MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 481 of 1164

CLUTCH MASTER CYLINDER H

/I f-------i- OWOHX-01

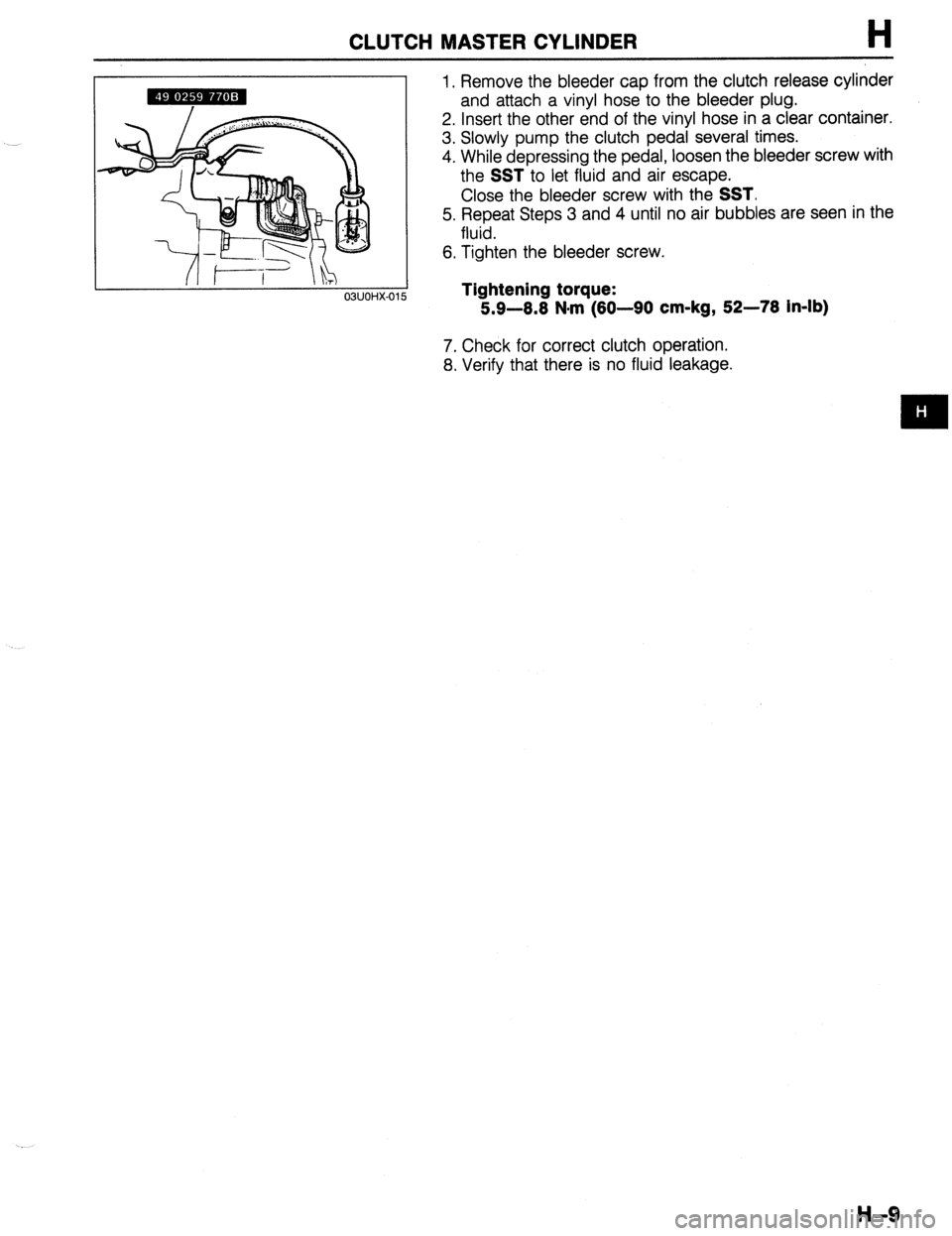

1. Remove the bleeder cap from the clutch release cylinder

and attach a vinyl hose to the bleeder plug.

2. Insert the other end of the vinyl hose in a clear container.

3. Slowly pump the clutch pedal several times.

4. While depressing the pedal, loosen the bleeder screw with

the

SST to let fluid and air escape.

Close the bleeder screw with the

SST.

5. Repeat Steps 3 and 4 until no air bubbles are seen in the

fluid.

6. Tighten the bleeder screw.

Tightening torque:

5.9-8.8 N#rn (80-90 cm-kg, 52-78 in-lb)

7. Check for correct clutch operation.

8. Verify that there is no fluid leakage.

H-9

Page 482 of 1164

H CLUTCH MASTER CYLINDER

OVERHAUL

Caution

l Clean the disassembled parts in solvent and blow through all ports and passages wlth com-

pressed air. .-J

1. Disassemble in the order shown in the figure, referring to Disassembly Note.

2. Inspect all parts and repair or replace as necessary.

3. Assemble in the reverse order of disassembly, referring to

Assembly Note.

I

1. Clip 7. Spacer

2. Hose 8. Primary cup

3. Joint Inspect for wear and cracks

4. Bushing 9. Return spring

5. Snap ring 10. Master cylinder body

Disassembly Note ..,.,..,.........,,,.,......... below Inspect cylinder bore for scoring and

Assembly Note . . . . . . . . . . . . . . . . . . . . . . . . . . . page H-l 1 corrosion

6. Piston and secondary cup assembly

Disassembly Note ,..................... page H-l 1

Assembly Note .,.,.......,...,......,.,,, page H-l 1

Inspect for wear, scoring and cracks

H-10

03UOHX-01

Disassembly Note

Snap ring

Caution

l Do not damage the push rod contact surface of the

piston.

1. Press the piston down and remove the snap ring with snap

ring pliers. -

Page 483 of 1164

CLUTCH MASTER CYLINDER H

SMUOHX-Ol!

03UOHX-02(

03UOHX-02

Piston and secondary cup assembly

Caution

l Hold a rag over the master cylinder to prevent the

piston and secondary cup assembly from jumping

out.

1. Remove the piston and secondary cup assembly, spacer,

and primary cup by applying compressed air through the

clutch pipe installation hole.

Assembly Note

Caution

l Before assembly, make sure all parts are completely

clean.

l Do not mix different brands of clutch fluid.

l Do not reuse the clutch fluid that was drained.

l Apply the specified clutch fluid to the piston and

secondary cup assembly, spacer, primary cup, and

cylinder bore before assembly.

l Replace parts with new ones whenever specified to

do so.

03UOHX-019

Piston and secondary cup assembly

1. Install the spring, primary cup, spacer, and piston and

secondary cup assembly, noting the proper direction of the

parts.

Snap ring

Caution

l Do not damage the push rod contact surface of the

piston.

1. While pressing the piston, install the snap ring.

H-l 1

Page 484 of 1164

H CLUTCH RELEASE CYLINDER

CLUTCH RELEASE CYLINDER

PREPARATION

SST

49 0259 7708 For

Wrench, flare nut e c$on;;;;;!&

clutch pipe

03UOHX-022

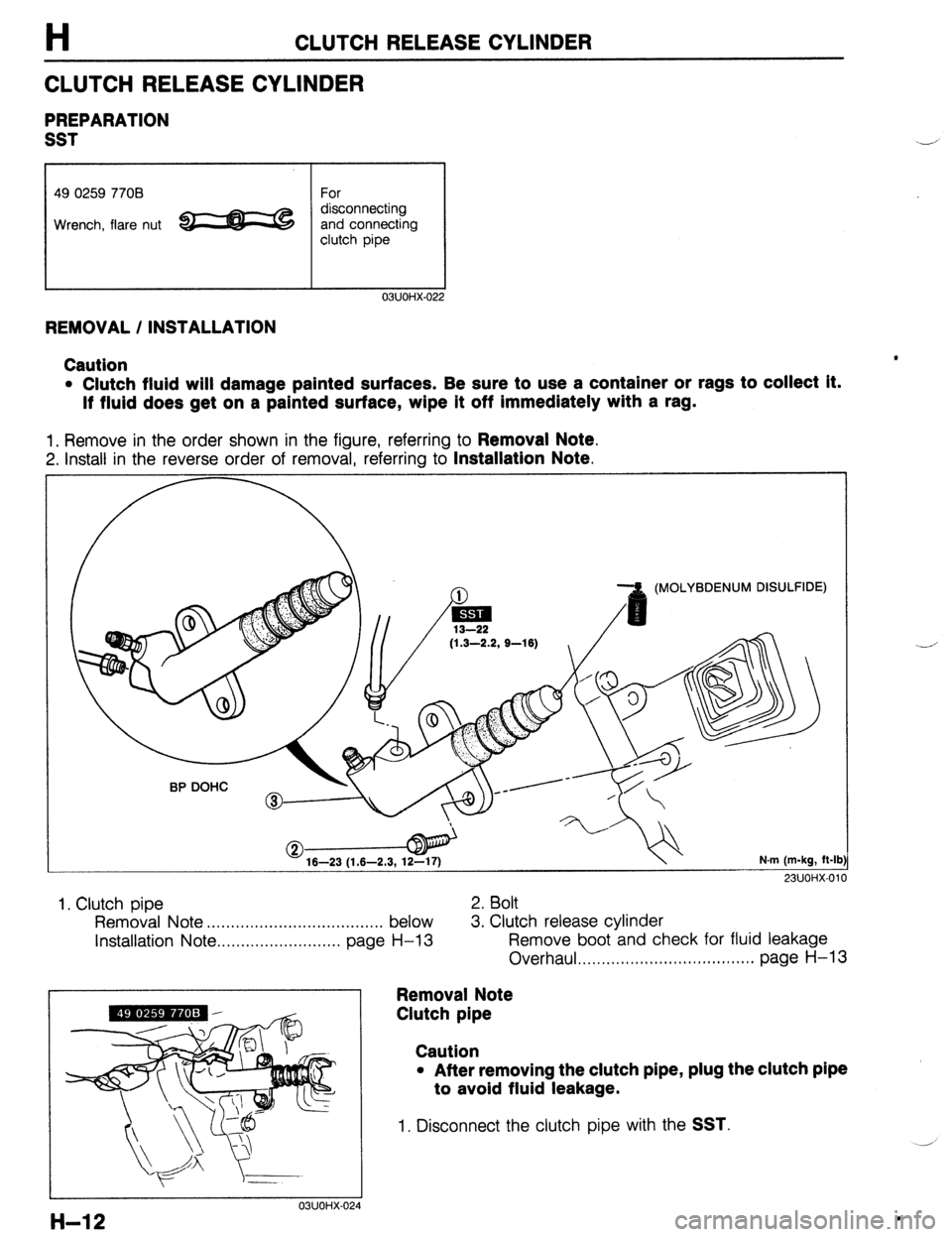

REMOVAL / INSTALLATION

Caution

l Clutch fluid will damage painted surfaces. Be sure to use a container or rags to collect it.

If fluid does get on a painted surface, wipe it off immediately with a rag.

1. Remove in the order shown in the figure, referring to Removal Note.

2. Install in the reverse order of removal, referring to Installation Note.

(MOLYBDENUM DISULFIDE)

(1.3-2.2, S-16)

16-23 (1.6-2.3, 12-17) N.m (m-kg, ft-lb

23UOi-K011

1, Clutch pipe 2. Bolt

Removal Note . . . . . . . . . . . . . . . . . . . . . . . ,........... . . below 3. Clutch release cylinder

installation Note . . . . . . . . . . . . . . . . . . . . . . . . . . page

H-13 Remove boot and check for fluid leakage

Overhaul . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . ...*. page H-13

Removal Note

Clutch pipe

03UOHX-024

Caution

l After removing the clutch pipe, plug the clutch pipe

to avoid fluid leakage.

1. Disconnect the clutch pipe with the SST.

H-12 .

Page 485 of 1164

CLUTCH RELEASE CYLINDER

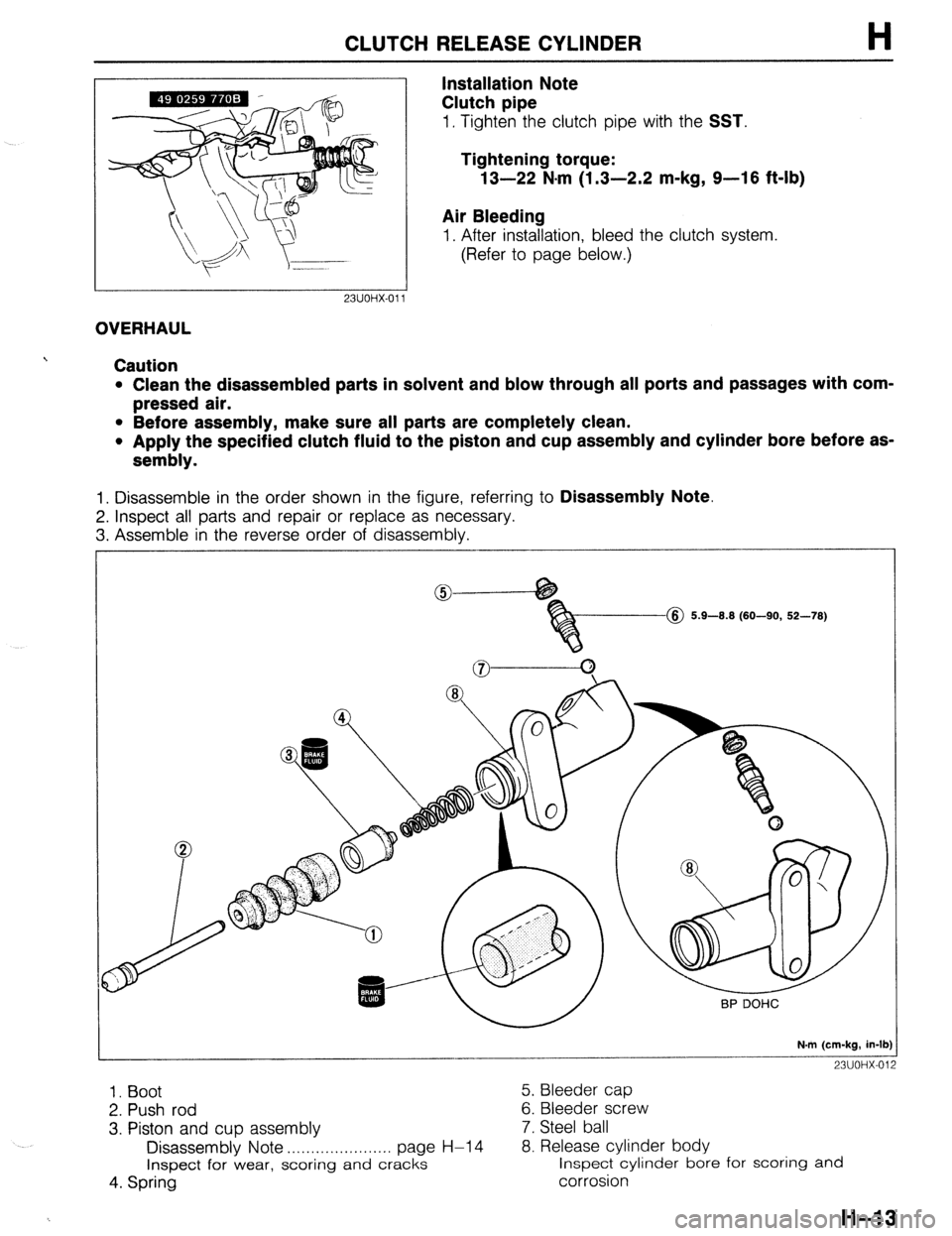

Installation Note

Clutch pipe

H

1. Tighten the clutch pipe with the SST.

Tightening torque:

13-22 N-m (1.3-2.2 m-kg, 9-16 ft-lb)

Air Bleeding

1. After installation, bleed the clutch system.

(Refer to page below.)

23UOHX-011

OVERHAUL

Caution

l Clean the disassembled parts in solvent and blow through all ports and passages with com-

pressed air.

l Before assembly, make sure all parts are completely clean.

l Apply the specified clutch fluid to the piston and cup assembly and cylinder bore before as-

sembly.

1. Disassemble in the order shown in the figure, referring to Disassembly Note.

2. Inspect all parts and repair or replace as necessary.

3. Assemble in the reverse order of disassembly.

@ 5.9-8.8 (60-90, 52-78)

N.m (cm-kg, in-lb)

23UOHX-012

1. Boot 5. Bleeder cap

2. Push rod 6. Bleeder screw

3. Piston and cup assembly 7. Steel ball

Disassembly Note . . . . . . . . . . . . . . . . . . . . . . page H-l 4 8. Release cylinder body

Inspect for wear, scoring

and cracks inspect cylinder bore for scoring and

4. Spring corrosion

H-13

Page 486 of 1164

H CLUTCH RELEASE CYLINDER, CLUTCH UNIT

Disassembly Note

Piston and cup assembly

Caution

l Hold a rag over the release cylinder to prevent the

piston and cup assembly from suddenly popping

out.

1. Remove the piston and cup assembly by applying com-

pressed air through the clutch pipe installation hole.

I

I

13UOHX-017

CLUTCH UNIT

PREPARATION

SST

49 EOll IA0

Brake set,

ring gear

49 EOll 104

Collor

(Part of

49 EOl 1 1 AO)

49 SE01 310A

Clutch disc

centering tool

49 1285 073

Chuck

IPart of

b9 1285 071) For

prevention of

engine rotation 49 EOll 103

Shaft

(Part of

49 EOl 1 1 AO)

For 49

EOI 1 105 prevention of

engine rotation Stopper 453

(Part of

49 EOl 1 IA0

4

For

installation of

clutch disc 49 1285 071

Puller, bearing

For

removal of pilot

bearing For

prevention of

engine rotation

For

prevention of

engine rotation

23UOHX-013

For

removal of pilot

H-14

Page 487 of 1164

CLUTCH UNIT

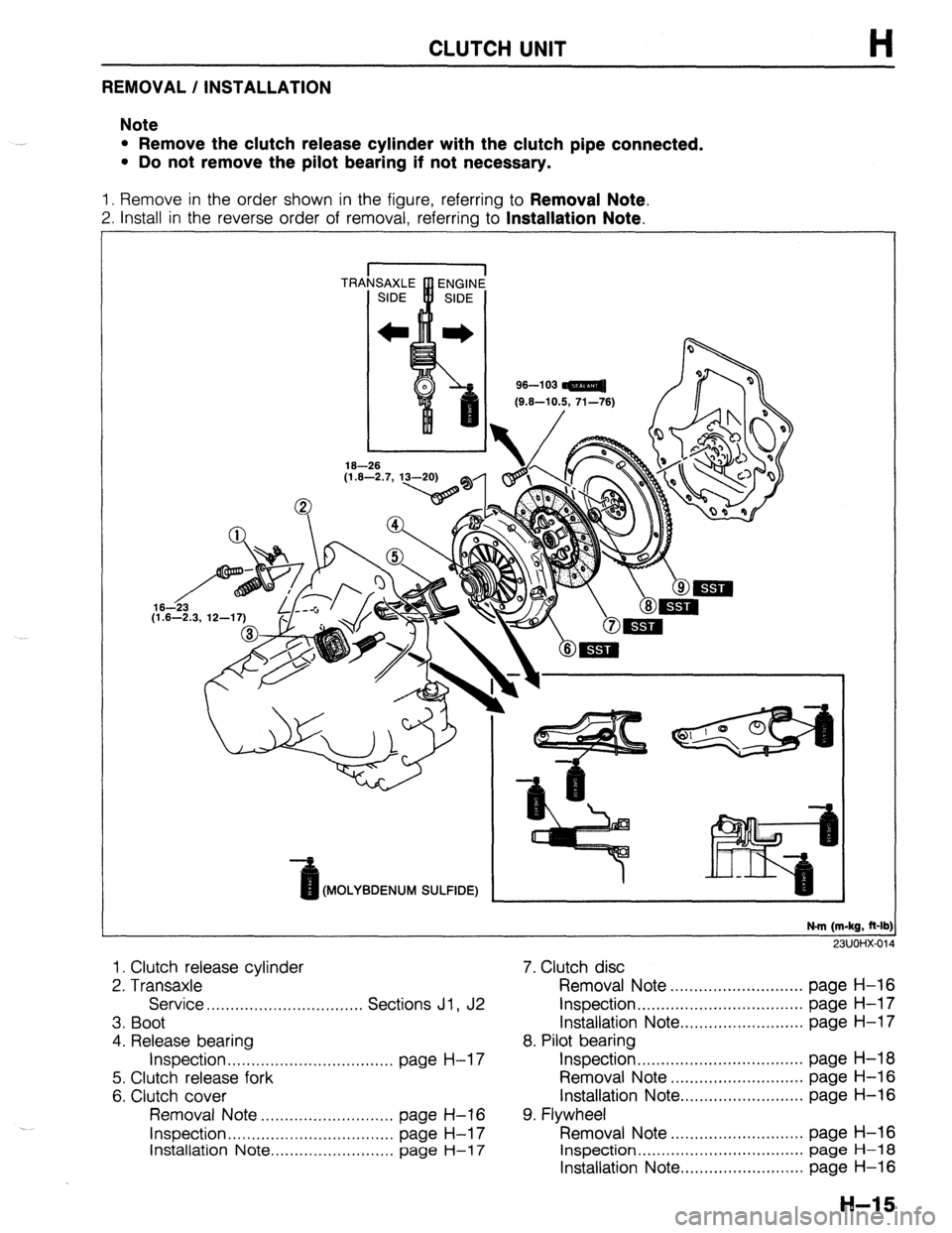

REMOVAL / INSTALLATION

Note

l Remove the clutch release cylinder with the clutch pipe connected.

l Do not remove the pilot bearing if not necessary.

1. Remove in the order shown in the figure, referring to Removal Note.

2. Install in the reverse order of removal, referring to Installation Note.

96-l 03

Kt.6-10.5. 71-761

(MOLYBDENUM SULFIDE)

N-m (m-kg, R-lb:

911 Im-4Y.fi,r

1. Clutch release cylinder

2. Transaxle

Service . . . . . . . . . . . . . . . . . . . . . . . . . ,....... Sections Jl , J2

3. Boot

4. Release bearing

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page H-l 7

5. Clutch release fork

6. Clutch cover

Removal Note ..,...........,,,.........,, page H-16

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . page H-l 7

Installation Note .,......................., page

H-l 7

7. Clutch disc

Removal Note ............................ page H-16

Inspection.. ................................. page H-l 7

Installation Note .......................... page H-l 7

8. Pilot bearing

Inspection ................................... page H-18

Removal Note ............................ page H-16

Installation Note.. ........................ page H-16

9. Flywheel

Removal Note ............................ page H-16

Inspection ................................... page H-18

Installation Note .......................... page H-16

H-15

Page 488 of 1164

H CLUTCH UNIT

/ 6fs 23UOHX-015

Removal Note

Clutch cover and disc

1. Install the SST or equivalent.

2. Loosen each bolt one turn at a time in a crisscross pattern

until spring tension is released. Then remove the clutch COV-

er and disc.

‘6

I

23UOHX-016

23UOHX-01

Pilot bearing

1. Remove the pilot bearing with the SST if necessary.

Flywheel

Note

l After removing the flywheel, inspect for oil leakage

past the crankshaft rear oil seal.

If necessary, replace the oil seal.

(Refer to Section B.) -J

1. Hold the flywheel with the SST or equivalent.

2. Remove the flywheel.

Installation Note

Flywheel

1. Wipe the bolts clean and apply sealant to the bolt threads.

2. Install the flywheel and the

SST or equivalent.

3. Tighten the bolts in the pattern shown.

Tightening torque:

96-103 N,m (9.6-10.5 m-kg, 71-76 ft-lb)

Pilot bearing

Note

l Install the pilot bearing flush with the flywheel.

1. Install the new bearing with a suitable pipe.

Bearing outer diameter: 35mm (1.376 in) .-’

Page 489 of 1164

CLUTCH UNIT, RELEASE BEARING, CLUTCH COVER, CLUTCH DISC H

L

13UOHX-01;

03UOHX-03 8

23UOHX-018

5

03UOHX-032

03UOHX-03

Clutch disc

1. Clean the clutch disc splines and main drive gear splines;

then apply organic molybdenum sulfide grease.

2. Hold the clutch disc in position with the

SST.

Clutch cover

1. Install the SST or equivalent.

2. Align the dowel holes with the flywheel dowels.

3. Tighten the bolts evenly and gradually in the pattern shown.

Tightening torque:

18-26 Nom (1.8-2.7 m-kg, 13-20 ft-lb)

RELEASE BEARING

INSPECTION

Note

l The clutch release bearing Is a sealed bearlng and

must not be washed in solvent.

1. Turn the bearing while applying force in the axial direction.

If the bearing sticks or has excessive resistance, replace it.

CLUTCH COVER

INSPECTION

Note

l Minor scoring or burning should be removed with

emery paper.

1. Inspect the contact surface of the clutch disc for scoring,

cracks, and burning. Repair or replace as necessary.

2. Inspect the contact surface of the clutch release bearing

for wear and cracks.

If there is wear or cracks, replace the clutch cover.

CLUTCH DISC

INSPECTION

Note

l Use sandpaper if the trouble is minor.

1. Inspect the lining surface for burning and oil contamination.

Replace the clutch disc if it is badly burned or oil soaked.

2. Inspect for loose facing rivets and rubbers.

Replace the clutch disc if either is loose.

H-17

Page 490 of 1164

CLUTCH DISC, PILOT BEARING, FLYWHEEL

9

13UOHX-020

03UOHX-03

03UOHX-0:

3. Measure the thickness of the lining at a rivet head on both

sides with vernier calipers.

Replace the clutch disc if its thickness is less than minimum.

Thickness: 0.3mm (0.012 in) min.

4. Measure the clutch disc runout with a dial indicator.

Replace the clutch disc if runout is excessive.

Runout: 0.7mm (0.027 in) max.

PILOT BEARING

INSPECTION

1. Turn the bearing while applying force in the axial direction.

If the bearing sticks or has excessive resistance, replace it.

---

FLYWHEEL

INSPECTION

Note

l Minor scoring or burning should be removed with

emery paper.

1. Inspect the contact surface of the clutch disc for scoring,

cracks, and burning; repair or replace as necessary.

2. Inspect the ring gear teeth for wear and damage. If neces-

sary, replace the ring gear.

3. Measure the flywheel runout with a dial indicator. Replace

the flywheel if runout is excessive.

Runout: 0.2mm (0.008 in) max.