MAZDA MX-5 1994 Owner's Manual

Manufacturer: MAZDA, Model Year: 1994, Model line: MX-5, Model: MAZDA MX-5 1994Pages: 1708, PDF Size: 82.34 MB

Page 21 of 1708

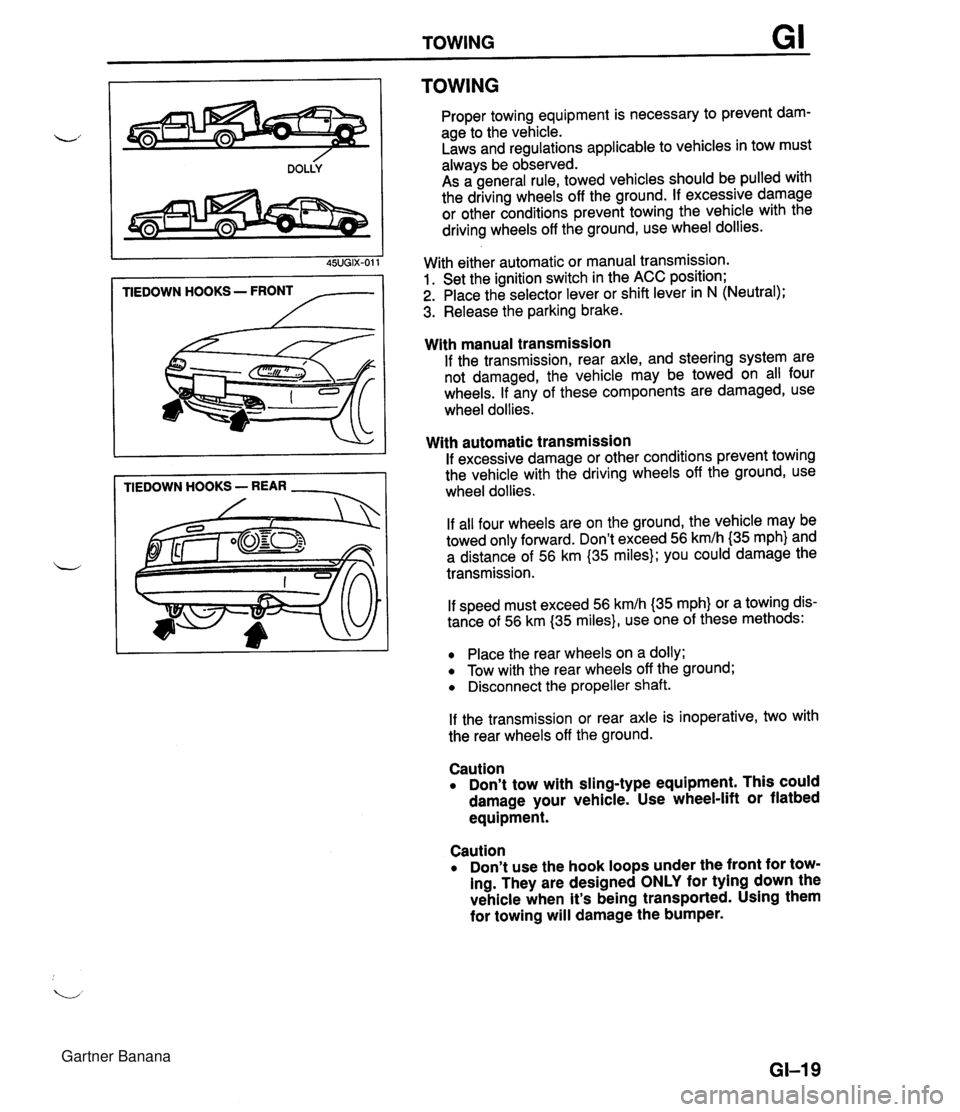

TOWING TIEDOWN HOOKS - FRONT /-- TIEDOWN HOOKS - REAR - TOWING Proper towing equipment is necessary to prevent dam- age to the vehicle. Laws and regulations applicable to vehicles in tow must always be observed. As a general rule, towed vehicles should be pulled with the driving wheels off the ground. If excessive damage or other conditions prevent towing the vehicle with the driving wheels off the ground, use wheel dollies. With either automatic or manual transmission. 1. Set the ignition switch in the ACC position; 2. Place the selector lever or shift lever in N (Neutral); 3. Release the parking brake. With manual transmission If the transmission, rear axle, and steering system are not damaged, the vehicle may be towed on all four wheels. If any of these components are damaged, use wheel dollies. With automatic transmission If excessive damage or other conditions prevent towing the vehicle with the driving wheels off the ground, use wheel dollies. If all four wheels are on the ground, the vehicle may be towed only forward. Don't exceed 56 kmlh {35 mph} and a distance of 56 km (35 miles); you could damage the transmission. If speed must exceed 56 kmlh (35 mph} or a towing dis- tance of 56 km (35 miles}, use one of these methods: Place the rear wheels on a dolly; Tow with the rear wheels off the ground; Disconnect the propeller shaft. If the transmission or rear axle is inoperative, two with the rear wheels off the ground. Caution Don't tow with sling-type equipment. This could damage your vehicle. Use wheel-lift or flatbed equipment. Caution Don't use the hook loops under the front for tow- ing. They are designed ONLY for tying down the vehicle when it's being transported. Using them for towing will damage the bumper. GI-I 9 Gartner Banana

Page 22 of 1708

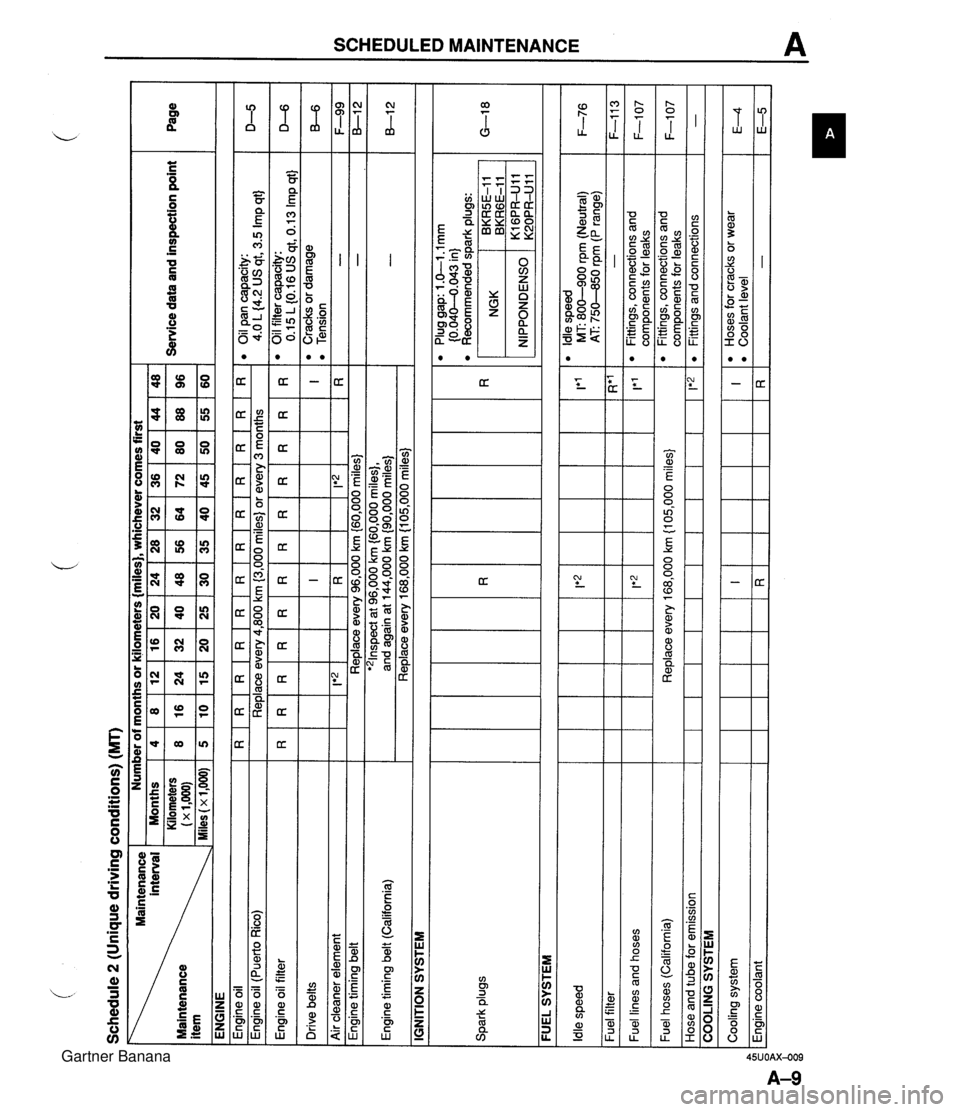

PRE-DELIVERY INSPECTION AND SCHEDULED MAINTENANCE PRE-DELIVERY INSPECTION . . . . . . . . . . . . . . . . . . A- 2 PRE-DELIVERY INSPECTION TABLE . . . . . . . . . . A- 2 SCHEDULED MAINTENANCE (EXCEPT CANADA) . . . . . . . . . . . . . . . . . . . . . . . . . . A- 3 SCHEDULE 1 (NORMAL DRIVING CONDITIONS) . . . . . . . . . . A- 3 SCHEDULE 2 (UNIQUE DRIVING CONDITIONS) . . . . . . . . . . . A- 8 SCHEDULED MAINTENANCE (CANADA) . . . . . . . . A-1 3 SCHEDULE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . A-1 3 45UOAX-001 Gartner Banana

Page 23 of 1708

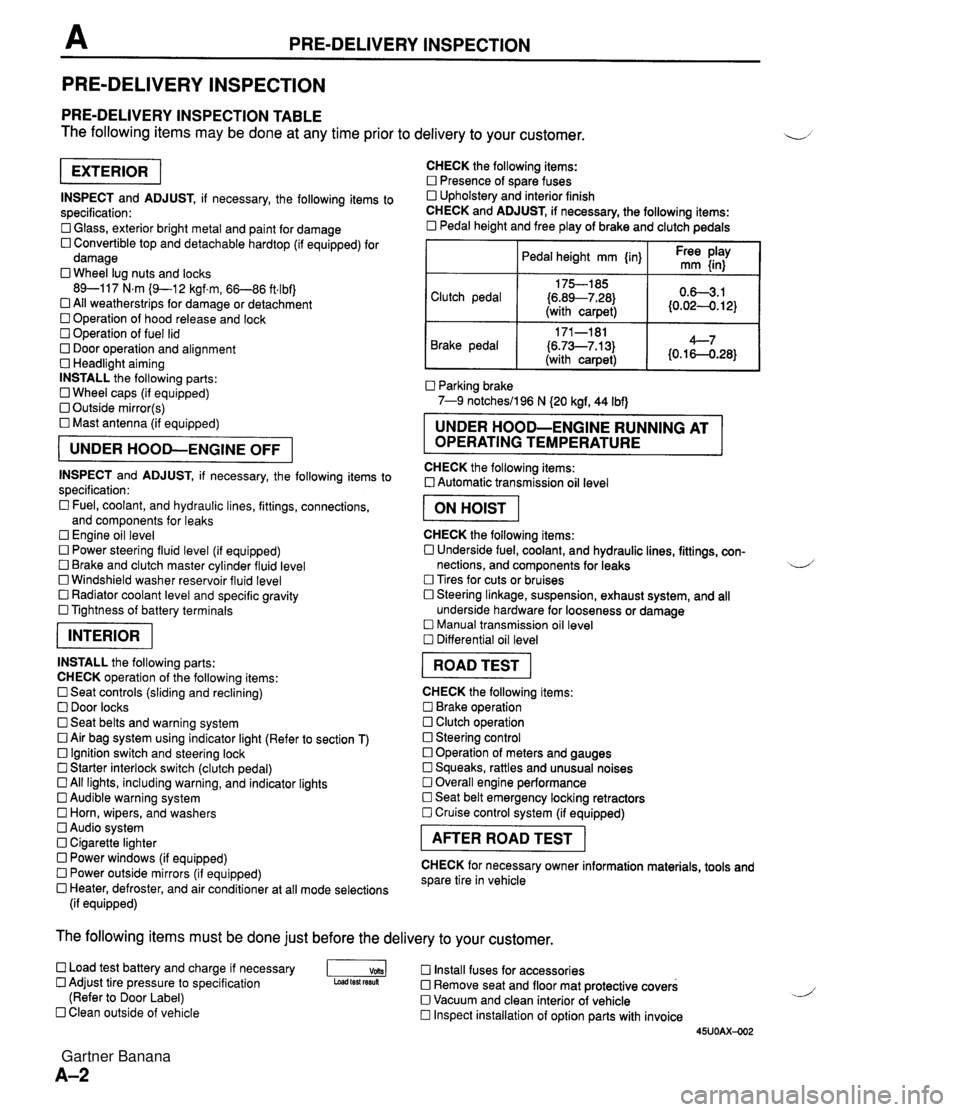

PRE-DELIVERY INSPECTION PRE-DELIVERY INSPECTION PRE-DELIVERY INSPECTION TABLE The following items may be done at any time prior to delivery to your customer. INSPECT and ADJUST, if necessary, the following items to specification: 0 Glass, exterior bright metal and paint for damage 0 Convertible top and detachable hardtop (if equipped) for damage 0 Wheel lug nuts and locks 89-117 N.m (9-1 2 kgf.m, 66-86 ft4bf) 0 All weatherstrips for damage or detachment Operation of hood release and lock Operation of fuel lid 0 Door operation and alignment Headlight aiming INSTALL the following parts: Wheel caps (if equipped) 0 Outside mirror(s) 0 Mast antenna (if equipped) UNDER HOOD-ENGINE OFF INSPECT and ADJUST, if necessary, the following items to specification : Fuel, coolant, and hydraulic lines, fittings, connections, and components for leaks Engine oil level 0 Power steering fluid level (if equipped) Brake and clutch master cylinder fluid level 0 Windshield washer reservoir fluid level 0 Radiator coolant level and specific gravity 0 Tightness of battery terminals pKiq INSTALL the following parts: CHECK operation of the following items: 0 Seat controls (sliding and reclining) 0 Door locks 0 Seat belts and warning system 0 Air bag system using indicator light (Refer to section T) Ignition switch and steering lock 0 Starter interlock switch (clutch pedal) All lights, including warning, and indicator lights 0 Audible warning system 0 Horn, wipers, and washers Audio system 0 Cigarette lighter Power windows (if equipped) 0 Power outside mirrors (if equipped) 0 Heater, defroster, and air conditioner at all mode selections (if equipped) CHECK the following items: Presence of spare fuses 0 Upholstery and interior finish CHECK and ADJUST, if necessary, the following items: 0 Pedal height and free play of brake and clutch pedals I Pedal height mm {in} I Ft: $iy I Clutch pedal {6.89--7.28) (with carpet) Parking brake 7-9 notchesil96 N (20 kgf, 44 Ibf) 0.63.1 (0.024. 12) Brake pedal RUNNING AT OPERATING TEMPERATURE CHECK the following items: 0 Automatic transmission oil level 171-181 (6.73--7.13) (with carpet) I ON HOIST I 4--7 {0.16-0.28} CHECK the following items: 0 Underside fuel, coolant, and hydraulic lines, fittings, con- nections, and components for leaks 4 Tires for cuts or bruises 0 Steering linkage, suspension, exhaust system, and all underside hardware for looseness or damage Manual transmission oil level Differential oil level I ROAD TEST I CHECK the following items: Brake operation Clutch operation 0 Steering control 0 Operation of meters and gauges Squeaks, rattles and unusual noises 0 Overall engine performance Seat belt emergency locking retractors 0 Cruise control system (if equipped) I AFTER ROAD TEST I CHECK for necessary owner information materials, tools and spare tire in vehicle The following items must be done just before the delivery to your customer. 0 Load test battery and charge if necessary -1 Install fuses for accessories Adjust tire pressure to specification Load test fesuk 0 Remove seat and floor mat protective covers (Refer to Door Label) 0 Vacuum and clean interior of vehicle Clean outside of vehicle Inspect installation of option parts with invoice 45UOAX-002 Gartner Banana

Page 24 of 1708

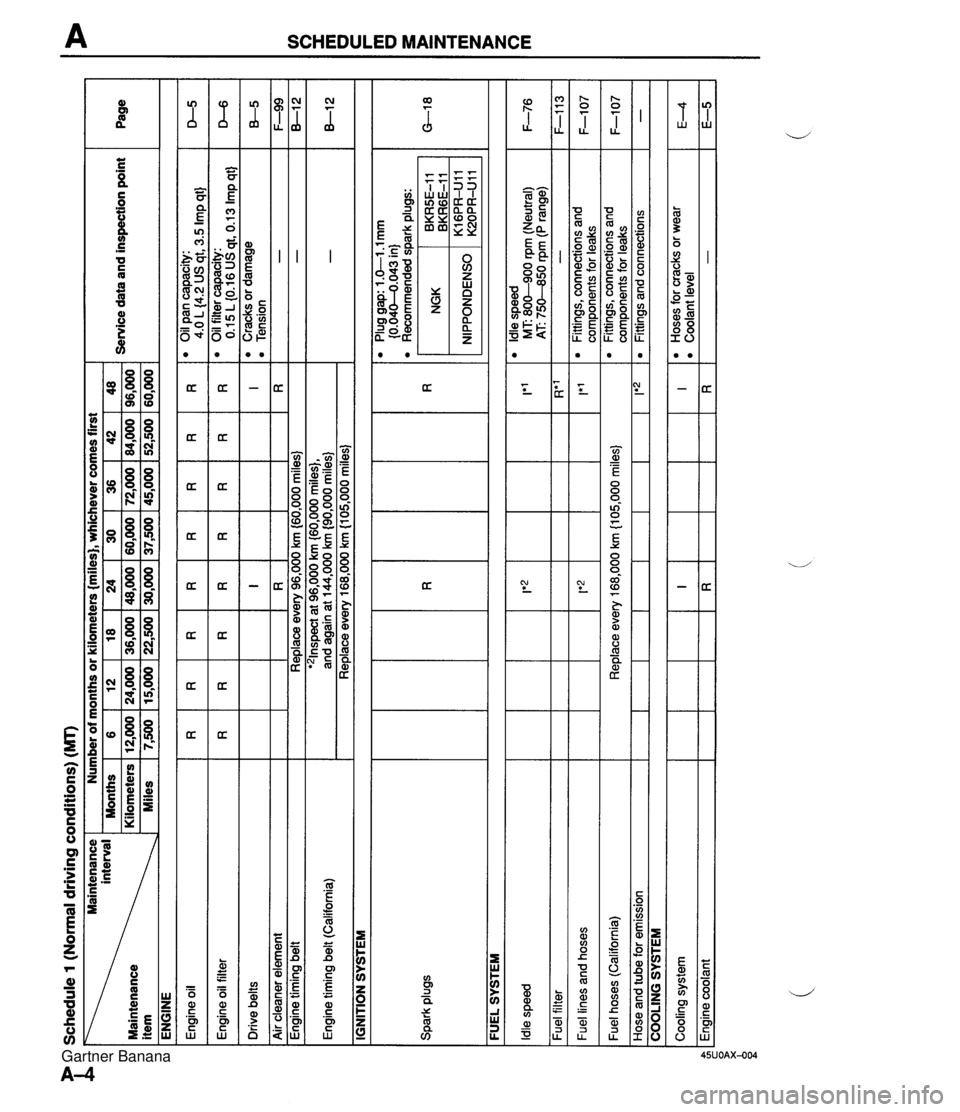

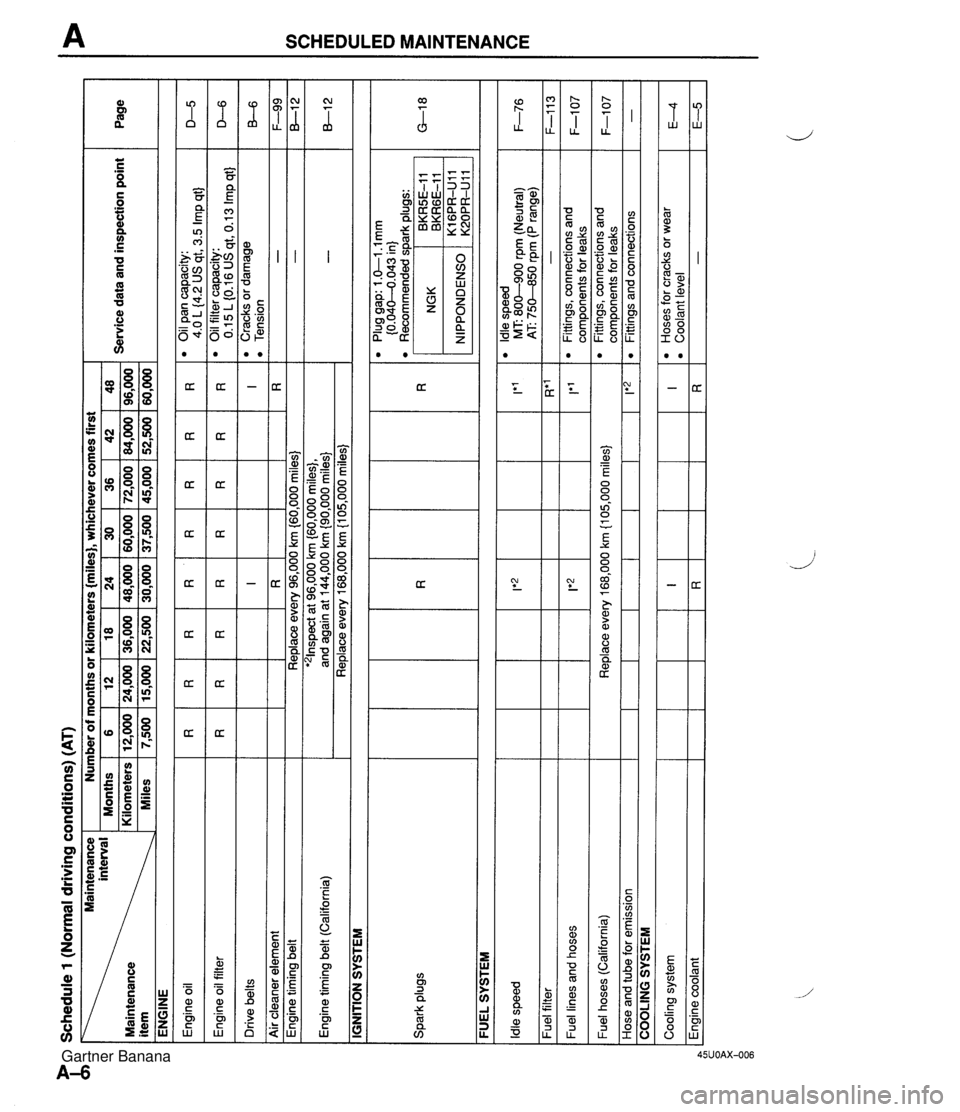

SCHEDULED MAINTENANCE (EXCEPT CANADA) Schedule 1 (Normal driving conditions) If the vehicle is mainly operated where none of the "unique driving conditions" apply. Schedule 2 (Unique driving conditions) Repeated short-distance driving. Driving in dusty conditions. Driving with extended use of brakes. Driving in areas where road salt or other corrosives are used. Driving on rough or muddy roads. Extended periods of idling or low-speed operation. r Driving for long periods in cold temperatures or extremely humid climates. SCHEDULE 1 (NORMAL DRIVING CONDITIONS) Chart symbols: I : Inspect, and repair, clean, or replace if necessary R : Replace L : Lubricate Remarks: After 48 months or 96,000 km {60,000 miles), continue to follow the described maintenance at the recommended intervals. *1 This maintenance is required for all states except California. However, we recommend that it also be performed on California vehicles. '2 This maintenance is recommended by Mazda. However, it is not necessary for emission warranty coverage or manufacturer recall liability. Gartner Banana

Page 25 of 1708

~3l~k ON11003 - LO 1-d LO 1-j E C 1-4 9L-3 suo!~~uuoz~ pue sbu!~! j syeal JO~ s~uauodwm pue suo!13auuo3 'S~U!U! j syeal~ol sluauodwo3 pue suo!i~auuo~ 's6u!w!j - (a6ue~ d) udJ 058--OSL W (le~lna~) udJ 006-008 :IN paads alp1 . Z,~ ] uo!ss!ua JO~ aqni pue asoH (e!u~o)!le=)) sasoq Ian j sasoq pue sau!~ land Jall!J land paads alPl hl!~ OOO'SOC~ ux 000'89 c ha~a awdatl lzl 1.H 1-1 2-1 2-1 Gartner Banana

Page 26 of 1708

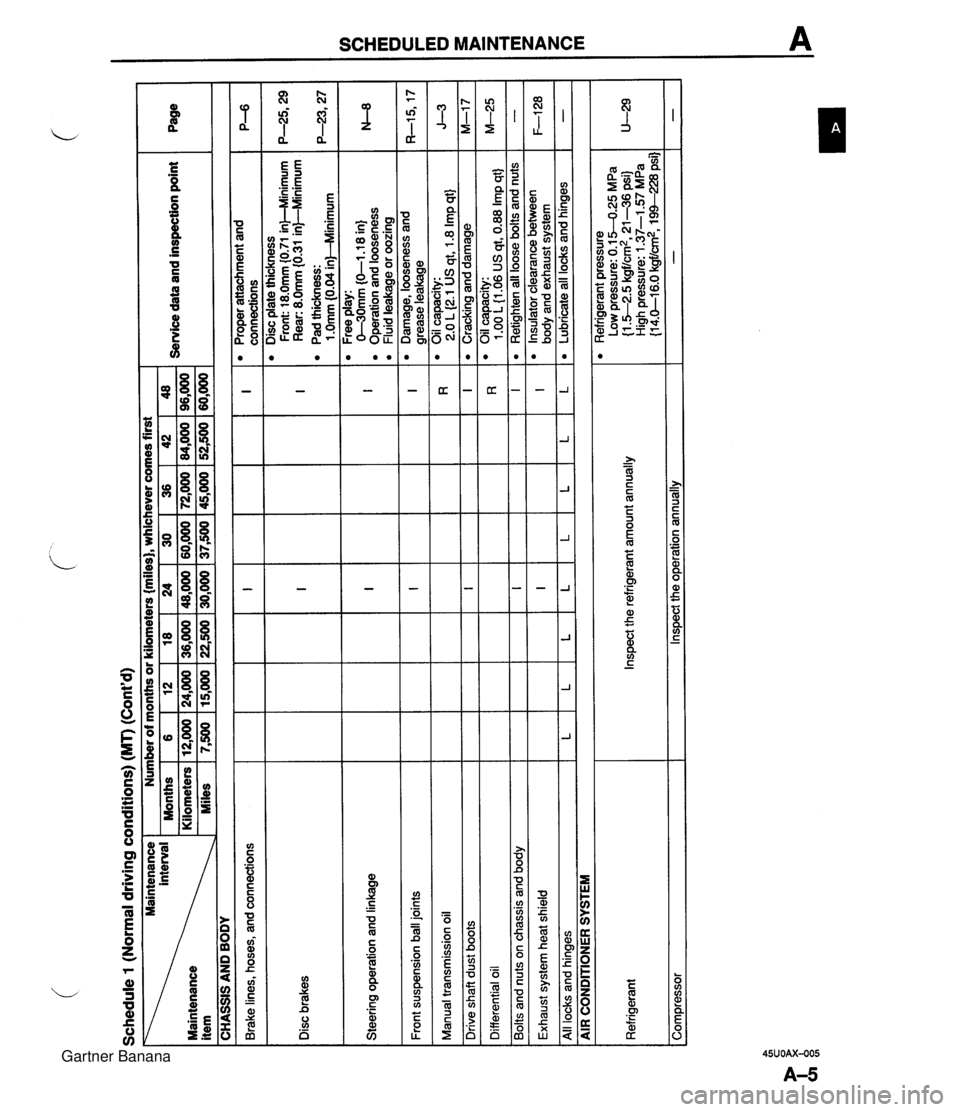

Schedule 1 (Normal driving conditions) (MT) (Cont'd) Maintenance 1 Number of months or kilometers {miles), whichever comes first I I 1 Months 1 6 18 124 130 136 142148 Service data and inspection point 36,000 1 48,000 1 60,000 1 72,000 1 84,000 1 96,000 Maintenance item I CHASSIS AND BODY Brake lines, hoses, and connections Disc plate thickness Front: 18.0mm (0.71 in)--Minimum I I 1 near: 8.0mm {o31 inFMnimum P-6 I Disc brakes I Pad thickness: I I I I I ~10mrn~0.04inMlinimum I Proper attachment and connections Steering operation and linkage I I I I I I I 0-3'0mm (0-1.1 8 in) Operation and looseness Fluid leakaae or oozina I I Front suspension ball joints I I Free play: I I I I I I I - - Manual transmission oil I I I I I , I Damage, looseness and I grease leakage Oil capacity: 2.0 L (2.1 US at. 1.8 Imp qtJ Ill I I I I I Cracking and damage I , I Oil capacity: I I I Differential oil I Drive shaft dust boots I Bolts and nuts on chassis and body I I I n I 1 .OO L {I .06 US qt, 0.88 Imp qt} Ill Exhaust system heat shield I I I I 1 Retiahten all loose bolts and nuts L All locks and hinges lLlLl - AIR CONDITIONER SYSTEM I L Refrigerant pressure Low pressure: 0.1 5-0.25 MPa {I -52.5 kgf/cm2, 21-36 psi) High pressure: 1.37-1 -57 MPa {I 4.0-1 6.0 kgf/cm2, 1 XI-228 psi] - L Corn~ressor I lnswct the o~eration annuallv Refrigerant L Inspect the refrigerant amount annually L I L " Insulator clearance between body and exhaust system Lubricate all locks and hinges F-128 - Gartner Banana

Page 27 of 1708

R31SAS BNl1003 - suo!pauuo~ pue s6u!u!j rn 1 z.l 1 uo!ss!Lua JO~ aqnl pue asoH sasoq pue sauy lanj - - R31SAS NOlllNOl z 1-4 z la 66-4 9--8 9-a s-a I ISJ!~ saluos rana4qq~ '{sal!lu) sJaiawol!y lo sqauolu lo JaqlunN a6ed uo!sual a6ewep JO sy~el3 rn Iib dw E 1.0 '~b sn 9 1-01 -t s 1.0 :Alpede3 ~alpg l!o I@ dw~ S'C 'lb sn z14 i O.P :I ud I rn 000'09 OOS'ZS OOO'SP OOE'LE OOO'OE OOS'ZZ OOO'SL OOS'L =I!W luau 000'96 ooo'm OOO'ZL ooo'w 000'8~ ~0'9~ OOO'PZ OW'ZL slaialuol!~ asueualu!el(y lu!od uo!padsu! pue eiep as!luaS 8b Zt 9E OE PZ 8 1 ZC 9 S4)u0w lehlalu! (e!u~oyle3) ilaq GU!LU!Q au!6u3 llaq 6u!u!l au!6u3 tuaurala Jaueap J!W - - - I tl tl {sal!~ 000'~0 11 wy 000'89 1 ha~a aaslda~ IW!w 000'06} UJY OOO'PP 1 K ~6e pue 'bl!~ 000'09} UY 000'96 le Wdsulz. {sal!~ 000'09} w 000'96 ha~a meldau tl I tl tl ltll I tl tl tl tl I tl tl tl tl tl tl tl tl sllaq a+a Jalpj I!O au!6u3 po au!6ua Gartner Banana

Page 28 of 1708

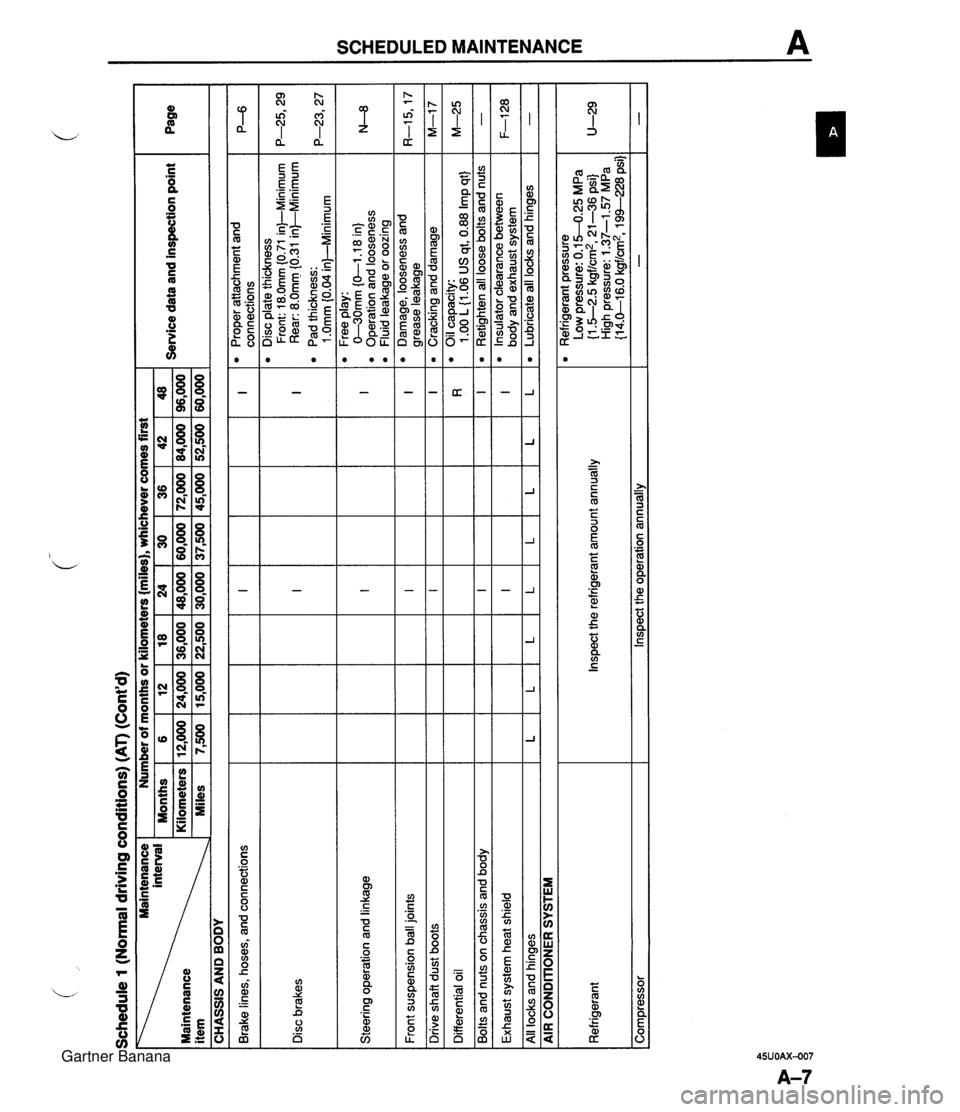

Schedule 1 (Normal driving conditions) (AT) (Cont'd) - .. .. Brake lines, hoses, and connections -- Front suspension ball joints Page I Disc brakes Steering operation and linkage I I 1 I I I I Drive shaft dust boots Ill CHASSIS AND BODY Service data and inspection point Maintenance Number of months or kilometers {miles), whichever comes first I I Differential oil I interval Months Maintenance Kilometers item Miles Exhaust system heat shield I 36 72,000 45,000 I I I I I I I I I 1 I I I I All locks and hinaes lLlLlLlLlLlLlL 6 12,000 7,500 Bolts and nuts on chassis and body - AIR CONDIIONER SYSTEM 42 84,000 52,500 I Ill 12 24,000 15,000 96,000 60,000 Proper attachment and connections Disc plate thickness Front: 18.0mm (0.71 in)-Minimum Rear: 8.0mm f0.31 in)--Minimum Pad thickness: 1 .Omm 10.04 inl-Minimum .-- Free play: C-30mm (0-1 .I 8 in) Operation and looseness Fluid leakage or oozing 18 36,000 22,500 Refrigerant Compressor Damage, looseness and arease leakaae Inspect the refrigerant amount annually Inspect the operation annually 24 48,000 30,000 30 60,000 37,500 Cracking and damage Oil capacity: 1 .OO L 11.06 US at. 0.88 Irn~ at} M-17 M-25 Retighten all loose bolts and nuts Insulator clearance between bodv and exhaust system Refrigerant pressure Low pressure: 0.1 5-0.25 MPa (1 .5-2.5 kgf/:, 21-36 psi) 1 LJ: High pressure: 1.37-1.57 MPa {I 4.0-1 6.0 kgf/cm2, 194--228 psi) - F-128 Lubricate all locks and hinges - Gartner Banana

Page 29 of 1708

A SCHEDULED MAINTENANCE Gartner Banana

Page 30 of 1708

a6ed I ~u!oci uowadsu! pue elep ao!ruas Gartner Banana