MITSUBISHI ECLIPSE 1990 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 141 of 391

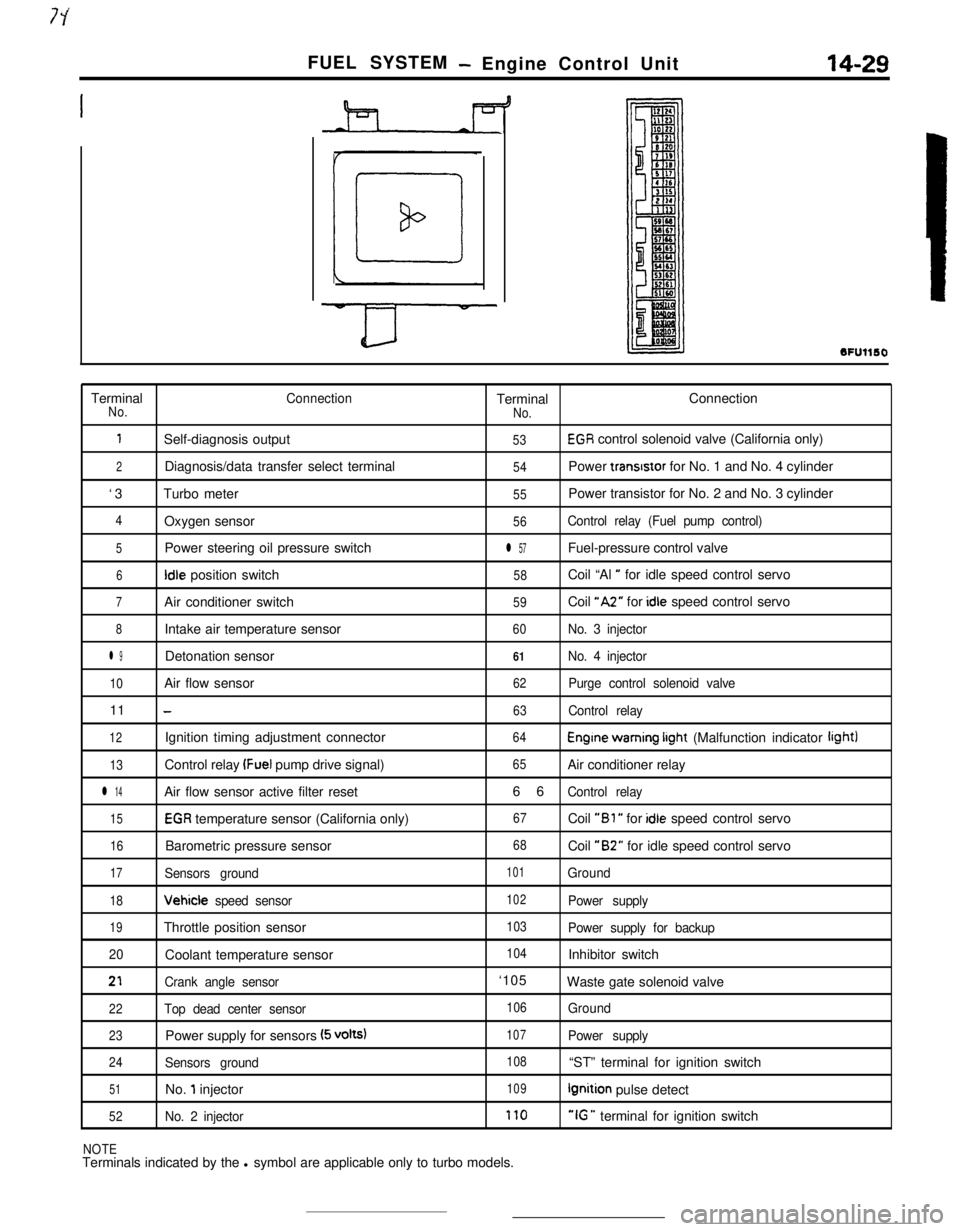

FUEL SYSTEM- Engine Control Unit14-29

SFUllSOTerminal

ConnectionTerminalConnectionNo.

No.

1Self-diagnosis output53EGR control solenoid valve (California only)

2Diagnosis/data transfer select terminal54Power transrstor for No. 1 and No. 4 cylinder

‘3Turbo meter

55Power transistor for No. 2 and No. 3 cylinder

4Oxygen sensor56Control relay (Fuel pump control)

5Power steering oil pressure switchl 57Fuel-pressure control valve

6Idle position switch58Coil “Al ” for idle speed control servo

7Air conditioner switch59Coil “A2” for idle speed control servo

8Intake air temperature sensor60No. 3 injector

l 9Detonation sensor61No. 4 injector

10Air flow sensor62Purge control solenoid valve11

-63Control relay

12Ignition timing adjustment connector64Engine warning irght (Malfunction indicator light)

13Control relay (Fuel pump drive signal)65Air conditioner relay

l 14Air flow sensor active filter reset66Control relay

15EGR temperature sensor (California only)67Coil “Bl ” for idle speed control servo

16Barometric pressure sensor68Coil “B2” for idle speed control servo

17Sensors ground101Ground

18Vehicle speed sensor102Power supply

19Throttle position sensor103Power supply for backup

20Coolant temperature sensor

104Inhibitor switch

21Crank angle sensor‘105

Waste gate solenoid valve

22Top dead center sensor106Ground

23Power supply for sensors (5 volts)107Power supply

24Sensors ground108“ST” terminal for ignition switch

51No. 1 injector109Ignition pulse detect

52No. 2 injector170“IG ” terminal for ignition switch

NOTETerminals indicated by the l symbol are applicable only to turbo models.

Page 142 of 391

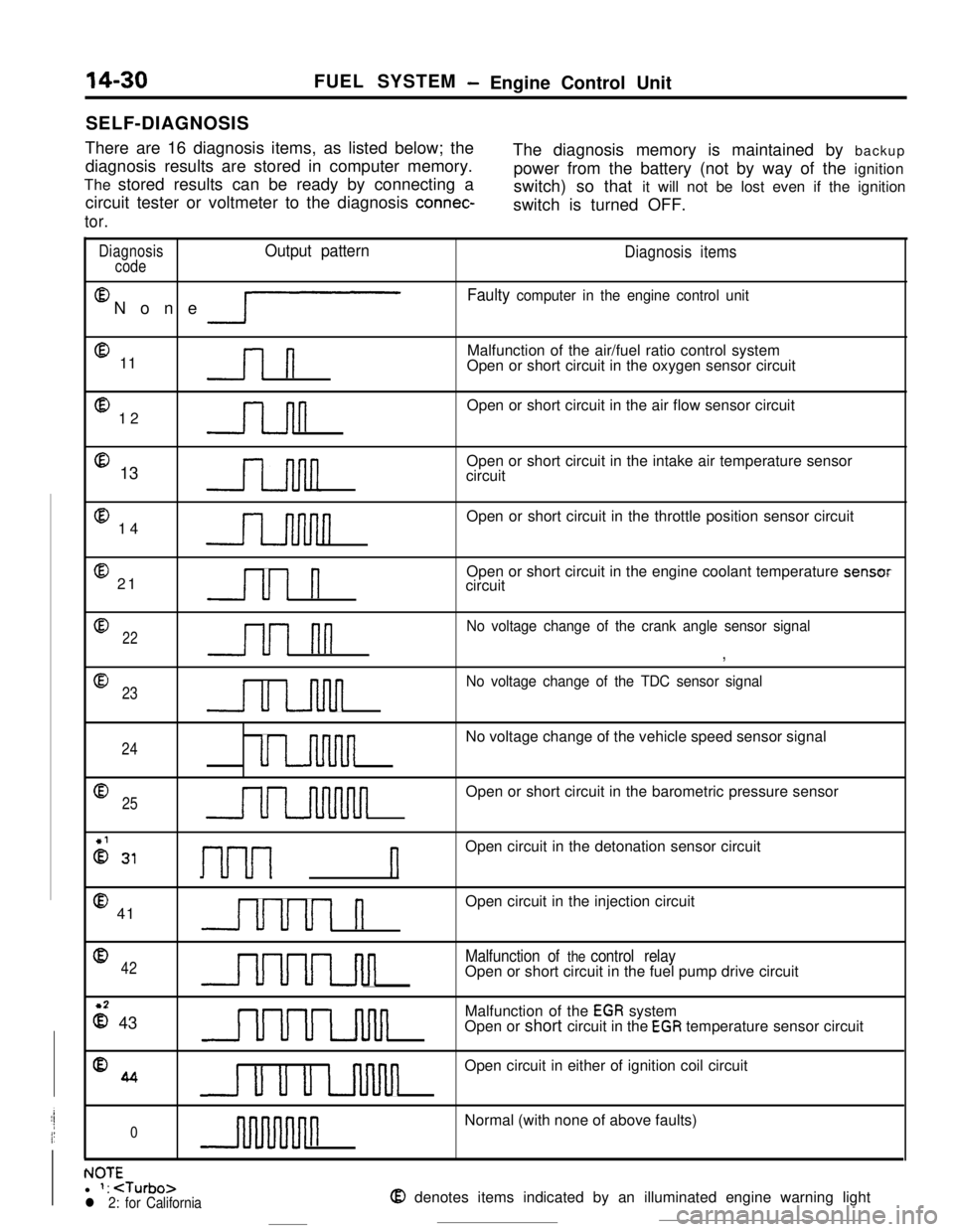

14-30SELF-DIAGNOSISFUEL SYSTEM- Engine Control Unit

There are 16 diagnosis items, as listed below; the

diagnosis results are stored in computer memory.The diagnosis memory is maintained by backup

The stored results can be ready by connecting apower from the battery (not by way of the ignition

circuit tester or voltmeter to the diagnosis

connec-switch) so that it will not be lost even if the ignition

switch is turned OFF.

tor.

DiagnosisOutput pattern

codeEl

None

lP

@ 11l-l

@ 12n@ 13

@ 14

@ 21Ul n

Diagnosis items

Faulty computer in the engine control unitMalfunction of the air/fuel ratio control system

Open or short circuit in the oxygen sensor circuit

Open or short circuit in the air flow sensor circuit

Open or short circuit in the intake air temperature sensor

circuit

Open or short circuit in the throttle position sensor circuit

Open or short circuit in the engine coolant temperature sensor

circuit

022u1 nn

No voltage change of the crank angle sensor signal

,

@

23

u u-inn

No voltage change of the TDC sensor signal

24uu-uvinnnnNo voltage change of the vehicle speed sensor signal

Q25uuuuuunnnnnOpen or short circuit in the barometric pressure sensor

2 31I-~-~---~ nOpen circuit in the detonation sensor circuit

@ 41uuul nOpen circuit in the injection circuit

042UUuLJul

Malfunction of the control relayOpen or short circuit in the fuel pump drive circuit

z 43UUULnlulMalfunction of the

EGR system

Open or short circuit in the EGR temperature sensor circuit

%4u u u uvinnOpen circuit in either of ignition coil circuit

0nNormal (with none of above faults)

. IA-r-NUltl 1:

Page 143 of 391

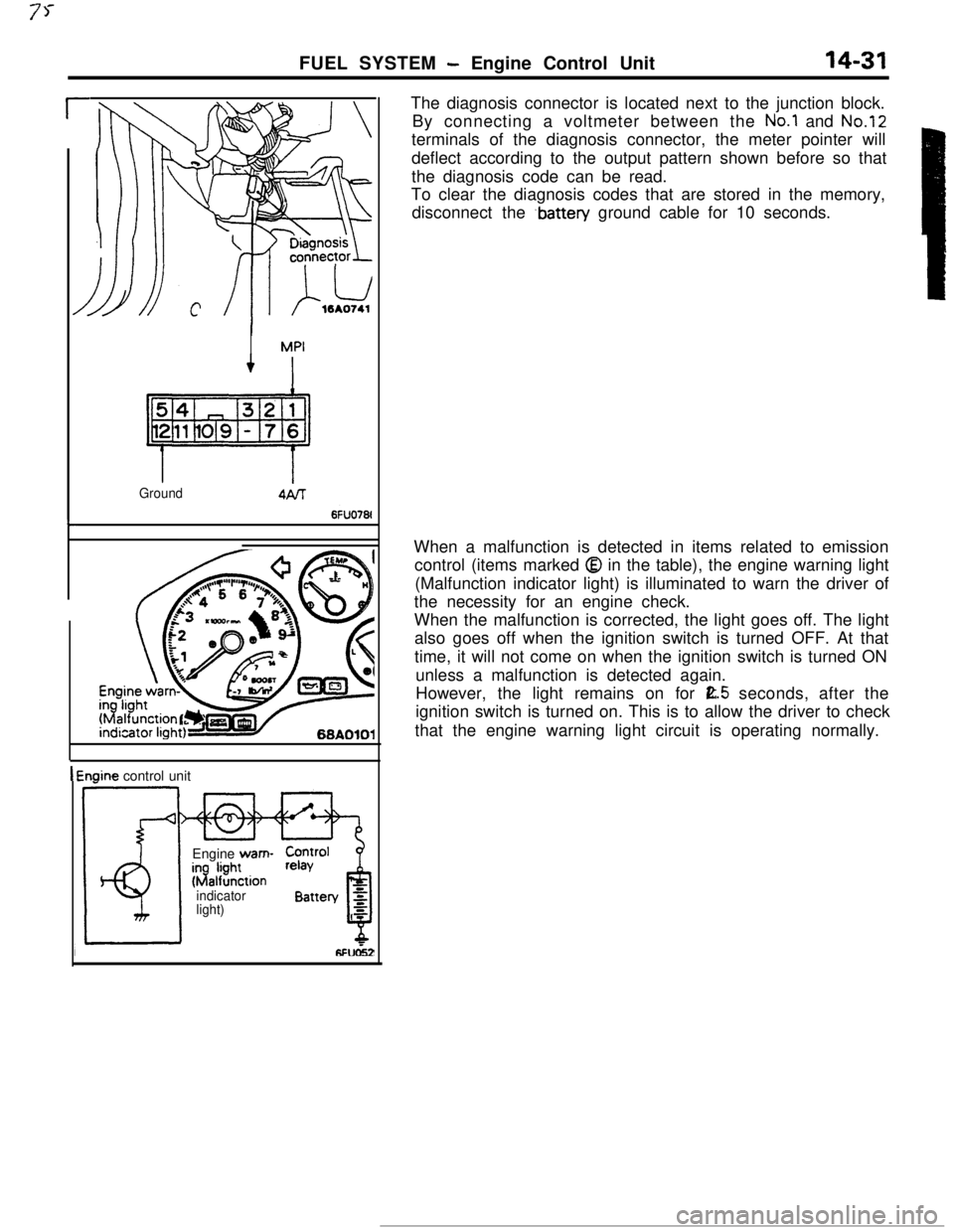

FUEL SYSTEM - Engine Control Unit14-31

r

L

IMPI

Ground

1 Engine control unit

Engine wam-

$b?Stionindicator

light)The diagnosis connector is located next to the junction block.

By connecting a voltmeter between the

No.1 and No.12terminals of the diagnosis connector, the meter pointer will

deflect according to the output pattern shown before so that

the diagnosis code can be read.

To clear the diagnosis codes that are stored in the memory,

disconnect the

.battery ground cable for 10 seconds.

When a malfunction is detected in items related to emission

control (items marked

Q in the table), the engine warning light

(Malfunction indicator light) is illuminated to warn the driver of

the necessity for an engine check.

When the malfunction is corrected, the light goes off. The light

also goes off when the ignition switch is turned OFF. At that

time, it will not come on when the ignition switch is turned ON

unless a malfunction is detected again.

However, the light remains on for

E.5 seconds, after the

ignition switch is turned on. This is to allow the driver to check

that the engine warning light circuit is operating normally.

Page 144 of 391

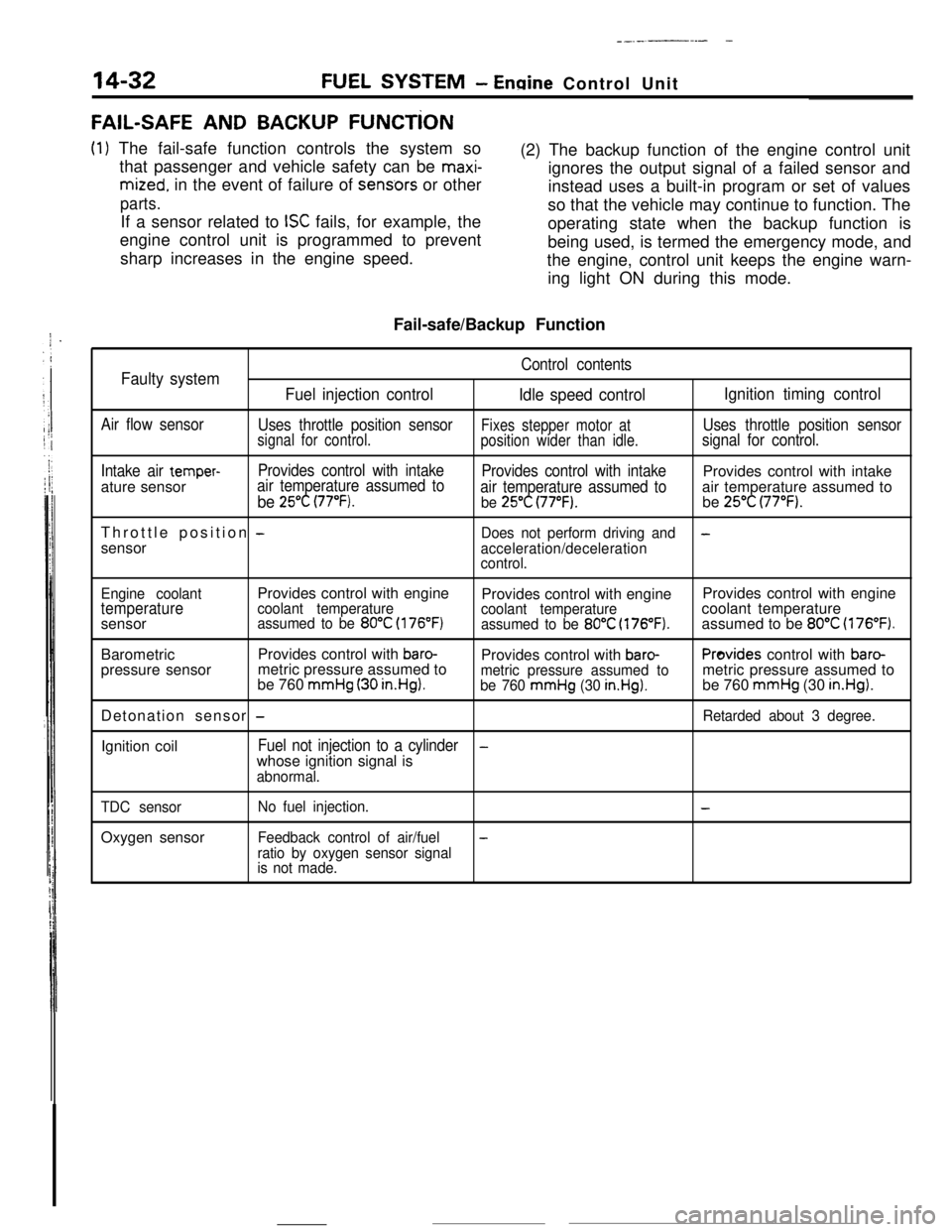

__.-~-..- -

FUEL SYSTEM- Ermine Control Unit

FAIL-SAFE AND BACKUP FUNCTiON

(1) The fail-safe function controls the system so

that passenger and vehicle safety can be

maxi-

mized. in the event of failure of sens.ors or other

parts.If a sensor related to

ISC fails, for example, the

engine control unit is programmed to prevent

sharp increases in the engine speed.(2) The backup function of the engine control unit

ignores the output signal of a failed sensor and

instead uses a built-in program or set of values

so that the vehicle may continue to function. The

operating state when the backup function is

being used, is termed the emergency mode, and

the engine, control unit keeps the engine warn-

ing light ON during this mode.

Fail-safe/Backup Function

Control contentsFaulty system

Fuel injection control

Idle speed controlIgnition timing control

Air flow sensor

Uses throttle position sensorFixes stepper motor atUses throttle position sensorsignal for control.

position wider than idle.signal for control.

Intake air

temper-Provides control with intake

Provides control with intakeProvides control with intake

ature sensorair temperature assumed to

be 25°C (77°F).air temperature assumed toair temperature assumed tobe 25°C (77°F).be 25°C (77°F).Throttle position

-Does not perform driving and-sensor

acceleration/deceleration

control.

Engine coolantProvides control with engine

Provides control with engineProvides control with engine

temperaturecoolant temperature

coolant temperaturecoolant temperature

sensorassumed to be 80°C (176°F)assumed to be 80°C (176°F).assumed to be 80°C (176°F).BarometricProvides control with

baro-Provides control with baro-Provides control with baro-pressure sensormetric pressure assumed to

be 760

mmHg (30 in.HgI.metric pressure assumed tometric pressure assumed tobe 760 mmHg (30 in.Hg).be 760 mmHg (30 in.Hg).Detonation sensor

-Retarded about 3 degree.Ignition coil

Fuel not injection to a cylinder-whose ignition signal is

abnormal.

TDC sensorOxygen sensor

No fuel injection.-

Feedback control of air/fuel-

ratio by oxygen sensor signal

is not made.

Page 145 of 391

FUEL SYSTEM- Fuel Injection Control14-33

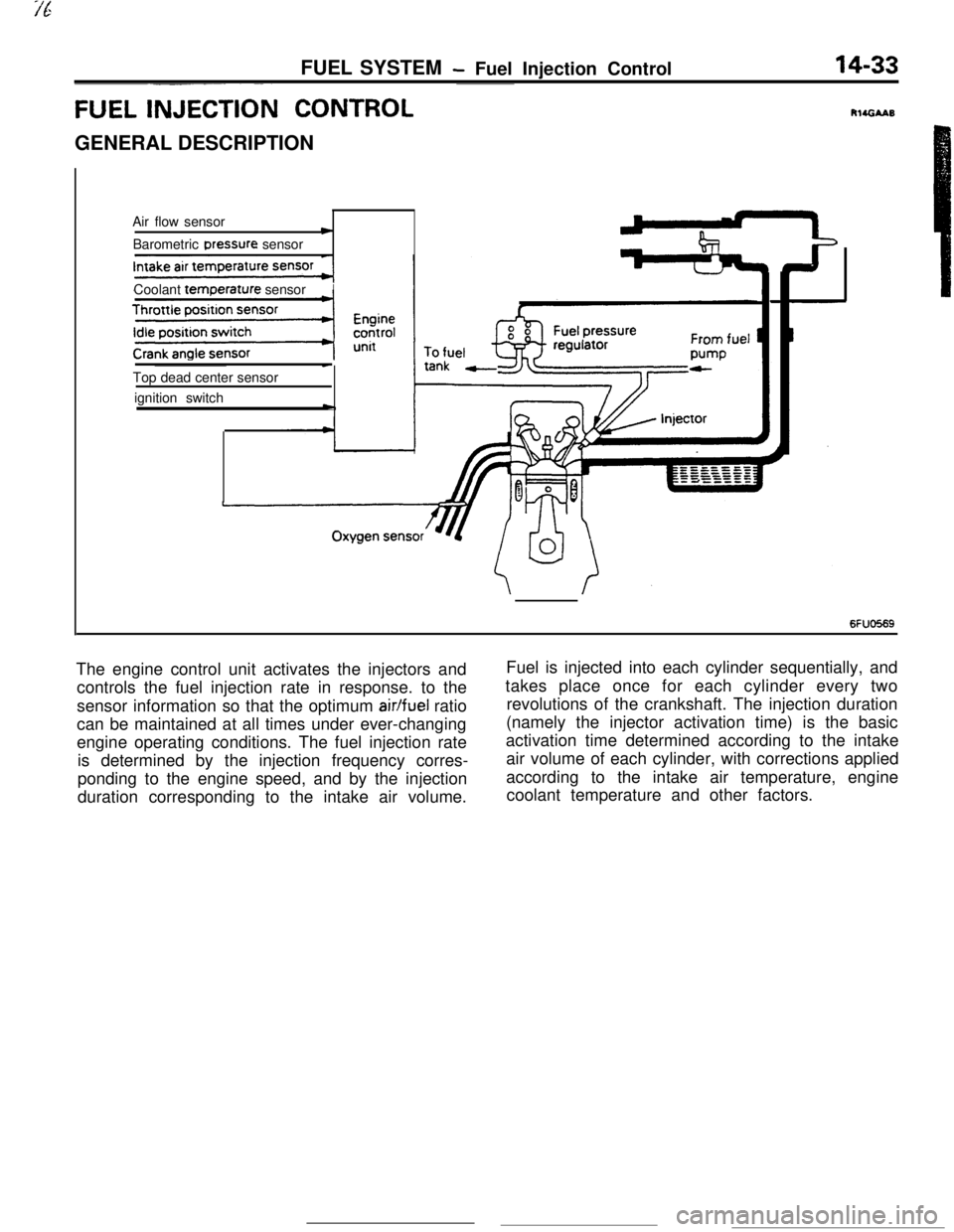

FUEL INJECTI& CONTROLGENERAL DESCRIPTION

Air flow sensor

cBarometric Dressure sensor

Coolant

temr3erature sensorITop dead center sensor

ignition switch

-

c

6FUO569The engine control unit activates the injectors andFuel is injected into each cylinder sequentially, and

controls the fuel injection rate in response. to thetakes place once for each cylinder every two

sensor information so that the optimum

air/fuel ratiorevolutions of the crankshaft. The injection duration

can be maintained at all times under ever-changing(namely the injector activation time) is the basic

engine operating conditions. The fuel injection rateactivation time determined according to the intake

is determined by the injection frequency corres-air volume of each cylinder, with corrections applied

ponding to the engine speed, and by the injectionaccording to the intake air temperature, engine

duration corresponding to the intake air volume.coolant temperature and other factors.

Page 146 of 391

-

14-34FUEL SYSTEM - Fuel Injection Control

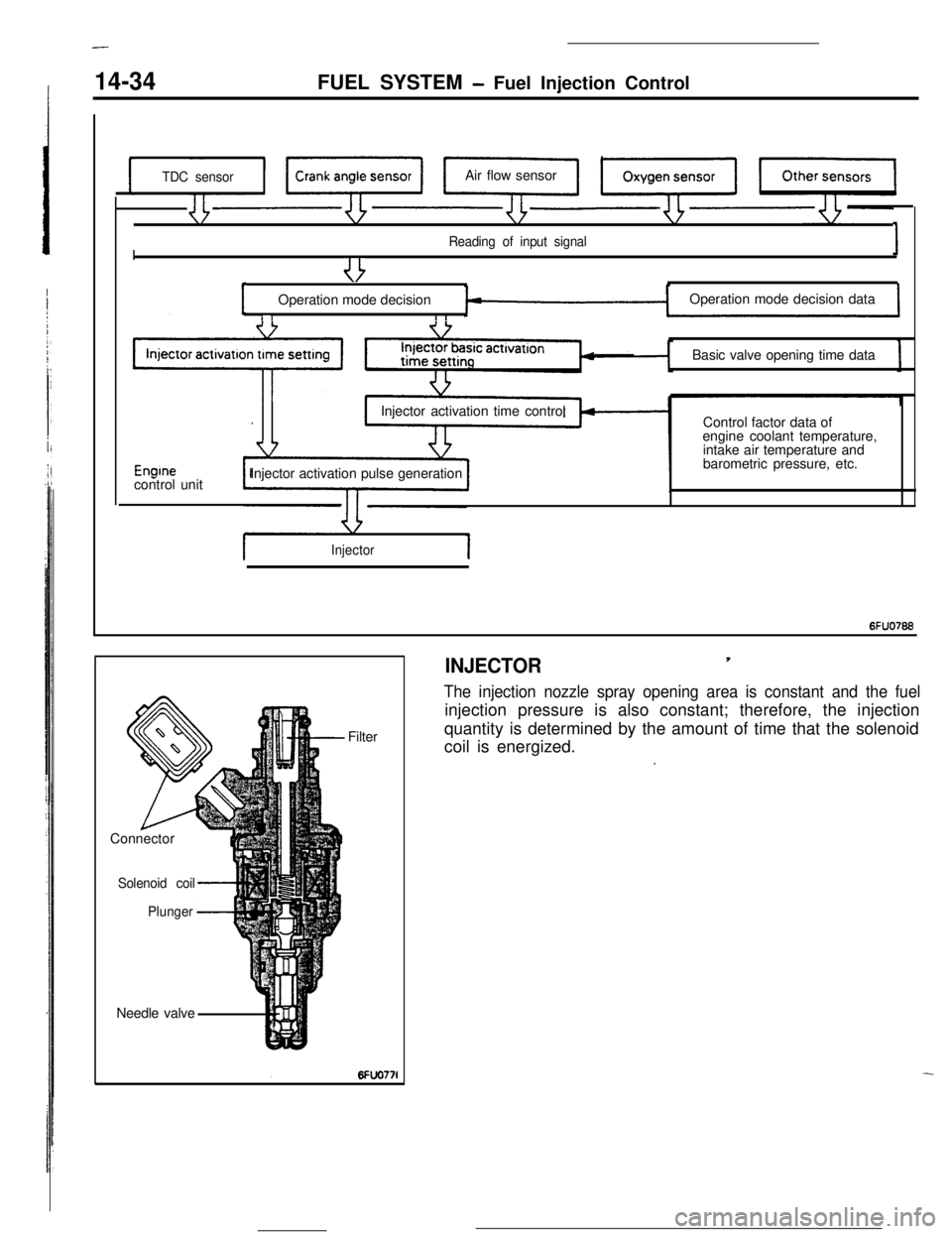

TDC sensorAir flow sensor

I

Reading of input signal1

I ,,

uOperation mode decisionOperation mode decision data

I rBasic valve opening time data

Enginecontrol unitInjector activation time control

Injector activation pulse generationControl factor data of

engine coolant temperature,

intake air temperature and

barometric pressure, etc.

Injector1

6FUO766Needle valveFilter

Connector

Solenoid coil

Plunger

-4

INJECTOR,

The injection nozzle spray opening area is constant and the fuelinjection pressure is also constant; therefore, the injection

quantity is determined by the amount of time that the solenoid

coil is energized.

.

Page 147 of 391

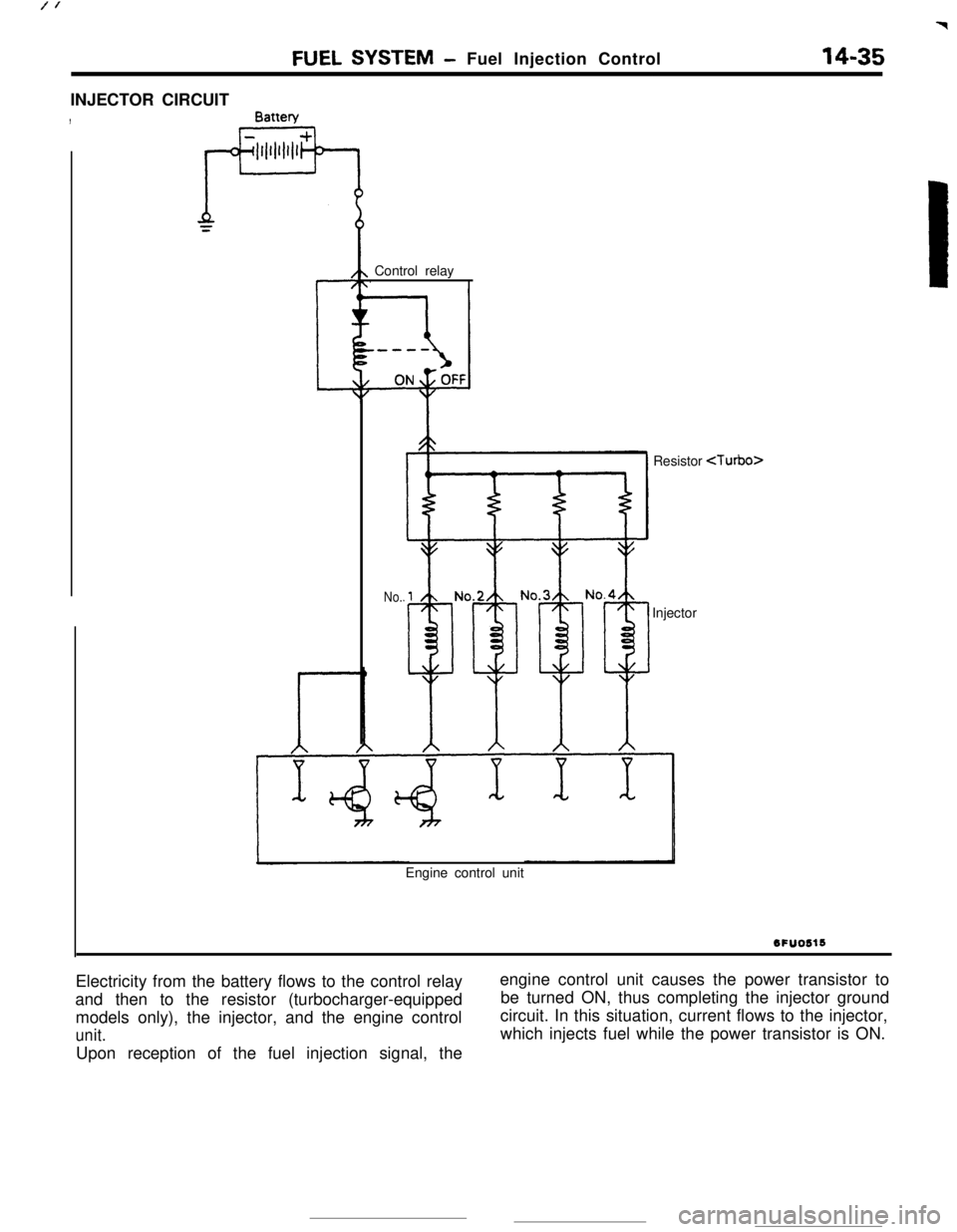

FUEL SYSTEM- Fuel Injection Control14-35INJECTOR CIRCUIT

,Battew

Control relay

Resistor

No.Injector

Engine control unit

6FU0516Electricity from the battery flows to the control relay

and then to the resistor (turbocharger-equipped

models only), the injector, and the engine control

unit.Upon reception of the fuel injection signal, theengine control unit causes the power transistor to

be turned ON, thus completing the injector ground

circuit. In this situation, current flows to the injector,

which injects fuel while the power transistor is ON.

Page 148 of 391

14-36FUEL SYSTEM- Fuel lniection Control

SFUOSlS

RESISTOR

co,.of the injector.

Because the injector must respond instantly to fuel-injection

signals, the number of windings of the coil is reduced in order

to facilitate current rise when the current is flowing in the coil.

By doing so, the resistance of the injector coil becomes smaller

and a greater amount of current can flow, with the result that

the calorific value of the injector coil becomes greater, and

1overheating occurs.

For this reason, for turbocharger-equipped models (which have

low resistance of the injector coil), a resistor is provided

between the power supply (+) and the injector in order to

regulate the amount of current flowing in the coil.

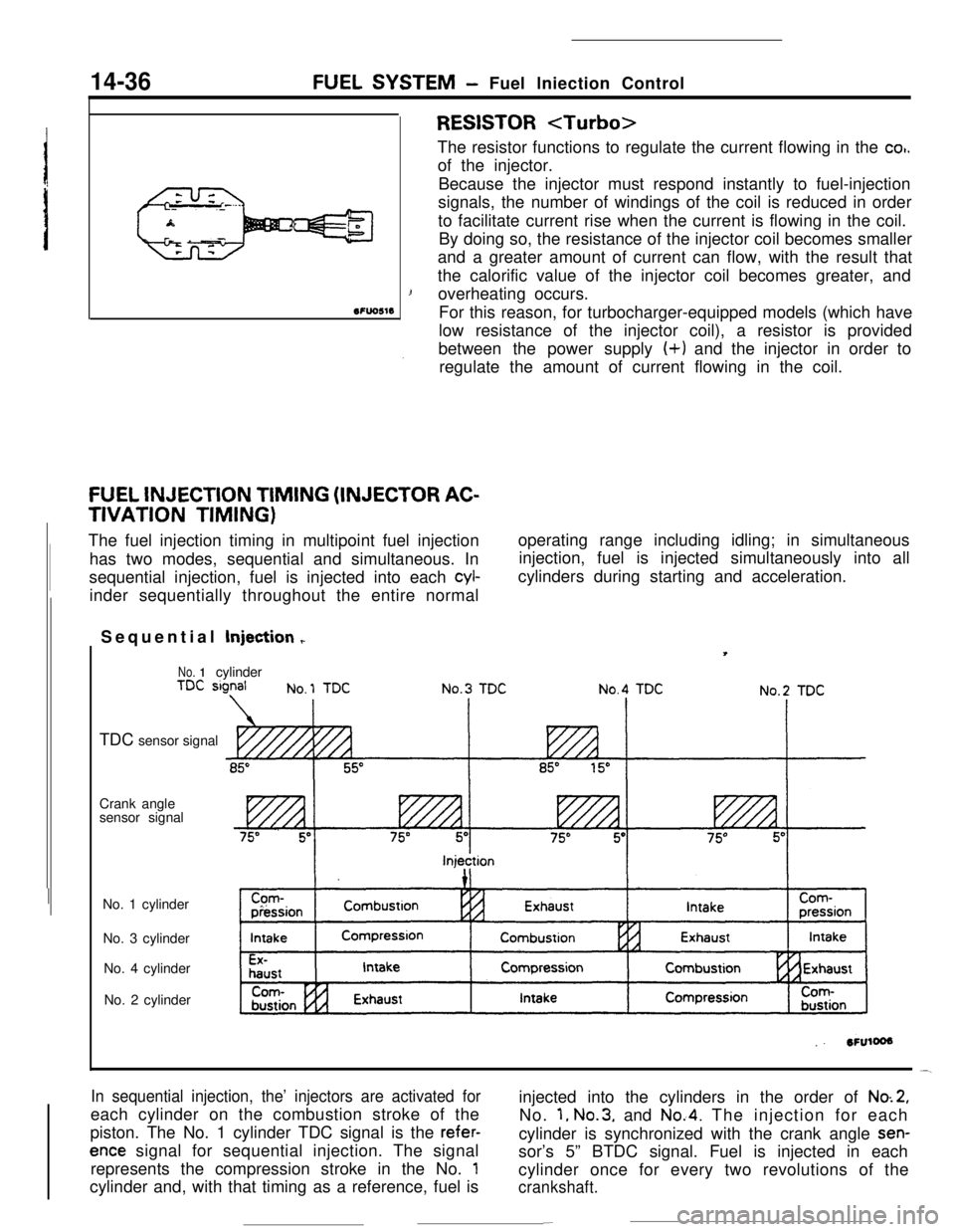

FUEL INJECTION TIMING (INJECTOR AC-

TIVATION TIMING)

The fuel injection timing in multipoint fuel injection

has two modes, sequential and simultaneous. In

sequential injection, fuel is injected into each

cyl-inder sequentially throughout the entire normaloperating range including idling; in simultaneous

injection, fuel is injected simultaneously into all

cylinders during starting and acceleration.

Sequential Injection

r

No. 1cylinder

TDC sensor signal

Crank angle

sensor signal

No. 1 cylinder

No. 3 cylinder

No. 4 cylinder

No. 2 cylinder

In sequential injection, the’ injectors are activated foreach cylinder on the combustion stroke of the

piston. The No. 1 cylinder TDC signal is the

refer-

ence signal for sequential injection. The signal

represents the compression stroke in the No.

1cylinder and, with that timing as a reference, fuel isinjected into the cylinders in the order of

No.2,No.

1, No.3, and No.4. The injection for each

cylinder is synchronized with the crank angle

sen-sor’s 5” BTDC signal. Fuel is injected in each

cylinder once for every two revolutions of the

crankshaft.

-

Page 149 of 391

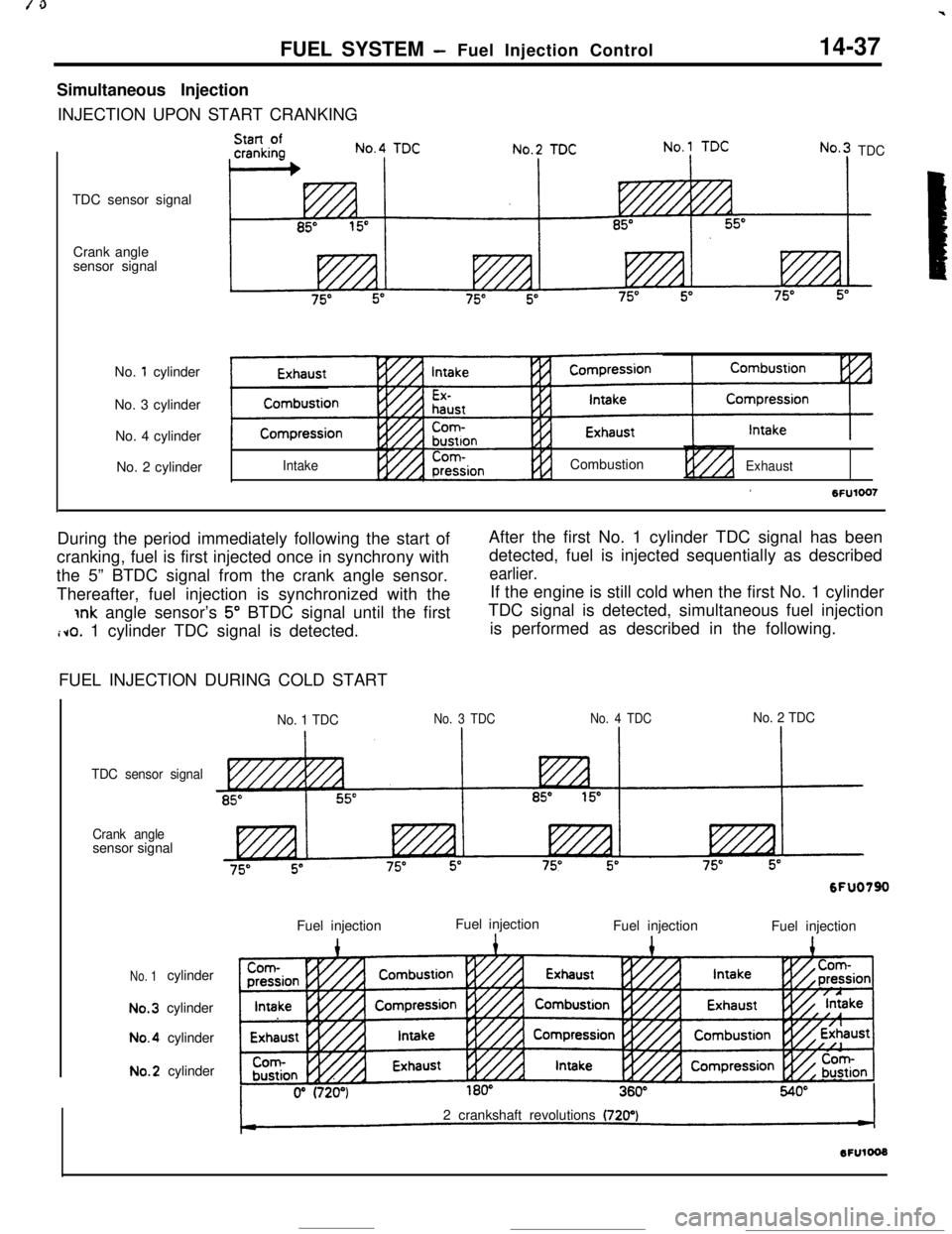

FUEL SYSTEM -Fuel Injection Control14-37Simultaneous Injection

INJECTION UPON START CRANKING

TDC sensor signal

Crank angle

sensor signal

No.

1 cylinder

No. 3 cylinder

No. 4 cylinder

No. 2 cylinder

TDC

IntakeCombustion

ExhaustDuring the period immediately following the start ofAfter the first No. 1 cylinder TDC signal has been

cranking, fuel is first injected once in synchrony withdetected, fuel is injected sequentially as described

the 5” BTDC signal from the crank angle sensor.

earlier.Thereafter, fuel injection is synchronized with theIf the engine is still cold when the first No. 1 cylinder

jnk angle sensor’s 5” BTDC signal until the firstTDC signal is detected, simultaneous fuel injection

i~o. 1 cylinder TDC signal is detected.is performed as described in the following.

FUEL INJECTION DURING COLD START

No. 1 TDCNo. 3 TDCNo. 4 TDCNo. 2 TDC

TDC sensor signal

Crank anglesensor signal

No. 1cylinderNo.3cylinderNo.4cylinderNo.2cylinder

6FUO790Fuel injection

1Fuel injection

Fuel injection1Fuel injection12 crankshaft revolutions

(720’)

Page 150 of 391

FUEL SYSTEM - Fuel Injection Control

When cranking the cold engine, fuel is injected into

all four cylinders simultaneously twice for every

crankshaft revolution, and fuel injection is synchro-

nized with the crank angle sensor’s 5” BTDC signal.

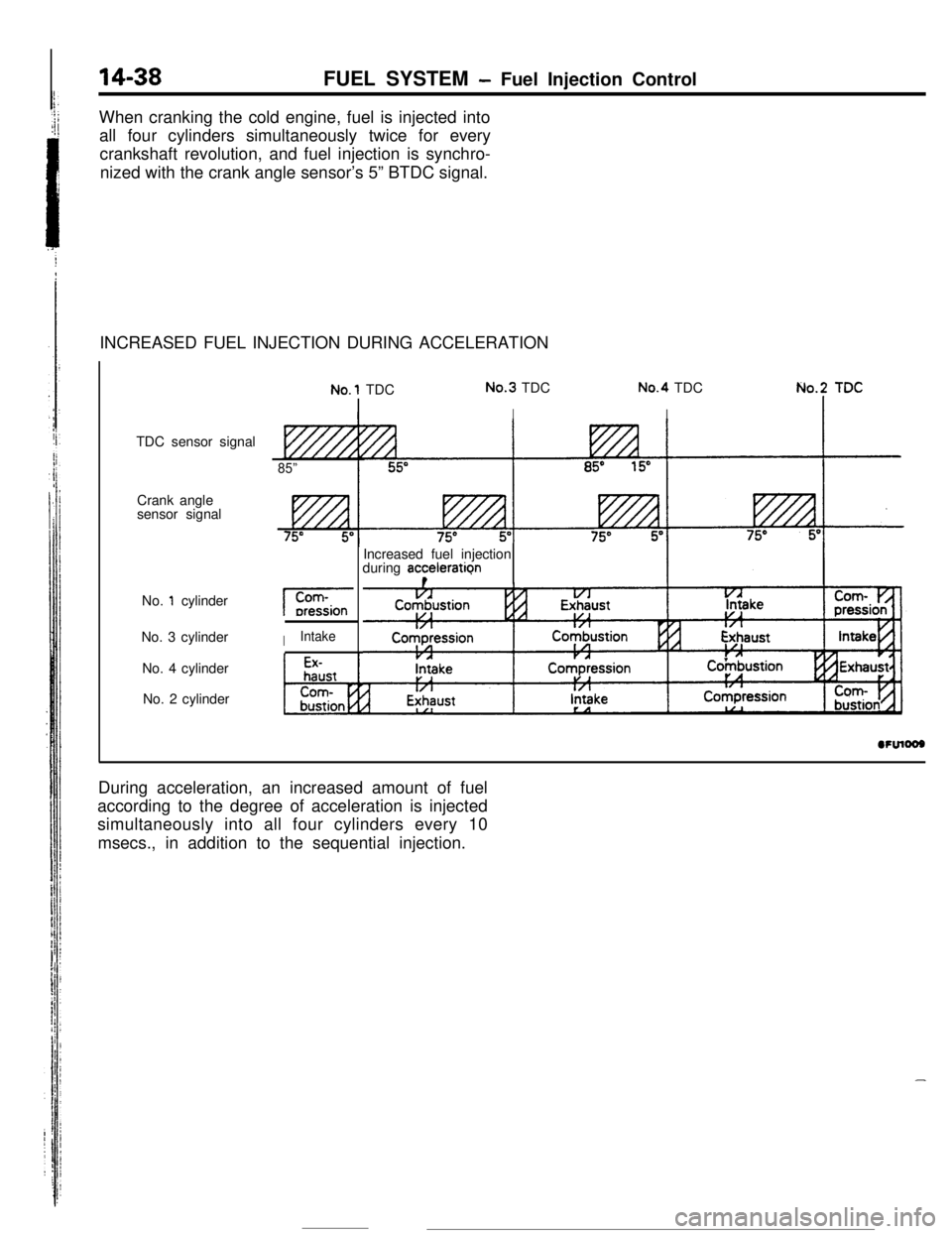

INCREASED FUEL INJECTION DURING ACCELERATION

No.1 TDC

TDC sensor signal

85”Crank angle

sensor signal

No.

1 cylinderINo. 3 cylinder

IIntakeNo.3 TDC

INo.4 TDCIIncreased fuel injection

during acceleratiqn

8

bxhaustNo. 4 cylinder

No. 2 cylinder

During acceleration, an increased amount of fuel

according to the degree of acceleration is injected

simultaneously into all four cylinders every 10

msecs., in addition to the sequential injection.

-