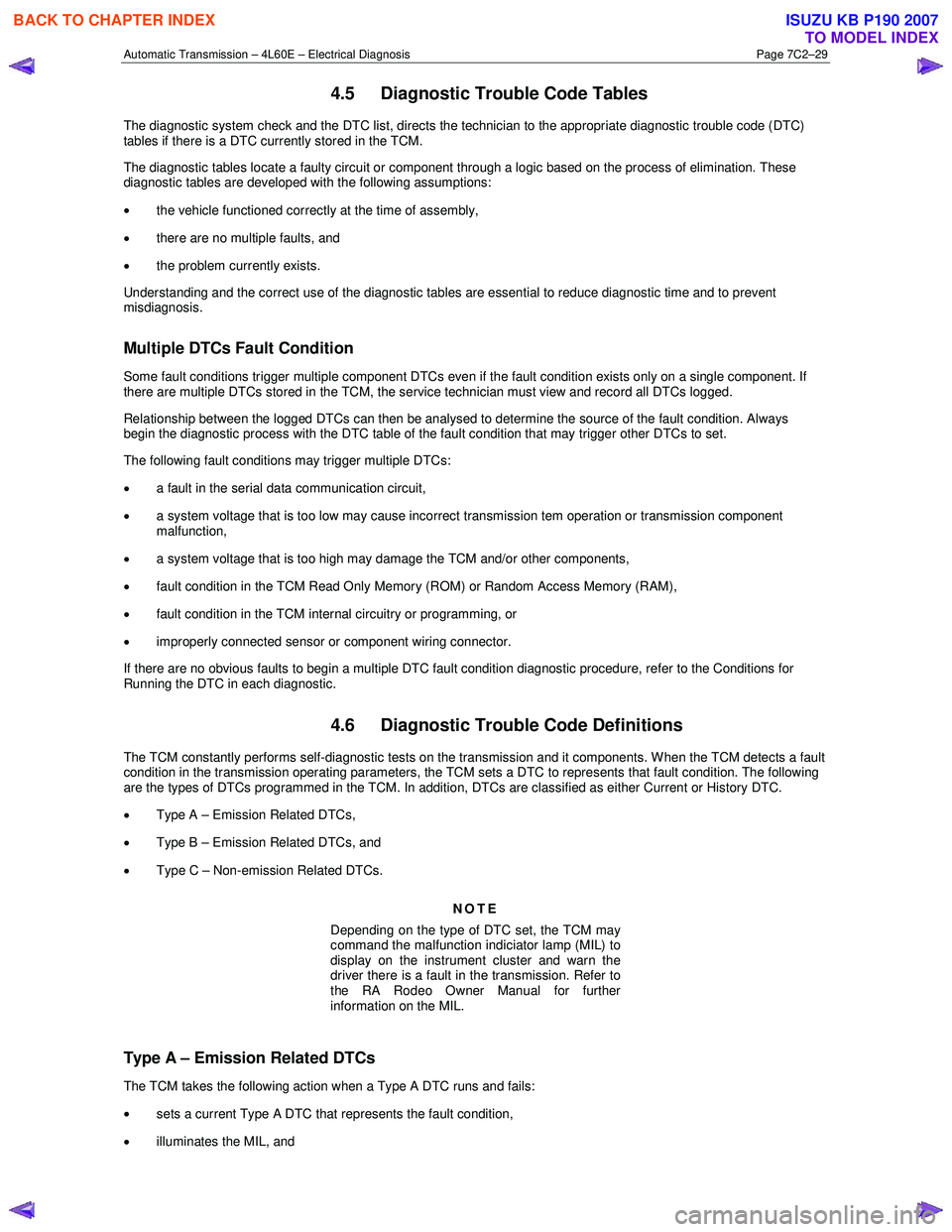

4.5 Diagnostic Trouble Code Tables

The diagnostic system check and the DTC list, directs the technician to the appropriate diagnostic trouble code (DTC)

tables if there is a DTC currently stored in the TCM.

The diagnostic tables locate a faulty circuit or component through a logic based on the process of elimination. These

diagnostic tables are developed with the following assumptions:

• the vehicle functioned correctly at the time of assembly,

• there are no multiple faults, and

• the problem currently exists.

Understanding and the correct use of the diagnostic tables are essential to reduce diagnostic time and to prevent

misdiagnosis.

Multiple DTCs Fault Condition

Some fault conditions trigger multiple component DTCs even if the fault condition exists only on a single component. If

there are multiple DTCs stored in the TCM, the service technician must view and record all DTCs logged.

Relationship between the logged DTCs can then be analysed to determine the source of the fault condition. Always

begin the diagnostic process with the DTC table of the fault condition that may trigger other DTCs to set.

The following fault conditions may trigger multiple DTCs:

• a fault in the serial data communication circuit,

• a system voltage that is too low may cause incorrect transmission tem operation or transmission component

malfunction,

• a system voltage that is too high may damage the TCM and/or other components,

• fault condition in the TCM Read Only Memory (ROM) or Random Access Memory (RAM),

• fault condition in the TCM internal circuitry or programming, or

• improperly connected sensor or component wiring connector.

If there are no obvious faults to begin a multiple DTC fault condition diagnostic procedure, refer to the Conditions for

Running the DTC in each diagnostic.

4.6 Diagnostic Trouble Code Definitions

The TCM constantly performs self-diagnostic tests on the transmission and it components. W hen the TCM detects a fault

condition in the transmission operating parameters, the TCM sets a DTC to represents that fault condition. The following

are the types of DTCs programmed in the TCM. In addition, DTCs are classified as either Current or History DTC.

• Type A – Emission Related DTCs,

• Type B – Emission Related DTCs, and

• Type C – Non-emission Related DTCs.

NOTE

Depending on the type of DTC set, the TCM may

command the malfunction indiciator lamp (MIL) to

display on the instrument cluster and warn the

driver there is a fault in the transmission. Refer to

the RA Rodeo Owner Manual for further

information on the MIL.

Type A – Emission Related DTCs

The TCM takes the following action when a Type A DTC runs and fails:

• sets a current Type A DTC that represents the fault condition,

• illuminates the MIL, and

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3817 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–31

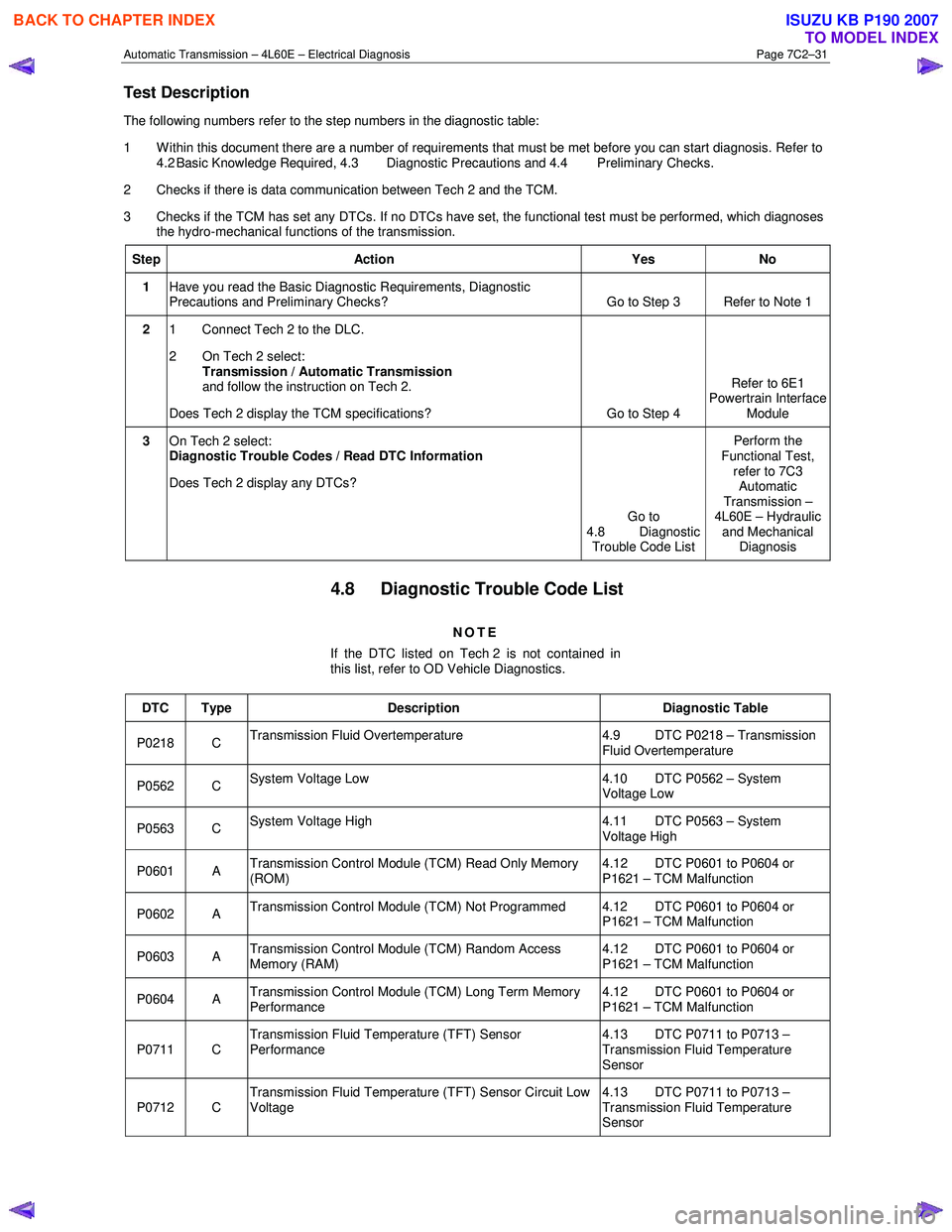

Test Description

The following numbers refer to the step numbers in the diagnostic table:

1 Within this document there are a number of requirements that must be met before you can start diagnosis. Refer to 4.2 Basic Knowledge Required, 4.3 Diagnostic Precautions and 4.4 Preliminary Checks.

2 Checks if there is data communication between Tech 2 and the TCM.

3 Checks if the TCM has set any DTCs. If no DTCs have set, the functional test must be performed, which diagnoses the hydro-mechanical functions of the transmission.

Step Action Yes No

1 Have you read the Basic Diagnostic Requirements, Diagnostic

Precautions and Preliminary Checks? Go to Step 3 Refer to Note 1

2

1 Connect Tech 2 to the DLC.

2 On Tech 2 select: Transmission / Automatic Transmission

and follow the instruction on Tech 2.

Does Tech 2 display the TCM specifications? Go to Step 4 Refer to 6E1

Powertrain Interface

Module

3 On Tech 2 select:

Diagnostic Trouble Codes / Read DTC Information

Does Tech 2 display any DTCs?

Go to

4.8 Diagnostic Trouble Code List Perform the

Functional Test, refer to 7C3 Automatic

Transmission –

4L60E – Hydraulic and Mechanical Diagnosis

4.8 Diagnostic Trouble Code List

NOTE

If the DTC listed on Tech 2 is not contained in

this list, refer to OD Vehicle Diagnostics.

DTC Type Description Diagnostic Table

P0218 C Transmission Fluid Overtemperature 4.9 DTC P0218 – Transmission

Fluid Overtemperature

P0562 C System Voltage Low 4.10 DTC P0562 – System

Voltage Low

P0563 C System Voltage High 4.11 DTC P0563 – System

Voltage High

P0601 A Transmission Control Module (TCM) Read Only Memory

(ROM) 4.12 DTC P0601 to P0604 or

P1621 – TCM Malfunction

P0602 A Transmission Control Module (TCM) Not Programmed 4.12 DTC P0601 to P0604 or

P1621 – TCM Malfunction

P0603 A Transmission Control Module (TCM) Random Access

Memory (RAM) 4.12 DTC P0601 to P0604 or

P1621 – TCM Malfunction

P0604 A Transmission Control Module (TCM) Long Term Memory

Performance 4.12 DTC P0601 to P0604 or

P1621 – TCM Malfunction

P0711 C Transmission Fluid Temperature (TFT) Sensor

Performance 4.13 DTC P0711 to P0713 –

Transmission Fluid Temperature

Sensor

P0712 C Transmission Fluid Temperature (TFT) Sensor Circuit Low

Voltage 4.13 DTC P0711 to P0713 –

Transmission Fluid Temperature

Sensor

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3818 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–32

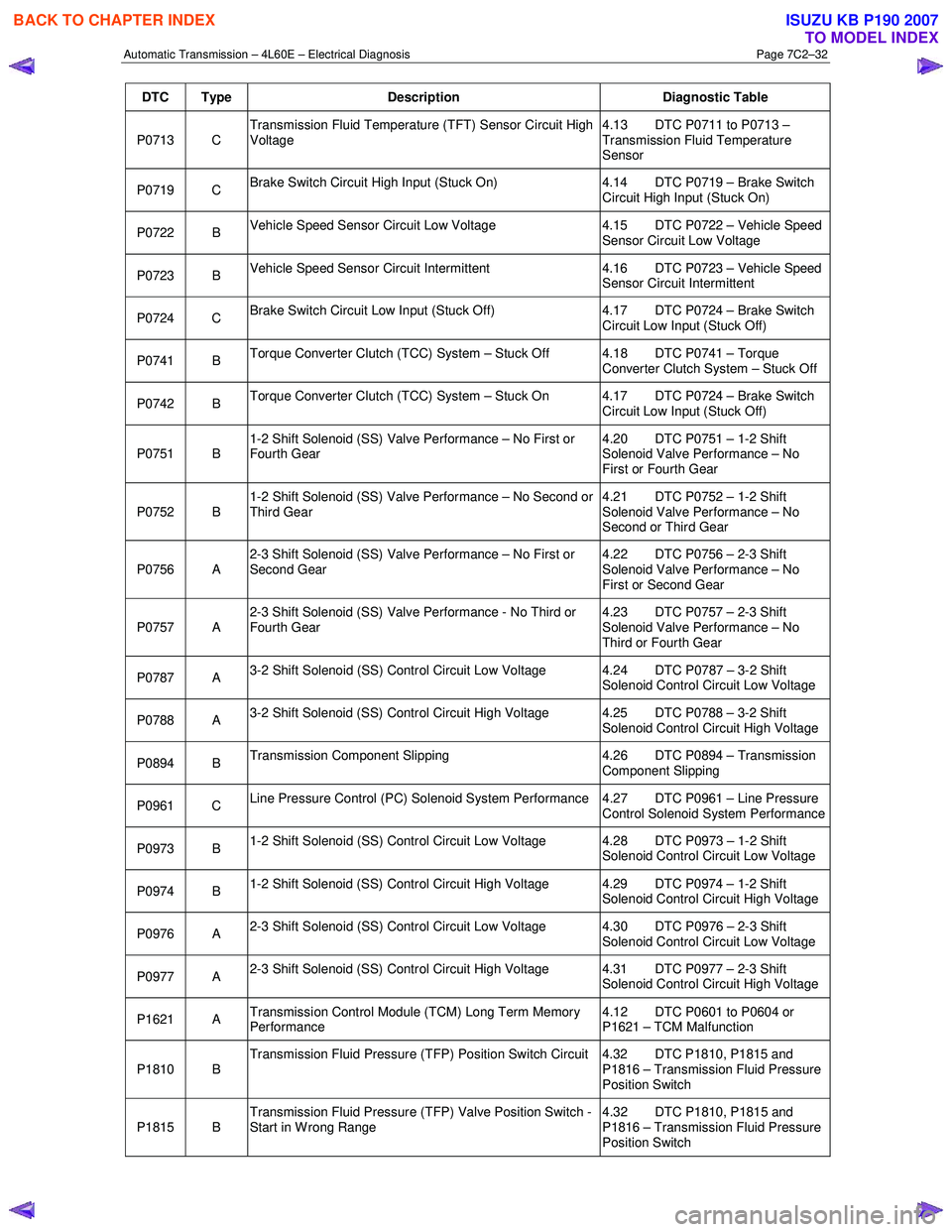

DTC Type Description Diagnostic Table

P0713 C Transmission Fluid Temperature (TFT) Sensor Circuit High

Voltage 4.13 DTC P0711 to P0713 –

Transmission Fluid Temperature

Sensor

P0719 C Brake Switch Circuit High Input (Stuck On) 4.14 DTC P0719 – Brake Switch

Circuit High Input (Stuck On)

P0722 B Vehicle Speed Sensor Circuit Low Voltage 4.15 DTC P0722 – Vehicle Speed

Sensor Circuit Low Voltage

P0723 B Vehicle Speed Sensor Circuit Intermittent 4.16 DTC P0723 – Vehicle Speed

Sensor Circuit Intermittent

P0724 C Brake Switch Circuit Low Input (Stuck Off) 4.17 DTC P0724 – Brake Switch

Circuit Low Input (Stuck Off)

P0741 B Torque Converter Clutch (TCC) System – Stuck Off 4.18 DTC P0741 – Torque

Converter Clutch System – Stuck Off

P0742 B Torque Converter Clutch (TCC) System – Stuck On 4.17 DTC P0724 – Brake Switch

Circuit Low Input (Stuck Off)

P0751 B 1-2 Shift Solenoid (SS) Valve Performance – No First or

Fourth Gear 4.20 DTC P0751 – 1-2 Shift

Solenoid Valve Performance – No

First or Fourth Gear

P0752 B 1-2 Shift Solenoid (SS) Valve Performance – No Second or

Third Gear 4.21 DTC P0752 – 1-2 Shift

Solenoid Valve Performance – No

Second or Third Gear

P0756 A 2-3 Shift Solenoid (SS) Valve Performance – No First or

Second Gear 4.22 DTC P0756 – 2-3 Shift

Solenoid Valve Performance – No

First or Second Gear

P0757 A 2-3 Shift Solenoid (SS) Valve Performance - No Third or

Fourth Gear 4.23 DTC P0757 – 2-3 Shift

Solenoid Valve Performance – No

Third or Fourth Gear

P0787 A 3-2 Shift Solenoid (SS) Control Circuit Low Voltage 4.24 DTC P0787 – 3-2 Shift

Solenoid Control Circuit Low Voltage

P0788 A 3-2 Shift Solenoid (SS) Control Circuit High Voltage 4.25 DTC P0788 – 3-2 Shift

Solenoid Control Circuit High Voltage

P0894 B Transmission Component Slipping 4.26 DTC P0894 – Transmission

Component Slipping

P0961 C Line Pressure Control (PC) Solenoid System Performance 4.27 DTC P0961 – Line Pressure

Control Solenoid System Performance

P0973 B 1-2 Shift Solenoid (SS) Control Circuit Low Voltage 4.28 DTC P0973 – 1-2 Shift

Solenoid Control Circuit Low Voltage

P0974 B 1-2 Shift Solenoid (SS) Control Circuit High Voltage 4.29 DTC P0974 – 1-2 Shift

Solenoid Control Circuit High Voltage

P0976 A 2-3 Shift Solenoid (SS) Control Circuit Low Voltage 4.30 DTC P0976 – 2-3 Shift

Solenoid Control Circuit Low Voltage

P0977 A 2-3 Shift Solenoid (SS) Control Circuit High Voltage 4.31 DTC P0977 – 2-3 Shift

Solenoid Control Circuit High Voltage

P1621 A Transmission Control Module (TCM) Long Term Memory

Performance 4.12 DTC P0601 to P0604 or

P1621 – TCM Malfunction

P1810 B Transmission Fluid Pressure (TFP) Position Switch Circuit 4.32 DTC P1810, P1815 and

P1816 – Transmission Fluid Pressure

Position Switch

P1815 B Transmission Fluid Pressure (TFP) Valve Position Switch -

Start in W rong Range 4.32 DTC P1810, P1815 and

P1816 – Transmission Fluid Pressure

Position Switch

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3829 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–43

Step Action Yes No

5 Perform the following procedure to verify the repair:

1 On Tech 2 select: Diagnostic Trouble Codes / Clear Engine & Transmission

DTCs.

2 Follow the instructions on Tech 2 and clear any DTCs.

3 Start the engine.

4 On Tech 2 select:

Diagnostic Trouble Codes / Read DTC Information.

Have any of the DTCs in this procedure set? Go to Step 2 Go to Step 6

6 On Tech 2 select:

Diagnostic Trouble Codes / Read DTC Information.

Does Tech 2 display any DTCs you have not diagnosed? Refer to

4.8 Diagnostic Trouble Code List System OK

When all diagnosis and repairs are completed, check the

system for correct operation.

4.13 DTC P0711 to P0713 – Transmission

Fluid Temperature Sensor

DTC Description

This diagnostic procedure supports the following DTCs:

• DTC P0711 – Transmission Fluid Temperature (TFT) Sensor Performance,

• DTC P0712 – Transmission Fluid Temperature (TFT) Sensor Circuit Low Voltage, and

• DTC P0713 – Transmission Fluid Temperature (TFT) Sensor Circuit High Voltage.

Circuit Description

The automatic transmission fluid temperature (TFT) sensor is part of the automatic transmission fluid pressure (TFP)

manual valve position switch. The automatic TFT sensor is a negative coefficient thermistor. The transmission control

module (TCM) supplies a 5 volt reference signal to the sensor and measures the voltage drop in the circuit. W hen the

transmission fluid is cold, the sensor resistance is high and the TCM detects high signal voltage. As the fluid temperature

increases, the resistance of the sensor decreases, which lowers the signal voltage. This diagnostic monitors the TFT

circuit. The circuit may be functional, but not in the normal operating range. This diagnostic indicates stuck, erratic,

intermittent, skewed, or inaccurate values, indicating poor system performance. The TFT range is -40 – 151°C.

Refer to 2 W iring Diagrams and Connector Chart to aid in diagnosis.

Conditions for Running the DTC

DTC P0711

• No DTC P0117, P0118, P0722 or P0723.

• DTC P0711 has not passed in the current ignition cycle.

• The engine run time is greater than 5 seconds.

• The transmission fluid temperature is -39 – 149°C.

• For conditions 1 and 2 in Conditions for Setting the DTC, the engine coolant temperature is greater than 70°C and

has changed by at least 50°C since start-up.

• For conditions 1 and 2 in Conditions for Setting the DTC, the TCC slip speed is 120 r.p.m. or greater for

600 seconds (10 minutes) cumulatively.

DTC P0712

The engine run time is greater than 5 seconds.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3831 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–45

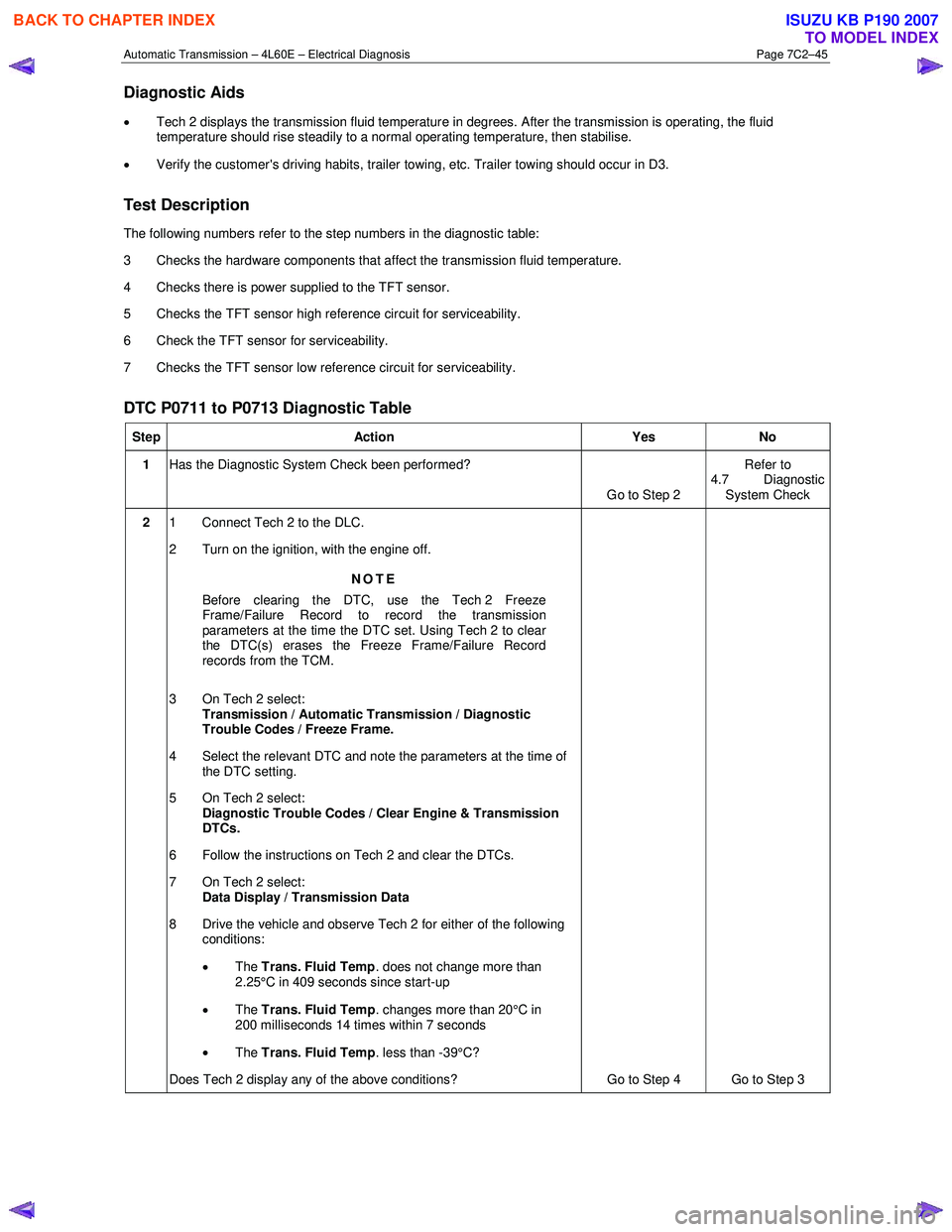

Diagnostic Aids

• Tech 2 displays the transmission fluid temperature in degrees. After the transmission is operating, the fluid

temperature should rise steadily to a normal operating temperature, then stabilise.

• Verify the customer's driving habits, trailer towing, etc. Trailer towing should occur in D3.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

3 Checks the hardware components that affect the transmission fluid temperature.

4 Checks there is power supplied to the TFT sensor.

5 Checks the TFT sensor high reference circuit for serviceability.

6 Check the TFT sensor for serviceability.

7 Checks the TFT sensor low reference circuit for serviceability.

DTC P0711 to P0713 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.7 Diagnostic System Check

2 1 Connect Tech 2 to the DLC.

2 Turn on the ignition, with the engine off.

NOTE

Before clearing the DTC, use the Tech 2 Freeze

Frame/Failure Record to record the transmission

parameters at the time the DTC set. Using Tech 2 to clear

the DTC(s) erases the Freeze Frame/Failure Record

records from the TCM.

3 On Tech 2 select: Transmission / Automatic Transmission / Diagnostic

Trouble Codes / Freeze Frame.

4 Select the relevant DTC and note the parameters at the time of the DTC setting.

5 On Tech 2 select:

Diagnostic Trouble Codes / Clear Engine & Transmission

DTCs.

6 Follow the instructions on Tech 2 and clear the DTCs.

7 On Tech 2 select: Data Display / Transmission Data

8 Drive the vehicle and observe Tech 2 for either of the following conditions:

• The Trans. Fluid Temp . does not change more than

2.25°C in 409 seconds since start-up

• The Trans. Fluid Temp . changes more than 20°C in

200 milliseconds 14 times within 7 seconds

• The Trans. Fluid Temp . less than -39°C?

Does Tech 2 display any of the above conditions? Go to Step 4 Go to Step 3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3832 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–46

Step Action Yes No

3 Inspect the transmission and related components for the following:

• transmission fluid level,

• transmission fluid cooling system restrictions / blockages,

• debris in the transmission fluid,

• incorrect line pressure,

• torque converter stator operation, and

• transmission overload.

W as a fault found and rectified? Go to Step 10 Check for an

intermittent fault in

the circuit, refer to

8A Electrical-Body and Chassis

4 1 Switch off the ignition.

2 Disconnect connector E-95 from the transmission.

3 Using a multimeter set to measure voltage, probe between harness connector E-95 pin 16 and a known ground.

Does the multimeter display 4.8 – 5.2 V? Go to Step 6 Go to Step 5

5 Test the TFT sensor signal circuit (between connectors E-95 pin 16

and C-96 pin 35) for a high resistance, open circuit, short to ground or

short to voltage fault condition.

Did you find and correct the condition? Go to Step 10 Go to Step 9

6 1 Switch off the ignition.

2 Remove the TCM fuses C-8 and EB-4, refer to 8A Electrical- Body and Chassis.

3 Using a multimeter set to measure resistance, probe between connector E95 pin 15 and a known ground.

Does the multimeter display less than 5 Ω? Go to Step 8 Go to Step 7

7 Using a multimeter, test between E-95 pin 15 and C-96 pin 30 for high

resistance, open circuit, short to ground or short to voltage fault

condition.

W as any fault found and rectified? Go to Step 10 —

8 Replace the TFT sensor, refer to 7C4 Automatic Transmission –

4L60E – On-vehicle Servicing.

NOTE

Check for damaged wiring (short to ground, short to

voltage, high resistance or open circuit) or poor

connections inside the transmission assembly before

replacing the TFT sensor.

Was the repair complete? Go to Step 10 —

9 Replace the TCM, refer to 7C4 Automatic Transmission – 4L60E –

On-vehicle Servicing

Was the repair completed? Go to Step 10

—

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3834 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–48

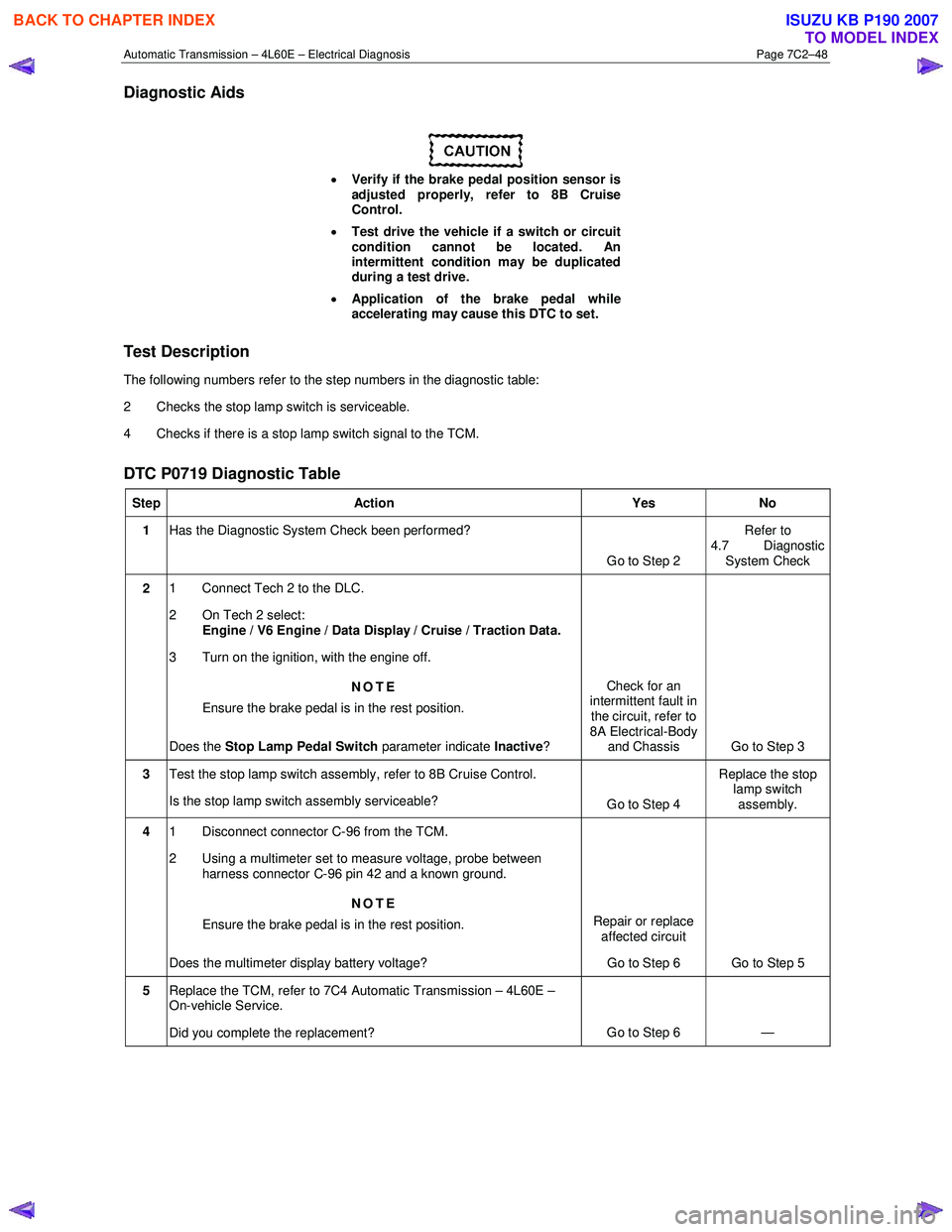

Diagnostic Aids

• Verify if the brake pedal position sensor is

adjusted properly, refer to 8B Cruise

Control.

• Test drive the vehicle if a switch or circuit

condition cannot be located. An

intermittent condition may be duplicated

during a test drive.

• Application of the brake pedal while

accelerating may cause this DTC to set.

Test Description

The following numbers refer to the step numbers in the diagnostic table:

2 Checks the stop lamp switch is serviceable.

4 Checks if there is a stop lamp switch signal to the TCM.

DTC P0719 Diagnostic Table

Step Action Yes No

1 Has the Diagnostic System Check been performed?

Go to Step 2 Refer to

4.7 Diagnostic System Check

2 1 Connect Tech 2 to the DLC.

2 On Tech 2 select: Engine / V6 Engine / Data Display / Cruise / Traction Data.

3 Turn on the ignition, with the engine off.

NOTE

Ensure the brake pedal is in the rest position.

Does the Stop Lamp Pedal Switch parameter indicate Inactive? Check for an

intermittent fault in

the circuit, refer to

8A Electrical-Body and Chassis Go to Step 3

3 Test the stop lamp switch assembly, refer to 8B Cruise Control.

Is the stop lamp switch assembly serviceable? Go to Step 4 Replace the stop

lamp switch

assembly.

4 1 Disconnect connector C-96 from the TCM.

2 Using a multimeter set to measure voltage, probe between harness connector C-96 pin 42 and a known ground.

NOTE

Ensure the brake pedal is in the rest position.

Does the multimeter display battery voltage? Repair or replace

affected circuit

Go to Step 6 Go to Step 5

5

Replace the TCM, refer to 7C4 Automatic Transmission – 4L60E –

On-vehicle Service.

Did you complete the replacement? Go to Step 6

—

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3835 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–49

Step Action Yes No

6 Perform the following procedure to verify the repair:

1 On Tech 2 select: Diagnostic Trouble Codes / Clear Engine & Transmission

DTCs

2 Follow the instructions on Tech 2 and clear any DTCs.

3 Operate the vehicle under the following conditions:

• Turn on the ignition, with the engine off for at least

2 seconds.

• Start the vehicle and idle for 5 seconds.

• Drive in D4 from 0 – 60 km/h 8 times in 1 ignition cycle.

4 On Tech 2 select:

Diagnostic Trouble Codes / Read DTC Information.

Has DTC P0719 set? Go to Step 2 Go to Step 7

7 On Tech 2 select:

Diagnostic Trouble Codes / Read DTC Information.

Does Tech 2 display any DTCs you have not diagnosed? Refer to

4.8 Diagnostic Trouble Code List System OK

When all diagnosis and repairs are completed, check the

system for correct operation.

4.15 DTC P0722 – Vehicle Speed Sensor

Circuit Low Voltage

DTC Description

This diagnostic procedure supports DTC P0722 Vehicle Speed Sensor Circuit Low Voltage.

Circuit Description

The vehicle speed sensor (VSS) provides vehicle speed information to the transmission control module (TCM). The VSS

is a permanent magnet generator. The sensor is mounted in the extension housing facing the rear internal gear which is

splined to the output shaft assembly. As the output shaft and internal gear rotate, the toothed rotor of the internal gear

produces AC voltage as the rotor teeth pass through the magnetic field of the sensor. The AC voltage level and the

number of pulses increase as the speed of the vehicle increases. The TCM converts the voltage to vehicle speed. The

TCM uses the output shaft speed signal to determine shift timing and torque converter clutch (TCC) scheduling.

If the TCM detects no vehicle speed when there is engine speed in a drive gear range, then DTC P0722 sets.

DTC P0722 is a type B DTC.

Refer to 2 W iring Diagrams and Connector Chart to aid in diagnosis.

Conditions for Running the DTC

• No DTCs P0723, P1810, P1815 or P1816.

• Ignition voltage is 8 – 18 V.

• TFT is -40°C – 150°C.

• The engine run time is greater than 5 seconds.

• The throttle position is greater than 12 percent.

• The engine torque is 108 – 882 Nm.

Conditions for Setting the DTC

The transmission output shaft speed is less than 50 r.p.m. for 3 seconds.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3837 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–51

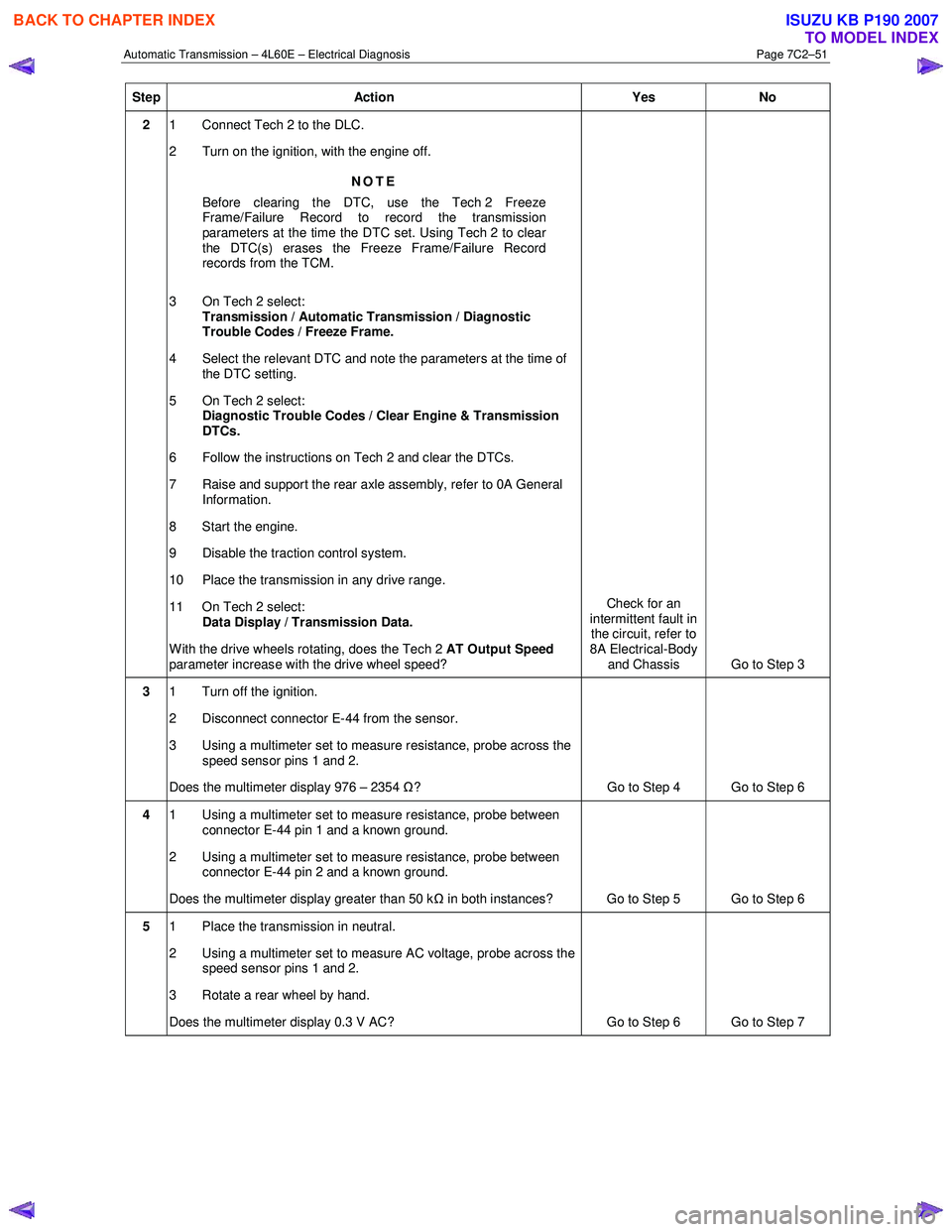

Step Action Yes No

2 1 Connect Tech 2 to the DLC.

2 Turn on the ignition, with the engine off.

NOTE

Before clearing the DTC, use the Tech 2 Freeze

Frame/Failure Record to record the transmission

parameters at the time the DTC set. Using Tech 2 to clear

the DTC(s) erases the Freeze Frame/Failure Record

records from the TCM.

3 On Tech 2 select: Transmission / Automatic Transmission / Diagnostic

Trouble Codes / Freeze Frame.

4 Select the relevant DTC and note the parameters at the time of the DTC setting.

5 On Tech 2 select:

Diagnostic Trouble Codes / Clear Engine & Transmission

DTCs.

6 Follow the instructions on Tech 2 and clear the DTCs.

7 Raise and support the rear axle assembly, refer to 0A General Information.

8 Start the engine.

9 Disable the traction control system.

10 Place the transmission in any drive range.

11 On Tech 2 select: Data Display / Transmission Data.

W ith the drive wheels rotating, does the Tech 2 AT Output Speed

parameter increase with the drive wheel speed? Check for an

intermittent fault in the circuit, refer to

8A Electrical-Body and Chassis Go to Step 3

3 1 Turn off the ignition.

2 Disconnect connector E-44 from the sensor.

3 Using a multimeter set to measure resistance, probe across the speed sensor pins 1 and 2.

Does the multimeter display 976 – 2354 Ω? Go to Step 4 Go to Step 6

4 1 Using a multimeter set to measure resistance, probe between

connector E-44 pin 1 and a known ground.

2 Using a multimeter set to measure resistance, probe between connector E-44 pin 2 and a known ground.

Does the multimeter display greater than 50 k Ω in both instances? Go to Step 5 Go to Step 6

5 1 Place the transmission in neutral.

2 Using a multimeter set to measure AC voltage, probe across the speed sensor pins 1 and 2.

3 Rotate a rear wheel by hand.

Does the multimeter display 0.3 V AC? Go to Step 6 Go to Step 7

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3838 of 6020

Automatic Transmission – 4L60E – Electrical Diagnosis Page 7C2–52

Step Action Yes No

6 1 Disconnect connector C-96 from the TCM.

2 Test circuits speed sensor circuits (between C-96 pin 16 and E-44 pin 2; C-96 pin 41 and E-44 pin 1) for the following

conditions:

• Short to ground

• Open circuit

• Short together

Did you find and correct the condition? Go to Step 9 Go to Step 8

7 Replace the vehicle speed sensor, refer to 7C4 Automatic

Transmission – 4L60E – On-vehicle Service.

Did you complete the replacement? Go to Step 9 —

8 Replace the TCM, refer to 7C4 Automatic Transmission – 4L60E –

On-vehicle Service.

Did you complete the replacement? Go to Step 9 —

9 Perform the following procedure to verify the repair:

1 On Tech 2 select: Diagnostic Trouble Codes / Clear Engine & Transmission

DTCs.

2 Follow the instructions on Tech 2 and clear any DTCs.

3 Operate the vehicle so the transmission output speed is greater than 500 r.p.m. for 3 seconds.

4 On Tech 2 select:

Diagnostic Trouble Codes / Read DTC Information.

Has DTC P0722 set? Go to Step 2 Go to Step 9

10 On Tech 2 select:

Diagnostic Trouble Codes / Read DTC Information.

Does Tech 2 display any DTCs you have not diagnosed? Refer to

4.8 Diagnostic Trouble Code List System OK

When all diagnosis and repairs are completed, check the system for correct operation.

4.16 DTC P0723 – Vehicle Speed Sensor

Circuit Intermittent

DTC Description

This diagnostic procedure supports DTC P0723 Vehicle Speed Sensor Circuit Intermittent.

Circuit Description

The vehicle speed sensor (VSS) provides vehicle speed information to the transmission control module (TCM). The VSS

is a permanent magnet generator. The sensor is mounted in the extension housing facing the rear internal gear which is

splined to the output shaft assembly. As the output shaft and internal gear rotate, the toothed rotor of the internal gear

produces AC voltage as the rotor teeth pass through the magnetic field of the sensor. The AC voltage level and the

number of pulses increase as the speed of the vehicle increases. The TCM converts the voltage to vehicle speed. The

TCM uses the output shaft speed signal to determine shift timing and torque converter clutch (TCC) scheduling.

If the TCM detects an unrealistic drop in output shaft speed, DTC P0723 sets. DTC P0723 is a type B DTC.

Refer to 2 W iring Diagrams and Connector Chart to aid in diagnosis.

Conditions for Running the DTC

• No DTCs P0722, P1810, P1815 or P1816.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007