LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: fuel consumption, fuel filter, c1725, oil temperature, warning light, service reset, timing belt

Page 3271 of 4500

NG: FIND CAUSE OF NOISE AND REMOVE IT

OK: Go to next step

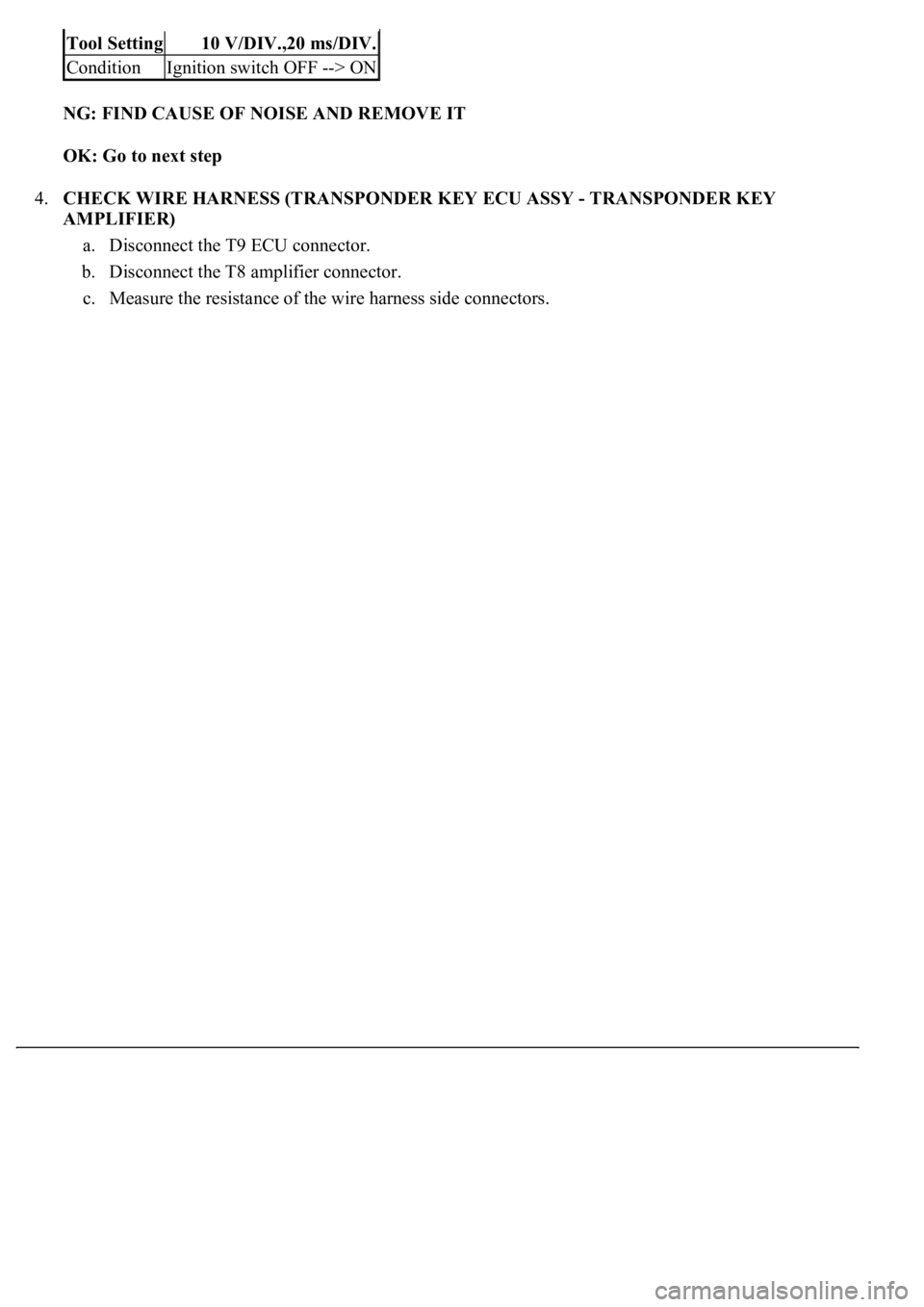

4.CHECK WIRE HARNESS (TRANSPONDER KEY ECU ASSY - TRANSPONDER KEY

AMPLIFIER)

a. Disconnect the T9 ECU connector.

b. Disconnect the T8 amplifier connector.

c. Measure the resistance of the wire harness side connectors.

Tool Setting10 V/DIV.,20 ms/DIV.

ConditionIgnition switch OFF --> ON

Page 3272 of 4500

Page 3273 of 4500

Fig. 41: Identifying T9 And T8 Amplifier Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

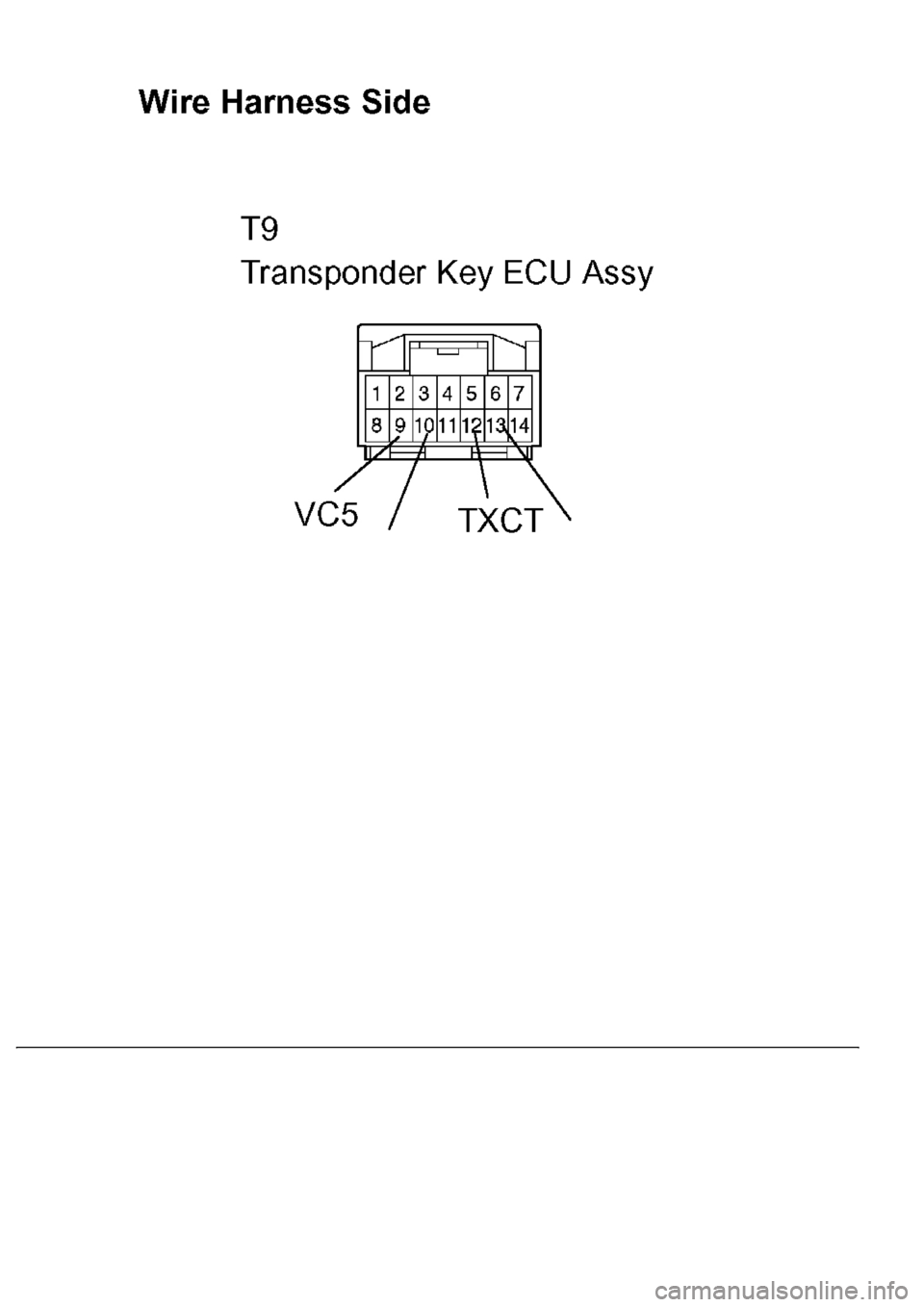

Standard:

TRANSPONDER KEY ECU - TRANSPONDER KEY AMPLIFIER - RESISTANCE TABLE

NG: REPAIR OR REPLACE HARNESS AND CONNECTOR

OK: Go to next step

5.CHECK OPERATION OF TRANSPONDER KEY AMPLIFIER

a. After replacing the transponder key amplifier with a normally functioning amplifier, check that the

engine starts.

OK: Engine starts.

NG: REPLACE TRANSPONDER KEY ECU ASSY

OK: END

CIRCUIT DESCRIPTION

This DTC is output when: 1) the ECM detects errors in its own communications with the transponder key ECU;

2) the ECM detects errors in the communication lines; and 3) the ECU communication ID between the

transponder key ECU and the ECM are different and an engine start is attempted.

Before troubleshooting for this DTC, make sure no transponder key ECU DTCs are present. If the transponder

key ECU has a key code related DTC, repair it first.

Fig. 42: DTC Reference Chart

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

WIRING DIAGRAM

Tester connectionSpecified condition

T9-10 (CODE) - T8-4 (CODE)Below 1 ohms

Page 3274 of 4500

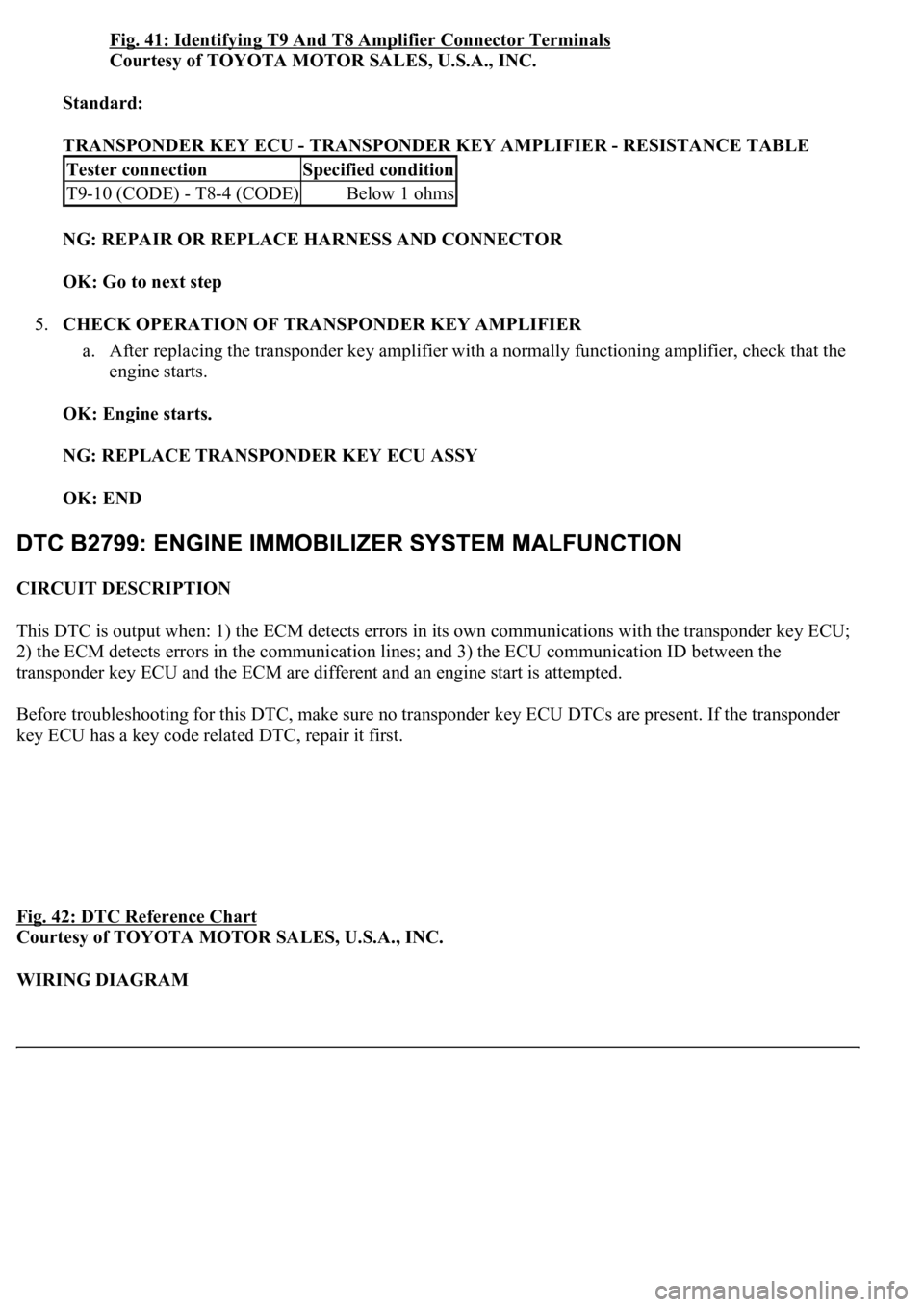

Fig. 43: DTC B2799 - Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION PROCEDURE

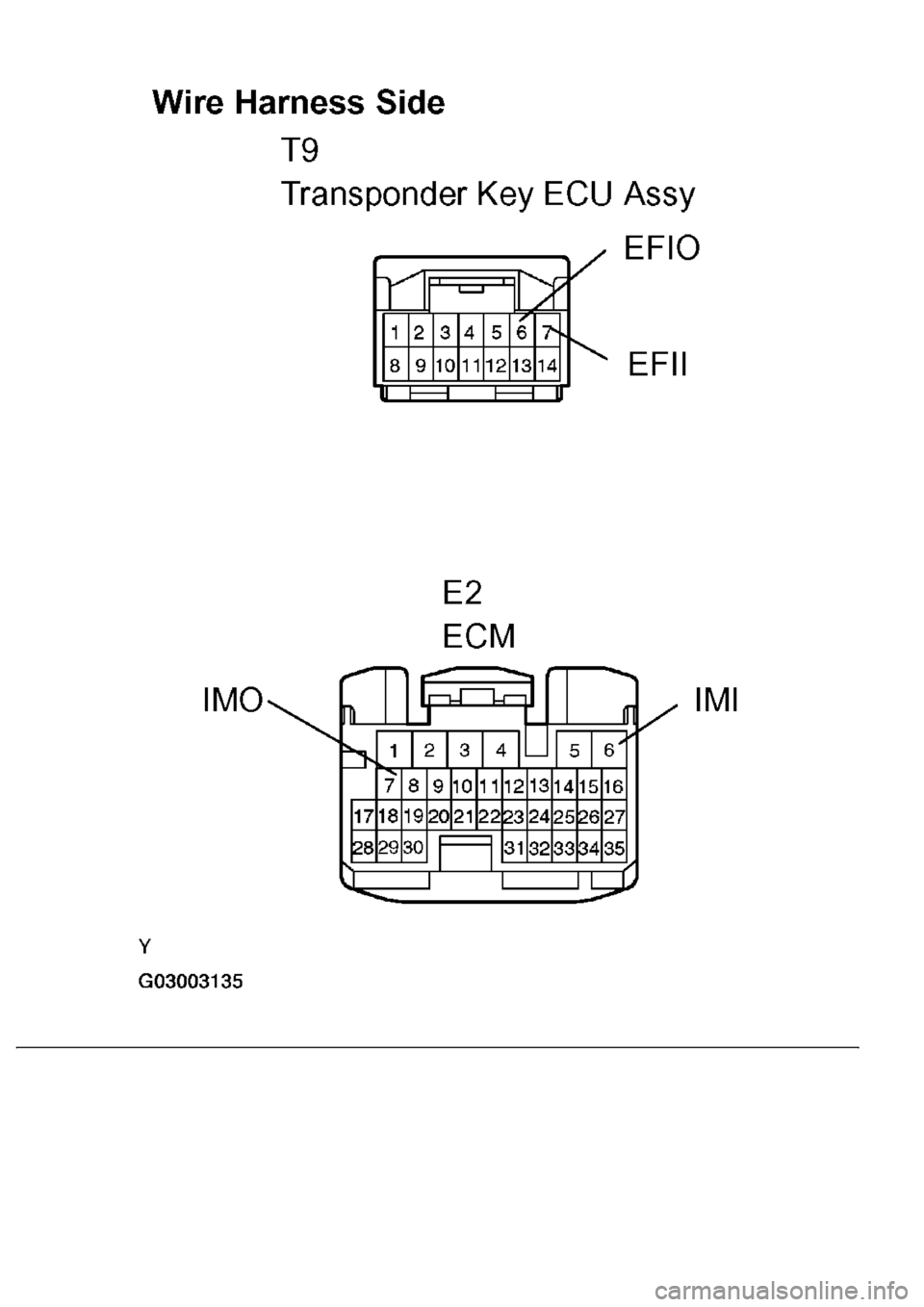

1.CHECK WIRE HARNESS (TRANSPONDER KEY ECU ASSY - ECM)

a. Disconnect the T9 ECU connector.

b. Disconnect the E2 ECM connector.

c. Measure the resistance of the wire harness side connectors.

Page 3275 of 4500

Page 3276 of 4500

Fig. 44: Identifying T9 ECU And E2 ECM Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Standard:

TRANSPONDER KEY ECU ASSY - ECM - RESISTANCE TABLE

NG: REPAIR OR REPLACE HARNESS AND CONNECTOR

OK: REPLACE ECM

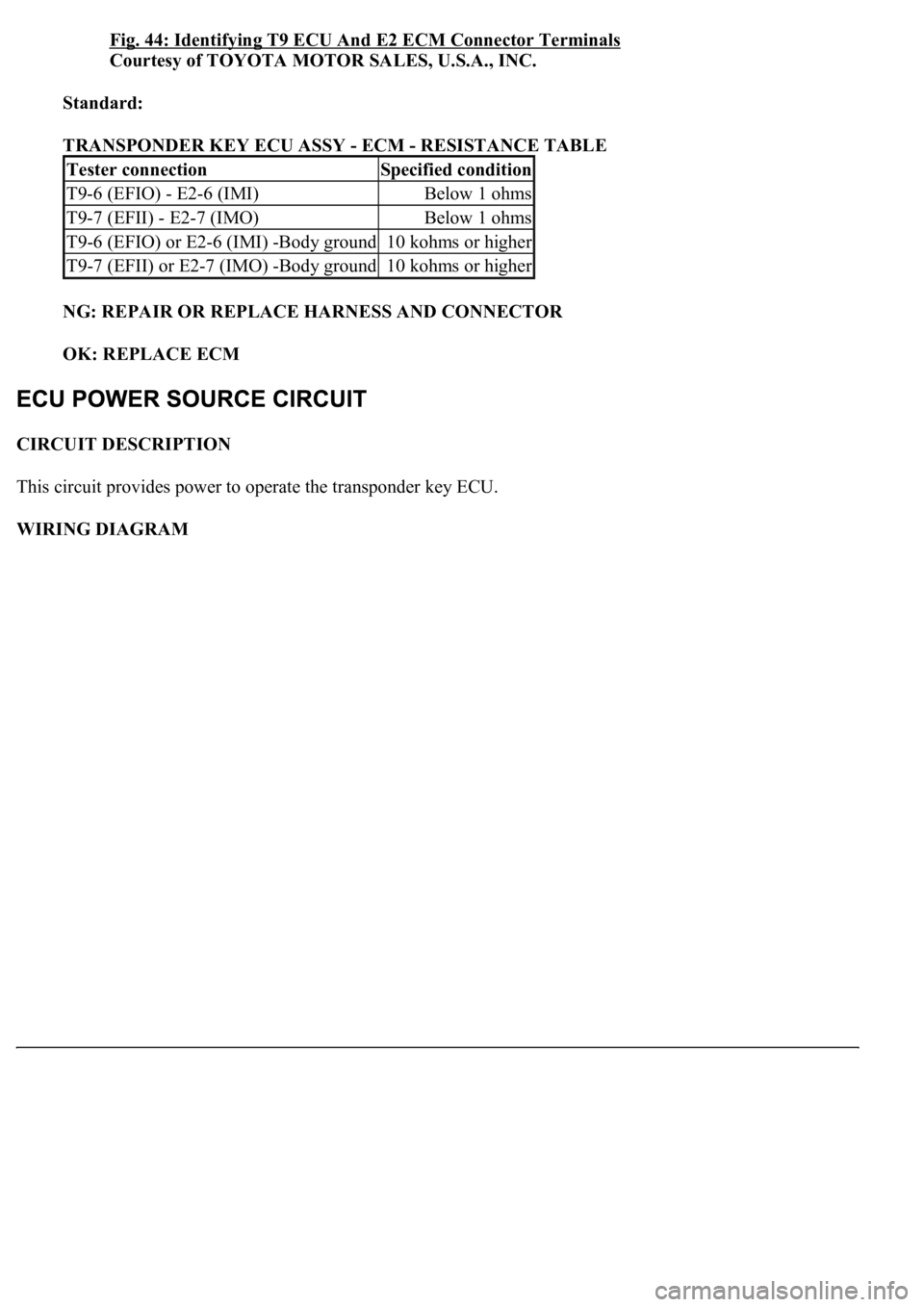

CIRCUIT DESCRIPTION

This circuit provides power to operate the transponder key ECU.

WIRING DIAGRAM

Tester connectionSpecified condition

T9-6 (EFIO) - E2-6 (IMI)Below 1 ohms

T9-7 (EFII) - E2-7 (IMO)Below 1 ohms

T9-6 (EFIO) or E2-6 (IMI) -Body ground10 kohms or higher

T9-7 (EFII) or E2-7 (IMO) -Body ground10 kohms or higher

Page 3277 of 4500

Fig. 45: ECU Power Source Circuit - Wiring Diagram

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

INSPECTION PROCEDURE

1.INSPECT FUSE (MPX-B1, AM2, D/C CUT)

a. Remove the MPX-B1 and AM2 fuses from the passenger side J/B.

b. Remove the D/C CUT fuse from the FL block.

c. Measure the resistance of the fuse.

Standard: Below 1ohms

NG: REPLACE FUSE

OK: Go to next step

Page 3278 of 4500

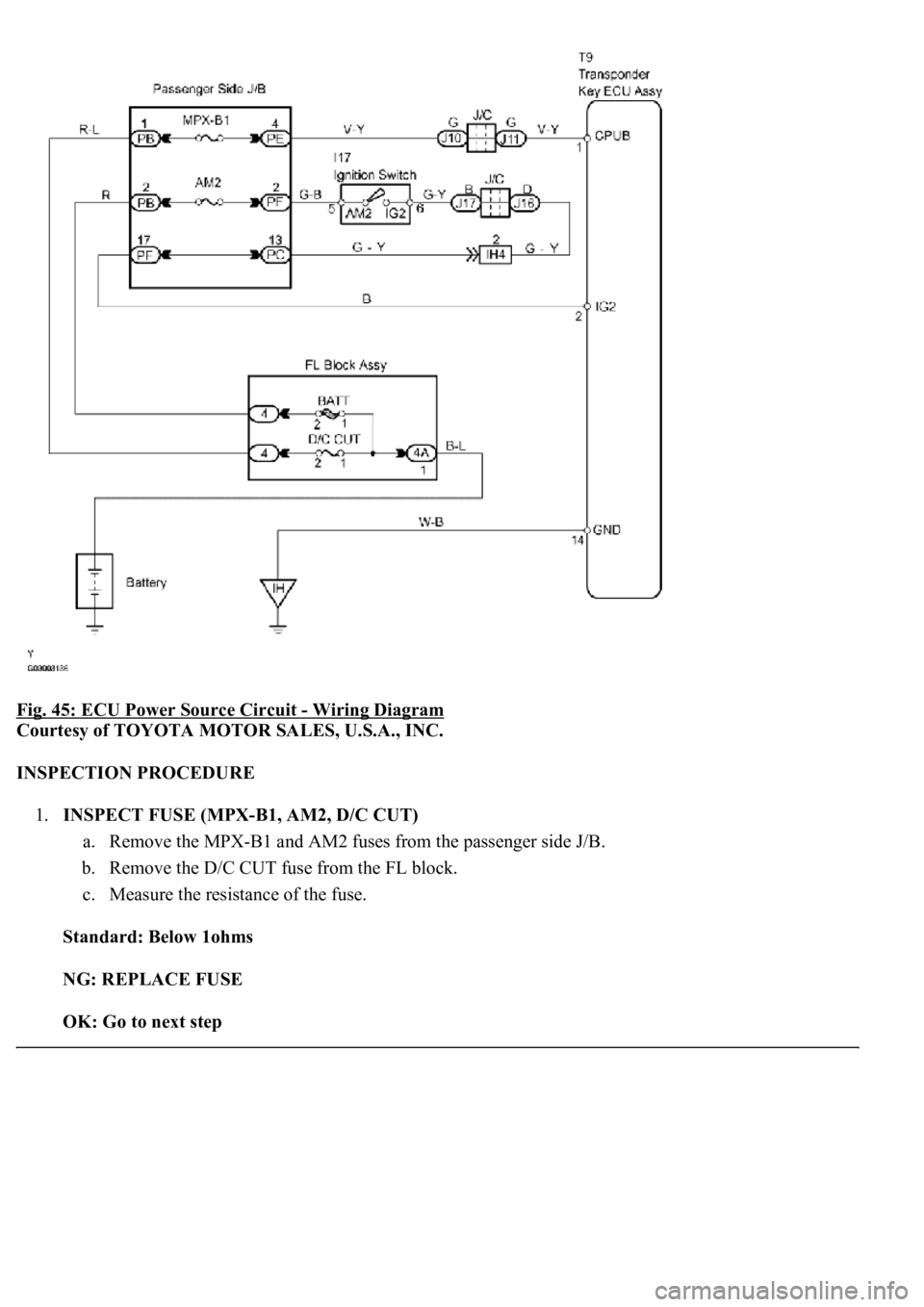

2.CHECK WIRE HARNESS (TRANSPONDER KEY ECU ASSY - BATTERY AND BODY

GROUND)

a. Disconnect the T9 ECU connector.

b. Measure the resistance and voltage of the wire harness side connector.

Fig. 46: Identifying T9 ECU Connector Terminals

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Standard:

TRANSPONDER KEY ECU - BATTERY AND BODY GROUND - RESISTANCE TABLE

NG: REPAIR OR REPLACE HARNESS AND CONNECTOR

OK: REPLACE TRANSPONDER KEY ECU ASSY

Tester ConnectionSpecified ConditionCondition

T9-1 (CPUB) -Body groundAlways10 to 14V

T9-2 (IG2) - Body groundIgnition switch OFF --> ON0V --> 10 to 14 V

T9-14 (GND) -Body groundAlwaysBelow 1 ohms

Page 3279 of 4500

INSPECTION

1.INSPECT ENGINE COOLANT (See REPLACEMENT

)

2.INSPECT ENGINE OIL (See ON

-VEHICLE INSPECTION )

3.INSPECT BATTERY (See REPLACEMENT

)

4.INSPECT AIR CLEANER FILTER ELEMENT SUB-ASSY

5.INSPECT SPARK PLUG (See REPLACEMENT

)

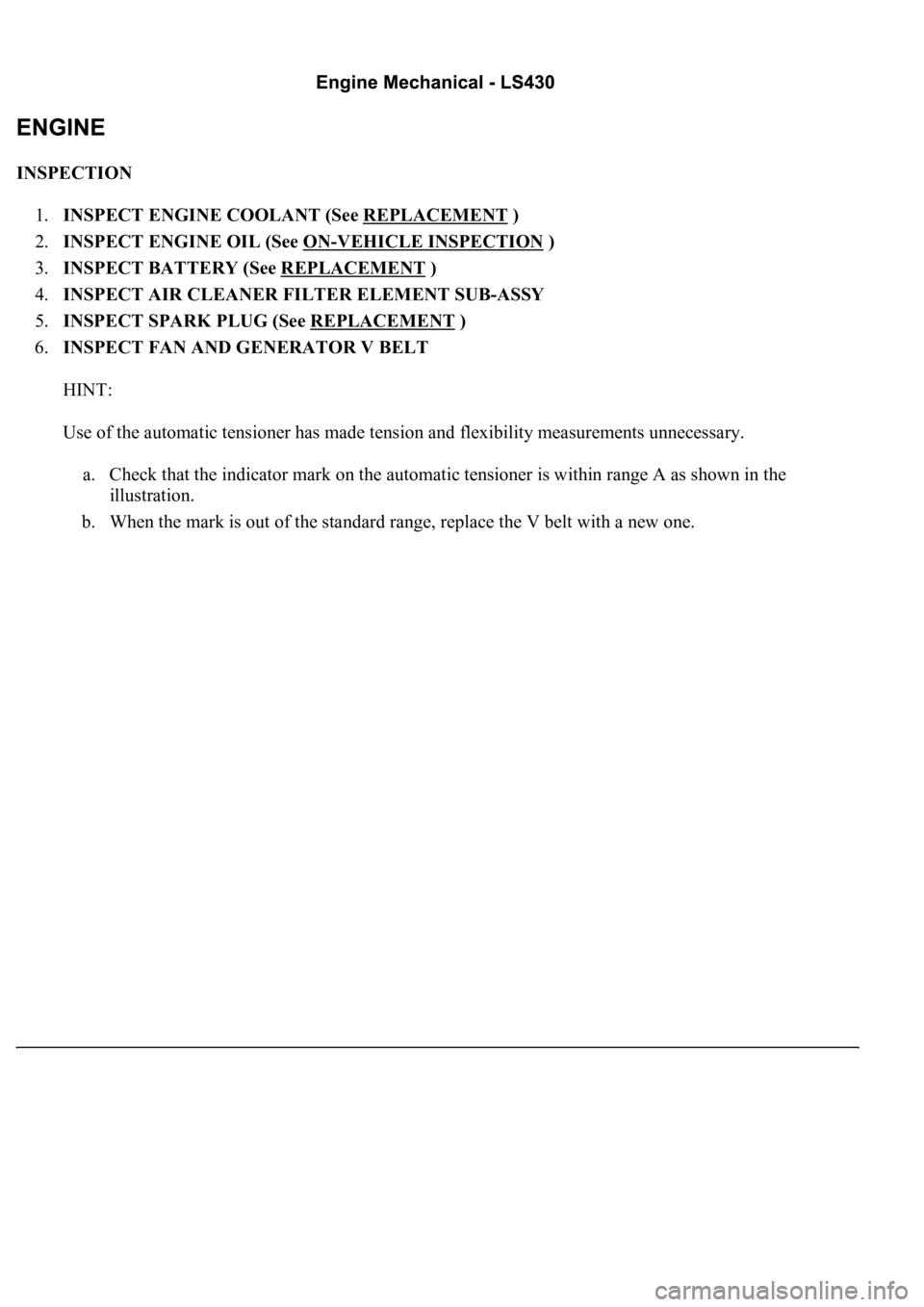

6.INSPECT FAN AND GENERATOR V BELT

HINT:

Use of the automatic tensioner has made tension and flexibility measurements unnecessary.

a. Check that the indicator mark on the automatic tensioner is within range A as shown in the

illustration.

b. When the mark is out of the standard range, replace the V belt with a new one.

Page 3280 of 4500

Fig. 1: Identifying Indicator Mark

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

HINT:

After installing the V belt, check that it fits properly in the ribbed grooves. Check with your hand to

confirm that the belt has not slipped out of the groove on the bottom of the crank pulley.

A "new belt" is a belt which has been used for less than 5 minutes on a running engine.

A "used belt" is a belt which has been used on a running engine for 5 minutes or more.

After installing a new belt, run the engine for approximately 5 minutes and then recheck the

tension.

Trending: airbag off, wiring diagram, USB, B2620, seat memory, pcv, Expansion Valve