MITSUBISHI ECLIPSE 1990 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 111 of 391

11-4

Isection

.w

IBearing

intercoaler

From LI/ To exhaust pipe

lmlilw - -..-..-_ -___- .._ ..__.

Page 112 of 391

INTAKE AND EXHAUST - Exhaust PipeII-5

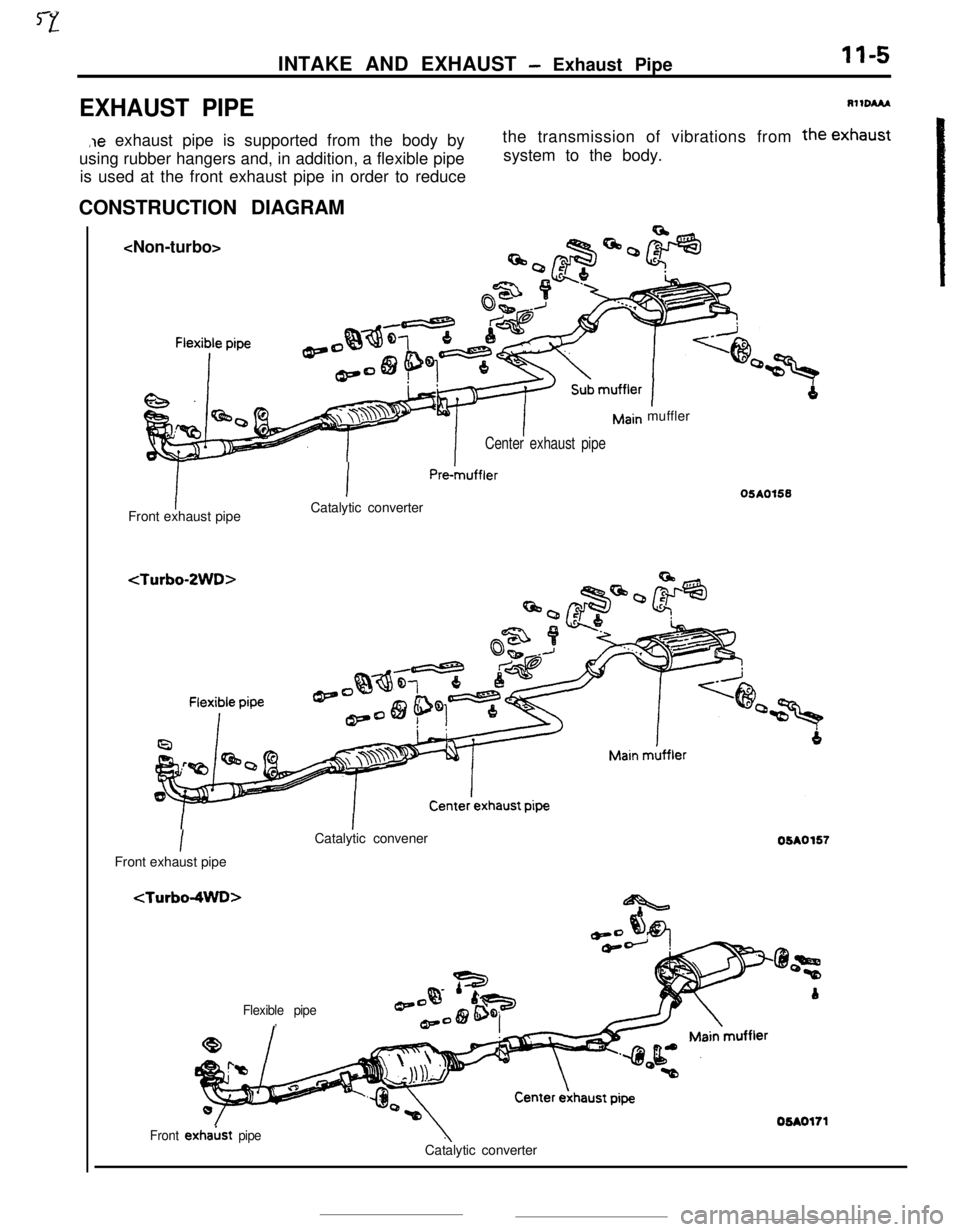

EXHAUST PIPERllDAM

,le exhaust pipe is supported from the body by

using rubber hangers and, in addition, a flexible pipe

is used at the front exhaust pipe in order to reducethe transmission of vibrations from the exhaust

system to the body.

CONSTRUCTION DIAGRAM

Center exhaust pipeFront exhaust pipe

IPm-muffler

Catalytic converter

Imuffler

IFront exhaust pipeCatalytic convener

Flexible pipe,05AO155

05A0157

Front exhakt pipeCatalytic converter

Page 113 of 391

---

14-1

FUEL

RWA---

ACCELERATOR COMPONENTS

.72

Auto-cruise Control Switch

:.............. 77

Self-diagnosis and Input-check Functions

injector................................................................34

PRESSURi

CONTROL ............................................................

31

Fuel Tank............................................................i

injector................................................................

Specifications

izi

INTAKE

il

Coolant Temperature Sensor

;iI

General Description

: .................... 24

ignition Timing Adjustment Terminal ............

CA/T>.................................... 26

i:

..........

.-.---__-...- -.---.

Page 114 of 391

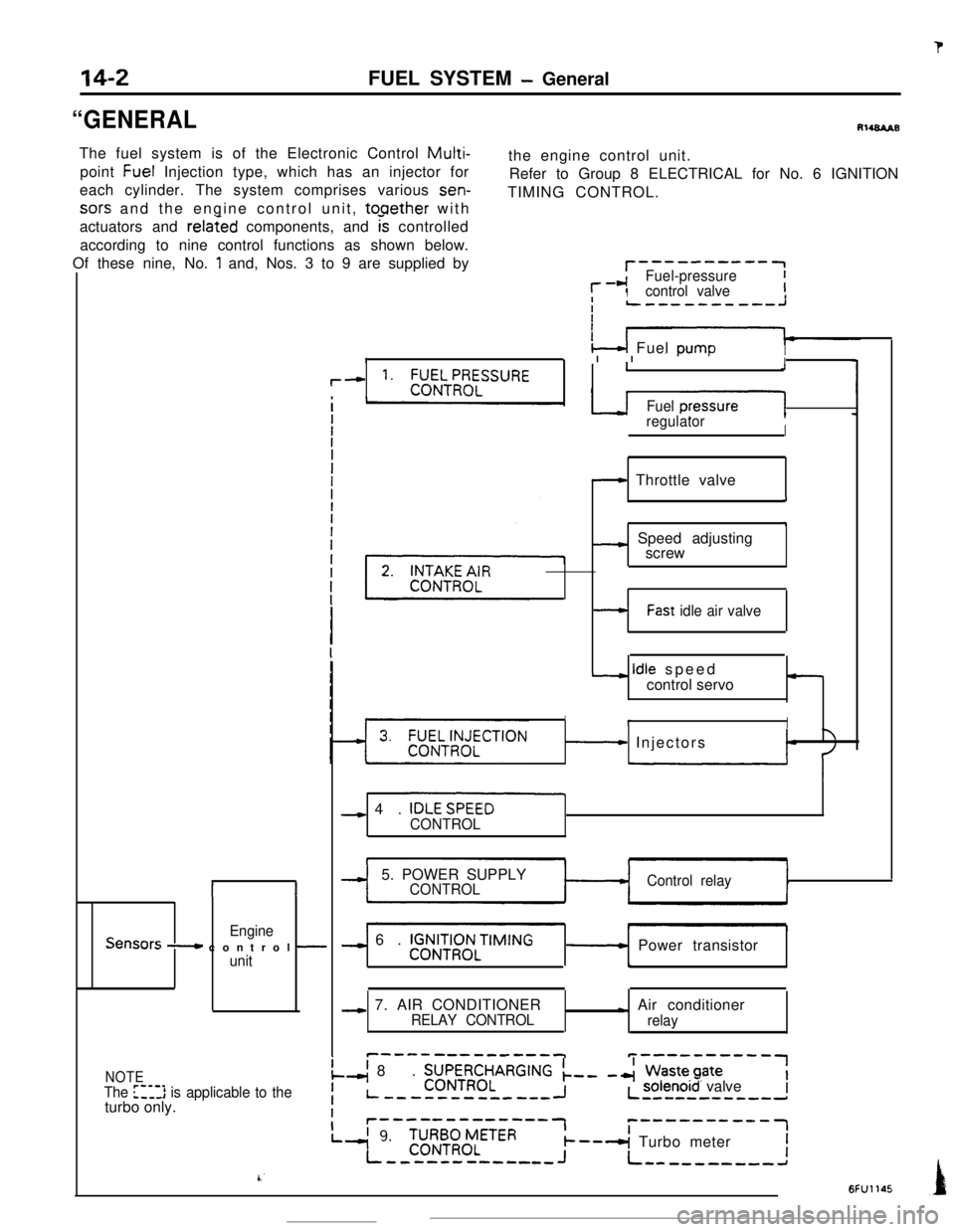

sors and the engine control unit, tooether with

actuators and

related components, and k controlled

according to nine control functions as shown below.

Of these nine, No.

1 and, Nos. 3 to 9 are supplied by

II

EngineSensors - control -unit

r--------‘-1

l--cIFuel-pressureIcontrol valveII

‘4 Fuel DumoI13 I I or-’I

,--c 1. ;;EILT!I;ELSSURE1J

Fuel presJ1regulatorI

- Throttle valve

i

7

_c Speed adjusting

screw

14-2

“GENERALFUEL SYSTEM

- GeneralRl484AB

The fuel system is of the Electronic Control

Multi-point Fuel Injection type, which has an injector forthe engine control unit.

each cylinder. The system comprises various sen-Refer to Group 8 ELECTRICAL for No. 6 IGNITION

TIMING CONTROL.

-Fast idle air valve

- idle speed

control servo-

IrI

- Injectors

- 4. IOLESPEEO

CONTROL

-I5. POWER SUPPLYCONTROLControl relay

-) 6. V$&iRq3NLTIMING- Power transistor

b

-c 7. AIR CONDITIONERRELAY CONTROL- Air conditioner

relay

c-------------Tp----------1

NOTEI

The [‘-,l> is applicable to theI

.-( 8. ZJJ\~RR~LARGING k-- -4 Wastepate

Liturbo only.-----w--------IL solenoid valve--B--------d

Ir-‘---‘---“‘-7c------v--w-1

L’ 9.

-I

‘C;RB;zLETER--A Turbo meterI--------c----J+ L----------a

k’6FU1145

Page 115 of 391

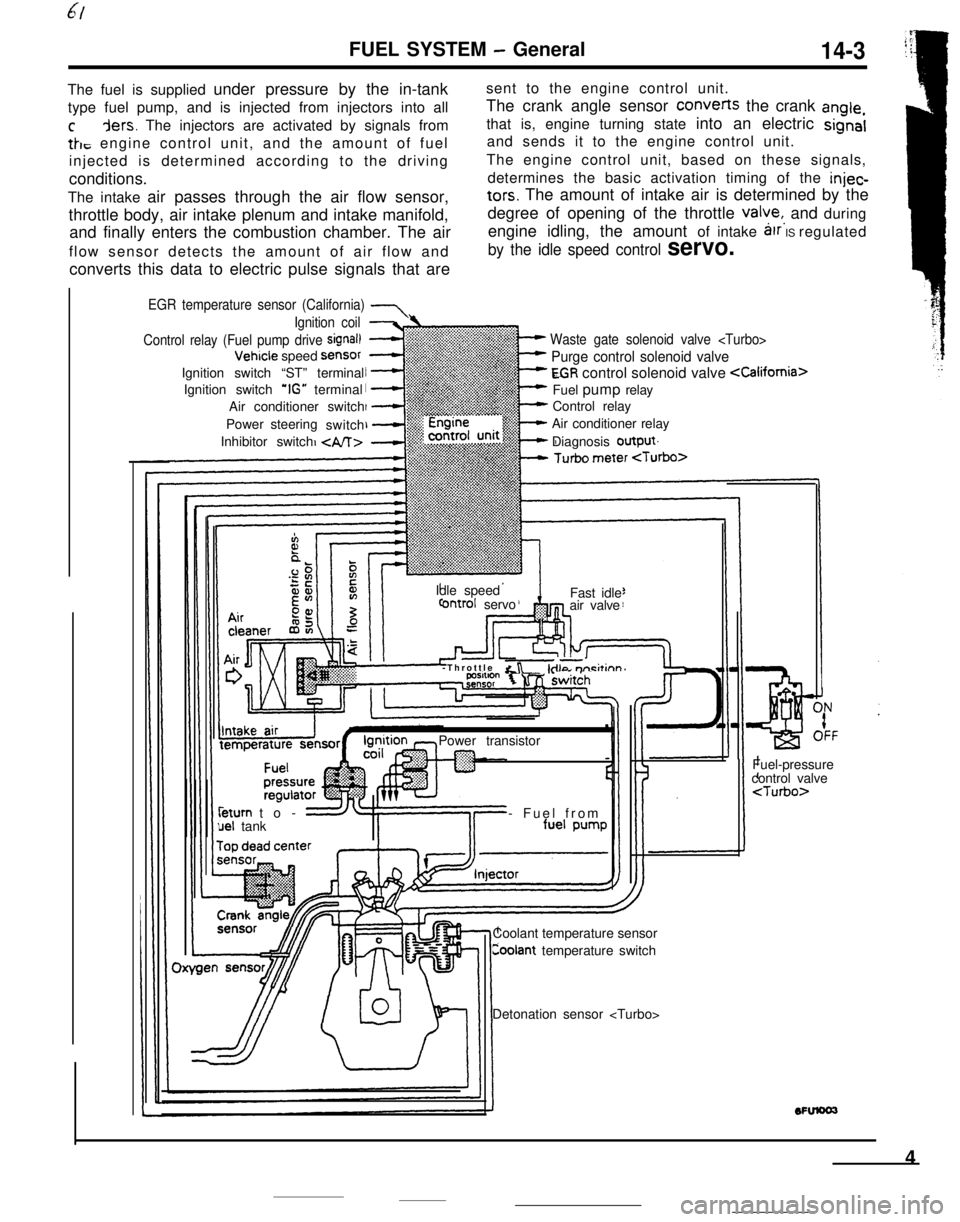

FUEL SYSTEM - General14-3The fuel is supplied under pressure by the in-tanksent to the engine control unit.

type fuel pump, and is injected from injectors into allThe crank angle sensor converts the crank

angle,

cders. The injectors are activated by signals fromthat is, engine turning state into an electric signal

tk, engine control unit, and the amount of fueland sends it to the engine control unit.

injected is determined according to the drivingThe engine control unit, based on these signals,

conditions.determines the basic activation timing of the

injec-The intake air passes through the air flow sensor,

tars. The amount of intake air is determined by the

throttle body, air intake plenum and intake manifold,degree of opening of the throttle

valye,, and during

and finally enters the combustion chamber. The airengine idling, the amount of intake

arr IS regulated

flow sensor detects the amount of air flow and

by the idle speed control servo.converts this data to electric pulse signals that are

EGR temperature sensor (California) 7

Waste gate solenoid valve

Purge control solenoid valve

EGR control solenoid valve

Control relay

Air conditioner relay

Diagnosis output

Ignition coil

Control relay (Fuel pump drive

signal)Vehicle speed

SensorIgnition switch “ST” terminal

Ignition switch

‘IG” terminal

Air conditioner switch

Power steering

switch

Inhibitor switch

Idle speed

ontrol servoFast idle

air valve

-Throttle

&r -kilo m-i&inn’Power transistorleturn to-

uel tank- Fuel from

Coolant temperature sensor

Coolant temperature switchFuel-pressure

control valve

4

Page 116 of 391

FUEL SYSTEM- duel Supply and Fuel Pressure Control

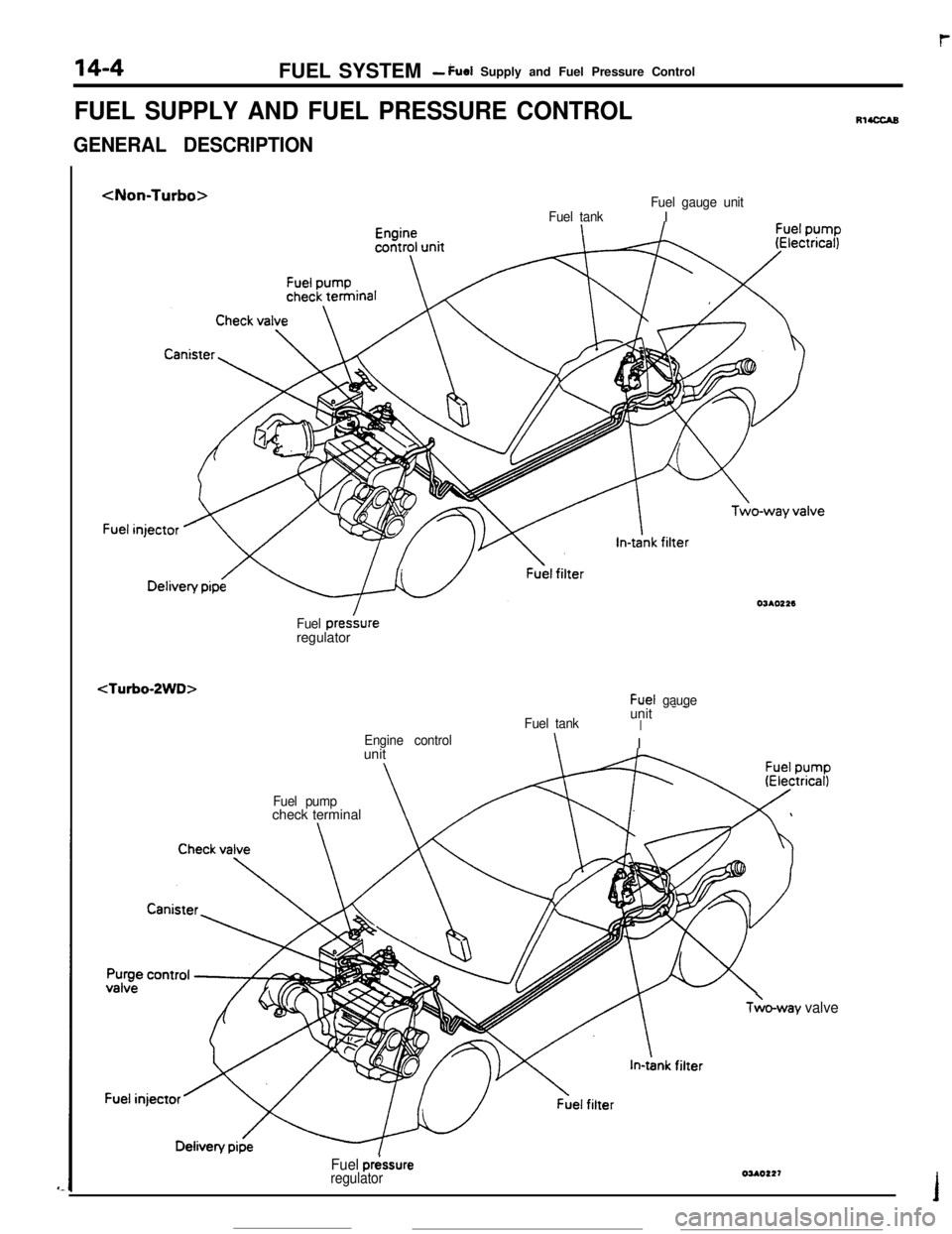

FUEL SUPPLY AND FUEL PRESSURE CONTROL

GENERAL DESCRIPTION

Fuel tankFuel gauge unitIOJAOt26

Fuel presbreregulator

Fuel tankunit - -IEngine control\I

unit

Fuel pumpcheck terminal\

TLo-way valve

Fuel p&sure

regulatorOUO227

RIUXAB

Page 117 of 391

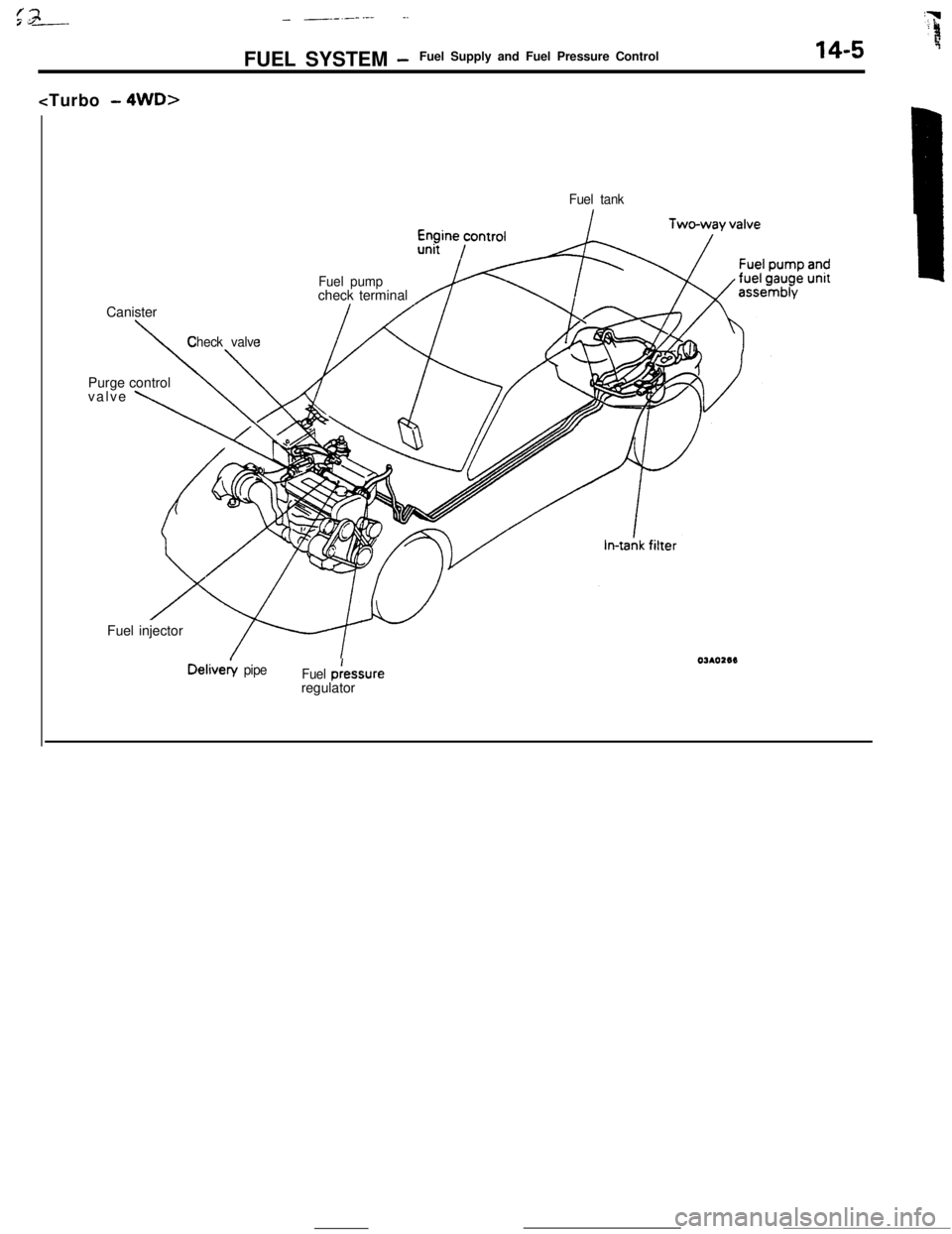

_ --_-_ .-..__FUEL SYSTEM

-Fuel Supply and Fuel Pressure Control14-5Canister

Fuel tank

Fuel pumpcheck terminal

\

Check valvePurge control

valve

\Fuel injectorDelivery

pipe

Fuel p:essure

regulator

Page 118 of 391

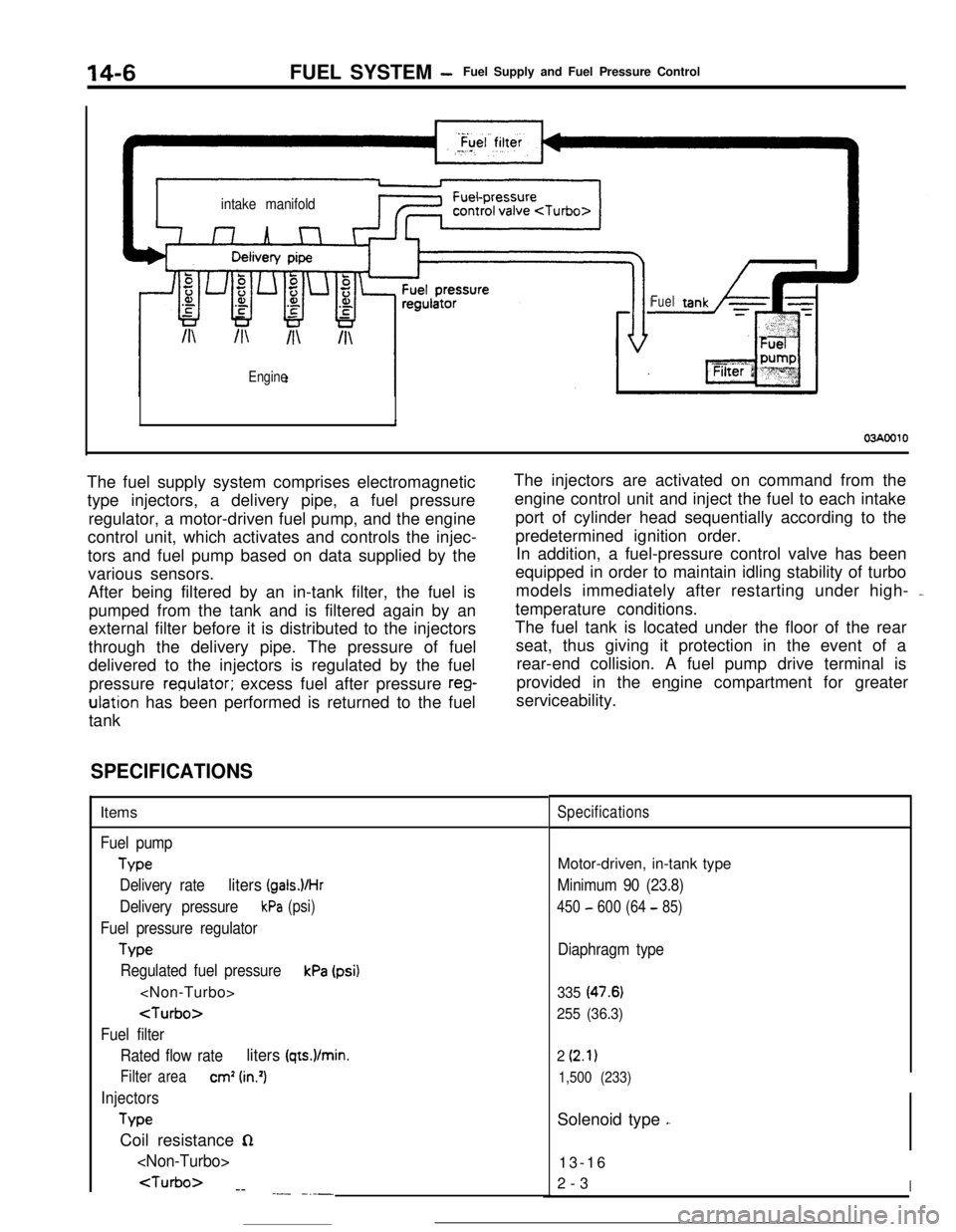

14-6FUEL SYSTEM -Fuel Supply and Fuel Pressure Control

intake manifold/I\

Engine

Fuel

03AOOlOThe fuel supply system comprises electromagnetic

type injectors, a delivery pipe, a fuel pressure

regulator, a motor-driven fuel pump, and the engine

control unit, which activates and controls the injec-

tors and fuel pump based on data supplied by the

various sensors.

After being filtered by an in-tank filter, the fuel is

pumped from the tank and is filtered again by an

external filter before it is distributed to the injectors

through the delivery pipe. The pressure of fuel

delivered to the injectors is regulated by the fuel

pressure

reoulator; excess fuel after pressure reg-ulation has been performed is returned to the fuel

tankThe injectors are activated on command from the

engine control unit and inject the fuel to each intake

port of cylinder head sequentially according to the

predetermined ignition order.

In addition, a fuel-pressure control valve has been

equipped in order to maintain idling stability of turbo

models immediately after restarting under high- -

temperature conditions.

The fuel tank is located under the floor of the rear

seat, thus giving it protection in the event of a

rear-end collision. A fuel pump drive terminal is

provided in the engine compartment for greater

serviceability.

-

SPECIFICATIONSItems

Fuel pump

Type

Delivery rate

liters (gals.VHr

Delivery pressurekPa (psi)

Fuel pressure regulator

Tvw

Regulated fuel pressurekPa (psi)

Fuel filter

Rated flow rate

liters (qts.)/min.

Filter areacm’ (in.‘)

Injectors

TypeCoil resistance

n

--

.- -_-_

SpecificationsMotor-driven, in-tank type

Minimum 90 (23.8)

450 - 600 (64 - 85)

Diaphragm type

335 (47.6)

255 (36.3)

2

(2.1)

1,500 (233)Solenoid type

,.13-16

2-3

I

Page 119 of 391

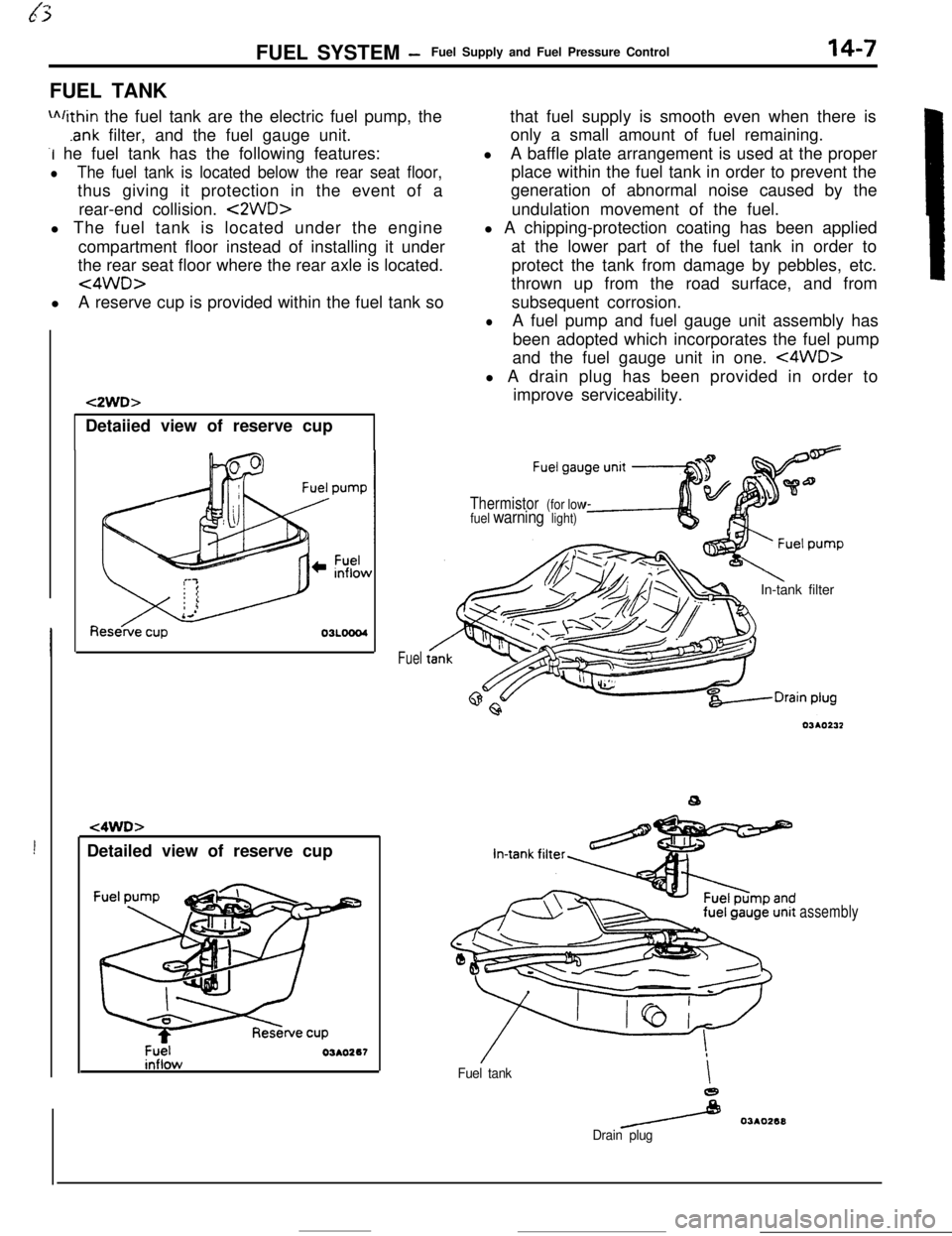

FUEL SYSTEM -Fuel Supply and Fuel Pressure Control14-7FUEL TANK

m/ithin the fuel tank are the electric fuel pump, the

.ank filter, and the fuel gauge unit.

-I he fuel tank has the following features:

lThe fuel tank is located below the rear seat floor,thus giving it protection in the event of a

rear-end collision.

<2WD>l The fuel tank is located under the engine

compartment floor instead of installing it under

the rear seat floor where the rear axle is located.

<4WD>lA reserve cup is provided within the fuel tank so

!Detailed view of reserve cup

t2WD>Detaiied view of reserve cup

t4WD>

Fuel03AO267

Fuelthat fuel supply is smooth even when there is

only a small amount of fuel remaining.

lA baffle plate arrangement is used at the proper

place within the fuel tank in order to prevent the

generation of abnormal noise caused by the

undulation movement of the fuel.

l A chipping-protection coating has been applied

at the lower part of the fuel tank in order to

protect the tank from damage by pebbles, etc.

thrown up from the road surface, and from

subsequent corrosion.

lA fuel pump and fuel gauge unit assembly has

been adopted which incorporates the fuel pump

and the fuel gauge unit in one.

<4WD>l A drain plug has been provided in order to

improve serviceability.

Thermistor (for low

fuel warning light)In-tank filter

Fuel tankI

e

/ 03AO268

Drain plug

assembly

Page 120 of 391

14-8

rFUEL SYSTEM

-Fuel Supply and Fuel Pressure Control

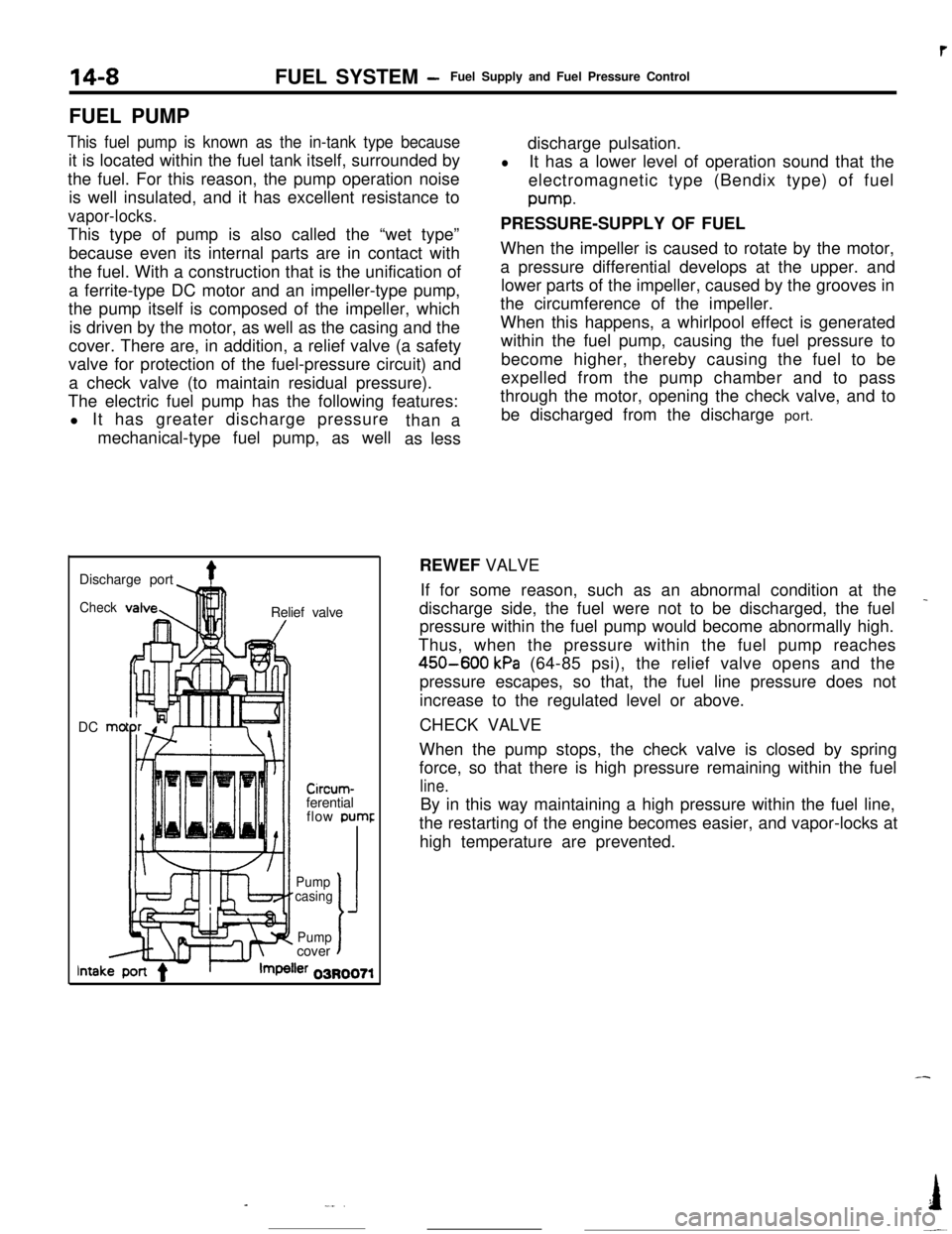

FUEL PUMP

This fuel pump is known as the in-tank type becauseit is located within the fuel tank itself, surrounded by

the fuel. For this reason, the pump operation noise

is well insulated, and it has excellent resistance to

vapor-locks.This type of pump is also called the “wet type”

because even its internal parts are in contact with

the fuel. With a construction that is the unification of

a ferrite-type DC motor and an impeller-type pump,

the pump itself is composed of the impeller, which

is driven by the motor, as well as the casing and the

cover. There are, in addition, a relief valve (a safety

valve for protection of the fuel-pressure circuit) and

a check valve (to maintain residual pressure).

The electric fuel pump has the following features:

l It has greater discharge pressure

mechanical-type fuel pump, as wellthan a

as lessdischarge pulsation.

lIt has a lower level of operation sound that the

electromagnetic type (Bendix type) of fuelpump.

PRESSURE-SUPPLY OF FUEL

When the impeller is caused to rotate by the motor,

a pressure differential develops at the upper. and

lower parts of the impeller, caused by the grooves in

the circumference of the impeller.

When this happens, a whirlpool effect is generated

within the fuel pump, causing the fuel pressure to

become higher, thereby causing the fuel to be

expelled from the pump chamber and to pass

through the motor, opening the check valve, and to

be discharged from the discharge port.

Discharge port

4Check!nRelief valve

DC mo

-lllll1 I/

Circum-ferential

flow pumr

II’ f-Pump

casing

J

Pumpcovert

lntakler 03R0071REWEF VALVE

If for some reason, such as an abnormal condition at the

_discharge side, the fuel were not to be discharged, the fuel

pressure within the fuel pump would become abnormally high.

Thus, when the pressure within the fuel pump reaches

450-600 kPa (64-85 psi), the relief valve opens and the

pressure escapes, so that, the fuel line pressure does not

increase to the regulated level or above.

CHECK VALVE

When the pump stops, the check valve is closed by spring

force, so that there is high pressure remaining within the fuel

line.By in this way maintaining a high pressure within the fuel line,

the restarting of the engine becomes easier, and vapor-locks at

high temperature are prevented.

-

-_..I

-~