MITSUBISHI ECLIPSE 1990 Owners Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1990Pages: 391, PDF Size: 15.27 MB

Page 91 of 391

9-6ENGINE -General Information

6EN0363.-- -- -.. _-44

Page 92 of 391

s’ y _._----,_ - k - ..-_ _ _

ENGINE- Base Engine9-7I

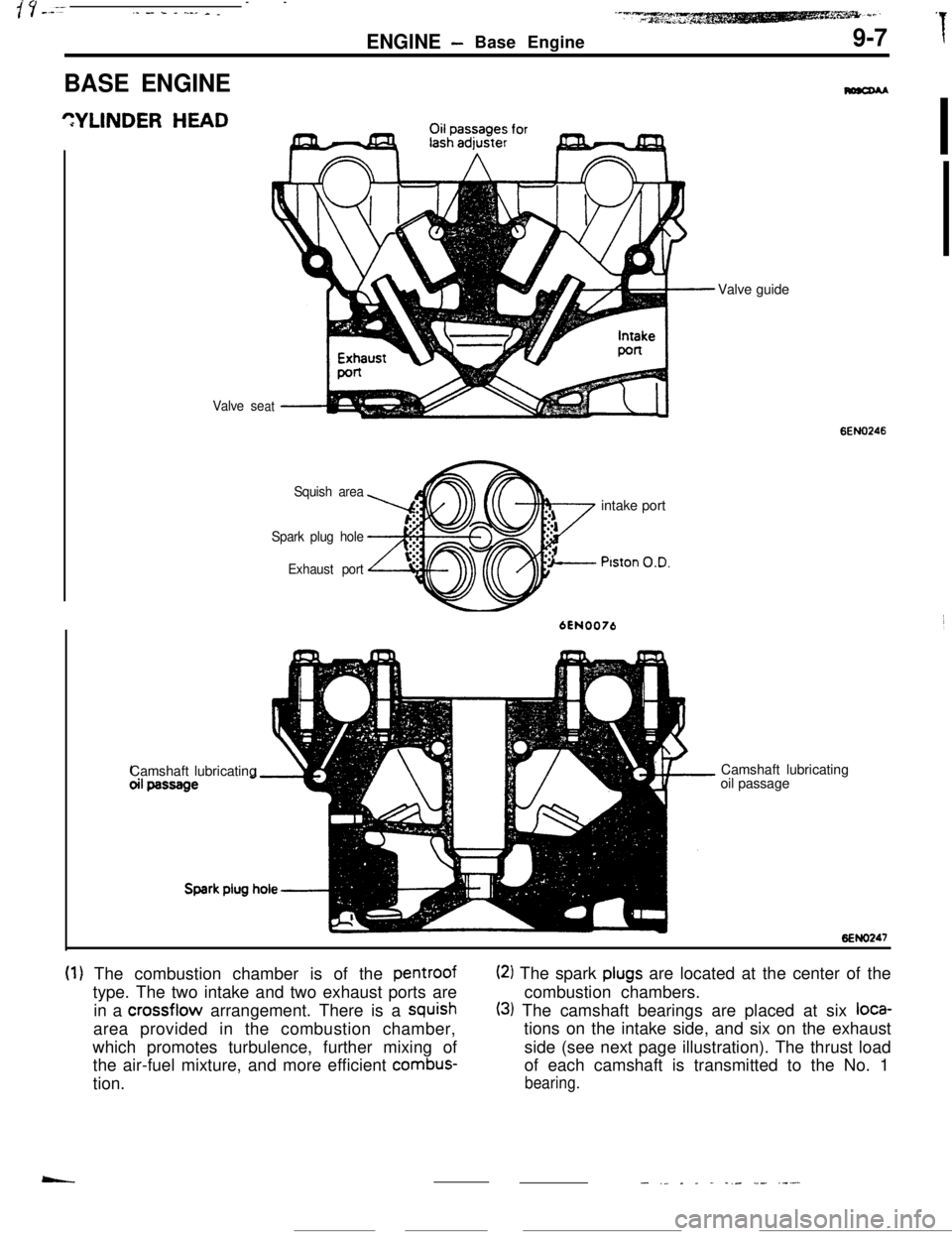

BASE ENGINE

Valve seat

Squish area

Spark plug hole

Exhaust portintake port

Piston O.D.

6EN0076Camshaft lubricatingValve guide

6ENO246Camshaft lubricating

oil passage

6ENO247

(1) The combustion chamber is of the pentroof(2) The spark plugs are located at the center of the

type. The two intake and two exhaust ports arecombustion chambers.

in a crossflow arrangement. There is a

squish(3) The camshaft bearings are placed at six loca-area provided in the combustion chamber,tions on the intake side, and six on the exhaust

which promotes turbulence, further mixing ofside (see next page illustration). The thrust load

the air-fuel mixture, and more efficient

combus-of each camshaft is transmitted to the No. 1

tion.

bearing.

- ._ _ _ - -,- -- .---

Page 93 of 391

9-8ENGINE - Base Engine

0

Ri

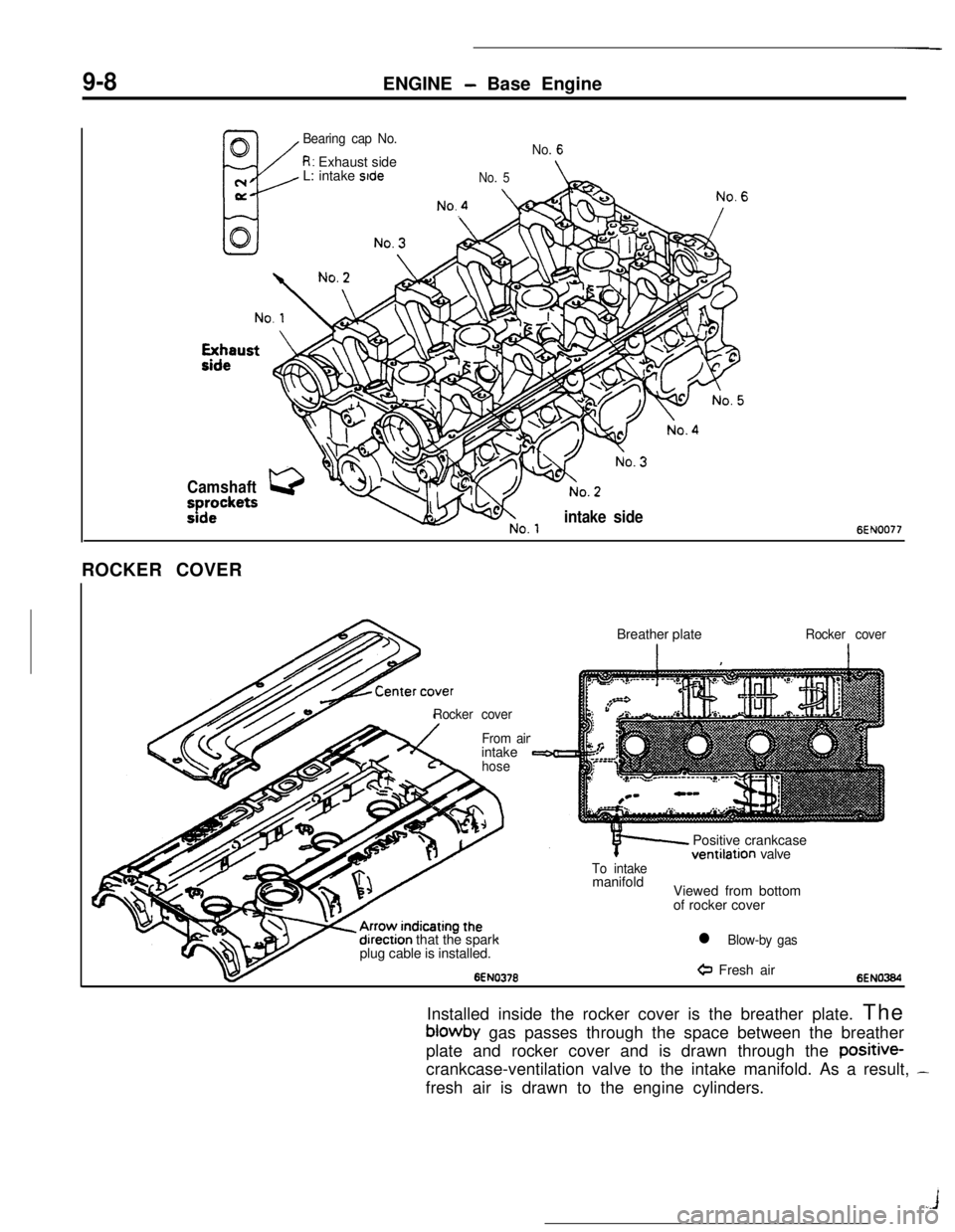

Bearing cap No.

No. 6R: Exhaust side

cyL: intake stdeNo. 5\-

CLNo.4 bd

P

j

CamshaftQsproc:kets -

sideintake sideno. 16EN0077ROCKER COVER

Rocker cover

From airintake

hose

erection that the spark

plug cable is installed.

6EN0378Breather plate

Rocker cover

To intakemanifoldPositive crankcase

ventilation valve

Viewed from bottom

of rocker cover

l Blow-by gas

C$ Fresh air6EN0384Installed inside the rocker cover is the breather plate. Theblowby gas passes through the space between the breather

plate and rocker cover and is drawn through the positive-

crankcase-ventilation valve to the intake manifold. As a result,

-fresh air is drawn to the engine cylinders.

Page 94 of 391

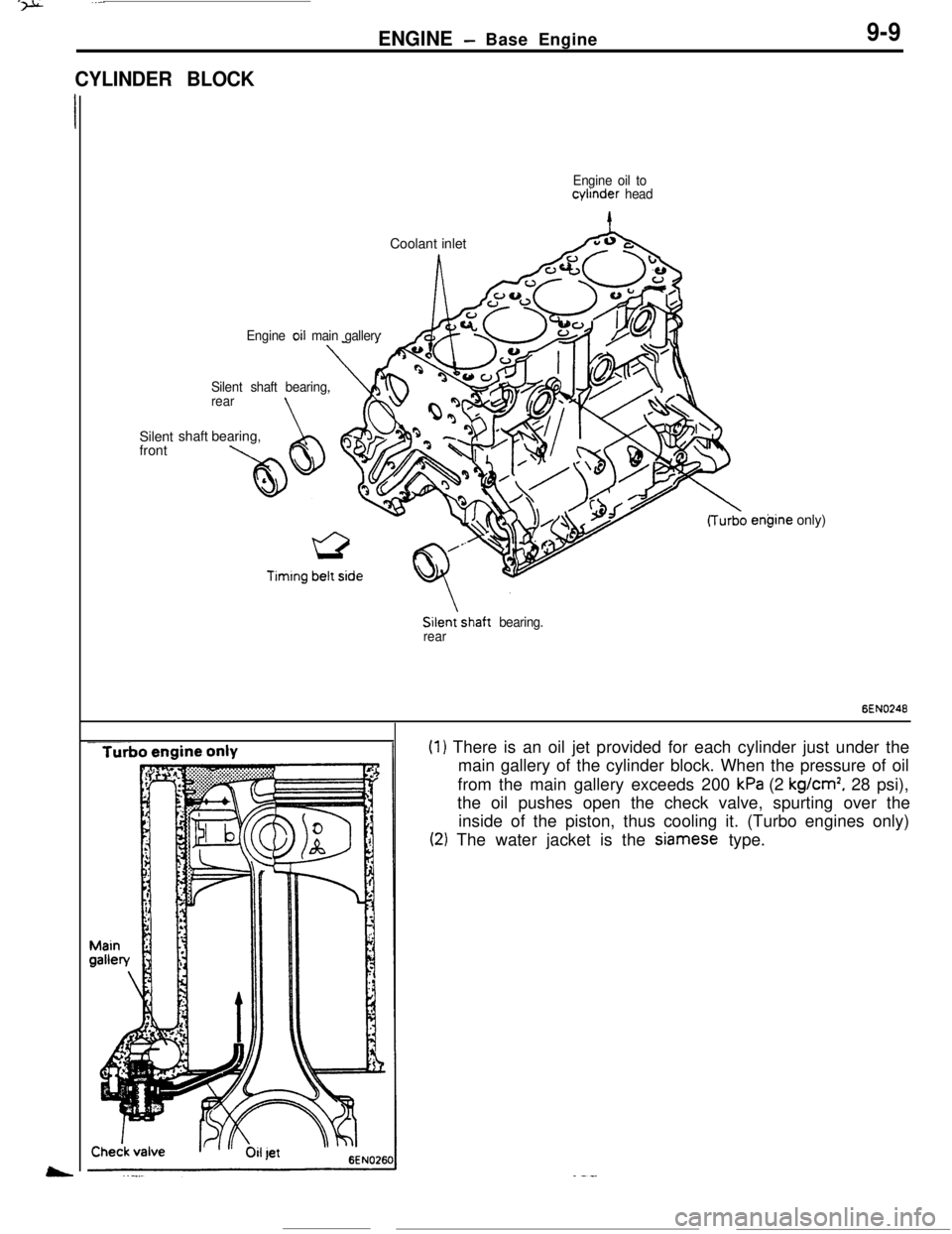

CYLINDER BLOCKENGINE

- Base Engine9-9

Engine oil tocylinder

headCoolant inlet

ASilent

front

Engine oil main gallery

Silent shaft bearing,

rear

\shaft bearing,

A taw

Silenishaft bearing.

rearengine only)

6EN0246

(1) There is an oil jet provided for each cylinder just under the

main gallery of the cylinder block. When the pressure of oil

from the main gallery exceeds 200

kPa (2 kg/cm’, 28 psi),

the oil pushes open the check valve, spurting over the

inside of the piston, thus cooling it. (Turbo engines only)

(2) The water jacket is the Siamese type.

Page 95 of 391

9-10PISTONENGINE- Base Engine

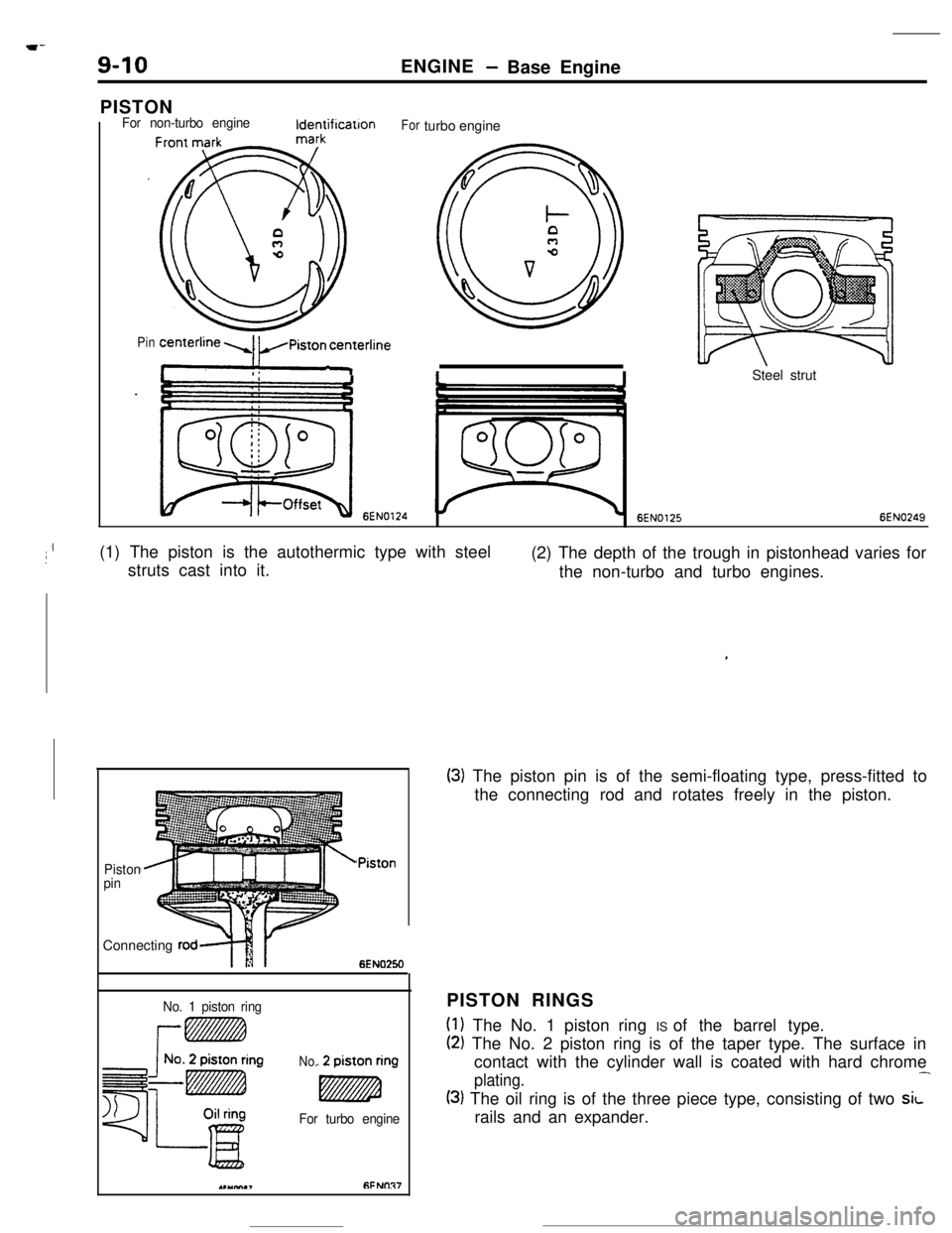

For non-turbo engineldentificatlonForturbo engine

Pin;nterline y FPiston ceyerline

6EN01246EN0125Steel strut6EN0249

Ij(1) The piston is the autothermic type with steel

struts cast into it..(2) The depth of the trough in pistonhead varies for

the non-turbo and turbo engines.

Piston

pinConnecting

rod?\i

~Piston

6EN0250

No. 1 piston ringPISTON RINGS

No.3

For turbo engine

(1) The No. 1 piston ring IS of the barrel type.

(2) The No. 2 piston ring is of the taper type. The surface in

contact with the cylinder wall is coated with hard chrome

plating.-

(3) The oil ring is of the three piece type, consisting of two sLrails and an expander.

.,YM,,fiFNflR7

,

(3) The piston pin is of the semi-floating type, press-fitted to

the connecting rod and rotates freely in the piston.

Page 96 of 391

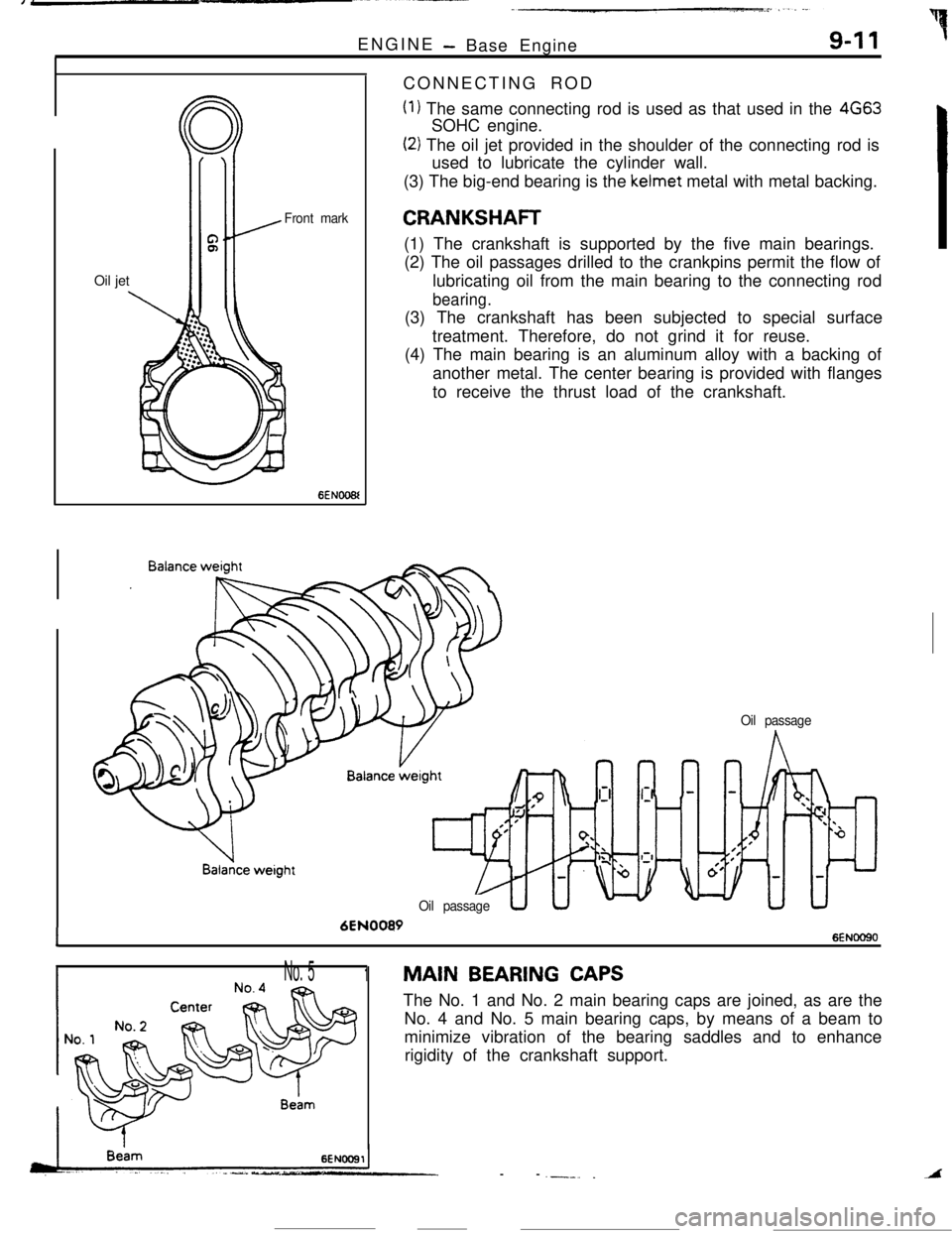

ENGINE- Base Engine9-11 7Oil jet

Front mark

6ENOO6lCONNECTING ROD

(1) The same connecting rod is used as that used in the 4663SOHC engine.

(2) The oil jet provided in the shoulder of the connecting rod is

used to lubricate the cylinder wall.

(3) The big-end bearing is the kelmet metal with metal backing.

CRANKSHAFT(1) The crankshaft is supported by the five main bearings.

(2) The oil passages drilled to the crankpins permit the flow of

lubricating oil from the main bearing to the connecting rod

bearing.(3) The crankshaft has been subjected to special surface

treatment. Therefore, do not grind it for reuse.

(4) The main bearing is an aluminum alloy with a backing of

another metal. The center bearing is provided with flanges

to receive the thrust load of the crankshaft.

Oil passage

6EN0089

16ENOOQO

Oil passage

INo. 51MAIN BEARING CAPSThe No. 1 and No. 2 main bearing caps are joined, as are the

No. 4 and No. 5 main bearing caps, by means of a beam to

minimize vibration of the bearing saddles and to enhance

rigidity of the crankshaft support.

--

.--. _A

Page 97 of 391

9-12

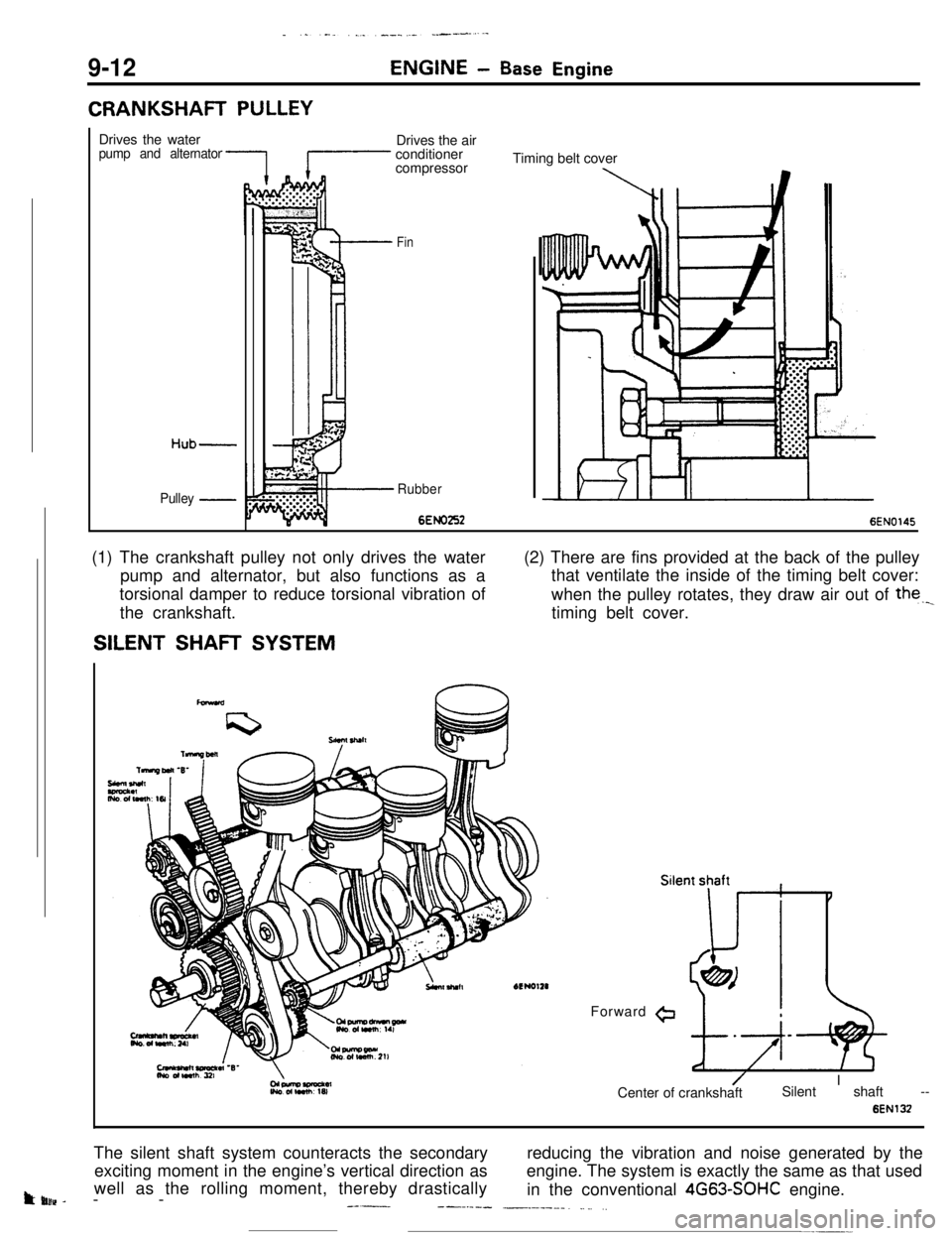

CRANKSHAFT PULLEY

ENGINE- Base EngineDrives the water

pump and alternator

Hub-

Pulley -Drives the air

conditioner

compressor

Fin

Rubber

6EMI2526EN0145 Timing belt cover

(1) The crankshaft pulley not only drives the water

pump and alternator, but also functions as a

torsional damper to reduce torsional vibration of

the crankshaft.

SILENT SHAFT SYSTEM(2) There are fins provided at the back of the pulley

that ventilate the inside of the timing belt cover:

when the pulley rotates, they draw air out of the._

timing belt cover.

Forward

@

/I

Center of crankshaftSilent shaft --

6ENl32The silent shaft system counteracts the secondaryreducing the vibration and noise generated by the

exciting moment in the engine’s vertical direction asengine. The system is exactly the same as that used

t uluv -well as the rolling moment, thereby drastically

in the conventional 4G63-SOHC engine.

-------_---.--- __.----_. _... ,.

Page 98 of 391

ENGINE - Base Engine9-13

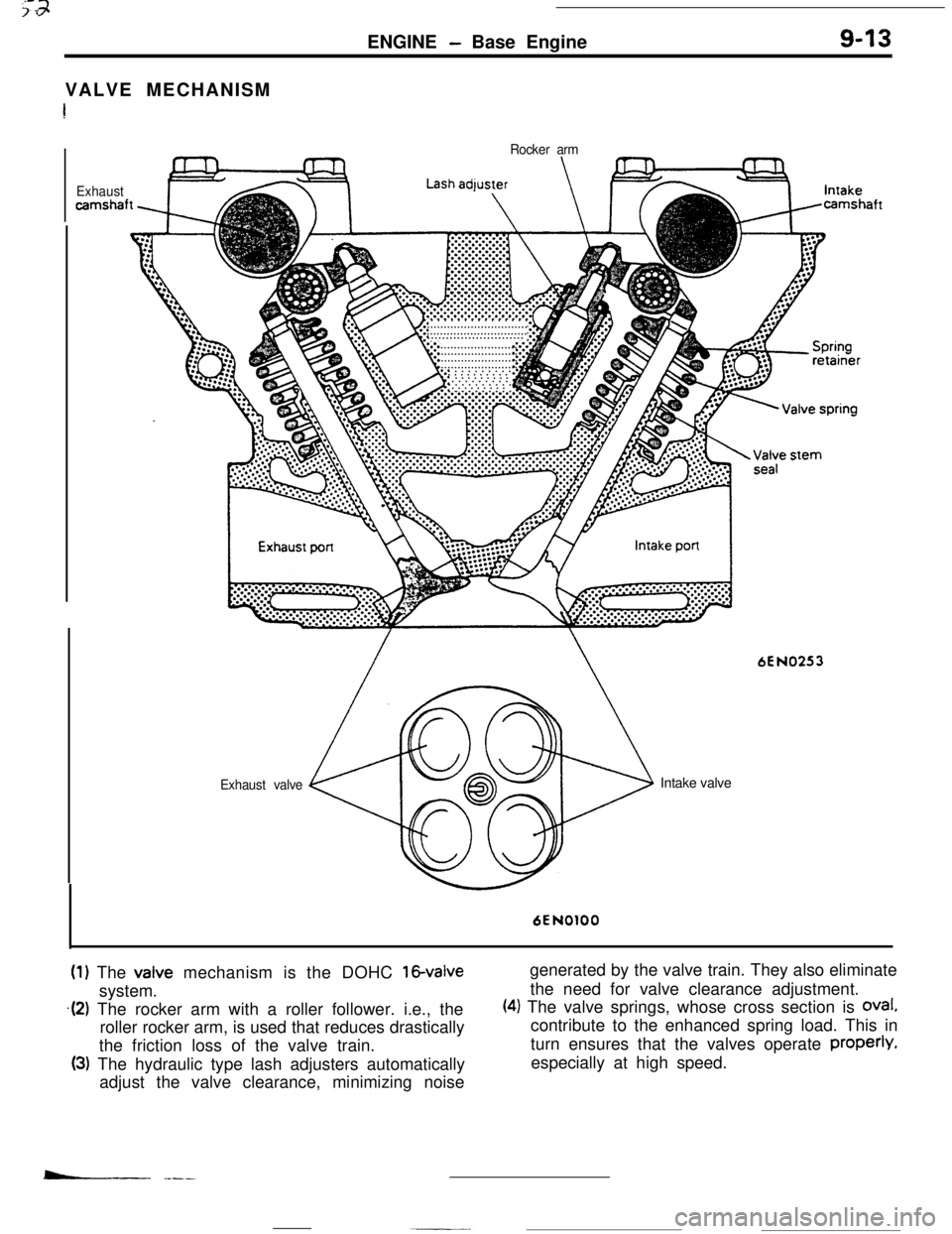

VALVE MECHANISM

!

Rocker arm

Exhaustcamshaf

...............

...............

..............................

........................................................

.......................

.......................

.......................

.................................

..........

.........

.........

..........

.........

..........

Exhaust valve

bENOIntake valve6ENOlOOIft

(1) The valve mechanism is the DOHC 16-valvesystem.

.(2) The rocker arm with a roller follower. i.e., the

roller rocker arm, is used that reduces drastically

the friction loss of the valve train.

(3) The hydraulic type lash adjusters automatically

adjust the valve clearance, minimizing noisegenerated by the valve train. They also eliminate

the need for valve clearance adjustment.

(4) The valve springs, whose cross section is oval.contribute to the enhanced spring load. This in

turn ensures that the valves operate properly.

especially at high speed.

- .---..

Page 99 of 391

ENGINE - Base Engine

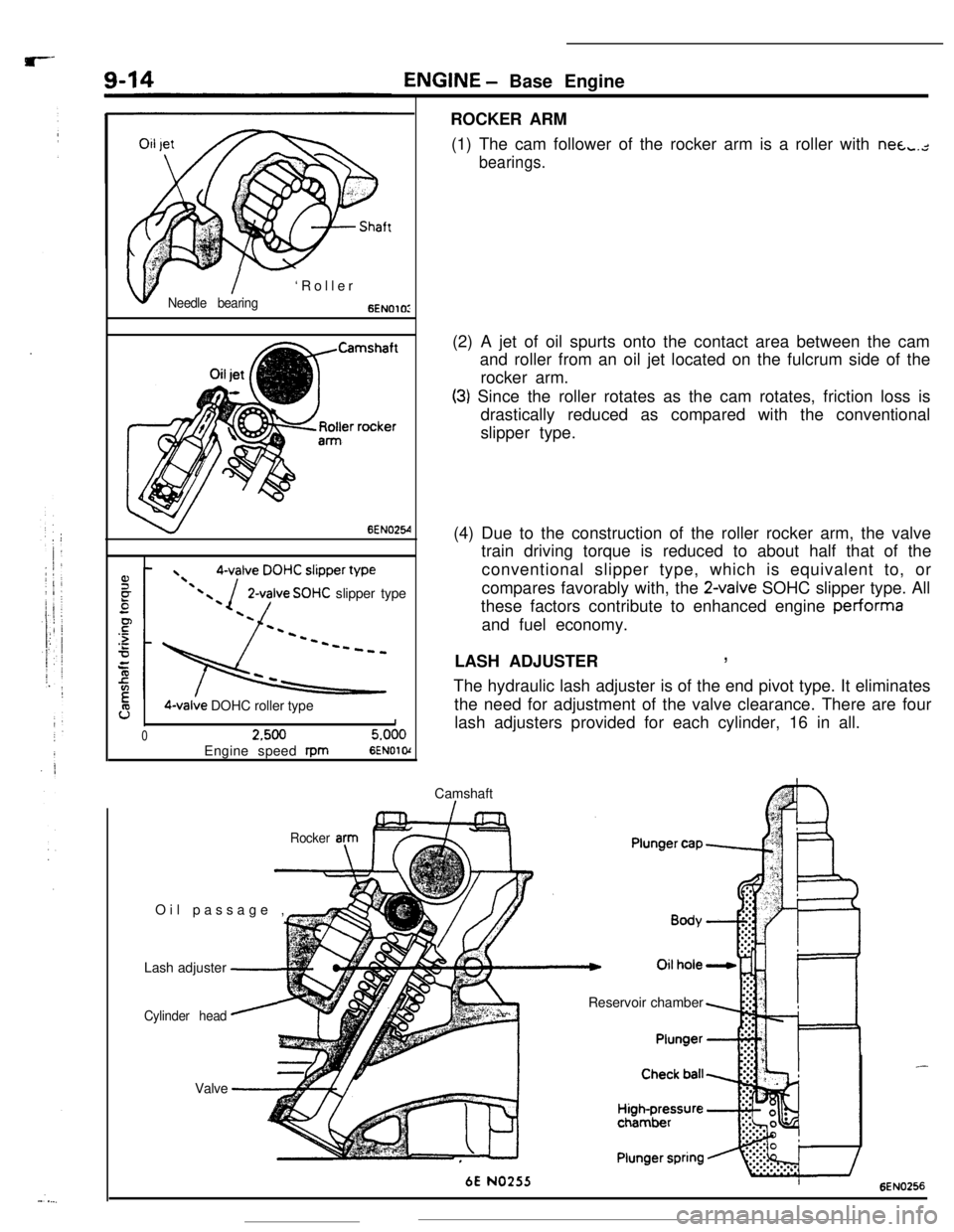

ROCKER ARM

(1) The cam follower of the rocker arm is a roller with nea,.,-

bearings.

v

,I$- I- ‘Roller

Needle bearing6ENOlOI

6EN025-4

2-valve SOHC slipper type

9O-valve DOHC roller type1

02.5005.000Engine speed

rpm6ENOl o(Camshaft

I-Oil passage ,

EIr(2) A jet of oil spurts onto the contact area between the cam

and roller from an oil jet located on the fulcrum side of the

rocker arm.

(3) Since the roller rotates as the cam rotates, friction loss is

drastically reduced as compared with the conventional

slipper type.

(4) Due to the construction of the roller rocker arm, the valve

train driving torque is reduced to about half that of the

conventional slipper type, which is equivalent to, or

compares favorably with, the

2-valve SOHC slipper type. All

these factors contribute to enhanced engine performa

and fuel economy.

LASH ADJUSTER

,The hydraulic lash adjuster is of the end pivot type. It eliminates

the need for adjustment of the valve clearance. There are four

lash adjusters provided for each cylinder, 16 in all.

Rocker anIF=Lash adjuster

-

Cylinder head

--Valve

‘-Reservoir chamber

6E NO255

-6EN0256

Page 100 of 391

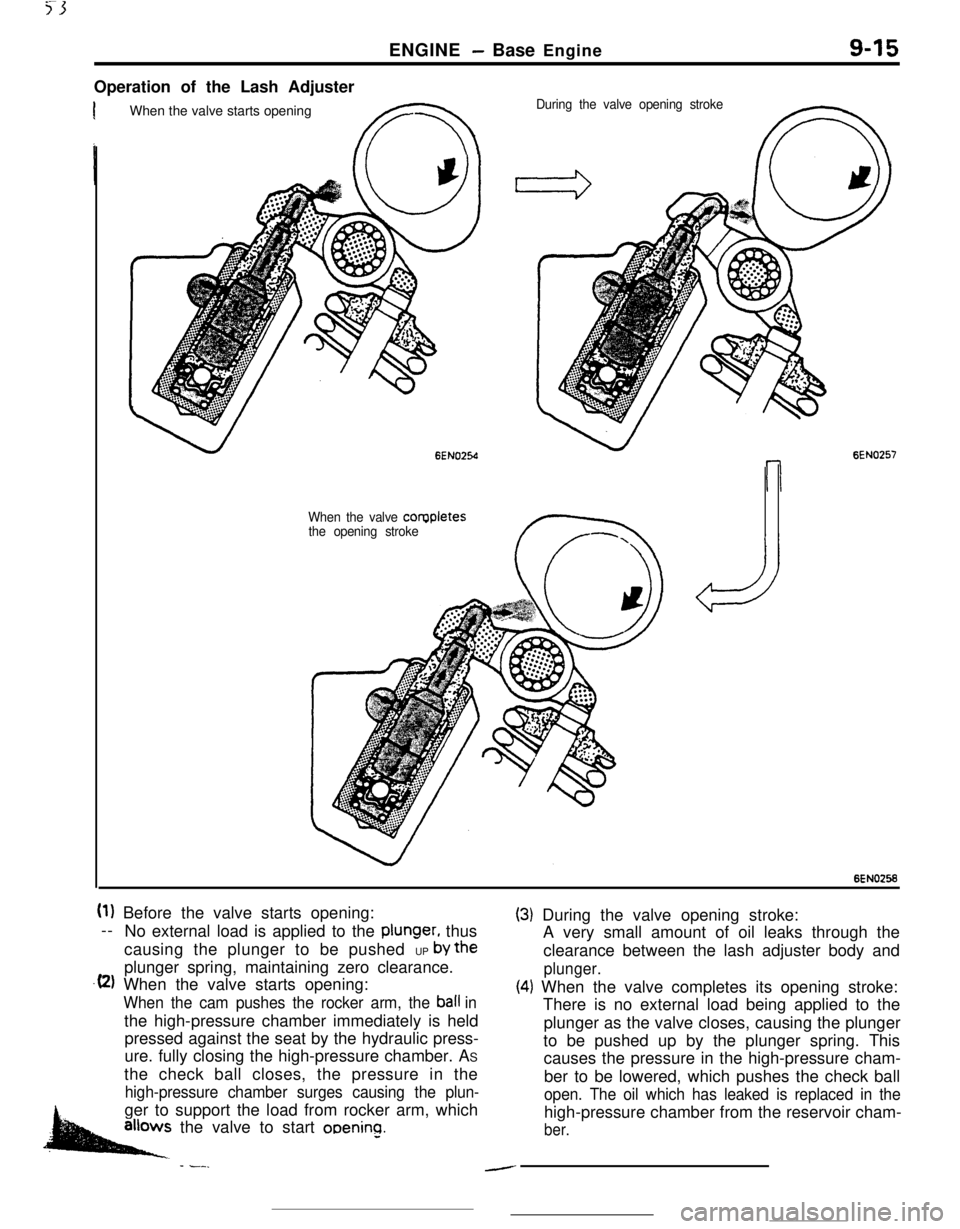

5-jENGINE- Base Engine9-15Operation of the Lash Adjuster

When the valve starts opening

/f-b

During the valve opening stroke

n

6EN0254

When the valve coiqpletesthe opening stroke

6EN0257

6EN0256

(1) Before the valve starts opening:

--

No external load is applied to the

plunger, thus

causing the plunger to be pushed UP

by theplunger spring, maintaining zero clearance.

.(2) When the valve starts opening:

When the cam pushes the rocker arm, the ball inthe high-pressure chamber immediately is held

pressed against the seat by the hydraulic press-

ure. fully closing the high-pressure chamber. AS

the check ball closes, the pressure in the

high-pressure chamber surges causing the plun-ger to support the load from rocker arm, which

.allows the valve to start ooenino.

- -__

(3) During the valve opening stroke:

A very small amount of oil leaks through the

clearance between the lash adjuster body and

plunger.

(4) When the valve completes its opening stroke:

There is no external load being applied to the

plunger as the valve closes, causing the plunger

to be pushed up by the plunger spring. This

causes the pressure in the high-pressure cham-

ber to be lowered, which pushes the check ball

open. The oil which has leaked is replaced in thehigh-pressure chamber from the reservoir cham-

ber.

-