sensor ISUZU KB P190 2007 Workshop Repair Manual

[x] Cancel search | Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3542 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–18

5 If the resistance is not within specifications, replace

the ECT sensor.

Engine Coolant Temperature Vs Resistance

Temperature °C Resistance – Ohms (

Ω)

-40 40490 – 50136

-20 14096 – 16827

-10 8642 – 10152

0 5466 – 6326

20 2351 – 2649

25 1941 – 2173

40 1118 – 1231

60 573 – 618

80 313 – 332

100 182 – 191

120 109 – 116

140 68 – 74

Reinstall

Reinstallation of the engine coolant temperature (ECT) sensor is the reverse of the removal procedure, noting the

following:

1 Tighten the ECT sensor to the correct torque specification.

Engine coolant temperature sensor

torque specification ............................................22.0 Nm

2 Refill the cooling system, refer to 6B1 Engine Cooling – V6.

3 Road test the vehicle and check for correct operation, taking particular note there is no coolant leakage.

2.7 Engine Control Module

Service of the engine control module (ECM) should normally consist of either replacement or ECM programming. If the

diagnostic procedures call for the ECM to be replaced, it should be first checked to ensure it is the correct part. If it is,

replace the faulty ECM.

Do not touch the ECM connector pins as

electrostatic discharge (ESD) damage may

result.

When removing or reinstalling the ECM wiring

harness connector/s, ensure the ignition

switch is in the OFF position and the battery

has been disconnected. Failure to do so may

result in damage to the ECM and / or

associated componentry.

Disconnection of the battery affects certain

vehicle electronic systems. Refer to 6D1-3

Battery - V6 before disconnecting the battery.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3546 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–22

3 Road test the vehicle and check for correct operation.

2.9 Engine Oil Level and Temperature

Sensor

To avoid personal injury, take care when

draining the engine oil or removing the engine

oil level and temperature sensor whilst the

engine is hot. Allow the engine to cool before

performing this procedure.

Remove

1 Turn the ignition switch off.

2 Raise the front and rear of the vehicle and support on safety stands, refer to 0A General Information for location of the jacking points.

3 Drain the engine oil, refer to 6A1 Engine Mechanical – V6.

Clean the area around the engine oil level

and temperature sensor (1) before removal to

avoid debris from entering the engine.

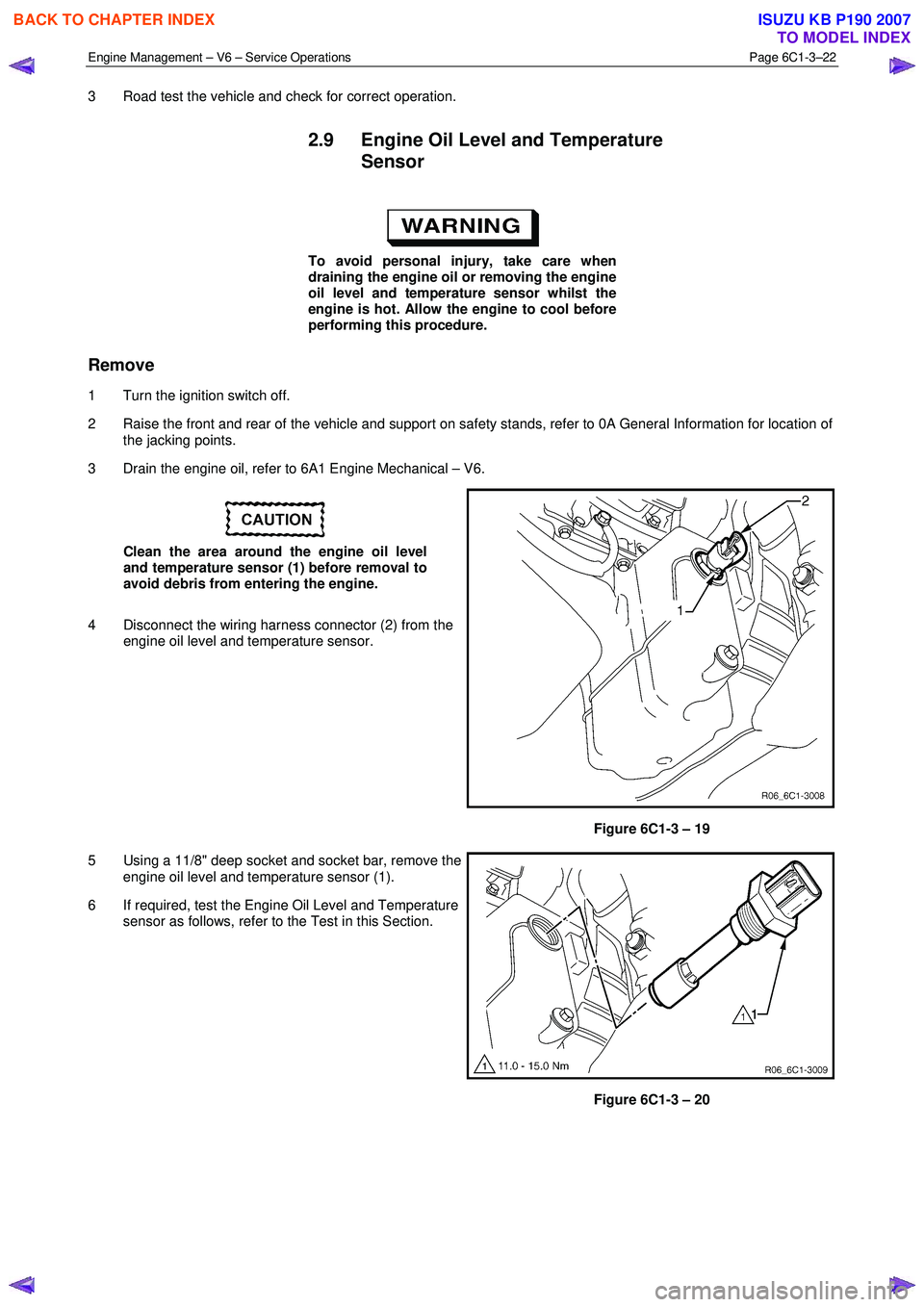

4 Disconnect the wiring harness connector (2) from the engine oil level and temperature sensor.

Figure 6C1-3 – 19

5 Using a 11/8" deep socket and socket bar, remove the engine oil level and temperature sensor (1).

6 If required, test the Engine Oil Level and Temperature sensor as follows, refer to the Test in this Section.

Figure 6C1-3 – 20

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3547 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–23

Test

Engine Oil Level Sensor Check

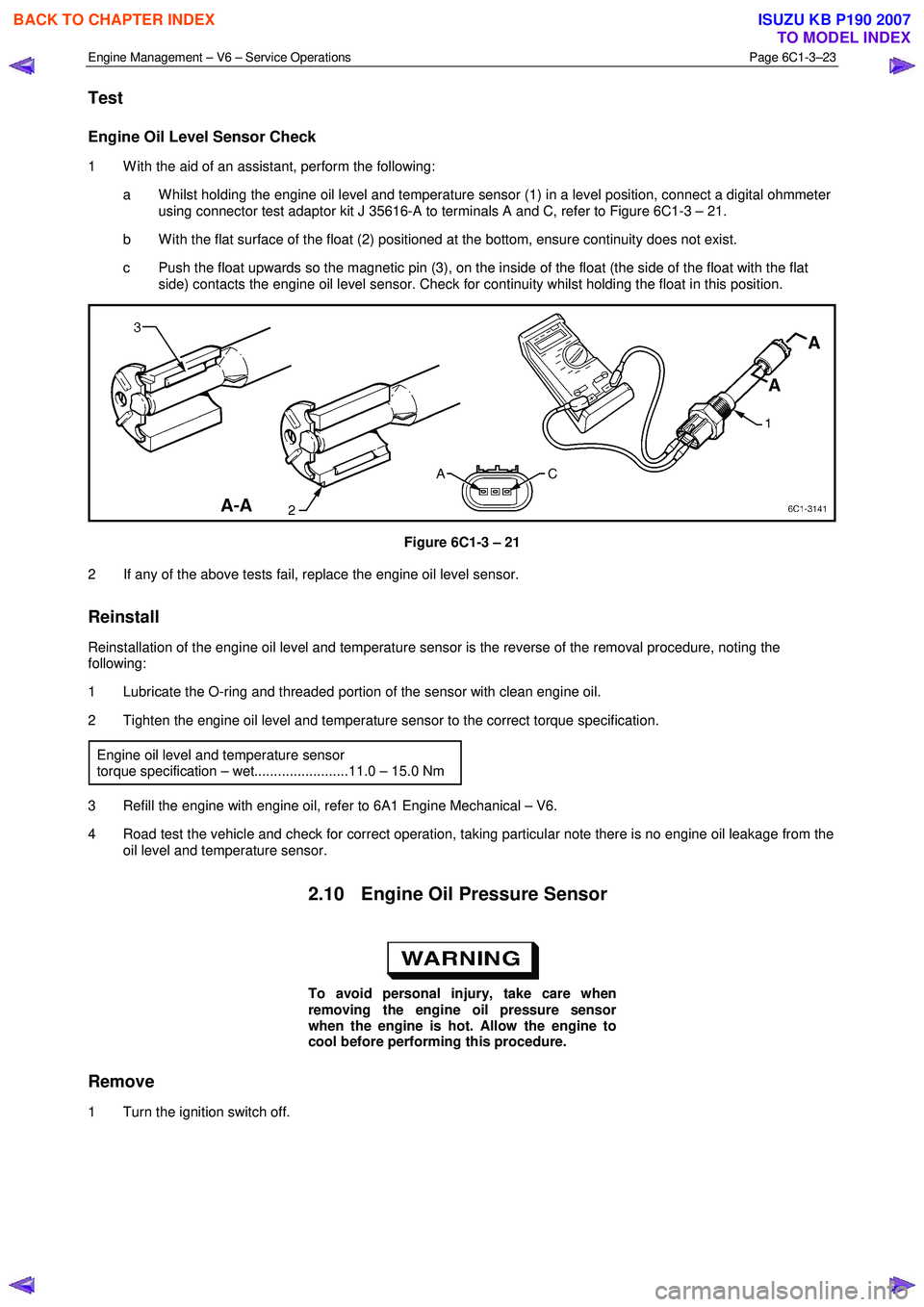

1 W ith the aid of an assistant, perform the following:

a W hilst holding the engine oil level and temperature sensor (1) in a level position, connect a digital ohmmeter using connector test adaptor kit J 35616-A to terminals A and C, refer to Figure 6C1-3 – 21.

b W ith the flat surface of the float (2) positioned at the bottom, ensure continuity does not exist.

c Push the float upwards so the magnetic pin (3), on the inside of the float (the side of the float with the flat side) contacts the engine oil level sensor. Check for continuity whilst holding the float in this position.

Figure 6C1-3 – 21

2 If any of the above tests fail, replace the engine oil level sensor.

Reinstall

Reinstallation of the engine oil level and temperature sensor is the reverse of the removal procedure, noting the

following:

1 Lubricate the O-ring and threaded portion of the sensor with clean engine oil.

2 Tighten the engine oil level and temperature sensor to the correct torque specification.

Engine oil level and temperature sensor

torque specification – wet........................11.0 – 15.0 Nm

3 Refill the engine with engine oil, refer to 6A1 Engine Mechanical – V6.

4 Road test the vehicle and check for correct operation, taking particular note there is no engine oil leakage from the oil level and temperature sensor.

2.10 Engine Oil Pressure Sensor

To avoid personal injury, take care when

removing the engine oil pressure sensor

when the engine is hot. Allow the engine to

cool before performing this procedure.

Remove

1 Turn the ignition switch off.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3548 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–24

Clean the area around the engine oil pressure

sensor before removal to avoid debris from

entering the engine.

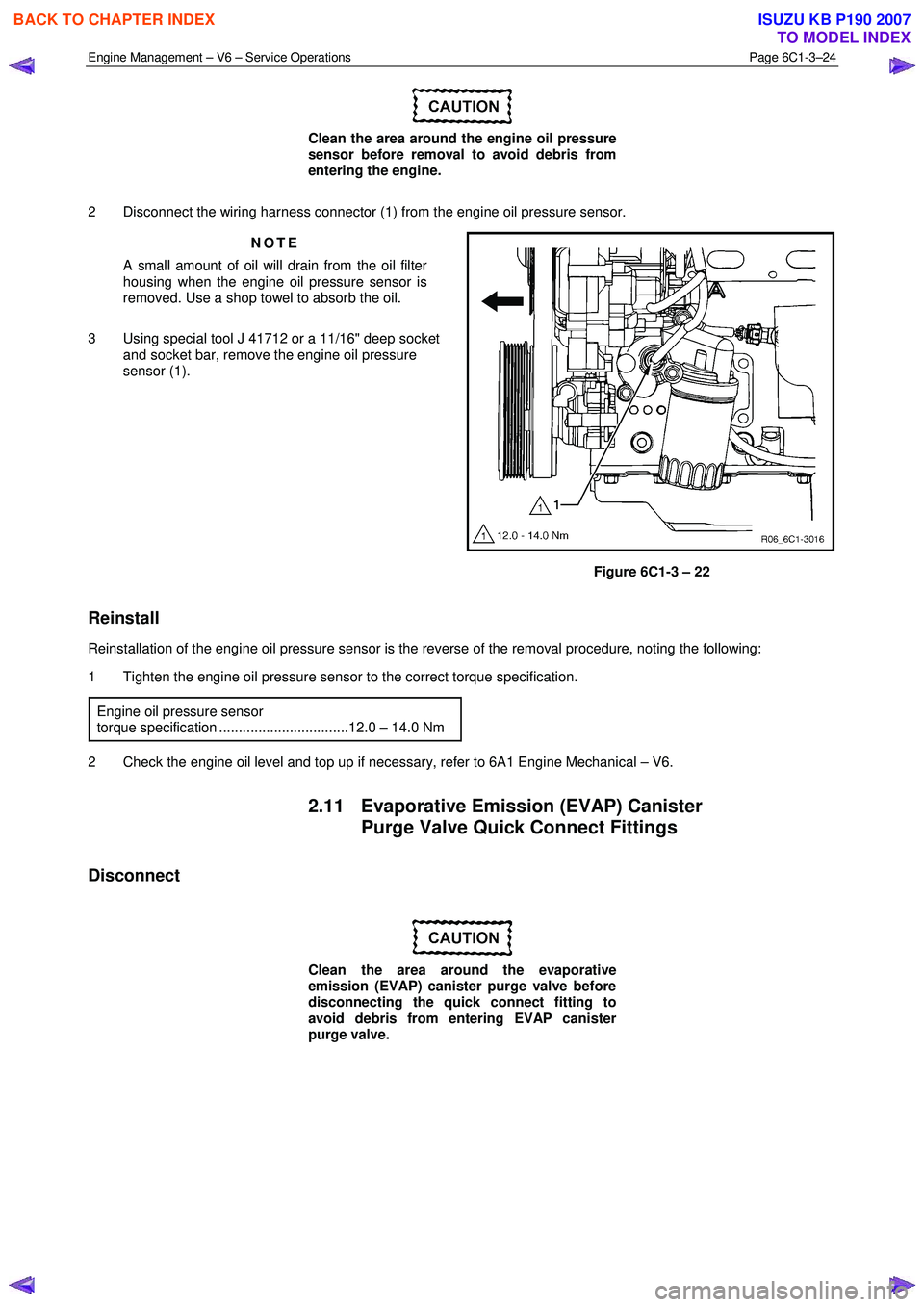

2 Disconnect the wiring harness connector (1) from the engine oil pressure sensor. NOTE

A small amount of oil will drain from the oil filter

housing when the engine oil pressure sensor is

removed. Use a shop towel to absorb the oil.

3 Using special tool J 41712 or a 11/16" deep socket and socket bar, remove the engine oil pressure

sensor (1).

Figure 6C1-3 – 22

Reinstall

Reinstallation of the engine oil pressure sensor is the reverse of the removal procedure, noting the following:

1 Tighten the engine oil pressure sensor to the correct torque specification.

Engine oil pressure sensor

torque specification .................................12.0 – 14.0 Nm

2 Check the engine oil level and top up if necessary, refer to 6A1 Engine Mechanical – V6.

2.11 Evaporative Emission (EVAP) Canister Purge Valve Quick Connect Fittings

Disconnect

Clean the area around the evaporative

emission (EVAP) canister purge valve before

disconnecting the quick connect fitting to

avoid debris from entering EVAP canister

purge valve.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3557 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–33

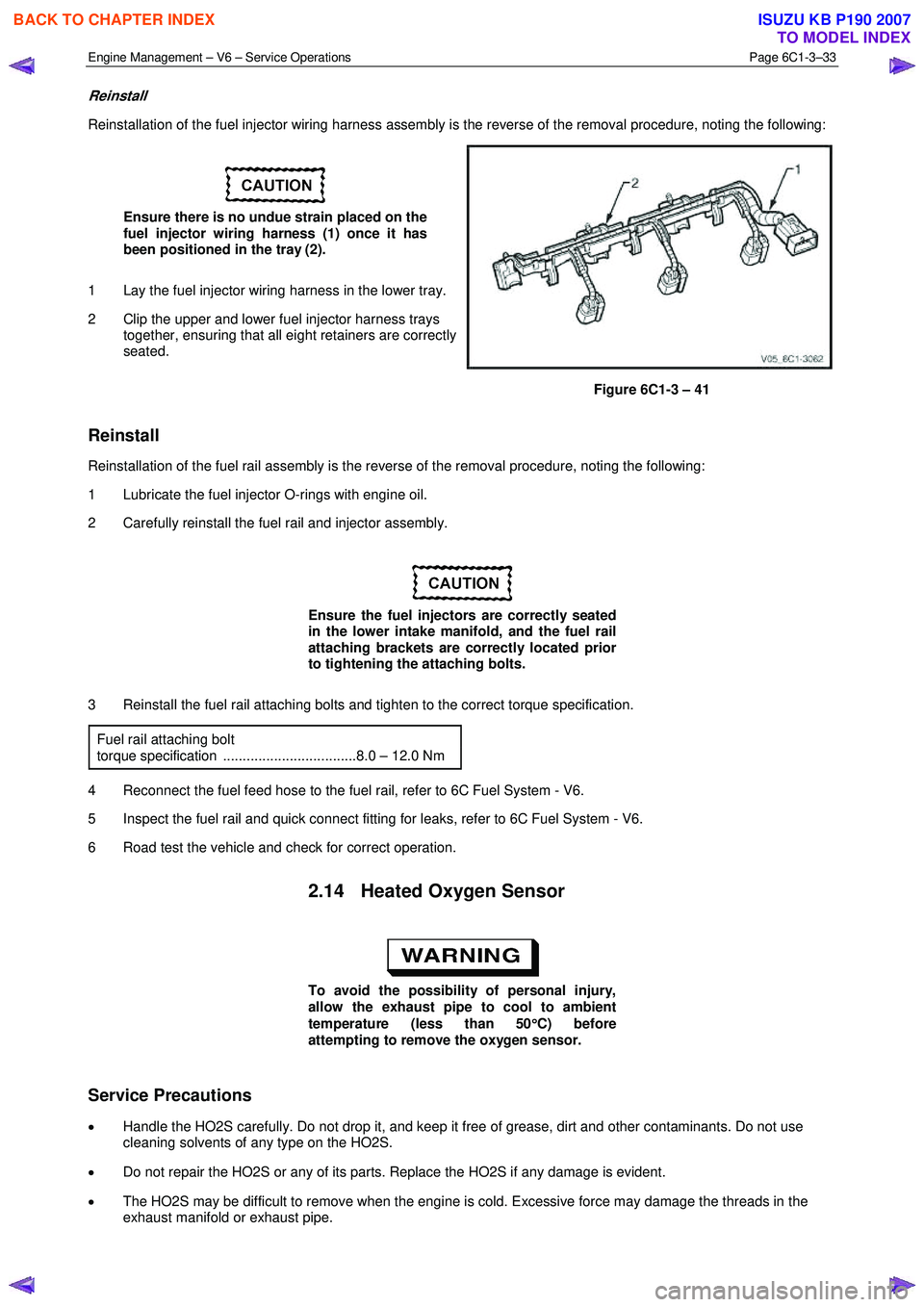

Reinstall

Reinstallation of the fuel injector wiring harness assembly is the reverse of the removal procedure, noting the following:

Ensure there is no undue strain placed on the

fuel injector wiring harness (1) once it has

been positioned in the tray (2).

1 Lay the fuel injector wiring harness in the lower tray.

2 Clip the upper and lower fuel injector harness trays together, ensuring that all eight retainers are correctly

seated.

Figure 6C1-3 – 41

Reinstall

Reinstallation of the fuel rail assembly is the reverse of the removal procedure, noting the following:

1 Lubricate the fuel injector O-rings with engine oil.

2 Carefully reinstall the fuel rail and injector assembly.

Ensure the fuel injectors are correctly seated

in the lower intake manifold, and the fuel rail

attaching brackets are correctly located prior

to tightening the attaching bolts.

3 Reinstall the fuel rail attaching bolts and tighten to the correct torque specification. Fuel rail attaching bolt

torque specification ..................................8.0 – 12.0 Nm

4 Reconnect the fuel feed hose to the fuel rail, refer to 6C Fuel System - V6.

5 Inspect the fuel rail and quick connect fitting for leaks, refer to 6C Fuel System - V6.

6 Road test the vehicle and check for correct operation.

2.14 Heated Oxygen Sensor

To avoid the possibility of personal injury,

allow the exhaust pipe to cool to ambient

temperature (less than 50 °

°°

°

C) before

attempting to remove the oxygen sensor.

Service Precautions

• Handle the HO2S carefully. Do not drop it, and keep it free of grease, dirt and other contaminants. Do not use

cleaning solvents of any type on the HO2S.

• Do not repair the HO2S or any of its parts. Replace the HO2S if any damage is evident.

• The HO2S may be difficult to remove when the engine is cold. Excessive force may damage the threads in the

exhaust manifold or exhaust pipe.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3558 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–34

• If the HO2S has been removed, but not replaced, anti-seize compound must be applied to the threads prior to

installation. New HO2S will already have the anti-seize compound applied.

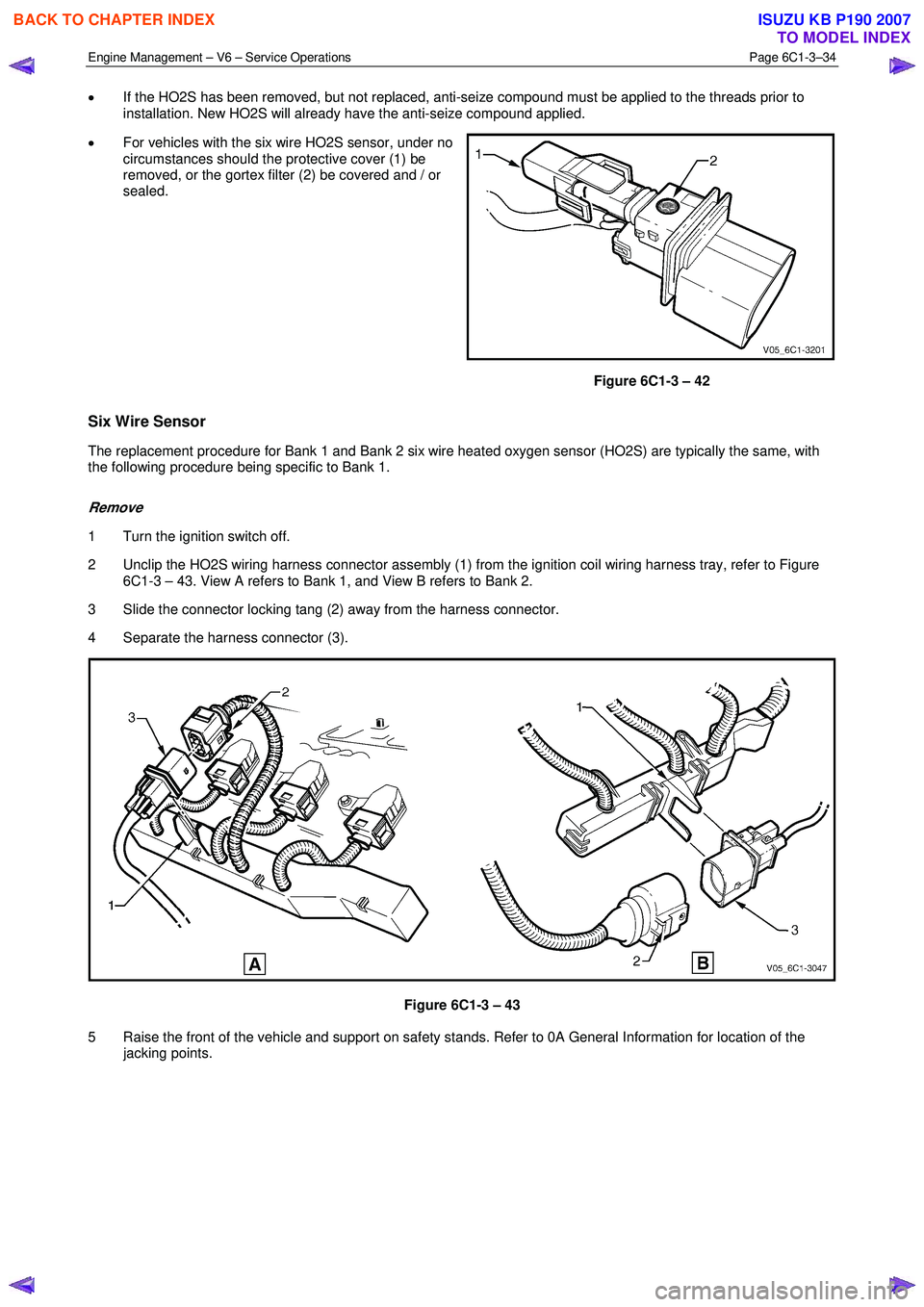

• For vehicles with the six wire HO2S sensor, under no

circumstances should the protective cover (1) be

removed, or the gortex filter (2) be covered and / or

sealed.

Figure 6C1-3 – 42

Six Wire Sensor

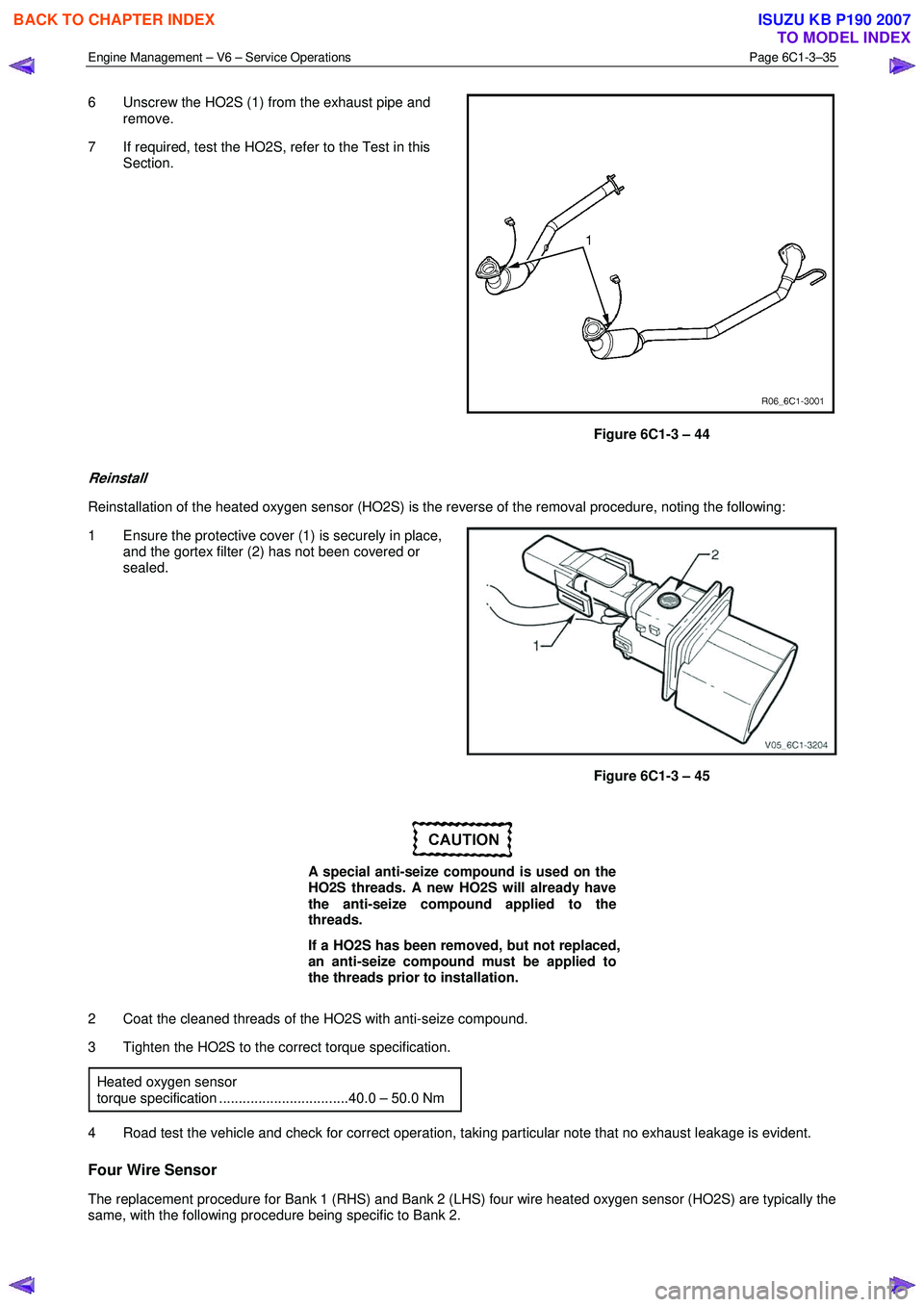

The replacement procedure for Bank 1 and Bank 2 six wire heated oxygen sensor (HO2S) are typically the same, with

the following procedure being specific to Bank 1.

Remove

1 Turn the ignition switch off.

2 Unclip the HO2S wiring harness connector assembly (1) from the ignition coil wiring harness tray, refer to Figure 6C1-3 – 43. View A refers to Bank 1, and View B refers to Bank 2.

3 Slide the connector locking tang (2) away from the harness connector.

4 Separate the harness connector (3).

Figure 6C1-3 – 43

5 Raise the front of the vehicle and support on safety stands. Refer to 0A General Information for location of the jacking points.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3559 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–35

6 Unscrew the HO2S (1) from the exhaust pipe and

remove.

7 If required, test the HO2S, refer to the Test in this Section.

Figure 6C1-3 – 44

Reinstall

Reinstallation of the heated oxygen sensor (HO2S) is the reverse of the removal procedure, noting the following:

1 Ensure the protective cover (1) is securely in place, and the gortex filter (2) has not been covered or

sealed.

Figure 6C1-3 – 45

A special anti-seize compound is used on the

HO2S threads. A new HO2S will already have

the anti-seize compound applied to the

threads.

If a HO2S has been removed, but not replaced,

an anti-seize compound must be applied to

the threads prior to installation.

2 Coat the cleaned threads of the HO2S with anti-seize compound.

3 Tighten the HO2S to the correct torque specification.

Heated oxygen sensor

torque specification .................................40.0 – 50.0 Nm

4 Road test the vehicle and check for correct operation, taking particular note that no exhaust leakage is evident.

Four Wire Sensor

The replacement procedure for Bank 1 (RHS) and Bank 2 (LHS) four wire heated oxygen sensor (HO2S) are typically the

same, with the following procedure being specific to Bank 2.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3560 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–36

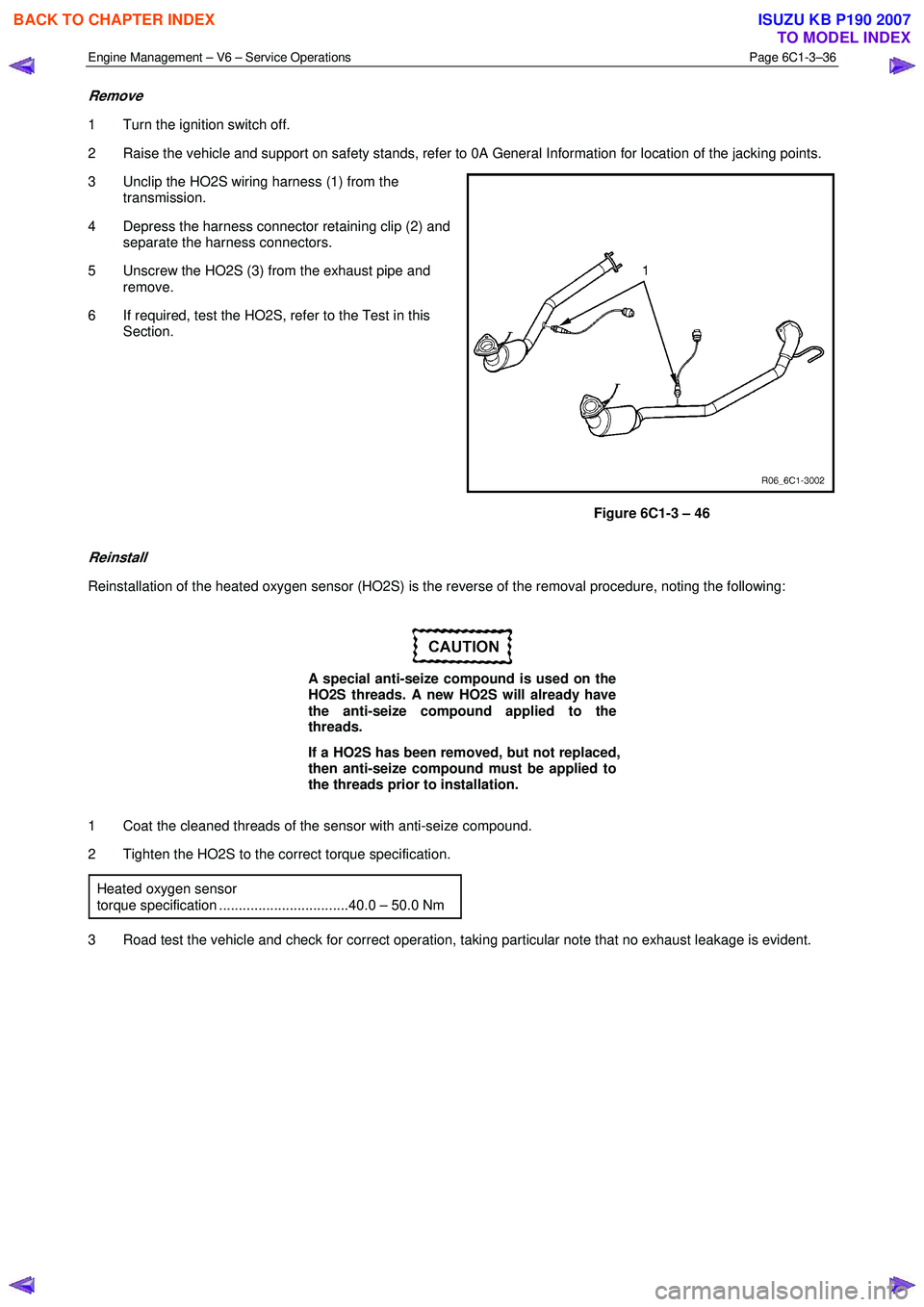

Remove

1 Turn the ignition switch off.

2 Raise the vehicle and support on safety stands, refer to 0A General Information for location of the jacking points.

3 Unclip the HO2S wiring harness (1) from the transmission.

4 Depress the harness connector retaining clip (2) and separate the harness connectors.

5 Unscrew the HO2S (3) from the exhaust pipe and remove.

6 If required, test the HO2S, refer to the Test in this Section.

Figure 6C1-3 – 46

Reinstall

Reinstallation of the heated oxygen sensor (HO2S) is the reverse of the removal procedure, noting the following:

A special anti-seize compound is used on the

HO2S threads. A new HO2S will already have

the anti-seize compound applied to the

threads.

If a HO2S has been removed, but not replaced,

then anti-seize compound must be applied to

the threads prior to installation.

1 Coat the cleaned threads of the sensor with anti-seize compound.

2 Tighten the HO2S to the correct torque specification.

Heated oxygen sensor

torque specification .................................40.0 – 50.0 Nm

3 Road test the vehicle and check for correct operation, taking particular note that no exhaust leakage is evident.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3561 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–37

Test

Under no circumstances should battery

voltage be applied to the heated oxygen

sensor (HO2S) heater.

To prevent component damage use connector

test adaptor kit J 35616-A.

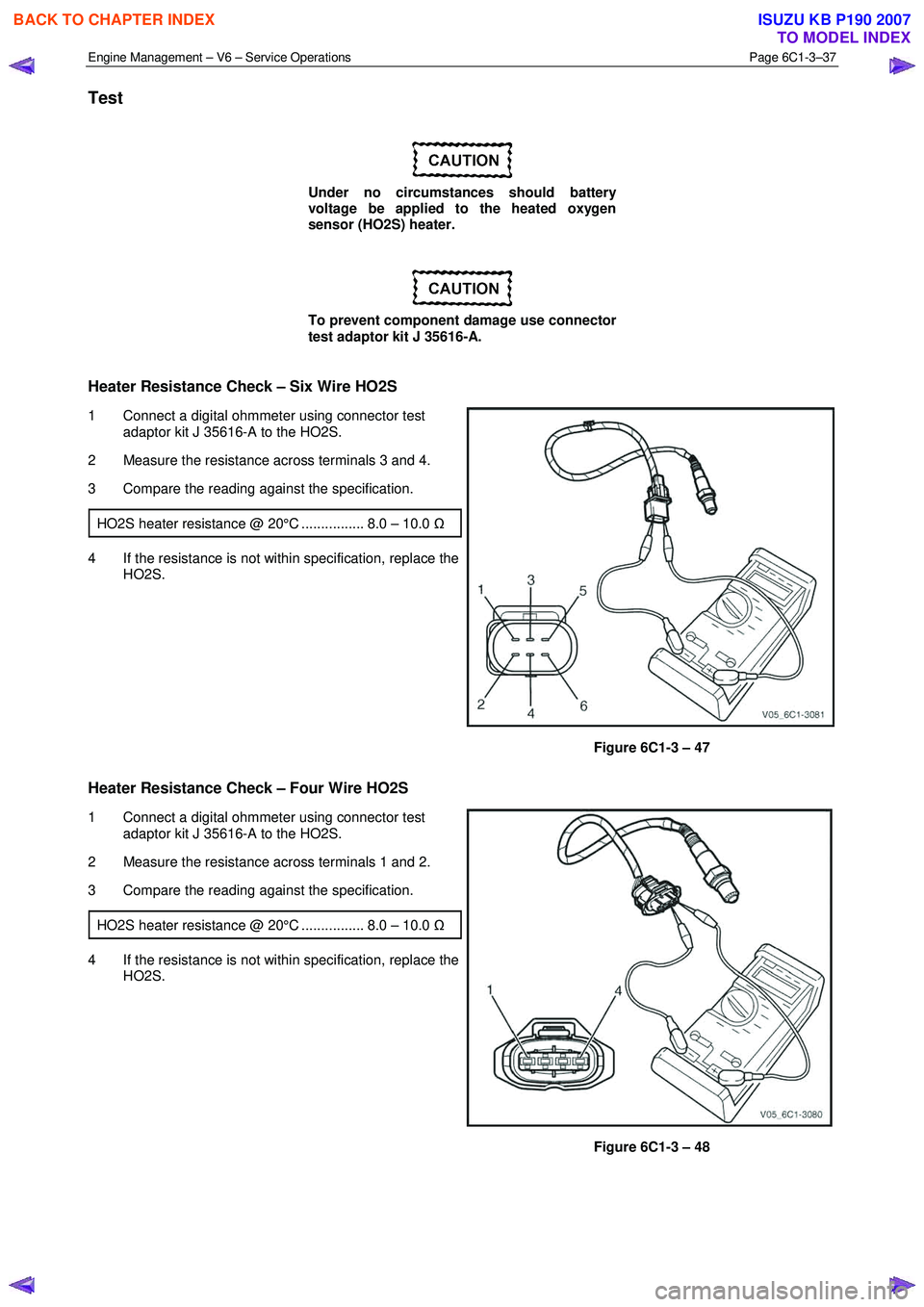

Heater Resistance Check – Six Wire HO2S

1 Connect a digital ohmmeter using connector test adaptor kit J 35616-A to the HO2S.

2 Measure the resistance across terminals 3 and 4.

3 Compare the reading against the specification.

HO2S heater resistance @ 20°C ................ 8.0 – 10.0 Ω

4 If the resistance is not within specification, replace the

HO2S.

Figure 6C1-3 – 47

Heater Resistance Check – Four Wire HO2S

1 Connect a digital ohmmeter using connector test

adaptor kit J 35616-A to the HO2S.

2 Measure the resistance across terminals 1 and 2.

3 Compare the reading against the specification.

HO2S heater resistance @ 20°C ................ 8.0 – 10.0 Ω

4 If the resistance is not within specification, replace the

HO2S.

Figure 6C1-3 – 48

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3564 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–40

Reinstall

Reinstallation of the ignition coil is the reverse of the removal procedure, noting the following:

1 Lubricate the ignition coil sealing rubber (1) with clean engine oil, and the inside of the ignition coil boot (2)

with talcum powder.

Figure 6C1-3 – 53

2 Reinstall the ignition coil by pushing down on the ignition coil to engage the sealing rubber in the camshaft cover.

Ensure the ignition coil is fully seated before

tightening the attaching bolt to the specified

torque.

3 Reinstall the ignition coil bolt and tighten to the correct torque specification. Ignition coil attaching bolt

torque specification ...................................7.0 – 11.0 Nm

4 Road test the vehicle and check for correct operation.

2.16 Intake Air Duct Assembly

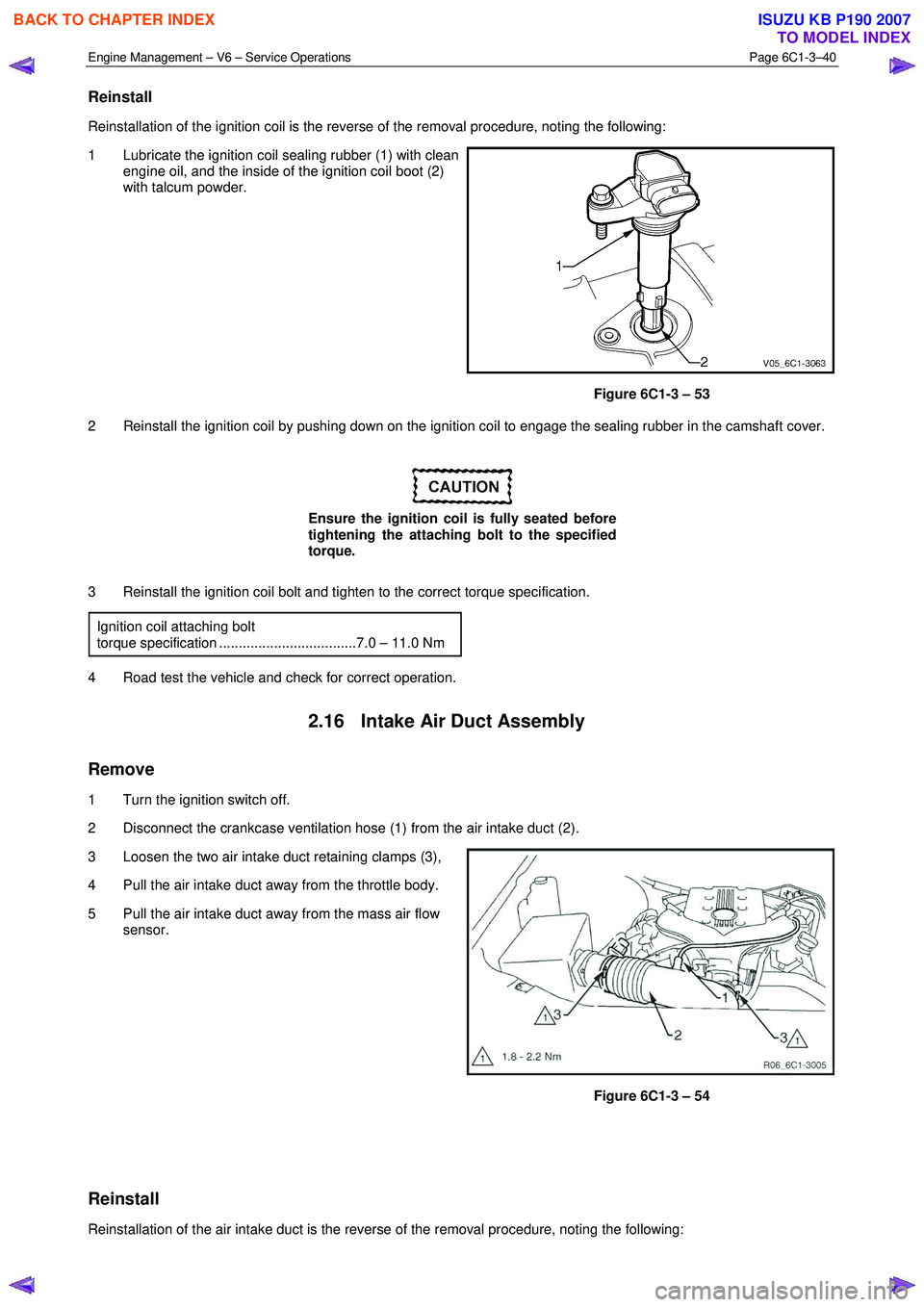

Remove

1 Turn the ignition switch off.

2 Disconnect the crankcase ventilation hose (1) from the air intake duct (2).

3 Loosen the two air intake duct retaining clamps (3),

4 Pull the air intake duct away from the throttle body.

5 Pull the air intake duct away from the mass air flow sensor.

Figure 6C1-3 – 54

Reinstall

Reinstallation of the air intake duct is the reverse of the removal procedure, noting the following:

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007