JAGUAR X308 1998 2.G Workshop Manual

Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 341 of 2490

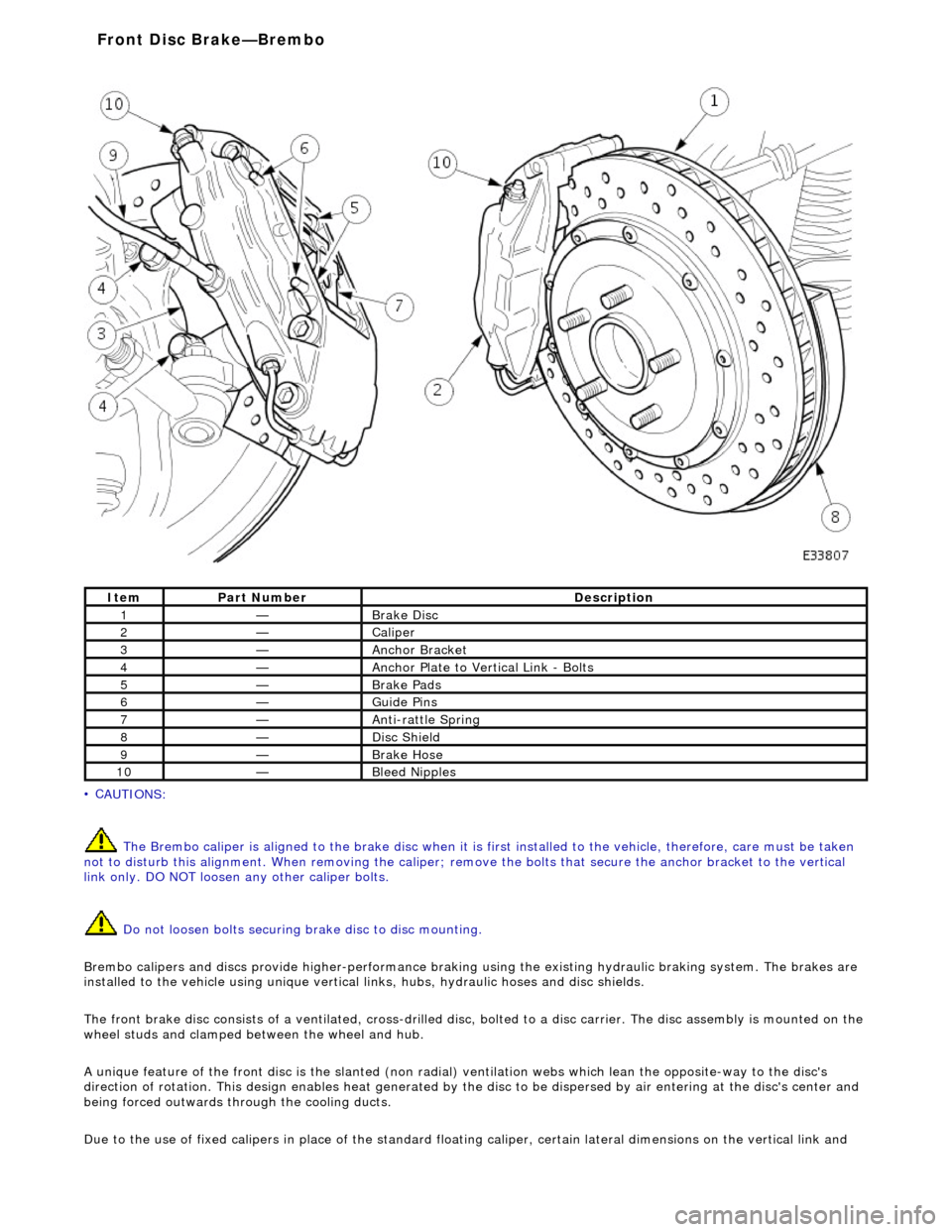

• C

AUTIONS:

The Brembo caliper is aligned to the brak e disc when it is first installed to the vehicle, therefore, care must be taken

not to disturb this alignment. When removi ng the caliper; remove the bolts that secure the anchor bracket to the vertical

link only. DO NOT loosen any other caliper bolts.

Do not loosen bolts securing brake disc to disc mounting.

Brembo calipers and discs provide higher -performance braking using the existing hydraulic braking system. The brakes are

installed to the vehicle using unique vertical links, hubs, hydraulic hoses and disc shields.

The front brake disc consists of a ventilated, cross-drilled disc, bolted to a disc carrier. The disc assemb ly is mounted on the

wheel studs and clamped be tween the wheel and hub.

A unique feature of the front disc is th e slanted (non radial) ventilation webs which lean the opposite-way to the disc's

direction of rotation. This design enables he at generated by the disc to be dispersed by air entering at the disc's center and

being forced outwards through the cooling ducts.

Due to the use of fixed calipers in place of the standard floating caliper, certain lateral dimensions on the vertical link and

It

em

Par

t Number

De

scription

1—B

rake Disc

2—Caliper

3—Anch

or Bracket

4—Anchor Pl

ate to Vertical Link - Bolts

5—Brake Pad

s

6—Guide P

ins

7—Anti-r

attle Spring

8—Di

sc Shield

9—Brake Hos

e

10—Bleed Nipp

les

Front Disc Brake—

Brembo

Page 342 of 2490

hub are critical to achieve correct clearan

ce and operation of

the brakes. Therefore special vertical links and hubs set within

a certain tolerance are inst alled with Brembo brakes.

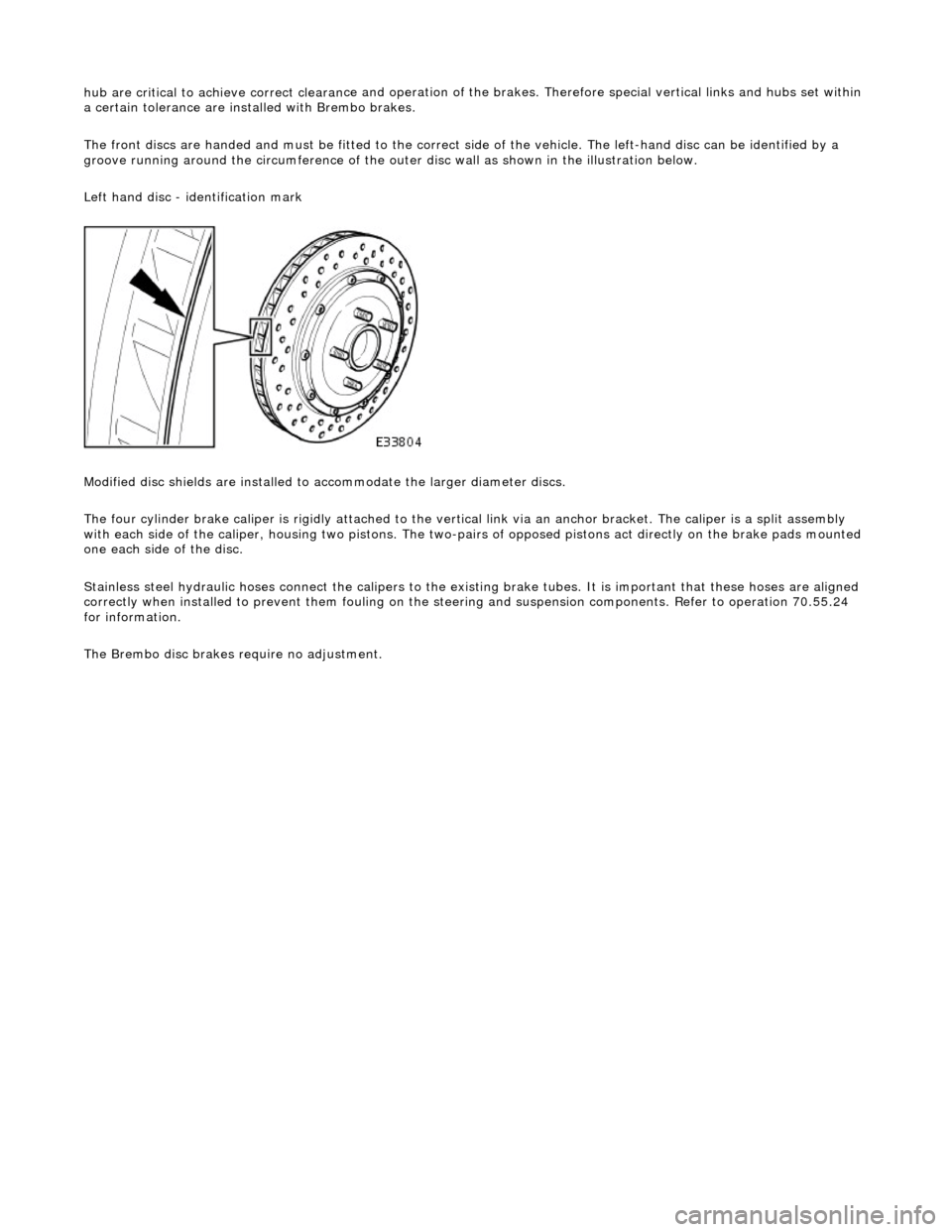

The front discs are handed and must be fitt ed to the correct side of the vehicle. The left-hand disc can be identified by a

groove running around the circumference of the outer disc wall as shown in the illustration below.

Left hand disc - identification mark

Modified disc shields are installed to accommodate the larger diameter discs.

The four cylinder brake caliper is rigidly attached to the vert ical link via an anchor bracket. The caliper is a split assembly

with each side of the caliper, housing two pistons. The two-pairs of opposed pistons act direct ly on the brake pads mounted

one each side of the disc.

Stainless steel hydraulic hoses connect the calipers to the existi ng brake tubes. It is important that these hoses are aligned

correctly when installed to pr event them fouling on the steering and suspen sion components. Refer to operation 70.55.24

for information.

The Brembo disc brakes require no adjustment.

Page 343 of 2490

Front Disc Brake - Brake CaliperVehicles

With: Standard Brakes

Re

moval and Installation

Remov

al

W

ARNING: BRAKE DUST, IF INHALED CAN DAMAGE YOUR

HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRESSED-AIR LINE TO DISPERSE BRAKE DUST INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking de vices are used on nuts and bolts throughout the vehicle.

These devices restrict the number of times a nut or bolt can be used. See section 100-00 for information.

Remove brake fluid spilla ge immediately from paint work, with clean water.

A new brake hose must be installe d when replacing a brake caliper.

The brake pad adhesive backing must not be reused, therefore always install new brake pads, irrespective of the

condition of the original pads when replacing a brake caliper. Always replace brake pads as an axle set.

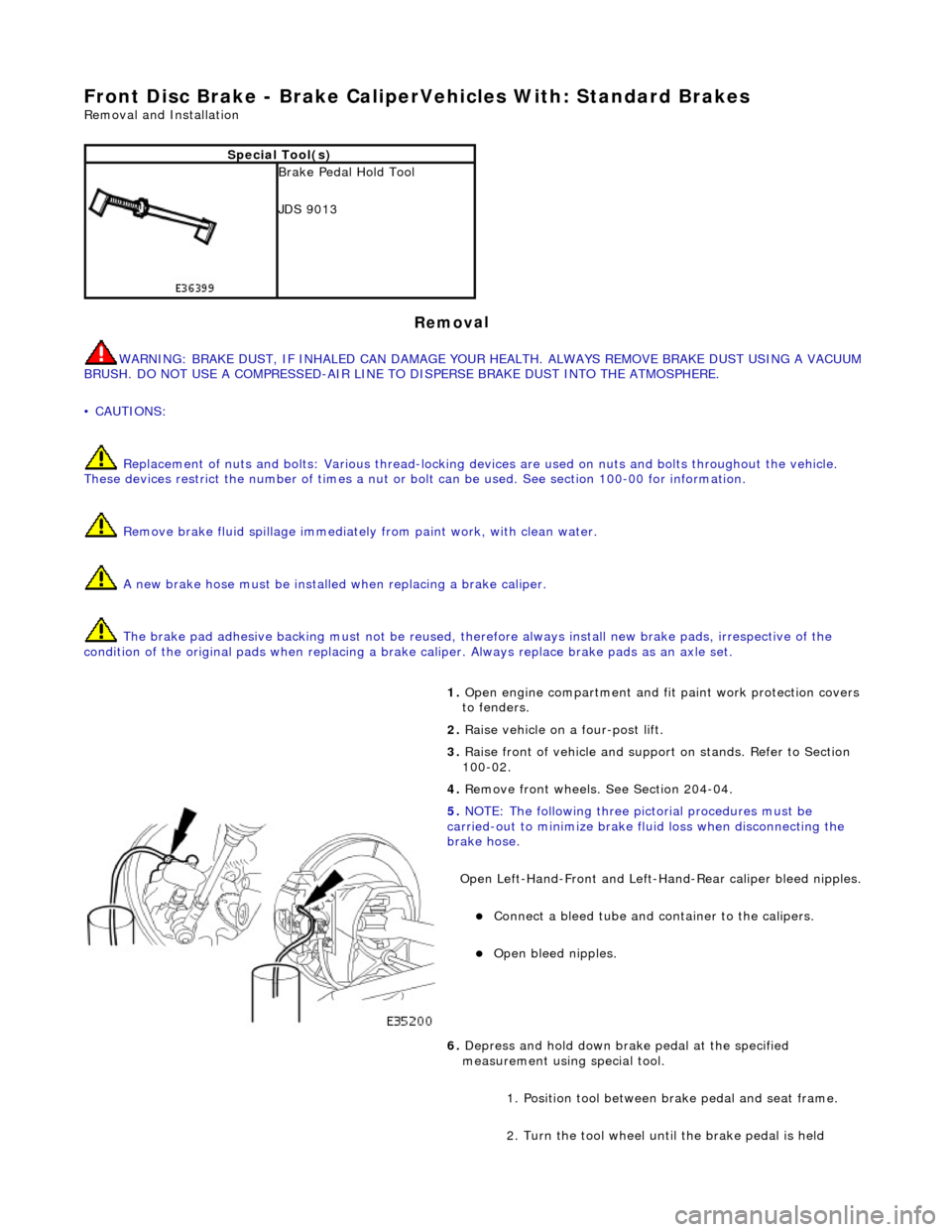

S

pecial Tool(s)

Brake Pedal

Hold Tool

JDS 9013

1. O

pen engine compartment and fit

paint work protection covers

to fenders.

2. Raise vehicle on a four-post lift.

3. Raise front of vehicle and support on stands. Refer to Section

100-02.

4. Remove front wheels. See Section 204-04.

5. NOTE

: The following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake hose.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

Connect

a bleed tube and co

ntainer to the calipers.

O

pen bleed nipples.

6. Depress and hold down brak e pedal at the specified

measurement using special tool.

1. Position tool between brake pedal and seat frame.

2. Turn the tool wheel unti l the brake pedal is held

Page 344 of 2490

60

mm down from its released position.

7. Close bleed nipples on both calipers.

Remove bleed tub e

s and containers.

Tigh

ten front bleed nipple

to 4-6 Nm.

Tigh

ten rear bleed n

ipple to 8-11 Nm.

8. CAUTIO

N: A new brake hose

must be installed when

replacing a brake caliper.

Disconnect brake hose from brake tube.

1. Unscrew brake tube union nut.

2. Remove nut from hose.

3. Remove hose from bracket.

Fit plug to brake tube.

9.

Re

move brake hose from caliper.

Remove an

d discard brake h

ose.

Fit plugs

to caliper por

t.

10. Remove caliper housing from caliper carrier.

1. Remove anti-rattle spring.

2. Remove dust covers.

3. Remove guide pins.

Page 345 of 2490

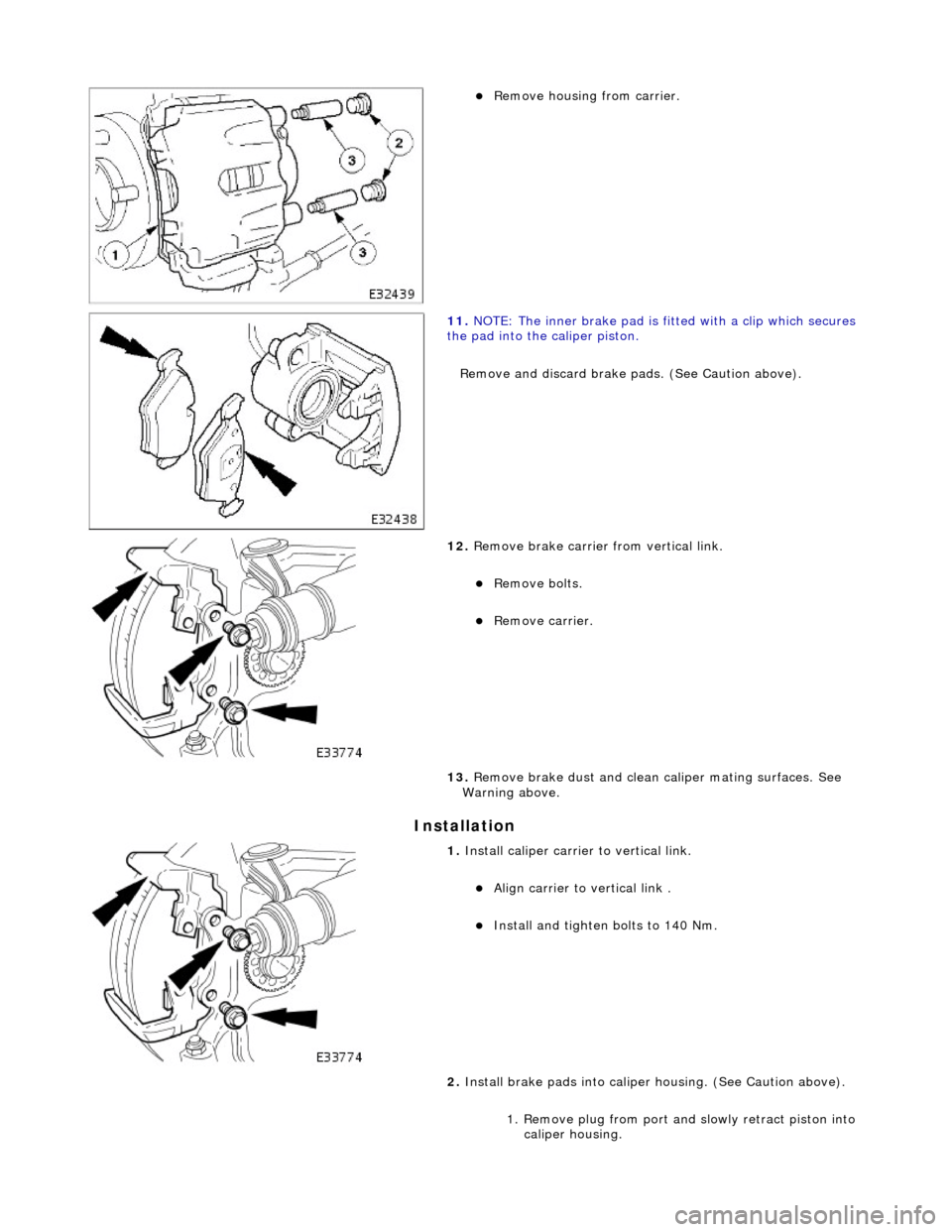

I

nstallation

R

emove housing from carrier.

11

.

NOTE: The inner brake pad is fitt ed with a clip which secures

the pad into the caliper piston.

Remove and discard brake pa ds. (See Caution above).

12

.

Remove brake carrier from vertical link.

Re

move bolts.

R

emove carrier.

13. Remove brake dust and clean caliper mating surfaces. See

Warning above.

1. Install

caliper carrier to vertical link.

Al

ign carrier to vertical link .

Install and tigh

ten bolts to 140 Nm.

2. Install brake pads in to caliper housing. (See Caution above).

1. Remove plug from port and slowly retract piston into caliper housing.

Page 346 of 2490

2.

Remove paper backing from pads to reveal adhesive

shim. Install brake pads, insert clip located on back of

inner pad into caliper piston.

3. Inst al

l caliper housing to caliper carrier.

Align hou

s

ing to carrier.

1. Install and tighten guide pins to 25-30 Nm.

2. Install dust covers.

3. Install anti-rattle spring.

4. NOTE : Th

e brake hose must only be installed with the vehicle's

body supported and the suspension hanging.

Install and tighten brake hose to caliper housing to 10-14 Nm.

5. NO

TE: Make sure the brake

hose does not twist when

tightening the hose lock-nut.

Connect brake hose to brake tube.

1. Position hose thread through bracket.

2. Install and tighten locking nut. Refer to Specifications, section 206-03.

3. Install and tighten brake- tube union nut. Refer to

Specifications, section 206-03.

6. Remove special tool from brake pedal.

7. Fit wheels. Refer to section 204-04.

8. NOTE: Make sure the brake hose is routed correctly.

Remove stands and lower vehicl e. Refer to section 100-02.

9. Bleed brake hydraulic system. See operation 70.25.03.

Page 347 of 2490

Front Disc Brake - Brake CaliperVehicles With: High Performance Brakes

Re

moval and Installation

Remov

al

S

pecial Tool(s)

Brake Pedal

Hold Tool

JDS 9013

1. WARNING: BRAKE DUST, IF INHALED CAN DAMAGE

YOUR HEALTH. ALWAYS REMOVE BRAKE DUST USING A VACUUM

BRUSH. DO NOT USE A COMPRE SSED-AIR LINE TO DISPERSE

BRAKE DUST INTO THE ATMOSPHERE.

• CAUTIONS:

Replacement of nuts and bolts: Various thread-locking

devices are used on nuts and bolts throughout the vehicle. These

devices restrict the number of ti mes a nut or bolt can be used.

See section 100-00 for information.

Remove brake fluid spillage immediately from paint work,

with clean water.

The Brembo caliper is aligned to the brake disc when it is

first installed to the vehicle, therefore, care must be taken not to

disturb this alignment. When removing the caliper; remove the

bolts that secure the anchor bracket to the vertical link only. DO

NOT loosen any other caliper bolts.

Open engine compartment and fit paint work protection covers

to fenders.

2. R

aise vehicle on a four-post lift.

3. Raise front of vehicle and support on stands. Refer to Section

100-02.

4. Remove front wheels. Refe r to operation 74.20.05.

5. NOTE

: The following three pictorial procedures must be

carried-out to minimize brake fl uid loss when disconnecting the

brake hose.

Open Left-Hand-Front and Left-H and-Rear caliper bleed nipples.

Connect

a bleed tube and co

ntainer to the calipers.

O

pen bleed nipples.

6. Depress and hold down brak e pedal at the specified

measurement using the special tool.

Page 348 of 2490

1.

Position tool between

brake pedal and seat frame.

2. Turn the tool wheel unti l the brake pedal is held

60mm down from its released position.

7. Close bleed nipples on both calipers.

Tigh ten bleed n

ipples to 12-16 Nm.

Remove bleed tub

e

s and containers.

8. Disc

onnect brake hose from brake tube.

1. Unscrew brake tube union nut.

2. Remove nut from hose.

3. Remove hose from bracket.

Fit plugs to brake tu

be and hose.

9. Re

lease brake hose from caliper.

R

e

move union bolt.

Remove an

d discard se

aling washers.

Inst

al

l plugs into caliper and hose.

10. Remove brake pads from caliper.

1. Remove 'R' clips.

2. Withdraw pins from caliper.

3. Remove anti-rattle spring.

Page 349 of 2490

I

nstallation

4

. Remove brake pads.

11

.

CAUTION: Only remove the bolts securing the caliper

anchor bracket to the vertical link. Refer to caution above for

more information.

Remove caliper from vertical link.

Re

move bolts.

12

.

Remove brake dust and clean mating surfaces. See Warning

above.

1. Install

caliper to vertical link.

Install and tigh

ten bolts to 180 Nm.

2. CAUTI

ONS:

Retracting the caliper piston may cause the fluid reservoir

to over-flow. Remove brake flui d spillage immediately from paint

work, with clean water.

Note the condition of pins and 'R' clips and replace if

necessary.

Install brake pads into caliper.

Sl

owly retract caliper pistons.

1. Install pads.

Page 350 of 2490

2.

Po

sition anti-rattle spring.

3. Install pins.

4. Install 'R' clips.

3. CAUTIO

N: The brake hose must

only be installed with the

vehicle's body supported and the suspension hanging.

Install brake hose to caliper.

Remove plugs f rom caliper and hose.

Instal

l new sealing washers.

Install and tigh

ten un

ion bolt to 22-26 Nm.

4.

NO

TE: Make sure the brake

hose does not twist when

tightening the hose lock-nut.

Connect brake hose to brake tube. 1. Position hose thread through bracket.

2. Install and tighten locking nut. Refer to Specifications, section 206-03.

3. Install and tighten brake- tube union nut. Refer to

Specifications, section 206-03.

5. Remove special tool from brake pedal.

6. Fit wheels. Refer to operation 74.20.05.

7. NOTE: Make sure the brake hose is routed correctly.

Remove stands and lower vehicl e. Refer to section 100-02.

8. Bleed brake hydraulic system. See operation 70.25.06.