MITSUBISHI LANCER 2005 Workshop Manual

Manufacturer: MITSUBISHI, Model Year: 2005, Model line: LANCER, Model: MITSUBISHI LANCER 2005Pages: 788, PDF Size: 45.98 MB

Page 161 of 788

REAR AXLE HUB ASSEMBLY

REAR AXLE27-5

REAR AXLE HUB ASSEMBLY

REMOVAL AND INSTALLATIONM1271002000381

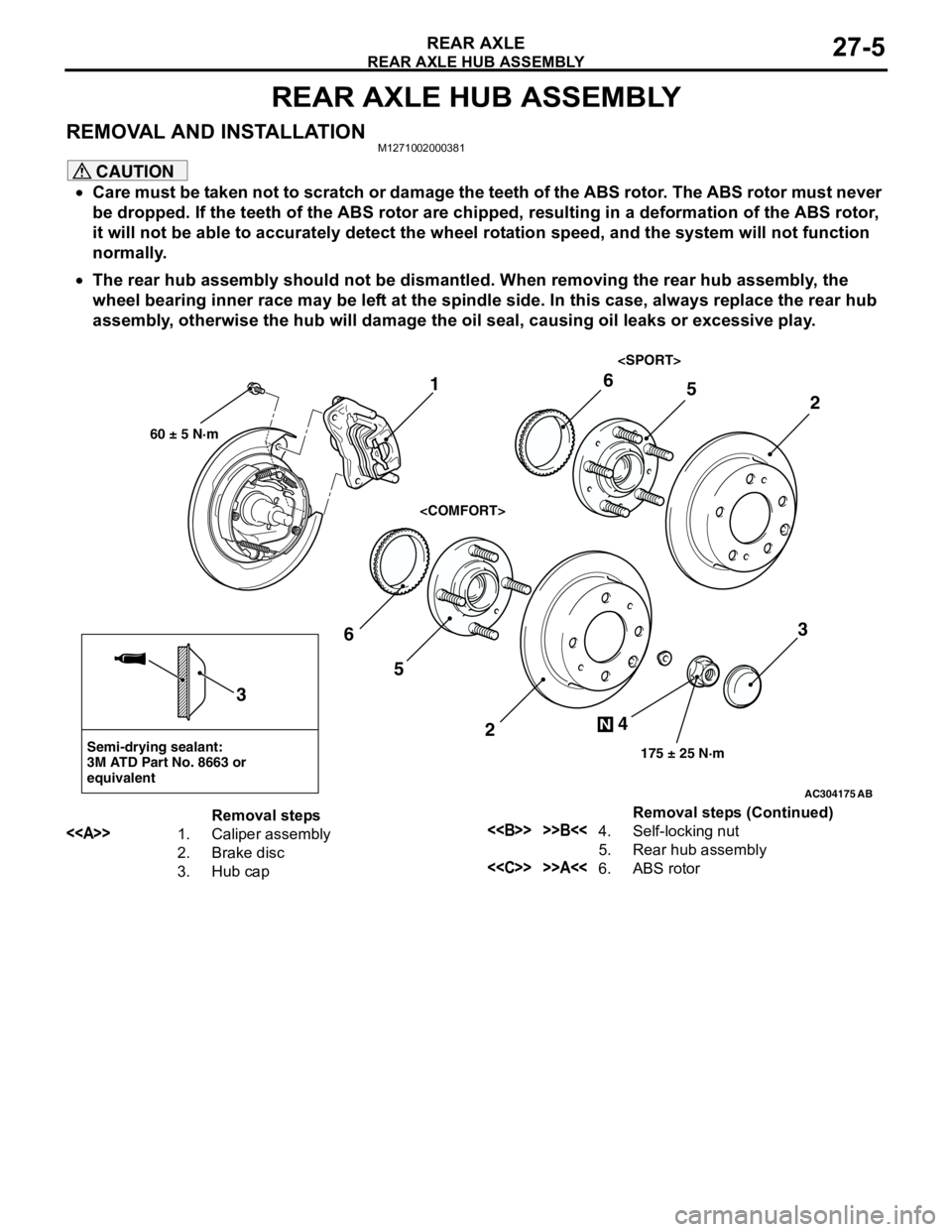

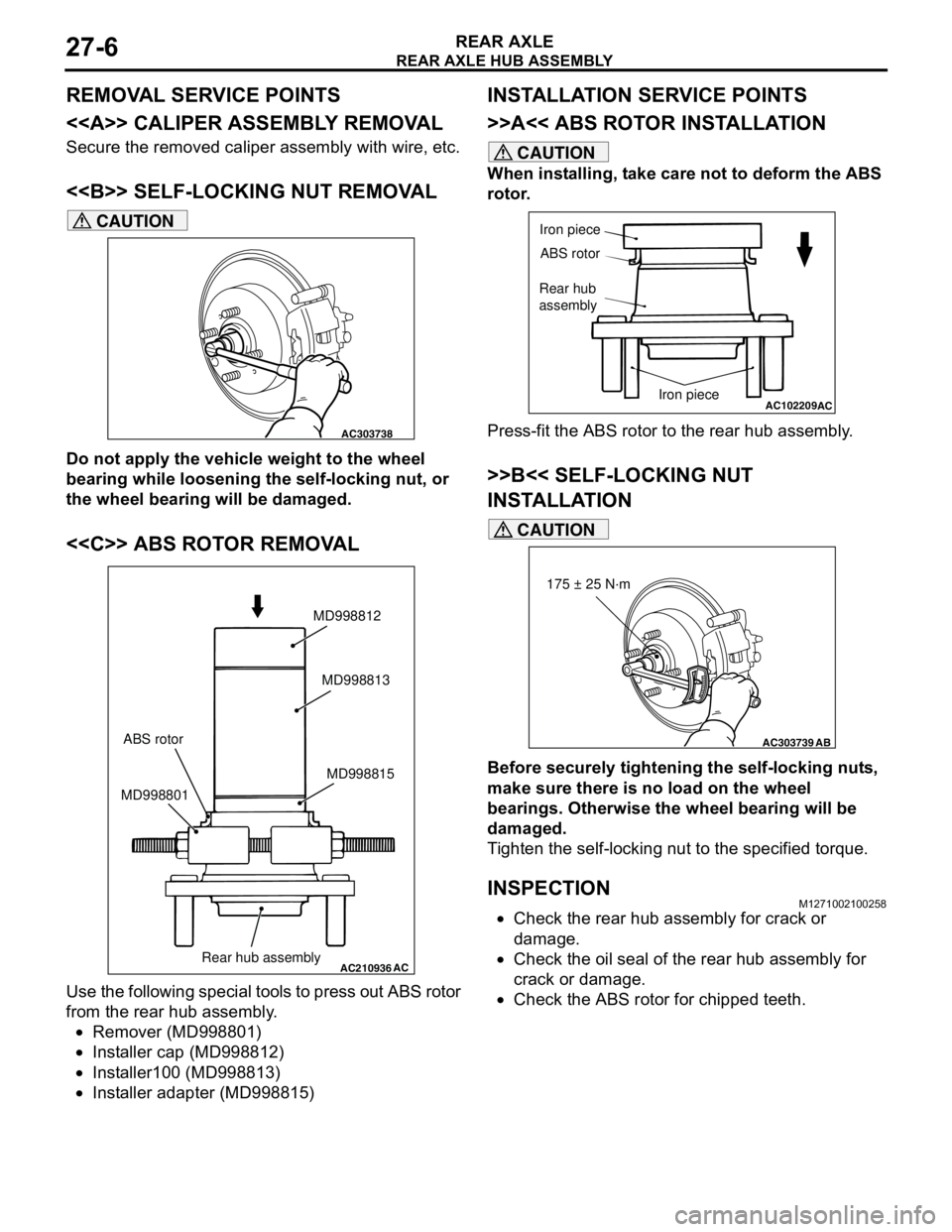

CAUTION

•Care must be taken not to scratch or damage the teeth of the ABS rotor. The ABS rotor must never

be dropped. If the teeth of the ABS rotor are chipped, resulting in a deformation of the ABS rotor,

it will not be able to accurately detect the wheel rotation speed, and the system will not function

normally.

•The rear hub assembly should not be dismantled. When removing the rear hub assembly, the

wheel bearing inner race may be left at the spindle side. In this case, always replace the rear hub

assembly, otherwise the hub will damage the oil seal, causing oil leaks or excessive play.

AC304175

Semi-drying sealant:

3M ATD Part No. 8663 or

equivalent

2

3

5 6

4

N

175 ± 25 N·m

3

AB

1

60 ± 5 N·m

2

56

Removal steps

<>1. Caliper assembly

2. Brake disc

3. Hub cap<> >>B<<4. Self-locking nut

5. Rear hub assembly

<

Page 162 of 788

Page 163 of 788

31-1

GROUP 31

WHEEL AND TYRE

CONTENTS

GENERAL INFORMATION . . . . . . . .31-2

SERVICE SPECIFICATIONS . . . . . . .31-2

TROUBLESHOOTING . . . . . . . . . . . .31-3

DIAGNOSIS . . . . . . . . . . . . . . . . . . . . . . . . 31-3

WHEEL BALANCE ACCURACY . . . . . . . . 31-4

ON-VEHICLE SERVICE . . . . . . . . . . .31-7

TYRE INFLATION PRESSURE CHECK . . . 31-7

TYRE WEAR CHECK . . . . . . . . . . . . . . . . . 31-7

WHEEL RUNOUT CHECK . . . . . . . . . . . . . 31-7

WHEEL AND TYRE . . . . . . . . . . . . . .31-7

INSTALLATION SERVICE POINT . . . . . . . 31-7

Page 164 of 788

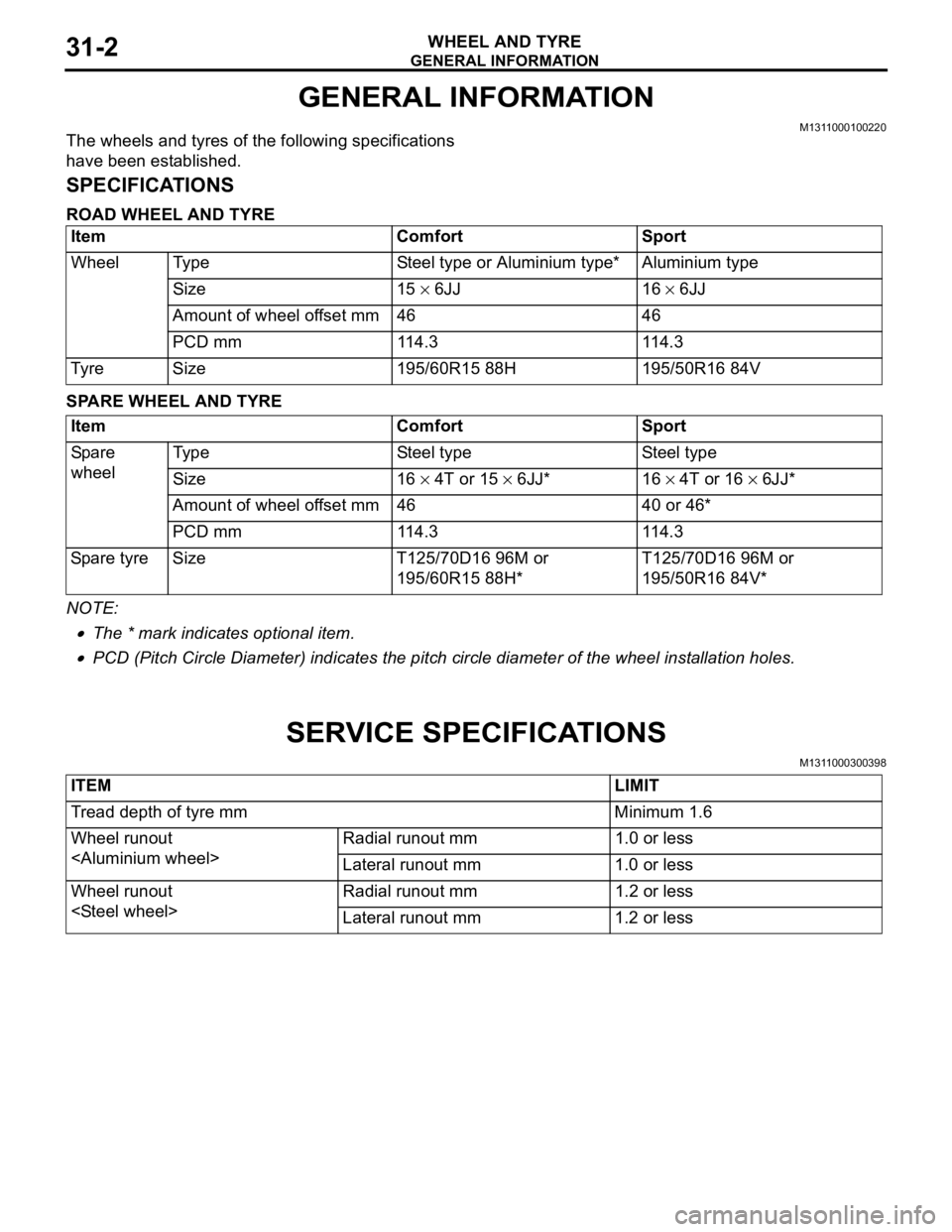

GENERAL INFORMATION

WHEEL AND TYRE31-2

GENERAL INFORMATION

M1311000100220The wheels and tyres of the following specifications

have been established.

SPECIFICATIONS

ROAD WHEEL AND TYRE

SPARE WHEEL AND TYRE

NOTE: .

•The * mark indicates optional item.

•PCD (Pitch Circle Diameter) indicates the pitch circle diameter of the wheel installation holes.

SERVICE SPECIFICATIONS

M1311000300398

Item Comfort Sport

Wheel Type Steel type or Aluminium type* Aluminium type

Size 15 × 6JJ 16 × 6JJ

Amount of wheel offset mm 46 46

PCD mm 114.3 114.3

Tyre Size 195/60R15 88H 195/50R16 84V

Item Comfort Sport

Spare

wheelType Steel type Steel type

Size 16 × 4T or 15 × 6JJ* 16 × 4T or 16 × 6JJ*

Amount of wheel offset mm 46 40 or 46*

PCD mm 114.3 114.3

Spare tyre Size T125/70D16 96M or

195/60R15 88H*T125/70D16 96M or

195/50R16 84V*

ITEM LIMIT

Tread depth of tyre mm Minimum 1.6

Wheel runout

Lateral runout mm 1.0 or less

Wheel runout

Lateral runout mm 1.2 or less

Page 165 of 788

TROUBLESHOOTING

WHEEL AND TYRE31-3

TROUBLESHOOTING

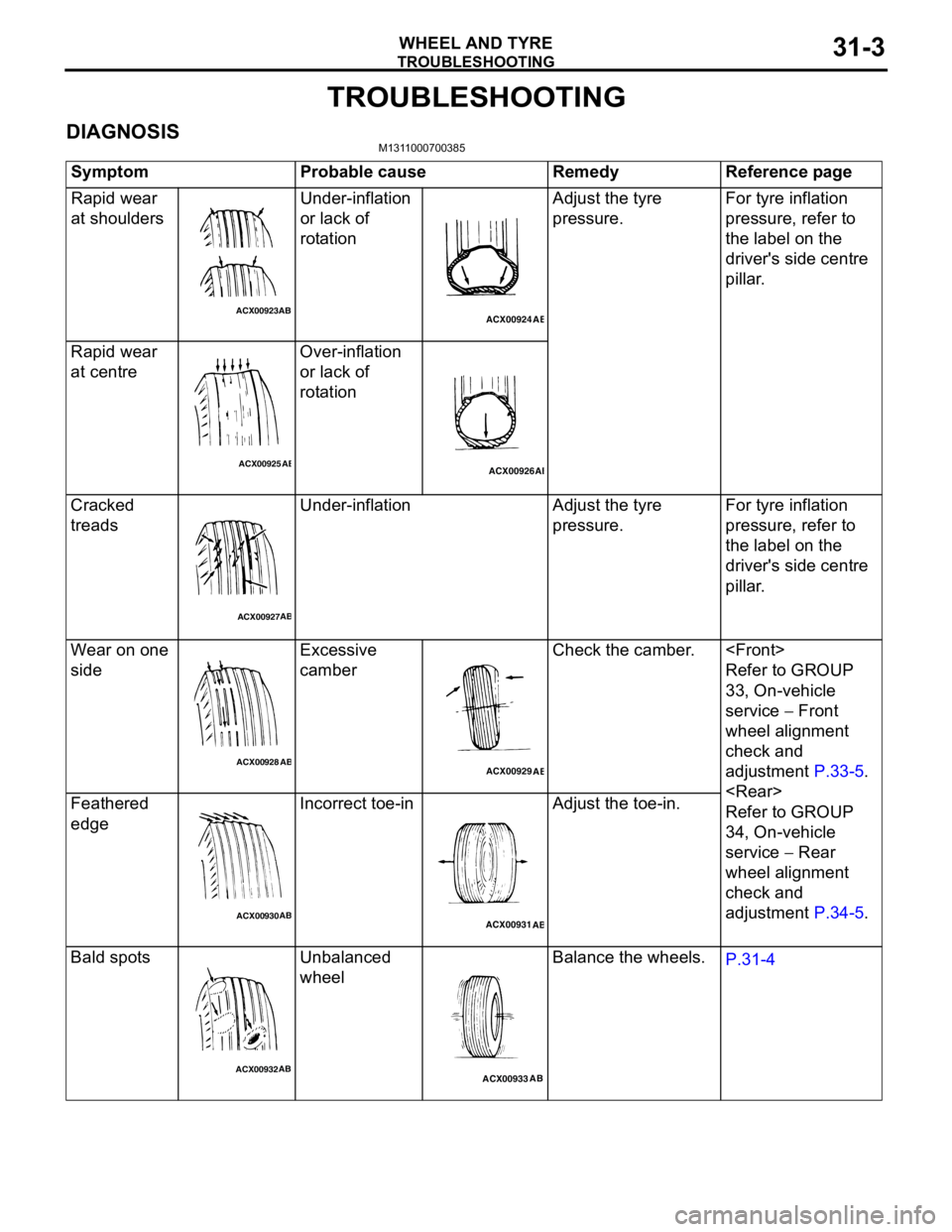

DIAGNOSISM1311000700385

Symptom Probable cause Remedy Reference page

Rapid wear

at shouldersUnder-inflation

or lack of

rotationAdjust the tyre

pressure.For tyre inflation

pressure, refer to

the label on the

driver's side centre

pillar.

Rapid wear

at centreOver-inflation

or lack of

rotation

Cracked

treadsUnder-inflation Adjust the tyre

pressure.For tyre inflation

pressure, refer to

the label on the

driver's side centre

pillar.

Wear on one

sideExcessive

camberCheck the camber.

Refer to GROUP

33, On-vehicle

service − Front

wheel alignment

check and

adjustment P.33-5.

Refer to GROUP

34, On-vehicle

service − Rear

wheel alignment

check and

adjustment P.34-5. Feathered

edgeIncorrect toe-in Adjust the toe-in.

Bald spots Unbalanced

wheelBalance the wheels.

P.31-4

ACX00923ABACX00924

AB

ACX00925ABACX00926AB

ACX00927AB

ACX00928

ABACX00929

AB

ACX00930ABACX00931

AB

ACX00932ABACX00933AB

Page 166 of 788

TROUBLESHOOTING

WHEEL AND TYRE31-4

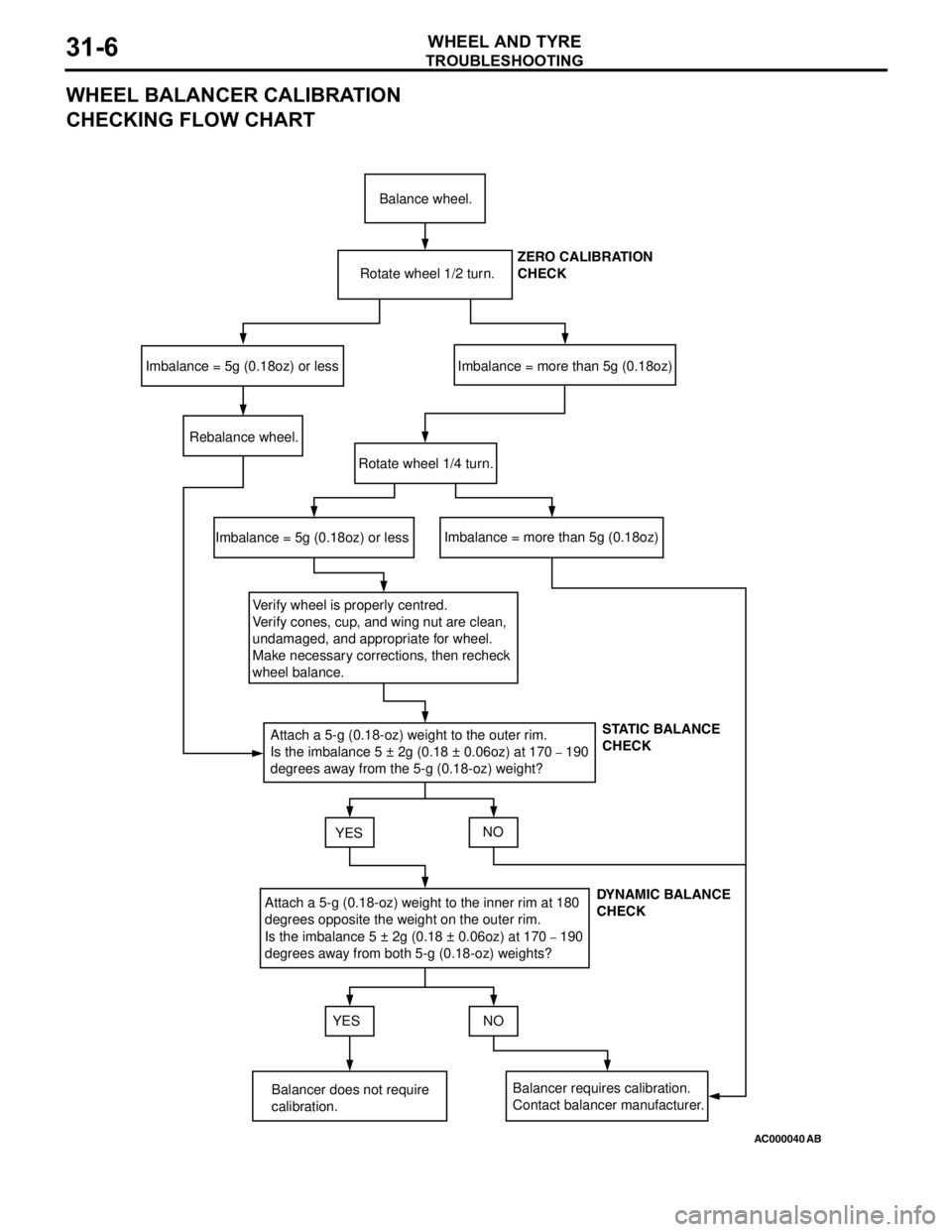

WHEEL BALANCE ACCURACYM1311001700247

PURPOSE

This section contains tips and procedures for

achieving accurate wheel balance. Steering wheel

vibration and/or body shake can result if any of these

procedures are not carefully observed.

1. Wheels and tyres must be properly mounted on a

balancer in order to achieve correct balance.

Centring the wheel on the shaft of the balancer is

essential for proper mounting.

2. Off-the-car wheel balancers must be calibrated

periodically to ensure good balancing results. An

inaccurately calibrated balancer could cause

unnecessary replacement of tyres, shocks,

suspension components, or steering components.

Check your balancer's calibration approximately

every 100 balances. Your wheel balancer's

instruction manual should include calibration

procedures. If the calibration procedures specifically

for your balancer are missing, use the generic steps

in this section for zero calibration, static balance, and

dynamic balance checks. The wheel balancer

calibration checks are also described in the

flowchart. (Refer to P.31-6).

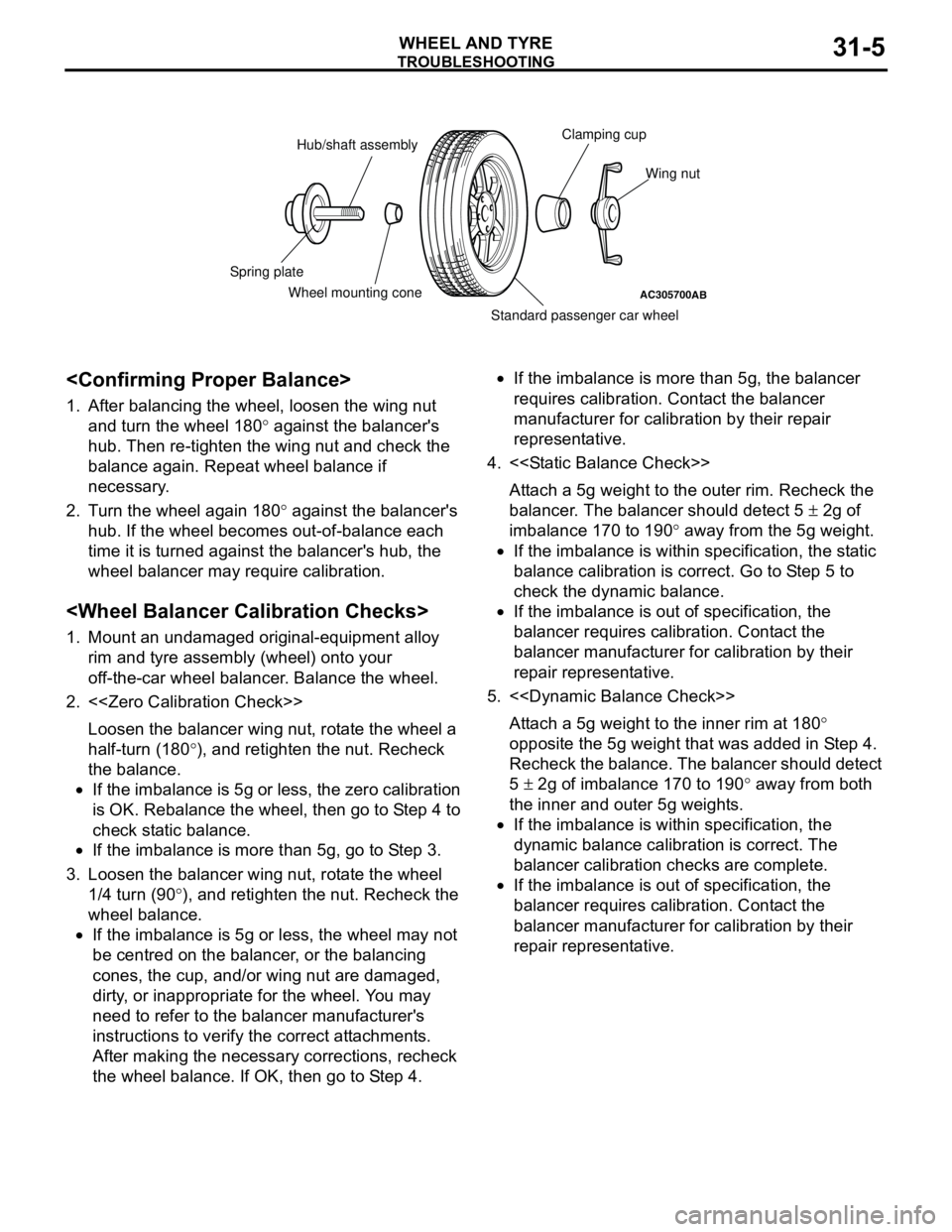

PROCEDURE

1. Confirm that the balancer's cone and the wheel

mounting cone are undamaged and free of dirt

and rust.

2. On this vehicle, the wheel's centre hole on the

hub side has a chamfered edge. Use a

back-mounting cone on your wheel balancer to

centre the wheel on the balancer shaft.

3. Install a wheel mounting cone. The appropriate

size cone for this vehicle is 67.0 mm.

4. Before balancing the wheel, remove any wheel

weights from both sides. Also check both sides for

any damage.

5. When installing wheel weights, hammer them at a

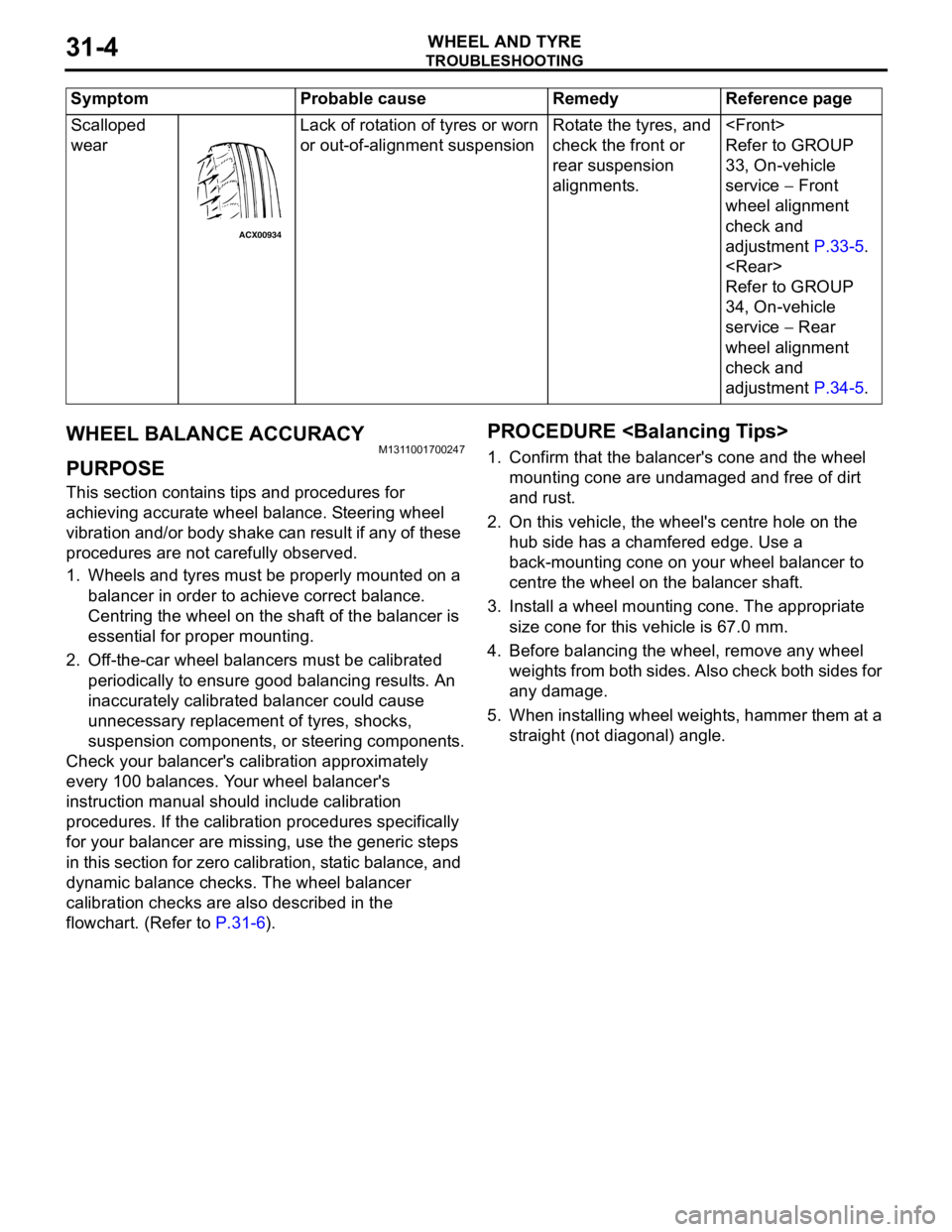

straight (not diagonal) angle. Scalloped

wearLack of rotation of tyres or worn

or out-of-alignment suspensionRotate the tyres, and

check the front or

rear suspension

alignments.

Refer to GROUP

33, On-vehicle

service − Front

wheel alignment

check and

adjustment P.33-5.

Refer to GROUP

34, On-vehicle

service − Rear

wheel alignment

check and

adjustment P.34-5. Symptom Probable cause Remedy Reference page

ACX00934

Page 167 of 788

TROUBLESHOOTING

WHEEL AND TYRE31-5

1. After balancing the wheel, loosen the wing nut

and turn the wheel 180° against the balancer's

hub. Then re-tighten the wing nut and check the

balance again. Repeat wheel balance if

necessary.

2. Turn the wheel again 180° against the balancer's

hub. If the wheel becomes out-of-balance each

time it is turned against the balancer's hub, the

wheel balancer may require calibration.

1. Mount an undamaged original-equipment alloy

rim and tyre assembly (wheel) onto your

off-the-car wheel balancer. Balance the wheel.

2. <

Loosen the balancer wing nut, rotate the wheel a

half-turn (180°), and retighten the nut. Recheck

the balance.

•If the imbalance is 5g or less, the zero calibration

is OK. Rebalance the wheel, then go to Step 4 to

check static balance.

•If the imbalance is more than 5g, go to Step 3.

3. Loosen the balancer wing nut, rotate the wheel

1/4 turn (90°), and retighten the nut. Recheck the

wheel balance.

•If the imbalance is 5g or less, the wheel may not

be centred on the balancer, or the balancing

cones, the cup, and/or wing nut are damaged,

dirty, or inappropriate for the wheel. You may

need to refer to the balancer manufacturer's

instructions to verify the correct attachments.

After making the necessary corrections, recheck

the wheel balance. If OK, then go to Step 4.•If the imbalance is more than 5g, the balancer

requires calibration. Contact the balancer

manufacturer for calibration by their repair

representative.

4. <

Attach a 5g weight to the outer rim. Recheck the

balancer. The balancer should detect 5 ± 2g of

imbalance 170 to 190° away from the 5g weight.

•If the imbalance is within specification, the static

balance calibration is correct. Go to Step 5 to

check the dynamic balance.

•If the imbalance is out of specification, the

balancer requires calibration. Contact the

balancer manufacturer for calibration by their

repair representative.

5. <

Attach a 5g weight to the inner rim at 180°

opposite the 5g weight that was added in Step 4.

Recheck the balance. The balancer should detect

5 ± 2g of imbalance 170 to 190° away from both

the inner and outer 5g weights.

•If the imbalance is within specification, the

dynamic balance calibration is correct. The

balancer calibration checks are complete.

•If the imbalance is out of specification, the

balancer requires calibration. Contact the

balancer manufacturer for calibration by their

repair representative.

AC305700AB

Hub/shaft assemblyClamping cup

Wing nut

Standard passenger car wheel Wheel mounting cone Spring plate

Page 168 of 788

TROUBLESHOOTING

WHEEL AND TYRE31-6

WHEEL BALANCER CALIBRATION

CHECKING FLOW CHART

AC000040

Balance wheel.

Rotate wheel 1/2 turn.

Imbalance = 5g (0.18oz) or lessImbalance = more than 5g (0.18oz)

Rebalance wheel.

Rotate wheel 1/4 turn.

Imbalance = 5g (0.18oz) or lessImbalance = more than 5g (0.18oz)

Verify wheel is properly centred.

Verify cones, cup, and wing nut are clean,

undamaged, and appropriate for wheel.

Make necessary corrections, then recheck

wheel balance.

Attach a 5-g (0.18-oz) weight to the outer rim.

Is the imbalance 5 ± 2g (0.18 ± 0.06oz) at 170

– 190

degrees away from the 5-g (0.18-oz) weight?

YESNO

Attach a 5-g (0.18-oz) weight to the inner rim at 180

degrees opposite the weight on the outer rim.

Is the imbalance 5 ± 2g (0.18 ± 0.06oz) at 170

– 190

degrees away from both 5-g (0.18-oz) weights?

YES NO

Balancer does not require

calibration.Balancer requires calibration.

Contact balancer manufacturer.ZERO CALIBRATION

CHECK

STATIC BALANCE

CHECK

DYNAMIC BALANCE

CHECK

AB

Page 169 of 788

ON-VEHICLE SERVICE

WHEEL AND TYRE31-7

ON-VEHICLE SERVICE

TYRE INFLATION PRESSURE CHECKM1311000900312

NOTE: For information on tyre inflation pressure,

refer to the label attached to the centre pillar on the

driver's side.

TYRE WEAR CHECKM1311001000334

Measure the tread depth of the tyres.

Minimum limit: 1.6 mm

If the remaining tread depth is less than the minimum

limit, replace the tyre.

NOTE: When the tread depth of the tyres is reduced

to 1.6 mm or less, wear indicators will appear.

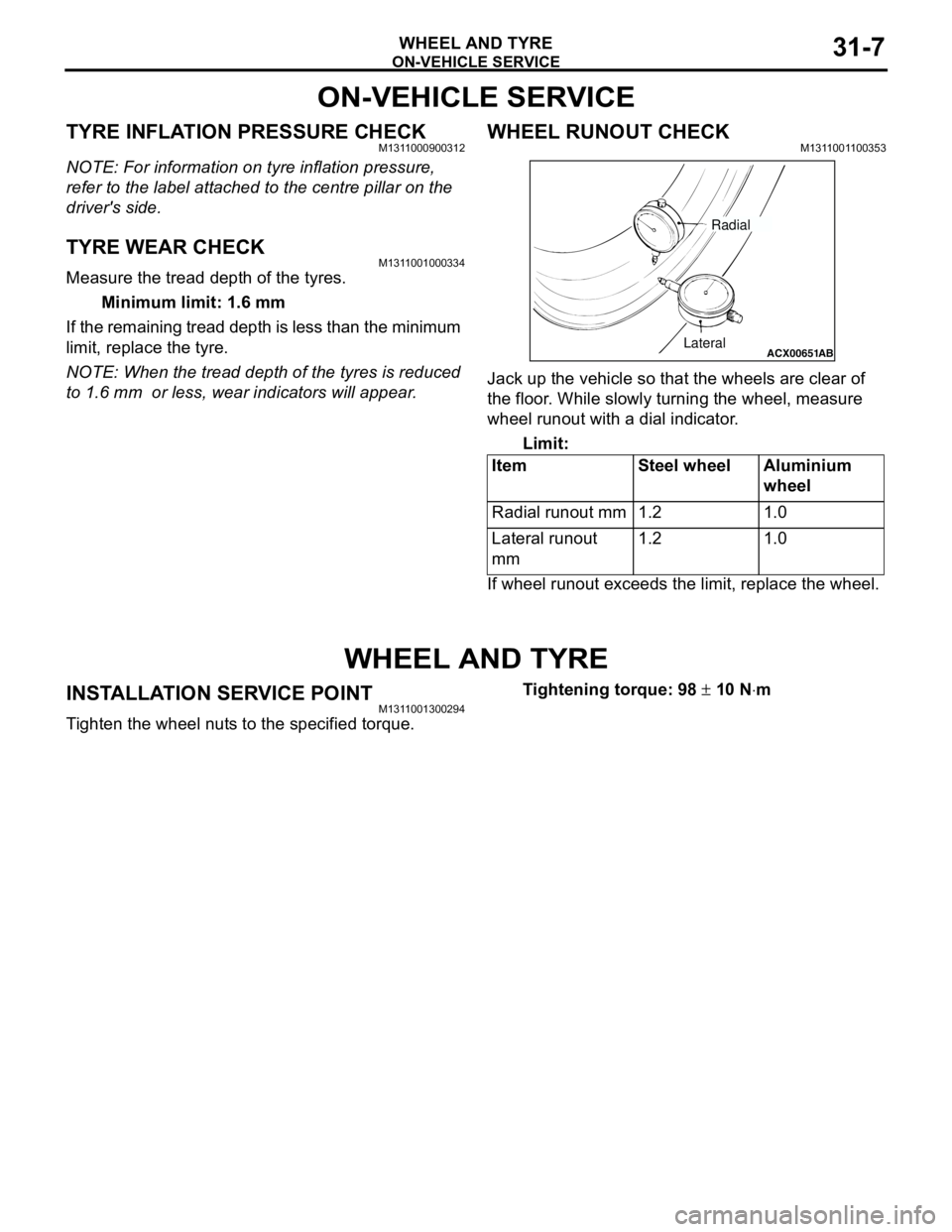

WHEEL RUNOUT CHECKM1311001100353

Jack up the vehicle so that the wheels are clear of

the floor. While slowly turning the wheel, measure

wheel runout with a dial indicator.

Limit:

If wheel runout exceeds the limit, replace the wheel.

WHEEL AND TYRE

INSTALLATION SERVICE POINTM1311001300294

Tighten the wheel nuts to the specified torque.Tightening torque: 98 ± 10 N⋅m Item Steel wheel Aluminium

wheel

Radial runout mm 1.2 1.0

Lateral runout

mm1.2 1.0

ACX00651

ABLateralRadial

Page 170 of 788

NOTES