panel JAGUAR X308 1998 2.G Manual PDF

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1809 of 2490

10. Disconnect radiator bottom hose.

1. Release hose retaining clip.

2. Disconnect hose.

11. Disconnect radiator top hose.

1. Release hose retaining clip.

2. Disconnect hose.

12. Disconnect connector from pressure switch.

13. Release radiator top retaining panel.

Remove bolts.

Page 1810 of 2490

14. Disconnect compressor to condenser discharge line from

condenser.

1. Remove bolt.

2. Discard O-ring seal.

3. Install suitable blanking plugs.

15. Disconnect condenser to receiver / drier line from receiver /

drier.

1. Remove bolt.

2. Discard O-ring seal.

3. Install suitable blanking plugs.

16. Remove radiator retaining panel.

1. Remove panel.

2. Remove mounting bushes.

17. Disconnect hood switch harness connector.

Page 1811 of 2490

Installation

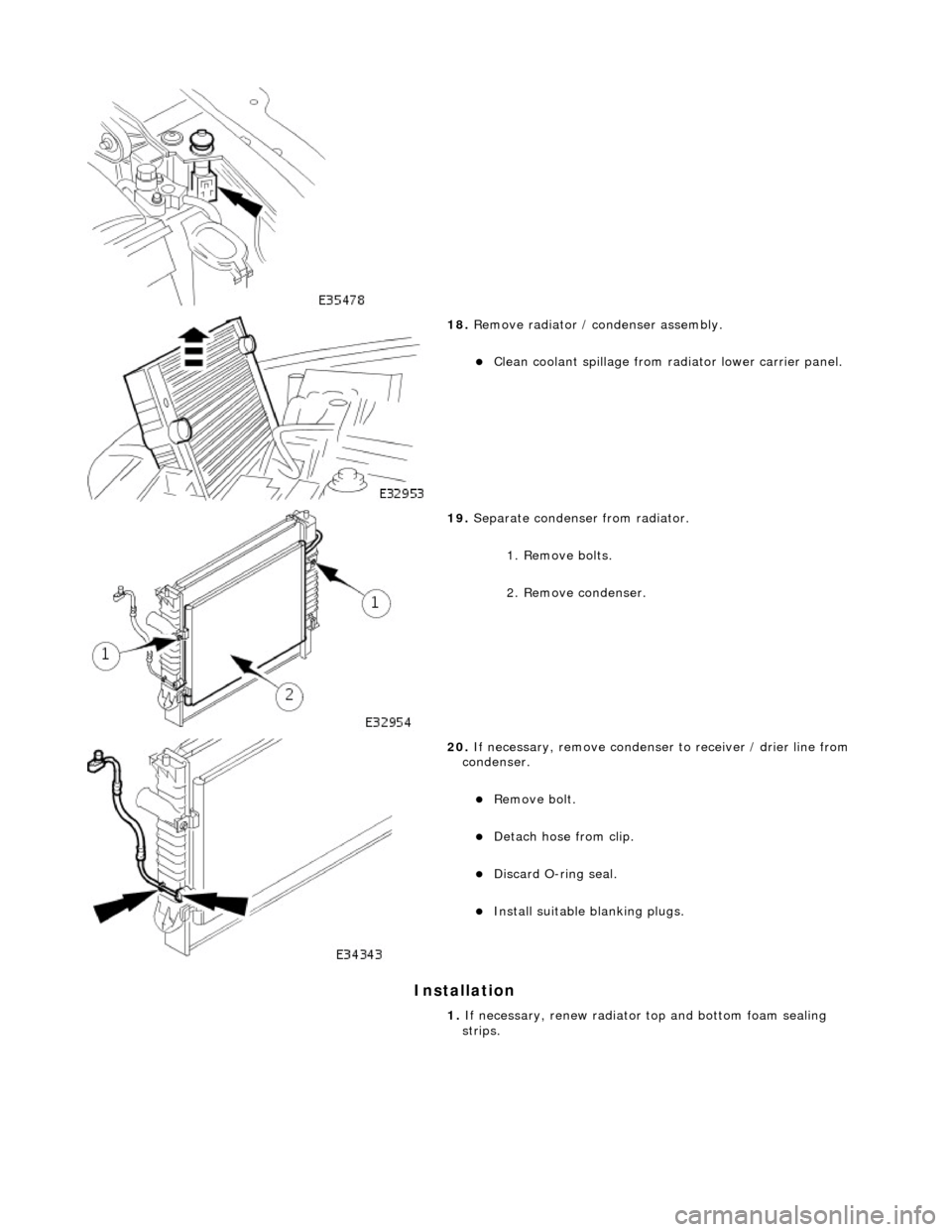

18. Remove radiator / condenser assembly.

Clean coolant spillage from radiator lower carrier panel.

19. Separate condenser from radiator.

1. Remove bolts.

2. Remove condenser.

20. If necessary, remove condenser to receiver / drier line from

condenser.

Remove bolt.

Detach hose from clip.

Discard O-ring seal.

Install suitable blanking plugs.

1. If necessary, renew radiator top and bottom foam sealing

strips.

Page 1814 of 2490

10. Connect radiator top hose to radiator.

1. Connect top hose.

2. Reposition and tighten hose clip.

11. Install radiator retaining panel.

Install bolts and sequenti ally tighten from center

outwards.

12. Connect radiator bottom hose to radiator.

1. Connect bottom hose.

2. Reposition and tighten hose clip.

13. Install twin fan and motor as sembly; refer to 26.25.12.

14. Connect pressure switch.

Page 1821 of 2490

Control Components - Control Components

Description and Operation

System Controls

The climate control system is controlled by : 1. 1. Manual input from the operator, via the center console located control panel.

2. 2. Automatically by means of the A/CCM.

Output is based upon input from the following devices:

Motorized In-car aspirator External air temperature sensor Coolant temperature sensor Heater 'air-off' (the temperature of the air leaving the matrix fins) temperature sensor Evaporator 'air-off' (the temperature of the air leaving the evaporator fins) temperature sensor Solar sensor Left hand blower recirculation / fresh air flap potentiometer Right hand blower recirculation / fresh air flap potentiometer Upper air distribution box (ADB) center and side face flap servomotor potentiometer ADB defrost flap servomotor potentiometer Air conditioning unit Foot flap servomotor potentiometer Air conditioning unit Cool Air Bypass flap servomotor potentiometer Thumbwheel controls on the facia vent assemblies which provide manu al adjustment of the airflow volume. Road and engine speed signals input to the A/CCM

Climate Control Panel

Communication between the control panel and the A/CCM is via a serial data communications link.

Switching the Climate Control system ON

The climate control system can be switched ON by pressing one of the following :

Ref #1 On / Off (resumes the system on in the previous settings).

Ref #10 A / C (resumes the system on in the previous settings).

Ref #11 AUTO (resumes the system on at the previous temperature setting).

Page 1827 of 2490

Maximum Cooling (temperature setting LO)

Air Conditioning Control Module (A/CCM)

Location

The A/CCM is located on the right hand side of the air conditioning unit and controls all system functions.

The temperature within the passenger compartment is continually compared with the temperature selected on the control

panel LCD. The A/CCM receives data input signals and compares these with signal s from the system temperature sensors

and feedback devices. Based on this information the A/CCM adjusts the air outlet temperatur e, airflow and distribution from

the air conditioning system in to the passenger compartment.

Identification

ItemControlOverride Allowed

Water valveFully closed (energised)-

BlowerMaximumYes

Fresh / recircRecirculationYes

Air distributionFace (state lamp OFF)Yes

A/C systemONYes

Cool air by-passFully open-

Page 1830 of 2490

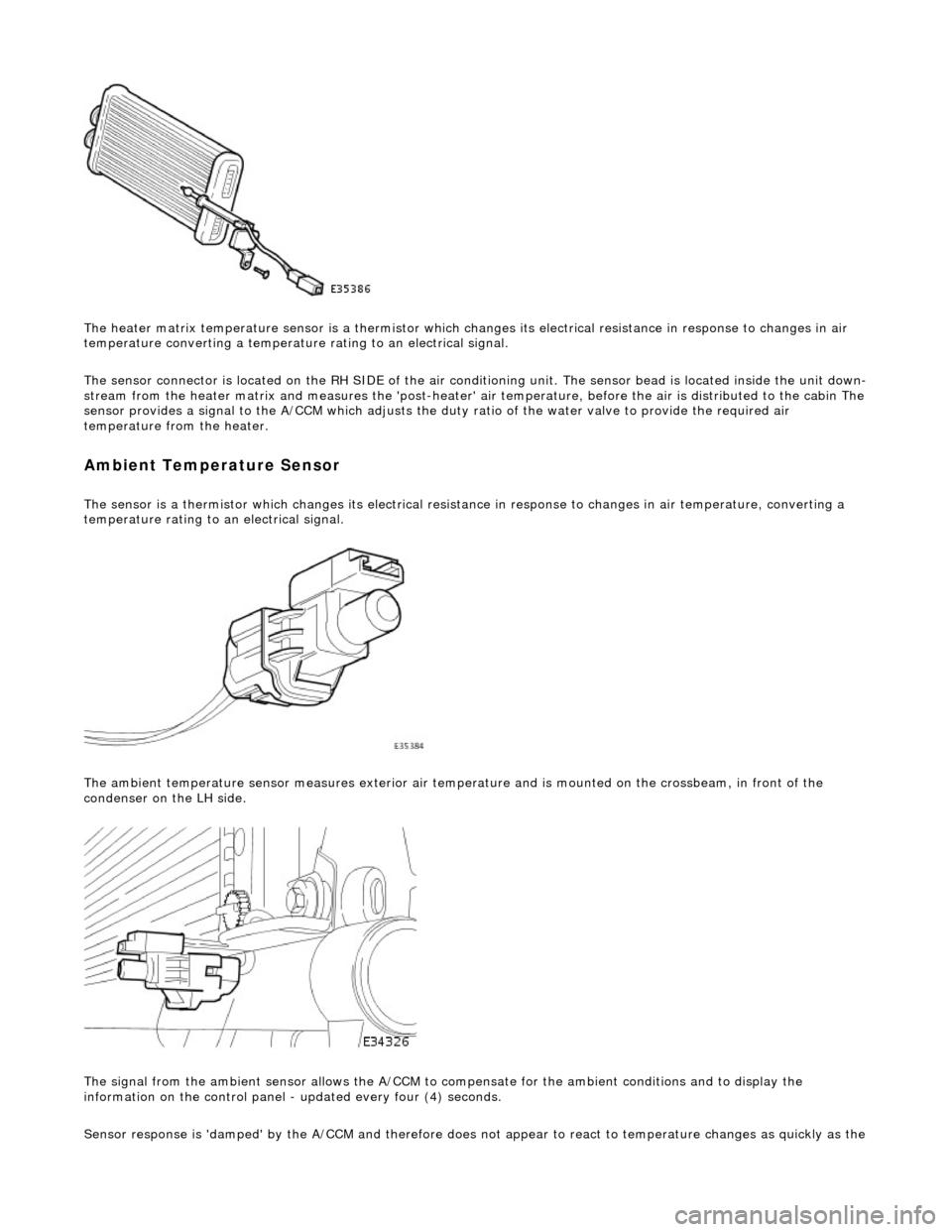

The heater matrix temperature sensor is a thermistor which changes its electrical resistance in response to changes in air

temperature converting a temperature rating to an electrical signal.

The sensor connector is located on the RH SIDE of the air conditioning unit. The sensor bead is located inside the unit down-

stream from the heater matrix and measures the 'post-heater' air temperature, before the air is distribu ted to the cabin The

sensor provides a signal to the A/CCM which adjusts the duty ratio of the water valve to provide the required air

temperature from the heater.

Ambient Temperature Sensor

The sensor is a thermistor which changes its electrical resistance in response to changes in air temperature, converting a

temperature rating to an electrical signal.

The ambient temperature sensor measures exterior air temper ature and is mounted on the crossbeam, in front of the

condenser on the LH side.

The signal from the ambient sensor allo ws the A/CCM to compensate for the ambient conditions and to display the

information on the control panel - updated every four (4) seconds.

Sensor response is 'damped' by the A/CCM and ther efore does not appear to react to temperature chan

ges as quickly as the

Page 1834 of 2490

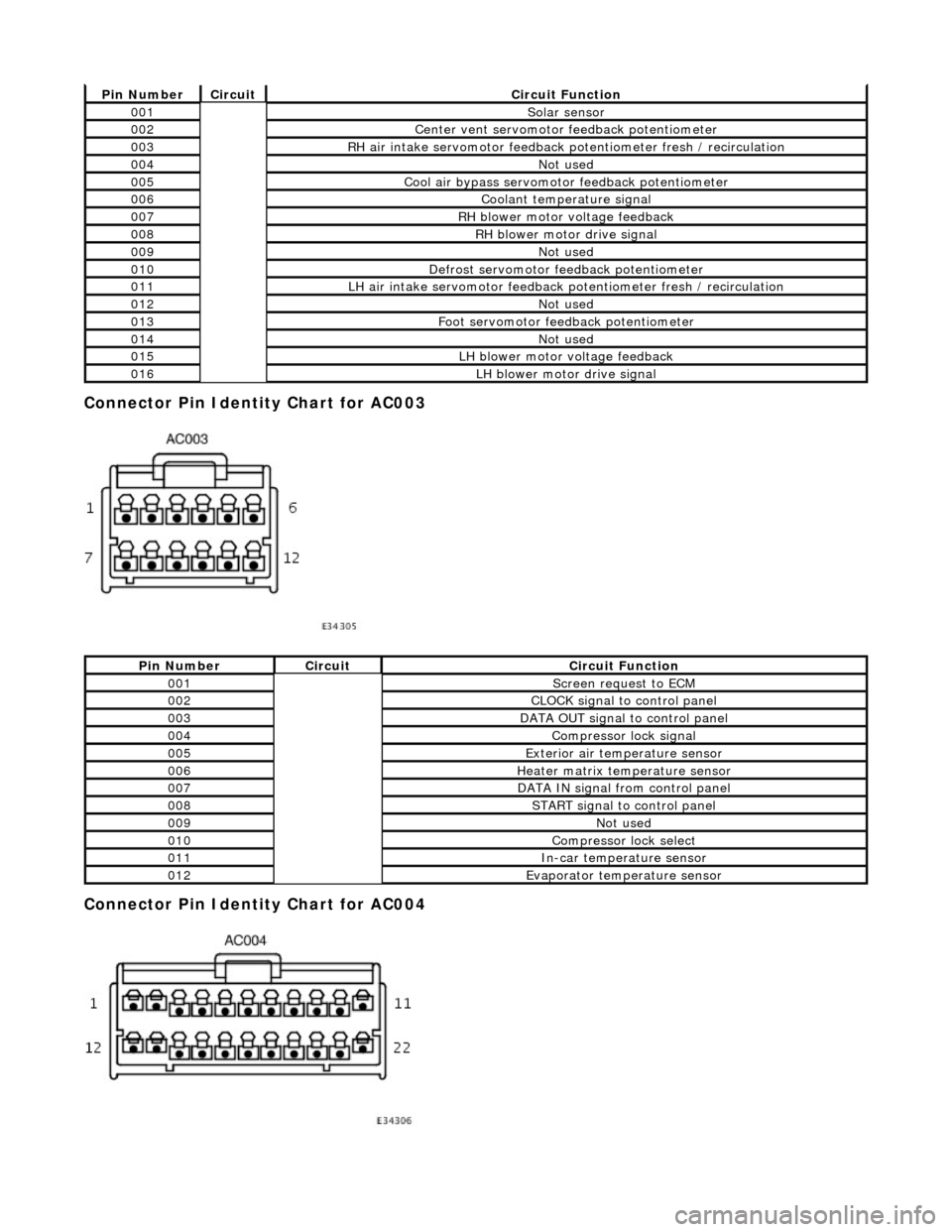

Connector Pin Identity Chart for AC003

Connector Pin Identity Chart for AC004

Pin NumberCircuitCircuit Function

001Solar sensor

002Center vent servomotor feedback potentiometer

003RH air intake servomotor feedback potentiometer fresh / recirculation

004Not used

005Cool air bypass servomotor feedback potentiometer

006Coolant temperature signal

007RH blower motor voltage feedback

008RH blower motor drive signal

009Not used

010Defrost servomotor feedback potentiometer

011LH air intake servomotor feedback potentiometer fresh / recirculation

012Not used

013Foot servomotor feedback potentiometer

014Not used

015LH blower motor voltage feedback

016LH blower motor drive signal

Pin NumberCircuitCircuit Function

001Screen request to ECM

002CLOCK signal to control panel

003DATA OUT signal to control panel

004Compressor lock signal

005Exterior air temperature sensor

006Heater matrix temperature sensor

007DATA IN signal from control panel

008START signal to control panel

009Not used

010Compressor lock select

011In-car temperature sensor

012Evaporator temperature sensor

Page 1835 of 2490

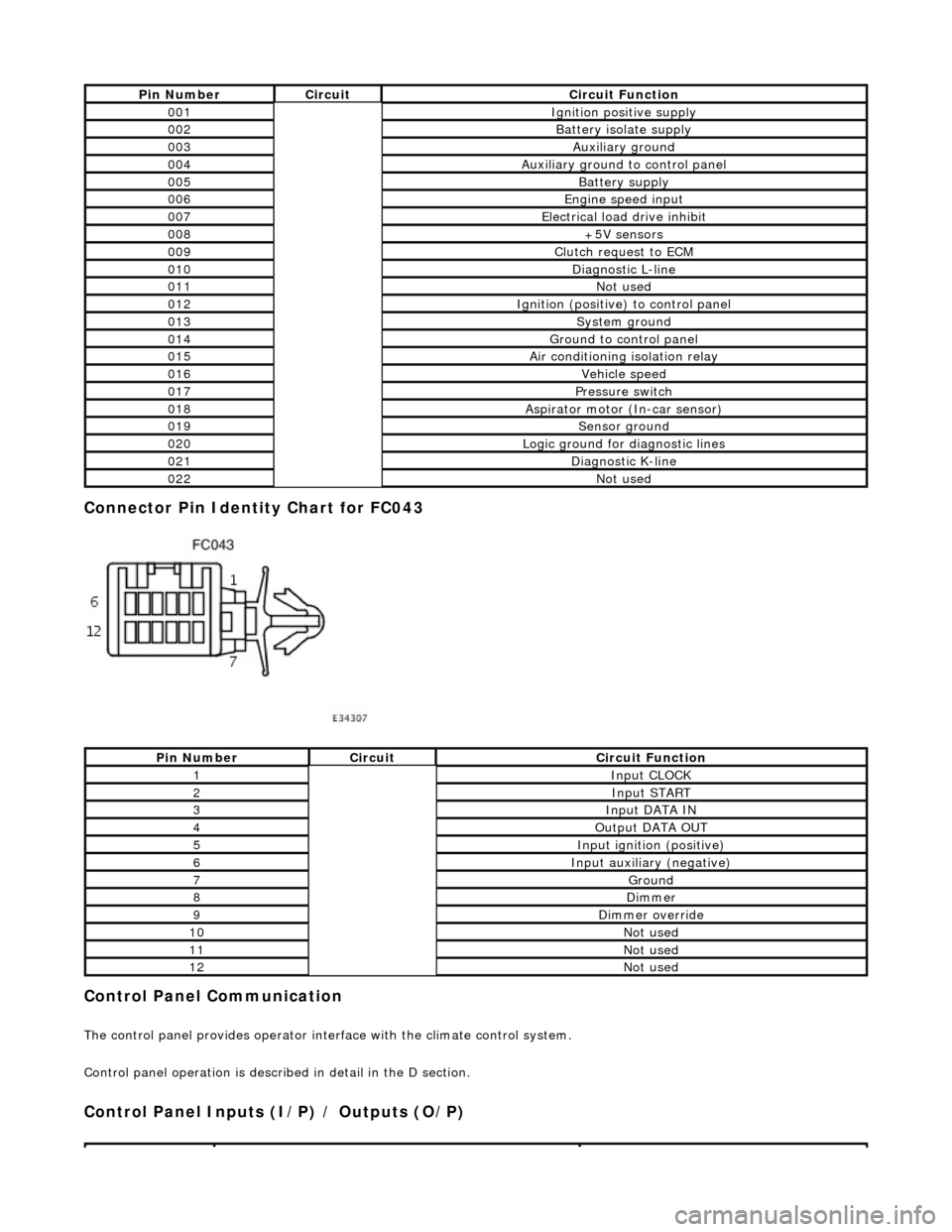

Connector Pin Identity Chart for FC043

Control Panel Communication

The control panel provides operator interface with the climate control system.

Control panel operation is described in detail in the D section.

Control Panel Inputs (I/P) / Outputs (O/P)

Pin NumberCircuitCircuit Function

001Ignition positive supply

002Battery isolate supply

003Auxiliary ground

004Auxiliary ground to control panel

005Battery supply

006Engine speed input

007Electrical load drive inhibit

008+5V sensors

009Clutch request to ECM

010Diagnostic L-line

011Not used

012Ignition (positive) to control panel

013System ground

014Ground to control panel

015Air conditioning isolation relay

016Vehicle speed

017Pressure switch

018Aspirator motor (In-car sensor)

019Sensor ground

020Logic ground for diagnostic lines

021Diagnostic K-line

022Not used

Pin NumberCircuitCircuit Function

1Input CLOCK

2Input START

3Input DATA IN

4Output DATA OUT

5Input ignition (positive)

6Input auxiliary (negative)

7Ground

8Dimmer

9Dimmer override

10Not used

11Not used

12Not used

Page 1836 of 2490

System Self-test

Control Panel Interrogation Procedure

The control panel has a self-diagnosis feature, and is capable of displaying and clearing stored fault codes.

Climate control is an integrated system, therefore it is recommended that the PDU is used for fault diagnosis. The fault

codes displayed with the control panel self -diagnosis feature are not as comprehensive as those of the PDU. The PDU will

display the relevant fault code, fault co de description and information of the system peripherals at the time the fault

occurred.

Fault Code Extraction and Deletion Procedure

Error information is stored in the A/CCM up to a maximum of 5 faults. Should a sensor fault occur there will be an audible

beep and the message Er will be displayed on the control panel display for 5 seco nds after ignition on. Please note that this

will happen only once in any ignition switch cycle. The error source may be accessed by the following procedure

This procedure must be completed through one complete cycle, 1 through 6

• NOTE: * Actuator codes do NOT equate to system fault codes.

• NOTE: Only codes 11, 15 and 21 (see Fault Code List ing) will cause audible beep and 'Er' display.

• NOTE: If '0' is displayed, there are no stored faul t codes, wait 30 seconds to allow system self-test.

The control panel display will flash repeatedly indicating a list of two digit numbers (see table for code analysis). Should a code be displayed accompanied by an audible beep, the fault is current and therefore still present within

the system. A code displayed without an accompanying 'bee p' indicates a fault had previously occurred but is not

present within the system.

• NOTE: It is advisable to check all areas indicated with cleared fault codes. Such faults may re-occur if intermittent

problems are present in the system.

To delete stored and cleared fault codes press 'R' and 'FAC E' buttons simultaneously. After investigating and correcting all stored faults, press the 'Push Off' button to restore normal operation with

default panel settings, ie AUTO at 24°C.

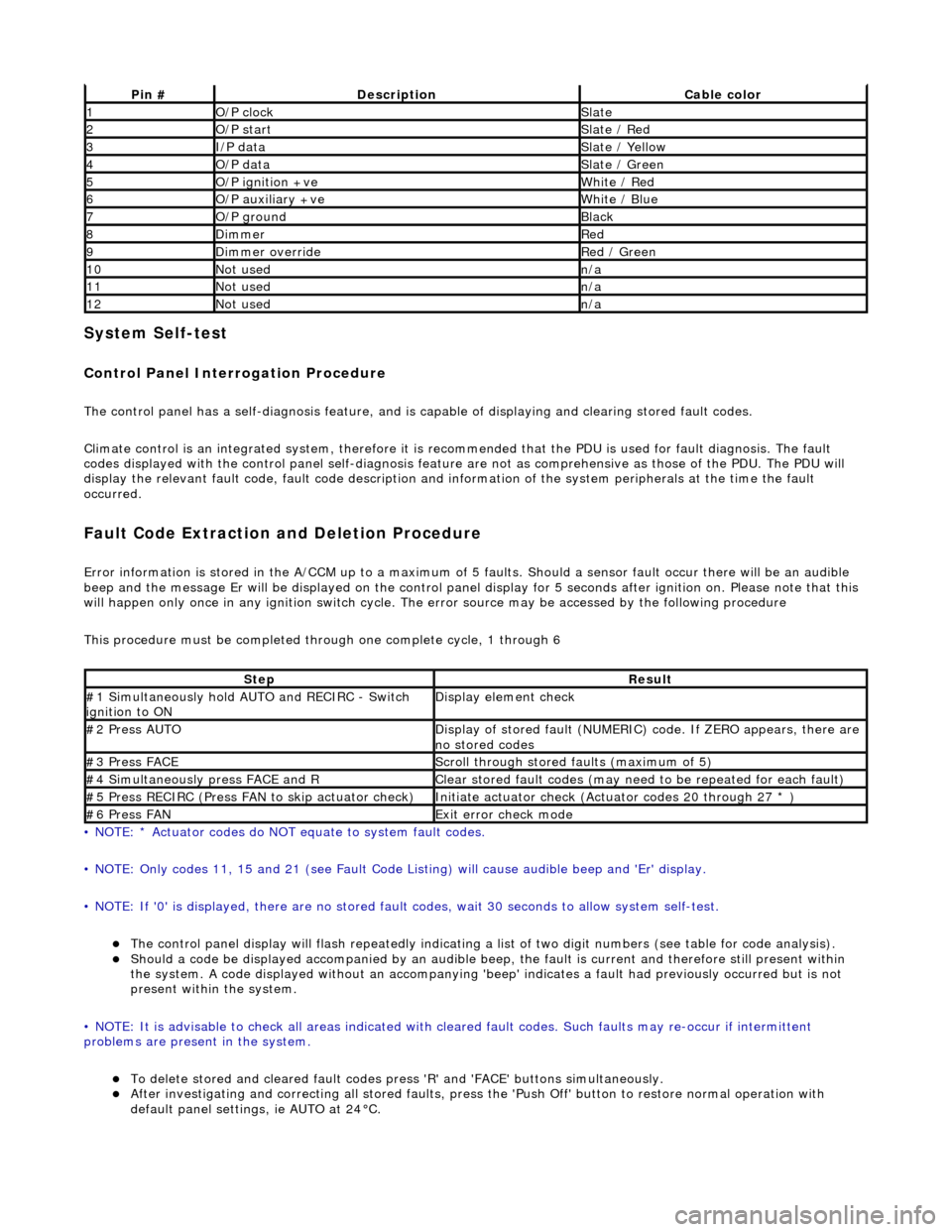

Pin #DescriptionCable color

1O/P clockSlate

2O/P startSlate / Red

3I/P dataSlate / Yellow

4O/P dataSlate / Green

5O/P ignition +veWhite / Red

6O/P auxiliary +veWhite / Blue

7O/P groundBlack

8DimmerRed

9Dimmer overrideRed / Green

10Not usedn/a

11Not usedn/a

12Not usedn/a

StepResult

#1 Simultaneously hold AU TO and RECIRC - Switch

ignition to ONDisplay element check

#2 Press AUTODisplay of stored fault (NUMERIC) code. If ZERO appears, there are

no stored codes

#3 Press FACEScroll through stored faults (maximum of 5)

#4 Simultaneously press FACE and RClear stored fault codes (may need to be repeated for each fault)

#5 Press RECIRC (Press FAN to skip actuator check)Initiate actuator check (Actuator codes 20 through 27 * )

#6 Press FANExit error check mode