panel JAGUAR X308 1998 2.G Repair Manual

[x] Cancel search | Manufacturer: JAGUAR, Model Year: 1998, Model line: X308, Model: JAGUAR X308 1998 2.GPages: 2490, PDF Size: 69.81 MB

Page 1774 of 2490

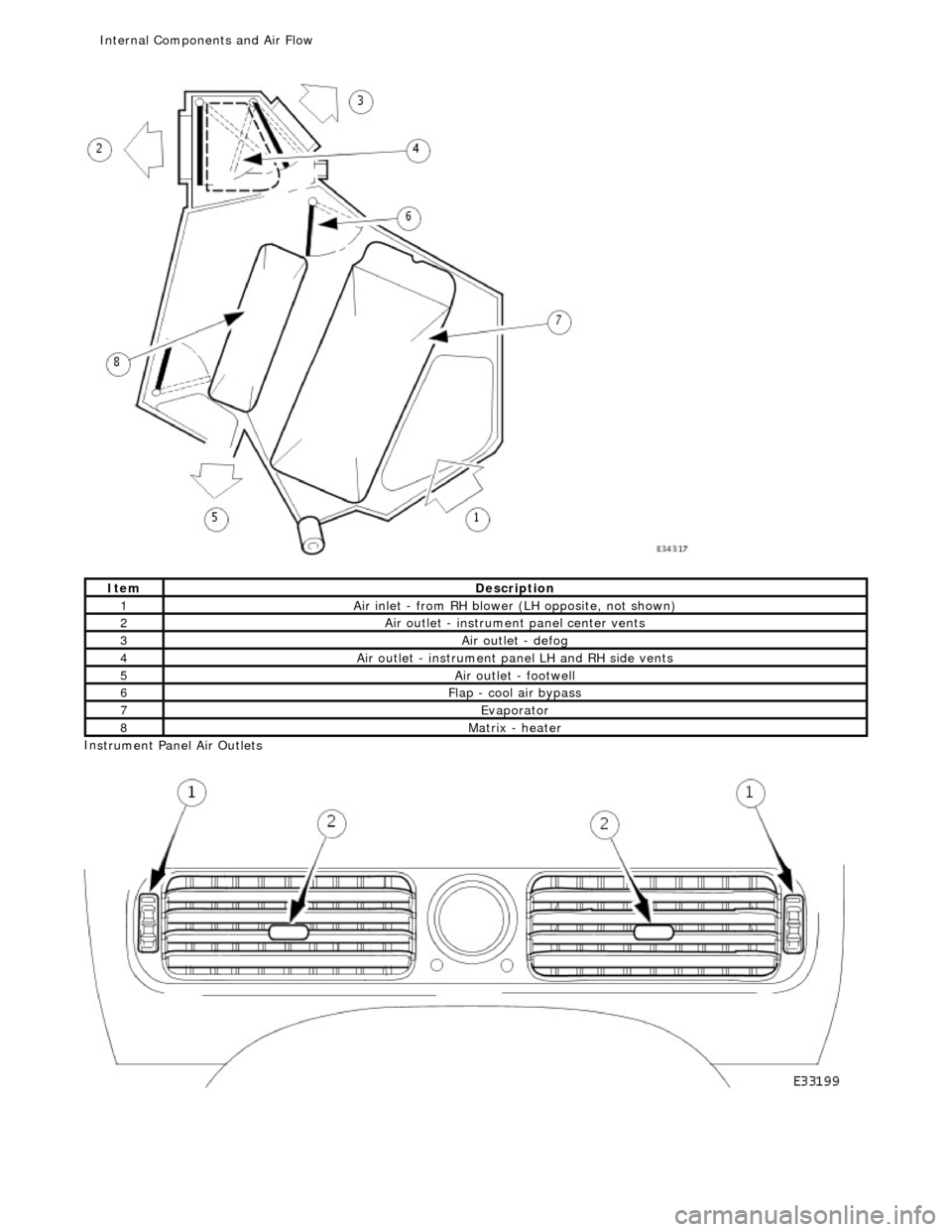

I n

strument Pane

l Air Outlets

Ite

m

De

scr

iption

1Ai

r i

nlet - from RH blower (LH opposite, not shown)

2Ai

r outl

et - instrument

panel center vents

3Air ou

tlet - defog

4Ai

r outl

et - instru

ment panel LH and RH side vents

5Air outl

et - footwell

6Flap -

cool air

bypass

7Evaporator

8Matrix -

heater

Internal Components and Ai

r Fl

ow

Page 1775 of 2490

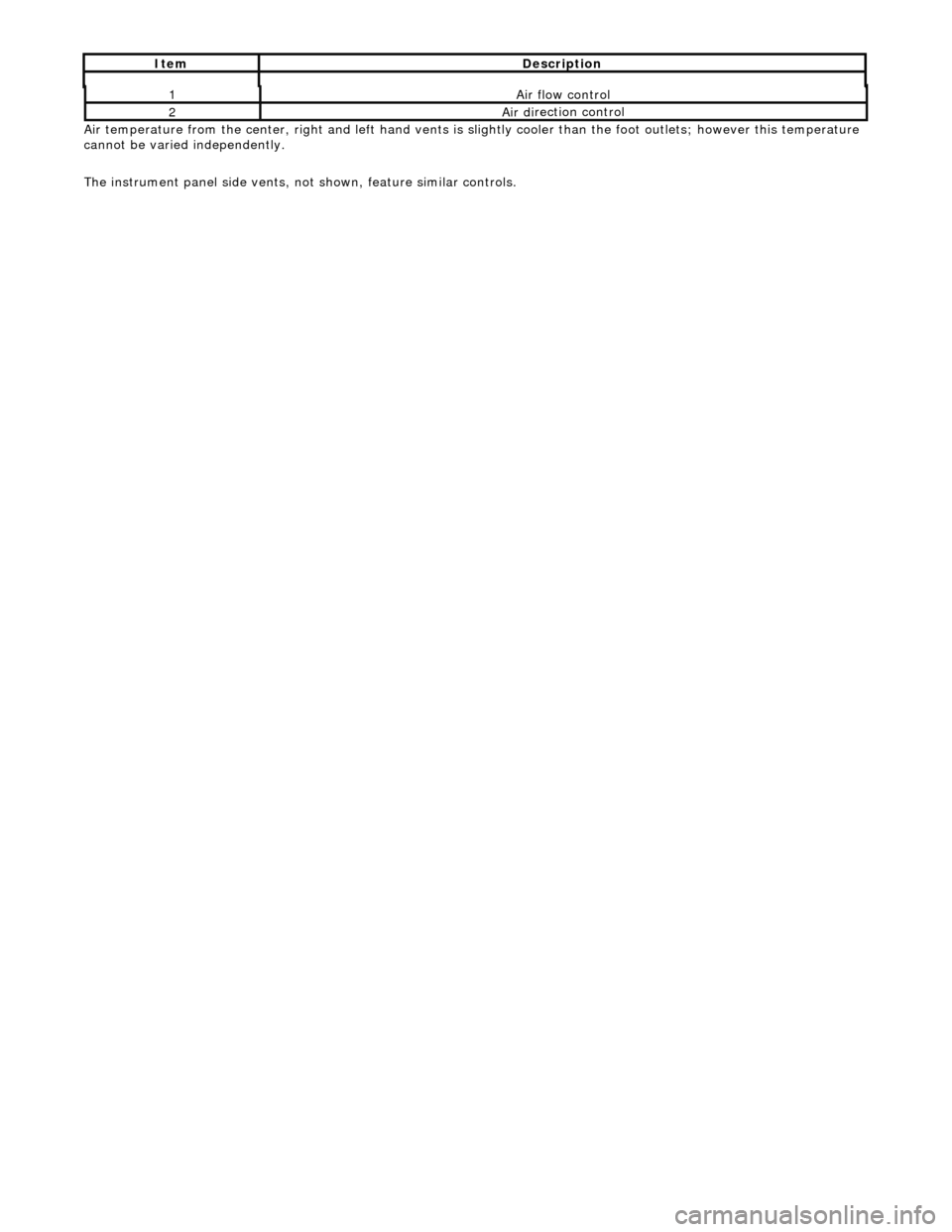

Ai

r temperature from the center, right and left

hand vents is slightly cooler than the foot outlets; however this temperature

cannot be varied independently.

The instrument panel side vents, not shown, feature similar controls.

1Ai

r flow control

2Air di

rection control

It

em

De

scription

Page 1777 of 2490

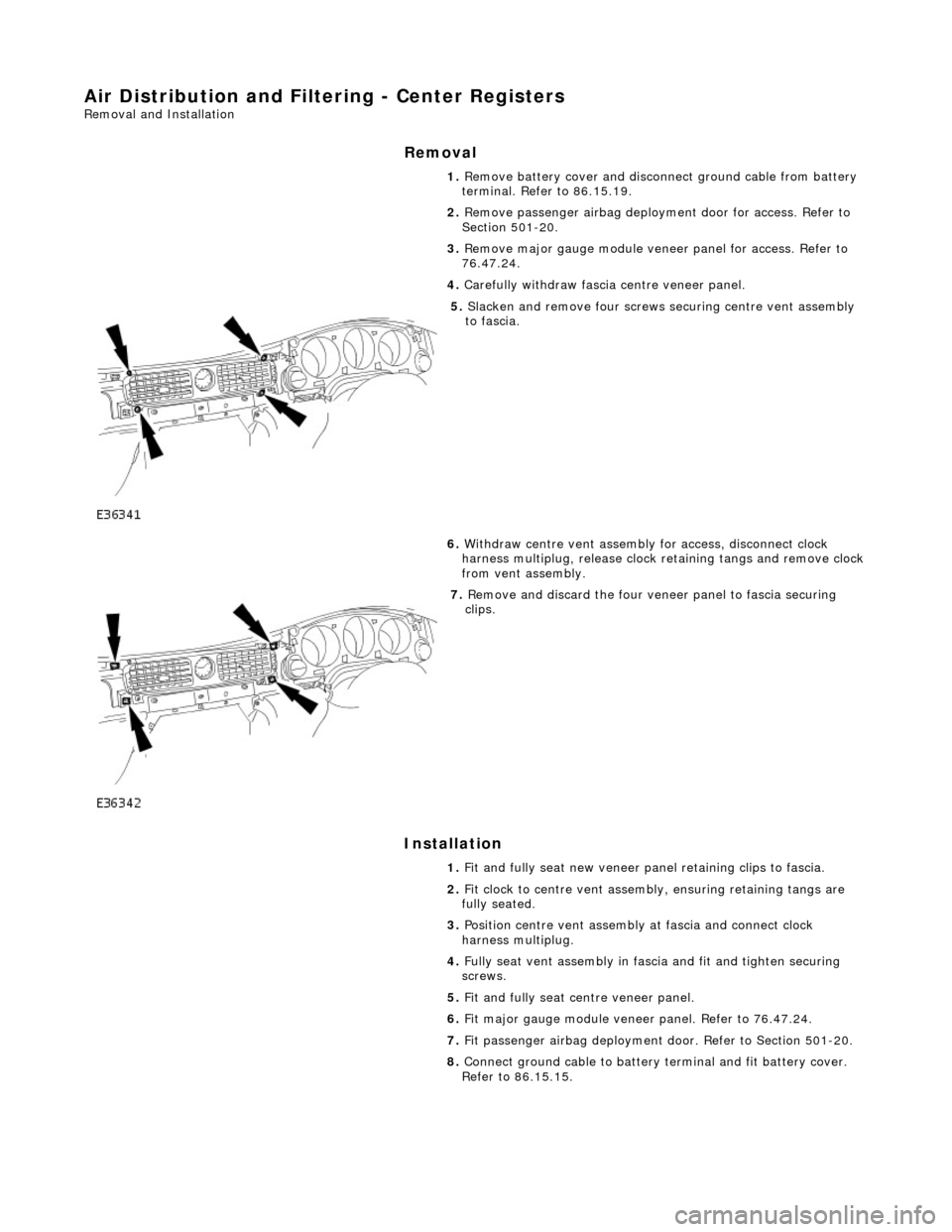

Air Distribution and Filtering - Center Registers

Removal and Installation

Removal

Installation

1.

Remove battery cover and disconnect ground cable from battery

terminal. Refer to 86.15.19.

2. Remove passenger airbag deployment door for access. Refer to

Section 501-20.

3. Remove major gauge module veneer panel for access. Refer to

76.47.24.

4. Carefully withdraw fascia centre veneer panel.

5. Slacken and remove four screws securing centre vent assembly

to fascia.

6. Withdraw centre vent assembly for access, disconnect clock

harness multiplug, release clock retaining tangs and remove clock

from vent assembly.

7. Remove and discard the four veneer panel to fascia securing

clips.

1. Fit and fully seat new veneer panel retaining clips to fascia.

2. Fit clock to centre vent assemb ly, ensuring retaining tangs are

fully seated.

3. Position centre vent assembly at fascia and connect clock

harness multiplug.

4. Fully seat vent assembly in fascia and fit and tighten securing

screws.

5. Fit and fully seat centre veneer panel.

6. Fit major gauge module veneer panel. Refer to 76.47.24.

7. Fit passenger airbag deployment door. Refer to Section 501-20.

8. Connect ground cable to battery terminal and fit battery cover.

Refer to 86.15.15.

Page 1780 of 2490

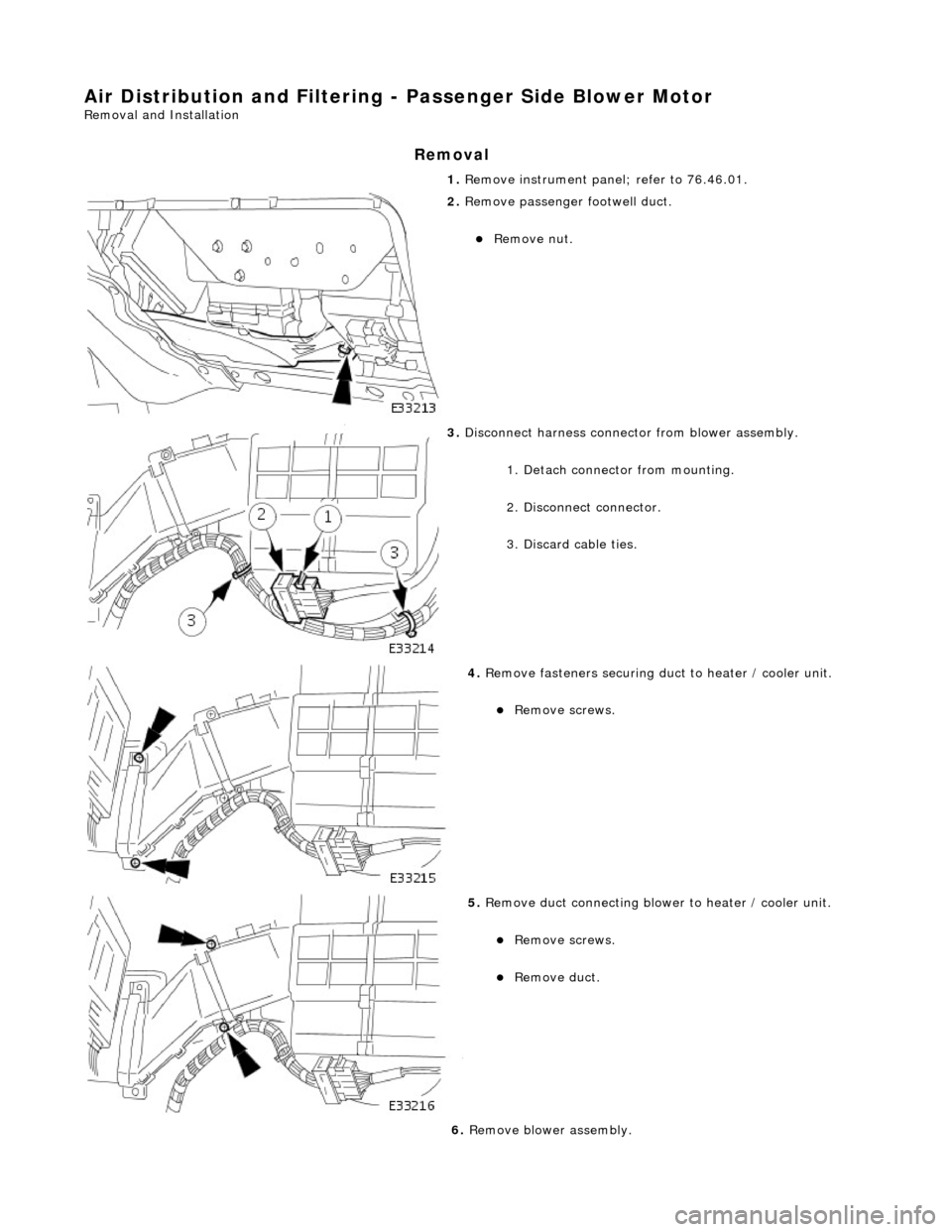

Air Distribution and Filtering - Passenger Side Blower Motor

Removal and Installation

Removal

1. Remove instrument panel; refer to 76.46.01.

2. Remove passenger footwell duct.

Remove nut.

3. Disconnect harness connector from blower assembly.

1. Detach connector from mounting.

2. Disconnect connector.

3. Discard cable ties.

4. Remove fasteners securing duct to heater / cooler unit.

Remove screws.

5. Remove duct connecting blower to heater / cooler unit.

Remove screws.

Remove duct.

6. Remove blower assembly.

Page 1782 of 2490

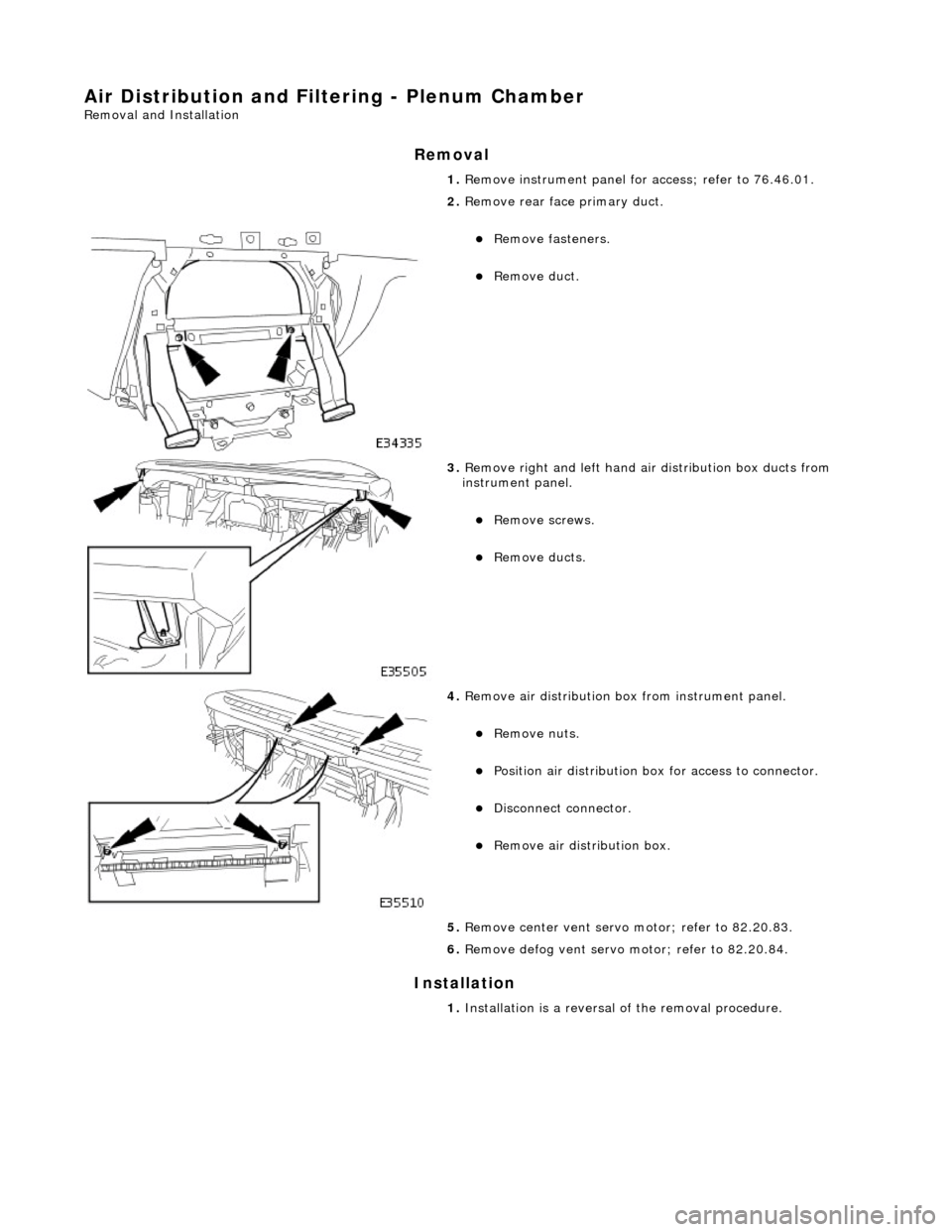

Air Distribution and Filtering - Plenum Chamber

Removal and Installation

Removal

Installation

1.

Remove instrument panel for access; refer to 76.46.01.

2. Remove rear face primary duct.

Remove fasteners.

Remove duct.

3. Remove right and left hand ai r distribution box ducts from

instrument panel.

Remove screws.

Remove ducts.

4. Remove air distribution bo x from instrument panel.

Remove nuts.

Position air distribution box for access to connector.

Disconnect connector.

Remove air distribution box.

5. Remove center vent servo motor; refer to 82.20.83.

6. Remove defog vent servo motor; refer to 82.20.84.

1. Installation is a reversal of the removal procedure.

Page 1785 of 2490

Engine speed (valve closed with the engine not running) Demand (set) temperature In-car temperature sensor Solar sensor

Re-heating of the refrigerated air is contro lled by the time that the water valve is open (i.e. not energised) over a six secon d

interval. The duty cycle of the water valve, the time open / time closed, is controlled by the A/CCM.

Maximum heating demand will cause the water valve to be fu lly open (not energised) to allow maximum coolant flow

through the heater matrix.

At Maximum cooling, the water va lve will be fully closed (energised) to prevent hot (engine temperature) coolant entering

the heater circuit; the pump however will continue to circulate coolant through both the heater matrix and water valve

bypass.

The water valve defaults open when the ignition is OFF.

Under engine stall conditions, when ignition is ON, the water valve will be open.

Water Pump Assembly

Located in the same area as the water valve, the water pump continually circulates coolant through the heater matrix

except when the conditions below apply:

The engine coolant is below 16°C. The ignition is OFF. Under engine stall conditions, when ignition is ON. Control panel OFF

Non return valves

The heater bypass hose has a non-return valve, located between the engine feed and return hoses. The valve prevents the

water pump from recirculating coolant fro m the heater at low engine speeds.

The flow indicator arrow embossed on the valve bo dy MUST point towards the coolant header tank.

CAUTION: Coolant flow will be compromi sed if either valve is fitted incorrectly. Observe the correct direction.

A second non-return valve is located betw een the water pump and water valve. This valve prevents hot coolant from flowing

into the heater with the engine switched off. The flow indicator arrow MUST point towards the water pump.

Heater feed and return hoses

The heater feed and return hoses are connected to the engine feed and return hoses by 'Quick-Fit' connection unions. The

feed hose has a Norma R20 connector and the return hose a Norma push and seal connector. The coolant system bleed

joints have Cobra clamps. All remaining hose connections have spring band hose clamps.

The engine feed hose is connected to the engine bypass hous ing and the engine return hose is connected to the engine

water pump.

Clamp Identification

Page 1787 of 2490

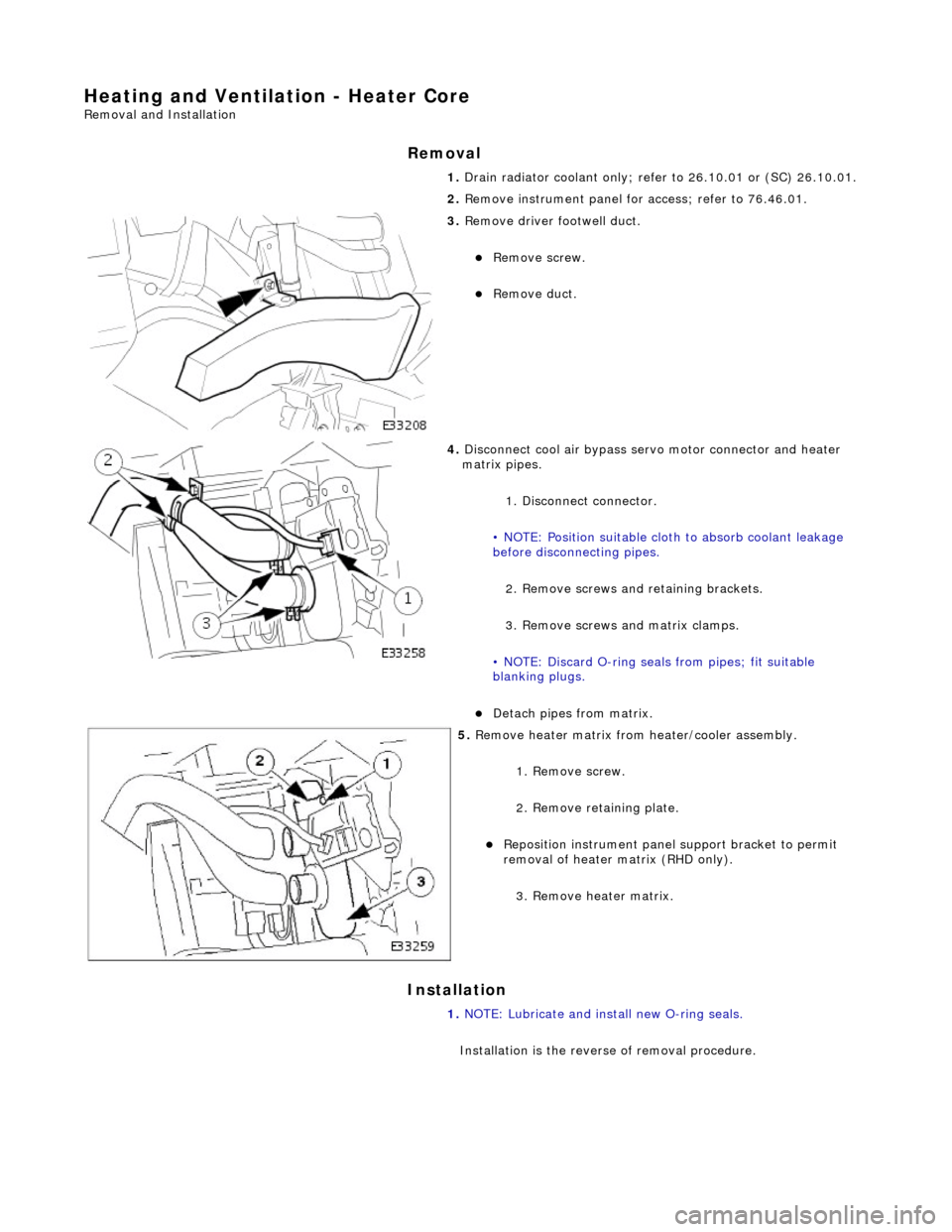

Heating and Ventilation - Heater Core

Removal and Installation

Removal

Installation

1.

Drain radiator coolant only; re fer to 26.10.01 or (SC) 26.10.01.

2. Remove instrument panel for access; refer to 76.46.01.

3. Remove driver footwell duct.

Remove screw.

Remove duct.

4. Disconnect cool air bypass serv o motor connector and heater

matrix pipes.

1. Disconnect connector.

• NOTE: Position suitable clot h to absorb coolant leakage

before disconnecting pipes.

2. Remove screws and retaining brackets.

3. Remove screws and matrix clamps.

• NOTE: Discard O-ring seals from pipes; fit suitable

blanking plugs.

Detach pipes from matrix.

5. Remove heater matrix from heater/cooler assembly.

1. Remove screw.

2. Remove retaining plate.

Reposition instrument panel support bracket to permit

removal of heater matrix (RHD only).

3. Remove heater matrix.

1. NOTE: Lubricate and install new O-ring seals.

Installation is the reverse of removal procedure.

Page 1788 of 2490

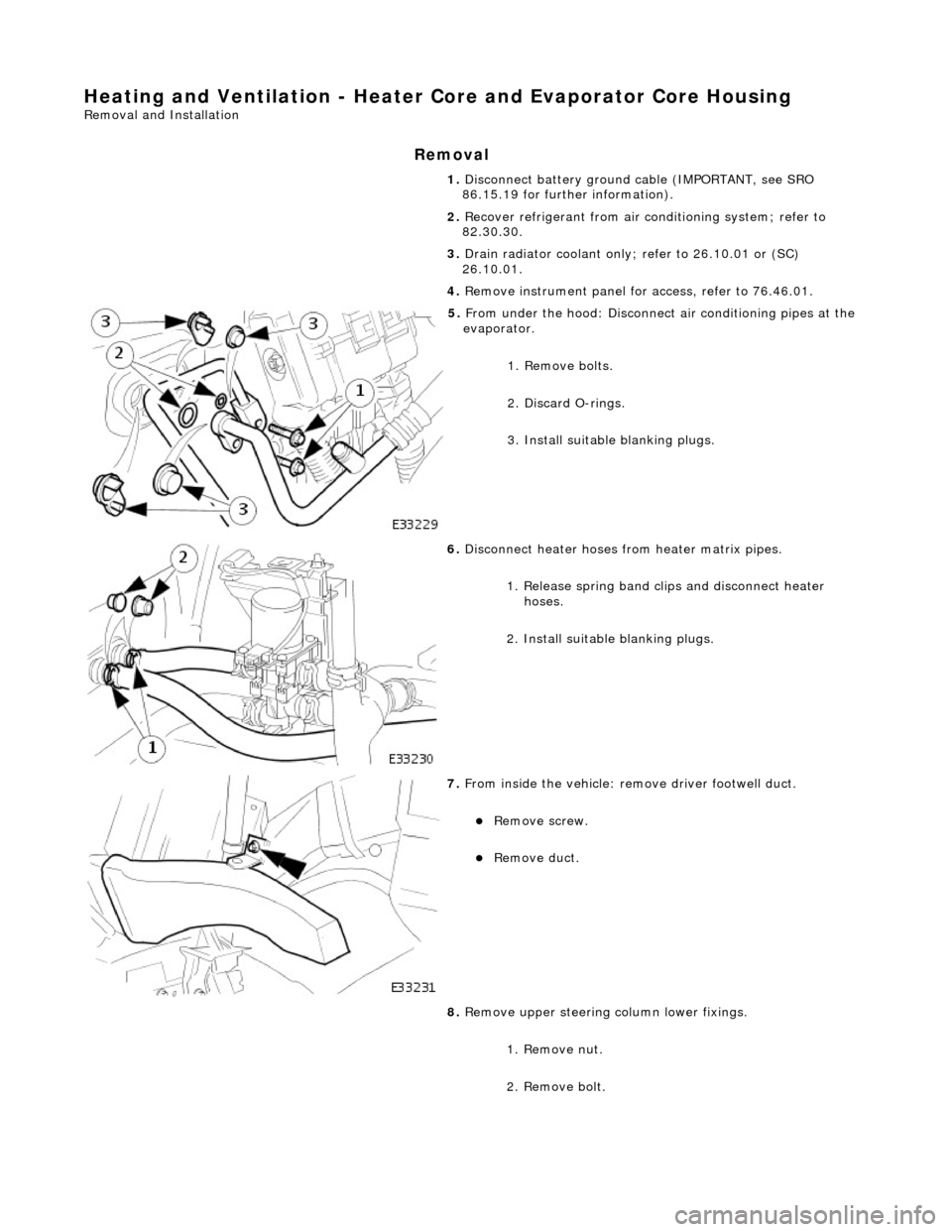

Heating and Ventilation - Heater Core and Evaporator Core Housing

Removal and Installation

Removal

1. Disconnect battery ground cable (IMPORTANT, see SRO

86.15.19 for further information).

2. Recover refrigerant from air co nditioning system; refer to

82.30.30.

3. Drain radiator coolant only; refer to 26.10.01 or (SC)

26.10.01.

4. Remove instrument panel for access, refer to 76.46.01.

5. From under the hood: Disconnect air conditioning pipes at the

evaporator.

1. Remove bolts.

2. Discard O-rings.

3. Install suitable blanking plugs.

6. Disconnect heater hoses from heater matrix pipes.

1. Release spring band clips and disconnect heater hoses.

2. Install suitable blanking plugs.

7. From inside the vehicle: re move driver footwell duct.

Remove screw.

Remove duct.

8. Remove upper steering column lower fixings.

1. Remove nut.

2. Remove bolt.

Page 1798 of 2490

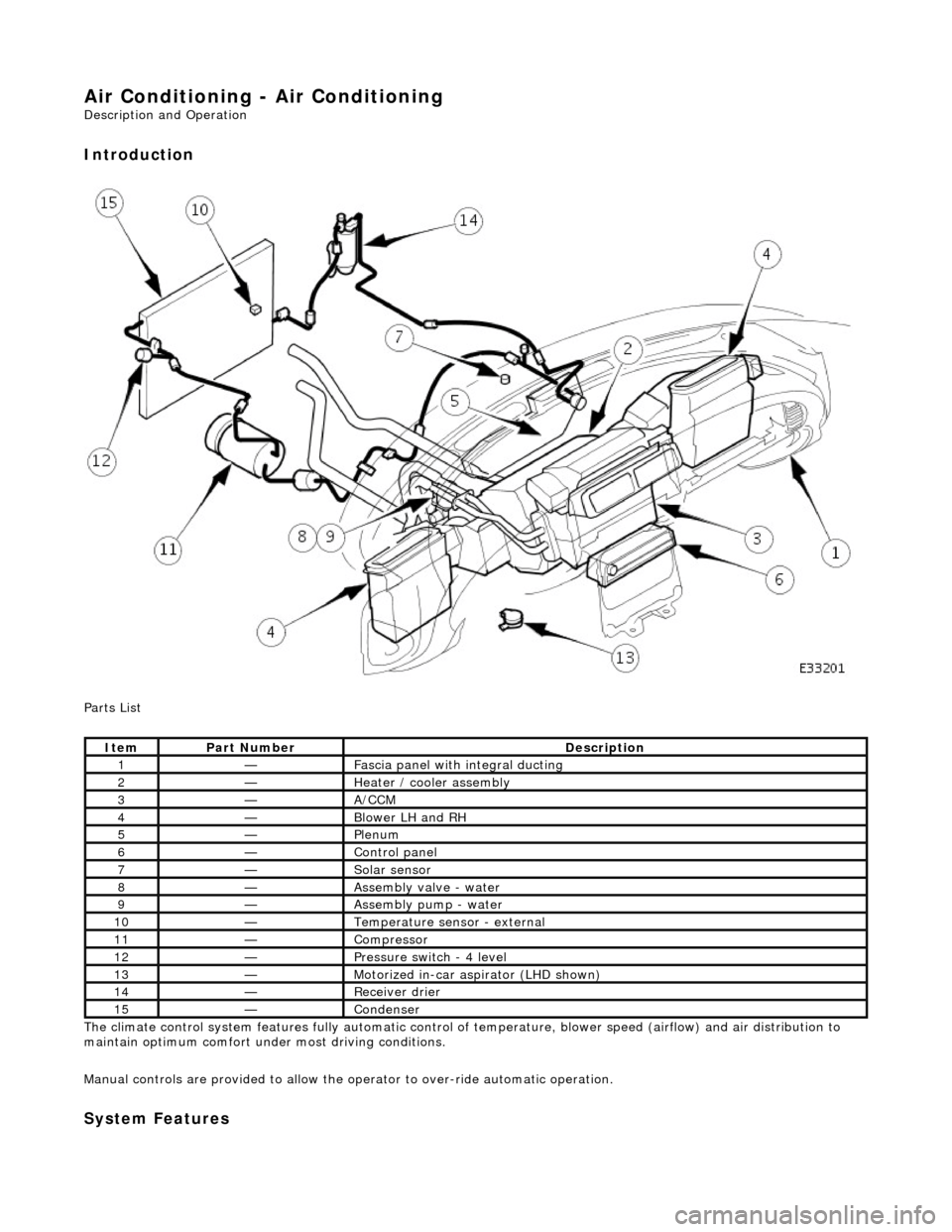

Air Conditioning - Air Conditioning

Description and Operation

Introduction

Parts List

The climate control system features fully automatic control of temperature, blower speed (airflow) and air distribution to

maintain optimum comfort under most driving conditions.

Manual controls are provided to allow the operator to over-ride automatic operation.

System Features

ItemPart NumberDescription

1—Fascia panel with integral ducting

2—Heater / cooler assembly

3—A/CCM

4—Blower LH and RH

5—Plenum

6—Control panel

7—Solar sensor

8—Assembly valve - water

9—Assembly pump - water

10—Temperature sensor - external

11—Compressor

12—Pressure switch - 4 level

13—Motorized in-car aspirator (LHD shown)

14—Receiver drier

15—Condenser

Page 1799 of 2490

Twin blower assemblies Center mounted evaporator, heater and air distribution unit Electric solenoid water valve controlled heating Electric water pump assembly Servo motor driven air distribution flaps Dedicated side glass defrost / demist vents External temperature sensor Motorised in-car aspirator Solar sensor

Electronic Control Panel

Liquid Crystal Display (LCD) Digital temperature display Manual fan speed level External temperature display Celsius / Fahrenheit selection Heated windshield switch (where fitted) Heated backlight switch Defrost switch Manual airflow distribution overrides (4) Access to self diagnostic system and error codes

Sensors

External ambient temperature sensor Motorized in-car aspirator Heater matrix temperature sensor Evaporator temperature sensor Solar sensor

These sensors feedback information to the Air Conditioning Control Module (A/CCM) which automatically adjusts air

temperature, airflow volume and distributi on from the air conditioning unit to maintain a stable passenger compartment

average temperature under changing weather conditions.

Major Components