ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 751 of 6020

5C-52 BRAKES

BRAKE CONTROL

REMOVAL AND INSTALLATION

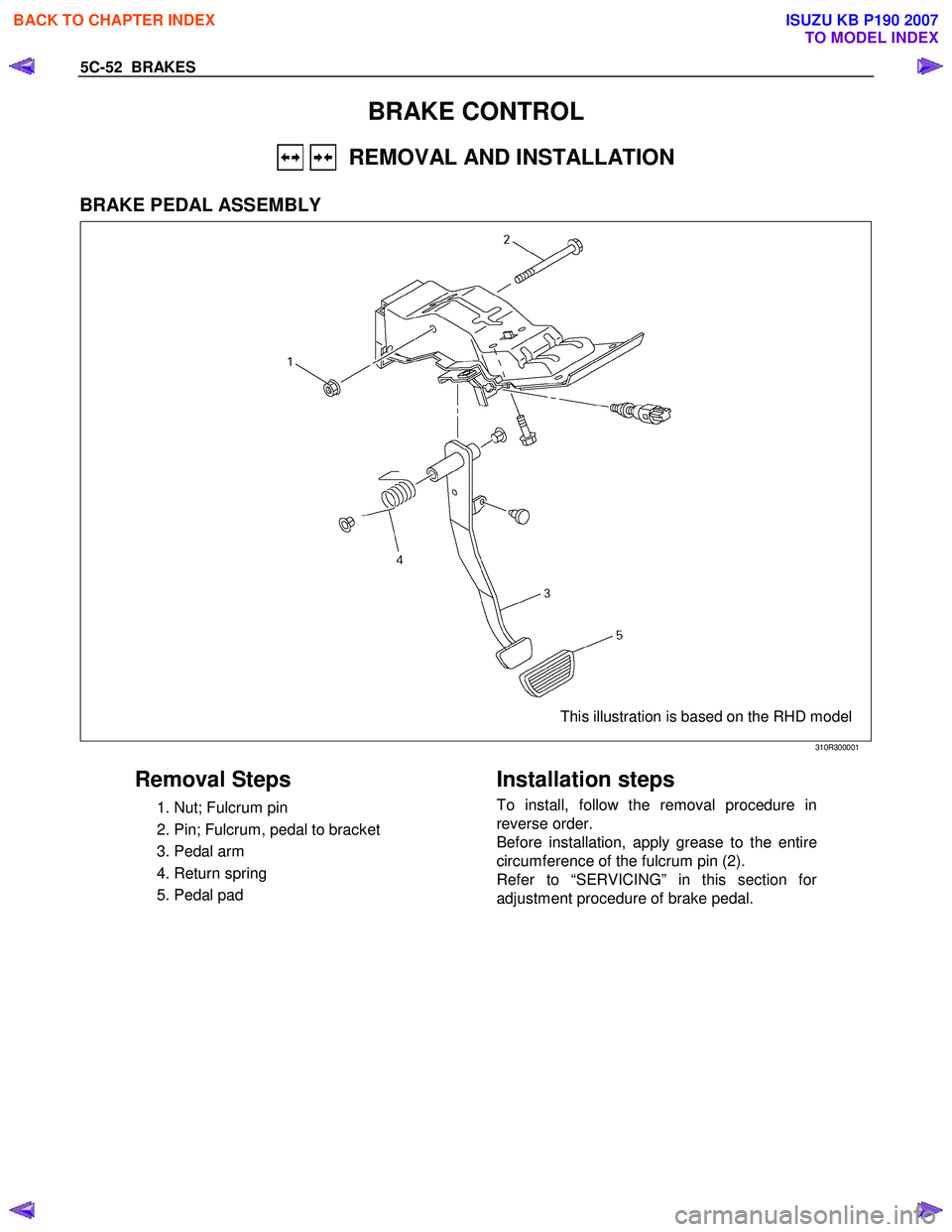

BRAKE PEDAL ASSEMBLY

This illustration is based on the RHD model

310R300001

Removal Steps

1. Nut; Fulcrum pin

2. Pin; Fulcrum, pedal to bracket

3. Pedal arm

4. Return spring

5. Pedal pad

Installation steps

To install, follow the removal procedure in

reverse order.

Before installation, apply grease to the entire

circumference of the fulcrum pin (2).

Refer to “SERVICING” in this section for

adjustment procedure of brake pedal.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 752 of 6020

BRAKES 5C-53

MASTER CYLINDER

REMOVAL AND INSTALLATION

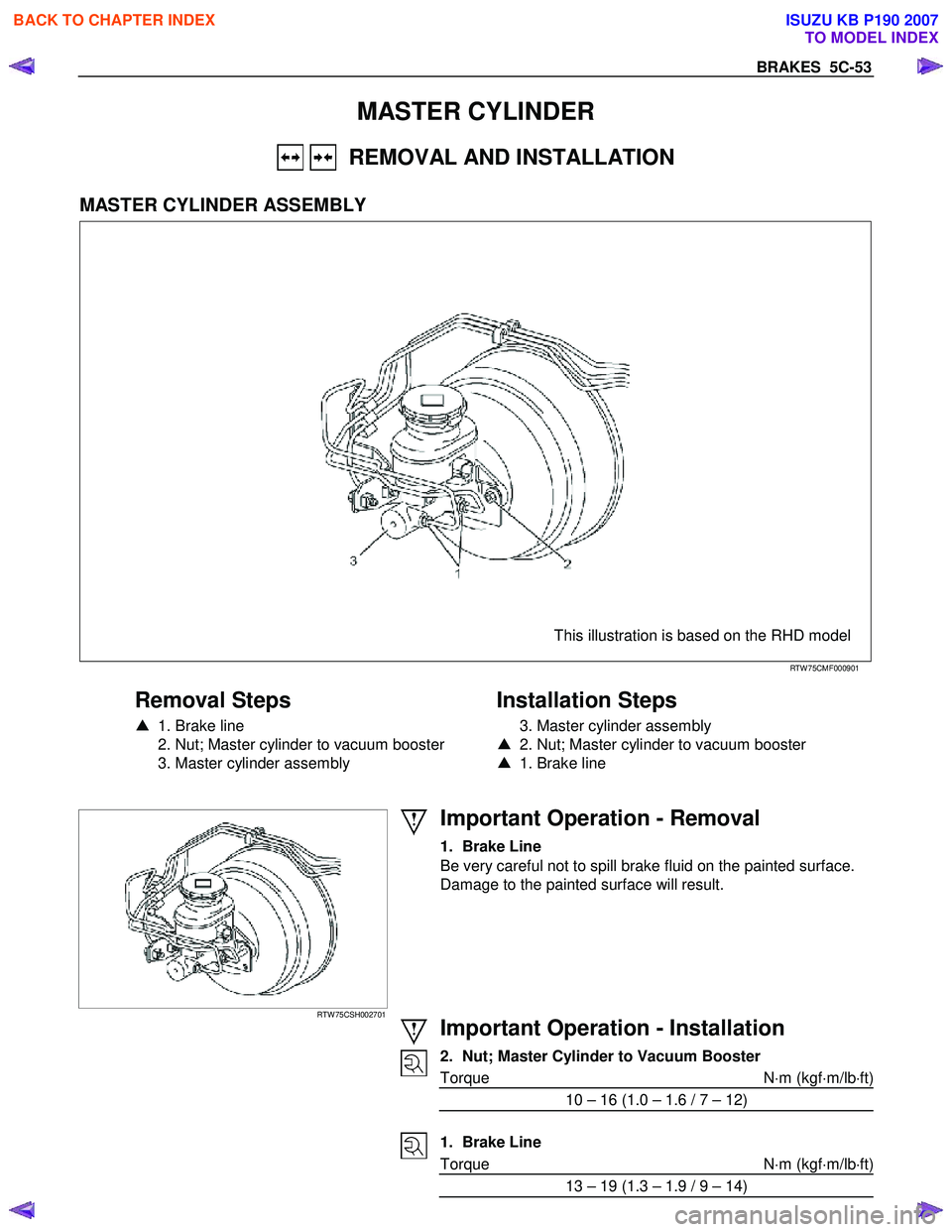

MASTER CYLINDER ASSEMBLY

This illustration is based on the RHD model

RTW 75CMF000901

Removal Steps

▲ 1. Brake line

2. Nut; Master cylinder to vacuum booster

3. Master cylinder assembly

Installation Steps

3. Master cylinder assembly

▲ 2. Nut; Master cylinder to vacuum booster

▲ 1. Brake line

RTW 75CSH002701

Important Operation - Removal

1. Brake Line

Be very careful not to spill brake fluid on the painted surface.

Damage to the painted surface will result.

Important Operation - Installation

2. Nut; Master Cylinder to Vacuum Booster

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

10 – 16 (1.0 – 1.6 / 7 – 12)

1. Brake Line

Torque N ⋅m (kgf ⋅m/lb ⋅ft)

13 – 19 (1.3 – 1.9 / 9 – 14)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 753 of 6020

5C-54 BRAKES

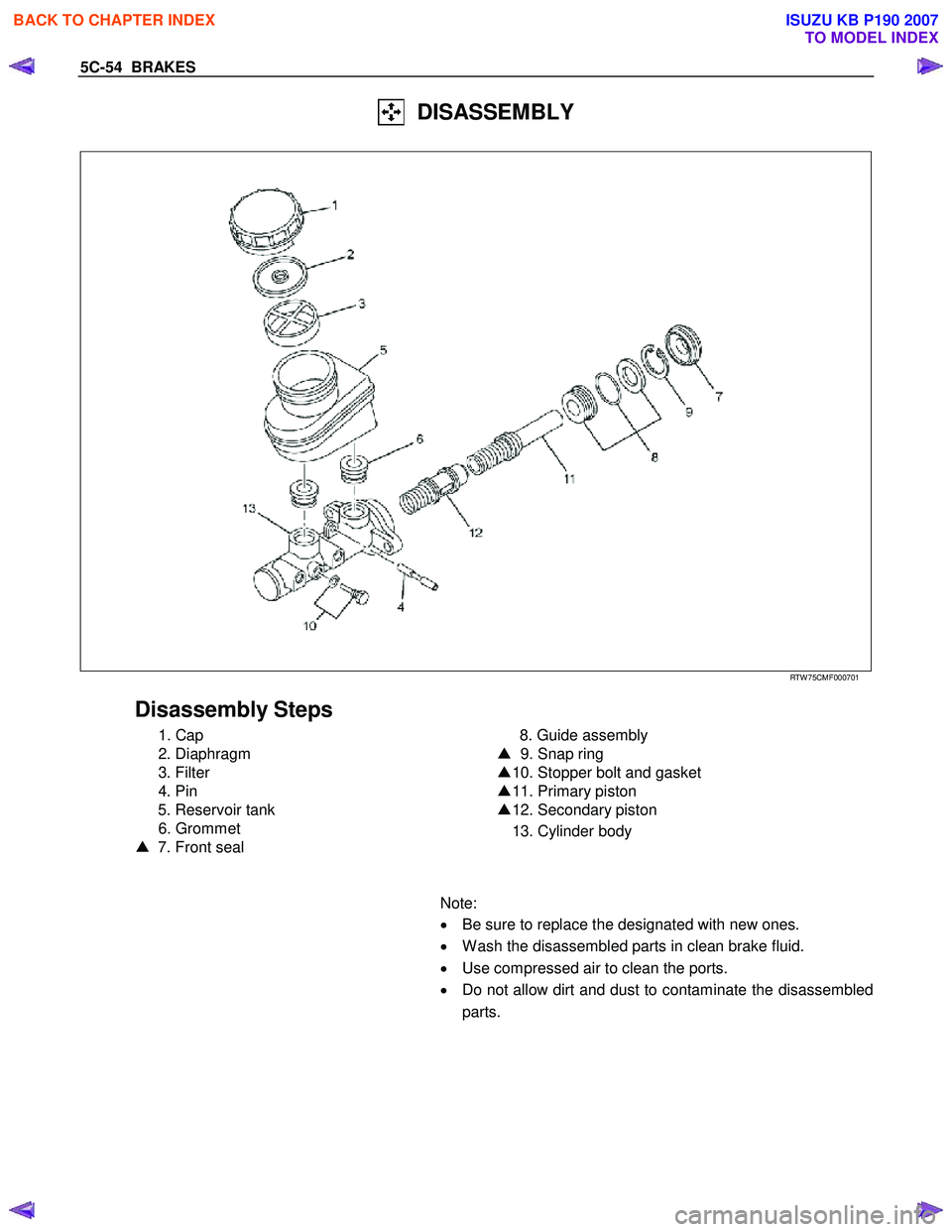

DISASSEMBLY

RTW 75CMF000701

Disassembly Steps

1. Cap

2. Diaphragm

3. Filter

4. Pin

5. Reservoir tank

6. Grommet

▲ 7. Front seal

8. Guide assembly

▲ 9. Snap ring

▲ 10. Stopper bolt and gasket

▲ 11. Primary piston

▲ 12. Secondary piston

13. Cylinder body

Note:

• Be sure to replace the designated with new ones.

• W ash the disassembled parts in clean brake fluid.

• Use compressed air to clean the ports.

• Do not allow dirt and dust to contaminate the disassembled

parts.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 754 of 6020

BRAKES 5C-55

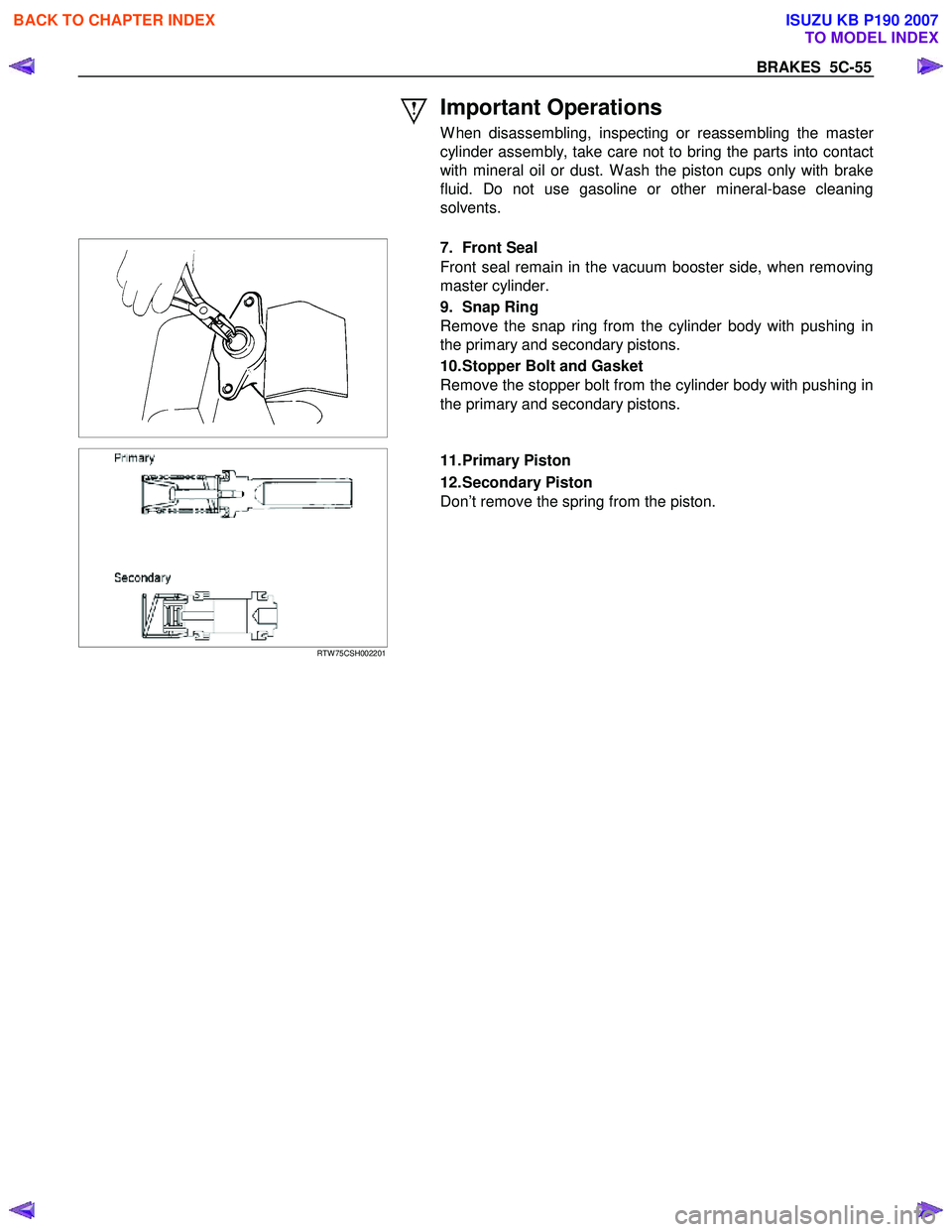

Important Operations

W hen disassembling, inspecting or reassembling the master

cylinder assembly, take care not to bring the parts into contact

with mineral oil or dust. W ash the piston cups only with brake

fluid. Do not use gasoline or other mineral-base cleaning

solvents.

7. Front Seal

Front seal remain in the vacuum booster side, when removing

master cylinder.

9. Snap Ring

Remove the snap ring from the cylinder body with pushing in

the primary and secondary pistons.

10. Stopper Bolt and Gasket

Remove the stopper bolt from the cylinder body with pushing in

the primary and secondary pistons.

RTW 75CSH002201

11. Primary Piston

12. Secondary Piston

Don’t remove the spring from the piston.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 755 of 6020

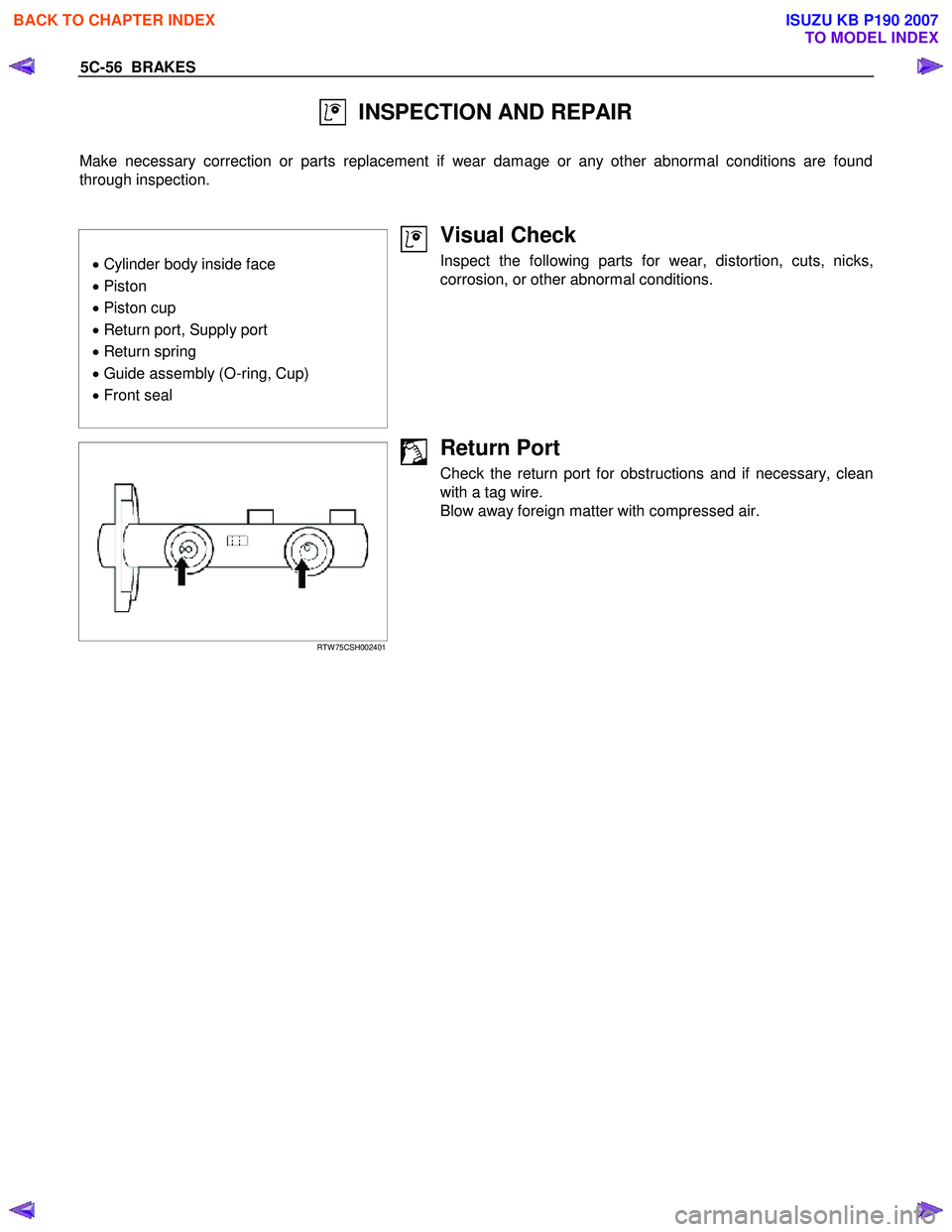

5C-56 BRAKES

INSPECTION AND REPAIR

Make necessary correction or parts replacement if wear damage or any other abnormal conditions are found

through inspection.

• Cylinder body inside face

• Piston

• Piston cup

• Return port, Supply port

• Return spring

• Guide assembly (O-ring, Cup)

• Front seal

Visual Check

Inspect the following parts for wear, distortion, cuts, nicks,

corrosion, or other abnormal conditions.

RTW 75CSH002401

Return Port

Check the return port for obstructions and if necessary, clean

with a tag wire.

Blow away foreign matter with compressed air.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 756 of 6020

BRAKES 5C-57

REASSEMBLY

RTW 75CMF000801

Reassembly Steps

▲ 1. Secondary piston

▲ 2. Primary piston

▲ 3. Guide assembly

▲ 4. Cylinder body

▲ 5. Stopper bolt and gasket

▲ 6. Snap ring

▲ 7. Grommet

▲

8. Reservoir tank

▲ 9. Pin

▲ 10. Filter

▲ 11. Diaphragm

▲ 12. Cap

▲ 13. Front seal

1. Secondary Piston

Lubricate the piston cups on the secondary piston assemblies

with brake fluid.

Note:

Be sure to use a new piston.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 757 of 6020

5C-58 BRAKES

RTW 75CSH002301

2. Primary Piston

Lubricate the piston cup on the primary piston assemblies with

brake fluid (1).

Note:

Be sure to use a new piston.

3. Guide Assembly

Lubricate the O-ring of guide assembly with brake fluid (2) and

the cup of guide assembly with rubber grease (3) (0.2 ~ 0.3g).

RTW 75CSH002001

4. Cylinder Body

Install the secondary piston and the primary piston to the

cylinder body.

Note:

The secondary piston long hole and the cylinder body stoppe

r

bolt hole must be aligned at installation.

5. Stopper Bolt and Gasket

Install the stopper bolt to the cylinder body (the piston long hole

must be aligned with the cylinder body installation hole).

Tighten the bolts to the specified torque.

Torque N ⋅m (kgf ⋅m/lb ⋅in)

2 - 3 (0.2 - 0.3 / 17 - 26)

6. Snap Ring

Press down on the primary piston and install the snap ring to

the cylinder body groove.

Note:

Be sure to use new snap ring.

7. Grommet

1. Install the grommets to the reservoir tank.

Note:

Be sure to use are new grommets.

2. Install the reservoir tank to the cylinder body.

8. Reservoir Tank

9. Pin

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 758 of 6020

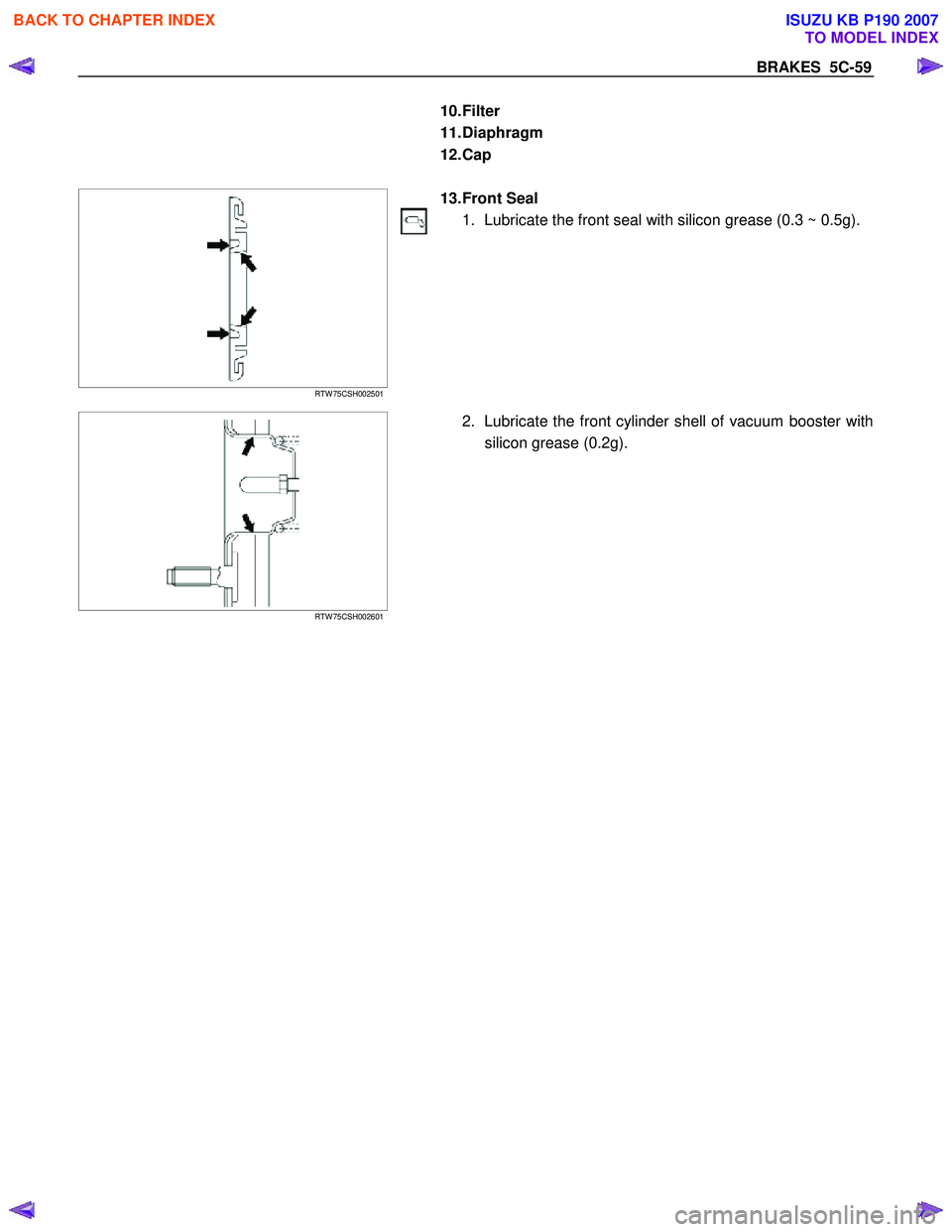

BRAKES 5C-59

10. Filter

11. Diaphragm

12. Cap

RTW 75CSH002501

13. Front Seal

1. Lubricate the front seal with silicon grease (0.3 ~ 0.5g).

RTW 75CSH002601

2. Lubricate the front cylinder shell of vacuum booster with

silicon grease (0.2g).

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 759 of 6020

5C-60 BRAKES

VACUUM BOOSTER

REMOVAL AND INSTALLATION

This illustration is based on the RHD model

RTW 75CMF000501

Removal Steps

▲ 1. Brake pipe

▲ 2. Master cylinder fixing nut

▲ 3. Bracket

▲ 4. Master cylinder assembly

5. Vacuum hose

6. Snap pin

7. Vacuum booster fixing nut

8. Gasket

9. Spacer

10. Vacuum booster assembly

Installation Steps

▲

10. Vacuum booster assembly

▲ 9. Spacer

▲ 8. Gasket

▲ 7. Vacuum booster fixing nut

▲ 6. Snap pin

▲ 5. Vacuum hose

4. Master cylinder assembly

3. Bracket

2. Master cylinder fixing nut

1. Brake pipe

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 760 of 6020

BRAKES 5C-61

RTW 75CSH002701

Important Operation-Removal

1. Brake pipe

W hen hurdling, be careful not to spill brake fluid over the

painted surfaces, as damage to the paint finish will result.

2. Master Cylinder Fixing Nut

3. Bracket

4. Master Cylinder Assembly

NOTE:

W hen removing the master cylinder from the vacuum booster,

be sure to get rid of the internal negative pressure of the

vacuum booster (by, for instance, disconnecting the vacuum

hose) in advance.

If any negative pressure remains in the vacuum booster, the

piston may possibly come out when the master cylinder is

being removed, letting the brake fluid run out.

W hile removing the master cylinder, do not hold the piston as it

can be easily pulled out.

Inspection and Repair

Vacuum Hose (The built in check valve)

360R300002

1) Inspect the check valve, which is installed inside the

vacuum hose.

2) Blow air into the hose from the booster side as shown in the illustration. The air should pass freely through the

hose.

3) Blow air into the hose from the engine side. The check valve should close to block the passage of air.

The vacuum hose and built-in check valve must be

replaced as a set if either is found to be defective.

Important Operation-Installation

10. Vacuum Booster Assembly

Note:

•

Adjustment of push rod of vacuum booster is not carried

out. W hen vacuum booster is damaged it exchanges for a

new article. (Push rod is adjusted)

• Measurement of primary piston position by the side o

f

master cylinder is unnecessary.

9. Spacer

8. Gasket

7. Vacuum Booster Fixing Nut

6. Snap Pin

Install the vacuum booster assembly to the dash panel and

pedal mounting bracket.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007