body JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 2053 of 2490

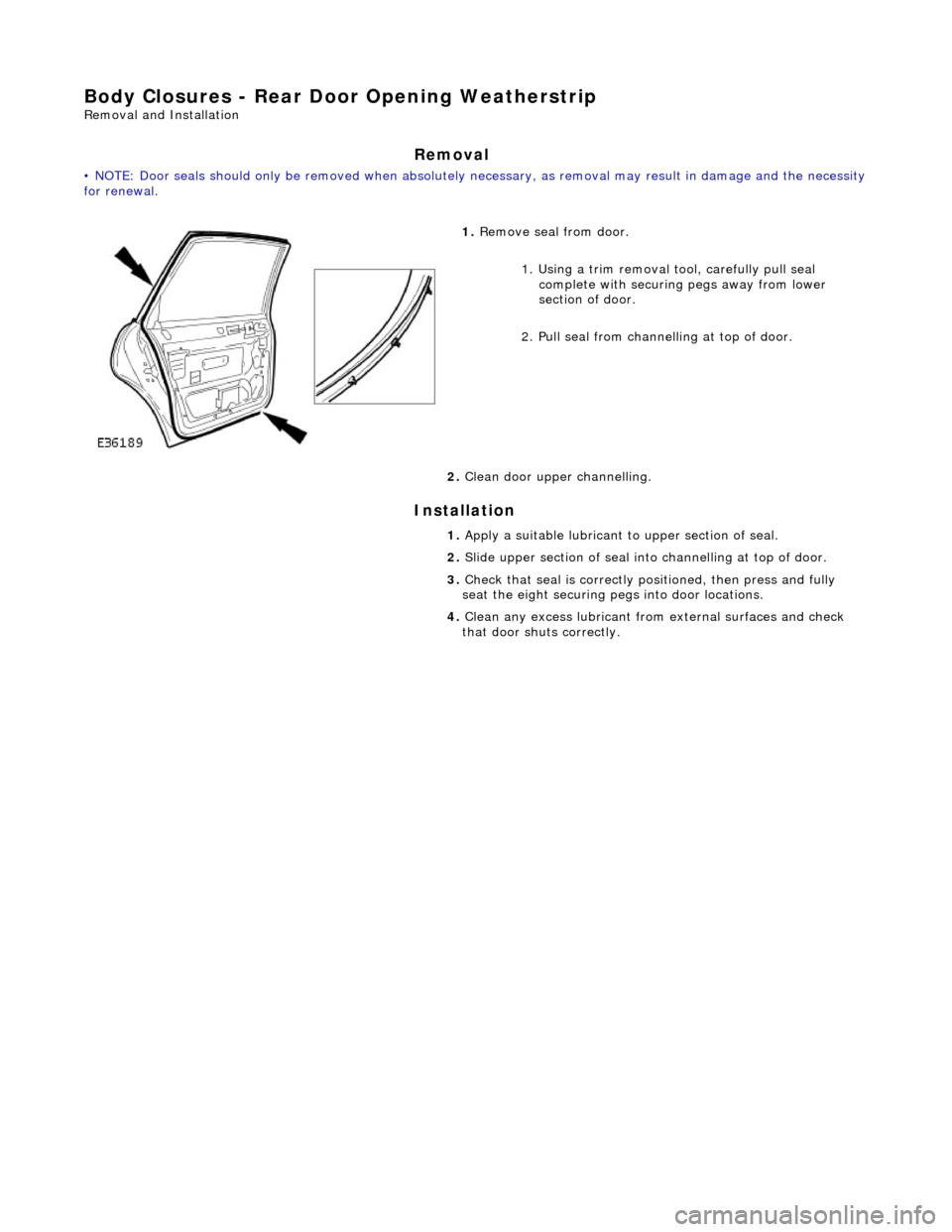

Body Closures - Rear Door Opening Weatherstrip

Removal and Installation

Removal

• NOTE: Door seals should only be removed when absolutely necessary, as removal may result in damage and the necessity for renewal.

Installation

1. Remove seal from door.

1. Using a trim removal tool, carefully pull seal complete with securing pegs away from lower

section of door.

2. Pull seal from chan nelling at top of door.

2. Clean door uppe r channelling.

1. Apply a suitable lubricant to upper section of seal.

2. Slide upper section of seal into channelling at top of door.

3. Check that seal is correctly positioned, then press and fully

seat the eight securing pegs into door locations.

4. Clean any excess lubricant from external surfaces and check

that door shuts correctly.

Page 2054 of 2490

Interior Trim and Ornamentation - Interior Trim

Description and Operation

Carpets

The passenger compartment carpet is a one piece moulded constr uction with integral sound deadening material, heel mats

and driver's footrest. The carpet is attach ed to the vehicle floor by plastic clips fitted below the door treadplates. Removal of the carpet necessitates re moval of the front seats, lifting of the centre console rear extens ion and removal of the heelboard

carpet.

Fascia

The full width, slush moulded, soft feel PVC fascia is mounted on an injection moulded armature and is faced with wood

veneer. In addition to the air conditioning and central, outer and demisting vents, it accepts instrument packs dedicated to

market requirements and a centrally mounted analogue clock.

Doors

The one-piece door casings are trimmed in UEV to match the seating, with wood veneer at the waistline and a carpet insert

at the front lower corner. Each casing is secured to the door inner panel by fir tree press fast eners along the lower section,

two armrest fixings at the centre and vene er panel dowels and fixings at the top. The armrests which are common to front

and rear doors, are trimmed in matching leather or UEV according to specification. The door switchpacks, dedicated to

driver and front or rear passenger, are in corporated in the armrests. A speaker is in stalled in the lower section of each door

and a tweeter is incorporated behind each interior door handle escutcheon. Where premium ICE is fitted, the front tweeters

are installed in the upper A posts.

A, B, C and D Posts

On each side,a grained UEV finisher trimmed to match the headlining is secured to the 'A' post and cantrail by fir tree

fasteners locating in BIW apertures. The upper 'D' post finisher is trimmed and secured in the same manner. The single

piece'B/C' post finishers, also finished in grained matching UEV, each have a front se at belt exit aperture and are secured to

the BIW by four spring clips and two fir tree fasteners.

Headlining

The one-piece headlining consists of a 6mm thick polyurethane foam membrane covered with suede effect knitted polyester. The headlining is secured to the BIW roof by body tangs, the roof console, sun visors, combined grab handles and coat

hooks, the cantrail finishers and where fitt ed, the sliding roof finisher and clips.

Trunk

Carpet covered trims line the trunk and are secured by fir tr ee fasteners to the sides and front inner panel. The carpet

covered, two-section, removable trunk fl oor provides access to the spare wheel and wheel changing equipment, the battery

and electrical carrier. The floor board rests on the spare wheel, with the front and rear edges locating in blocks on the fuel

tank backboard and the rear of the body. The support blocks provide for two floor he ight settings to accommodate either a

space saver or full size spare wheel.A moulded finisher covering the rear of the trunk below the sill is secured to the rear

panel by tabs and fir tree fasteners. Finish er panels fitted to the rear lamp units provide trunk interior access to the lamps.

The trunk lid underside is fitted with a removabl e moulded liner and two trunk illumination lights.

Page 2062 of 2490

Interior Trim and Ornamentation - Engine Cover

Removal and Installation

Removal

Installation

1.

Remove the passenger side and dr iver side bulkhead covers.

For additional informat ion, refer to Section 501

-02 Front End Body Panels.

2. Remove the engine cover.

1. To install, reverse the removal procedure.

Page 2086 of 2490

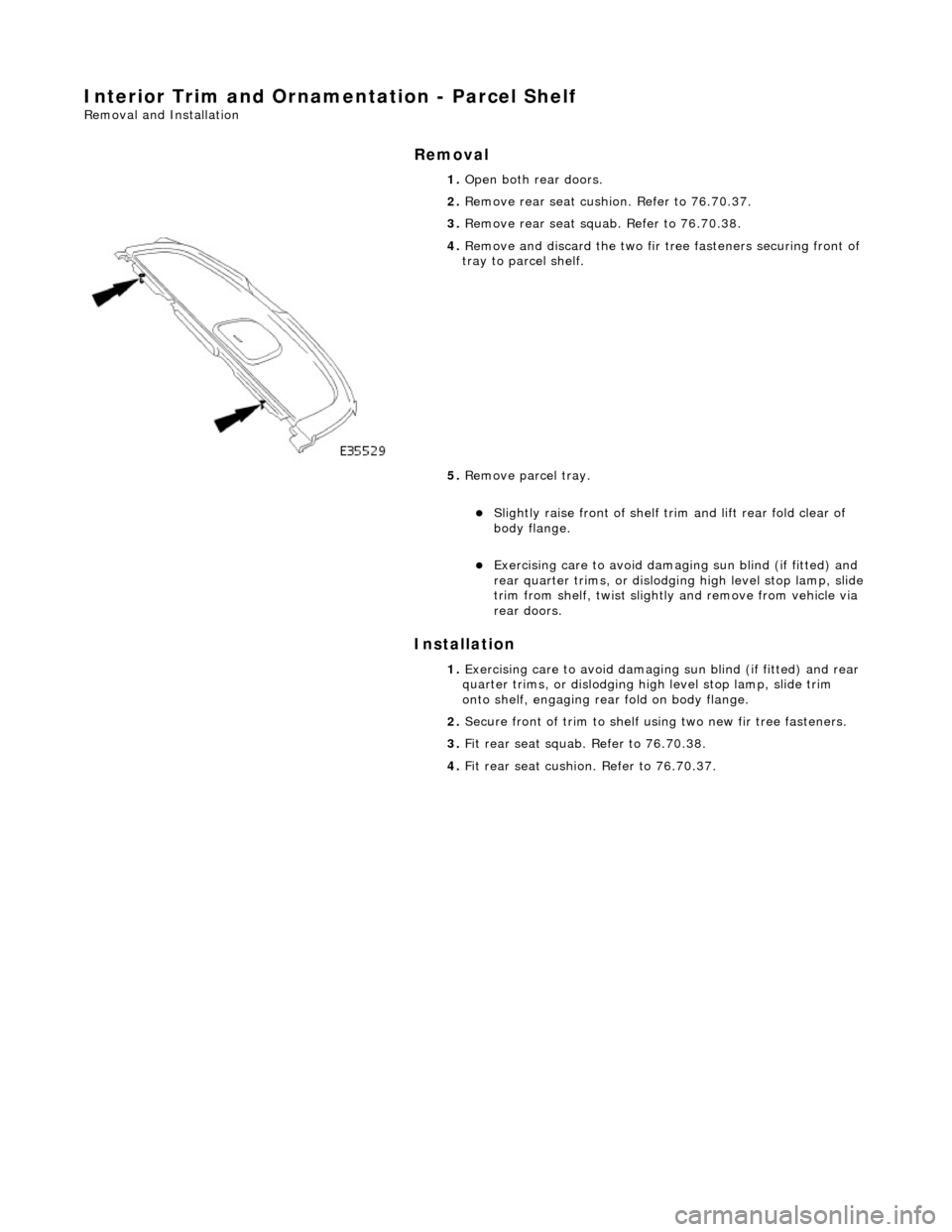

Interior Trim and Ornamentation - Parcel Shelf

Removal and Installation

Removal

Installation

1.

Open both rear doors.

2. Remove rear seat cushion. Refer to 76.70.37.

3. Remove rear seat squa b. Refer to 76.70.38.

4. Remove and discard the two fir tr ee fasteners securing front of

tray to parcel shelf.

5. Remove parcel tray.

Slightly raise front of shelf trim and lift rear fold clear of

body flange.

Exercising care to avoid dama ging sun blind (if fitted) and

rear quarter trims, or dislodging high level stop lamp, slide trim from shelf, twist slightly and remove from vehicle via

rear doors.

1. Exercising care to avoid damaging sun blind (if fitted) and rear

quarter trims, or dislodging hi gh level stop lamp, slide trim

onto shelf, engaging rear fold on body flange.

2. Secure front of trim to shelf using two new fir tr ee fasteners.

3. Fit rear seat squab. Refer to 76.70.38.

4. Fit rear seat cushion. Refer to 76.70.37.

Page 2099 of 2490

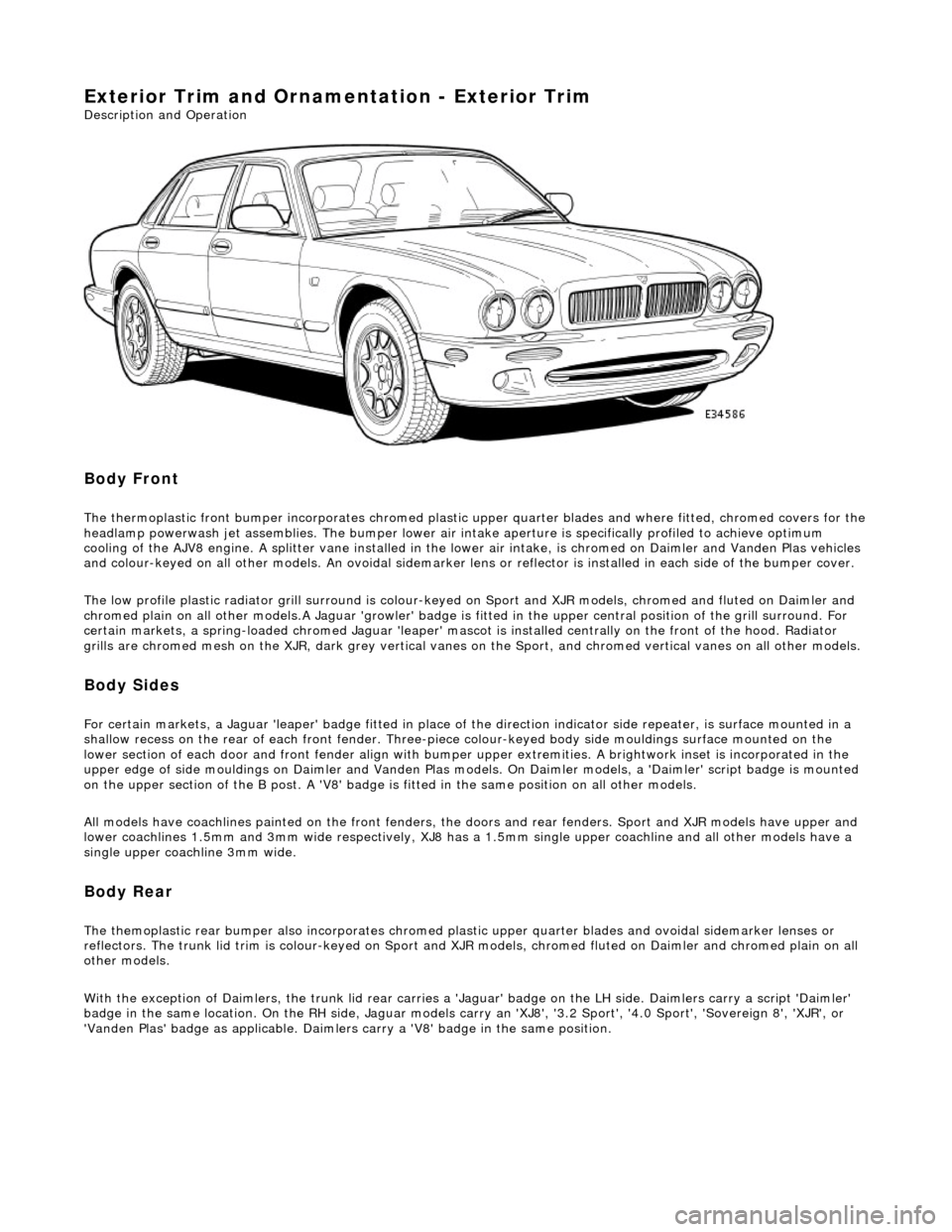

Exterior Trim and Ornamentation - Exterior Trim

Description and Operation

Body Front

The thermoplastic front bumper incorporates chromed plastic upper quarter blades and where fitted, chromed covers for the headlamp powerwash jet assemblie s. The bumper lower air intake aperture is specifically profiled to achieve optimum

cooling of the AJV8 engine. A splitter vane installed in the lowe r air intake, is chromed on Daimler and Vanden Plas vehicles

and colour-keyed on all other models. An ov oidal sidemarker lens or reflector is installed in each side of the bumper cover.

The low profile plastic radiator grill surround is colour-keyed on Sport and XJR mo dels, chromed and fluted on Daimler and

chromed plain on all other models .A Jaguar 'growler' badge is fitted in the upper central positi on of the grill surround. For

certain markets, a spring-loaded chromed Ja guar 'leaper' mascot is installed centrally on the front of the hood. Radiator

grills are chromed mesh on the XJR, dark grey vertical vanes on the Sport, and chromed ve rtical vanes on all other models.

Body Sides

For certain markets, a Jaguar 'l eaper' badge fitted in place of the direction indicator side re peater, is surface mounted in a

shallow recess on the rear of each fro nt fender. Three-piece colour-keyed body side mouldings surface mounted on the

lower section of each door and front fender align with bumper upper extremities. A brightwork inset is incorporated in the

upper edge of side mouldings on Daimler and Vanden Plas models. On Daimler models, a 'Daimler' script badge is mounted

on the upper section of the B post. A 'V8' badge is fitted in the same position on all other models.

All models have coachlines painted on th e front fenders, the doors and rear fender s. Sport and XJR models have upper and

lower coachlines 1.5mm an d 3mm wide respectively, XJ8 has a 1.5mm single upper coachline and all other models have a

single upper coachline 3mm wide.

Body Rear

The themoplastic rear bumper also inco rporates chromed plastic upper quarter blades and ovoi dal sidemarker lenses or

reflectors. The trunk lid trim is colour-keyed on Sport and XJ R models, chromed fluted on Daimler and chromed plain on all

other models.

With the exception of Daimlers, the trunk lid rear carries a 'Jaguar' badge on the LH side. Daimlers carry a script 'Daimler'

badge in the same location. On th e RH side, Jaguar models carry an 'XJ8', '3.2 Sport', '4.0 Sport', 'Sovereign 8', 'XJR', or

'Vanden Plas' badge as applic able. Daimlers carry a 'V8' badge in the same position.

Page 2103 of 2490

Exterior Trim and Ornamentation - Door Moulding

Removal and Installation

Removal

Installation

1.

Apply suitable protecti ve tape to immediately adjacent areas of

paintwork.

2. Using a hand-held heat gun, appply heat uniformly along

moulding length.

3. Applying local heat at one end and using a suitable thin lever

to avoid damaging paintwork, progressively ease moulding

away from door panel.

4. Discard moulding and remove protective tape.

5. Remove any residual adhesive and thoroughly clean area using

white spirit.

1. NOTE: Optimum adhesion is achi eved by warming body panel

and moulding to 65deg C.

Using white spirit ensure that mounting area is clean, dry and

de-greased.

2. Remove protective backing tape from moulding.

3. NOTE: Do not allow moulding to contact the body panel until it

is correctly aligned.

Heat moulding and moun ting area to 65degC.)

4. Aligning with adjacent mouldings or to match opposite side of

vehicle, press new moulding firmly onto body panel.

5. Apply hand pressure along moulding length to ensure

satisfactory adhesion.

6. Allow moulding and door panel to cool , then thoroughly clean

both using white spirit.

7. Apply a coat of suitab le polish to moulding and body panel.

Page 2104 of 2490

Exterior Trim and Ornamentation - Front Fender Moulding

Removal and Installation

Removal

Installation

1.

Apply suitable protecti ve tape to immediately adjacent areas of

paintwork.

2. Using a hand-held heat gun, appply heat uniformly along

moulding length.

3. Applying local heat at one end and using a suitable thin lever

to avoid damaging paintwork, progressively ease moulding

away from fender.

4. Discard moulding and remove protective tape.

5. Remove any residual adhesive and thoroughly clean area using

white spirit.

1. NOTE: Optimum adhesion is achi eved by warming body panel

and moulding to 65deg C.

Using white spirit ensure that mounting area is clean, dry and

de-greased.

2. Remove protective backing tape from moulding.

3. NOTE: Do not allow moulding to contact the fender until it is

correctly aligned.

Heat moulding and mounting area to 65deg C.

4. Aligning with adjacent mouldings or to match opposite side of

vehicle, press new mouldi ng firmly onto fender.

5. Apply hand pressure along moulding length to ensure

satisfactory adhesion.

6. Allow moulding and fender to cool , then thoroughly clean both

using white spirit.

7. Apply a coat of suitable poli sh to moulding and fender.

Page 2179 of 2490

Glass, Frames and Mechanisms - Glass, Frames and Mechanisms

Description and Operation

Fixed Glass

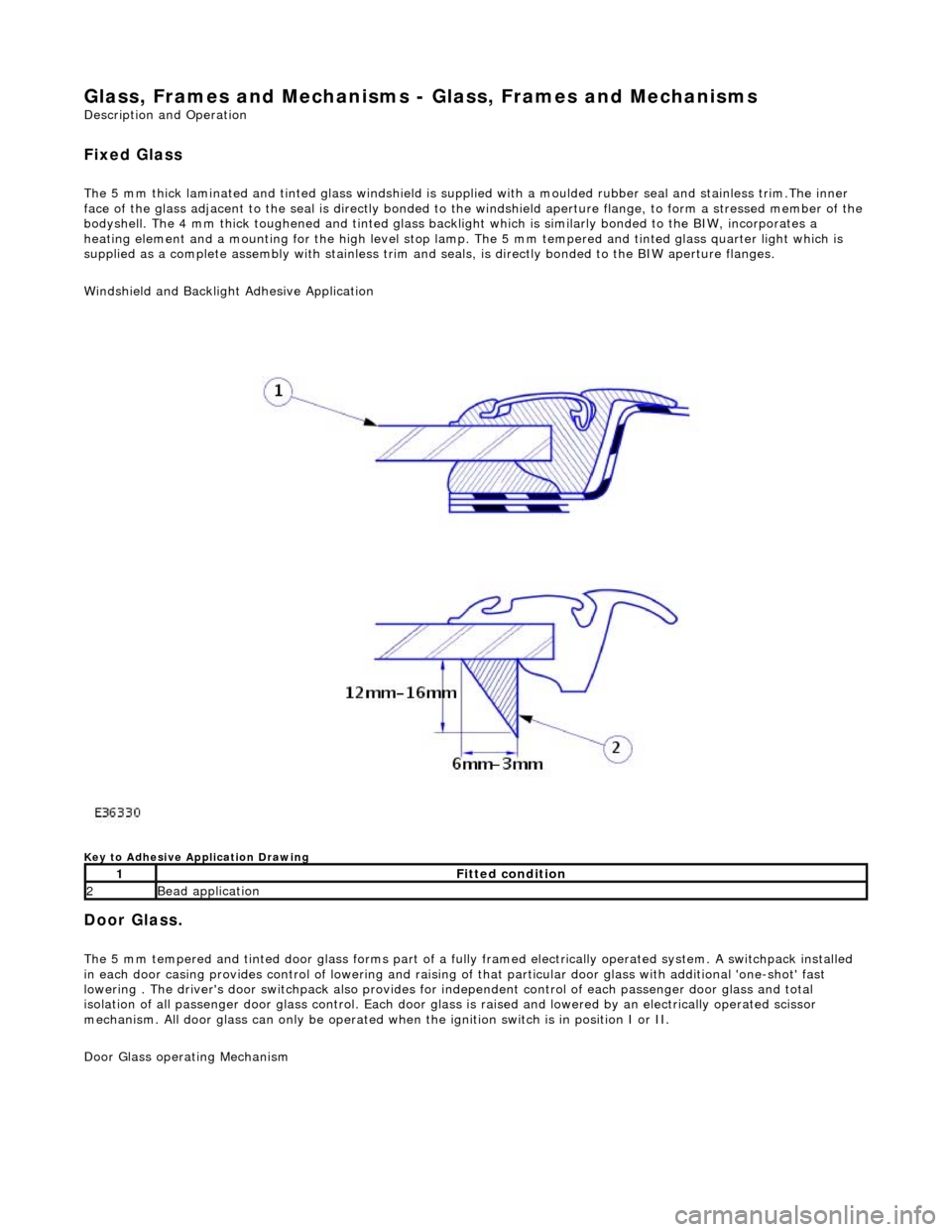

The 5 mm thick laminated and tinted glas s windshield is supplied with a moulded rubber seal and stainless trim.The inner

face of the glass adjacent to the seal is directly bonded to the windshield aperture flange, to form a stressed member of the

bodyshell. The 4 mm thick toughened and tinted glass backlight which is similarly bonded to the BIW, incorporates a

heating element and a mounting for the high level stop lamp. The 5 mm tempered and tinted glass quarter light which is

supplied as a complete assembly with stainless trim and seals, is directly bonded to the BIW aperture flanges.

Windshield and Backlight Adhesive Application

Key to Adhesive Application Drawing

Door Glass.

The 5 mm tempered and tinted door glass forms part of a fully framed electrically operated system. A switchpack installed

in each door casing provides control of lowering and raising of that particular d oor glass with additional 'one-shot' fast

lowering . The driver's door switchpack also provides for independent control of each passenger door glass and total

isolation of all passenger door glass control. Each door glas s is raised and lowered by an electrically operated scissor

mechanism. All door glass can only be operated wh en the ignition switch is in position I or II.

Door Glass operating Mechanism

1Fitted condition

2Bead application

Page 2200 of 2490

Glass, Frames and Mechanisms - Rear Quarter Window Glass

Removal and Installation

Removal

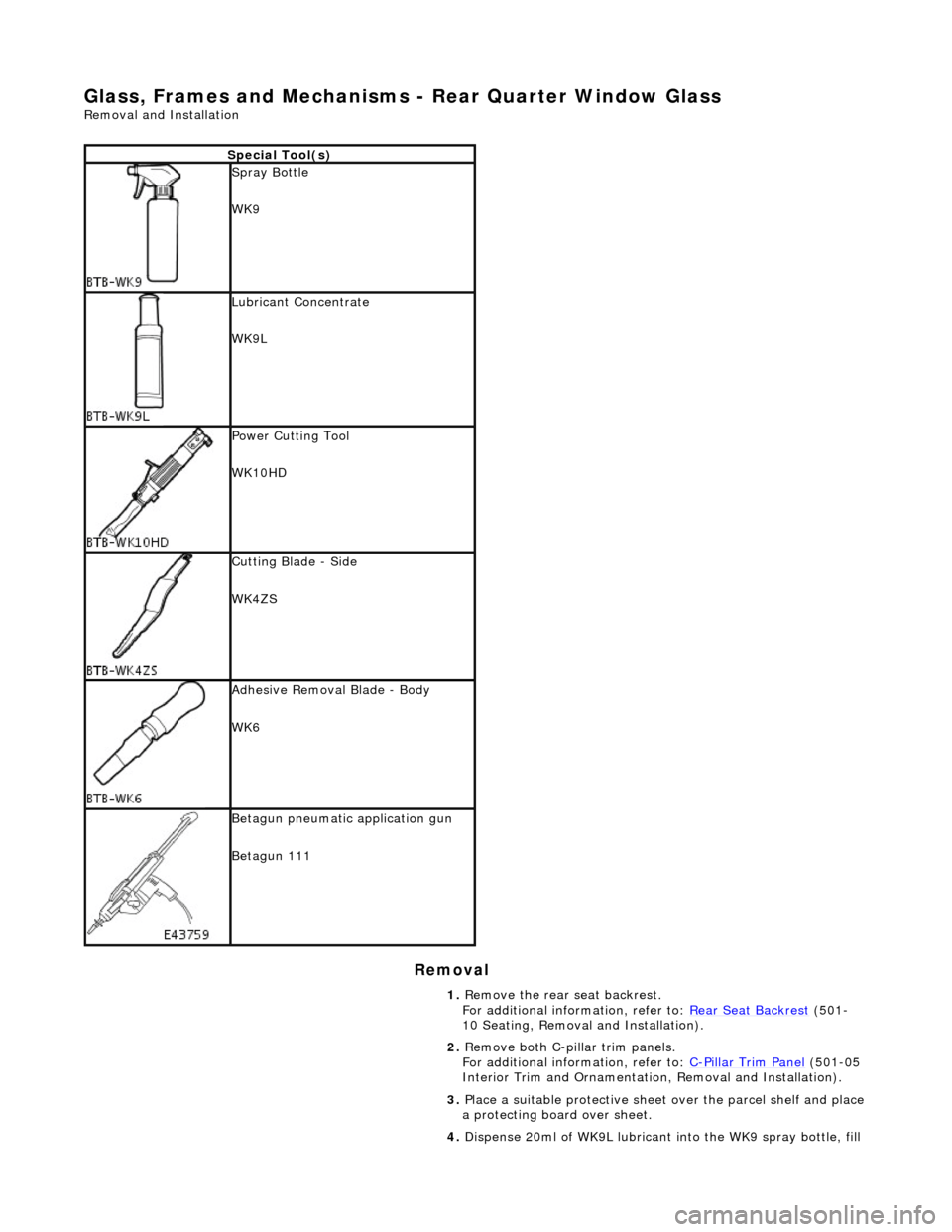

Special Tool(s)

Spray Bottle

WK9

Lubricant Concentrate

WK9L

Power Cutting Tool

WK10HD

Cutting Blade - Side

WK4ZS

Adhesive Removal Blade - Body

WK6

Betagun pneumatic application gun

Betagun 111

1. Remove the rear seat backrest.

For additional information, refer to: Rear Seat Backrest

(501-

10 Seating, Removal and Installation).

2. Remove both C-pill ar trim panels.

For additional information, refer to: C

-Pillar Trim Panel (501-05

Interior Trim and Ornamentatio n, Removal and Installation).

3. Place a suitable protective sheet over the parcel shelf and place

a protecting boar d over sheet.

4. Dispense 20ml of WK9L lubricant into the WK9 spray bottle, fill

Page 2201 of 2490

Installation

the spray bottle with water and mix.

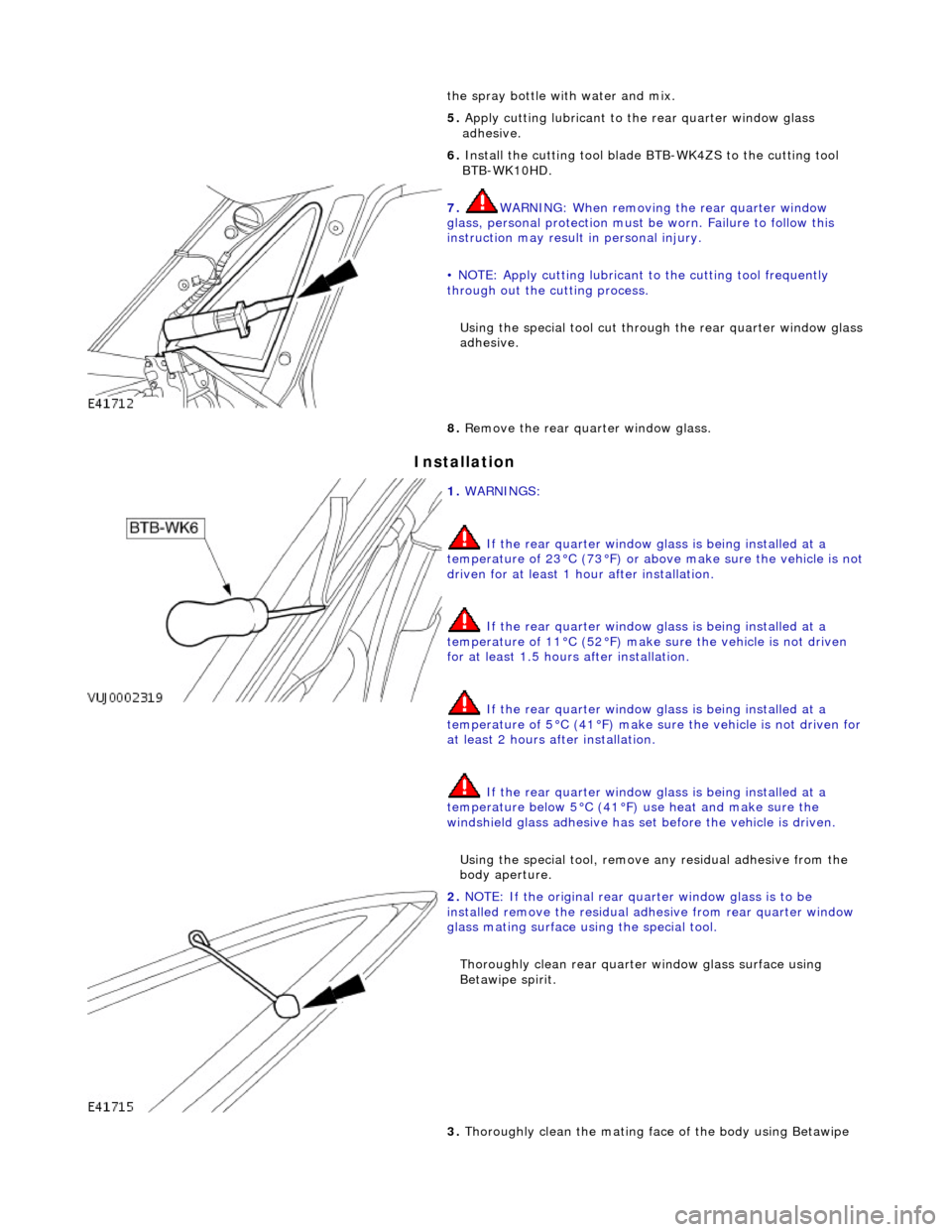

5. Apply cutting lubricant to the rear quarter window glass

adhesive.

6. Install the cutting tool blade BTB-WK4ZS to the cutting tool

BTB-WK10HD.

7. WARNING: When removing the rear quarter window

glass, personal protec tion must be worn. Failure to follow this

instruction may result in personal injury.

• NOTE: Apply cutting lubricant to the cutting tool frequently

through out the cutting process.

Using the special tool cut throug h the rear quarter window glass

adhesive.

8. Remove the rear quarter window glass.

1. WARNINGS:

If the rear quarter window glass is being installed at a

temperature of 23°C (73°F) or abov e make sure the vehicle is not

driven for at least 1 hour after installation.

If the rear quarter window glass is being installed at a

temperature of 11°C (52°F) make sure the vehicle is not driven

for at least 1.5 hours after installation.

If the rear quarter window glass is being installed at a

temperature of 5°C (41°F) make su re the vehicle is not driven for

at least 2 hours after installation.

If the rear quarter window glass is being installed at a

temperature below 5°C (41°F) use heat and make sure the

windshield glass adhesive has set before the vehicle is driven.

Using the special tool, remove any residual adhe sive from the

body aperture.

2. NOTE: If the original rear qu arter window glass is to be

installed remove the residual ad hesive from rear quarter window

glass mating surface using the special tool.

Thoroughly clean rear quarte r window glass surface using

Betawipe spirit.

3. Thoroughly clean the mating face of the body using Betawipe