MITSUBISHI ECLIPSE 1990 Service Manual

ECLIPSE 1990

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57103/w960_57103-0.png

MITSUBISHI ECLIPSE 1990 Service Manual

Trending: fuel reserve, tow, ABS, rod, oil capacity, seats, change time

Page 101 of 391

9-16ENGINE- Base Engine

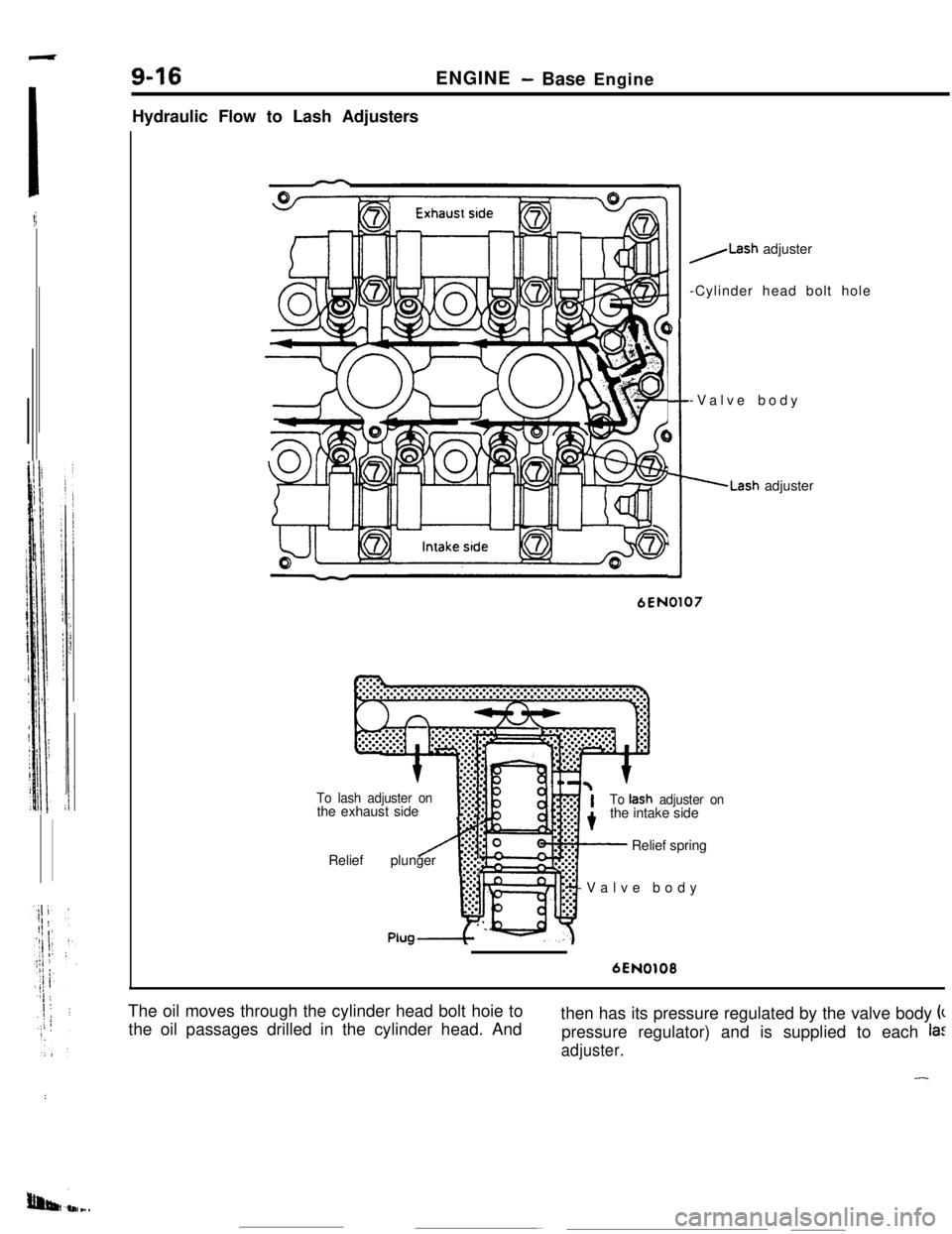

Hydraulic Flow to Lash Adjusters

To lash adjuster onthe exhaust side

P

)

5-Valve body

.Lash adjuster

6EN0107

:.-.

2:.

4

‘.’Relief plunger

I?.,:.:.;

/Lash adjuster

-Cylinder head bolt hole

PlugTo

tash adjuster onthe intake side

Relief spring

-Valve body

6EN0108The oil moves through the cylinder head bolt hoie to

the oil passages drilled in the cylinder head. Andthen has its pressure regulated by the valve body k

pressure regulator) and is supplied to each

la:

adjuster.

-:

Page 102 of 391

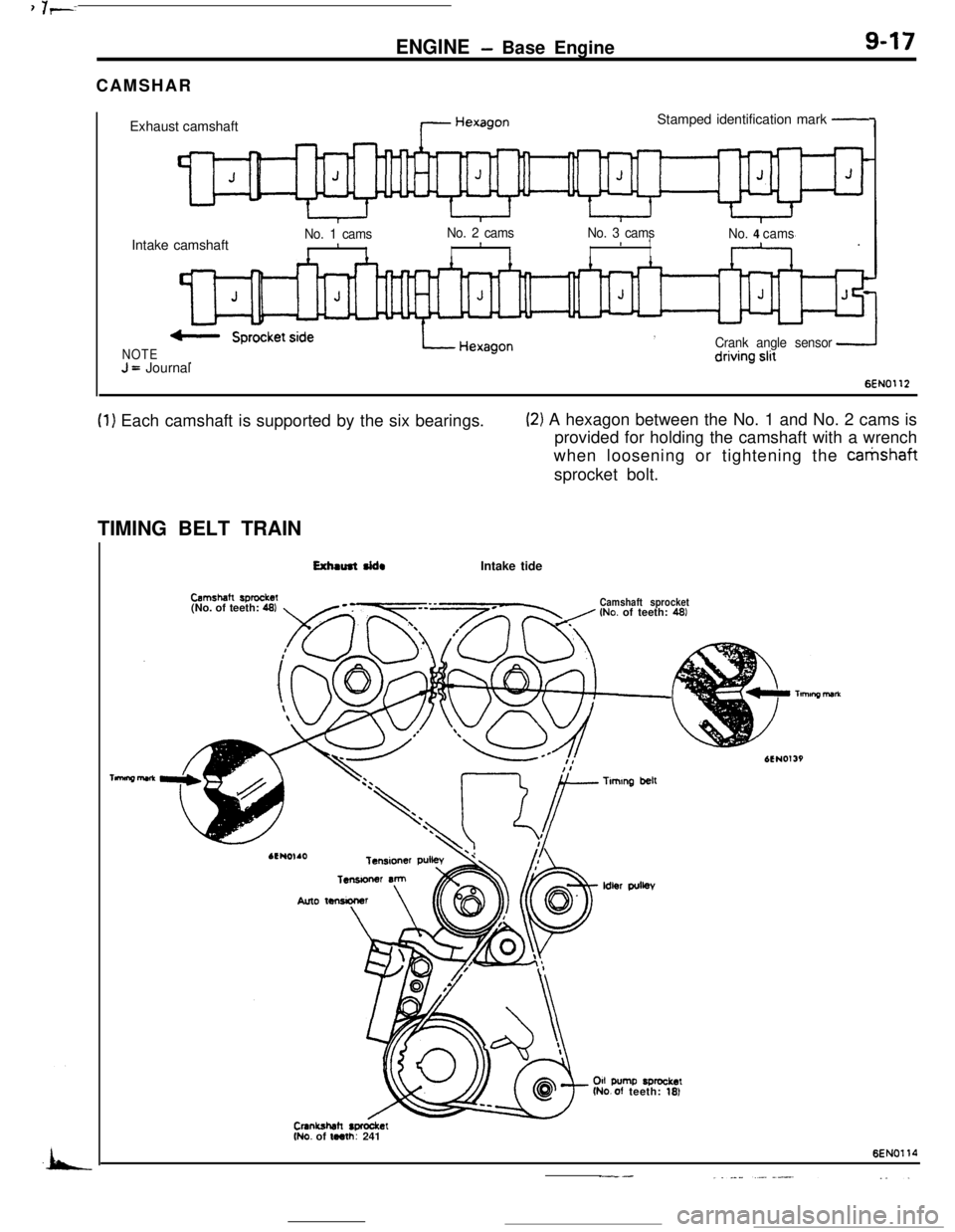

ENGINE- Base Engine9-17CAMSHAR

Exhaust camshaftStamped identification mark

-

-

k--JL---J

No. 1 camsNo. 2 camsNo. 3 cams

No. 4 camsIntake camshaftIt’ II’ II1

NOTEJ = Journal

Crank angle sensor6EN0112

(1) Each camshaft is supported by the six bearings.(2) A hexagon between the No. 1 and No. 2 cams is

provided for holding the camshaft with a wrench

when loosening or tightening the

catishaftsprocket bolt.

TIMING BELT TRAIN

Exhmmt rid.Intake tide

Camshatt sprookec(No. of teeth: 461Camshaft sprocket(No. of teeth: 461

MN0139

6tNOl10

011 Pump stmoket(No. o! teeth: 18)

Crankshatr spmokst(No. of loath: 2416EN0114

Page 103 of 391

9-18ENGINE- Base Engine

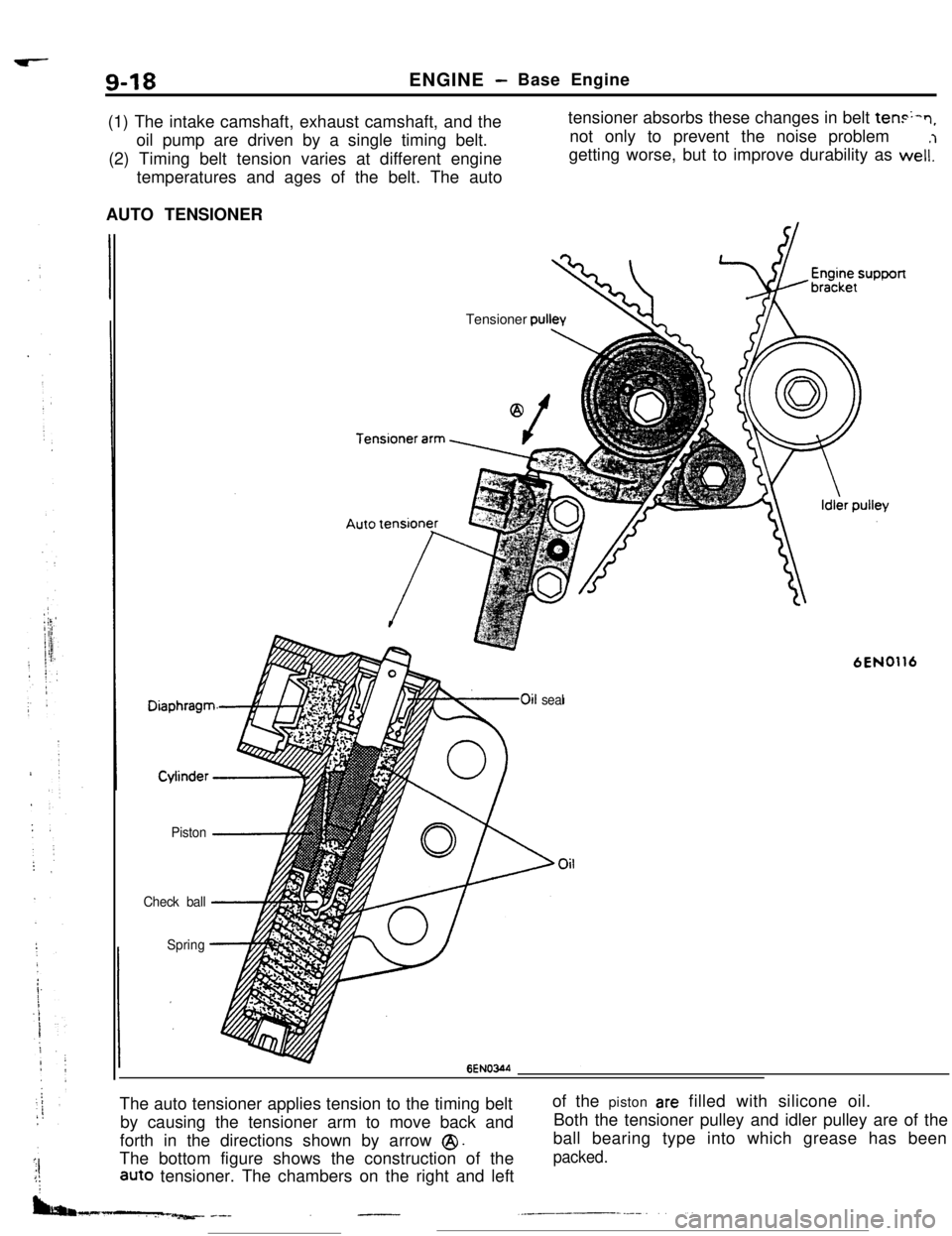

(1) The intake camshaft, exhaust camshaft, and the

oil pump are driven by a single timing belt.

(2) Timing belt tension varies at different engine

temperatures and ages of the belt. The autotensioner absorbs these changes in belt

ten+n,not only to prevent the noise problem

getting worse, but to improve durability as weli’l

AUTO TENSIONER

Piston -1

Check ball-4,

SpringTensioner

cwllev

6EN0116

LOoil seal

6ENOWThe auto tensioner applies tension to the timing belt

by causing the tensioner arm to move back and

forth in the directions shown by arrow

@I.The bottom figure shows the construction of the

aUt0 tensioner. The chambers on the right and leftof the piston

are filled with silicone oil.

Both the tensioner pulley and idler pulley are of the

ball bearing type into which grease has been

packed.

Page 104 of 391

,_-.._-~_._. I _ ‘... ----

ENGINE- Base Engine9-19

Reservoir

chamber/

Reservoir

chamber

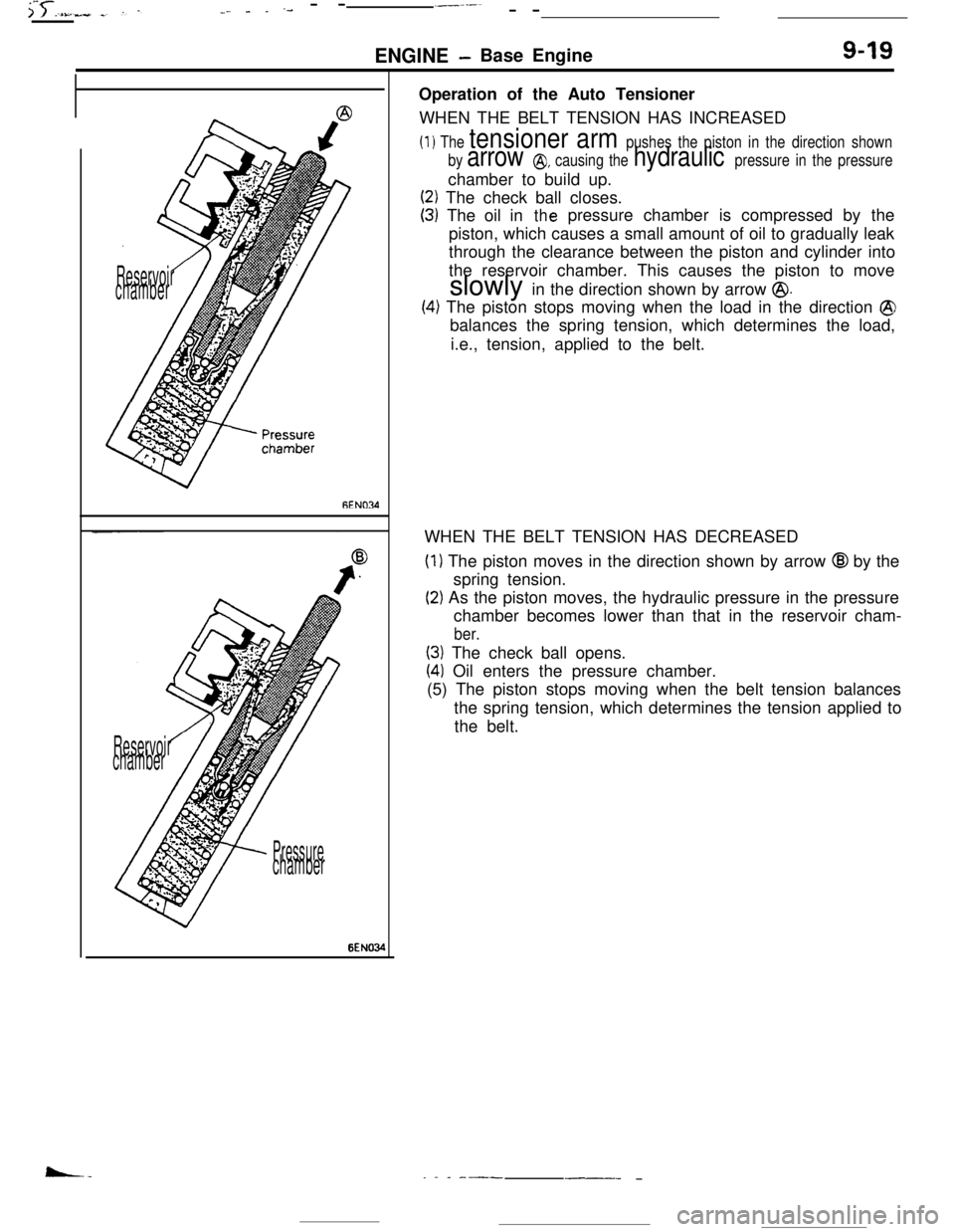

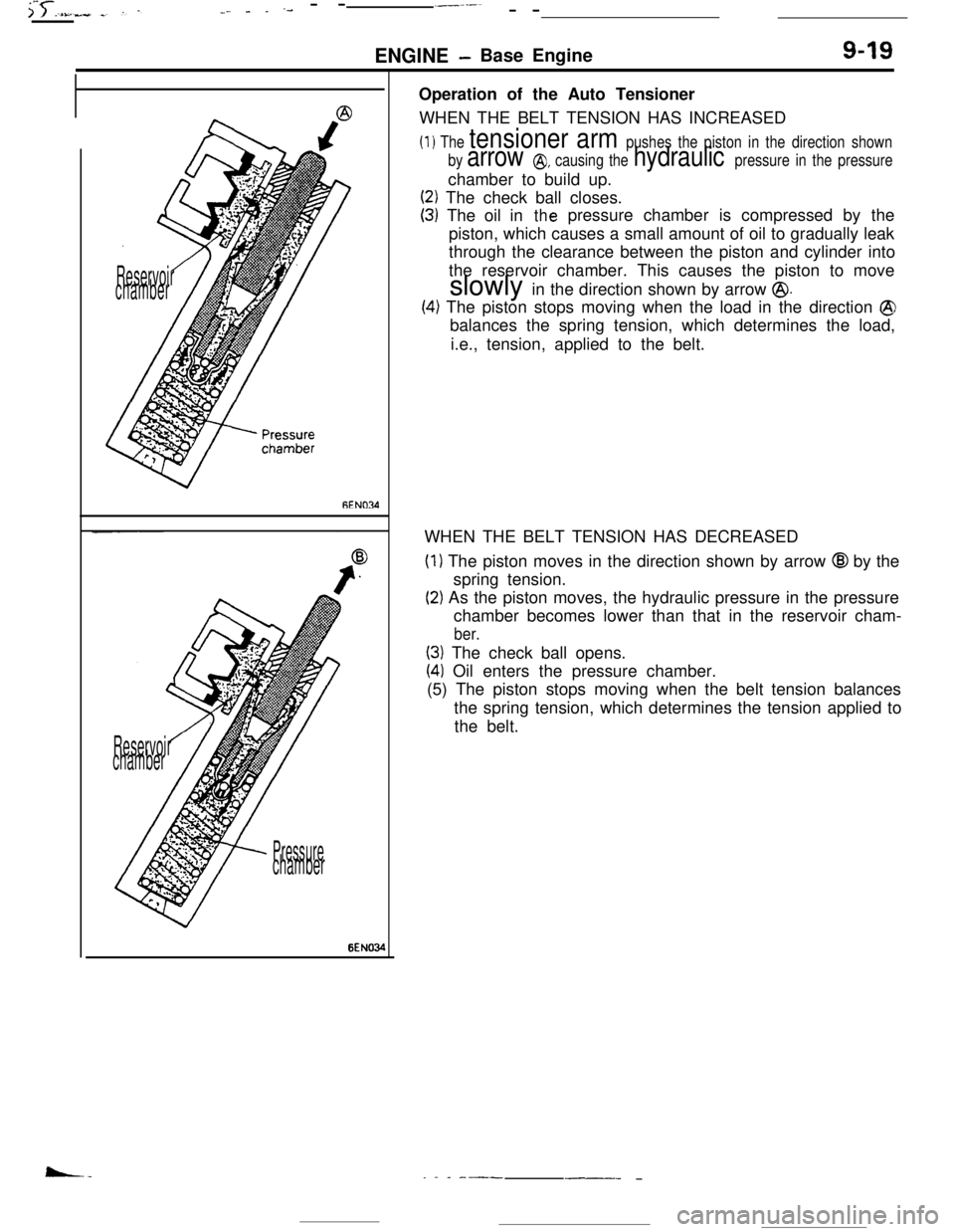

PressurechamberOperation of the Auto Tensioner

WHEN THE BELT TENSION HAS INCREASED

(1) The tensioner arm pushes the piston in the direction shown

by

arrow @, causing the hydraulic pressure in the pressurechamber to build up.

(2) The check ball closes.

(3) The oil inthepressure chamber is compressed by the

piston, which causes a small amount of oil to gradually leak

through the clearance between the piston and cylinder into

the reservoir chamber. This causes the piston to move

slowly in the direction shown by arrow

@.

(4) The piston stops moving when the load in the direction @balances the spring tension, which determines the load,

i.e., tension, applied to the belt.

WHEN THE BELT TENSION HAS DECREASED

(1) The piston moves in the direction shown by arrow @I by the

spring tension.

(2) As the piston moves, the hydraulic pressure in the pressure

chamber becomes lower than that in the reservoir cham-

ber.

(3) The check ball opens.

(41 Oil enters the pressure chamber.

(5) The piston stops moving when the belt tension balances

the spring tension, which determines the tension applied to

the belt.

_ . _ ---___- -

Page 105 of 391

9-20ENGINE- Lubricathn System

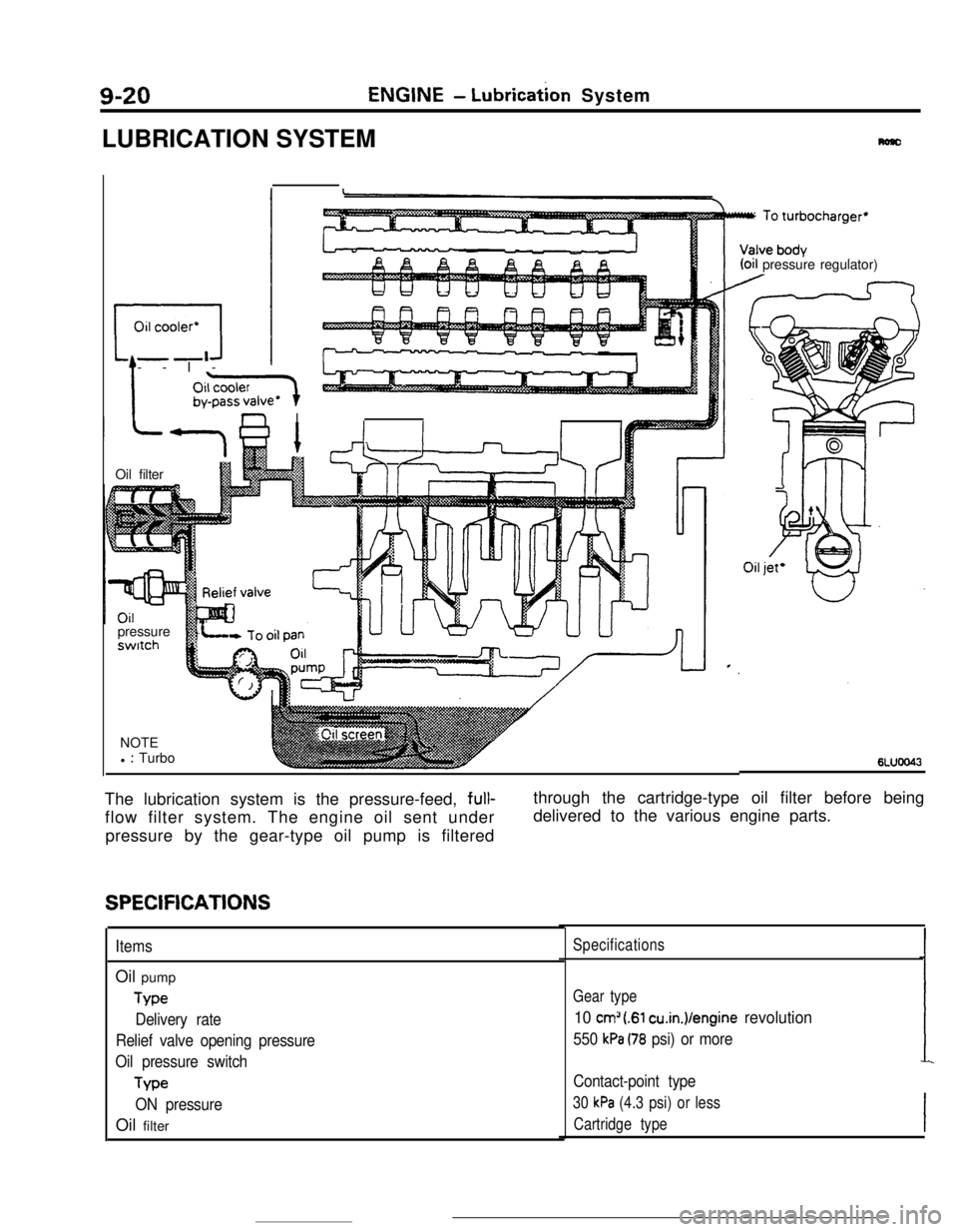

LUBRICATION SYSTEM

nasllOil cooler*

r-4--I-

(oil pressure regulator)

I

n I-1Oil filter

pressureswttch

NOTE

l

: Turbo6LUOO43The lubrication system is the pressure-feed, full-

flow filter system. The engine oil sent under

pressure by the gear-type oil pump is filteredthrough the cartridge-type oil filter before being

delivered to the various engine parts.

SPECIFICATIONS

ItemsOil pump

Type

Delivery rate

Relief valve opening pressure

Oil pressure switch

Type

ON pressureOil filter

Specifications

Gear type

10 cm” (.Sl cu.in.)/engine revolution

550 kPa (78 psi) or more

Contact-point type

30 kPa (4.3 psi) or less

Cartridge type

Page 106 of 391

L1ENGINE

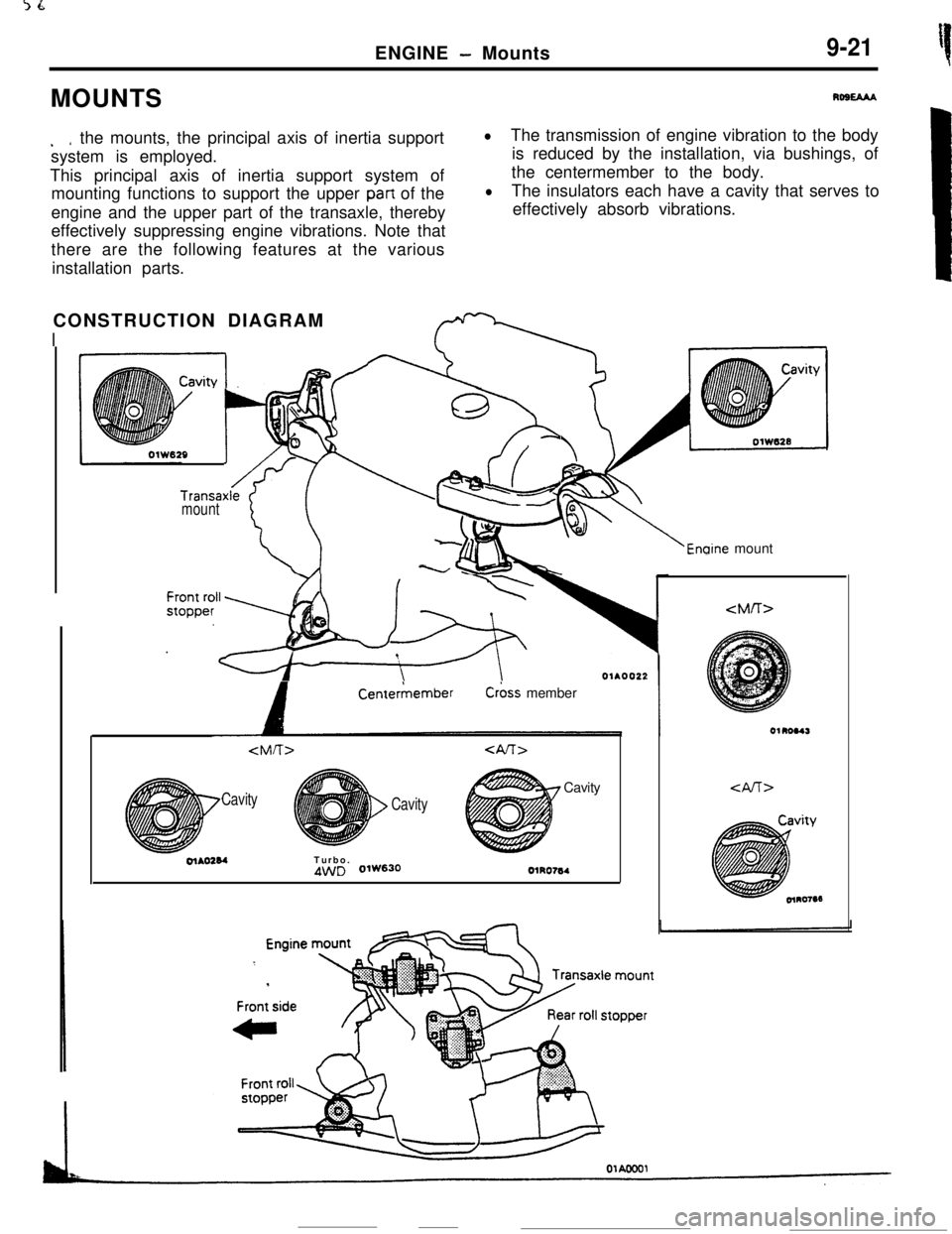

- Mounts9-21MOUNTS

Rost3u

. *the mounts, the principal axis of inertia support

system is employed.

This principal axis of inertia support system of

mounting functions to support the upper

part of the

engine and the upper part of the transaxle, thereby

effectively suppressing engine vibrations. Note that

there are the following features at the various

installation parts.

lThe transmission of engine vibration to the body

is reduced by the installation, via bushings, of

the centermember to the body.

lThe insulators each have a cavity that serves to

effectively absorb vibrations.

CONSTRUCTION DIAGRAM

I

Transaxlemount

‘i::

+g

/v 1b-8

8-,

Enaine mount

A

CenterkemberC&s member

Cavity

CavityCavityolAO284Turbo.

4WD 0lW630OlRO764

Page 107 of 391

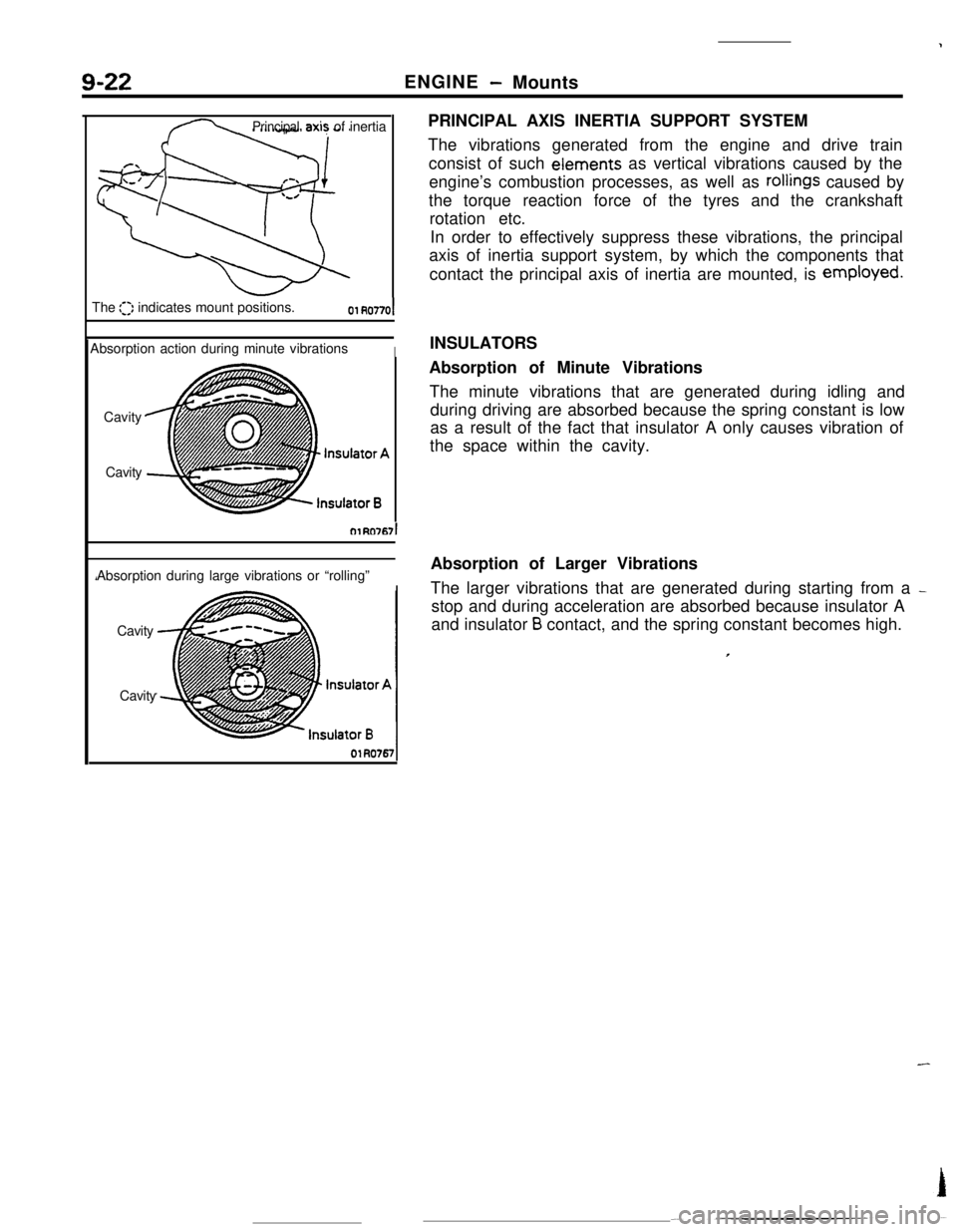

9-22ENGINE- Mounts

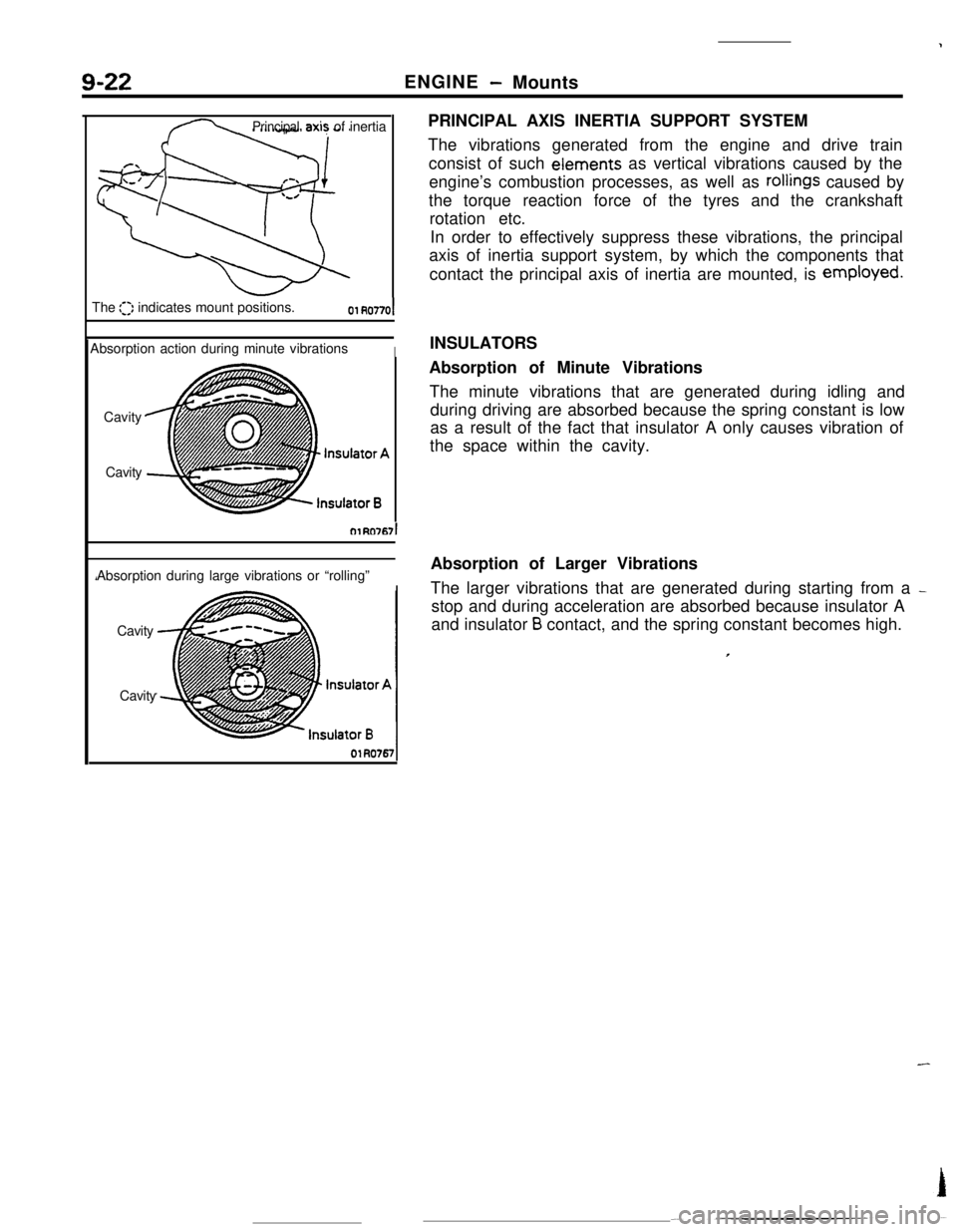

Principalaxi? of inertia

The

::I: indicates mount positions.01 RO77OlAbsorption action during minute vibrations

ICavity

CavityOlRcl767l

Absorption during large vibrations or “rolling”

Cavity

CavityPRINCIPAL AXIS INERTIA SUPPORT SYSTEM

The vibrations generated from the engine and drive train

consist of such eiements as vertical vibrations caused by the

engine’s combustion processes, as well as

rollings caused by

the torque reaction force of the tyres and the crankshaft

rotation etc.

In order to effectively suppress these vibrations, the principal

axis of inertia support system, by which the components that

contact the principal axis of inertia are mounted, is employed.

INSULATORS

Absorption of Minute Vibrations

The minute vibrations that are generated during idling and

during driving are absorbed because the spring constant is low

as a result of the fact that insulator A only causes vibration of

the space within the cavity.

Absorption of Larger Vibrations

The larger vibrations that are generated during starting from a

_stop and during acceleration are absorbed because insulator A

and insulator

B contact, and the spring constant becomes high.

Page 108 of 391

?/.-

II-I

INTAKE AN

3EXHAUST MANIFOLD 2 INTAKE MANIFOLDL........................................ ............................................

..-......................

5

_...--

Page 109 of 391

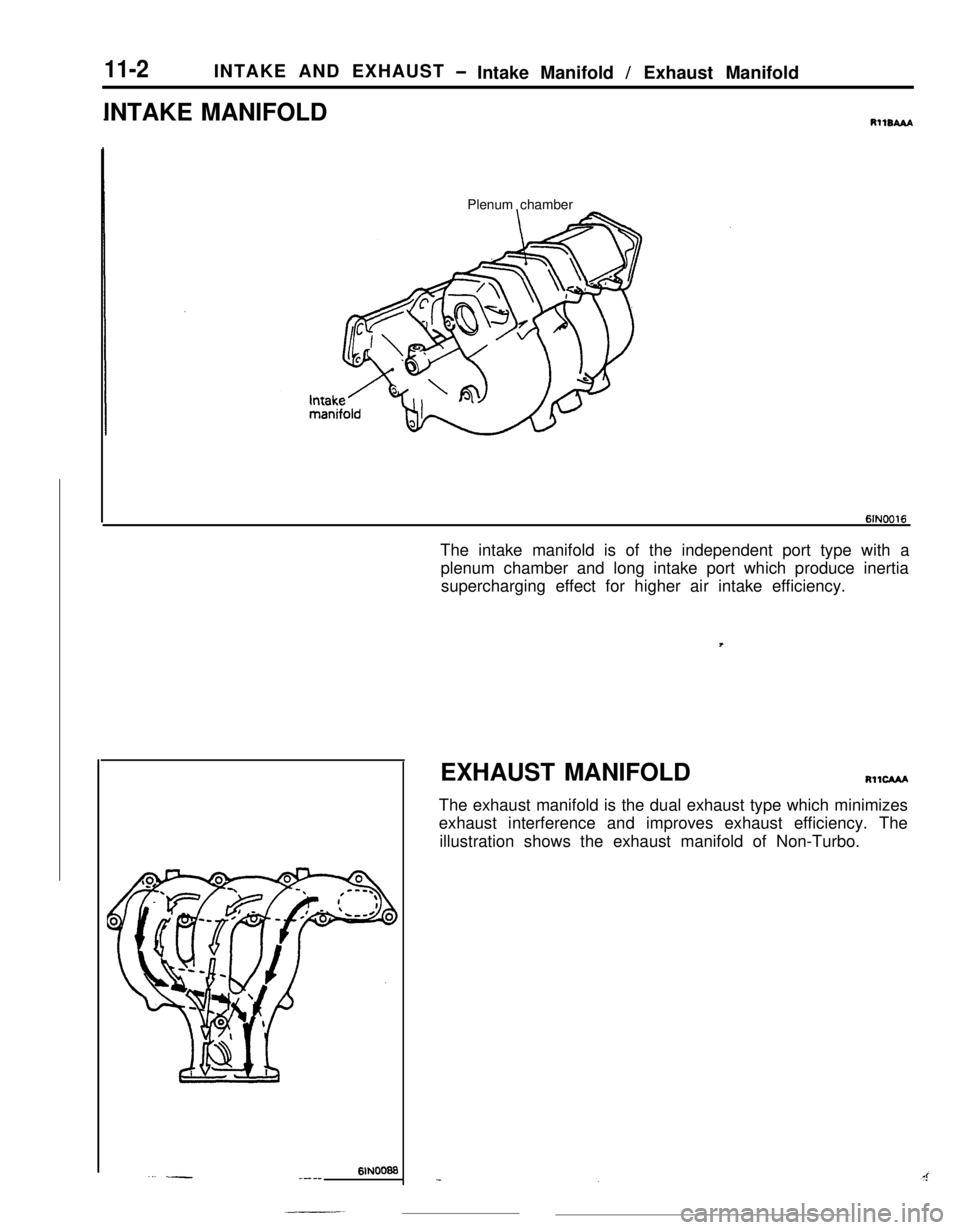

11-2 INTAKE AND EXHAUS T -Intake Manifold / Exhaust Manifold

RllmAA

Plenum chamber

6lNoo16

The intake manifold is of the independent port type with a

61N00@3..’ --_---

EXHAUST MANIFOLDRllcAM

The exhaust manifold is the dual exhaust type which minimizes

Page 110 of 391

rg_m

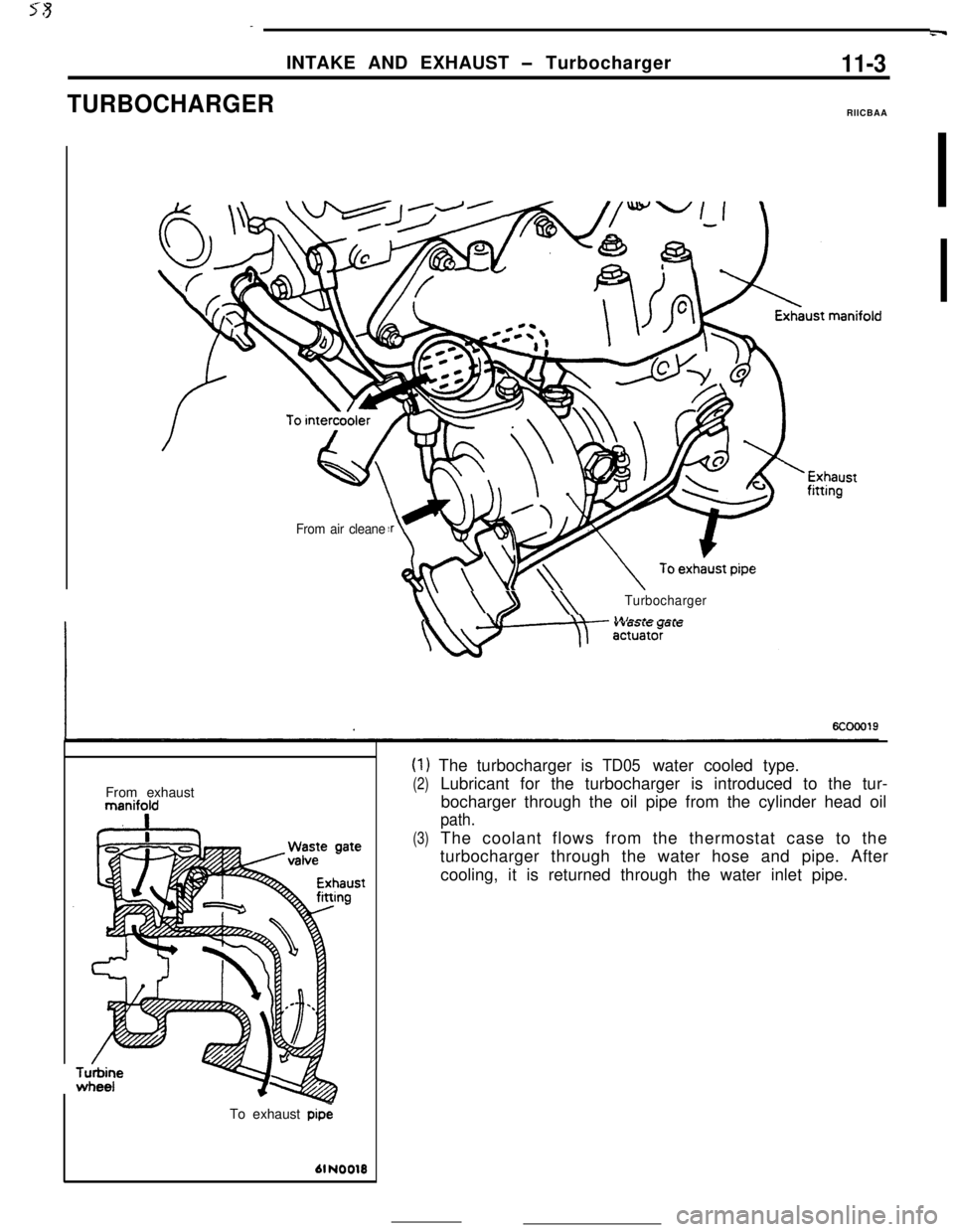

INTAKE AND EXHAUST - Turbocharger

13 \Turbocharger

manifold

-J

To exhaust pipe

61 NO010

(1) The turbocharger is TD05 water cooled type.

Trending: headrest, window, fuel filter, child seat, instrument cluster, instrument panel, remote start