ISUZU KB P190 2007 Workshop Manual PDF

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 71 of 6020

HEATER AND AIR CONDITIONING 1-37

refrigerant container.

1) Make sure the evacuation process is correctly completed.

2) Connect the center-hose of the manifold gauge to the refrigerant container. •

••

•

Turn the charge valve handle counterclockwise to purge

to the charging line and purge any air exiting in the

center-hose of the manifold gauge.

3) Open the low-pressure hand valve and charge the refrigerant about 200 g (0.44 lbs.). •

••

•

Make sure the high-pressure hand valve is closed.

•

••

•

Avoid charging the refrigerant by turning the refrigerant

container upside down.

4) Close the low-pressure hand valve of the manifold gauge. •

••

•

Check to ensure that the degree of pressure does not

change.

5) Check the refrigerant leaks by using a HFC-134a leak detector. •

••

•

If a leak occurs, repair the leak connection, and start all

over again from the first step of evacuation.

6) If no leaks are found, open the low-pressure hand valve of the manifold gauge. Then continue charging refrigerant to

the system. •

••

•

W hen charging the system becomes difficult:

(1) Run the engine at Idling and close the all vehicle doors.

(2) A/C switch is "ON".

(3) Set the fan control knob (fan switch) to its highest position.

(4) Set air source selector lever to “RECIRC”

WARNING

BE ABSOLUTELY SURE NOT TO OPEN THE HIGH-

PRESSURE HAND VALVE. SHOULD THE HIGH-

PRESSURE HAND VALVE BE OPENED, THE HIGH-

PRESSURE REFRIGERANT GAS WOULD FLOW

BACKWARD, AND THIS MAY CAUSE THE REFRIGERANT

CONTAINER TO BURST.

7) W hen the refrigerant container is emptied, use the following procedure to replace it with a new refrigerant container.

(1) Close the low-pressure hand valve.

(2) Raise the needle upward and remove the charge valve.

(3) Reinstall the charge valve to the new refrigerant container.

(4) Purge any air existing in the center hose of the manifold gauge.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 72 of 6020

1-38 HEATER AND AIR CONDITIONING

8) Charge the system to the specified amount and then close the low-pressure hand valve.

Refrigerant Amount g(lbs)

4JA1-T, 4JH1-TC, C24SE 720 (1.59)

4JJ1-TC (Standard Output)

4JJ1-TC (High Output)

4JK1-TC (High Output)

650 (1.43)

9) Check for refrigerant leaks by using a HFC-134a leak detector.

• A fully charged system is indicated by the sight glass on

the receiver/drier being free of any bubbles (Refer to

"Reading Sight Glass").

• Check the high and low pressure value of the manifold

gauge. (Refer to “CHECKING REFRIGERANT SYSTEM

W ITH MAINFOLD GAUGE” in SERVICE

INFORMATION.)

Immediately after charging refrigerant, both high and low

pressures are slightly high and to the left of the gauge, but they

settle down to the guide pressure valves as shown below:

• Ambient temperature; 30 ∼35 °C (86 ∼95 °F)

• Guide pressure

High-pressure side;

Approx. 1373 ∼1670 kPa (14 ∼17 kg/cm

2 / 199 ∼242 psi)

Low-pressure side;

Approx. 127 ∼245 kPa (1.3 ∼2.5 kg/cm

2 / 18 ∼36 psi)

10) Close the low pressure hand valve and charge valve of the refrigerant container.

11) Stop the air conditioning and the engine.

12) Disconnect the high and low pressure hoses from the manifold gauge fittings.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 73 of 6020

HEATER AND AIR CONDITIONING 1-39

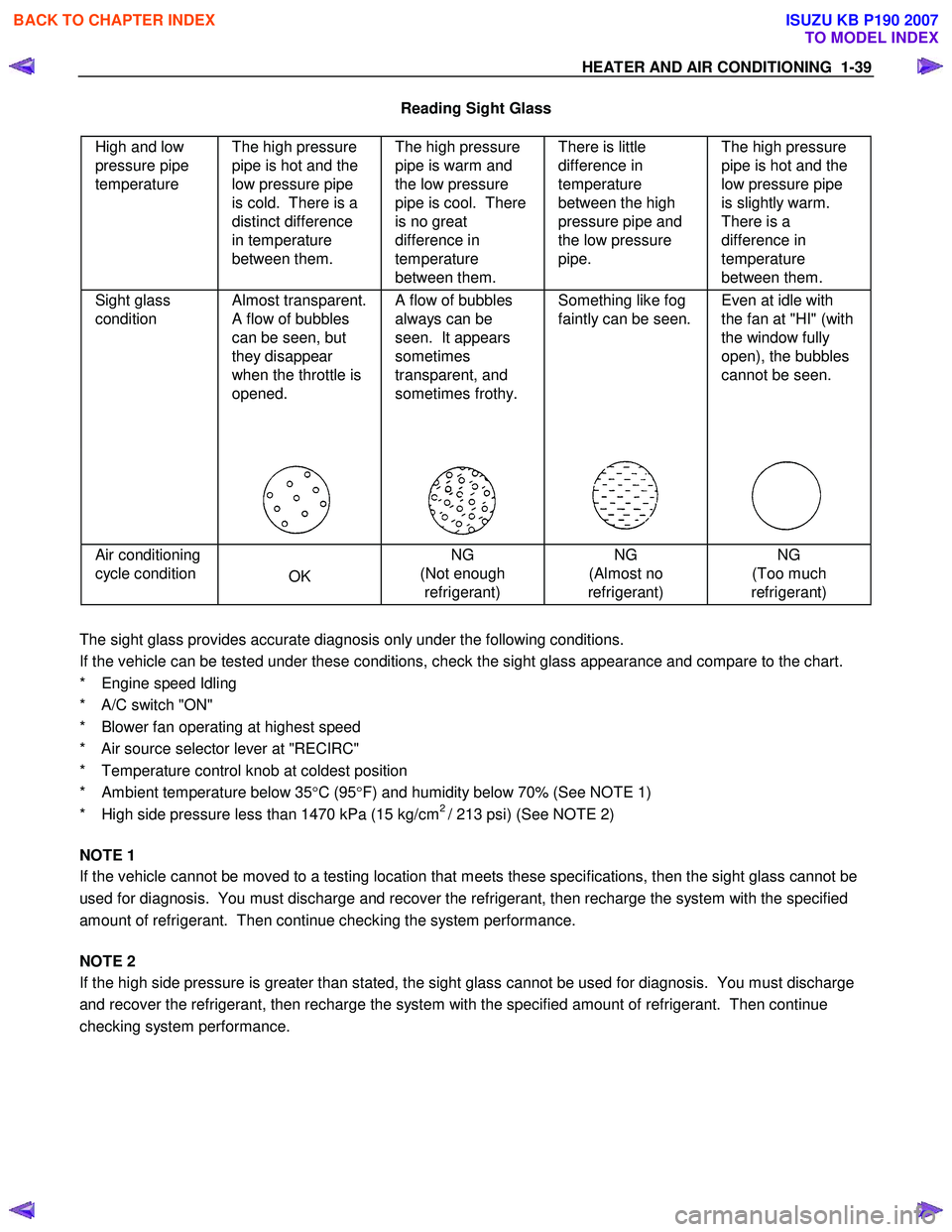

Reading Sight Glass

High and low

pressure pipe

temperature The high pressure

pipe is hot and the

low pressure pipe

is cold. There is a

distinct difference

in temperature

between them. The high pressure

pipe is warm and

the low pressure

pipe is cool. There

is no great

difference in

temperature

between them. There is little

difference in

temperature

between the high

pressure pipe and

the low pressure

pipe. The high pressure

pipe is hot and the

low pressure pipe

is slightly warm.

There is a

difference in

temperature

between them.

Sight glass

condition Almost transparent.

A flow of bubbles

can be seen, but

they disappear

when the throttle is

opened.

A flow of bubbles

always can be

seen. It appears

sometimes

transparent, and

sometimes frothy.

Something like fog

faintly can be seen.

Even at idle with

the fan at "HI" (with

the window fully

open), the bubbles

cannot be seen.

Air conditioning

cycle condition

OK NG

(Not enough refrigerant) NG

(Almost no

refrigerant) NG

(Too much

refrigerant)

The sight glass provides accurate diagnosis only under the following conditions.

If the vehicle can be tested under these conditions, check the sight glass appearance and compare to the chart.

* Engine speed Idling

* A/C switch "ON"

* Blower fan operating at highest speed

* Air source selector lever at "RECIRC"

* Temperature control knob at coldest position

* Ambient temperature below 35 °C (95 °F) and humidity below 70% (See NOTE 1)

* High side pressure less than 1470 kPa (15 kg/cm

2 / 213 psi) (See NOTE 2)

NOTE 1

If the vehicle cannot be moved to a testing location that meets these specifications, then the sight glass cannot be

used for diagnosis. You must discharge and recover the refrigerant, then recharge the system with the specified

amount of refrigerant. Then continue checking the system performance.

NOTE 2

If the high side pressure is greater than stated, the sight glass cannot be used for diagnosis. You must discharge

and recover the refrigerant, then recharge the system with the specified amount of refrigerant. Then continue

checking system performance.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 74 of 6020

1-40 HEATER AND AIR CONDITIONING

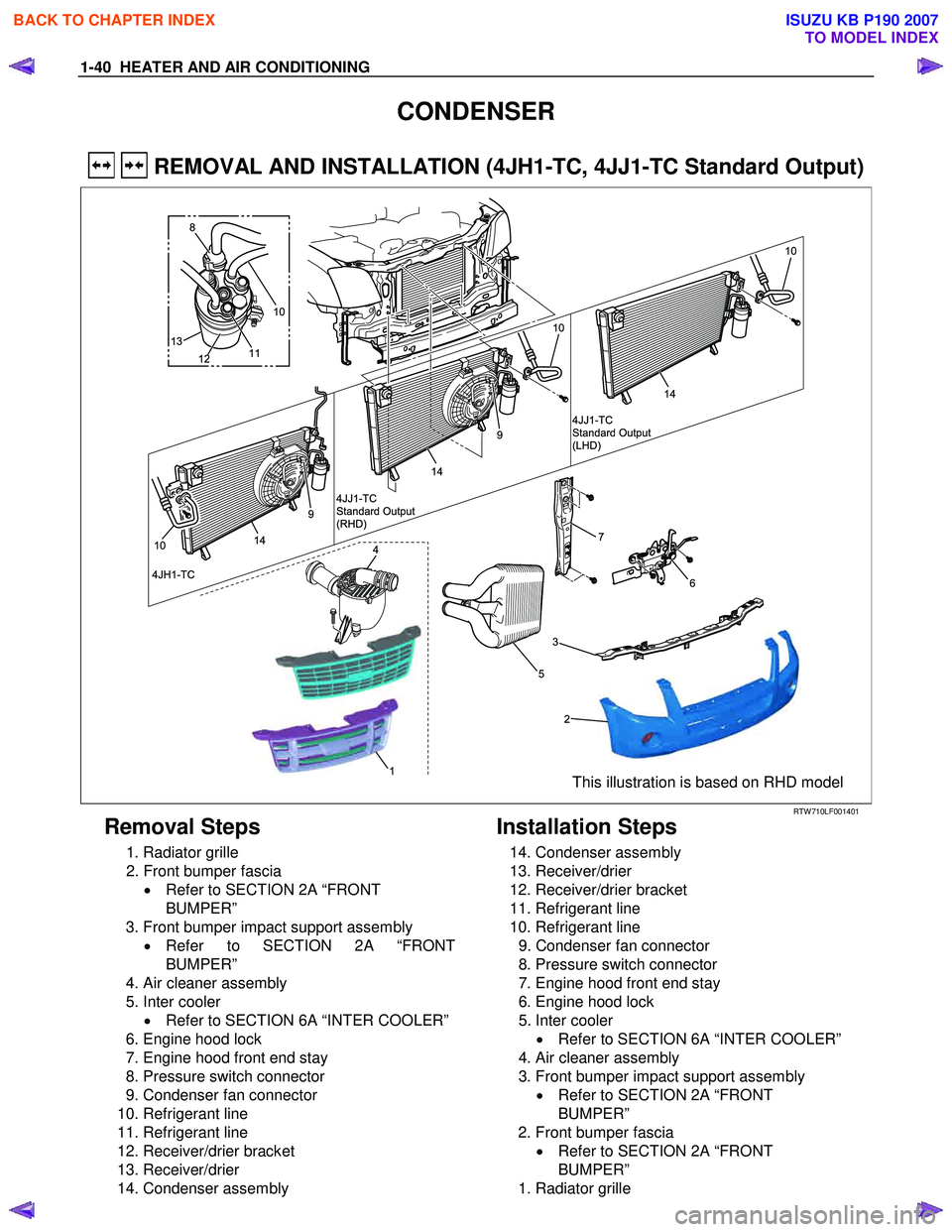

CONDENSER

REMOVAL AND INSTALLATION (4JH1-TC, 4JJ1-TC Standard Output)

13

12

8

10

11

14

10

9

6

7

5

2

3

1

41410

4JH1-TC 4JJ1-TC

Standard Output

(RHD)

14

10

4JJ1-TC

Standard Output

(LHD)

9

This illustration is based on RHD model

RTW 710LF001401

Removal Steps

1. Radiator grille

2. Front bumper fascia • Refer to SECTION 2A “FRONT

BUMPER”

3. Front bumper impact support assembly • Refer to SECTION 2A “FRONT

BUMPER”

4. Air cleaner assembly

5. Inter cooler • Refer to SECTION 6A “INTER COOLER”

6. Engine hood lock

7. Engine hood front end stay

8. Pressure switch connector

9. Condenser fan connector

10. Refrigerant line

11. Refrigerant line

12. Receiver/drier bracket

13. Receiver/drier

14. Condenser assembly

Installation Steps

14. Condenser assembly

13. Receiver/drier

12. Receiver/drier bracket

11. Refrigerant line

10. Refrigerant line

9. Condenser fan connector

8. Pressure switch connector

7. Engine hood front end stay

6. Engine hood lock

5. Inter cooler • Refer to SECTION 6A “INTER COOLER”

4. Air cleaner assembly

3. Front bumper impact support assembly • Refer to SECTION 2A “FRONT

BUMPER”

2. Front bumper fascia • Refer to SECTION 2A “FRONT

BUMPER”

1. Radiator grille

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 75 of 6020

HEATER AND AIR CONDITIONING 1-41

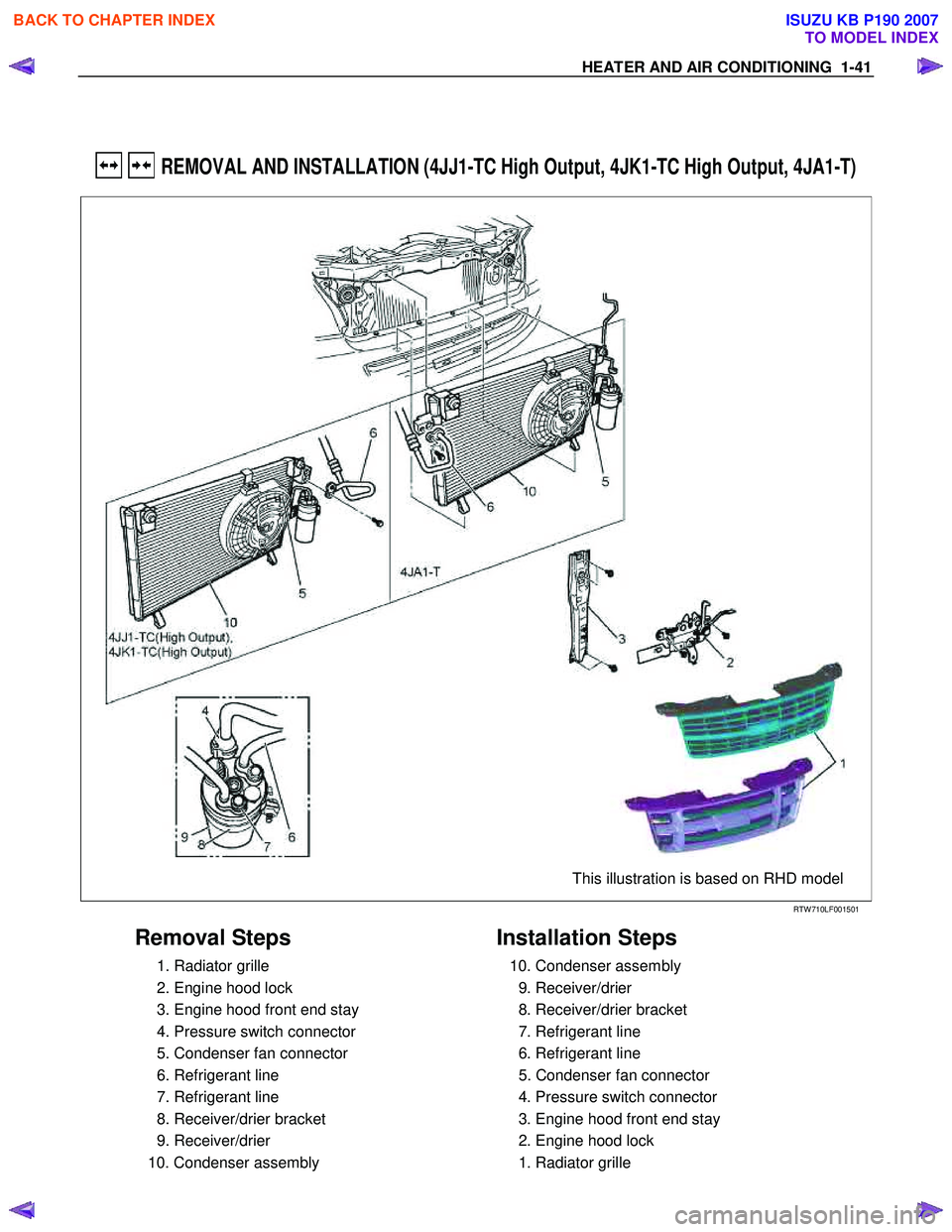

REMOVAL AND INSTALLATION (4JJ1-TC High Output, 4JK1-TC High Output, 4JA1-T)

This illustration is based on RHD model

RTW 710LF001501

Removal Steps

1. Radiator grille

2. Engine hood lock

3. Engine hood front end stay

4. Pressure switch connector

5. Condenser fan connector

6. Refrigerant line

7. Refrigerant line

8. Receiver/drier bracket

9. Receiver/drier

10. Condenser assembly

Installation Steps

10. Condenser assembly

9. Receiver/drier

8. Receiver/drier bracket

7. Refrigerant line

6. Refrigerant line

5. Condenser fan connector

4. Pressure switch connector

3. Engine hood front end stay

2. Engine hood lock

1. Radiator grille

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 76 of 6020

1-42 HEATER AND AIR CONDITIONING

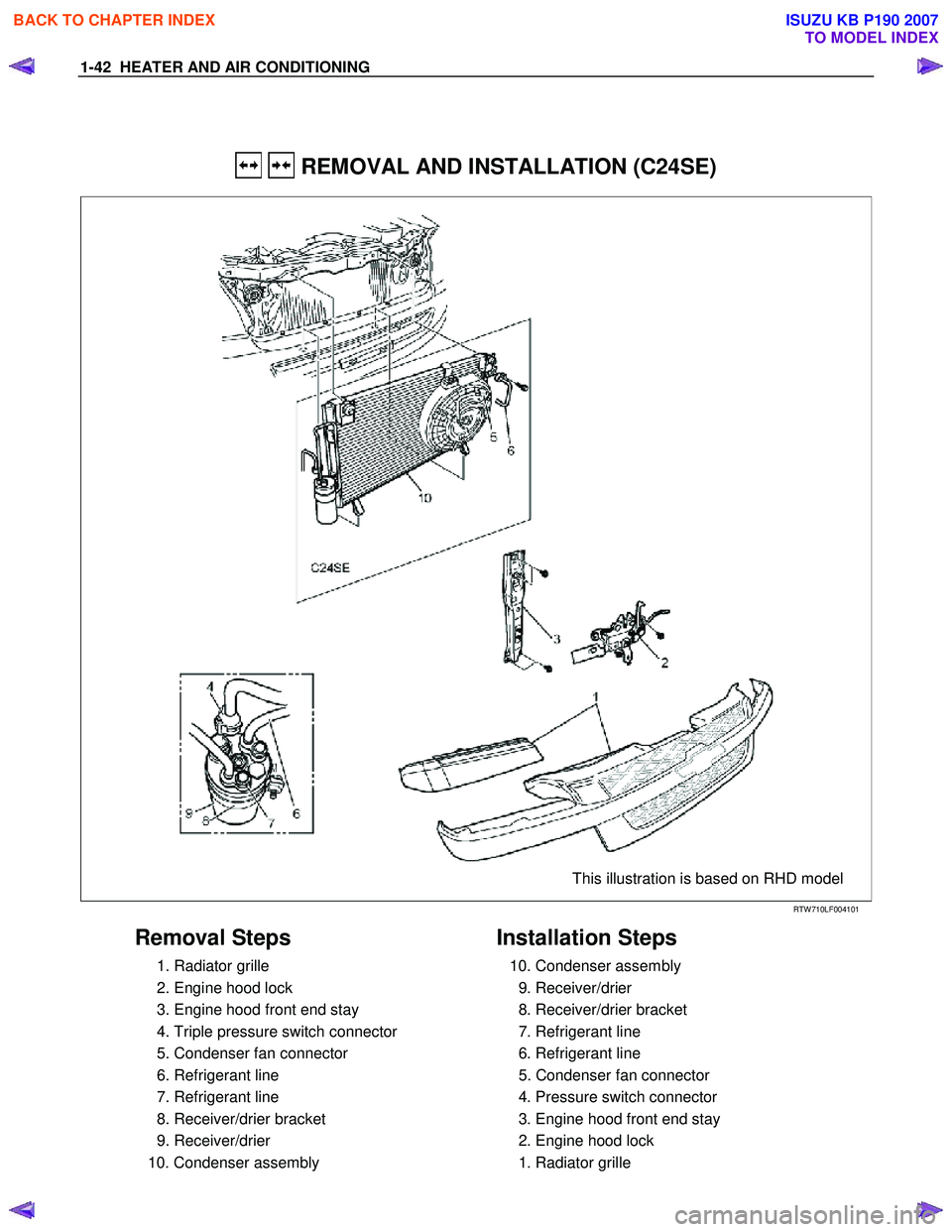

REMOVAL AND INSTALLATION (C24SE)

This illustration is based on RHD model

RTW 710LF004101

Removal Steps

1. Radiator grille

2. Engine hood lock

3. Engine hood front end stay

4. Triple pressure switch connector

5. Condenser fan connector

6. Refrigerant line

7. Refrigerant line

8. Receiver/drier bracket

9. Receiver/drier

10. Condenser assembly

Installation Steps

10. Condenser assembly

9. Receiver/drier

8. Receiver/drier bracket

7. Refrigerant line

6. Refrigerant line

5. Condenser fan connector

4. Pressure switch connector

3. Engine hood front end stay

2. Engine hood lock

1. Radiator grille

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 77 of 6020

HEATER AND AIR CONDITIONING 1-43

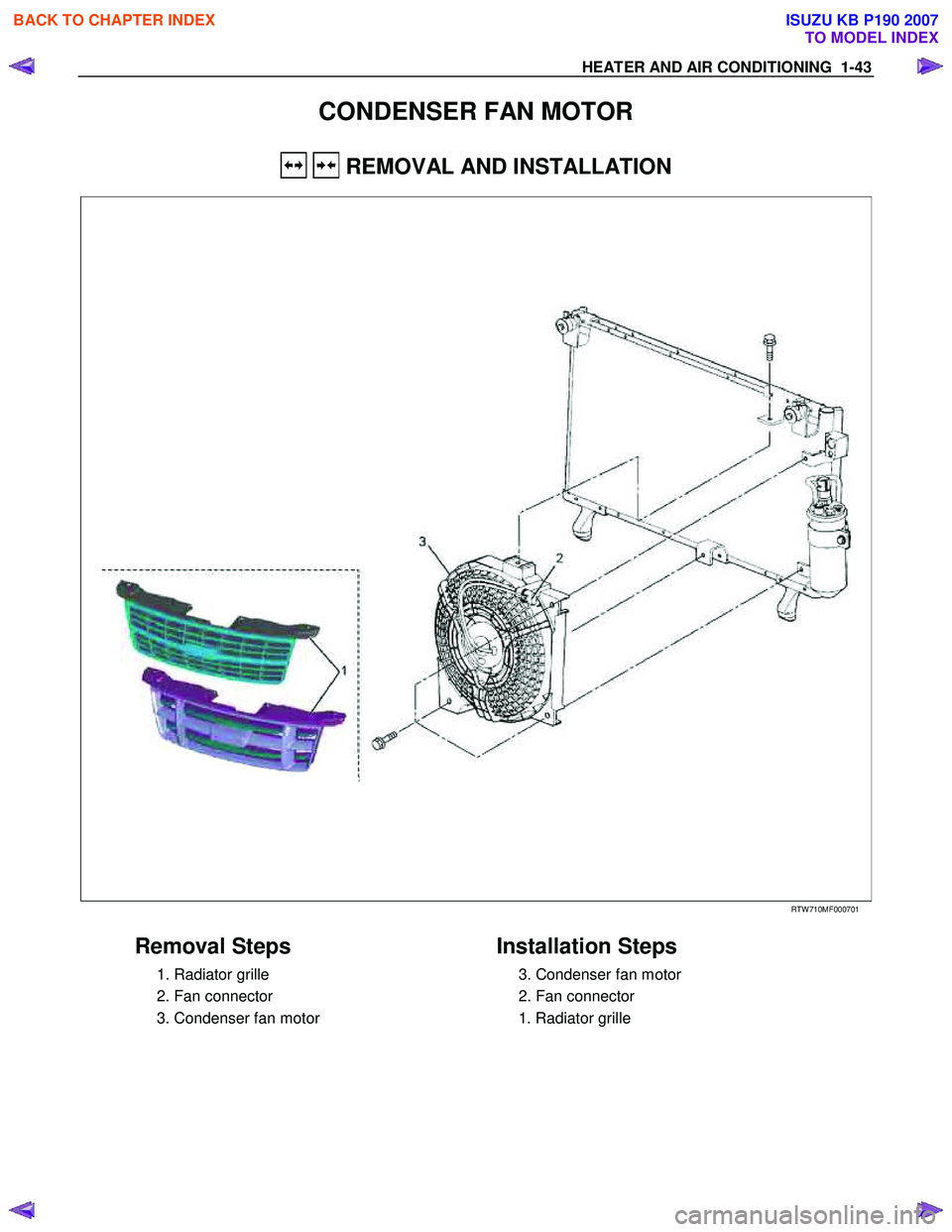

CONDENSER FAN MOTOR

REMOVAL AND INSTALLATION

RTW 710MF000701

Removal Steps

1. Radiator grille

2. Fan connector

3. Condenser fan motor

Installation Steps

3. Condenser fan motor

2. Fan connector

1. Radiator grille

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 78 of 6020

1-44 HEATER AND AIR CONDITIONING

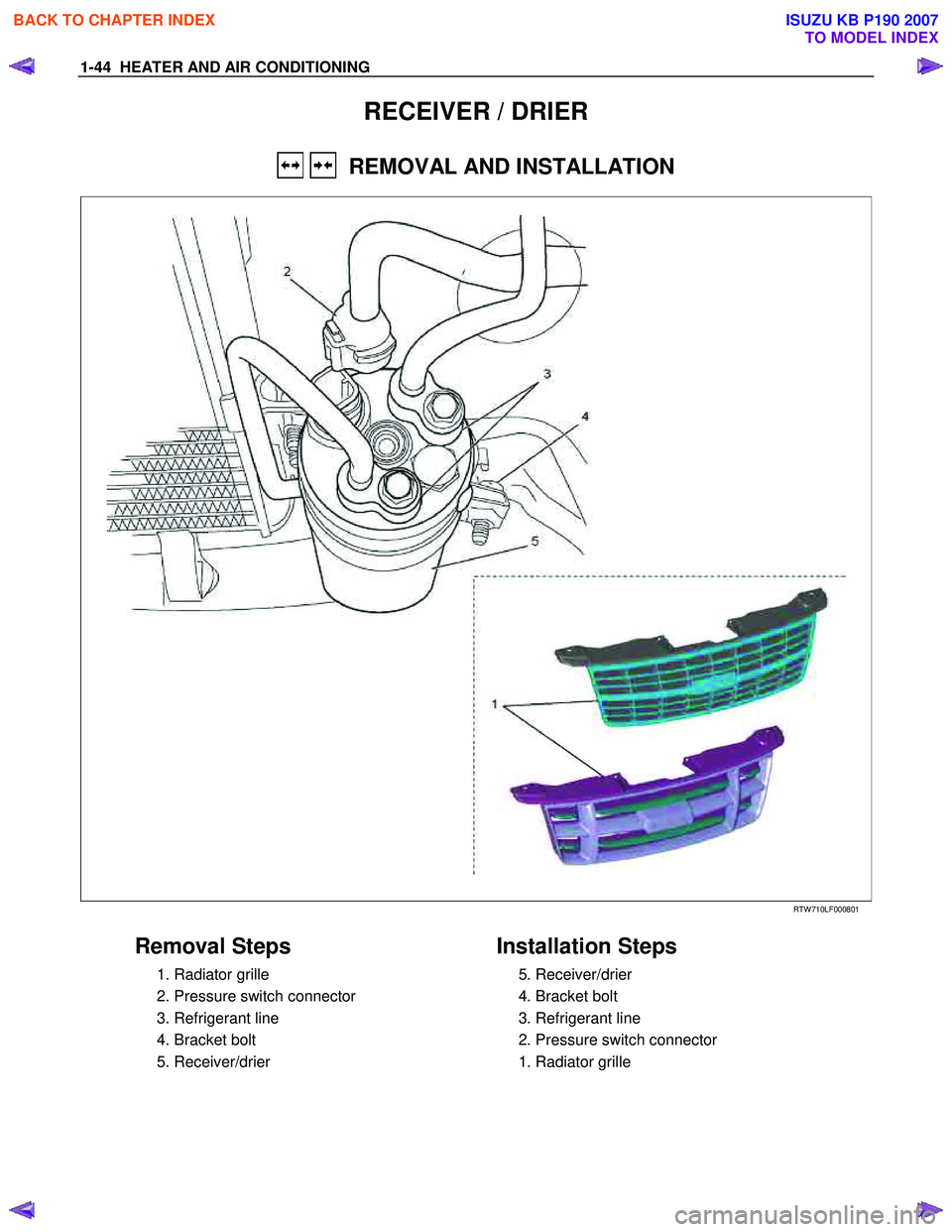

RECEIVER / DRIER

REMOVAL AND INSTALLATION

RTW 710LF000801

Removal Steps

1. Radiator grille

2. Pressure switch connector

3. Refrigerant line

4. Bracket bolt

5. Receiver/drier

Installation Steps

5. Receiver/drier

4. Bracket bolt

3. Refrigerant line

2. Pressure switch connector

1. Radiator grille

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 79 of 6020

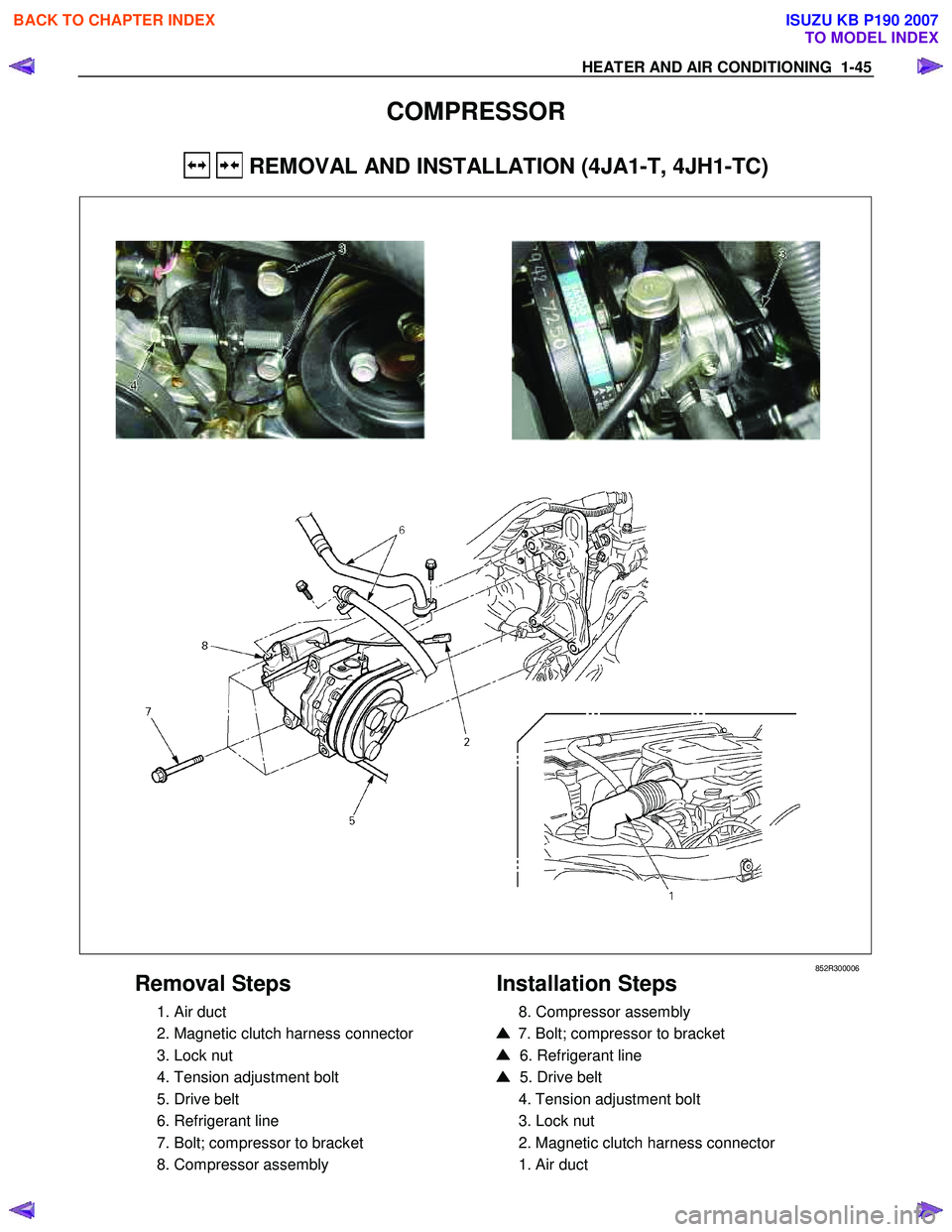

HEATER AND AIR CONDITIONING 1-45

COMPRESSOR

REMOVAL AND INSTALLATION (4JA1-T, 4JH1-TC)

852R300006

Removal Steps

1. Air duct

2. Magnetic clutch harness connector

3. Lock nut

4. Tension adjustment bolt

5. Drive belt

6. Refrigerant line

7. Bolt; compressor to bracket

8. Compressor assembly

Installation Steps

8. Compressor assembly

7. Bolt; compressor to bracket

6. Refrigerant line

5. Drive belt

4. Tension adjustment bolt

3. Lock nut

2. Magnetic clutch harness connector

1. Air duct

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 80 of 6020

1-46 HEATER AND AIR CONDITIONING

Important Operations - Installation

7. Bolt; Compressor to Bracket

N⋅m (kgf ⋅m/lb ⋅ft)

Torque 44 (4.5/33)

6. Refrigerant Line

N⋅m (kgf ⋅m/lb ⋅in)

Torque 11 ∼19 (1.1/95 ∼1.9/168)

5. Drive Belt

Refer to SECTION 6A “COOLING SYSTEM”.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007