MITSUBISHI ECLIPSE 1991 Service Manual

ECLIPSE 1991

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57104/w960_57104-0.png

MITSUBISHI ECLIPSE 1991 Service Manual

Trending: oil pressure, battery location, battery capacity, coolant level, rear view mirror, octane, roof

Page 971 of 1216

-

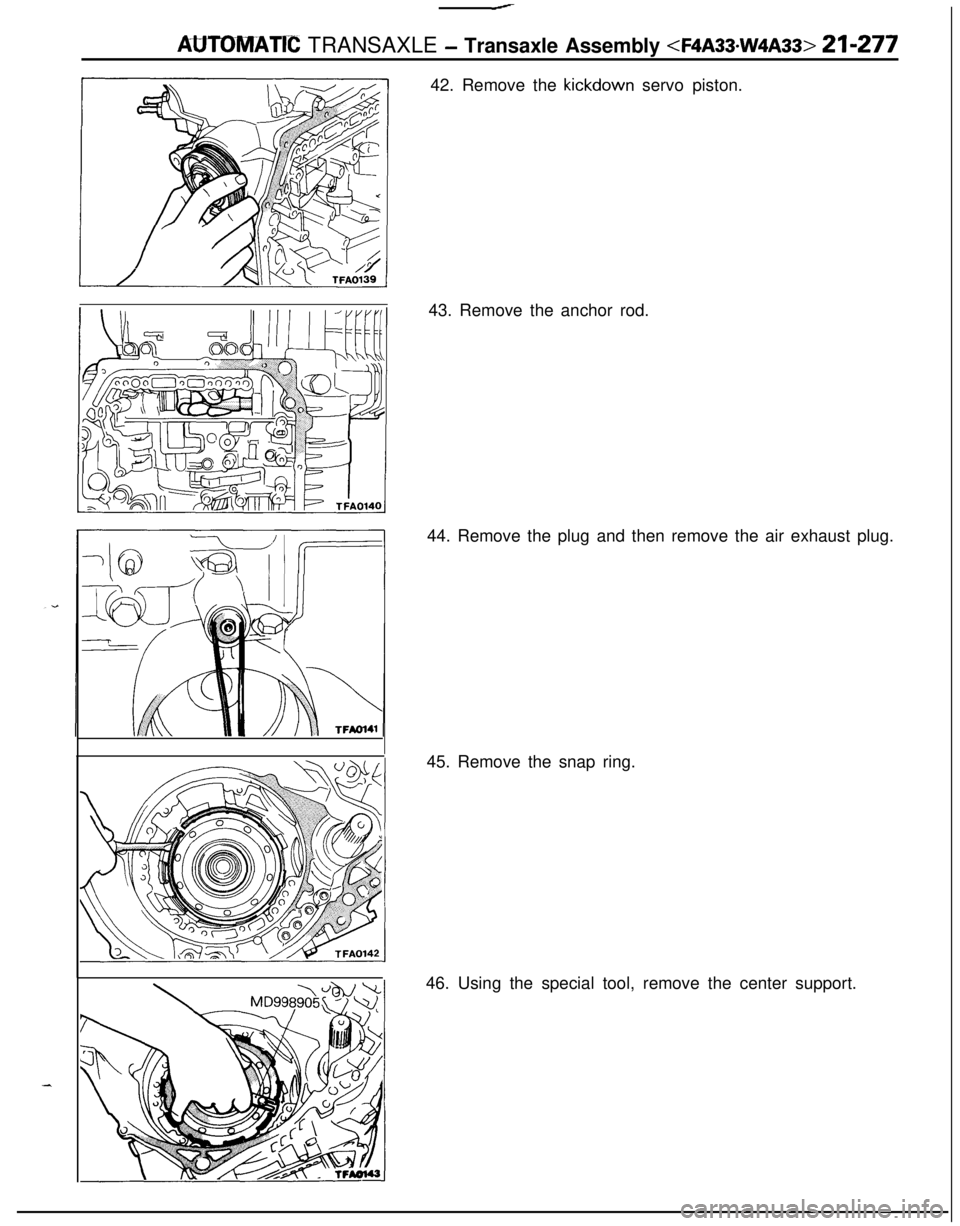

AUlDlpTATTc TRANSAXLE - Transaxle Assembly 21-27742. Remove the

kickdown servo piston.

43. Remove the anchor rod.

44. Remove the plug and then remove the air exhaust plug.

45. Remove the snap ring.

46. Using the special tool, remove the center support.

Page 972 of 1216

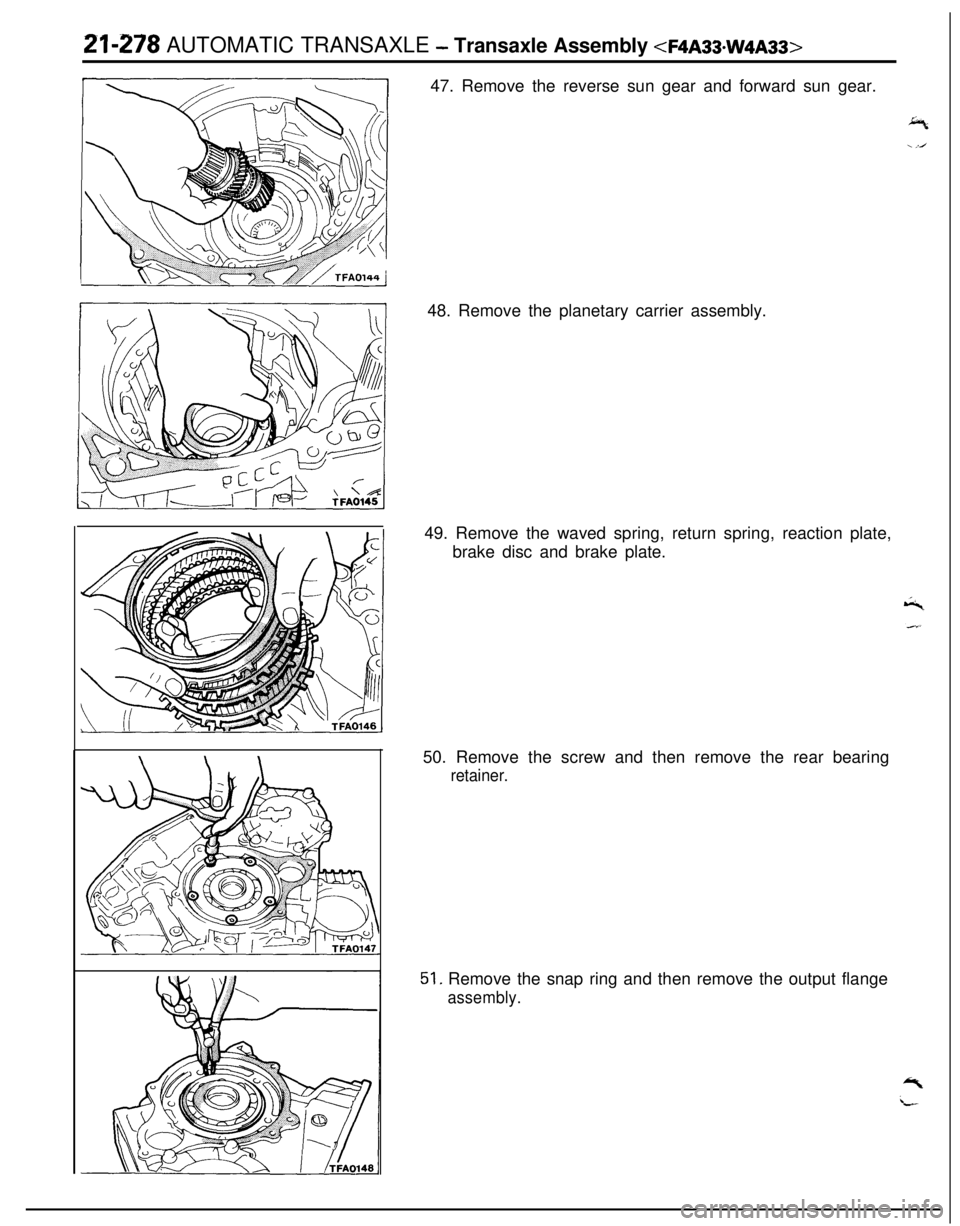

21-278 AUTOMATIC TRANSAXLE - Transaxle Assembly 47. Remove the reverse sun gear and forward sun gear.

648. Remove the planetary carrier assembly.

49. Remove the waved spring, return spring, reaction plate,

brake disc and brake plate.

50. Remove the screw and then remove the rear bearing

retainer.

51. Remove the snap ring and then remove the output flange

assembly.

Page 973 of 1216

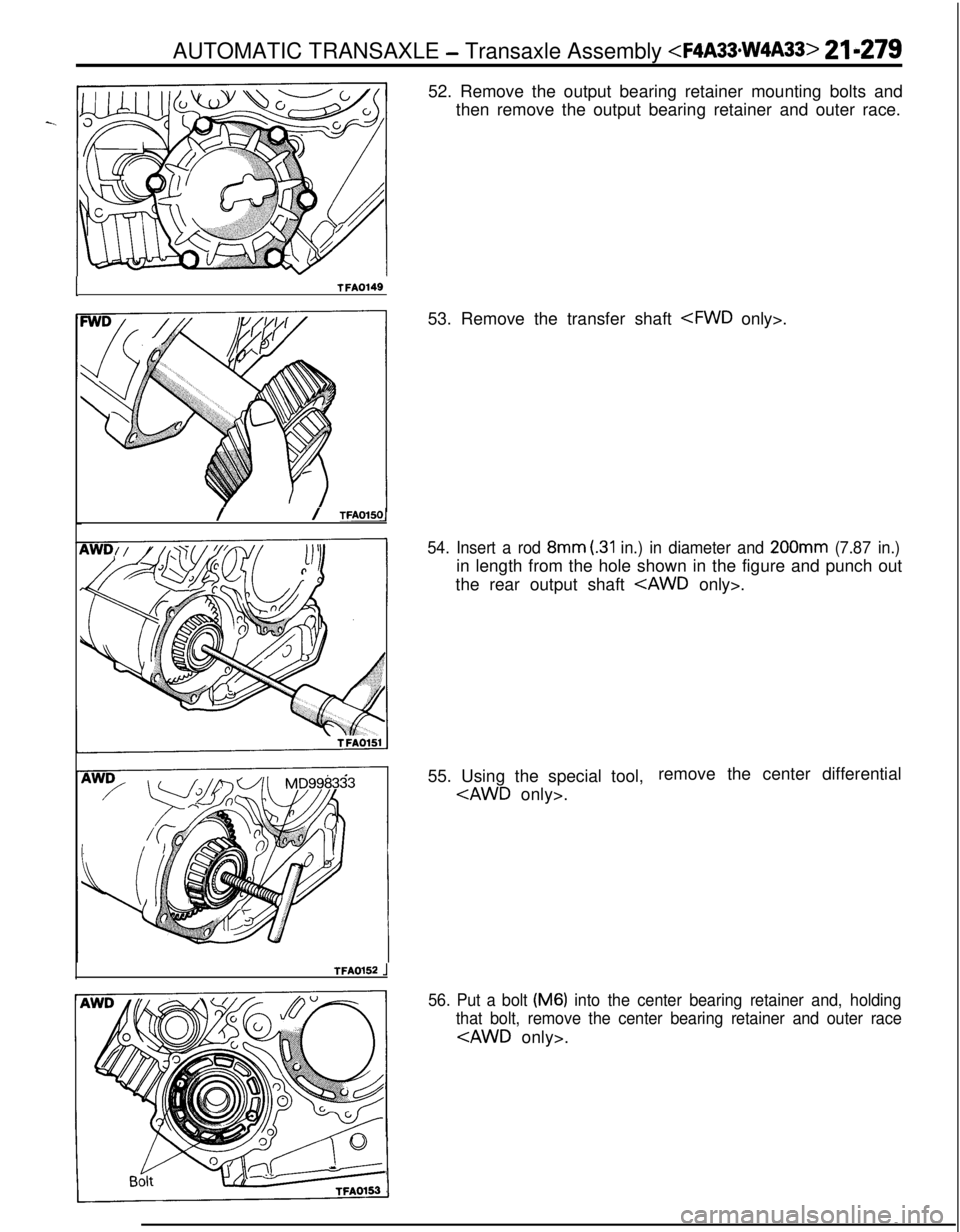

ITFA014952. Remove the output bearing retainer mounting bolts and

then remove the output bearing retainer and outer race.

// TFAOlSOl53. Remove the transfer shaft .

54. Insert a rod 8mm (.31 in.) in diameter and 200mm (7.87 in.)in length from the hole shown in the figure and punch out

the rear output shaft

. AUTOMATIC TRANSAXLE

- Transaxle Assembly 21-279

TFA0152 .j55. Using the special tool,remove the center differential

.

56. Put a bolt (M6) into the center bearing retainer and, holding

that bolt, remove the center bearing retainer and outer race

.

Page 974 of 1216

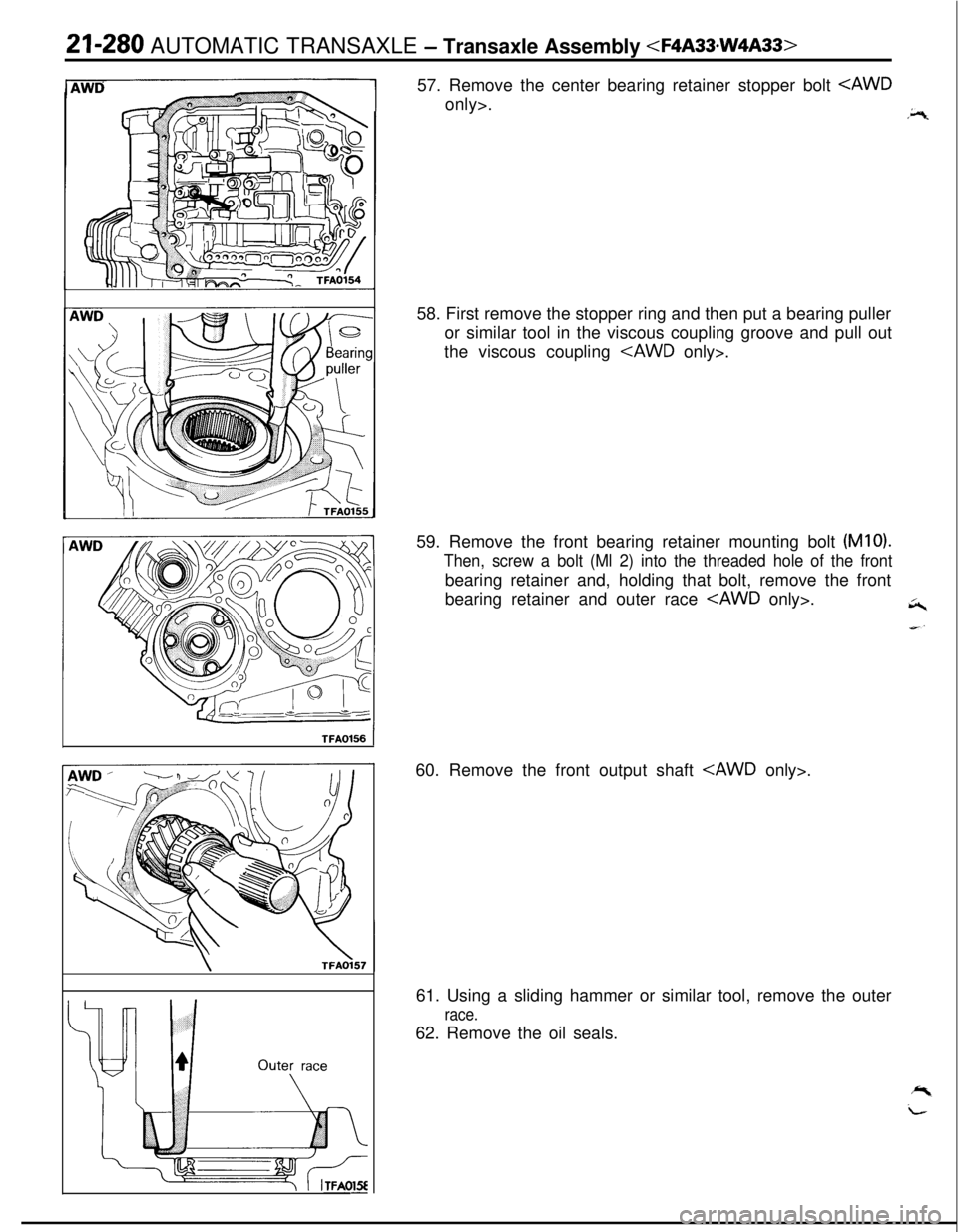

21-280 AUTOMATIC TRANSAXLE - Transaxle Assembly 57. Remove the center bearing retainer stopper bolt

.

A.

TFA0156 158. First remove the stopper ring and then put a bearing puller

or similar tool in the viscous coupling groove and pull out

the viscous coupling

.

59. Remove the front bearing retainer mounting bolt

(MIO).

Then, screw a bolt (Ml 2) into the threaded hole of the frontbearing retainer and, holding that bolt, remove the front

bearing retainer and outer race

.660. Remove the front output shaft

.

61. Using a sliding hammer or similar tool, remove the outer

race.62. Remove the oil seals.

Page 975 of 1216

AUTOMATIC TRANSAXLE - Transaxle Assembly 21281TFA0159

iWD (Front side)

MD998803

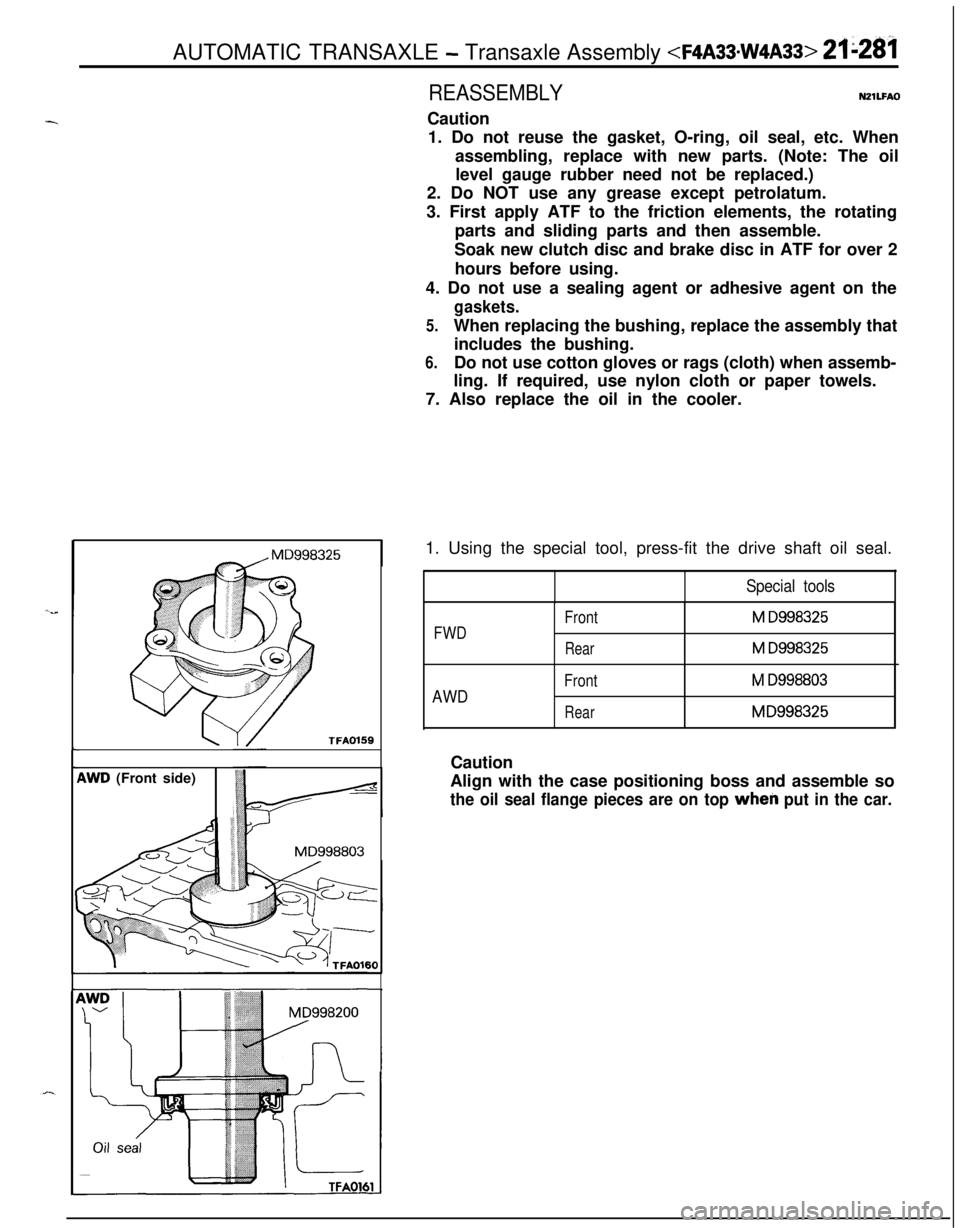

REASSEMBLYCautionNZlLFAO1. Do not reuse the gasket, O-ring, oil seal, etc. When

assembling, replace with new parts. (Note: The oil

level gauge rubber need not be replaced.)

2. Do NOT use any grease except petrolatum.

3. First apply ATF to the friction elements, the rotating

parts and sliding parts and then assemble.

Soak new clutch disc and brake disc in ATF for over 2

hours before using.

4. Do not use a sealing agent or adhesive agent on the

gaskets.

5.When replacing the bushing, replace the assembly that

includes the bushing.

6.Do not use cotton gloves or rags (cloth) when assemb-

ling. If required, use nylon cloth or paper towels.

7. Also replace the oil in the cooler.

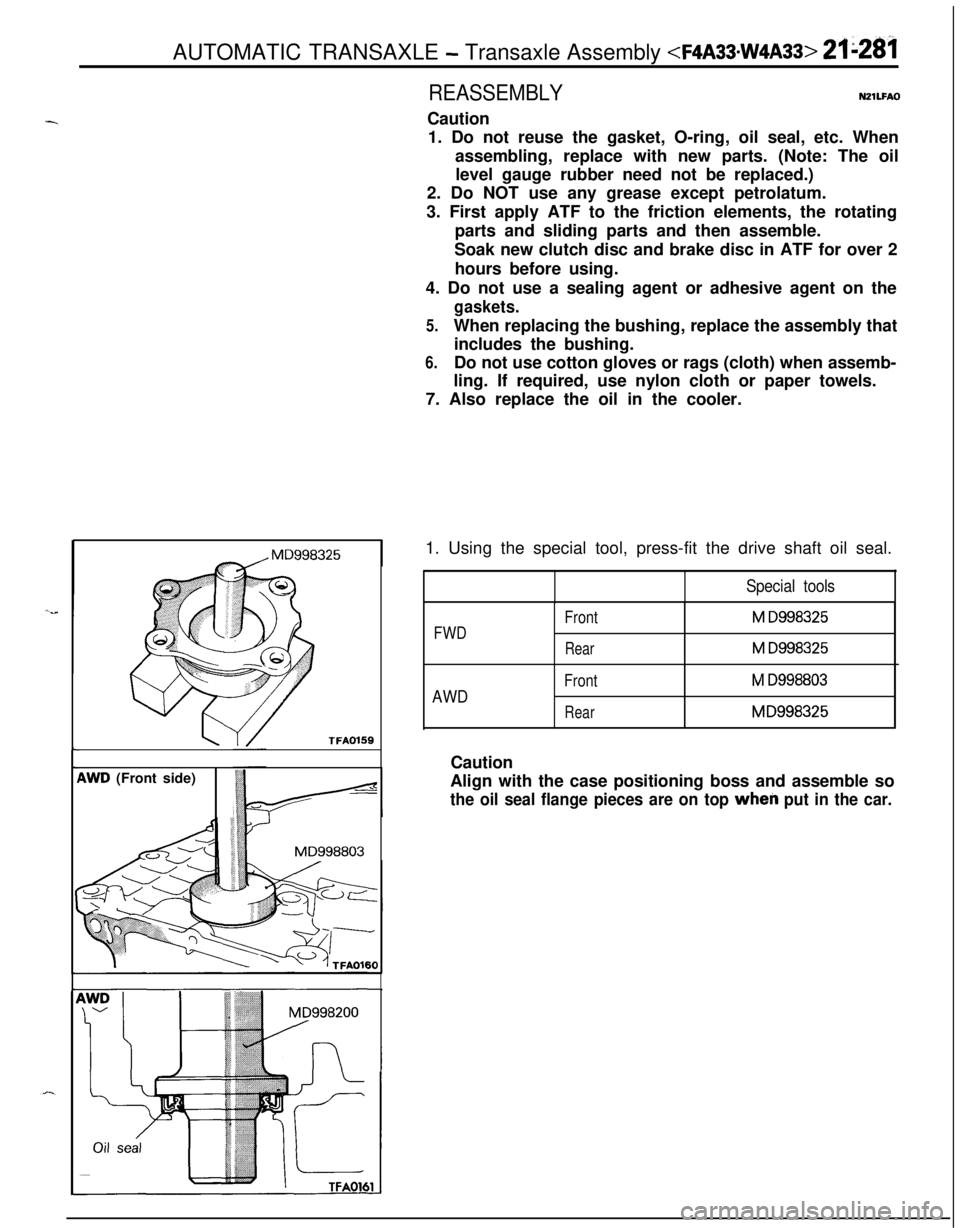

1. Using the special tool, press-fit the drive shaft oil seal.

Special tools

FWD

AWD

FrontM D998325

RearM D998325

Front

M D998803

RearMD998325Caution

Align with the case positioning boss and assemble so

the oil seal flange pieces are on top wheh put in the car.

Page 976 of 1216

21-282 AUTOMATIC TRANSAXLE - Transaxle Assembly

\TFAOi57

AWDTFAOl63

bearing retainerTFA0156

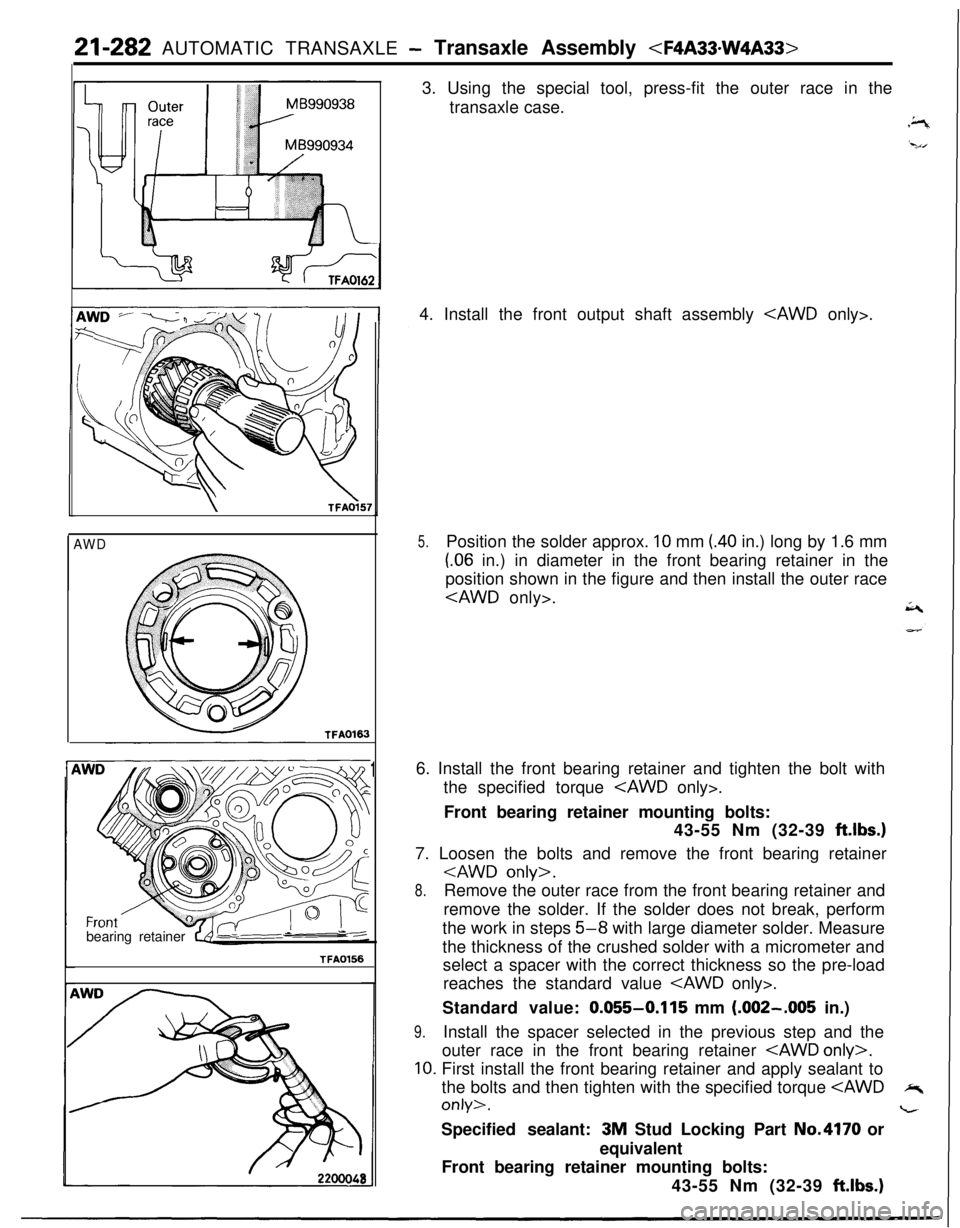

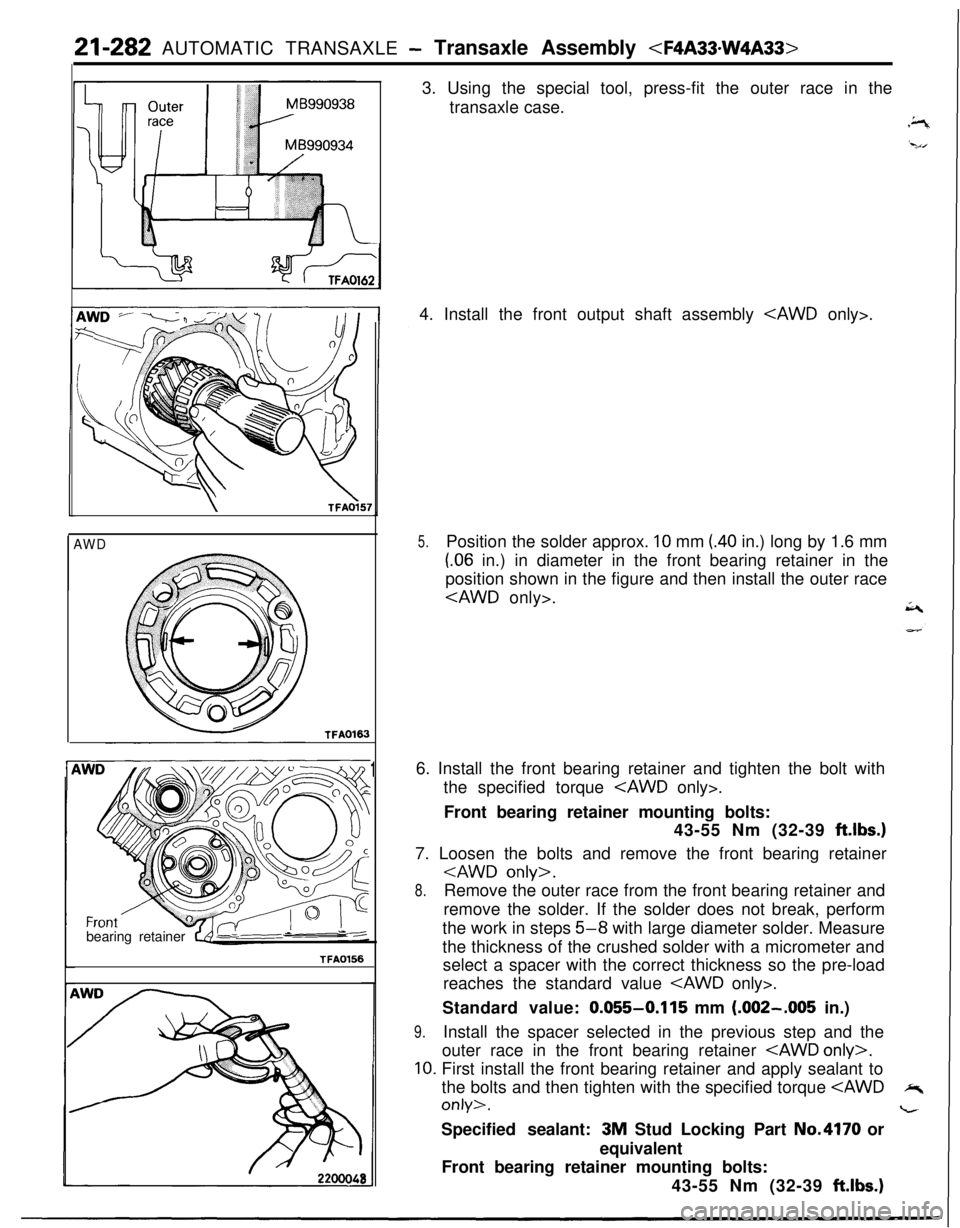

13. Using the special tool, press-fit the outer race in the

transaxle case.

4. Install the front output shaft assembly

.

5.Position the solder approx. 10 mm (.40 in.) long by 1.6 mm

(.06 in.) in diameter in the front bearing retainer in the

position shown in the figure and then install the outer race

cAWD only>.A6. Install the front bearing retainer and tighten the bolt with

the specified torque

.

Front bearing retainer mounting bolts:

43-55 Nm (32-39

ft.lbs.)7. Loosen the bolts and remove the front bearing retainer

.

8.Remove the outer race from the front bearing retainer and

remove the solder. If the solder does not break, perform

the work in steps

5-8 with large diameter solder. Measure

the thickness of the crushed solder with a micrometer and

select a spacer with the correct thickness so the pre-load

reaches the standard value

.

Standard value:

0.055-0.115 mm (.002-.005 in.)

9.Install the spacer selected in the previous step and the

outer race in the front bearing retainer

.

10. First install the front bearing retainer and apply sealant to

the bolts and then tighten with the specified torque

only>.kSpecified sealant: 3M Stud Locking Part No.4170 or

equivalent

Front bearing retainer mounting bolts:

43-55 Nm (32-39

ftlbs.)

Page 977 of 1216

AUTOMATIC TRANSAXLE - Transaxle Assemblv 21-283

6990936TFA016411. Using a bearing puller, support the viscous coupling and

insert in the case. Then, install the stopper ring

only>.12. Using the special tool, install the outer race in the center

bearing retainer.

.13. Install the center bearing retainer stopper bolt

only>.Center bearing retainer stopper bolt:

4-6 Nm (3-4

ft.lbs.)14. Install the center bearing retainer so the projection of the

stopper bolt fits in the groove of the center bearing retainer

.

15. Install the special tool in the center differential and install

the center differential in the transaxle case

.

Page 978 of 1216

21-284 AUTOMATIC TRANSAXLE - Transaxle Assemblv

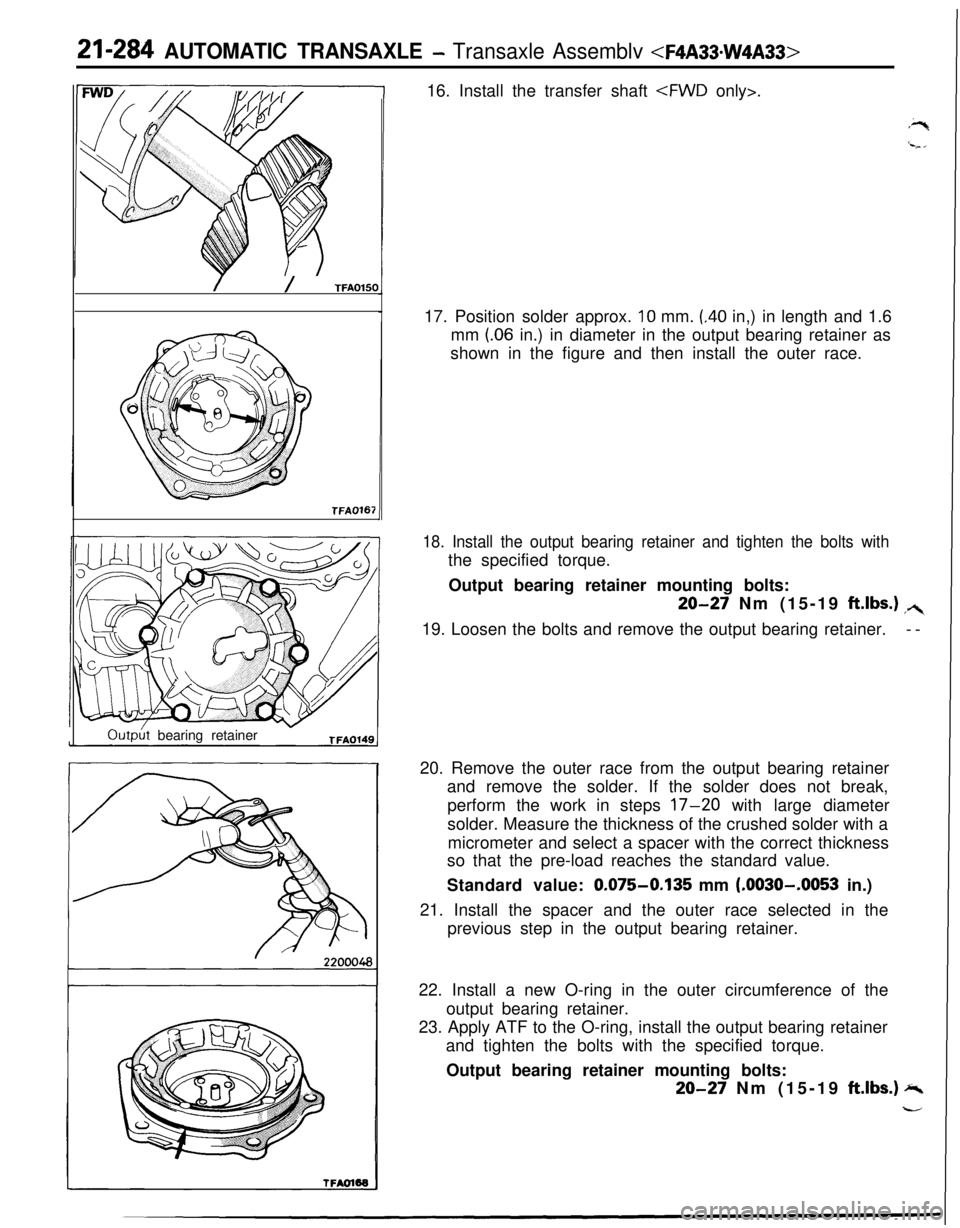

//TFAOlSO

TFA0167

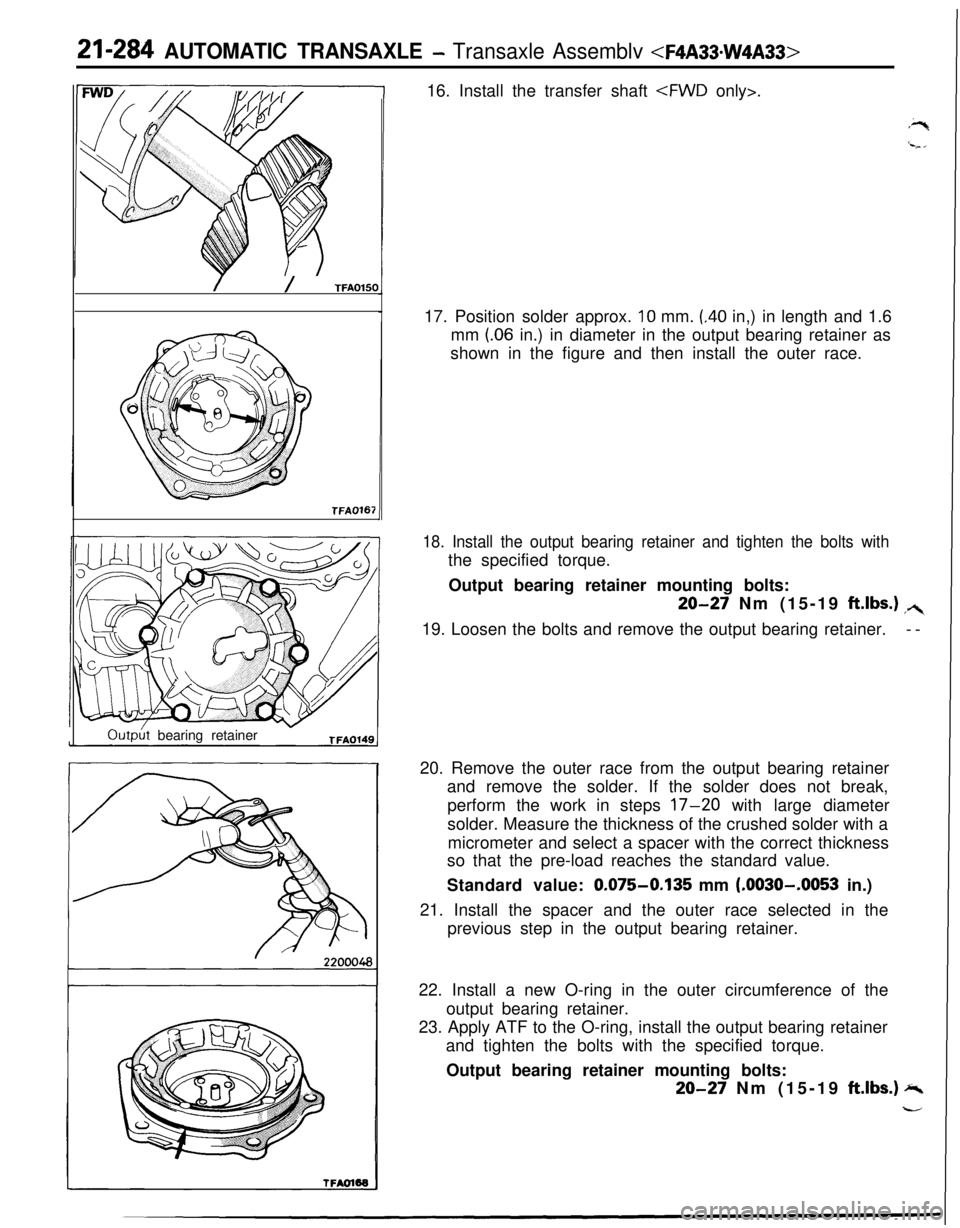

Outph bearing retainerTFAOl4916. Install the transfer shaft .

17. Position solder approx.

10 mm. (.40 in,) in length and 1.6

mm

(06 in.) in diameter in the output bearing retainer as

shown in the figure and then install the outer race.

18. Install the output bearing retainer and tighten the bolts withthe specified torque.

Output bearing retainer mounting bolts:

20-27 Nm (15-19 ft.lbs.) ,+19. Loosen the bolts and remove the output bearing retainer.--

20. Remove the outer race from the output bearing retainer

and remove the solder. If the solder does not break,

perform the work in steps

17-20 with large diameter

solder. Measure the thickness of the crushed solder with a

micrometer and select a spacer with the correct thickness

so that the pre-load reaches the standard value.

Standard value:

0.075-0.135 mm (.0030--0053 in.)

21. Install the spacer and the outer race selected in the

previous step in the output bearing retainer.

22. Install a new O-ring in the outer circumference of the

output bearing retainer.

23. Apply ATF to the O-ring, install the output bearing retainer

and tighten the bolts with the specified torque.

Output bearing retainer mounting bolts:

20-27 Nm (15-19 ft.lbs.) -

-

Page 979 of 1216

AUTOMATIC TRANSAXLE - Transaxle Assembly 21-285

r..

Thrustearing #IO

TFAOlM

\

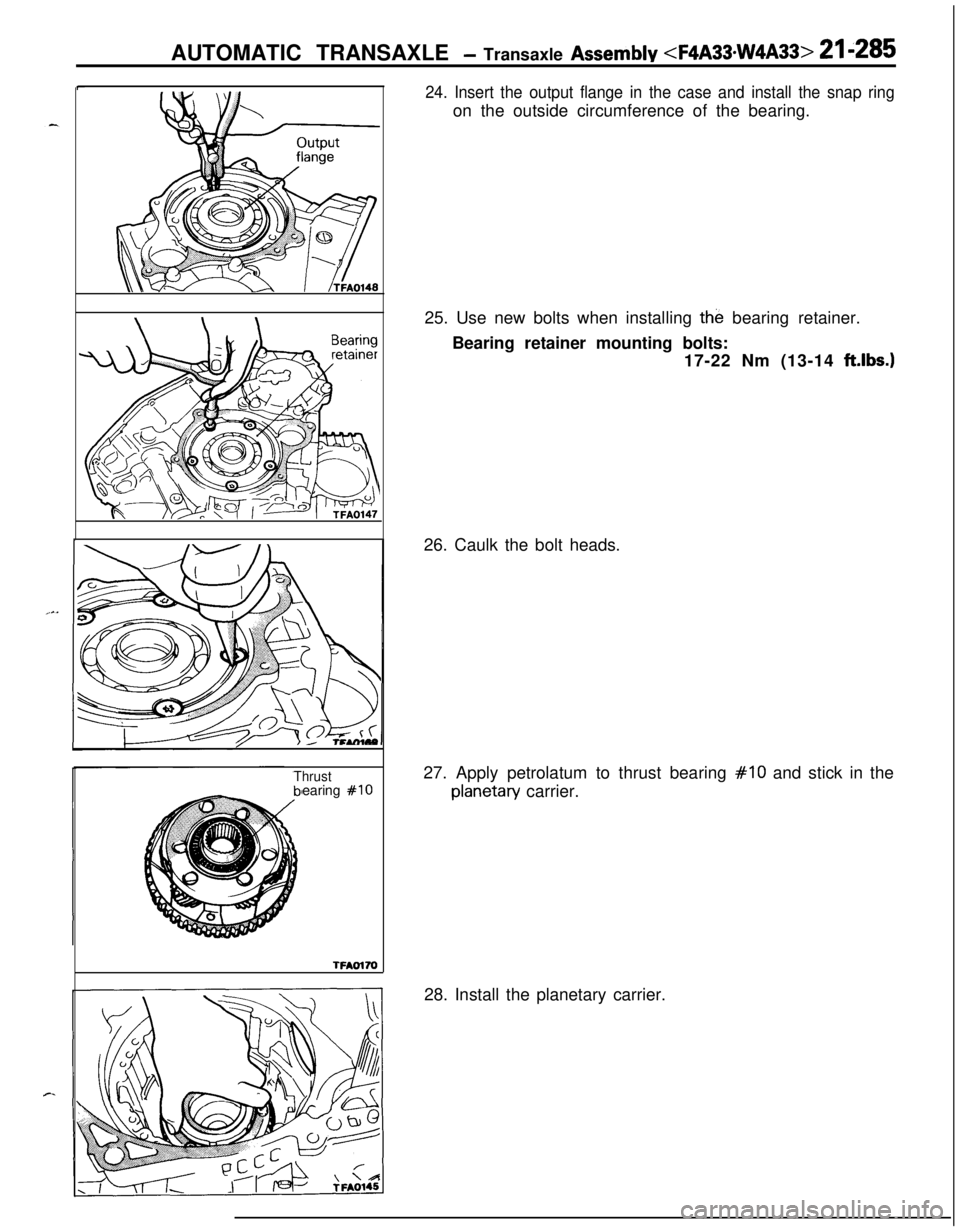

24. Insert the output flange in the case and install the snap ringon the outside circumference of the bearing.

25. Use new bolts when installing

the bearing retainer.

Bearing retainer mounting bolts:

17-22 Nm (13-14

ft.lbs.126. Caulk the bolt heads.

27. Apply petrolatum to thrust bearing

#IO and stick in the

planetary carrier.

28. Install the planetary carrier.

Page 980 of 1216

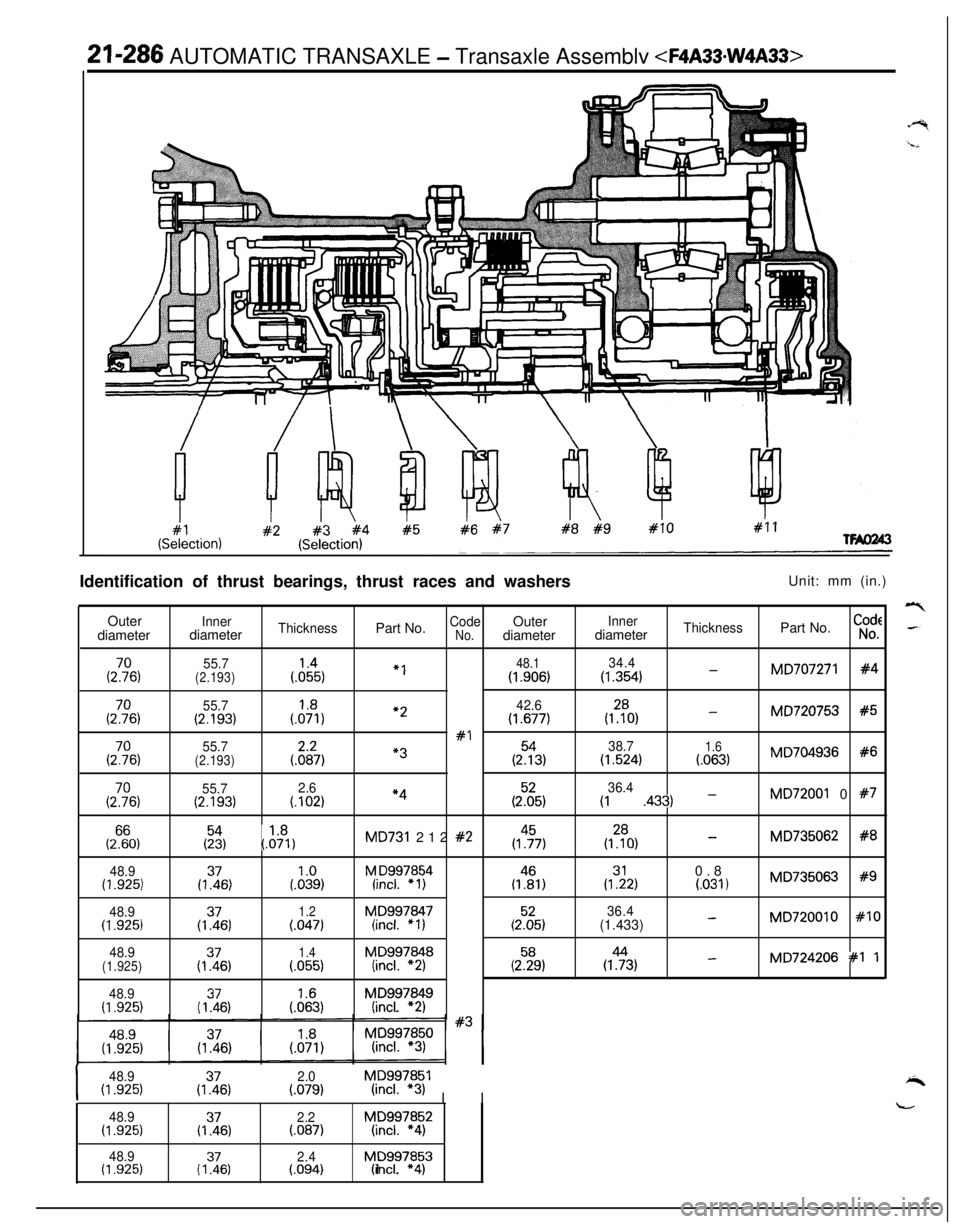

21-286 AUTOMATIC TRANSAXLE - Transaxle Assemblv Identification of thrust bearings, thrust races and washersUnit: mm (in.)

Outer

diameter(2?6,(2Y6,

(2’706,(27%(2T0,

48.9(I ,925)

48.9(I ,925)

48.9(1.925)

48.9(I ,925)

Inner

ThicknessPart No.CodeOuterInnerNo.diameterdiameterThicknessPart No.

diametercE,c

55.71.4*I48.134.4(2.193)(055)(1.906)(1.354) -MD707271 #4

55.71.8(2.193)(.071)‘242.6(I .677)(l?YO) -MD720753 #5

#I55.7c.z7r*3(25;3,38.71.6

(2.193)(I ,524)(.063)MD704936 #6

55.72.636.4(2.193)(.I021*4(25:5,(I ,433) -MD72001 0 #7

(Z,(.El,MD731 212 #2$7,(12130, -MD735062 #8(1?6)

1.0M D997854(.039)(incl. *I)(I%,(I?210.8LO31 1MD735063 #9

(I?&1.2MD997847(25:5,36.4(.047)(incl. *I)(1.433) -MD720010 #IO

(13:6,1.4MD997848(055)(incl. “2)(2Y9,(I?31 -MD724206 #I 1

( 13:6,(.I%,yy7qgI .

I

48.92.0MD997851(I ,925)(1%6,(.079)(incl. “3)

I IL48.9

2.2MD997852(I ,925)(1?6,(.087)(incl. *4)

48.9

( 1?6,2.4(I .925)(.094)y.~~~7~~“,3I .

Trending: check oil, center console, transmission oil, fuel type, coolant capacity, warning light, engine specifications