MITSUBISHI ECLIPSE 1991 Service Manual

Manufacturer: MITSUBISHI, Model Year: 1991, Model line: ECLIPSE, Model: MITSUBISHI ECLIPSE 1991Pages: 1216, PDF Size: 67.42 MB

Page 1021 of 1216

AUTOMATIC TRANSAXLE - Valve Body21-327

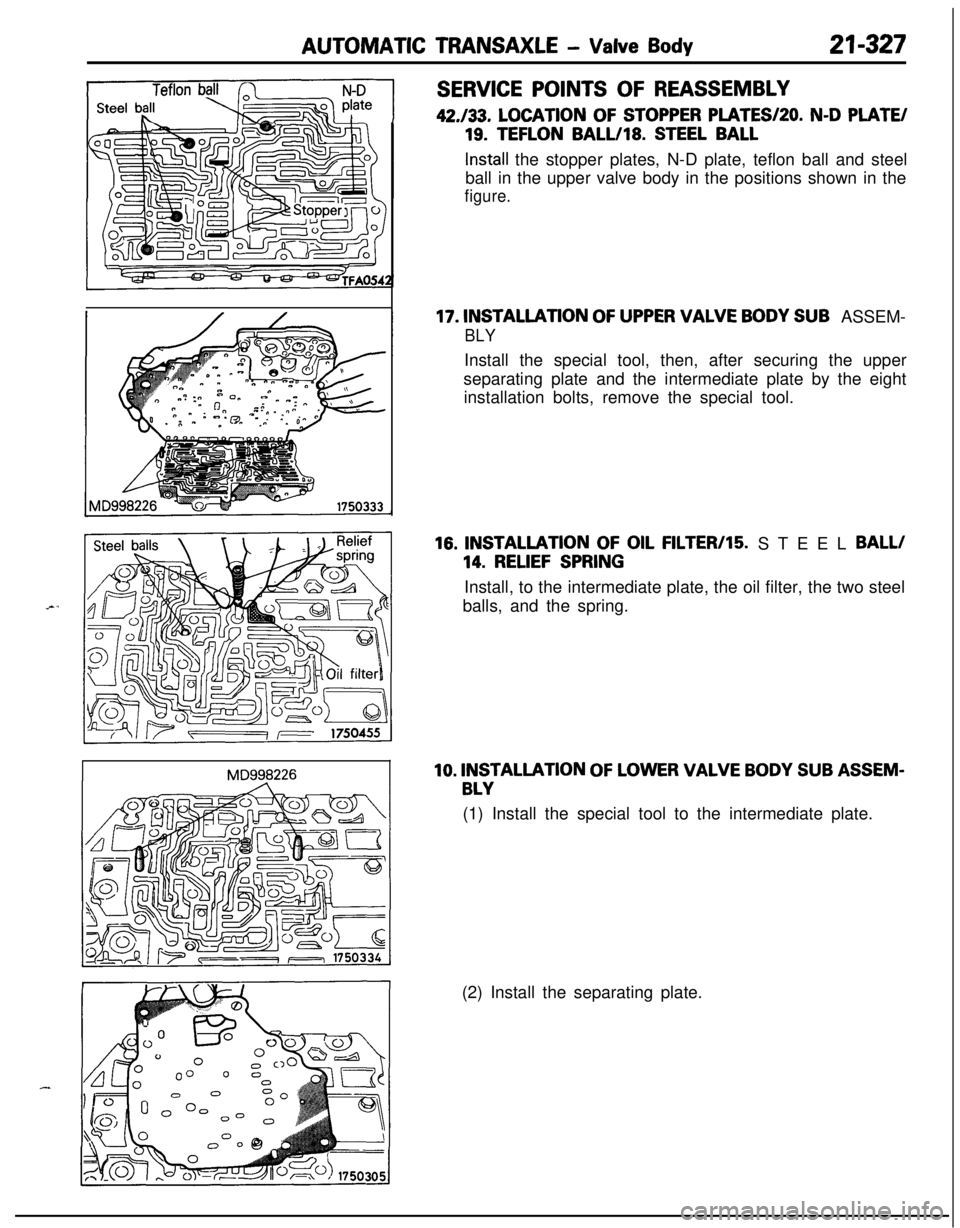

SERVICE POINTS OF REASSEMBLY42./33.

LOCATION OF STOPPER PLATES/SO. N-D PLATE/

19. TEFLON BALL/18. STEEL BALL

Install the stopper plates, N-D plate, teflon ball and steel

ball in the upper valve body in the positions shown in the

figure.

17. INSTALLATION OF UPPER VALVE BODY SUB ASSEM-

BLYInstall the special tool, then, after securing the upper

separating plate and the intermediate plate by the eight

installation bolts, remove the special tool.

MD998226

18. INSTALLATION OF OIL FILTER/IS. STEEL BALL/

14. RELIEF SPRINGInstall, to the intermediate plate, the oil filter, the two steel

balls, and the spring.

10. INSTALLATION OF LOWER VALVE BODY SUB ASSEM-

BLY(1) Install the special tool to the intermediate plate.

(2) Install the separating plate.

Page 1022 of 1216

21-328AUTOMATIC TRANSAXLE - Valve Bodv

XSV-ASkV-Brj,,SV (FJA22)TFAM80(3) After securing the lower valve body by

the installationbolt, remove the special tool.

Sk

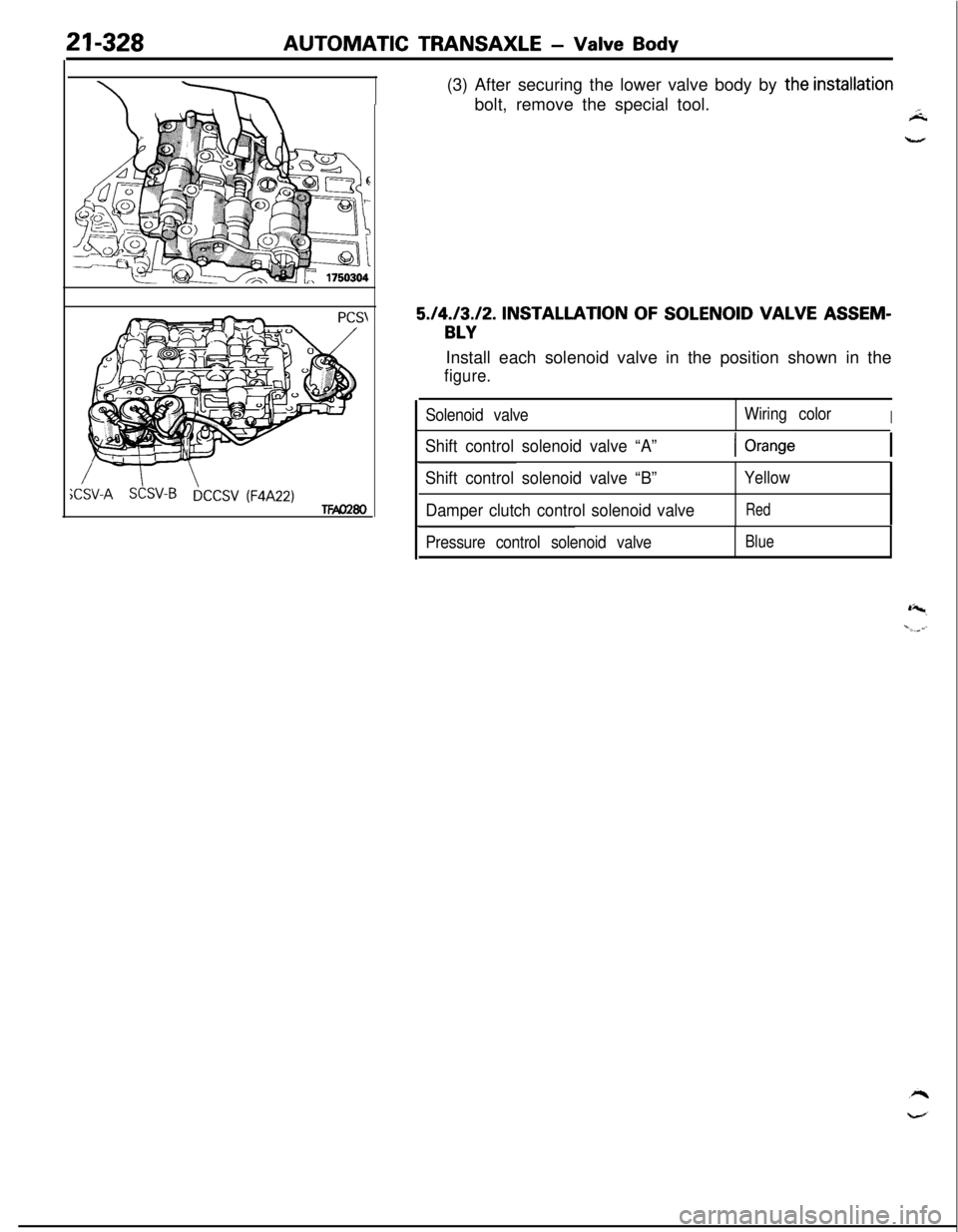

5./4./3./2. INSTALLATION OF SOLENOID VALVE ASSEM-

BLYInstall each solenoid valve in the position shown in the

figure.

Solenoid valveWiring colorI

Shift control solenoid valve “A”

Shift control solenoid valve “B”

Damper clutch control solenoid valve

Yellow

Red

Pressure control solenoid valveBlue

Page 1023 of 1216

AUTOMATIC TRANSAXLE - Center Differential

CENTER DIFFERENTIAL

- DISASSEMBLY AND REASSEMBLY

21-329

NZlLWM

TEA0261

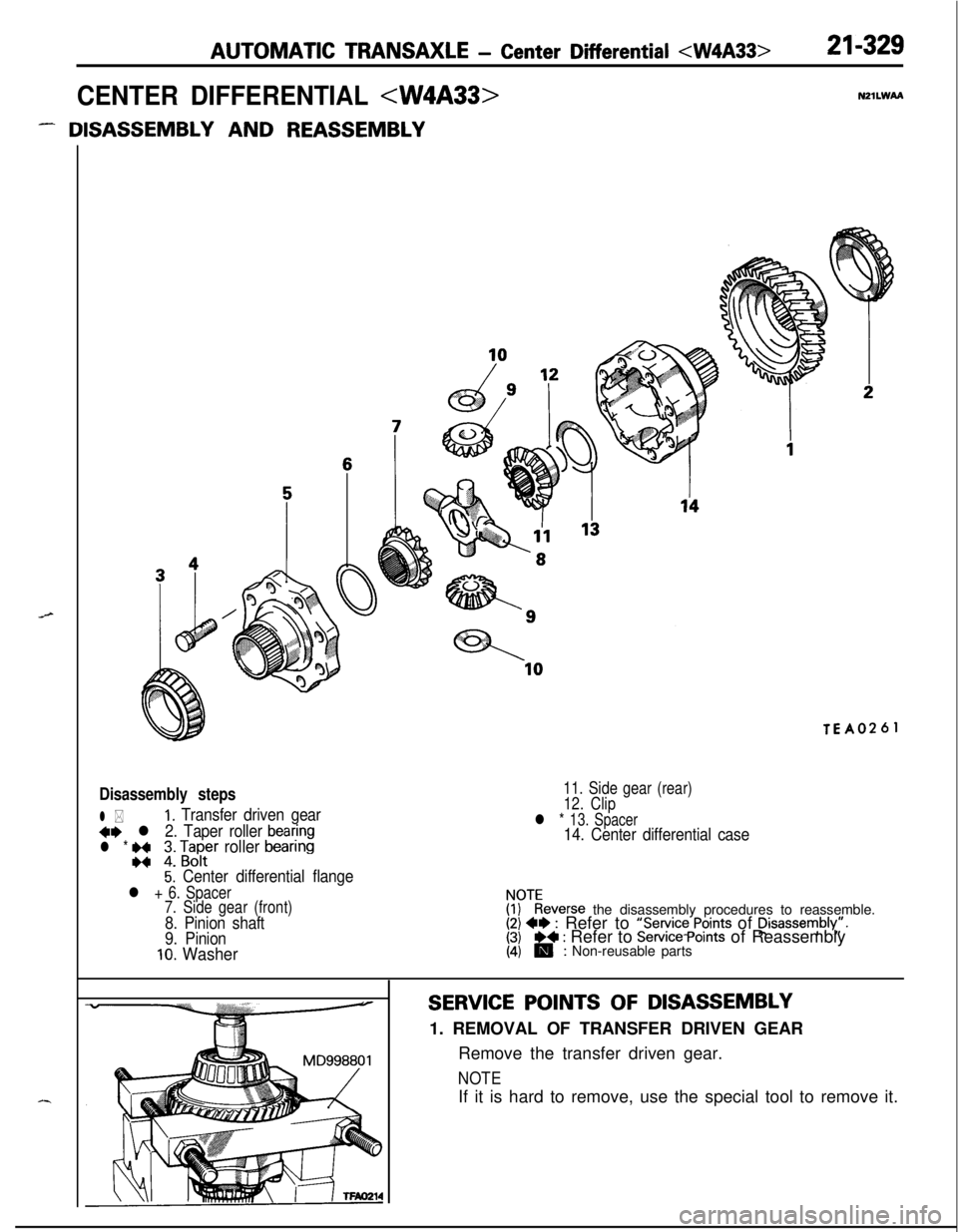

Disassembly steps

l *1. Transfer driven gear

+e l 2. Taper roller bearing

l * :zi. poy;r roller beanng

5: Center differential flange

l + 6. Spacer

7. Side gear (front)

8. Pinion shaft

9. Pinion

10. Washer

11. Side gear (rear)

12. Clip

l * 13. Spacer14. Center differential case

FEeverse the disassembly procedures to reassemble.(2) +e : Refer to ZServjce Pojnts of Disassembly’:‘.1::4 : Refer to Serwce Points of Reassembly&I: Non-reusable parts

SERVICE POINTS OF DISASSEMBLY1. REMOVAL OF TRANSFER DRIVEN GEAR

Remove the transfer driven gear.

NOTEIf it is hard to remove, use the special tool to remove it.

Page 1024 of 1216

21-330AUTOMATIC TRANSAXLE - Center Differential

2. REMOVAL OF TAPER ROLLER BEARING

Using the special tool, remove the taper roller bearing from/icthe transfer driven gear.

‘;-

3. REMOVAL OF TAPER ROLLER BEARING

Using the special tool, remove the taper roller bearing fromthe center differential flange.

SERVICE POINTS OF REASSEMBLY

13.16. SELECTION OF SPACERS(1) Install the spacer, side gear (rear), pinion, washer and

pinion shaft in the center differential case.

rs,(2) While pressing the pinion shaft, select the thickest

-m ,-’spacer to gently rotate the pinion.

(3) Install the side gear (front), spacer and center differen-

tial flange and tighten the bolts with the specified

torque.Center differential

drive gear bolt:

70-80 Nm (51-57 ft.lbs.)(4) Using the front output shaft, rotate the side gear front

and select the thickest spacer to gently rotate the side

gear front.

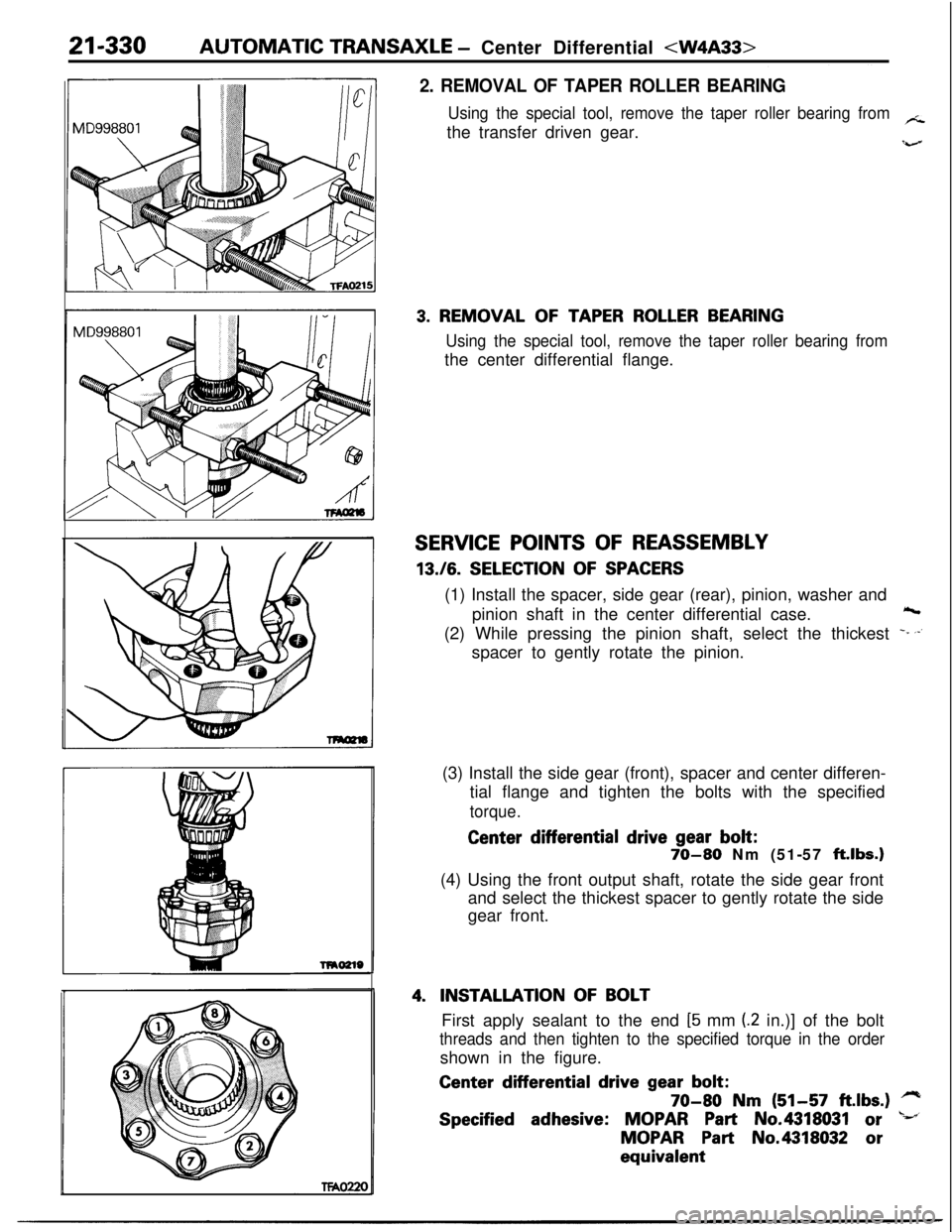

4.INSTALLATION OF BOLTFirst apply sealant to the end

[5 mm (2 in.)] of the bolt

threads and then tighten to the specified torque in the ordershown in the figure.Center differential

drive gear bolt:

70-80 Nm (51-57 ft.lbs.) *

Specified adhesive: MOPAR Part No.4318031 or +’MOPAR

Part No.4318032 orequivalent

Page 1025 of 1216

AUTOMATIC TRANSAXLE - Center Differential

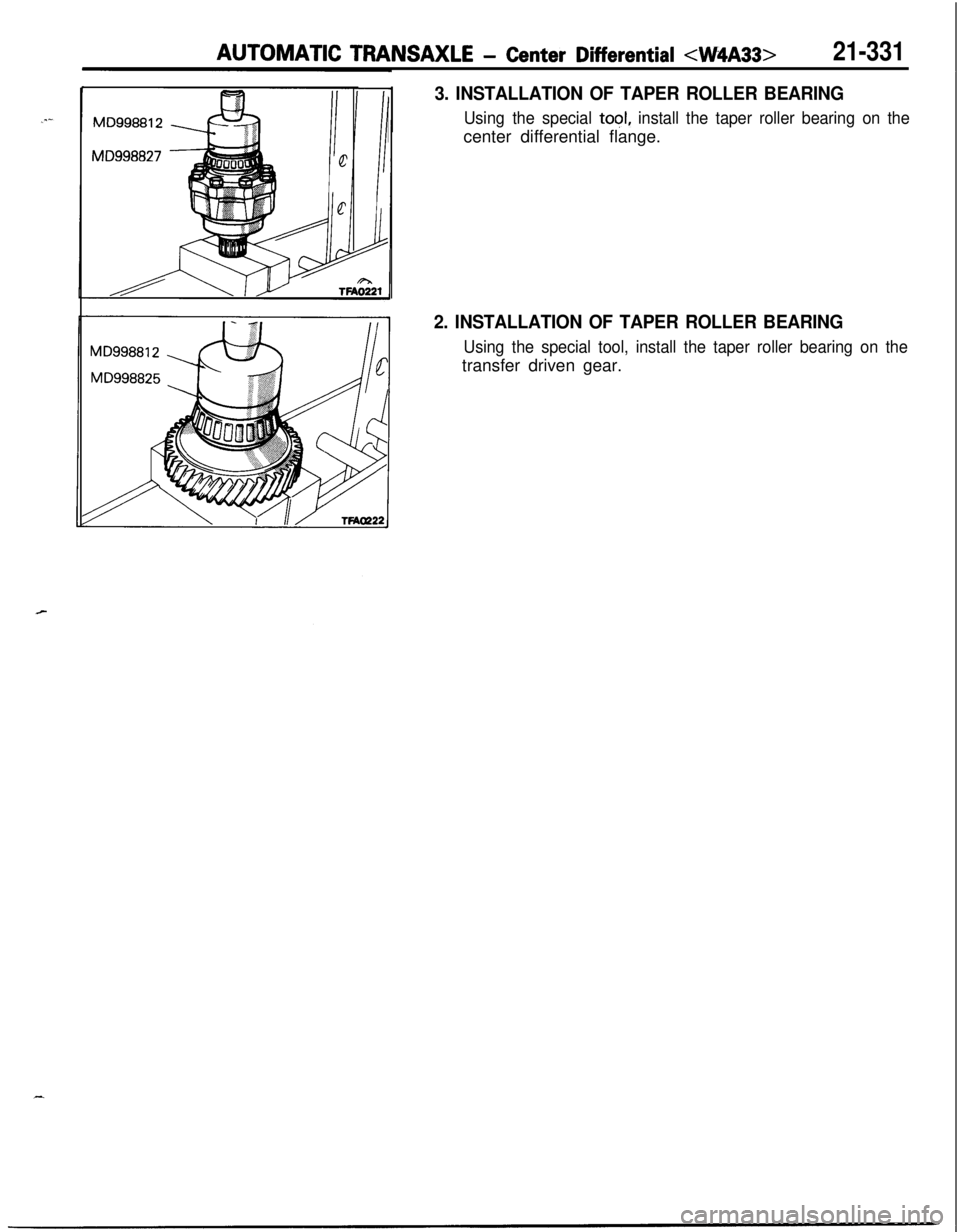

3. INSTALLATION OF TAPER ROLLER BEARING

Using the special tool, install the taper roller bearing on thecenter differential flange.

2. INSTALLATION OF TAPER ROLLER BEARING

Using the special tool, install the taper roller bearing on thetransfer driven gear.

Page 1026 of 1216

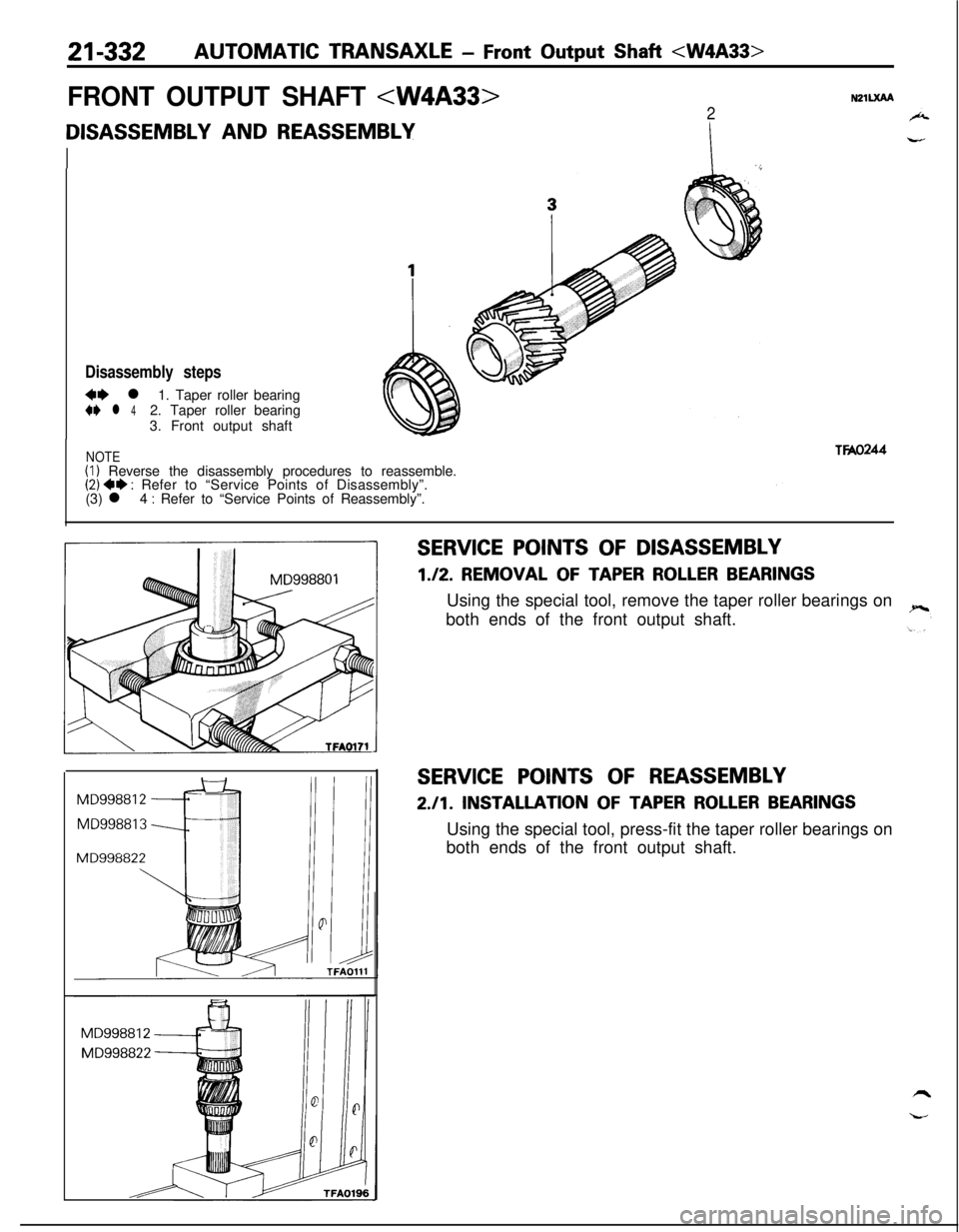

21-332AUTOMATIC TRANSAXLE - Front Output Shaft

FRONT OUTPUT SHAFT

DISASSEMBLY AND REASSEMBLY

II

NZlLXAA

Disassembly steps

*I) l 1. Taper roller bearing+e l 42. Taper roller bearing

3. Front output shaft

NOTE(I) Reverse the disassembly procedures to reassemble.(2) +I) : Refer to “Service Points of Disassembly”.

(3) l 4 : Refer to “Service Points of Reassembly”.

SERVICE POINTS OF DISASSEMBLY1./2. REMOVAL

OF TAPER ROLLER BEARINGSUsing the special tool, remove the taper roller bearings on

both ends of the front output shaft.

MD998822

SERVICE POINTS OF REASSEMBLY

2./l. INSTALLATION OF TAPER ROLLER BEARINGSUsing the special tool, press-fit the taper roller bearings on

both ends of the front output shaft.

Page 1027 of 1216

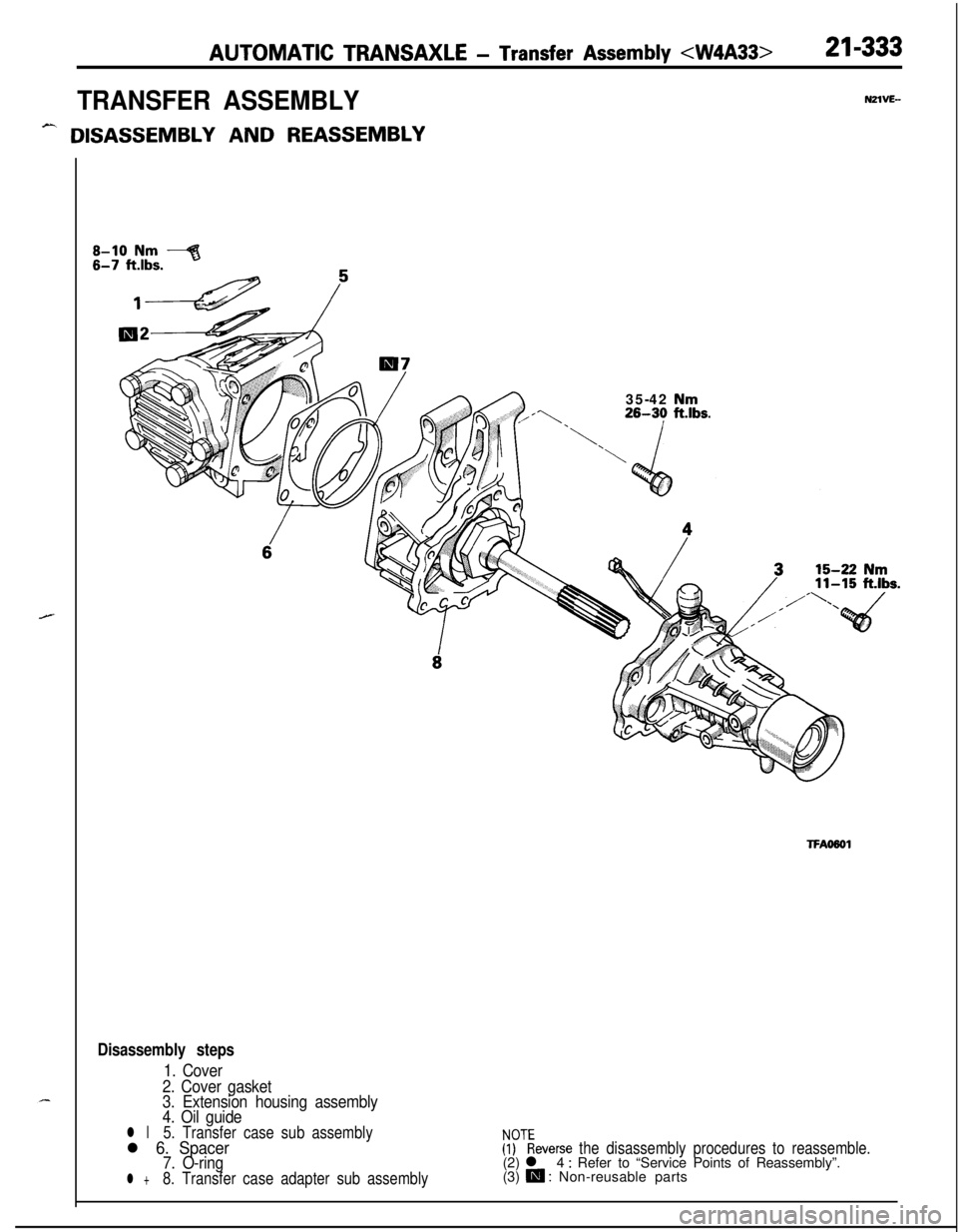

AUTOMATIC TRANSAXLE - Transfer Assembly

TRANSFER ASSEMBLY

- DISASSEMBLY AND REASSEMBLY

21-333

NElVE-35-42

Nm26-30 ft.lbs.

TFAO601

Disassembly steps

1. Cover

2. Cover gasket

3. Extension housing assembly

4. Oil guide

l I5. Transfer case sub assemblyl 6. Spacer7. O-ring

l +8. Transfer case adapter sub assembly

$?everse the disassembly procedures to reassemble.(2) l 4 : Refer to “Service Points of Reassembly”.

(3) m : Non-reusable parts

Page 1028 of 1216

21-334AUTOMATIC TRANSAXLE - Transfer Assemblv

2210050

-TifAO315

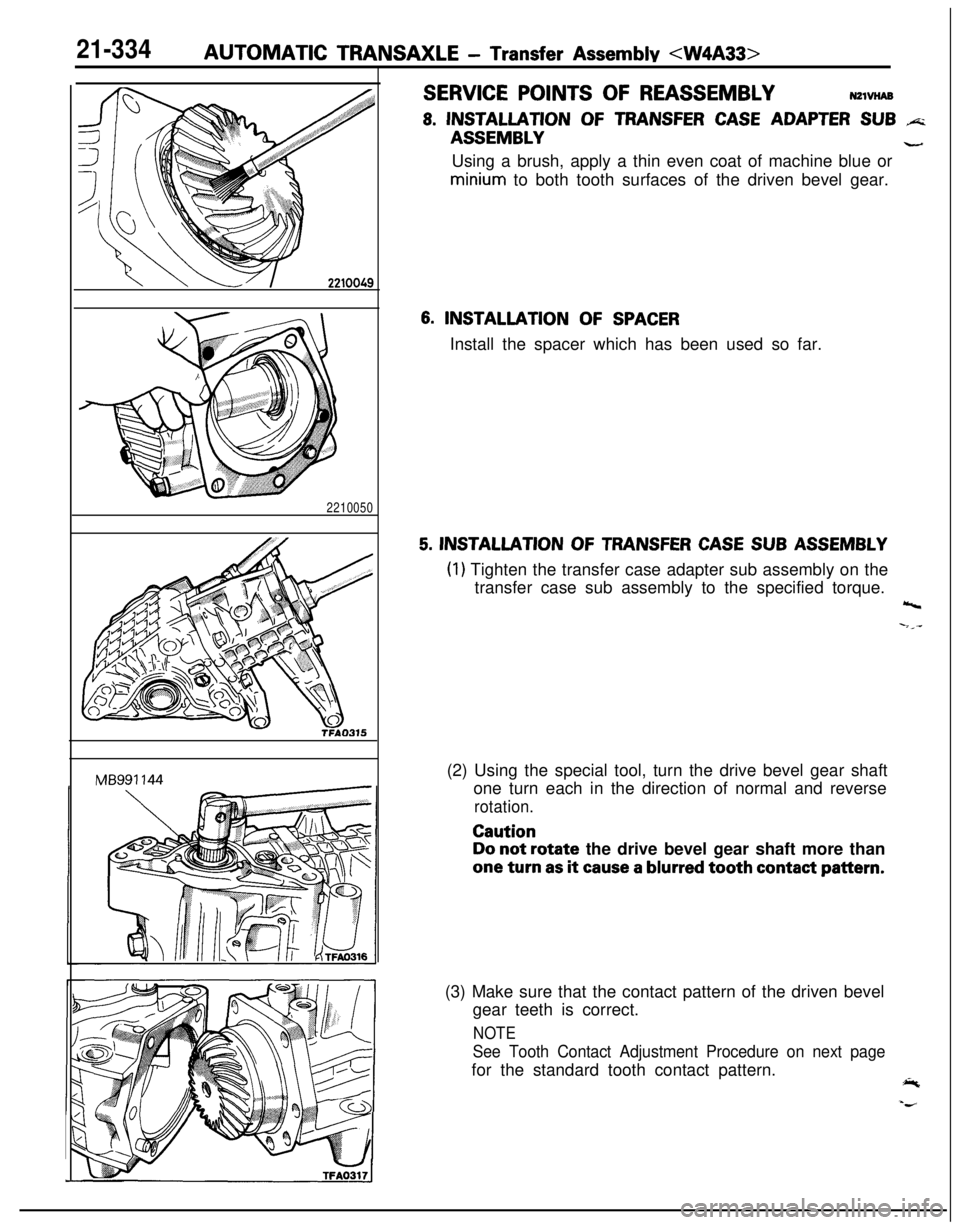

SERVICE POINTS OF REASSEMBLYWmnAE

8. INSTALLATION OF TRANSFER CASE ADAPTER SUB +=GASSEMBLY

-Using a brush, apply a thin even coat of machine blue orminium to both tooth surfaces of the driven bevel gear.

6. INSTALLATION OF SPACERInstall the spacer which has been used so far.

5. INSTALLATION OF TRANSFER CASE SUB ASSEMBLY

(1) Tighten the transfer case adapter sub assembly on the

transfer case sub assembly to the specified torque.

\

-;--.(2) Using the special tool, turn the drive bevel gear shaft

one turn each in the direction of normal and reverse

rotation.Caution

Do not rotate the drive bevel gear shaft more thanone turn

as it cause a blurred tooth contact pattern.

MB991144(3) Make sure that the contact pattern of the driven bevel

gear teeth is correct.

NOTE

See Tooth Contact Adjustment Procedure on next pagefor the standard tooth contact pattern.

4

-am--

Page 1029 of 1216

AUTOMATIC TRANSAXLE - Transfer Assembly

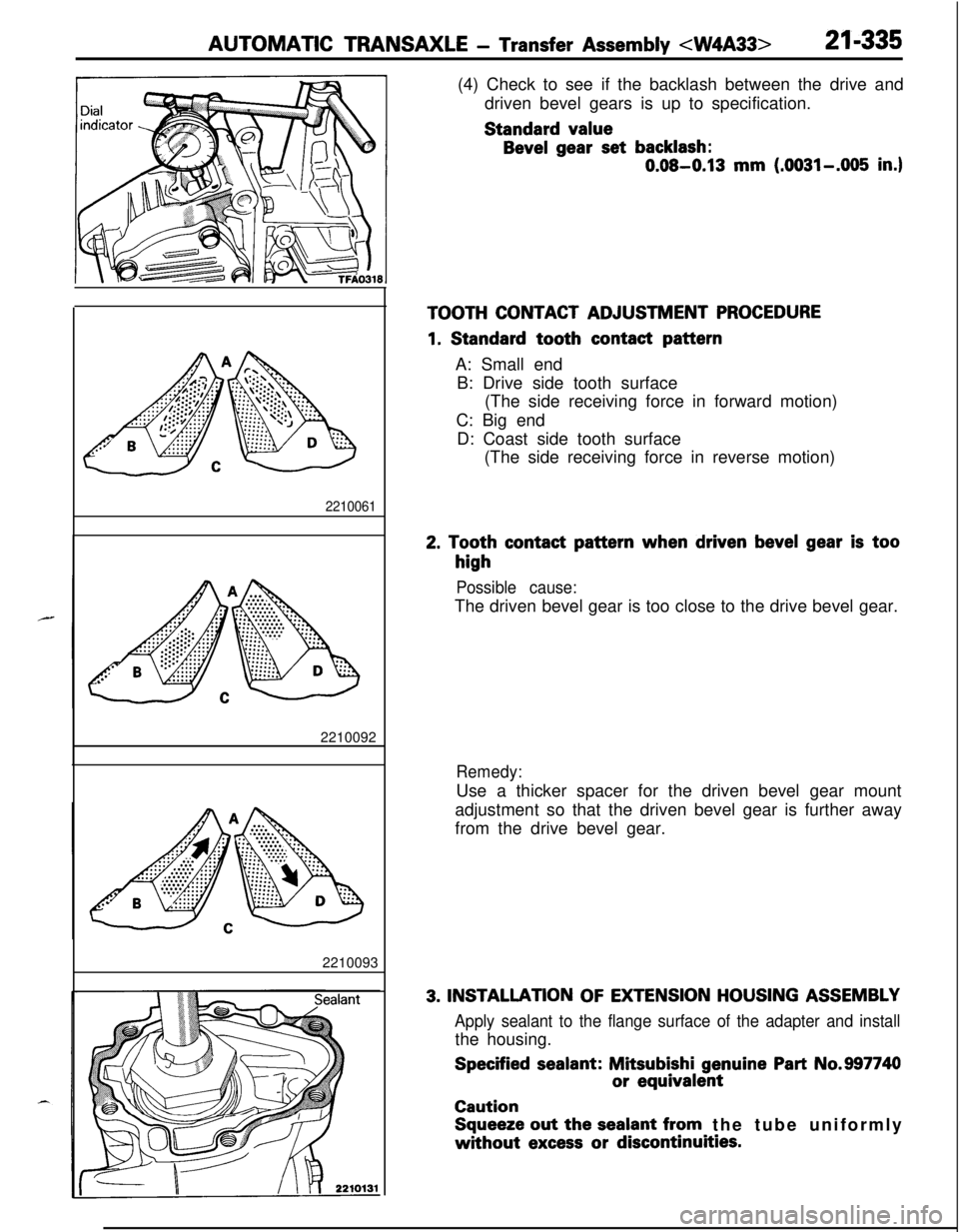

driven bevel gears is up to specification.Standard value

Bevel gear set backlash:

0.08-0.13 mm (.0031-.005 in.)

22100612210092

2210093

TOOTH CONTACT ADJUSTMENT PROCEDURE

1. Standard tooth contact pattern

A: Small end

B: Drive side tooth surface

(The side receiving force in forward motion)

C: Big end

D: Coast side tooth surface

(The side receiving force in reverse motion)

2. Tooth contact pattern when driven bevel gear is too

high

Possible cause:The driven bevel gear is too close to the drive bevel gear.

Remedy:Use a thicker spacer for the driven bevel gear mount

adjustment so that the driven bevel gear is further away

from the drive bevel gear.

3. INSTALLATlON OF EXTENSION HOUSING ASSEMBLY

Apply sealant to the flange surface of the adapter and installthe housing.

Specified sealant: Mitsubishi genuine Part No.997740Caution

or equivalentSqueeze out

the sealant from the tube uniformly

without excess or discontinuities.

Page 1030 of 1216

21-336AUTOMATIC TRANSAXLE - Transfer Assembly

2210095

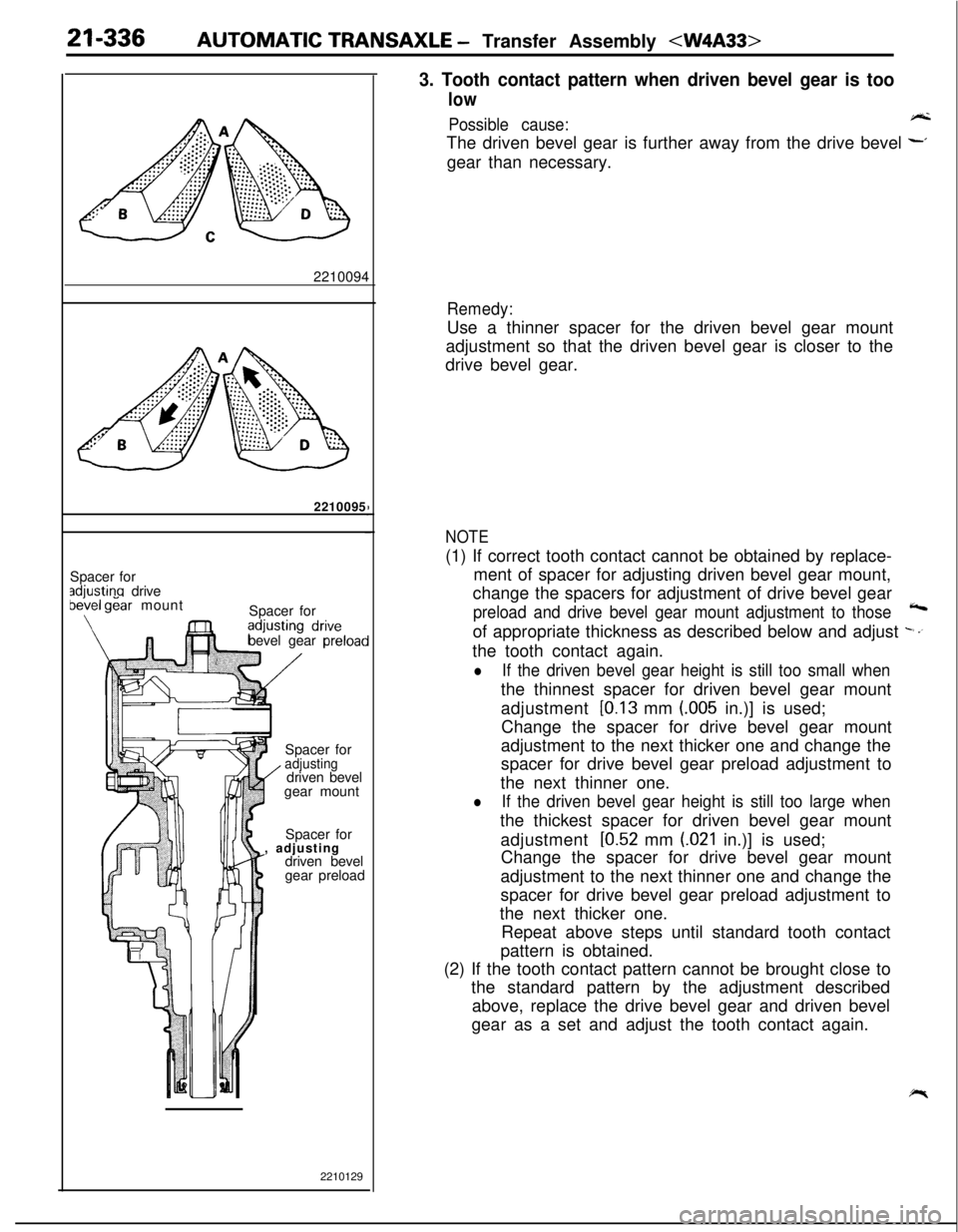

Spacer for

adiustina drivebekel gear mount

\Spacer for

bevel gear preloacSpacer for

adjusting/ driven bevel

gear mount

Spacer for

, adjusting

driven bevel

gear preload

2210129

3. Tooth contact pattern when driven bevel gear is too

low

Possible cause:A-kThe driven bevel gear is further away from the drive bevel

~gear than necessary.

Remedy:Use a thinner spacer for the driven bevel gear mount

adjustment so that the driven bevel gear is closer to the

drive bevel gear.

NOTE(1) If correct tooth contact cannot be obtained by replace-

ment of spacer for adjusting driven bevel gear mount,

change the spacers for adjustment of drive bevel gear

preload and drive bevel gear mount adjustment to those4of appropriate thickness as described below and adjust

-.’the tooth contact again.

lIf the driven bevel gear height is still too small whenthe thinnest spacer for driven bevel gear mount

adjustment

[0.13 mm (.005 in.)] is used;

Change the spacer for drive bevel gear mount

adjustment to the next thicker one and change the

spacer for drive bevel gear preload adjustment to

the next thinner one.

lIf the driven bevel gear height is still too large whenthe thickest spacer for driven bevel gear mount

adjustment

[0.52 mm (021 in.)] is used;

Change the spacer for drive bevel gear mount

adjustment to the next thinner one and change the

spacer for drive bevel gear preload adjustment to

the next thicker one.

Repeat above steps until standard tooth contact

pattern is obtained.

(2) If the tooth contact pattern cannot be brought close to

the standard pattern by the adjustment described

above, replace the drive bevel gear and driven bevel

gear as a set and adjust the tooth contact again.