panel JAGUAR X308 1998 2.G Workshop Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1959 of 2490

Exterior Lighting - Side Turn Signal Lamp

Removal and Installation

Removal

Installation

1. Remove side repeater lamp.

Applying downward pressure, compress retaining clips and

release lamp upper edge from fender.

Withdraw lamp from panel and disconnect harness

connector.

1. Position lamp at fender and connect harness connector.

2. Position lower edge of lamp in fender aperture and apply

downward pressure to compress clip.

3. Pivot lamp to seat upper edge in fender.

Page 1963 of 2490

Rear courtesy/ reading lamps

Each rear quarter of the passenger compartment is fitted with combined lighting units comprising; a rear courtesy lamp and

reading lamp. The courtesy lamps operate automatically whenever a rear door is opened; the reading lamps function when

the integral switches are operated by occupants of the vehicle.

Trunk lamps

The trunk trim panel is fitted with lamps which operate auto matically whenever the trunk lid is opened; the switch is

incorporated within the latch mechanism.

Vanity mirror lamps

The vanity mirror lamps, two on each sun visor, operate auto matically when the mirror flap is opened, provided the sun

visor spindle is engage d in the stowage clip.

Operation

The BPM provides an enable signal for the glovebox, vanity mirror, trunk lid and map lamps. Actuation of the relevant

switch provides an earth path to the lamp.

The rear passenger reading lamps receive a supply di rect from fuse F10 in the RH heelboard fuse-box.

The front and rear courtesy lamps have separa te fade functions controlled by the BPM.

The door hazard / puddle lamps are controll ed locally by the relevant Door Module.

Fault analysis must be undertaken using the PDU, refer to Diagnosis and Testing.

Refer to the relevant Electrical Guid e for details of circuit operation.

Page 1982 of 2490

Module Communications Network - Battery Junction Box (BJB)

Removal and Installation

Removal

1. Disconnect battery ground cable; refer to 86.15.19.

2. Remove cover from fuse box.

1. Release securing tangs.

2. Remove cover.

3. Remove positive supply power cable.

1. Displace cover.

2. Remove nut.

3. Disconnect cable.

4. Displace fuse box from mounting panel for access.

1. Release securing latch, upwards.

Release fuse box from mountin g panel by displacement

towards spare wheel.

5. Remove fuse box.

1. Identify and disconne ct harness connectors.

Page 1984 of 2490

Module Communications Network - Central Junction Box (CJB) Removal and Installation

Removal

Installation

1. Disconnect battery ground cable; refer to 86.15.19.

2. Remove heelboard trim panel.

3. Remove positive supply power cable and displace fuse box.

1. Displace cover.

Remove nut which secures posi tive cable to fuse box.

2. Disconnect cable.

3. Remove nuts.

4. Remove fuse box.

Identify and disconnect harness connectors.

5. Remove fuses and relay.

1. Remove relay.

2. Identify each fuse and remove them.

The value and position of each fuse is illustrated on the lid of the

trunk compartment fuse box - for all fuse boxes on the vehicle.

1. Installation is reverse of removal.

2. Reconnect battery ground cable; refer to 86.15.15.

Page 1985 of 2490

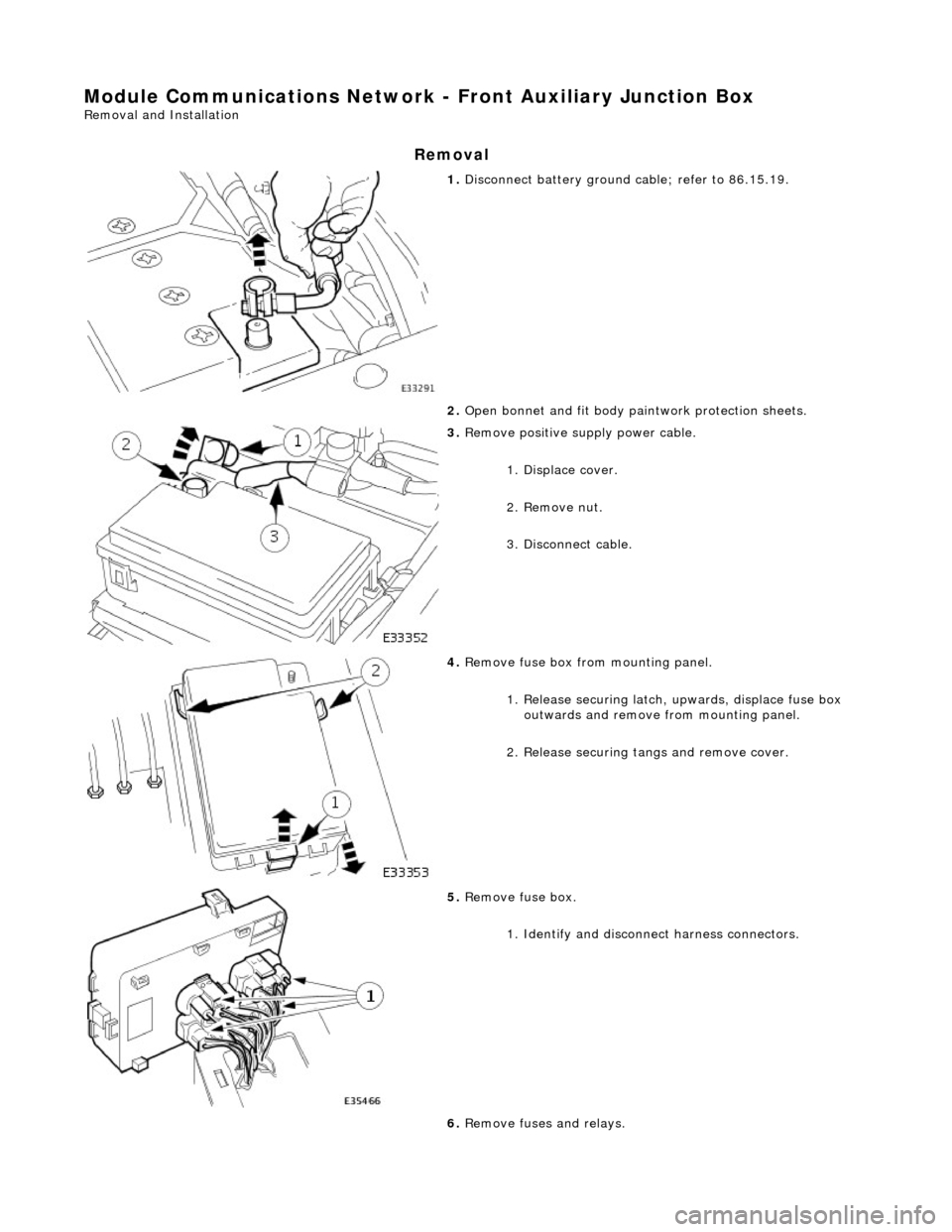

Module Communications Network - Front Auxiliary Junction Box

Removal and Installation

Removal

1. Disconnect battery ground cable; refer to 86.15.19.

2. Open bonnet and fit body pa intwork protection sheets.

3. Remove positive supply power cable.

1. Displace cover.

2. Remove nut.

3. Disconnect cable.

4. Remove fuse box fro m mounting panel.

1. Release securing latch, upwards, displace fuse box

outwards and remove from mounting panel.

2. Release securing tangs and remove cover.

5. Remove fuse box.

1. Identify and disconne ct harness connectors.

6. Remove fuses and relays.

Page 1987 of 2490

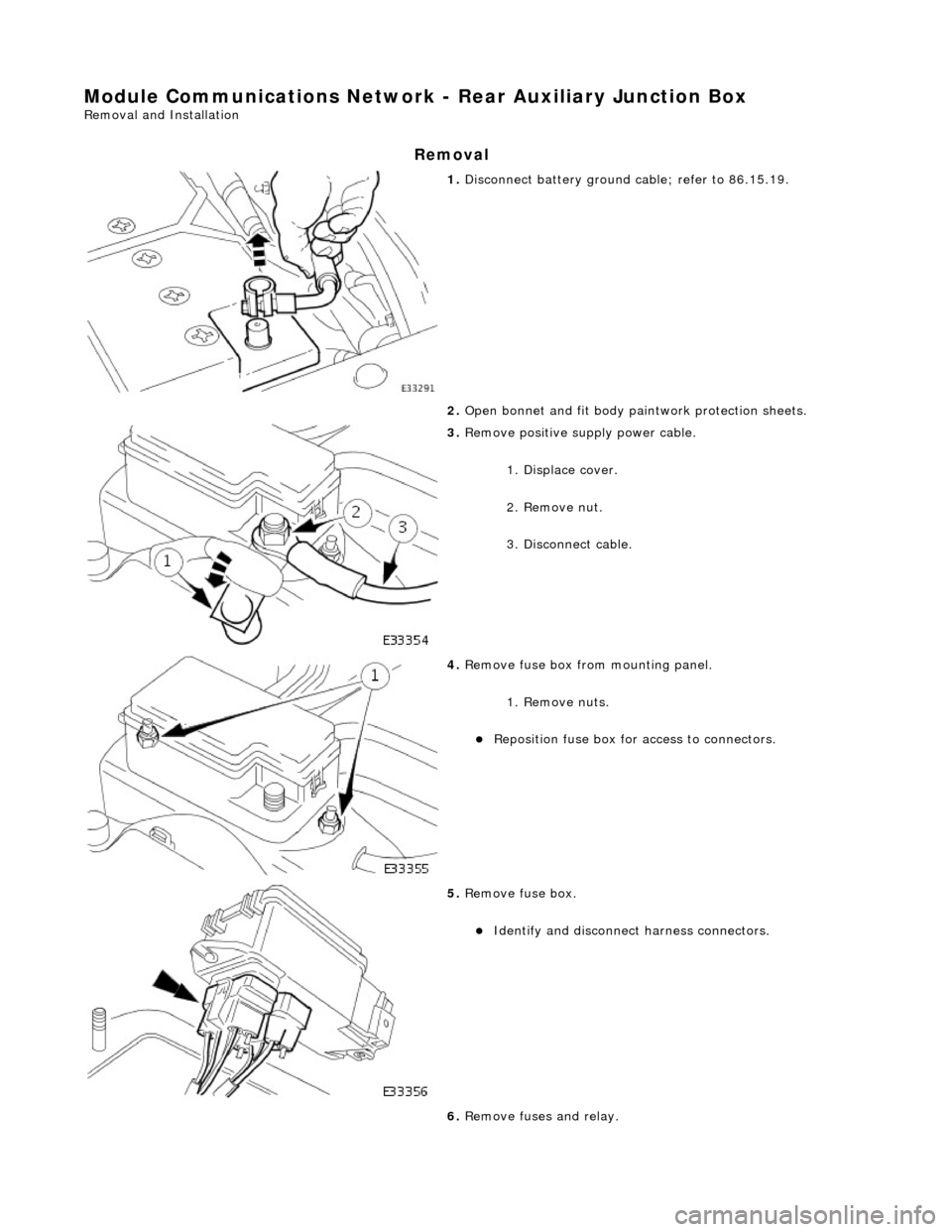

Module Communications Network - Rear Auxiliary Junction Box

Removal and Installation

Removal

1. Disconnect battery ground cable; refer to 86.15.19.

2. Open bonnet and fit body pa intwork protection sheets.

3. Remove positive supply power cable.

1. Displace cover.

2. Remove nut.

3. Disconnect cable.

4. Remove fuse box fro m mounting panel.

1. Remove nuts.

Reposition fuse box for access to connectors.

5. Remove fuse box.

Identify and disconnect harness connectors.

6. Remove fuses and relay.

Page 2019 of 2490

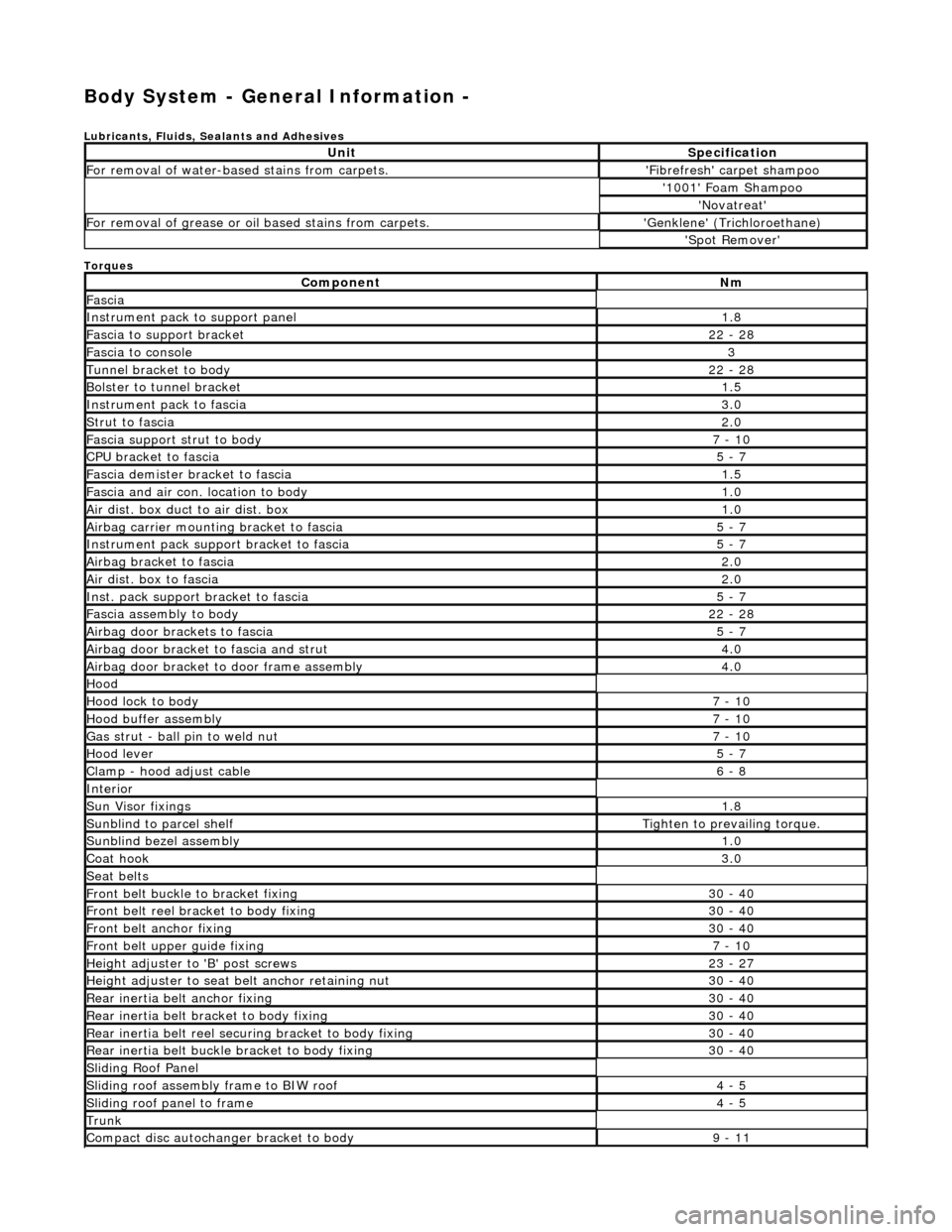

Body System - General Information -

Lubricants, Fluids, Sealants and Adhesives

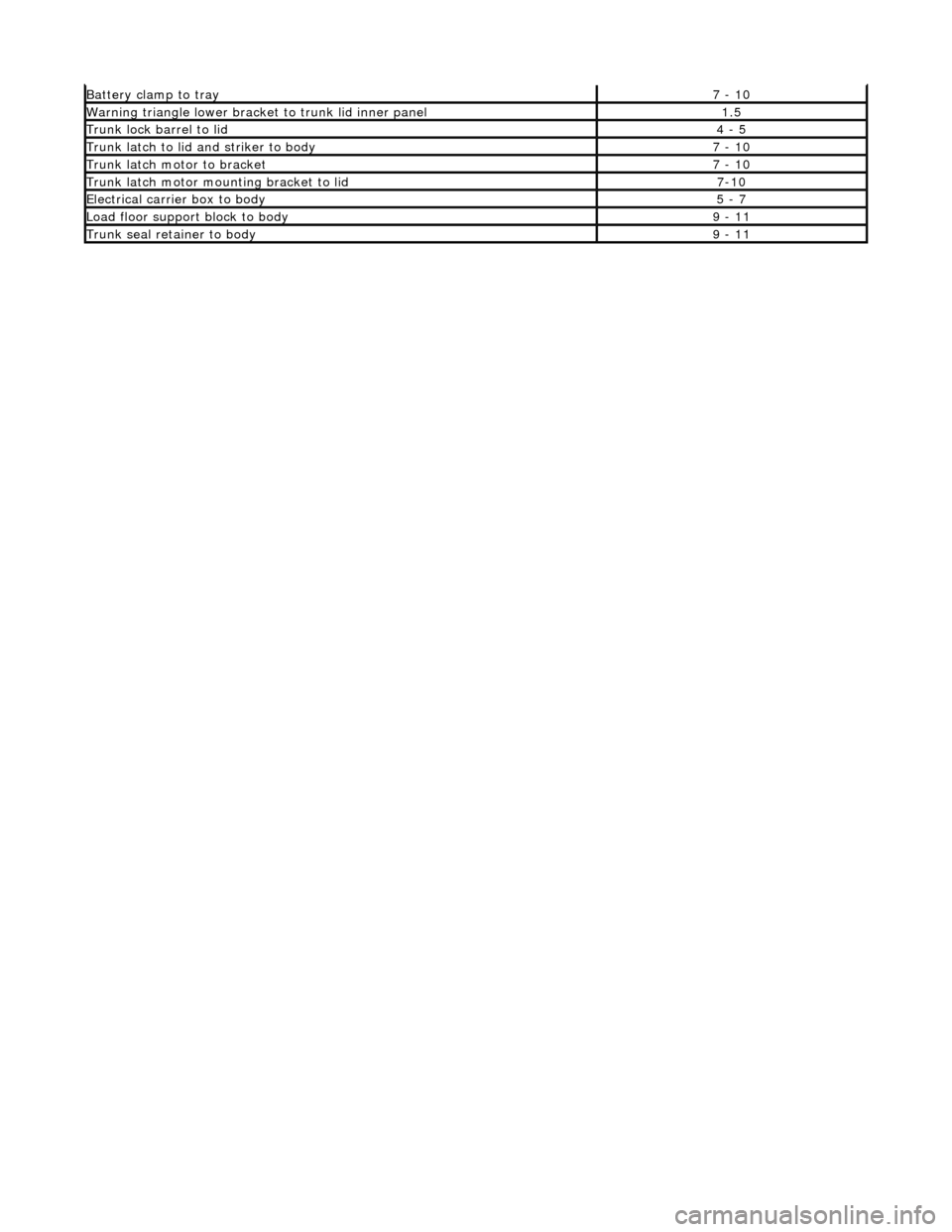

Torques

UnitSpecification

For removal of water-based stains from carpets.'Fibrefresh' carpet shampoo

'1001' Foam Shampoo

'Novatreat'

For removal of grease or oil based stains from carpets.'Genklene' (Trichloroethane)

'Spot Remover'

ComponentNm

Fascia

Instrument pack to support panel1.8

Fascia to support bracket22 - 28

Fascia to console3

Tunnel bracket to body22 - 28

Bolster to tunnel bracket1.5

Instrument pack to fascia3.0

Strut to fascia2.0

Fascia support strut to body7 - 10

CPU bracket to fascia5 - 7

Fascia demister bracket to fascia1.5

Fascia and air con. location to body1.0

Air dist. box duct to air dist. box1.0

Airbag carrier mounting bracket to fascia5 - 7

Instrument pack suppo rt bracket to fascia5 - 7

Airbag bracket to fascia2.0

Air dist. box to fascia2.0

Inst. pack support bracket to fascia5 - 7

Fascia assembly to body22 - 28

Airbag door brackets to fascia5 - 7

Airbag door bracket to fascia and strut4.0

Airbag door bracket to door frame assembly4.0

Hood

Hood lock to body7 - 10

Hood buffer assembly7 - 10

Gas strut - ball pin to weld nut7 - 10

Hood lever5 - 7

Clamp - hood adjust cable6 - 8

Interior

Sun Visor fixings1.8

Sunblind to parcel shelfTighten to prevailing torque.

Sunblind bezel assembly1.0

Coat hook3.0

Seat belts

Front belt buckle to bracket fixing30 - 40

Front belt reel bracket to body fixing30 - 40

Front belt anchor fixing30 - 40

Front belt upper guide fixing7 - 10

Height adjuster to 'B' post screws23 - 27

Height adjuster to seat belt anchor retaining nut30 - 40

Rear inertia belt anchor fixing30 - 40

Rear inertia belt bracket to body fixing30 - 40

Rear inertia belt reel secu ring bracket to body fixing30 - 40

Rear inertia belt buckle bracket to body fixing30 - 40

Sliding Roof Panel

Sliding roof assembly frame to BIW roof4 - 5

Sliding roof panel to frame4 - 5

Trunk

Compact disc autochanger bracket to body9 - 11

Page 2020 of 2490

Battery clamp to tray7 - 10

Warning triangle lower bracket to trunk lid inner panel1.5

Trunk lock barrel to lid4 - 5

Trunk latch to lid and striker to body7 - 10

Trunk latch motor to bracket7 - 10

Trunk latch motor mounting bracket to lid7-10

Electrical carrier box to body5 - 7

Load floor support block to body9 - 11

Trunk seal retainer to body9 - 11

Page 2021 of 2490

Body System - General Information - Body

Description and Operation

This section covers the following areas of the vehicle body:

Front end body panels

Body closures

Aperture seals

Door seals

Instrument panel, console and radio

Centre console

Handles, locks, latches and mechanisms

Wipers and washers

Glass, frames and mechanisms

Fascia

Fuel filler flap assembly

Sun visors

Seating

Interior trim and ornamentation

Exterior trim and ornamentation

Rear view mirrors

Rear parcel tray

Roof console

Bumpers

Occupant restraints

Sliding roof

Steering column cowl

Underscuttle pad

Front End Body Panels

A false bulkhead together with two insulation covers, are installed between the engine compartment and the BIW front

bulkhead to provide optimum insulation ag ainst noise and heat intrusion. Two plenum braces bolted between the BIW upper toeboards and the plenum further increase bodyshell structural integrity. The plastic ra diator grill and vane block achieve

weight reductions over steel parts and provid e high resistance to front end corrosion.

Page 2022 of 2490

Body closures

Each front and rear door consists of a welded, mild steel inner frame and an outer panel. The outer panel is welded to the

waist rail and cheater of the inner frame, then bonded and clinched to fo rm the door assembly. Cosmetic PVC bead is

applied to all clinch joints. Sp onge rubber seals are mounted on the doors. Inte rnal insulation is provided by a foam water

shedder attached to the door by double-sided adhesive tape.

The door aperture B/C posts are reinforced over their full height to fully satisfy all forthcoming European and Federal side

impact legislation. The hood consists of one piece inner and outer panels clinched and bonded together, with cosmetic bead

PVC sealant applied to all clinch joints. Th e hood pivots at the front on two hinges each secured by bolts to the hood front

underside and the BIW front upper crossmem ber. Two gas struts secured to the hood by pivot pins and snap-on couplings,

support the hood in the open position. A full width insulating pad is secured by screws to the underside of the hood. A

sponge rubber tubular seal is mounted tran sversely towards the front of the hood underside. The trunk lid is of similar

construction to the hood, consisting of inner and outer pa nels clinched and bonded together and PVC bead sealed.

Incorporating a removable moulded liner and two trunk illuminati on lights, the trunk lid is supported when open, by two gas

struts, each secured to the inner wheel arch and trunk hinge by snap fittin gs. For some markets, a warning triangle is

attached to a bracket on the trunk lid underside and is retained in the open position by a rubber block.

Fascia

One-piece slush-moulded fascia on inject ion moulded armature and steel cross-rail reinforcement. Fascia support brackets

set with BIW to achieve close tolerance fit of fascia to bo dy eliminate necessity for adjustment following removal and

installation..

Fuel Filler Flap

The fuel filler comprising a hinged flap attached to the body decking panel by tw o nuts, incorporates a rubber buffer, snap-

in striker, hinge spring and fuel cap stowage magnet. The rubber fuel bowl moulding is attached via a steel armature to the

body reinforcement panel by five M5 nuts and is retained at the filler neck by a clip. The mating drain tube is fitted with an

internal filter. The fuel filler flap latch mechanism attached to the fuel bowl armatu re by two M5 nuts, includes a locking pin

and actuator which are both se rviceable items. The latch actuator operates independently from the central locking system;

it is driven directly by the se curity and locking control module. Locking of the fuel filler flap is achi eved only by operation of

the key or by the remote rf transmitter.

Seating

All front seats are equipped with electric height adjustment. In addition, both seats are available with manual or power

forward and rearward adjustment, manual or power operated headrest adjustment, 12 way electric adjustment, memory

controlled 12 way seat adjustment and integral seat heating. A side air bag module is installe d in the outboard squab wing

of each front seat. Each front seat has a non-handed, one-piece frame incorporatin g cushion and squab frames, side air bag

support bracket and seat adjuster mechanis ms. Seat switchpacks are installed on the outboard side of driver and passenger

seats and control modules are installed in the base of each seat . The standard rear seat is of fixed, bench type with full

width removable cushion. For certain mark ets, two individual rear seats are available as an option on long wheelbase

models. Both type s of rear seat are available with th ermostatically controlled heating of the cushion and sq uab. Individual

rear seats are electrically adjustable fo r squab re cline (via cushion fore and af t movement), head restraint height and

lumbar support. Separate motors provide ad justment of each seat cushion and head restraint and an electrically driven air

compressor provides variation of lumbar support. Seat adjustment is controlled via switches installed on a panel in an

extension to the centre console.Both the driver and front pass enger seat are secured to the vehicle floor at four points.

Interior Trim

The one-piece door casings are trimmed in UEV to match the seating, with wood veneer at the waistline and a carpet insert

at the front lower corner. Each casing is secured to the door inner panel by fir tree fastener s along the lower section, two

armrest fixings at the centre and veneer panel dowels and fixings at the top. The armrests which are common to front and

rear doors, are trimmed in matc hing leather or UEV according to specification. Switchpacks dedicated to driver and front or

rear passenger, are incorporated in the ar mrests. A speaker is installed in the lower section of each door and a tweeter is

incorporated behind each interior door handle escutcheon. where premium ICE is fitted, the front tweeters are installed in

the upper A posts. On each side, a graine d UEV finisher trimmed to match the head lining is secured to the 'A' post and

cantrail by fir tree fasteners locating in BIW apertures. Th e upper 'D' post finisher is trimmed and secured in the same

manner. The single piece'B' post finishers, also finished in grained matching UEV, each have a front seat belt exit aperture

and are secured to the BIW by four spring clips and two fir tree fasteners. The one-piece headlining consists of a 6mm thick

polyurethane foam membrane covered with suede effect knitted polyester. The headlining is secured to the BIW roof by

body tangs, the roof console, sun visors, combined grab handles and coat hooks, th e cantrail finishers and where fitted, the