ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 261 of 6020

FRONT ALIGNMENT 3A-13

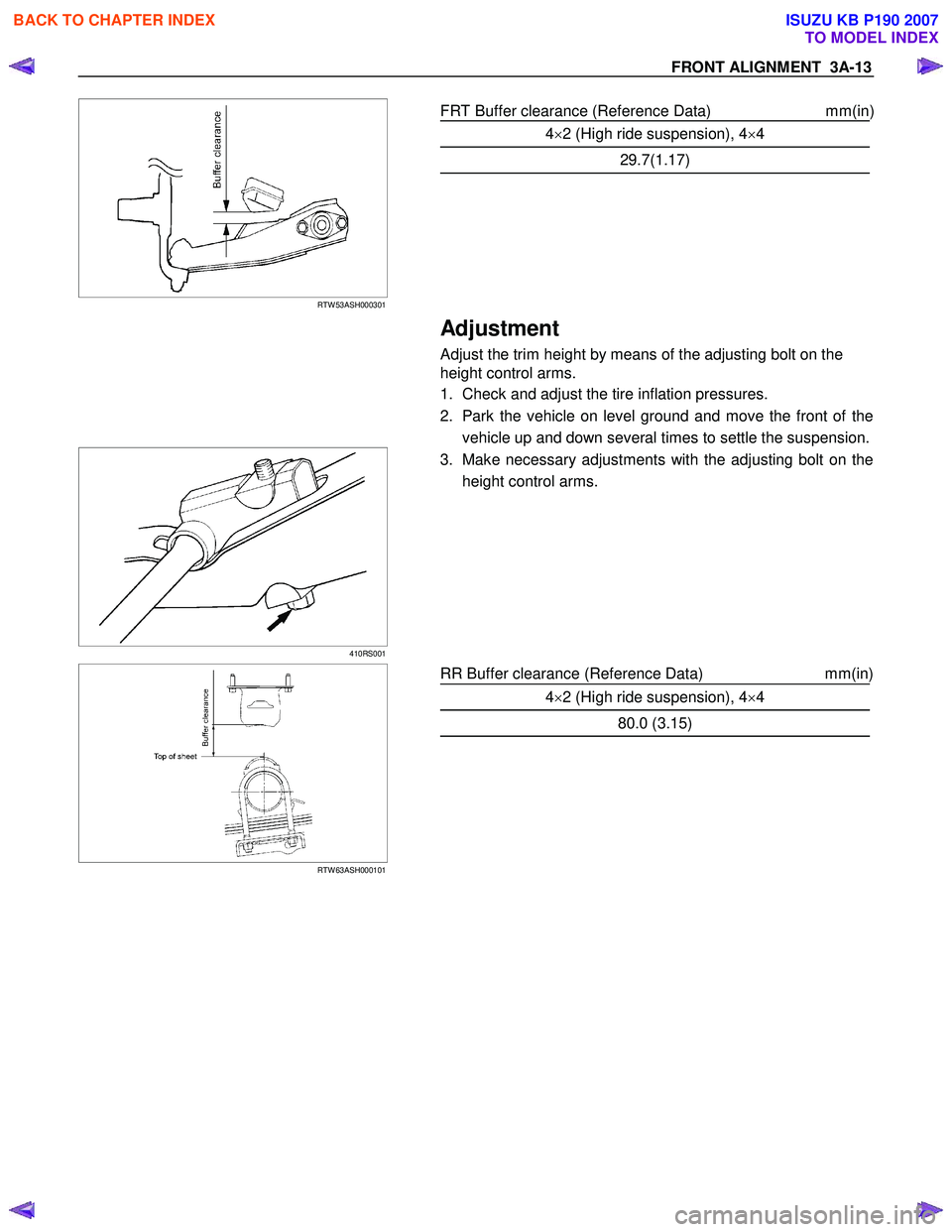

RTW 53ASH000301

FRT Buffer clearance (Reference Data) mm(in)

4×2 (High ride suspension), 4 ×4

29.7(1.17)

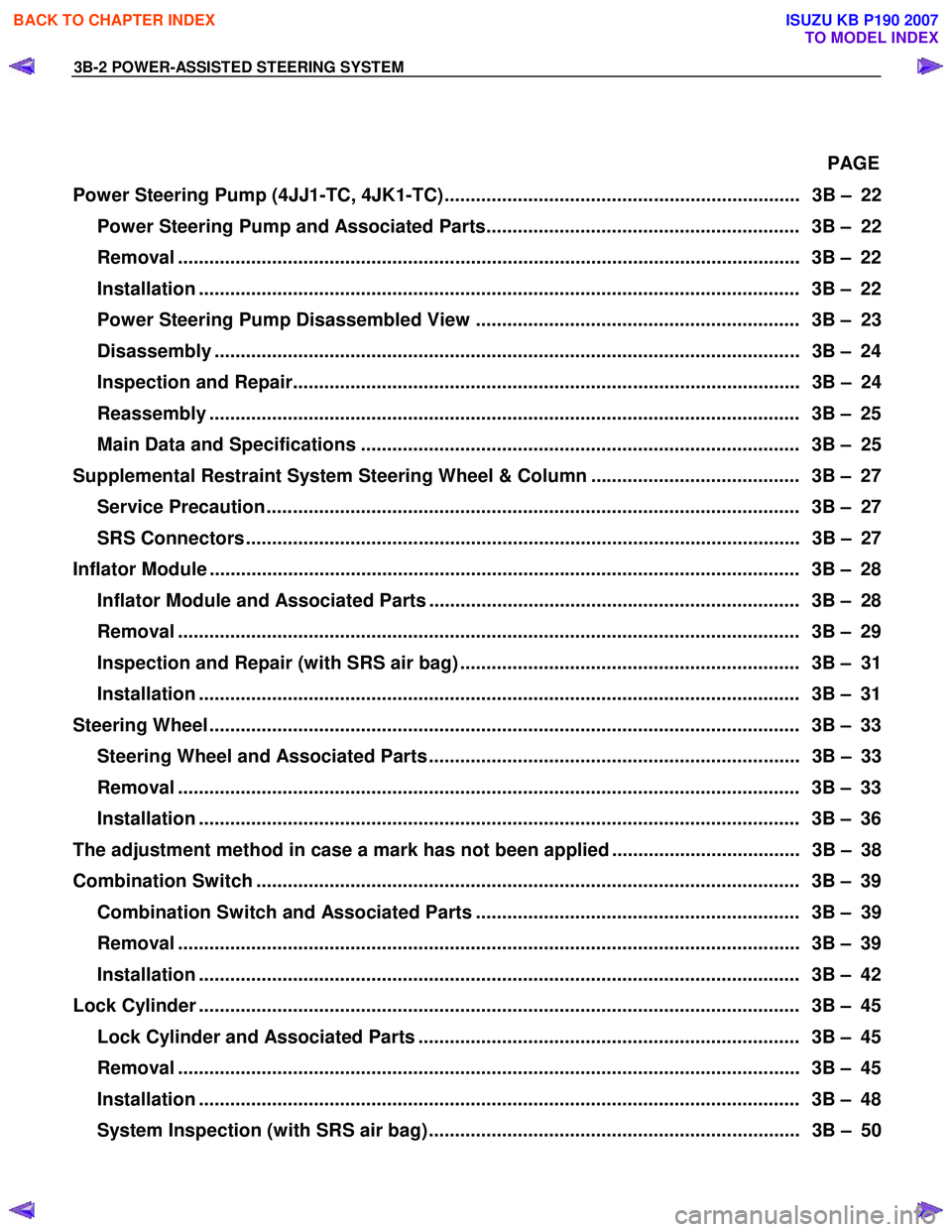

Adjustment

Adjust the trim height by means of the adjusting bolt on the

height control arms.

1. Check and adjust the tire inflation pressures.

2. Park the vehicle on level ground and move the front of the vehicle up and down several times to settle the suspension.

410RS001

3. Make necessary adjustments with the adjusting bolt on the

height control arms.

RTW 63ASH000101

RR Buffer clearance (Reference Data)

mm(in)

4×2 (High ride suspension), 4 ×4

80.0 (3.15)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 262 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-1

SECTION 3B

POWER-ASSISTED STEERING SYSTEM

TABLE OF CONTENTS

PAGE

General Description......................................................................................................... 3B – 4

Power Steering System Test .......................................................................................... 3B – 7

Maintenance .................................................................................................................... . 3B – 8

Fluid Level .................................................................................................................... .... 3B – 8

Bleeding The Power Steering System ........................................................................... 3B – 8

Bleeding Procedure ......................................................................................................... 3B – 8

Flushing The Power Steering System............................................................................ 3B – 8

Steering Wheel Free Play Inspection ............................................................................. 3B – 9

Front End Alignment Inspection and Adjustment......................................................... 3B – 9

Special Tools .................................................................................................................. . 3B – 10

Power Steering Unit......................................................................................................... 3B – 11

Power Steering Unit and Associated Parts............................................................... 3B – 11

Removal ....................................................................................................................... 3B – 11

Installation ................................................................................................................... 3B – 12

Power Steering Unit Disassembled View.................................................................. 3B – 13

Disassembly ................................................................................................................ 3B – 14

Inspection and Repair................................................................................................. 3B – 14

Reassembly ................................................................................................................. 3B – 14

Main Data and Specifications .................................................................................... 3B – 15

Special Tools ............................................................................................................... 3B – 16

Power Steering Pump...................................................................................................... 3B – 17

Power Steering Pump and Associated Parts (4JH1-TC, 4JA1-T) ............................ 3B – 17

Removal ....................................................................................................................... 3B – 17

Installation ................................................................................................................... 3B – 17

Power Steering Pump Disassembled View .............................................................. 3B – 18

Disassembly ................................................................................................................ 3B – 19

Inspection and Repair................................................................................................. 3B – 19

Reassembly ................................................................................................................. 3B – 20

Main Data and Specifications .................................................................................... 3B – 20

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 263 of 6020

3B-2 POWER-ASSISTED STEERING SYSTEM

PAGE

Power Steering Pump (4JJ1-TC, 4JK1-TC) .................................................................... 3B – 22 Power Steering Pump and Associated Parts............................................................ 3B – 22

Removal ....................................................................................................................... 3B – 22

Installation ................................................................................................................... 3B – 22

Power Steering Pump Disassembled View .............................................................. 3B – 23

Disassembly ................................................................................................................ 3B – 24

Inspection and Repair................................................................................................. 3B – 24

Reassembly ................................................................................................................. 3B – 25

Main Data and Specifications .................................................................................... 3B – 25

Supplemental Restraint System Steering Wheel & Column ........................................ 3B – 27 Service Precaution ...................................................................................................... 3B – 2 7

SRS Connectors .......................................................................................................... 3B – 2 7

Inflator Module ................................................................................................................ . 3B – 28

Inflator Module and Associated Parts ....................................................................... 3B – 28

Removal ....................................................................................................................... 3B – 29

Inspection and Repair (with SRS air bag) ................................................................. 3B – 31

Installation ................................................................................................................... 3B – 31

Steering Wheel................................................................................................................. 3B – 33

Steering Wheel and Associated Parts ....................................................................... 3B – 33

Removal ....................................................................................................................... 3B – 33

Installation ................................................................................................................... 3B – 36

The adjustment method in case a mark has not been applied .................................... 3B – 38

Combination Switch ........................................................................................................ 3B – 39

Combination Switch and Associated Parts .............................................................. 3B – 39

Removal ....................................................................................................................... 3B – 39

Installation ................................................................................................................... 3B – 42

Lock Cylinder .................................................................................................................. . 3B – 45

Lock Cylinder and Associated Parts ......................................................................... 3B – 45

Removal ....................................................................................................................... 3B – 45

Installation ................................................................................................................... 3B – 48

System Inspection (with SRS air bag) ....................................................................... 3B – 50

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 264 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-3

PAGE

Steering Column .............................................................................................................. 3 B – 51

Steering Column and Associated Parts .................................................................... 3B – 51

Removal ....................................................................................................................... 3B – 51

Inspection .................................................................................................................... 3B – 54

Installation ................................................................................................................... 3B – 55

System Inspection (with SRS air bag) ....................................................................... 3B – 57

Supplemental Restraint System Steering Wheel & Column and Associated Parts ... 3B – 58 Main Data and Specifications .................................................................................... 3B – 58

Special Tools ............................................................................................................... 3B – 58

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 265 of 6020

3B-4 POWER-ASSISTED STEERING SYSTEM

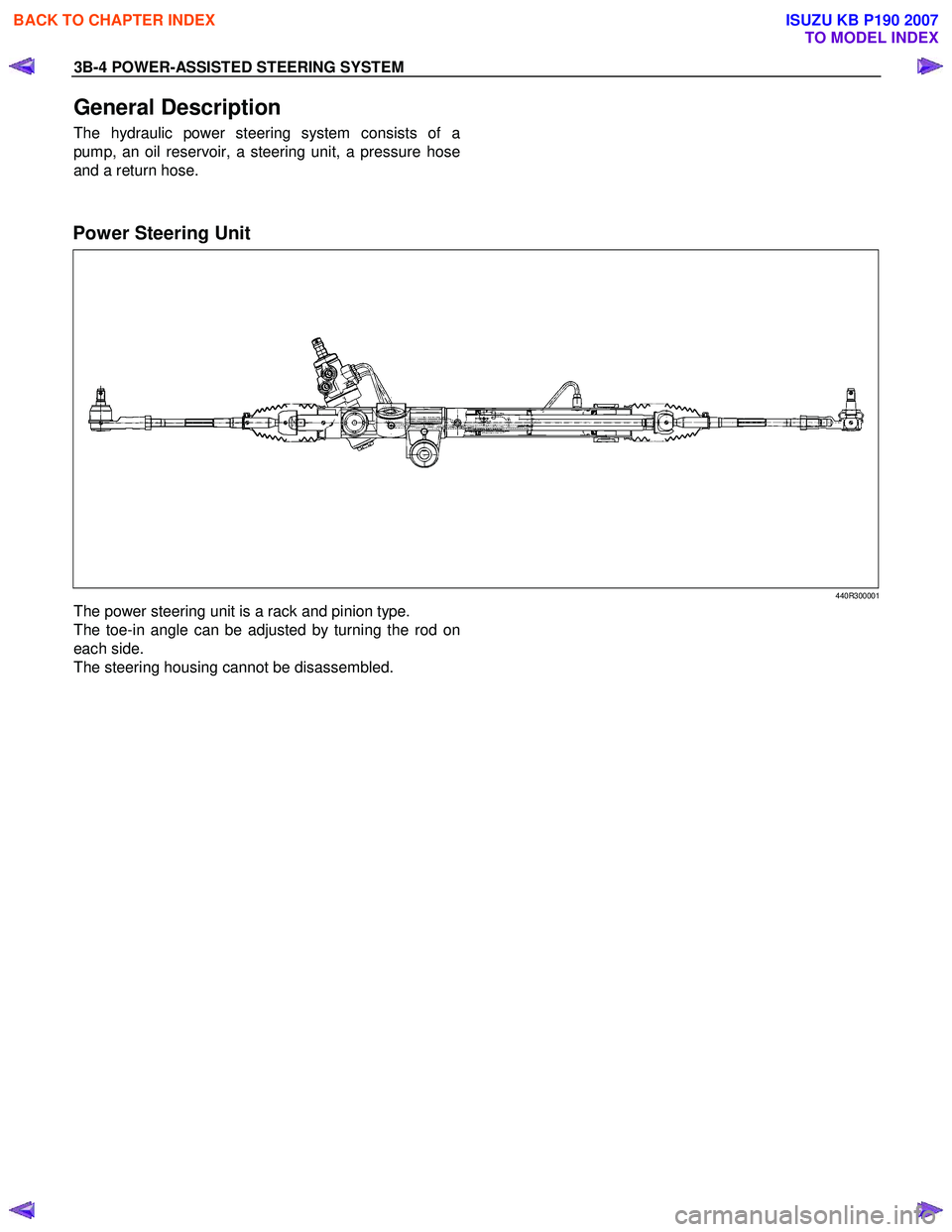

General Description

The hydraulic power steering system consists of a

pump, an oil reservoir, a steering unit, a pressure hose

and a return hose.

Power Steering Unit

440R300001

The power steering unit is a rack and pinion type.

The toe-in angle can be adjusted by turning the rod on

each side.

The steering housing cannot be disassembled.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 266 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-5

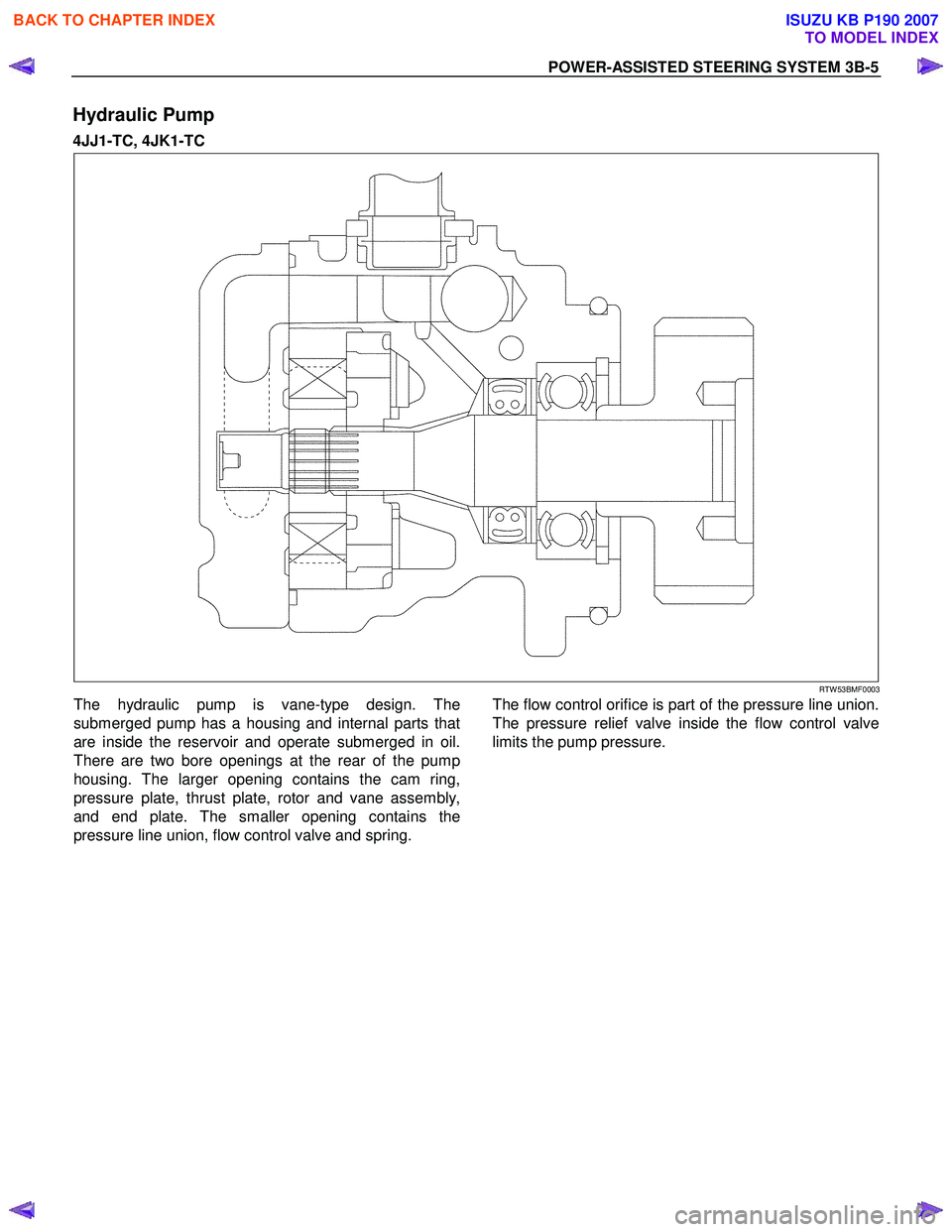

Hydraulic Pump

4JJ1-TC, 4JK1-TC

RTW 53BMF0003

The hydraulic pump is vane-type design. The

submerged pump has a housing and internal parts that

are inside the reservoir and operate submerged in oil.

There are two bore openings at the rear of the pump

housing. The larger opening contains the cam ring,

pressure plate, thrust plate, rotor and vane assembly,

and end plate. The smaller opening contains the

pressure line union, flow control valve and spring.

The flow control orifice is part of the pressure line union.

The pressure relief valve inside the flow control valve

limits the pump pressure.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 267 of 6020

3B-6 POWER-ASSISTED STEERING SYSTEM

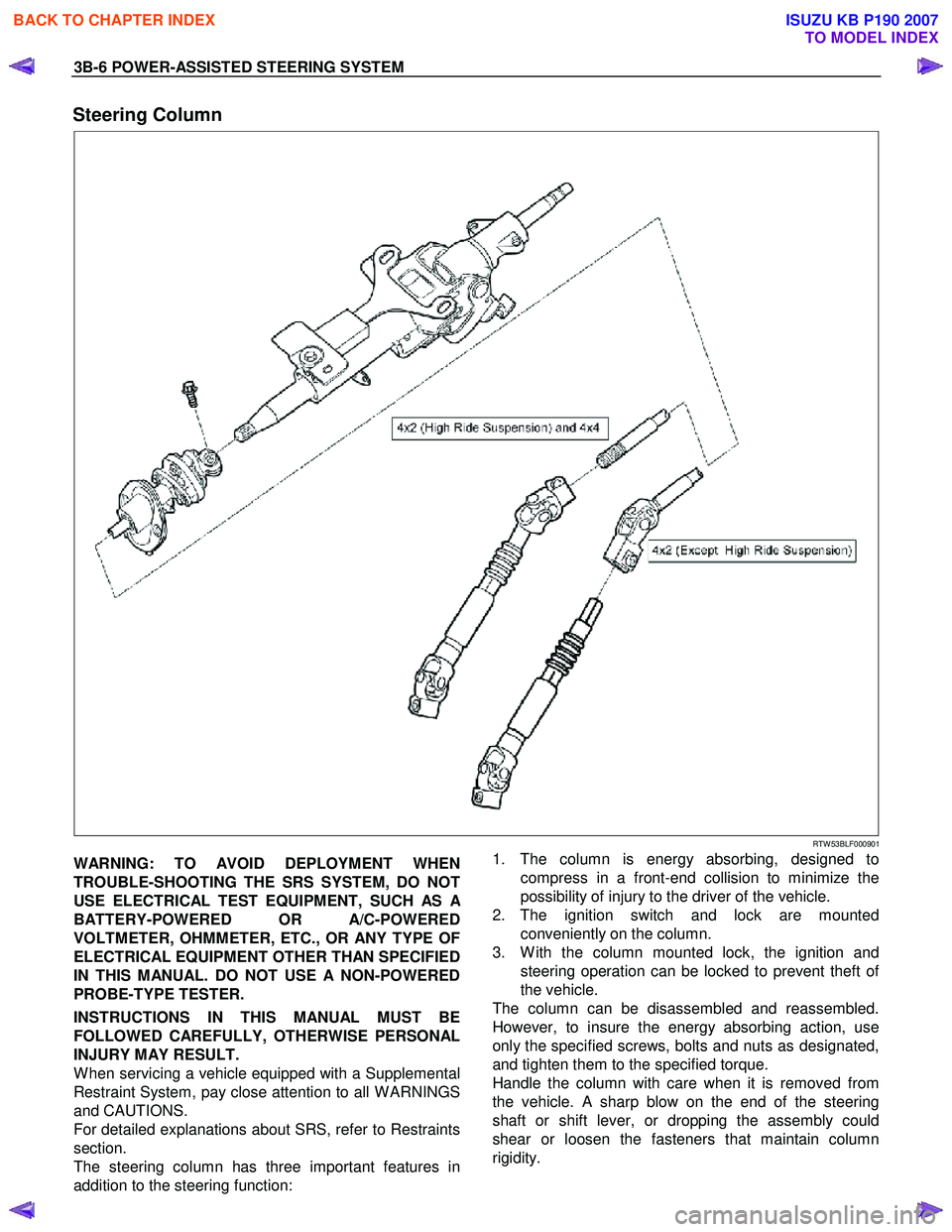

Steering Column

RTW 53BLF000901

WARNING: TO AVOID DEPLOYMENT WHEN

TROUBLE-SHOOTING THE SRS SYSTEM, DO NOT

USE ELECTRICAL TEST EQUIPMENT, SUCH AS

A

BATTERY-POWERED OR A/C-POWERED

VOLTMETER, OHMMETER, ETC., OR ANY TYPE OF

ELECTRICAL EQUIPMENT OTHER THAN SPECIFIED

IN THIS MANUAL. DO NOT USE A NON-POWERED

PROBE-TYPE TESTER.

INSTRUCTIONS IN THIS MANUAL MUST BE

FOLLOWED CAREFULLY, OTHERWISE PERSONAL

INJURY MAY RESULT.

W hen servicing a vehicle equipped with a Supplemental

Restraint System, pay close attention to all W ARNINGS

and CAUTIONS.

For detailed explanations about SRS, refer to Restraints

section.

The steering column has three important features in

addition to the steering function:

1. The column is energy absorbing, designed to

compress in a front-end collision to minimize the

possibility of injury to the driver of the vehicle.

2. The ignition switch and lock are mounted conveniently on the column.

3. W ith the column mounted lock, the ignition and steering operation can be locked to prevent theft o

f

the vehicle.

The column can be disassembled and reassembled.

However, to insure the energy absorbing action, use

only the specified screws, bolts and nuts as designated,

and tighten them to the specified torque.

Handle the column with care when it is removed from

the vehicle. A sharp blow on the end of the steering

shaft or shift lever, or dropping the assembly could

shear or loosen the fasteners that maintain column

rigidity.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 268 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-7

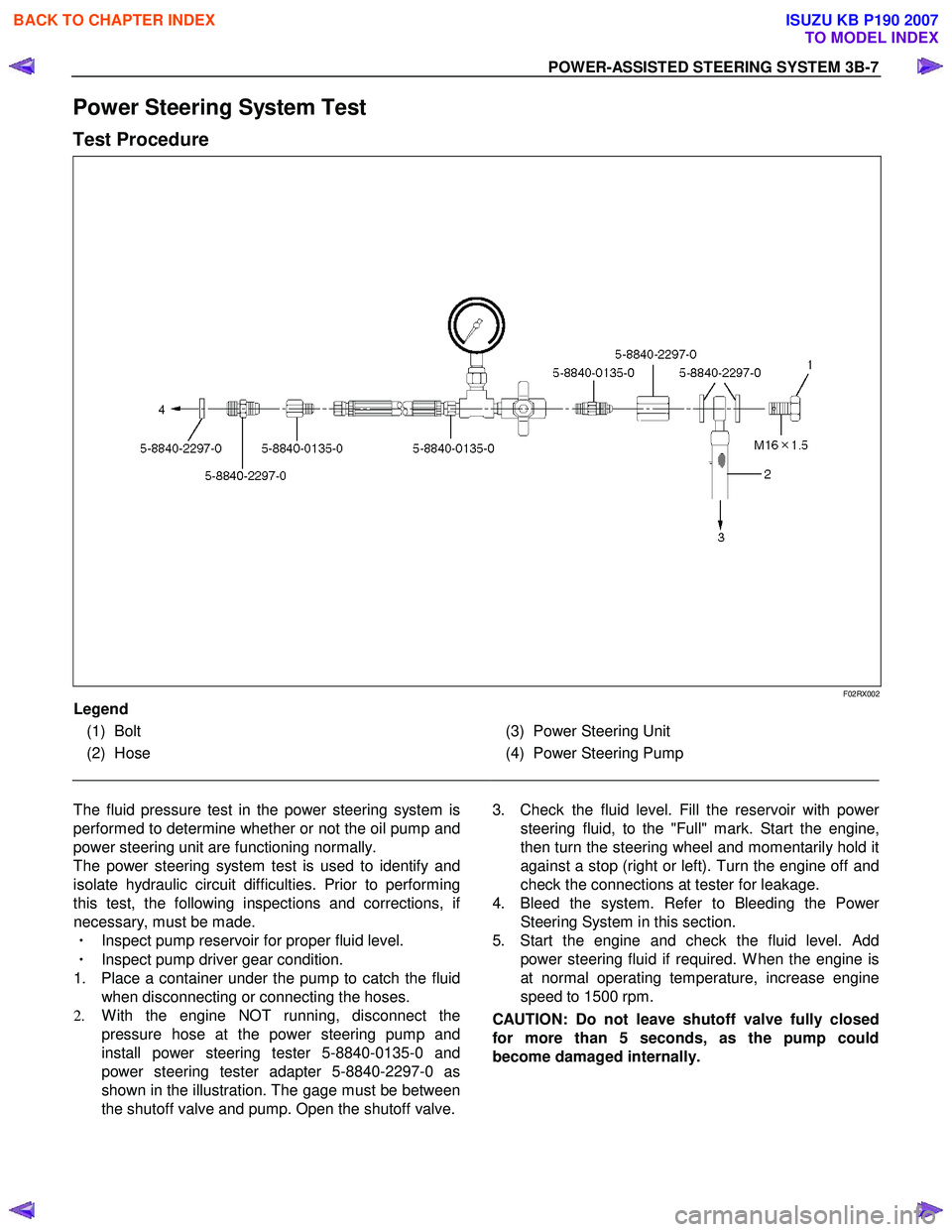

Power Steering System Test

Test Procedure

F02RX002

Legend

(1) Bolt

(2) Hose

(3) Power Steering Unit

(4) Power Steering Pump

The fluid pressure test in the power steering system is

performed to determine whether or not the oil pump and

power steering unit are functioning normally.

The power steering system test is used to identify and

isolate hydraulic circuit difficulties. Prior to performing

this test, the following inspections and corrections, i

f

necessary, must be made.

・ Inspect pump reservoir for proper fluid level.

・ Inspect pump driver gear condition.

1. Place a container under the pump to catch the fluid when disconnecting or connecting the hoses.

2. W ith the engine NOT running, disconnect the

pressure hose at the power steering pump and

install power steering tester 5-8840-0135-0 and

power steering tester adapter 5-8840-2297-0 as

shown in the illustration. The gage must be between

the shutoff valve and pump. Open the shutoff valve.

3. Check the fluid level. Fill the reservoir with powe

r

steering fluid, to the "Full" mark. Start the engine,

then turn the steering wheel and momentarily hold it

against a stop (right or left). Turn the engine off and

check the connections at tester for leakage.

4. Bleed the system. Refer to Bleeding the Powe

r

Steering System in this section.

5. Start the engine and check the fluid level. Add power steering fluid if required. W hen the engine is

at normal operating temperature, increase engine

speed to 1500 rpm.

CAUTION: Do not leave shutoff valve fully closed

for more than 5 seconds, as the pump could

become damaged internally.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 269 of 6020

3B-8 POWER-ASSISTED STEERING SYSTEM

6. Fully close the shutoff valve. Record the highest

pressures.

・ If the pressure recorded is within 9800-10300 kPa

(100-105 kg/cm

2/1422-1493psi), the pump is

functioning within its specifications.

・ If the pressure recorded is higher than 10300 kPa

(105 kg/cm

2/1493psi), the valve in the pump is

defective.

・ If the pressure recorded is lower than 9800 kPa

(100 kg/cm

2/1422psi), the valve or the rotating

assembly in the pump is defective.

7. If the pump pressures are within specifications, leave the valve open and turn (or have someone

else turn) the steering wheel fully in both directions.

Record the highest pressures and compare with the

maximum pump pressure recorded in step 6. If this

pressure cannot be built up at either side of the

power steering unit, the power steering unit is

leaking internally and must be replaced.

8. Shut the engine off, remove the testing gauge.

9. Reconnect the pressure hose, check the fluid level and make the needed repairs.

10. If the problem still exists, the steering and front suspension must be thoroughly examined.

Maintenance

The hydraulic system should be kept clean, the fluid

level in the reservoir should be checked at regula

r

intervals and fluid added when required. Refer to

Recommended Fluids and Lubricants in General

Information section for the type of fluid to be used and

the intervals for filling.

If the system contains some dirt, flush it as described in

this section. If it is exceptionally dirty, the pump must be

completely disassembled before further usage. (The

steering unit cannot be disassembled.)

All tubes, hoses, and fittings should be inspected for

leakage at regular intervals. Fittings must be tight. Make

sure the clips, clamps and supporting tubes and hoses

are in place and properly secured.

Power steering hoses and lines must not be twisted,

kinked or tightly bent. Air in the system will cause

spongy action and noisy operation. W hen a hose is

disconnected or when fluid is lost, for any reason, the

system must be bled after refilling. Refer to Bleeding the

Power Steering System in this section.

・ Inspect gear for looseness or damage.

・ Inspect hoses to insure they are not touching an

y

other parts of the vehicle.

・ Inspect fluid level and fill to the proper level.

Fluid Level

1. Run the engine until the power steering fluid

reaches normal operating temperature, about 55 °

C (130 °F), then shut the engine off.

2. Check the level of fluid in the reservoir.

3. If the fluid level is low, add power steering fluid as

specified in General Information to the proper level

and install the receiver cap.

4. W hen checking the fluid level after the steering system has been serviced, air must be bled from

the system. Refer to Bleeding the Power Steering

System in this section.

Bleeding the Power Steering System

W hen a power steering pump or unit has been installed,

or an oil line has been disconnected, the air that has

entered the system must be bled out before the vehicle

is operated. If air is allowed to remain in the powe

r

steering fluid system, noisy and unsatisfactory operation

of the system may result.

Bleeding Procedure

W hen bleeding the system, and any time fluid is added

to the power steering system, be sure to use only powe

r

steering fluid as specified in General Information.

1. Fill the pump fluid reservoir to the proper level and let the fluid settle for at least two minutes.

2. Start the engine and let it run for a few seconds. Do not turn the steering wheel. Then turn the engine

off.

3. Add fluid if necessary.

4. Repeat the above procedure until the fluid level remains constant after running the engine.

5. Raise and support the front end of the vehicle so that the wheels are off the ground.

6. Start the engine. Slowly turn the steering wheel right and left, lightly contacting the wheel stops.

7. Add power steering fluid if necessary.

8. Lower the vehicle, set the steering wheel at the straight forward position after turning it to its full

steer positions 2 or 3 times, and stop the engine.

9. Check the fluid level and refill as required.

10. If the fluid is extremely foamy, allow the vehicle to settle for a few minutes, then repeat the above

procedure.

Flushing the Power Steering System

1. Raise and support the front end of the vehicle off

the ground until the wheels are free to turn.

2. Remove the fluid return line at the pump inlet connector and plug the connector port on the pump.

Direct the line toward a large container to catch the

draining fluid.

3. W hile running the engine at idle, fill the reservoi

r

with new power steering fluid. Turn the steering

wheel in both directions. Do not contact or hold the

steering wheel to the wheel stops. This will cause

the pump to go to pressure relief mode, which ma

y

cause a sudden fluid overflow at the reservoir.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 270 of 6020

POWER-ASSISTED STEERING SYSTEM 3B-9

4. Install all the lines and hoses. Fill the system with

new power steering fluid and bleed the system as

described in Bleeding the Power Steering System.

Operate the engine for about 15 minutes.

Remove the pump return line at the pump inlet and

plug the connection on the pump. W hile refilling the

reservoir, check the draining fluid for contamination.

If foreign matter is still evident, replace all lines,

disassemble and clean or replace the powe

r

steering system components. Do not re-use any

drained power steering fluid.

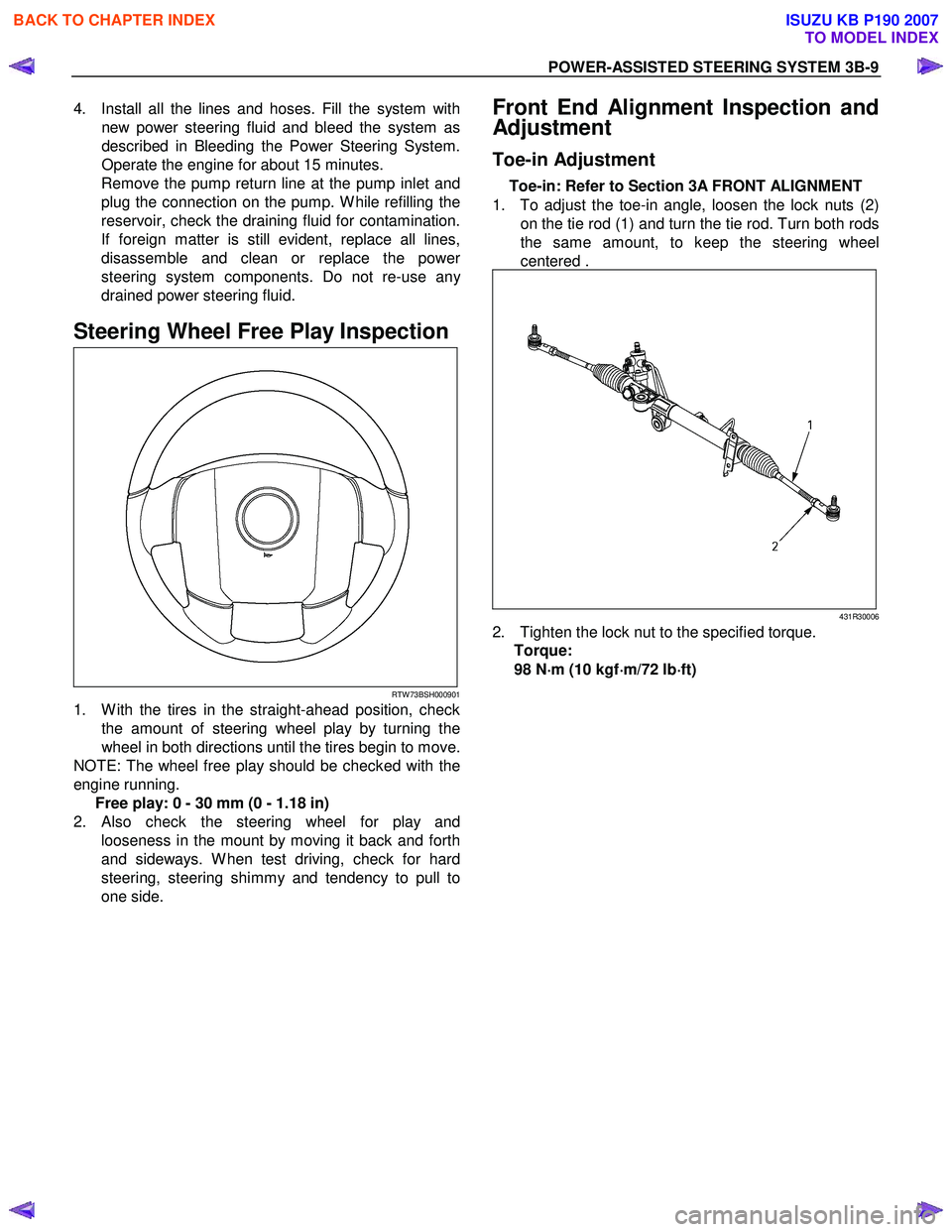

Steering Wheel Free Play Inspection

RTW 73BSH000901

1. W ith the tires in the straight-ahead position, check the amount of steering wheel play by turning the

wheel in both directions until the tires begin to move.

NOTE: The wheel free play should be checked with the

engine running. Free play: 0 - 30 mm (0 - 1.18 in)

2.

Also check the steering wheel for play and

looseness in the mount by moving it back and forth

and sideways. W hen test driving, check for hard

steering, steering shimmy and tendency to pull to

one side.

Front End Alignment Inspection and

Adjustment

Toe-in Adjustment

Toe-in: Refer to Section 3A FRONT ALIGNMENT

1. To adjust the toe-in angle, loosen the lock nuts (2) on the tie rod (1) and turn the tie rod. Turn both rods

the same amount, to keep the steering wheel

centered .

431R30006

2. Tighten the lock nut to the specified torque. Torque:

98 N ⋅

⋅⋅

⋅

m (10 kgf ⋅

⋅⋅

⋅

m/72 lb ⋅

⋅⋅

⋅

ft)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007