MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 451 of 1164

CHARGING SYSTEM G

Disassembly / Assembly

1. Disassemble in the order shown in the figure.

2. Inspect all parts and repair or replace as necessary.

3. Assemble in the reverse order of disassembly.

P-105 N.m (9.5-11 m-kg, 61-79 ft.lb)

N-m (cm-kg, in-l

OBUOGX-0

1. Pulley 6. Rectifier

2. Front cover Inspection .,,,..,,,,.....,,.,.,,............. page G-13

3. Rotor 7. Brush holder assembly

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page G-12 Inspection

4. Rear bracket (Brush and brush spring) . . . . . . . . . page G-13

5. Stator 8. Bearing

Inspection . . . . . . . . . . . . . . . . . . . . . . . . page G-l 2 Inspection .,.,,...,......,......,............ page G-13

G-l 1

Page 452 of 1164

![MAZDA PROTEGE 1992 Workshop Manual G CHARGING SYSTEM

23UOGX-OO!

23UOGX-00

03UOGX-02,

03UOGX-02

Inspection

Rotor

1. Measure the resistance between the slip rings with an

ohmmeter.

Specification: 3.5-4.5Q [at 20°C (66OF)]

2. I MAZDA PROTEGE 1992 Workshop Manual G CHARGING SYSTEM

23UOGX-OO!

23UOGX-00

03UOGX-02,

03UOGX-02

Inspection

Rotor

1. Measure the resistance between the slip rings with an

ohmmeter.

Specification: 3.5-4.5Q [at 20°C (66OF)]

2. I](/img/28/57077/w960_57077-451.png)

G CHARGING SYSTEM

23UOGX-OO!

23UOGX-00

03UOGX-02,

03UOGX-02

Inspection

Rotor

1. Measure the resistance between the slip rings with an

ohmmeter.

Specification: 3.5-4.5Q [at 20°C (66OF)]

2. If not within specification, replace the rotor.

3. (1) Check continuity between each slip ring and the core

with an ohmmeter.

(2) Replace the rotor if there is continuity.

4. Check if the slip ring surface is rough. Use fine sandpaper

to repair it if necessary.

Stator

1. Check for continuity between the stator coil leads with an

ohmmeter.

2. Replace the stator it there is no continuity.

3. Check continuity between the stator coil leads and the core

with an ohmmeter.

4. Replace the stator if there is continuity.

G-12

Page 453 of 1164

CHARGING SYSTEM G

L

23UOGX.00

P2 I9

WEAR LIMIT

03UOGX-021

03UOGX-02C

03UOGXz

Rectifier

1. Check continuity of the diodes with an ohmmeter.

Negative

E

B

T

Pl, P2,

P3

Pl, P2, P3

Positive

PI,

P2, P3

E

B

T

Continuity

Yes

No

No

No

Yes

Yes

2. Replace the rectifier if necessary.

Brush

If a brush is worn almost to or beyond the limit, replace the

brushes.

Standard: 21Smm (0.848 in)

Minimum: 8.0mm (0.315 in)

Brush spring

1. Measure the force of the brush spring with a spring pres-

sure gauge.

2. Replace the spring if necessary.

Standard force:

3.1-4.3 N (320-440 g, 11.3-15.5 oz)

Minimum: 1.6-2.4 N (160-240 g, 5.6-8.5 oz)

Note

l Read the spring pressure with the brush tip project-

ing 2mm (0.079 in).

Bearing

1. Check for abnormal noise, looseness, or sticking

2. Replace the bearing(s) if necessary.

G-l 3

Page 454 of 1164

G CHARGING SYSTEM

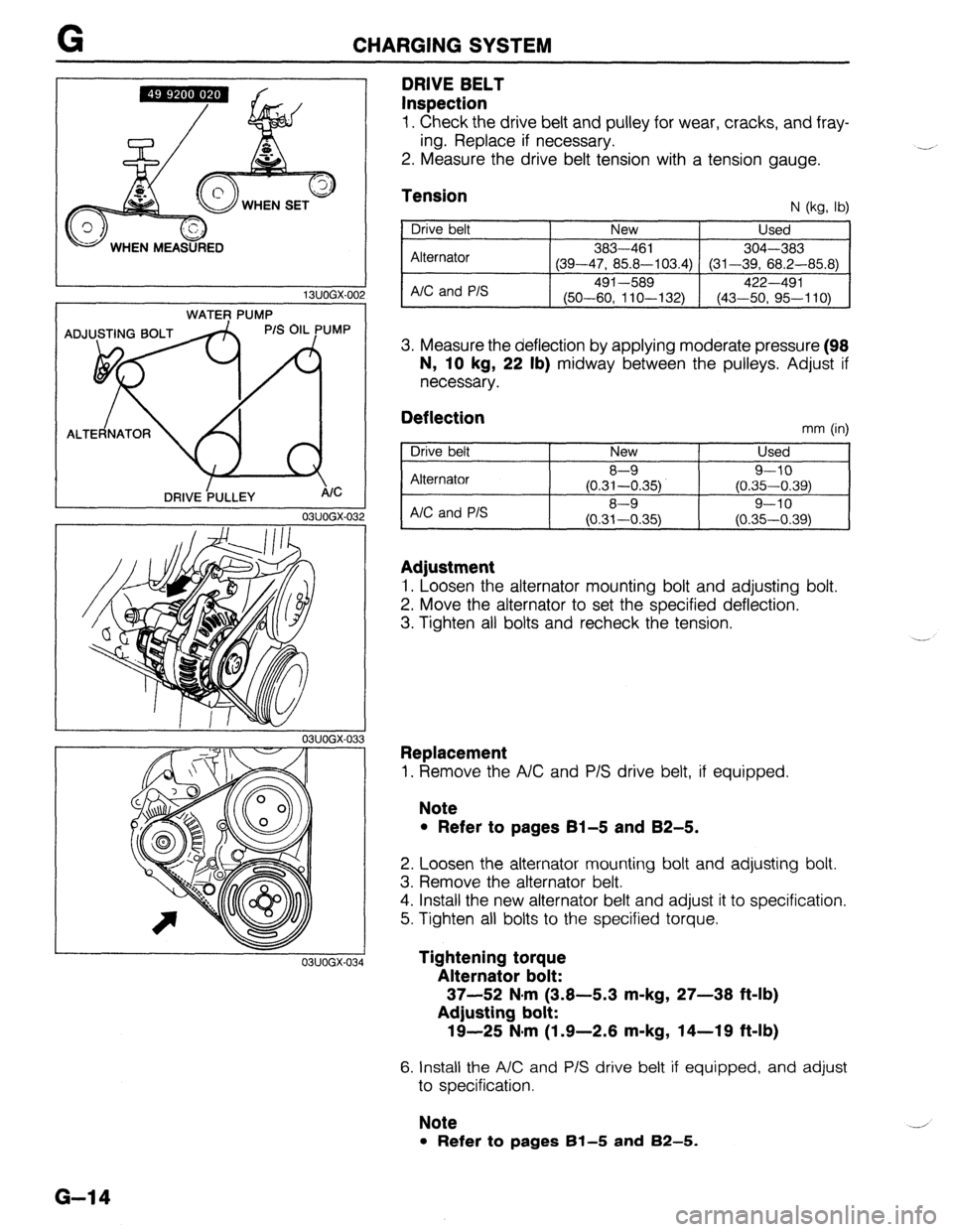

WATER PUMP 13UOGX-00,

03UOGX-03:

I /I I III

I f 03UOGX-03:

03UOGX-034

DRIVE BELT

Inspection

1. Check the drive belt and pulley for wear, cracks, and fray-

ing. Replace if necessary.

2. Measure the drive belt tension with a tension gauge. .-A

Tension N (kg, lb)

Drive belt

Alternator

A/C and P/S New Used

383-461

304-303

(39-47, 85.8-103.4) (31-39, 68.2-85.8)

491-589 422-491

(50-60, 11 O-l 32) (43-50, 95-110)

3. Measure the deflection by applying moderate pressure (98

N, 10

kg, 22 lb) midway between the pulleys. Adjust if

necessary.

Deflection mm (in)

Drive belt

Alternator

AIC and P/S New Used

8-9 9-10

(0.31-0.35) (0.35-0.39)

8-9 9-10

(0.31-0.35) (0.35-0.39)

Adjustment

1. Loosen the alternator mounting bolt and adjusting bolt.

2. Move the alternator to set the specified deflection.

3. Tighten all bolts and recheck the tension.

Replacement

1. Remove the A/C and P/S drive belt, if equipped.

Note

l Refer to pages 61-5 and 82-5.

2. Loosen the alternator mounting bolt and adjusting bolt.

3. Remove the alternator belt.

4. Install the new alternator belt and adjust it to specification.

5. Tighten all bolts to the specified torque.

Tightening torque

Alternator bolt:

37-52 N#rn (3.8-5.3 m-kg, 27-38 ft-lb)

Adjusting bolt:

19-25 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

6. Install the A/C and P/S drive belt if equipped, and adjust

to specification.

Note

l Refer to pages 61-5 and 82-5.

G-14

Page 455 of 1164

IGNITION SYSTEM G

IGNITION SYSTEM

PREPARATION

SST

49 NO18 001

Adapter Harness

CIRCUIT DIAGRAM

ECU

T

IGNITION SWITCH

,

I

DISTRIBUTOR

7

1 ZL BATTERY

IGNITER

03UOGX-03t

G-15

Page 456 of 1164

G IGNITION SYSTEM

TROUBLESHOOTING

iTEP

INSPECTION

ACTION

1

Check if MIL illuminates when engine is running Yes Check for malfunction code number

and perform troubleshooting (TEN ter-

minal grounded) c7 Section F

No Go to next step

2 Drsconnect high-tension lead from distributor and

Yes

check for strong blue spark while cranking en-

l Check distributor cap and rotor v page G-22

gine * Check high-tension lead

KP page G-19 c7 page G-17

+ Ignition system normal

No

Go to next step

3 Check if resistance of ignition coil is OK

Yes

Go to next step ~7

page G-19

Specification (at 20°C [66”9):

Primary coil winding: 0.81-0.99Q No

Replace ignition coil

Secondary coil winding: IO-16 kQ

-i

Check if resistance of high-tension leads is OK Yes Go to next step

D= page G-17

Specification: 16 kQ per 1 m (3.28 ft)

No Replace high-tension lead

5 Check if igniter is OK

m- page G-23 Yes

Replace ECU

No

Replace igniter

03UOGX-03

G-16

Page 457 of 1164

IGNITION SYSTEM G

r

03UOGX-03

SOHC

LOCK BOLTS

DOHC

A LOCK BOLTS I 03UOGX-0’

03UOGX-C

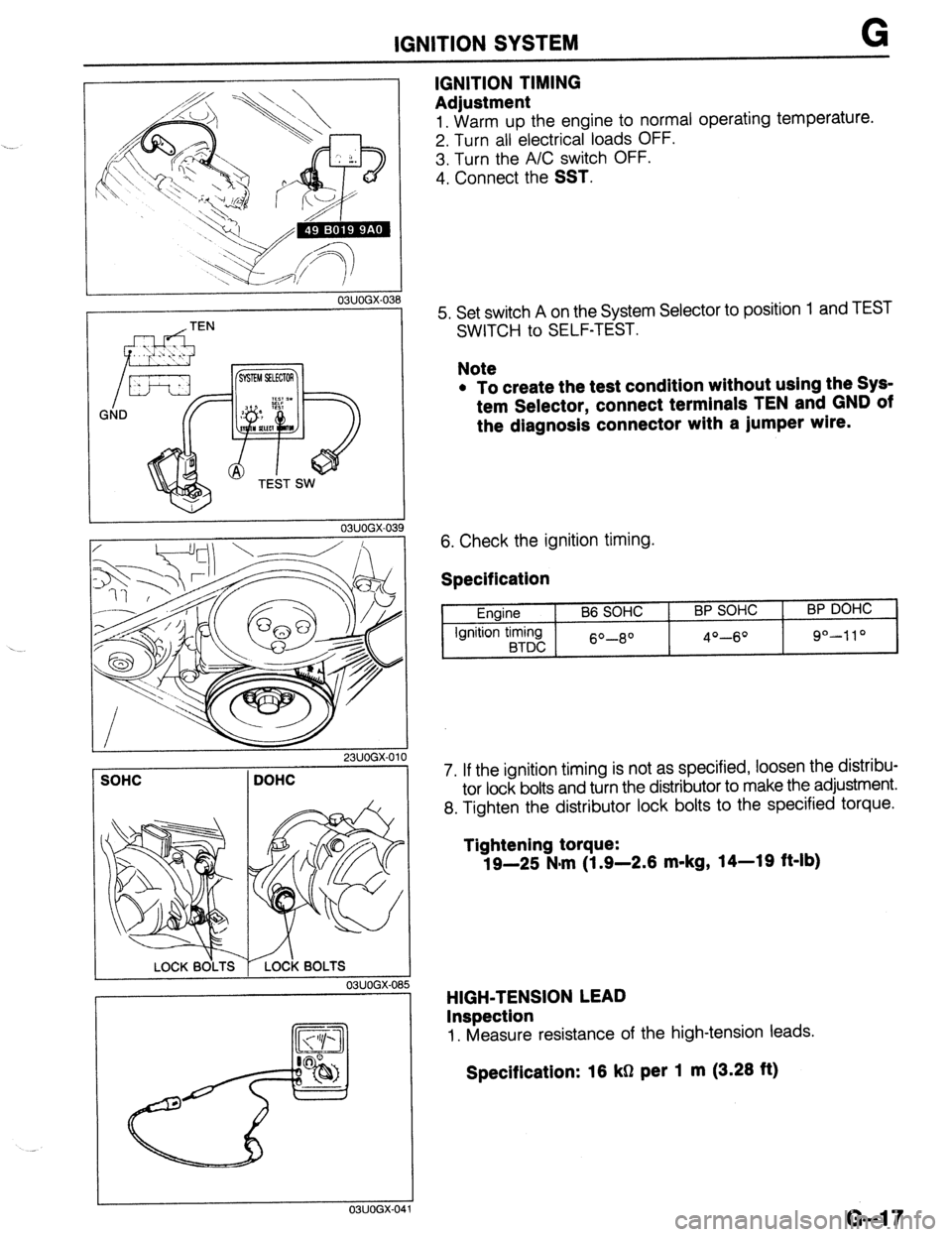

IGNITION TIMING

Adjustment

1. Warm UD the enaine to normal operating temperature.

2. Turn all ‘electricarloads OFF.

3. Turn the A/C switch OFF.

4. Connect the

SST.

5. Set switch A on the System Selector to position

SWITCH to SELF-TEST. 1 and TEST

Note

l To create the test condition without using the Sys-

tem Selector, connect terminals TEN and GND of

the diagnosis connector with a jumper wlre.

6. Check the ignition timing.

Specification

Engine

Ignition timing

BTDC B6 SOHC BP SOHC

60-8O 4O-6O

BP DOHC

9°-110

7. If the ignition timing is not as specified, loosen the distribu-

tor lock bolts and turn the distributor to make the adjustment.

8. Tighten the distributor lock bolts to the specified torque.

Tightening torque:

19-25 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

HIGH-TENSION LEAD

Inspection

1. Measure resistance of the high-tension leads.

Specification: 16 kg per 1 m (3.26 ft)

G-l 7

Page 458 of 1164

G IGNITION SYSTEM

-.-.. .----___ 03UOGX-042

03UOGX-04

--.---- J

03UOGX-044

WEAR AND CARBON

/

c- -BURNT

PLUG GAP

L--

c

DAMAGE AND

,llllll....*llll,lllf DETERIORATIOF

; -,DAMAGE

03UOGX.04

G-18

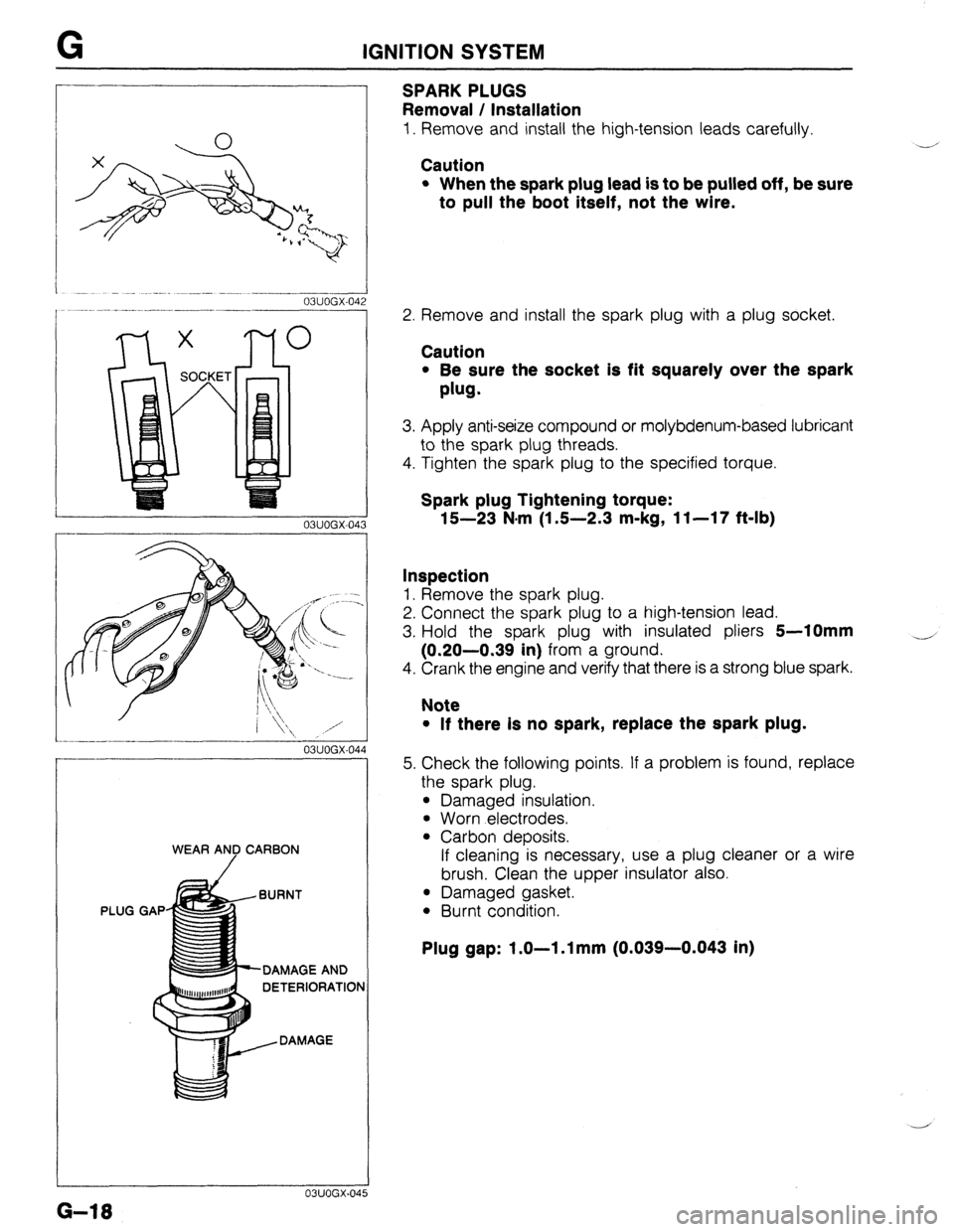

SPARKPLUGS

Removal / Installation

1. Remove and install the high-tension leads carefully.

Caution

l When the spark plug lead is to be pulled off, be sure

to pull the boot itself, not the wire.

Y’

2. Remove and install the spark plug with a plug socket.

Caution

l Be sure the socket is fit squarely over the spark

plug.

3. Apply anti-seize compound or molybdenum-based lubricant

to the spark plug threads.

4. Tighten the spark plug to the specified torque.

Spark plug Tightening torque:

15-23 N.m (1 S-2.3 m-kg, 11-17 f&lb)

Inspection

1. Remove the spark plug.

2. Connect the spark plug to a high-tension lead.

3. Hold the spark plug with insulated pliers

5-10mm

(0.20-0.39 in) from a ground.

4. Crank the engine and verify that there is a strong blue spark.

4

Note

l If there Is no spark, replace the spark plug.

5. Check the following points. If a problem is found, replace

the spark plug.

l Damaged insulation.

l Worn electrodes.

l Carbon deposits.

If cleaning is necessary, use a plug cleaner or a wire

brush. Clean the upper insulator also.

l Damaged gasket.

l Burnt condition.

Plug gap: 1.0-l .l mm (0.039-0.043 in)

Page 459 of 1164

IGNITION SYSTEM . . . ._,

03UOGX-04

Lszl /

P

0 V

- 23UOGX-OC

03UOGX-048

03UOGX-04

03UOGX-0%

IGNITION COIL

Inspection

Spark test

1. Disconnect the high-tension lead from the distributor.

2. Hold it with insulated pliers 5-l

Omm (0.20-0.39 in) from

a ground.

3. Crank the engine and verify that a strong blue spark is

visible.

4. If there is no spark, disconnect the connector from the igni-

tion coil and check for voltage at the positive (+) terminal

of the connector with the ignition switch in the ON position.

Specification: Battery voltage

5. If there is no voltage, check the main fuse, ignition switch,

and wire harness.

Primary coil winding

1. Use an ohmmeter and measure resistance of the primary

coil winding. If not within specification, replace the coil.

Prlmary coil resistance: 0.81-0.99112 (at 2O*C [88*F])

Secondary coil winding

1. Use an ohmmeter and measure resistance of the secon-

dary coil winding. If not within specification replace the coil.

Secondary coil resistance: lo-18 kQ (at 20°C [68*F])

Insulation of case

1. Use a 500V megger tester to measure the insulation resis-

tance between each terminal and the case.

Speclficatlon: 10 MS1 min.

G-19

Page 460 of 1164

G IGNITION SYSTEM

I

03UOGX~051

03UOGX-052

DISTRIBUTOR

Spark Test

1. Disconnect the high-tension lead from each spark plug.

2. Hold each insulator with pliers

5-10mm (0.20-0.39 in)

from a ground.

3. Crank the engine and verify that a strong blue spark is

visible.

Electronic Advance Inspection

1. Verify that the ignition timing advances with engine ac-

celeration.

G-20 ._... -~

._ _