ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 1071 of 6020

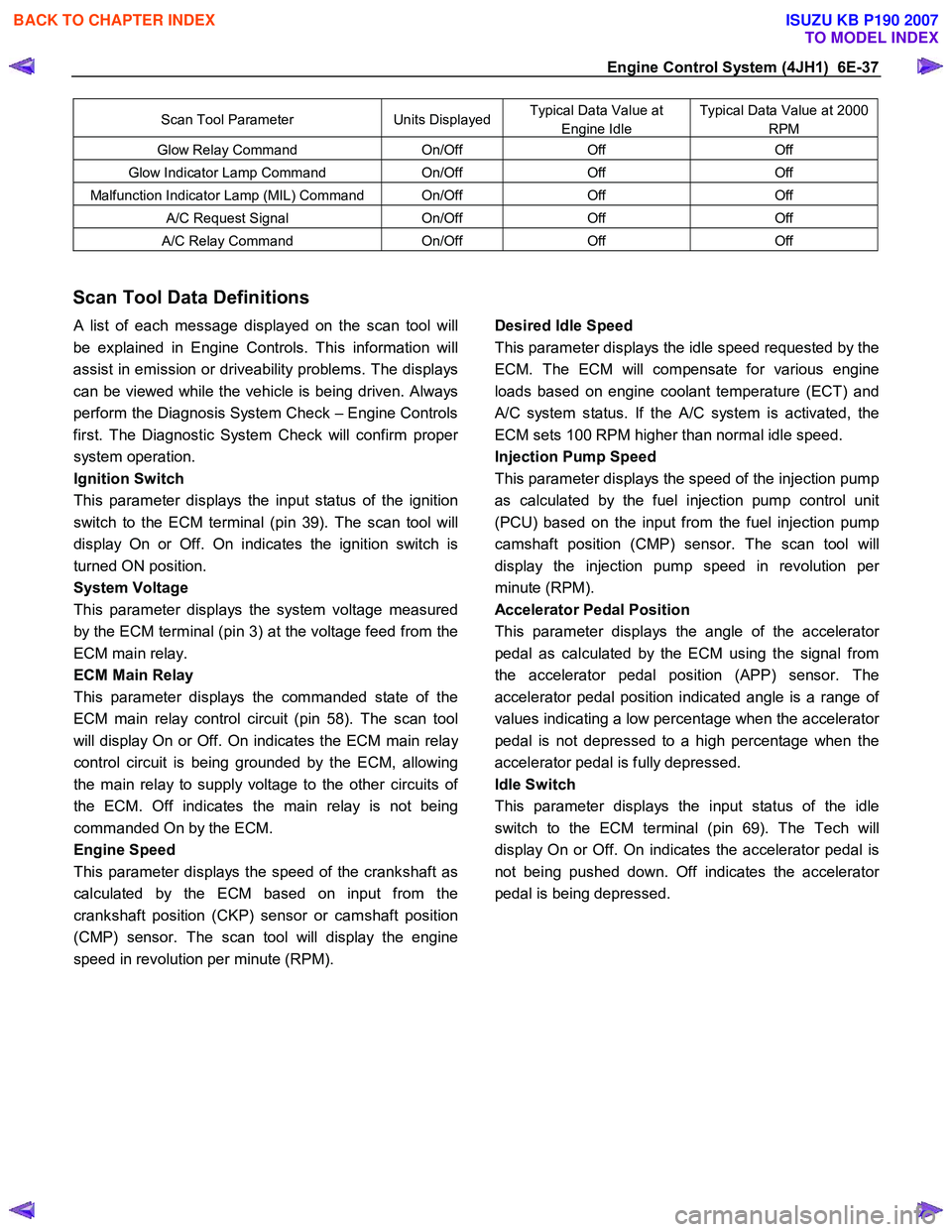

Engine Control System (4JH1) 6E-37

Scan Tool Parameter Units DisplayedTypical Data Value at

Engine Idle

Typical Data Value at 2000

RPM

Glow Relay Command On/Off Off Off

Glow Indicator Lamp Command On/Off Off Off

Malfunction Indicator Lamp (MIL) Command On/Off Off Off

A/C Request Signal On/Off Off Off

A/C Relay Command On/Off Off Off

Scan Tool Data Definitions

A list of each message displayed on the scan tool will

be explained in Engine Controls. This information will

assist in emission or driveability problems. The displays

can be viewed while the vehicle is being driven. Always

perform the Diagnosis System Check – Engine Controls

first. The Diagnostic System Check will confirm prope

r

system operation.

Ignition Switch

This parameter displays the input status of the ignition

switch to the ECM terminal (pin 39). The scan tool will

display On or Off. On indicates the ignition switch is

turned ON position.

System Voltage

This parameter displays the system voltage measured

by the ECM terminal (pin 3) at the voltage feed from the

ECM main relay.

ECM Main Relay

This parameter displays the commanded state of the

ECM main relay control circuit (pin 58). The scan tool

will display On or Off. On indicates the ECM main rela

y

control circuit is being grounded by the ECM, allowing

the main relay to supply voltage to the other circuits o

f

the ECM. Off indicates the main relay is not being

commanded On by the ECM.

Engine Speed

This parameter displays the speed of the crankshaft as

calculated by the ECM based on input from the

crankshaft position (CKP) sensor or camshaft position

(CMP) sensor. The scan tool will display the engine

speed in revolution per minute (RPM).

Desired Idle Speed

This parameter displays the idle speed requested by the

ECM. The ECM will compensate for various engine

loads based on engine coolant temperature (ECT) and

A/C system status. If the A/C system is activated, the

ECM sets 100 RPM higher than normal idle speed.

Injection Pump Speed

This parameter displays the speed of the injection pump

as calculated by the fuel injection pump control unit

(PCU) based on the input from the fuel injection pump

camshaft position (CMP) sensor. The scan tool will

display the injection pump speed in revolution pe

r

minute (RPM).

Accelerator Pedal Position

This parameter displays the angle of the accelerato

r

pedal as calculated by the ECM using the signal from

the accelerator pedal position (APP) sensor. The

accelerator pedal position indicated angle is a range o

f

values indicating a low percentage when the accelerator

pedal is not depressed to a high percentage when the

accelerator pedal is fully depressed.

Idle Switch

This parameter displays the input status of the idle

switch to the ECM terminal (pin 69). The Tech will

display On or Off. On indicates the accelerator pedal is

not being pushed down. Off indicates the accelerato

r

pedal is being depressed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1072 of 6020

6E-38 Engine Control System (4JH1)

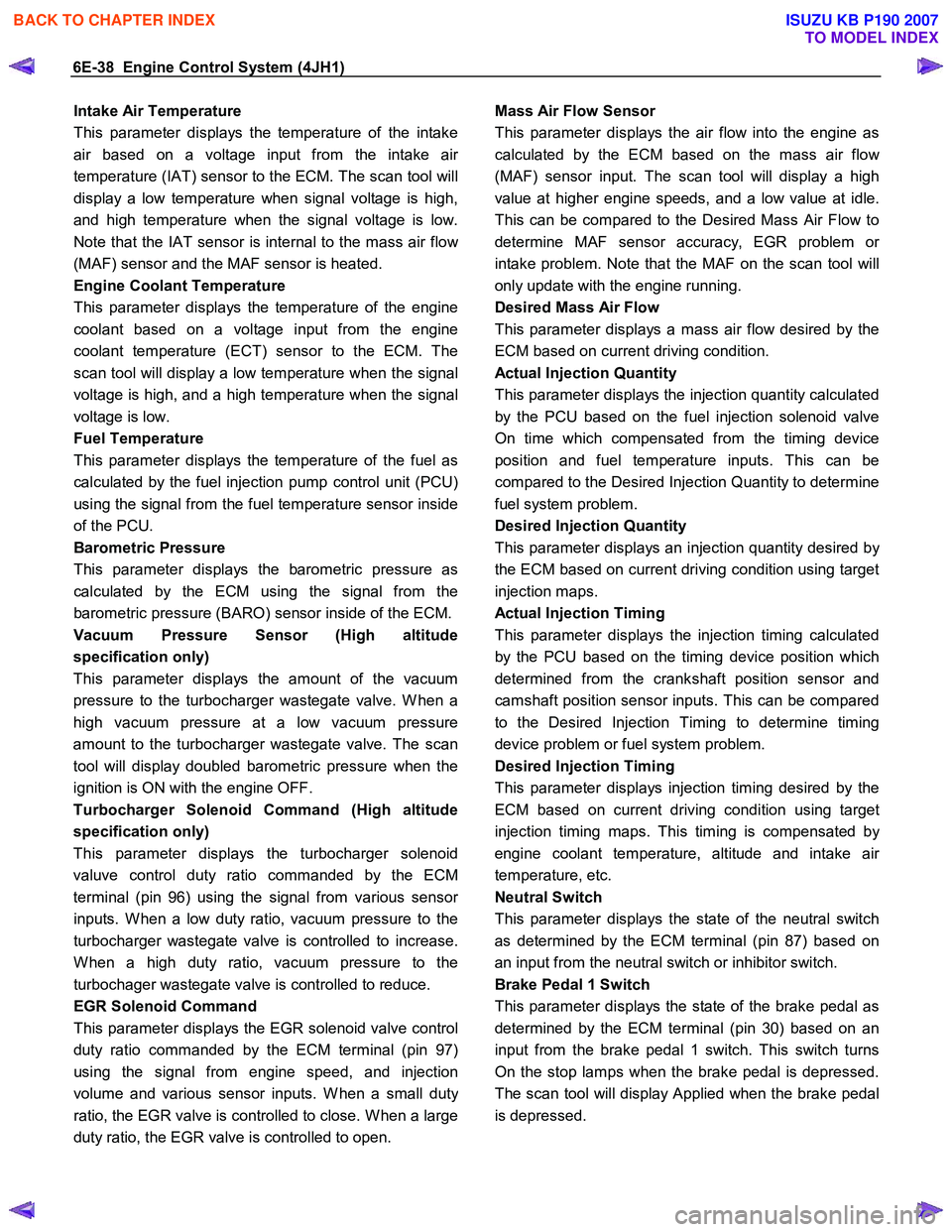

Intake Air Temperature

This parameter displays the temperature of the intake

air based on a voltage input from the intake ai

r

temperature (IAT) sensor to the ECM. The scan tool will

display a low temperature when signal voltage is high,

and high temperature when the signal voltage is low.

Note that the IAT sensor is internal to the mass air flo

w

(MAF) sensor and the MAF sensor is heated.

Engine Coolant Temperature

This parameter displays the temperature of the engine

coolant based on a voltage input from the engine

coolant temperature (ECT) sensor to the ECM. The

scan tool will display a low temperature when the signal

voltage is high, and a high temperature when the signal

voltage is low.

Fuel Temperature

This parameter displays the temperature of the fuel as

calculated by the fuel injection pump control unit (PCU)

using the signal from the fuel temperature sensor inside

of the PCU.

Barometric Pressure

This parameter displays the barometric pressure as

calculated by the ECM using the signal from the

barometric pressure (BARO) sensor inside of the ECM.

Vacuum Pressure Sensor (High altitude

specification only)

This parameter displays the amount of the vacuum

pressure to the turbocharger wastegate valve. W hen a

high vacuum pressure at a low vacuum pressure

amount to the turbocharger wastegate valve. The scan

tool will display doubled barometric pressure when the

ignition is ON with the engine OFF.

Turbocharger Solenoid Command (High altitude

specification only)

This parameter displays the turbocharger solenoid

valuve control duty ratio commanded by the ECM

terminal (pin 96) using the signal from various senso

r

inputs. W hen a low duty ratio, vacuum pressure to the

turbocharger wastegate valve is controlled to increase.

W hen a high duty ratio, vacuum pressure to the

turbochager wastegate valve is controlled to reduce.

EGR Solenoid Command

This parameter displays the EGR solenoid valve control

duty ratio commanded by the ECM terminal (pin 97)

using the signal from engine speed, and injection

volume and various sensor inputs. W hen a small dut

y

ratio, the EGR valve is controlled to close. W hen a large

duty ratio, the EGR valve is controlled to open.

Mass Air Flow Sensor

This parameter displays the air flow into the engine as

calculated by the ECM based on the mass air flo

w

(MAF) sensor input. The scan tool will display a high

value at higher engine speeds, and a low value at idle.

This can be compared to the Desired Mass Air Flow to

determine MAF sensor accuracy, EGR problem o

r

intake problem. Note that the MAF on the scan tool will

only update with the engine running.

Desired Mass Air Flow

This parameter displays a mass air flow desired by the

ECM based on current driving condition.

Actual Injection Quantity

This parameter displays the injection quantity calculated

by the PCU based on the fuel injection solenoid valve

On time which compensated from the timing device

position and fuel temperature inputs. This can be

compared to the Desired Injection Quantity to determine

fuel system problem.

Desired Injection Quantity

This parameter displays an injection quantity desired b

y

the ECM based on current driving condition using target

injection maps.

Actual Injection Timing

This parameter displays the injection timing calculated

by the PCU based on the timing device position which

determined from the crankshaft position sensor and

camshaft position sensor inputs. This can be compared

to the Desired Injection Timing to determine timing

device problem or fuel system problem.

Desired Injection Timing

This parameter displays injection timing desired by the

ECM based on current driving condition using target

injection timing maps. This timing is compensated b

y

engine coolant temperature, altitude and intake ai

r

temperature, etc.

Neutral Switch

This parameter displays the state of the neutral switch

as determined by the ECM terminal (pin 87) based on

an input from the neutral switch or inhibitor switch.

Brake Pedal 1 Switch

This parameter displays the state of the brake pedal as

determined by the ECM terminal (pin 30) based on an

input from the brake pedal 1 switch. This switch turns

On the stop lamps when the brake pedal is depressed.

The scan tool will display Applied when the brake pedal

is depressed.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1073 of 6020

Engine Control System (4JH1) 6E-39

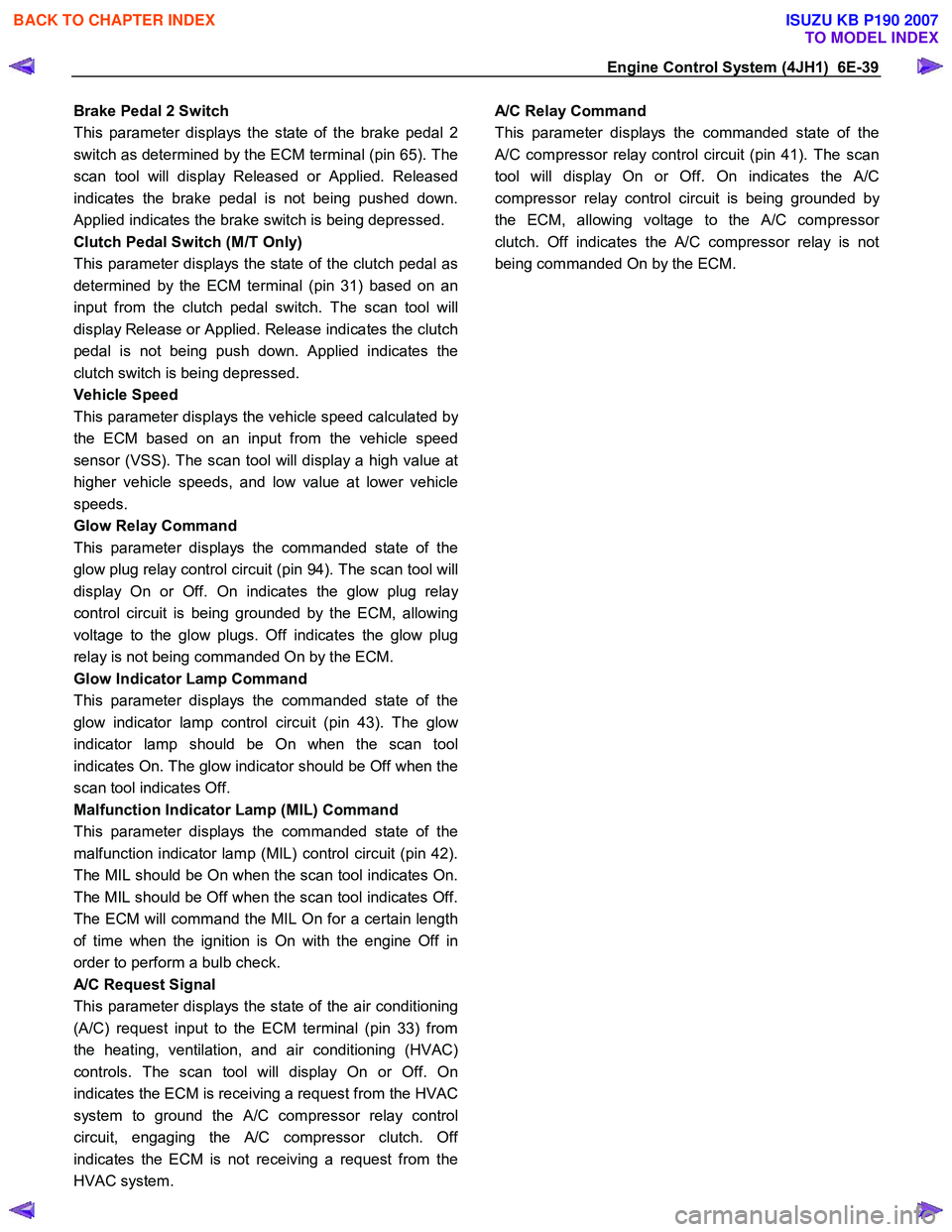

Brake Pedal 2 Switch

This parameter displays the state of the brake pedal 2

switch as determined by the ECM terminal (pin 65). The

scan tool will display Released or Applied. Released

indicates the brake pedal is not being pushed down.

Applied indicates the brake switch is being depressed.

Clutch Pedal Switch (M/T Only)

This parameter displays the state of the clutch pedal as

determined by the ECM terminal (pin 31) based on an

input from the clutch pedal switch. The scan tool will

display Release or Applied. Release indicates the clutch

pedal is not being push down. Applied indicates the

clutch switch is being depressed.

Vehicle Speed

This parameter displays the vehicle speed calculated b

y

the ECM based on an input from the vehicle speed

sensor (VSS). The scan tool will display a high value at

higher vehicle speeds, and low value at lower vehicle

speeds.

Glow Relay Command

This parameter displays the commanded state of the

glow plug relay control circuit (pin 94). The scan tool will

display On or Off. On indicates the glow plug rela

y

control circuit is being grounded by the ECM, allowing

voltage to the glow plugs. Off indicates the glow plug

relay is not being commanded On by the ECM.

Glow Indicator Lamp Command

This parameter displays the commanded state of the

glow indicator lamp control circuit (pin 43). The glo

w

indicator lamp should be On when the scan tool

indicates On. The glow indicator should be Off when the

scan tool indicates Off.

Malfunction Indicator Lamp (MIL) Command

This parameter displays the commanded state of the

malfunction indicator lamp (MIL) control circuit (pin 42).

The MIL should be On when the scan tool indicates On.

The MIL should be Off when the scan tool indicates Off.

The ECM will command the MIL On for a certain length

of time when the ignition is On with the engine Off in

order to perform a bulb check.

A/C Request Signal

This parameter displays the state of the air conditioning

(A/C) request input to the ECM terminal (pin 33) from

the heating, ventilation, and air conditioning (HVAC)

controls. The scan tool will display On or Off. On

indicates the ECM is receiving a request from the HVAC

system to ground the A/C compressor relay control

circuit, engaging the

A/C compressor clutch. Off

indicates the ECM is not receiving a request from the

HVAC system.

A/C Relay Command

This parameter displays the commanded state of the

A/C compressor relay control circuit (pin 41). The scan

tool will display On or Off. On indicates the

A/C

compressor relay control circuit is being grounded b

y

the ECM, allowing voltage to the A/C compressor

clutch. Off indicates the A/C compressor relay is not

being commanded On by the ECM.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1074 of 6020

6E-40 Engine Control System (4JH1)

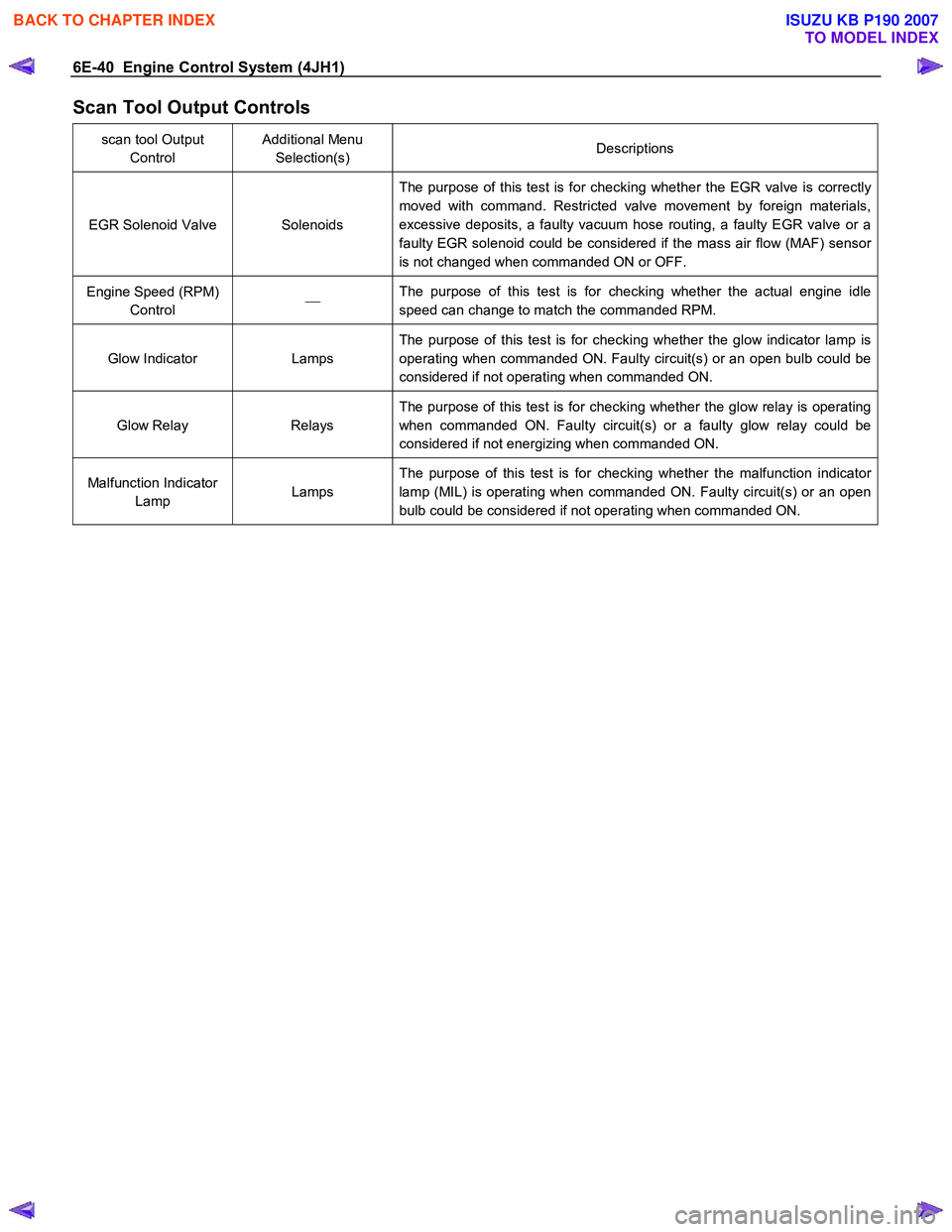

Scan Tool Output Controls

scan tool Output Control Additional Menu

Selection(s) Descriptions

EGR Solenoid Valve Solenoids The purpose of this test is for checking whether the EGR valve is correctly

moved with command. Restricted valve movement by foreign materials,

excessive deposits, a faulty vacuum hose routing, a faulty EGR valve or a

faulty EGR solenoid could be considered if the mass air flow (MAF) sensor

is not changed when commanded ON or OFF.

Engine Speed (RPM) Control

The purpose of this test is for checking whether the actual engine idle

speed can change to match the commanded RPM.

Glow Indicator Lamps The purpose of this test is for checking whether the glow indicator lamp is

operating when commanded ON. Faulty circuit(s) or an open bulb could be

considered if not operating when commanded ON.

Glow Relay Relays The purpose of this test is for checking whether the glow relay is operating

when commanded ON. Faulty circuit(s) or a faulty glow relay could be

considered if not energizing when commanded ON.

Malfunction Indicator Lamp Lamps The purpose of this test is for checking whether the malfunction indicator

lamp (MIL) is operating when commanded ON. Faulty circuit(s) or an open

bulb could be considered if not operating when commanded ON.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1075 of 6020

Engine Control System (4JH1) 6E-41

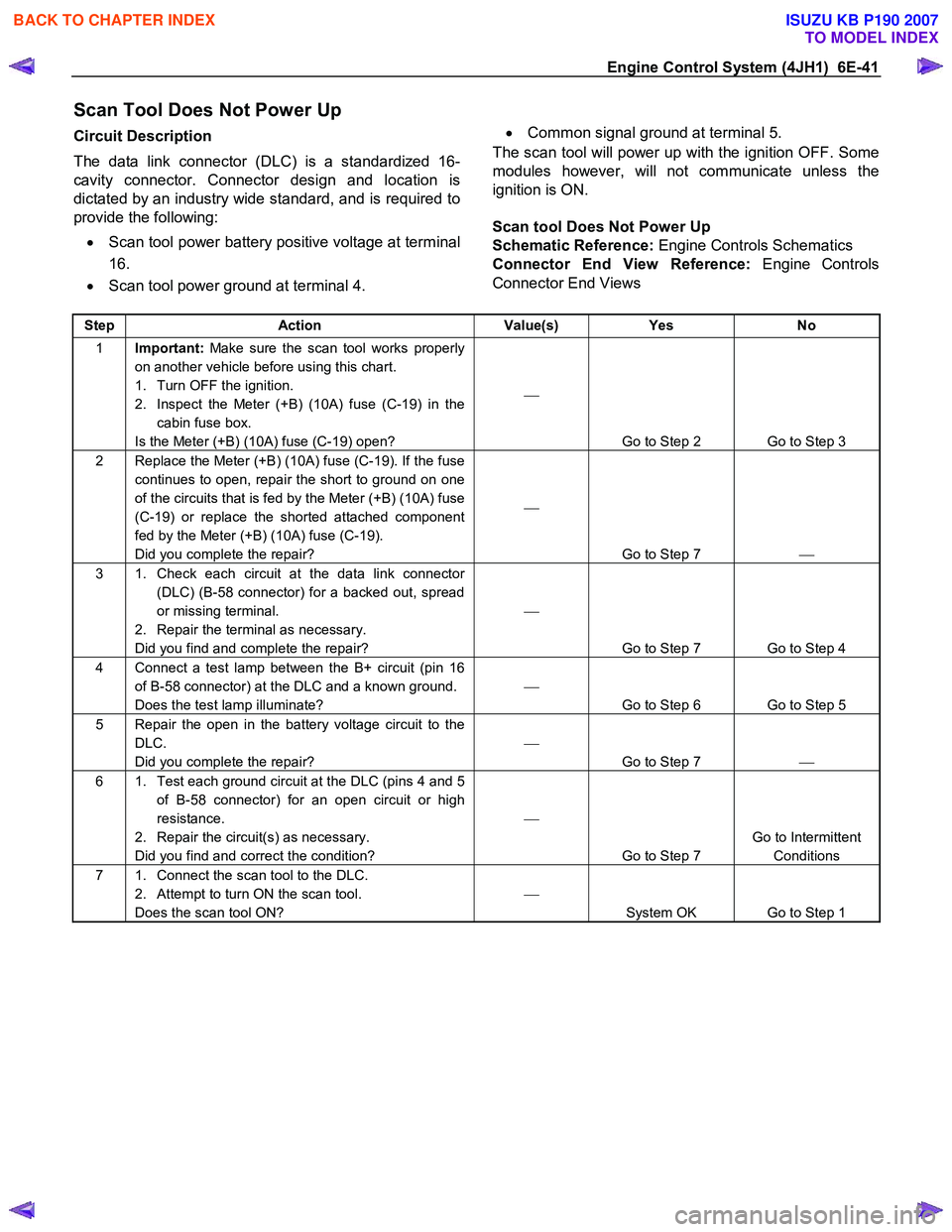

Scan Tool Does Not Power Up

Circuit Description

The data link connector (DLC) is a standardized 16-

cavity connector. Connector design and location is

dictated by an industry wide standard, and is required to

provide the following:

• Scan tool power battery positive voltage at terminal

16.

• Scan tool power ground at terminal 4.

•

Common signal ground at terminal 5.

The scan tool will power up with the ignition OFF. Some

modules however, will not communicate unless the

ignition is ON.

Scan tool Does Not Power Up

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views

Step Action Value(s) Yes No

1 Important: Make sure the scan tool works properly

on another vehicle before using this chart.

1. Turn OFF the ignition.

2. Inspect the Meter (+B) (10A) fuse (C-19) in the cabin fuse box.

Is the Meter (+B) (10A) fuse (C-19) open?

Go to Step 2 Go to Step 3

2 Replace the Meter (+B) (10A) fuse (C-19). If the fuse continues to open, repair the short to ground on one

of the circuits that is fed by the Meter (+B) (10A) fuse

(C-19) or replace the shorted attached component

fed by the Meter (+B) (10A) fuse (C-19).

Did you complete the repair?

Go to Step 7

3 1. Check each circuit at the data link connector

(DLC) (B-58 connector) for a backed out, spread

or missing terminal.

2. Repair the terminal as necessary.

Did you find and complete the repair?

Go to Step 7 Go to Step 4

4 Connect a test lamp between the B+ circuit (pin 16 of B-58 connector) at the DLC and a known ground.

Does the test lamp illuminate?

Go to Step 6 Go to Step 5

5 Repair the open in the battery voltage circuit to the DLC.

Did you complete the repair?

Go to Step 7

6 1. Test each ground circuit at the DLC (pins 4 and 5

of B-58 connector) for an open circuit or high

resistance.

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 7 Go to Intermittent

Conditions

7 1. Connect the scan tool to the DLC. 2. Attempt to turn ON the scan tool.

Does the scan tool ON?

System OK Go to Step 1

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1076 of 6020

6E-42 Engine Control System (4JH1)

Scan Tool Does Not Communicate with Keyword 2000 Device

Circuit Description

The engine control module (ECM), transmission control

module (TCM) and anti-theft (keyless entry) control unit

(ACU) all communicate with the scan tool over the

Keyword 2000 serial data link. However, the ECM and

fuel injection pump control unit (PCU) communicates

with each other over the controller area network (CAN)

link. The CAN link is not used for communication with

the scan tool and is shared only between the ECM and

PCU.

Diagnostic Aids

The following conditions will cause a loss of Keyword

2000 serial data communication between the TCM and

EHCU or between the scan tool and any control module:

• A Keyword 2000 serial data circuit open.

• A Keyword 2000 serial data circuit shorted to

ground.

• A Keyword 2000 serial data circuit shorted to

voltage.

•

An internal condition within a module or connector

on the Keyword 2000 serial data circuit, that causes

a short to voltage or ground to the Keyword 2000

serial data circuit.

• Open ground circuit (pin 5) at the DLC.

Scan tool Does Not Communicate with Keyword

2000 Device

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 1. Install the scan tool. 2. Turn ON the ignition, with the engine OFF.

3. Attempt to communicate with the listed control modules. • Engine control module (ECM)

• Transmission control module (TCM) (A/T

only)

• Electronic hydraulic control unit (EHCU)

Does the scan tool communicate with all the listed

control modules?

Go to Step 3 Go to Step 8

3 Does the scan tool communicate with the ECM?

Go to Step 4 Go to Lost

Communication with The ECM

4 Does the scan tool communicate with the TCM?

Go to Step 5 Go to Diagnostic

System Check Transmission Control

5 Does the scan tool communicate with the EHCU?

Go to Step 6 Go to Diagnostic

System Brake

6 Test the Keyword 2000 serial data circuit for an intermittently short to ground or intermittently short to

voltage. Then, test the Keyword 2000 serial data

circuit for an intermittently open (based on which

control module did not communicate) at the

connection in the circuit.

Did you find and correct the condition?

Go to Step 15 System OK

7 Test the data link connector (DLC) ground circuit at terminal 5 for an open circuit or poor connection.

Did you find and correct the condition?

Go to Step 15 Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1077 of 6020

Engine Control System (4JH1) 6E-43

Step Action Value(s) Yes No

8 1. Turn OFF the ignition.

2. Disconnect the ECM C-56 and C-57 harness connectors.

3. Turn ON the ignition, with the engine OFF.

4. Attempt to communicate with the TCM and EHCU.

Does the scan tool communicate with the TCM and

EHCU?

Go to Step 12 Go to Step 9

9 1. Turn OFF the ignition. 2. Reconnect the ECM C-56 and C-57 harness connectors.

3. Disconnect the TCM A and B harness connectors.

4. Turn ON the ignition, with the engine OFF.

5. Attempt to communicate with the ECM and EHCU.

Does the scan tool communicate with the ECM and

EHCU?

Go to Step 13 Go to Step 10

10 1. Turn OFF the ignition. 2. Reconnect the TCM A and B harness connectors.

3. Disconnect the EHCU C-67 harness connectors.

4. Turn ON the ignition, with the engine OFF.

5. Attempt to communicate with the ECM and TCM.

Does the scan tool communicate with the ECM and

TCM?

Go to Step 14 Go to Step 11

11 Repair the short to ground or short to voltage on the Keyword 2000 serial data circuit between the DLC

and ECM, TCM and EHCU.

Did you complete the repair?

Go to Step 15

12 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 15

13 Important: Replacement TCM must be

programmed.

Replace the TCM. Refer to Transmission Control

Module (TCM) Replacement in the transmission

section.

Did you complete the replacement?

Go to Step 15

14 Replace the EHCU. Refer to Electronic Hydraulic

Control Unit in the anti-lock brake system section.

Did you complete the replacement?

Go to Step 15

15 Attempt to communicate with the ECM, TCM and

EHCU.

Does the scan tool communicate with the ECM, TCM

and EHCU?

System OK Go to Step 2

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1078 of 6020

6E-44 Engine Control System (4JH1)

Lost Communication with The Engine Control Module (ECM)

Circuit Description

The engine control module (ECM), transmission control

module (TCM) and electronic hydraulic control unit

(EHCU) all communicate with the scan tool over the

Keyword 2000 serial data link. However, the ECM and

fuel injection pump control unit (PCU) communicates

with each other over the controller area network (CAN)

link. The CAN link is not used for communication with

the scan tool and is shared only between the ECM and

PCU.

Lost Communication with The Engine Control

Module (ECM)

Schematic Reference: Engine Controls Schematics

Connector End View Reference: Engine Controls

Connector End Views or Engine Control Module (ECM)

Connector End Views

Step Action Value(s) Yes No

1 Did you perform the Diagnostic System Check-

Engine Controls?

Go to Step 2 Go to Diagnostic

System Check-

Engine Controls

2 Attempt to establish engine control module (ECM) communications with the scan tool.

Does the ECM communicate with the scan tool?

Go to Intermittent

Conditions Go to Step 3

3 Check the ECM C-56 and C-57 connectors for poor connections.

Did you find and correct the condition?

Go to Step 17 Go to Step 4

4 Check the electronic hydraulic control unit (EHCU)

C-67 connector for poor connection.

Did you find and correct the condition?

Go to Step 17 Go to Step 5

5 1. Turn ON the ignition, with the engine OFF. 2. Check the ECM (30A) (SFB-4), ECM (10A) fuse (EB-4) and Engine (15A) fuse (C-6).Replace and

retest if open. If any fuse continues to open,

check for a short to ground on each circuit fed by

that fuse.

3. Turn OFF the ignition.

4. Disconnect the ECM C-56 harness connector.

5. Turn ON the ignition, with the engine OFF.

6. Connect a test lamp to ground and check for voltage at the ignition voltage supply circuit at the

ECM (pin 39 of C-56 connector).

Does the test lamp illuminate?

Go to Step 6 Go to Step 14

6 1. Turn OFF the ignition. 2. Connect a DMM between the Keyword 2000 serial data circuit at the ECM (pin 35 of C-56

connector) and the EHCU (pin 11 of C-67

connector).

3. Test the circuits for an open circuit or high resistance.

4. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 17 Go to Step 7

7 1. Turn OFF the ignition. 2. Connect a DMM between the Keyword 2000 serial data circuit at the EHCU (pin 11 of C-67

connector) and the DLC (pin 7 of B-58

connector).

3. Test the circuits for an open circuit or high resistance.

4. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 17 Go to Step 8

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1079 of 6020

Engine Control System (4JH1) 6E-45

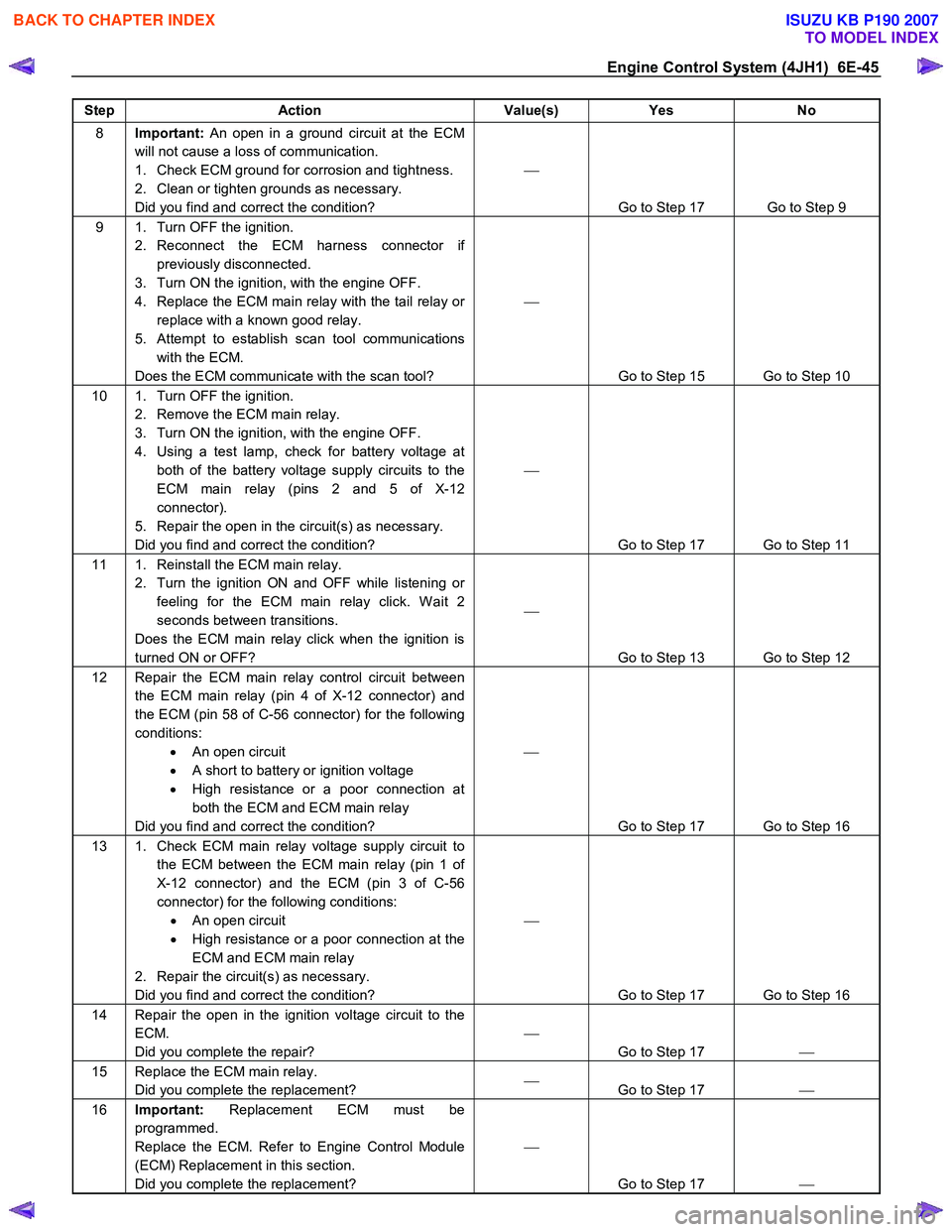

Step Action Value(s) Yes No

8 Important: An open in a ground circuit at the ECM

will not cause a loss of communication.

1. Check ECM ground for corrosion and tightness.

2. Clean or tighten grounds as necessary.

Did you find and correct the condition?

Go to Step 17 Go to Step 9

9 1. Turn OFF the ignition. 2. Reconnect the ECM harness connector if previously disconnected.

3. Turn ON the ignition, with the engine OFF.

4. Replace the ECM main relay with the tail relay or replace with a known good relay.

5. Attempt to establish scan tool communications with the ECM.

Does the ECM communicate with the scan tool?

Go to Step 15 Go to Step 10

10 1. Turn OFF the ignition. 2. Remove the ECM main relay.

3. Turn ON the ignition, with the engine OFF.

4. Using a test lamp, check for battery voltage at both of the battery voltage supply circuits to the

ECM main relay (pins 2 and 5 of X-12

connector).

5. Repair the open in the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 17 Go to Step 11

11 1. Reinstall the ECM main relay. 2. Turn the ignition ON and OFF while listening or feeling for the ECM main relay click. W ait 2

seconds between transitions.

Does the ECM main relay click when the ignition is

turned ON or OFF?

Go to Step 13 Go to Step 12

12 Repair the ECM main relay control circuit between the ECM main relay (pin 4 of X-12 connector) and

the ECM (pin 58 of C-56 connector) for the following

conditions: • An open circuit

• A short to battery or ignition voltage

• High resistance or a poor connection at

both the ECM and ECM main relay

Did you find and correct the condition?

Go to Step 17 Go to Step 16

13 1. Check ECM main relay voltage supply circuit to the ECM between the ECM main relay (pin 1 of

X-12 connector) and the ECM (pin 3 of C-56

connector) for the following conditions: • An open circuit

• High resistance or a poor connection at the

ECM and ECM main relay

2. Repair the circuit(s) as necessary.

Did you find and correct the condition?

Go to Step 17 Go to Step 16

14 Repair the open in the ignition voltage circuit to the ECM.

Did you complete the repair?

Go to Step 17

15 Replace the ECM main relay.

Did you complete the replacement?

Go to Step 17

16 Important: Replacement ECM must be

programmed.

Replace the ECM. Refer to Engine Control Module

(ECM) Replacement in this section.

Did you complete the replacement?

Go to Step 17

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 1080 of 6020

6E-46 Engine Control System (4JH1)

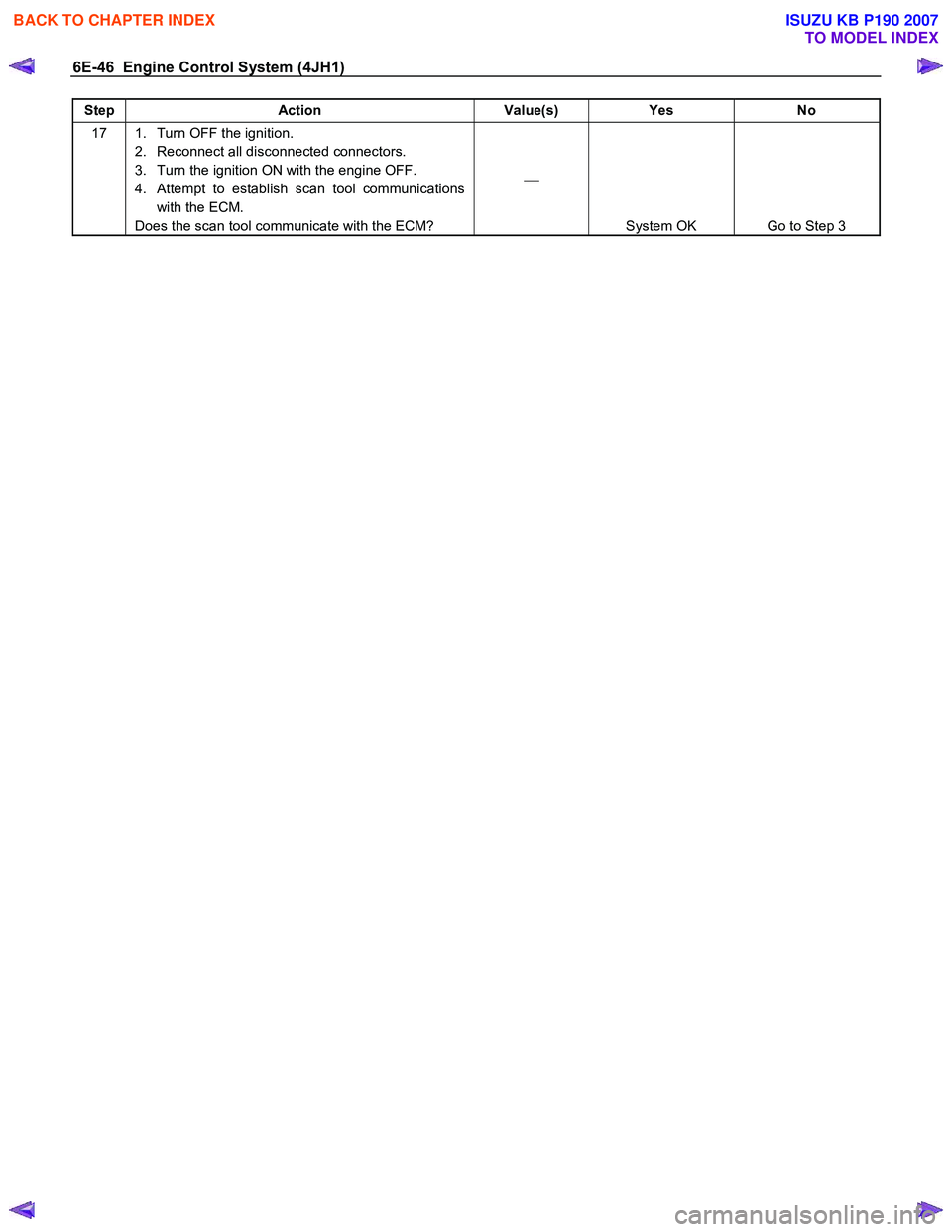

Step Action Value(s) Yes No

17 1. Turn OFF the ignition.

2. Reconnect all disconnected connectors.

3. Turn the ignition ON with the engine OFF.

4. Attempt to establish scan tool communications with the ECM.

Does the scan tool communicate with the ECM?

System OK Go to Step 3

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007