MITSUBISHI ECLIPSE 1990 Manual PDF

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 71 of 391

. ...>A . ..-rr7.e.~/._.. . . . . ,ELECTRICAL

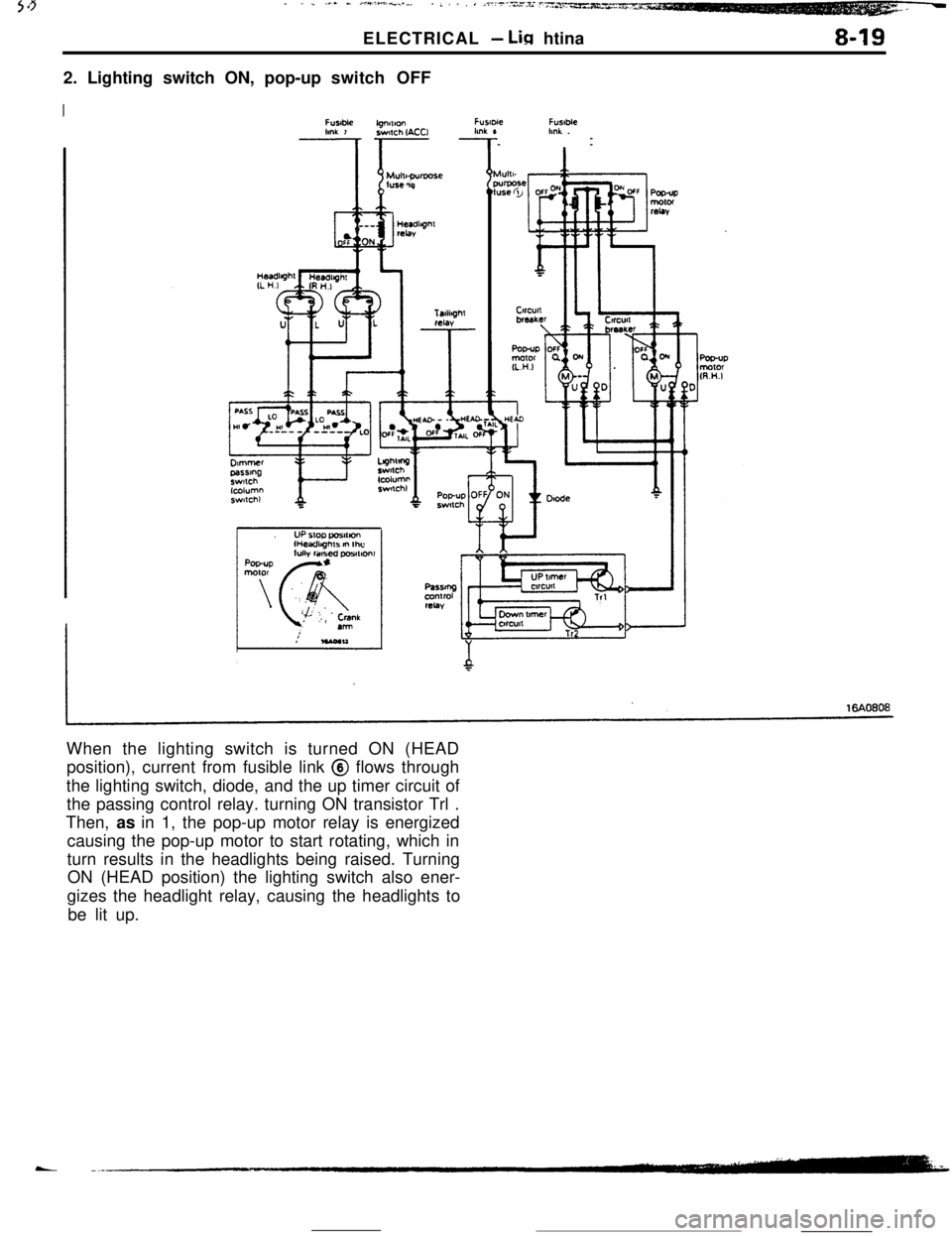

- Lin htina8-192. Lighting switch ON, pop-up switch OFF

IFtmbk

mr 7FlIU-ieFusableknk .

--

When the lighting switch is turned ON (HEAD

position), current from fusible link @ flows through

the lighting switch, diode, and the up timer circuit of

the passing control relay. turning ON transistor Trl .

Then, as in 1, the pop-up motor relay is energized

causing the pop-up motor to start rotating, which in

turn results in the headlights being raised. Turning

ON (HEAD position) the lighting switch also ener-

gizes the headlight relay, causing the headlights to

be lit up.

Page 72 of 391

_ -. _ -.__-ELECTRICAL

- Lighting

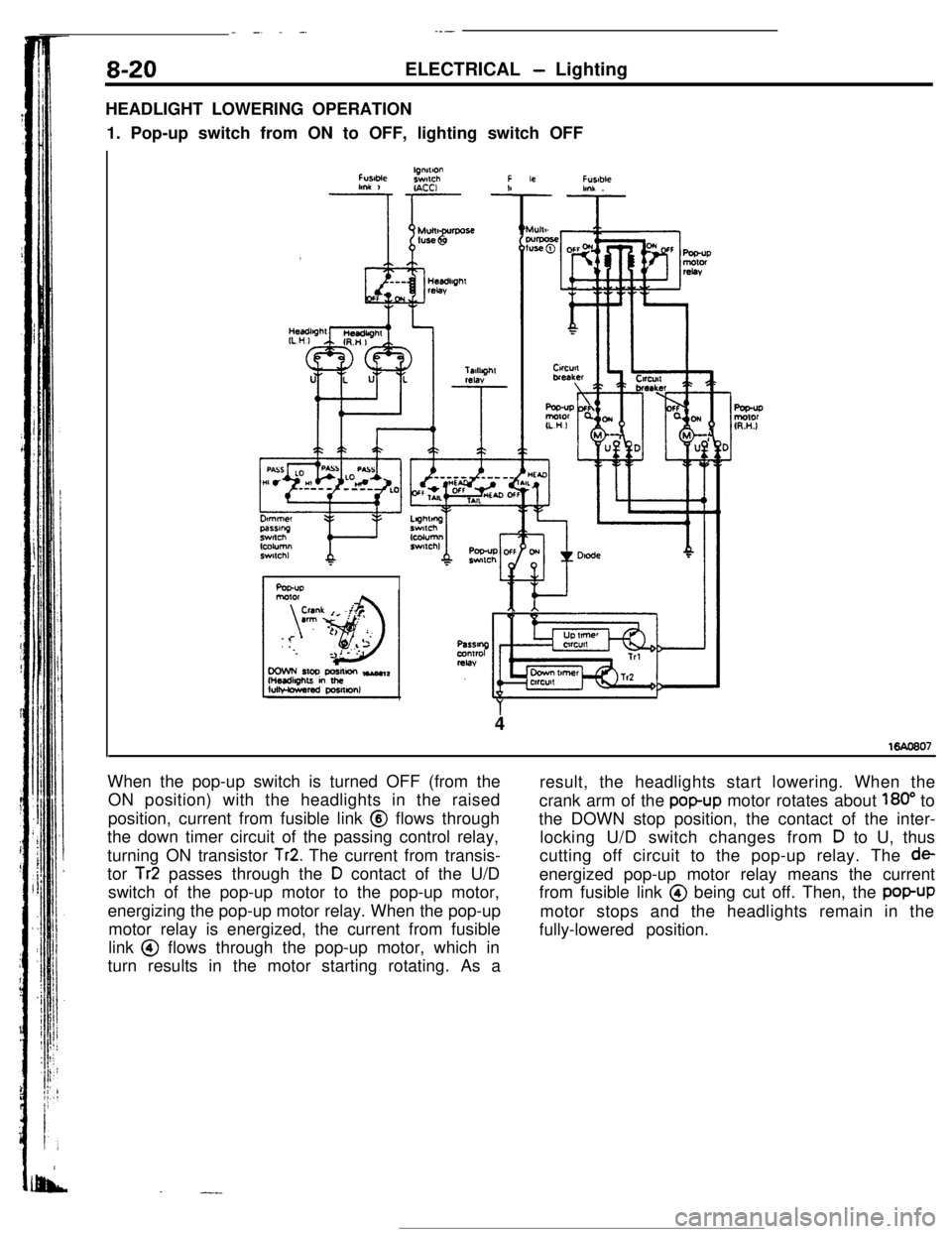

HEADLIGHT LOWERING OPERATION

1. Pop-up switch from ON to OFF, lighting switch OFF

FUslMelgnnlonswlchFlmk 1r- -!IACCI

Ar

Fusablehnk .

4

When the pop-up switch is turned OFF (from the

ON position) with the headlights in the raised

position, current from fusible link @ flows through

the down timer circuit of the passing control relay,

turning ON transistor

Tr2. The current from transis-

tor

Tr2 passes through the D contact of the U/D

switch of the pop-up motor to the pop-up motor,

energizing the pop-up motor relay. When the pop-up

motor relay is energized, the current from fusible

link @ flows through the pop-up motor, which in

turn results in the motor starting rotating. As a

.-.-result, the headlights start lowering. When the

crank arm of the

popup motor rotates about 180” to

the DOWN stop position, the contact of the inter-

locking U/D switch changes from

D to U, thus

cutting off circuit to the pop-up relay. The

deenergized pop-up motor relay means the current

from fusible link @ being cut off. Then, the

popUPmotor stops and the headlights remain in the

fully-lowered position.

Page 73 of 391

37..-. _.-.a*/ _ --‘-:.iA -i .- -..., mpv,,ELECTRICAL

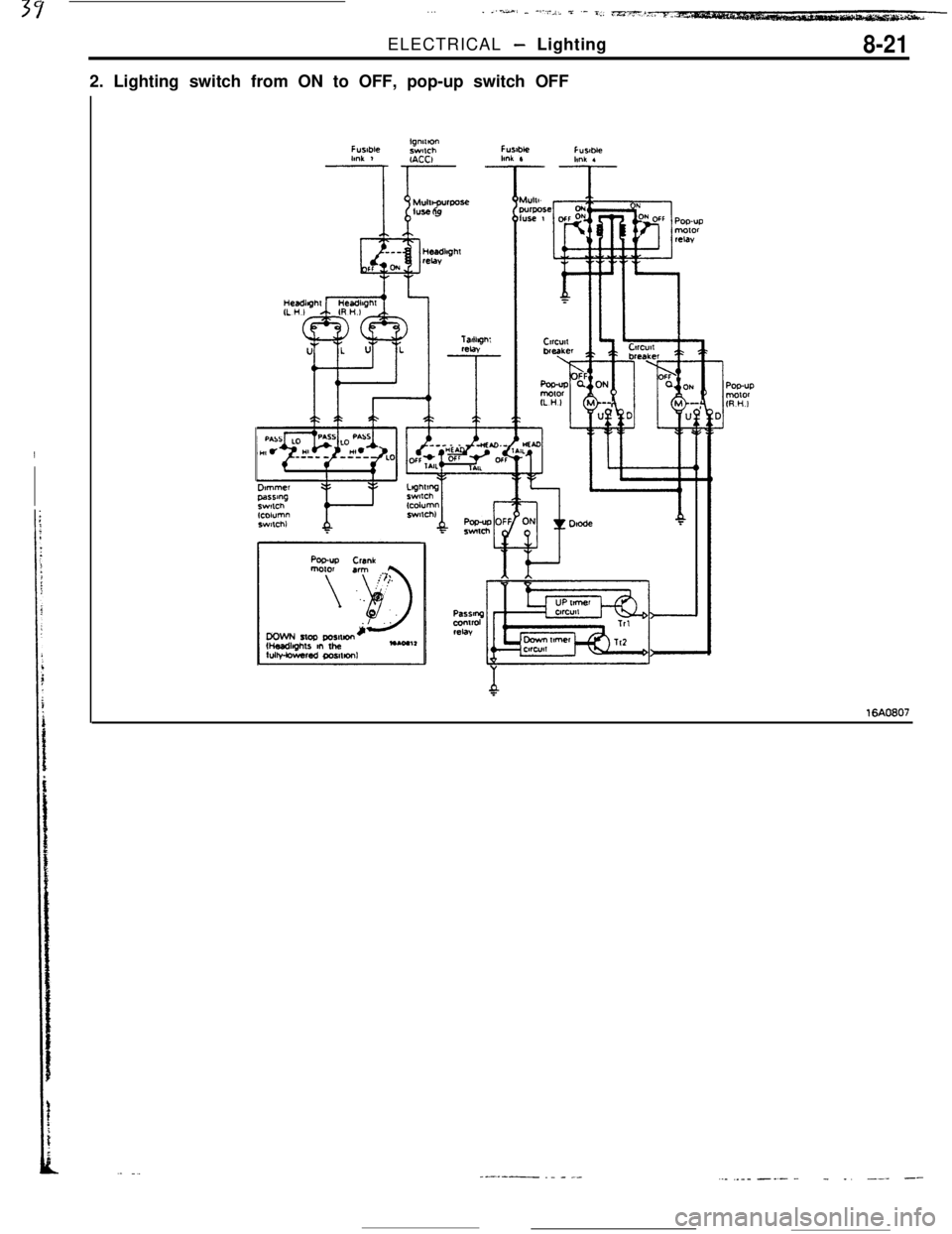

- Lighting8-212. Lighting switch from ON to OFF, pop-up switch OFF

-

16AO607

--.---- ._ - _-.._ ..-_ -_- -- _. --- --

Page 74 of 391

8-22ELECTRICAL - Lighting--Ignition ON

switch OFF

prDoor ON

switch OFF

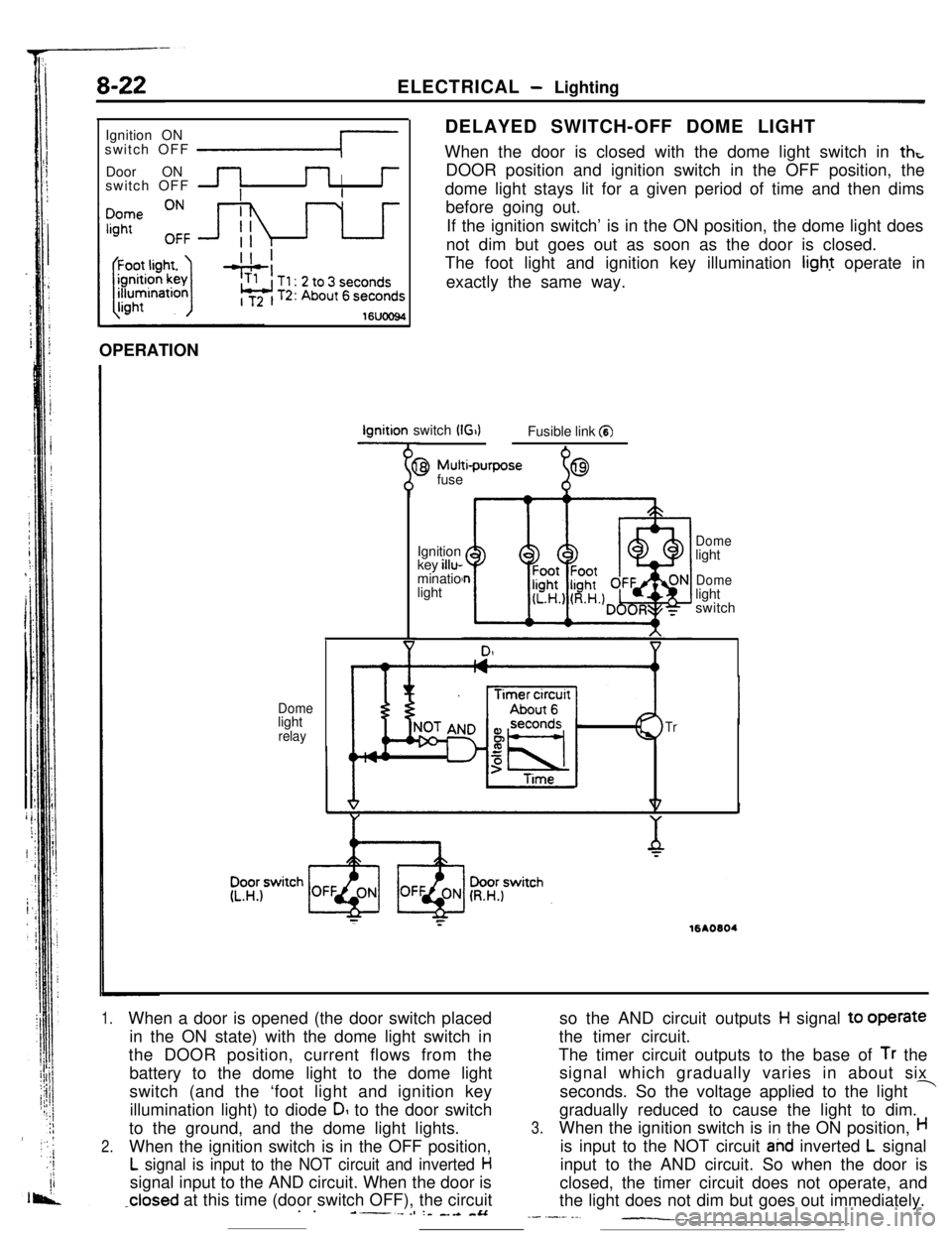

IDELAYED SWITCH-OFF DOME LIGHT

When the door is closed with the dome light switch in

thtDOOR position and ignition switch in the OFF position, the

dome light stays lit for a given period of time and then dims

before going out.

If the ignition switch’ is in the ON position, the dome light does

not dim but goes out as soon as the door is closed.

The foot light and ignition key illumination light operate in

exactly the same way.

16UOO94OPERATIONIgnition switch

(G)Fusible link a

Domelight

relay

9 Mutti-purpose

fuse

%69Ignition

key illu-

minatio

light

Domelight

Domelight

switch

Tr

;:16AO604

1.When a door is opened (the door switch placed

in the ON state) with the dome light switch in

the DOOR position, current flows from the

battery to the dome light to the dome light

switch (and the ‘foot light and ignition key

illumination light) to diode

DI to the door switch

to the ground, and the dome light lights.

2.When the ignition switch is in the OFF position,

L signal is input to the NOT circuit and inverted Hsignal input to the AND circuit. When the door is

-closed at this time (door switch OFF), the circuit

. .----es :- _.a -&Aso the AND circuit outputs

H signal to operate

the timer circuit.

The timer circuit outputs to the base of

Tr the

signal which gradually varies in about six

seconds. So the voltage applied to the light

-gradually reduced to cause the light to dim.

3.When the ignition switch is in the ON position,His input to the NOT circuit

ahd inverted L signal

input to the AND circuit. So when the door is

closed, the timer circuit does not operate, and

the light does not dim but goes out immediately.

_- .-._. ._-__._

Page 75 of 391

ELECTRICAL- Ermine Electrical8-23

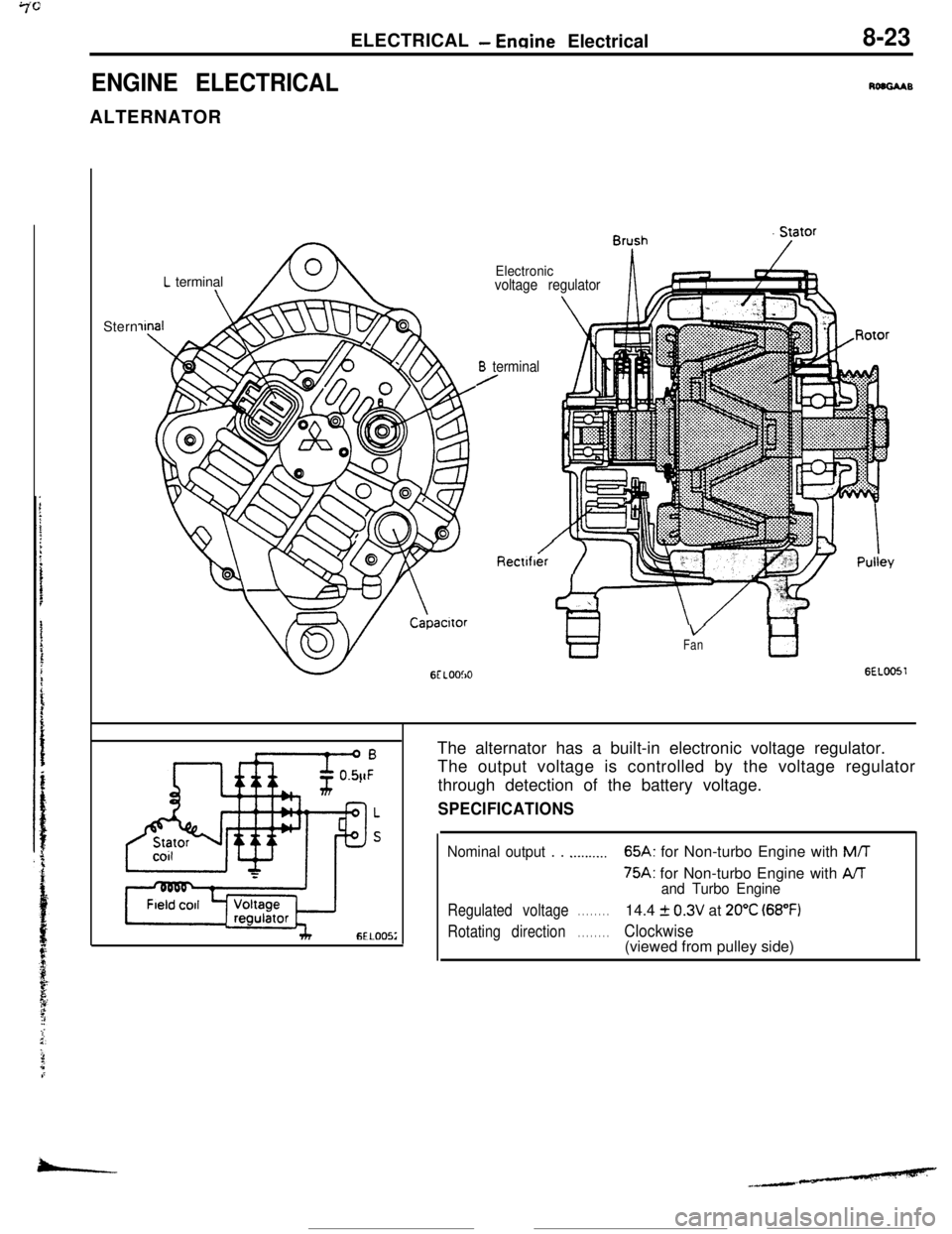

ENGINE ELECTRICALRoaGAABALTERNATOR

L terminal\Stern

Electronicvoltage regulator

B terminal/

Rectlfber‘i ‘IT

VFantl

GEL0051The alternator has a built-in electronic voltage regulator.

The output voltage is controlled by the voltage regulator

through detection of the battery voltage.

SPECIFICATIONS

Nominal output . . .._...._..65A: for Non-turbo Engine with M/T

75A: for Non-turbo Engine with AAand Turbo Engine

Regulated voltage. . . . . . . .14.4 f 0.3V at 20°C (68°F)

Rotating direction. . . . . . . .Clockwise(viewed from pulley side)

-

Page 76 of 391

.-

8-24ELECTRICAL- Engine Electrical

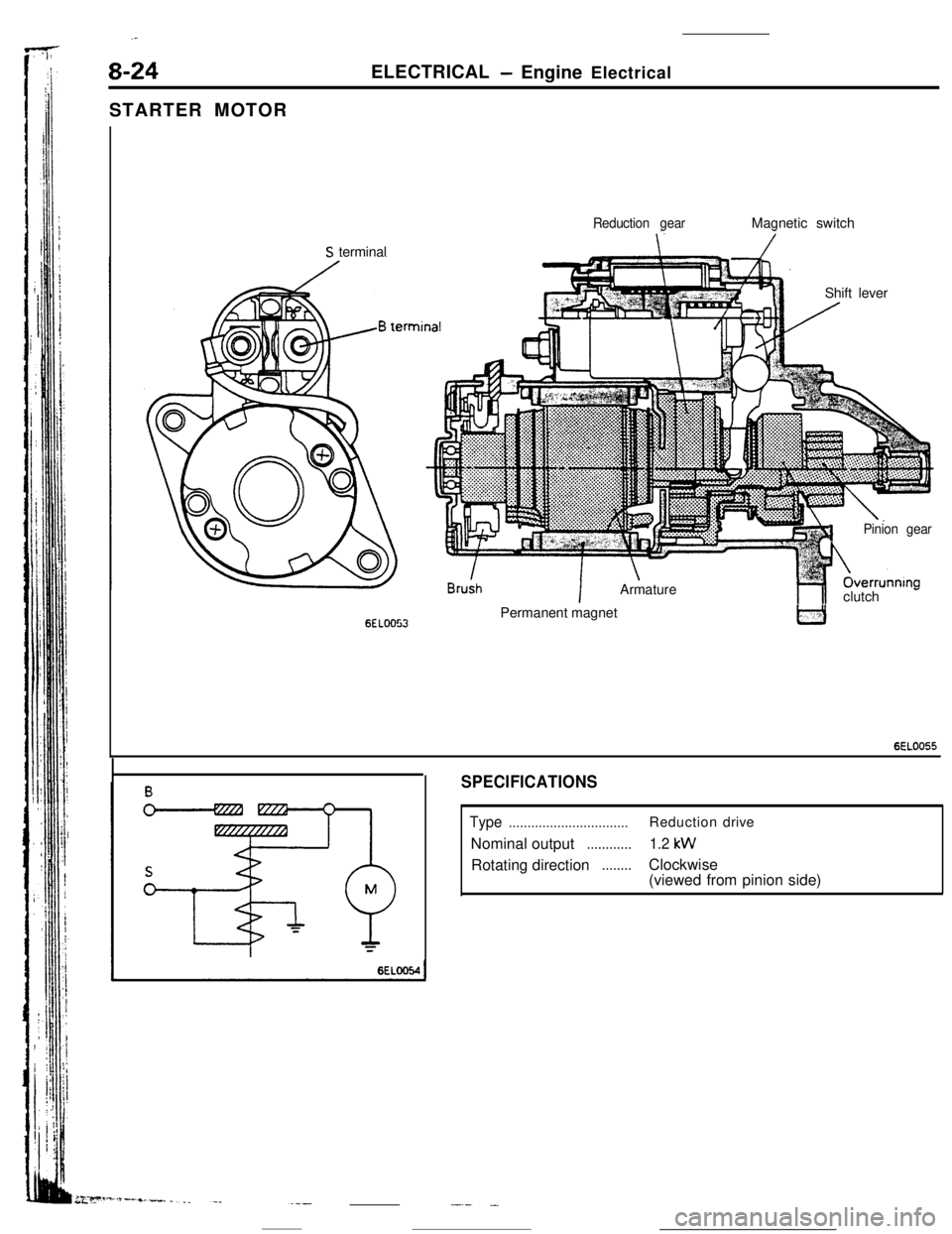

STARTER MOTOR

Reduction gearMagnetic switch

S terminal

Shift lever

6ELOO53

!n

IArmature

1Pinion gearOverrunnIng

hlclutch -Permanent magnet

6EL0055

SPECIFICATIONS

Type................................Reductiondrive

Nominal output

............1.2 kWRotating direction

........Clockwise

(viewed from pinion side)

-.- .-

Page 77 of 391

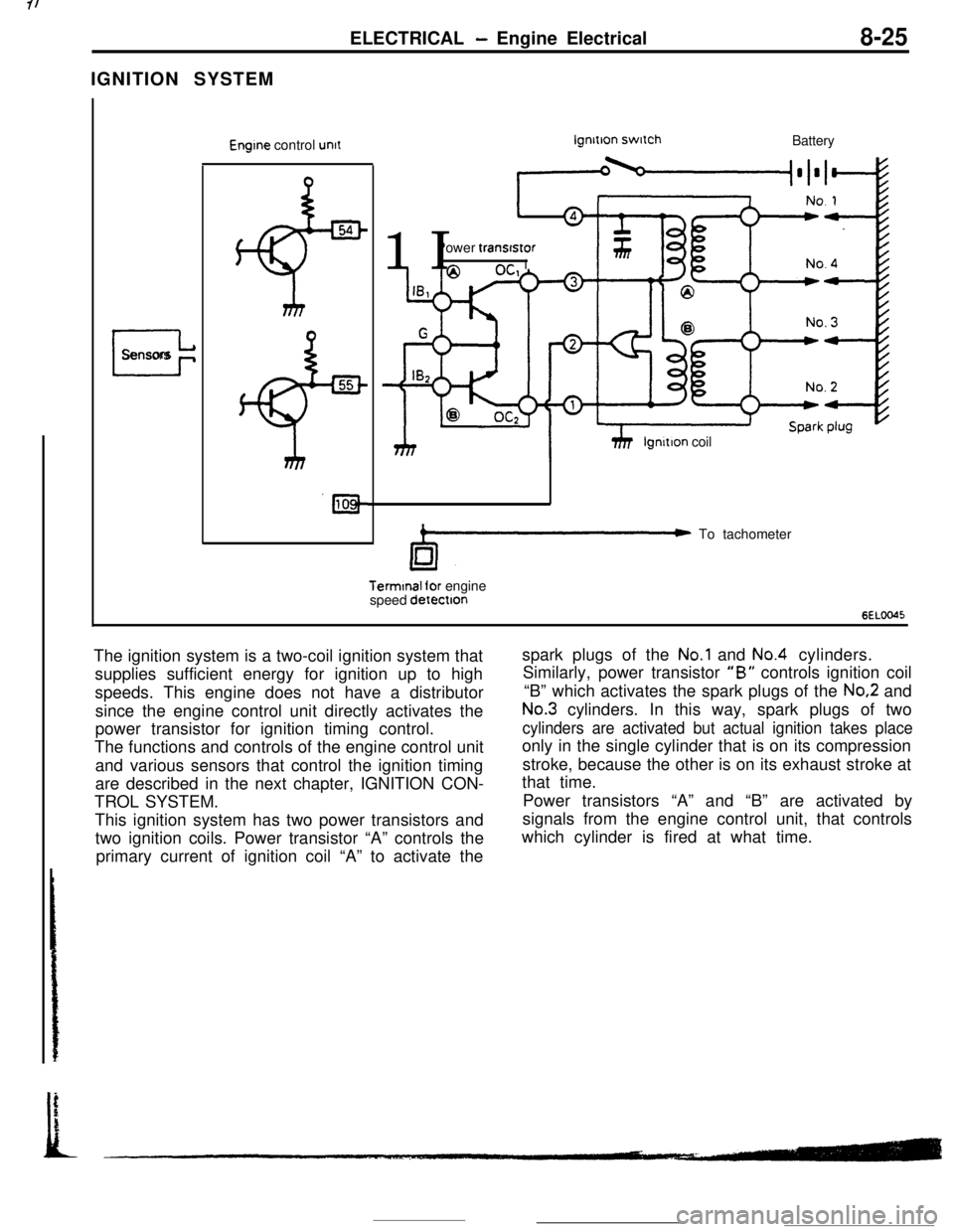

IGNITION SYSTEMELECTRICAL - Engine Electrical8-25

I

Sensors

Engine control unitlgnltlon switch

Battery

11 IPower transfstor

hhP 1

Ilgnltion coil

C To tachometerTerminal for engine

speed detectton

6ELOO45The ignition system is a two-coil ignition system that

supplies sufficient energy for ignition up to high

speeds. This engine does not have a distributor

since the engine control unit directly activates the

power transistor for ignition timing control.

The functions and controls of the engine control unit

and various sensors that control the ignition timing

are described in the next chapter, IGNITION CON-

TROL SYSTEM.

This ignition system has two power transistors and

two ignition coils. Power transistor “A” controls the

primary current of ignition coil “A” to activate thespark plugs of the

No.1 and No.4 cylinders.

Similarly, power transistor

“B” controls ignition coil

“B” which activates the spark plugs of the

No.2 and

No.3 cylinders. In this way, spark plugs of two

cylinders are activated but actual ignition takes placeonly in the single cylinder that is on its compression

stroke, because the other is on its exhaust stroke at

that time.

Power transistors “A” and “B” are activated by

signals from the engine control unit, that controls

which cylinder is fired at what time.

Page 78 of 391

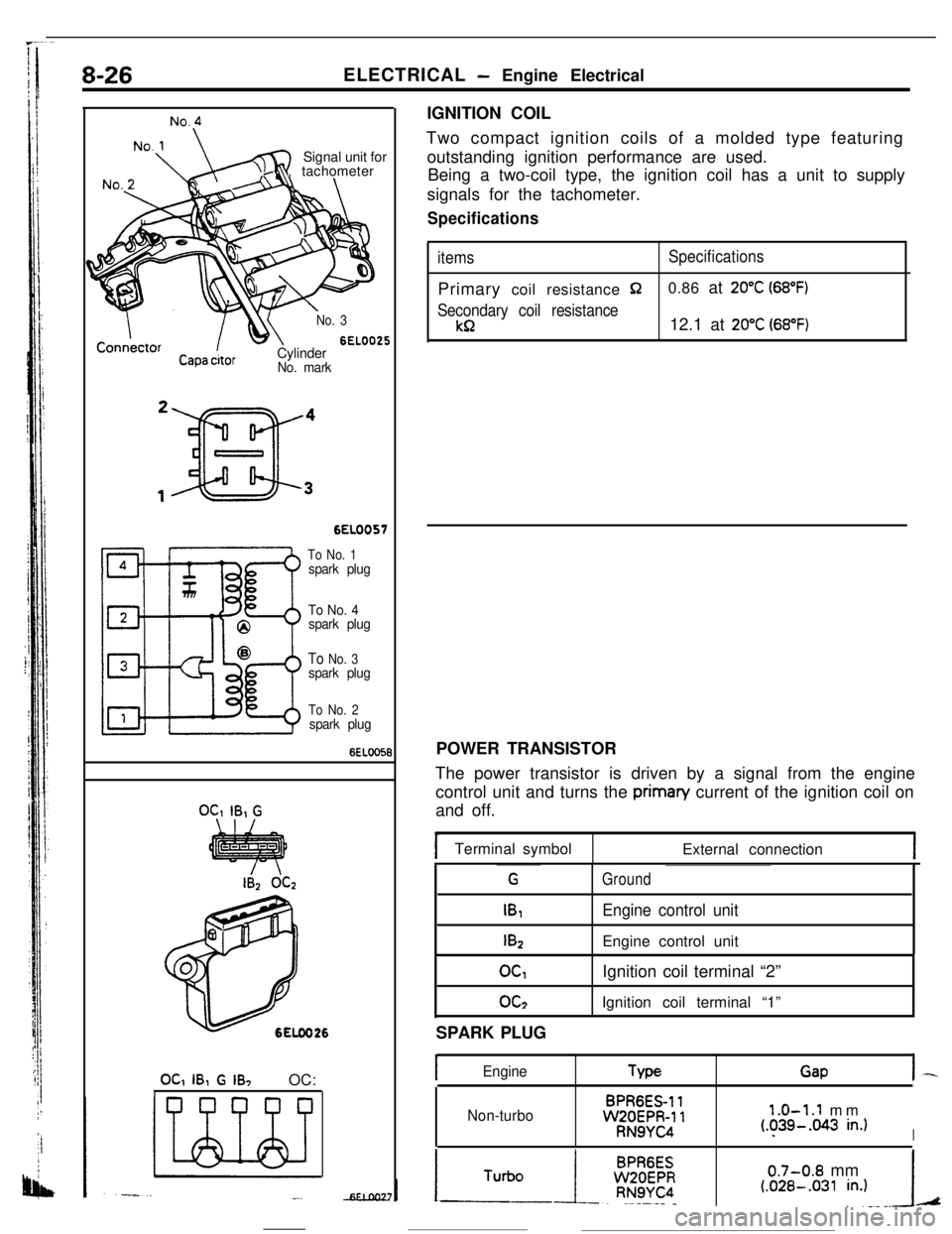

8-26ELECTRICAL - Engine Electrical

No.:

4Signal unit for

, tachometer

71

x

No. 3

6EL0025

Capa &orCylinderNo. mark

6EL0057

To No. 1spark plug

To No. 4

spark plug

To No. 3spark plug

To No. 2spark plug

6EL005t

OC,IB, G

OC, IB, G IB, OC:IGNITION COIL

Two compact ignition coils of a molded type featuring

outstanding ignition performance are used.

Being a two-coil type, the ignition coil has a unit to supply

signals for the tachometer.

Specifications

itemsSpecificationsPrimary coil resistance

$20.86 at 20°C (68°F)

Secondary coil resistance

kR12.1 at 20°C (68°F)POWER TRANSISTOR

The power transistor is driven by a signal from the engine

control unit and turns the priman/ current of the ignition coil on

and off.

Terminal symbol

External connection

G

IB,

I&

Ground

Engine control unitEngine control unit

OGoc2Ignition coil terminal “2”

Ignition coil terminal “1”

SPARK PLUG

IEngineTypeGapI-

Non-turboBPR6ES-11WZOEPR-11RN9YC4

1.0-1.1 mm(.?39-.043 in.)I

0.7-0.8 mm(.OZB-.031 in.)A

Page 79 of 391

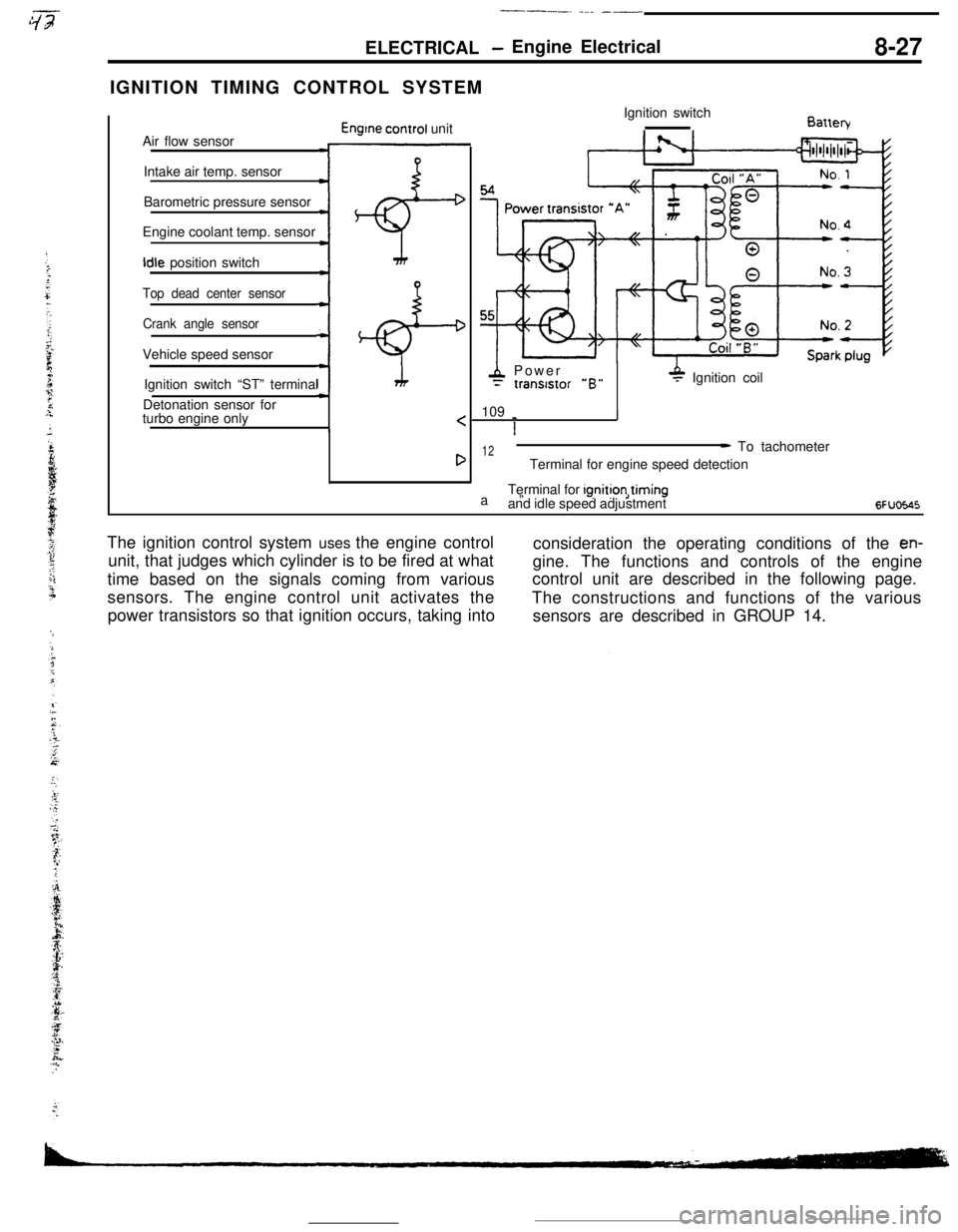

-----. _-- ___ELECTRICAL

- Engine Electrical8-27IGNITION TIMING CONTROL SYSTEM

Air flow sensor

Engtne control unit

Intake air temp. sensor

Barometric pressure sensor

Engine coolant temp. sensorIdle position switch

:+

Top dead center sensor

Crank angle sensorVehicle speed sensor

;+Ignition switch “ST” terminal

Detonation sensor for

turbo engine only

4 Power= tranststor “B”P Ignition coil

109

_

I

1

12a”- To tachometer

Terminal for engine speed detection

Terminal for ignition,timing

and idle speed adjustment

6FUoE.45The ignition control system uses the engine control

consideration the operating conditions of the

en-unit, that judges which cylinder is to be fired at what

gine. The functions and controls of the engine

time based on the signals coming from variouscontrol unit are described in the following page.

sensors. The engine control unit activates the

The constructions and functions of the various

power transistors so that ignition occurs, taking into

sensors are described in GROUP 14.

Page 80 of 391

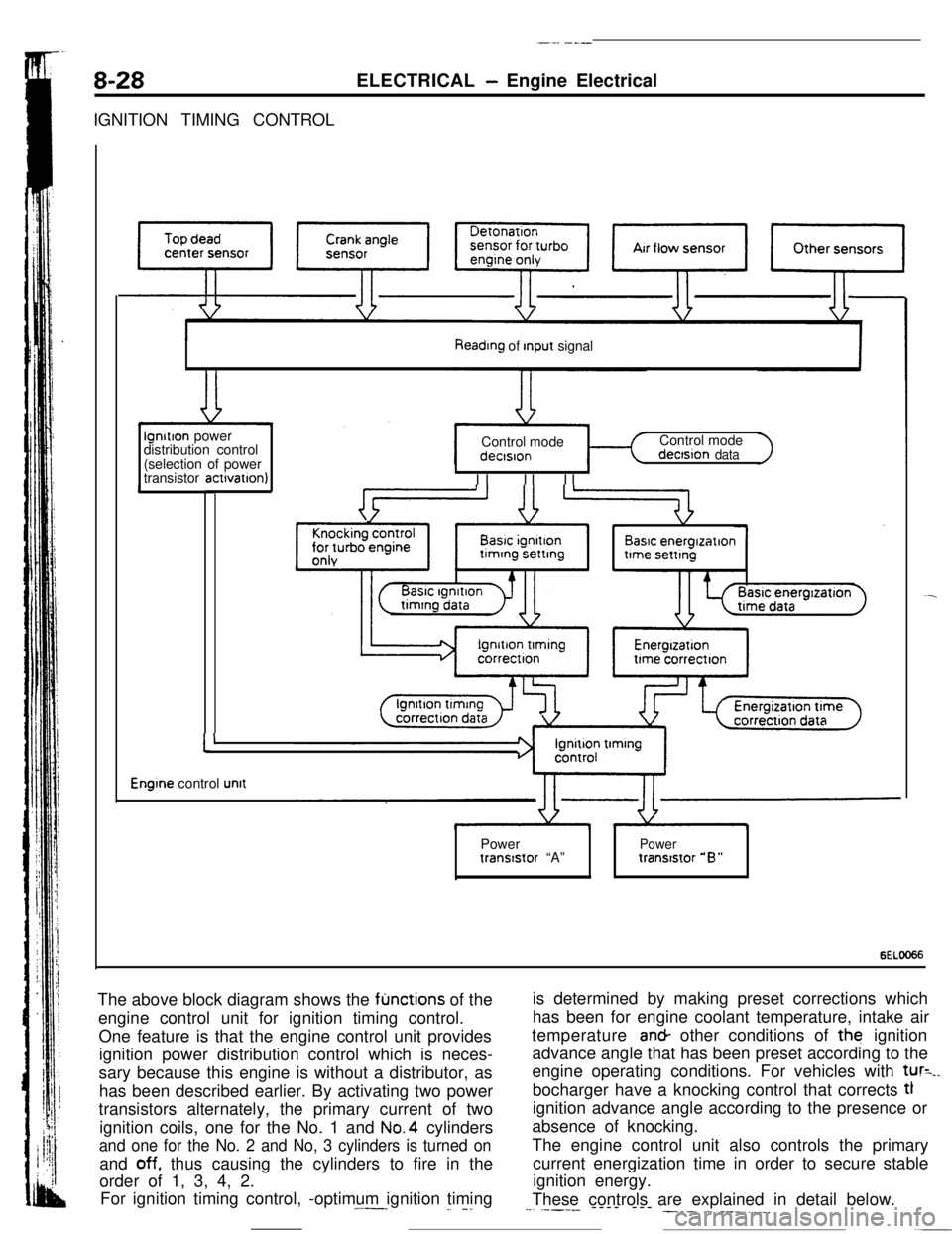

8-28ELECTRICAL- Engine Electrical

IGNITION TIMING CONTROL

Reading of Input signallgnitlon power

distribution control

(selection of power

transistor actlvatlon)Control mode

I II II IControl mode

dectsion data

Basic energlzatlon

I’

Engine control unitPower

Powertranststor “A”tranststor “B”

6ELOO66The above block diagram shows the

fljnctions of the

engine control unit for ignition timing control.

One feature is that the engine control unit provides

ignition power distribution control which is neces-

sary because this engine is without a distributor, as

has been described earlier. By activating two power

transistors alternately, the primary current of two

ignition coils, one for the No. 1 and No.4 cylinders

and one for the No. 2 and No, 3 cylinders is turned onand

off. thus causing the cylinders to fire in the

order of 1, 3, 4, 2.

For ignition timing control, -optimum ignition timing.^--_

_. -.is determined by making preset corrections which

has been for engine coolant temperature, intake air

temperature an& other conditions of the ignition

advance angle that has been preset according to the

engine operating conditions. For vehicles with

tur=_.bocharger have a knocking control that corrects tl

ignition advance angle according to the presence or

absence of knocking.

The engine control unit also controls the primary

current energization time in order to secure stable

ignition energy.

These controls are explained in detail below.

--. .----- ---- --- ___. .-. ___.,.__