NISSAN TEANA 2008 Service Manual

Manufacturer: NISSAN, Model Year: 2008, Model line: TEANA, Model: NISSAN TEANA 2008Pages: 5121, PDF Size: 69.03 MB

Page 2431 of 5121

PRECAUTIONS

FAX-3

< PRECAUTION >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000003890158

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the “SRS AIRBAG” and

“SEAT BELT” of this Service Manual.

WARNING:

• To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

Improper maintenance, including incorrect removal and installation of the SRS, can lead to personal

injury caused by unintentional activation of the system. For removal of Spiral Cable and Air Bag

Module, see the “SRS AIRBAG”.

Never use electrical test equipment on any circuit related to the SRS unless instructed to in this Ser-

vice Manual. SRS wiring harnesses can be identified by yellow and/or orange harnesses or harness

connectors.

Precaution Necessary for Steering Wheel Rotation after Battery Disconnect

INFOID:0000000003890159

NOTE:

Before removing and installing any control units, first turn the push-button ignition switch to the LOCK posi-

tion, then disconnect both battery cables.

After finishing work, confirm that all control unit connectors are connected properly, then re-connect both

battery cables.

Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If a DTC is detected, perform trouble diagnosis according to self-diagnosis results.

This vehicle is equipped with a push-button ignition switch and a steering lock unit.

If the battery is disconnected or discharged, the steering wheel will lock and cannot be turned.

If turning the steering wheel is required with the battery disconnected or discharged, follow the procedure

below before starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables.

NOTE:

Supply power using jumper cables if battery is discharged.

2. Turn the push-button ignition switch to ACC position.

(At this time, the steering lock will be released.)

3. Disconnect both battery cables. The steering lock will remain released with both battery cables discon-

nected and the steering wheel can be turned.

4. Perform the necessary repair operation.

5. When the repair work is completed, re-connect both battery cables. With the brake pedal released, turn

the push-button ignition switch from ACC position to ON position, then to LOCK position. (The steering

wheel will lock when the push-button ignition switch is turned to LOCK position.)

6. Perform self-diagnosis check of all control units using CONSULT-III.

Precautions for Drive ShaftINFOID:0000000003811071

CAUTION:

Note the following precautions when disassembling and assembling drive shaft.

Never disassemble joint sub-assembly because it is non-overhaul parts.

Perform work in a dust-free location.

Before disassembling and assembling, clean the parts.

Prevent the entry of foreign objects during disassembly of the service location.

Page 2432 of 5121

FAX-4

< PRECAUTION >

PRECAUTIONS

Disassembled parts must be carefully reassembled in the correct order. If work is interrupted, a

clean cover must be placed over parts.

Paper waste must be used. Never use fabric shop cloths because of the danger of lint adhering to

parts.

Disassembled parts (except for rubber parts) should be cleaned with kerosene which shall be

removed by blowing with air or wiping with paper waste.

Page 2433 of 5121

PREPARATION

FAX-5

< PREPARATION >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

PREPARATION

PREPARATION

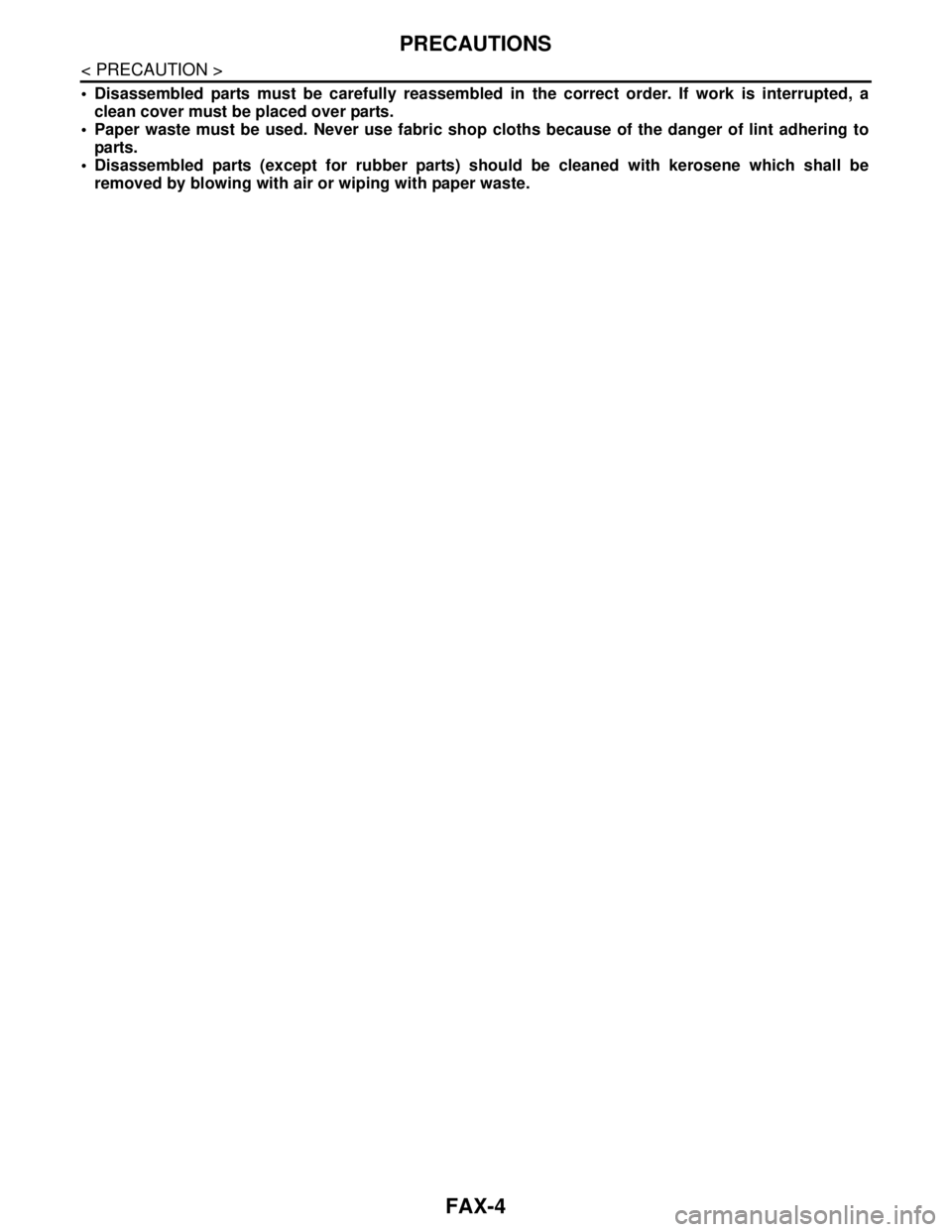

Special Service ToolINFOID:0000000003811072

Tool number

Tool nameDescription

KV40107300

Boot band crimping toolInstalling boot band

KV40107500

Drive shaft attachmentRemoving drive shaft

KV38107900

Protector

a: 32 mm (1.26 in) dia.Installing drive shaft

ZZA1229D

ZZA1230D

PDIA1183J

Page 2434 of 5121

FAX-6

< ON-VEHICLE MAINTENANCE >

FRONT WHEEL HUB AND KNUCKLE

ON-VEHICLE MAINTENANCE

FRONT WHEEL HUB AND KNUCKLE

InspectionINFOID:0000000003811074

MOUNTING INSPECTION

Make sure that the mounting conditions (looseness, backlash) of each component and component conditions

(wear, damage) are normal.

WHEEL BEARING INSPECTION

Move wheel hub and bearing assembly in the axial direction by hand. Make sure there is no looseness of

wheel bearing.

Rotate wheel hub and make sure there is no unusual noise or other irregular conditions. If there is any of

irregular conditions, replace wheel hub and bearing assembly.Standard

Axial end play : Refer to FAX-35, "

Wheel Bearing".

Page 2435 of 5121

FRONT DRIVE SHAFT

FAX-7

< ON-VEHICLE MAINTENANCE >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

FRONT DRIVE SHAFT

InspectionINFOID:0000000003811075

Check drive shaft mounting point and joint for looseness and other damage.

Check boot for cracks and other damage.

CAUTION:

Replace drive shaft assembly when noise or vibration occur from drive shaft.

Page 2436 of 5121

FAX-8

< ON-VEHICLE REPAIR >

FRONT WHEEL HUB AND KNUCKLE

ON-VEHICLE REPAIR

FRONT WHEEL HUB AND KNUCKLE

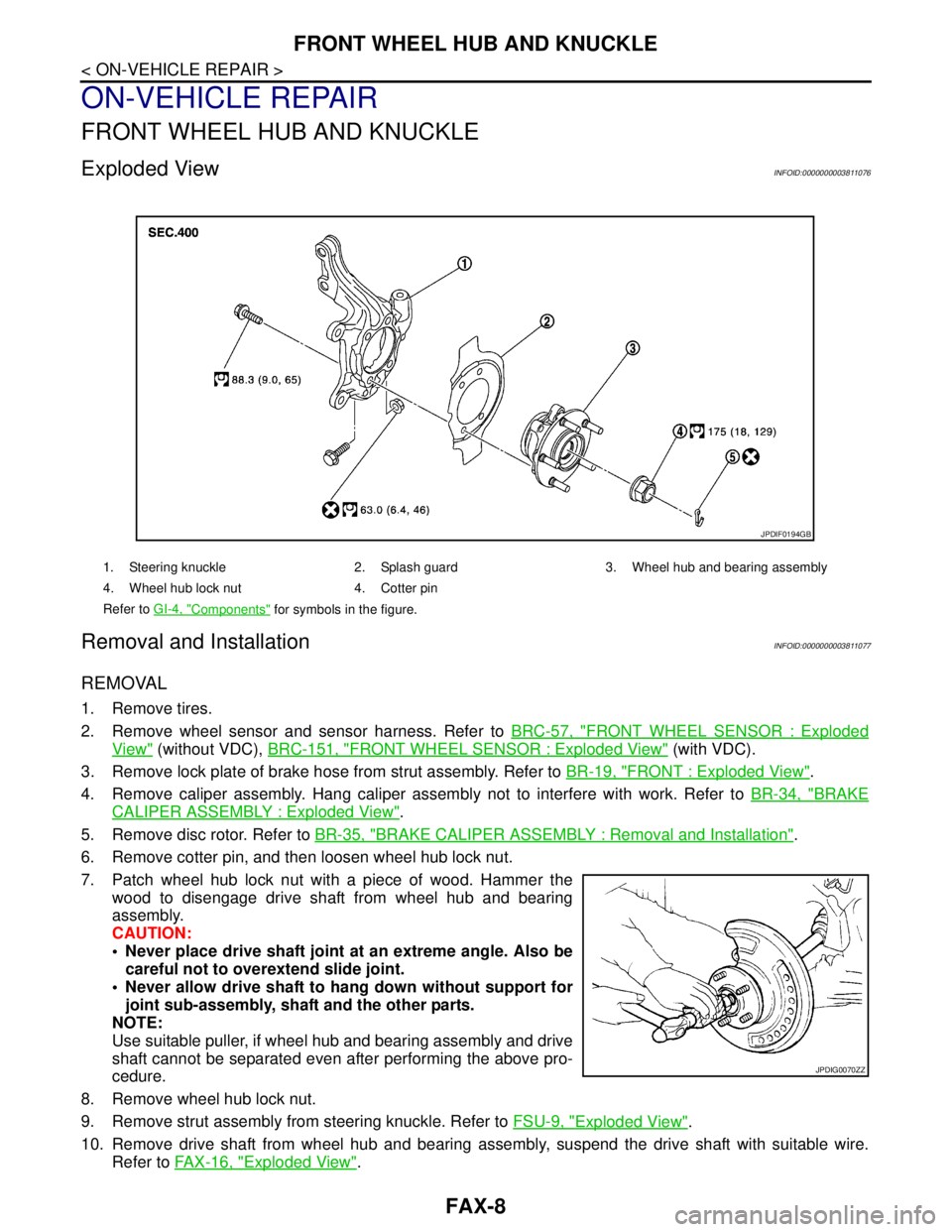

Exploded ViewINFOID:0000000003811076

Removal and InstallationINFOID:0000000003811077

REMOVAL

1. Remove tires.

2. Remove wheel sensor and sensor harness. Refer to BRC-57, "

FRONT WHEEL SENSOR : Exploded

View" (without VDC), BRC-151, "FRONT WHEEL SENSOR : Exploded View" (with VDC).

3. Remove lock plate of brake hose from strut assembly. Refer to BR-19, "

FRONT : Exploded View".

4. Remove caliper assembly. Hang caliper assembly not to interfere with work. Refer to BR-34, "

BRAKE

CALIPER ASSEMBLY : Exploded View".

5. Remove disc rotor. Refer to BR-35, "

BRAKE CALIPER ASSEMBLY : Removal and Installation".

6. Remove cotter pin, and then loosen wheel hub lock nut.

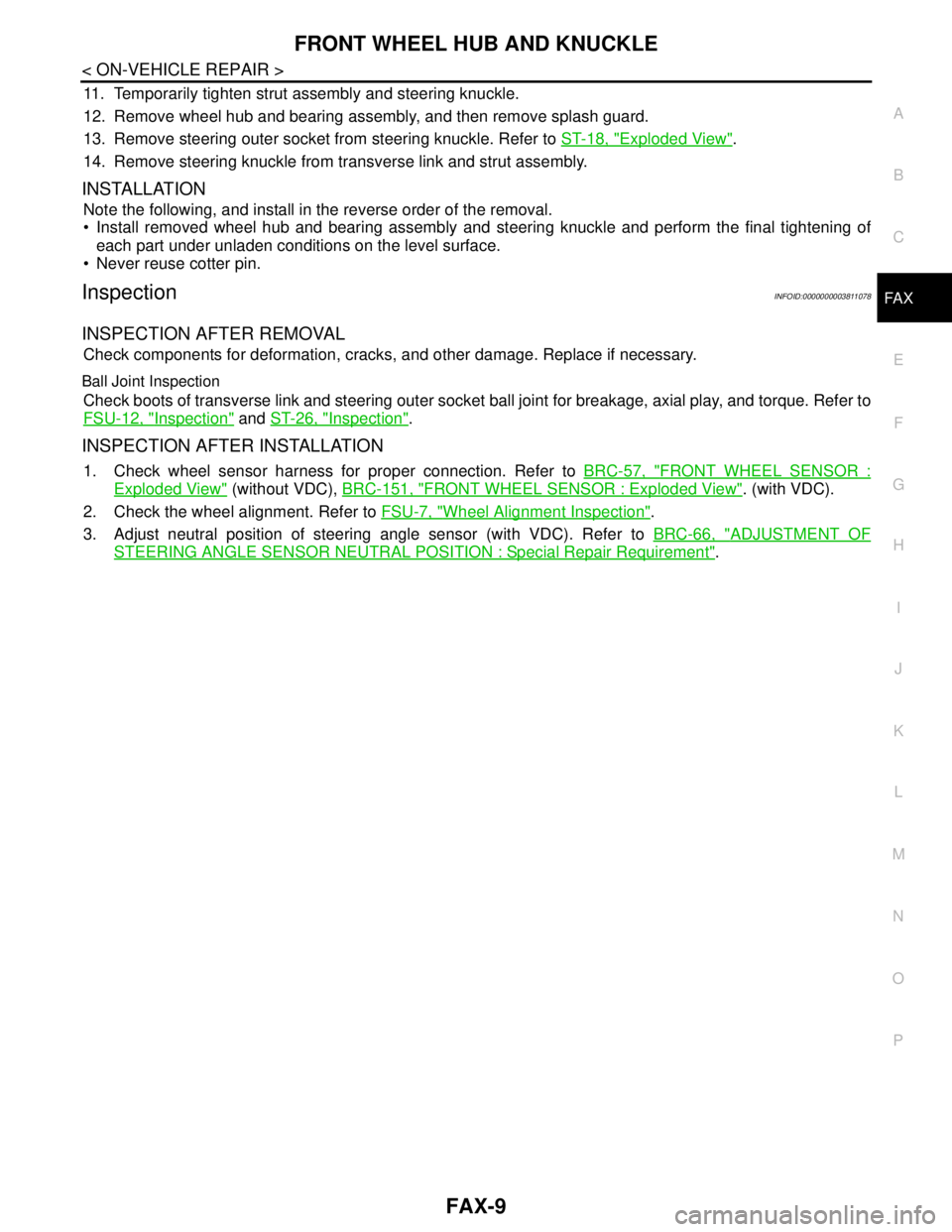

7. Patch wheel hub lock nut with a piece of wood. Hammer the

wood to disengage drive shaft from wheel hub and bearing

assembly.

CAUTION:

Never place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

Never allow drive shaft to hang down without support for

joint sub-assembly, shaft and the other parts.

NOTE:

Use suitable puller, if wheel hub and bearing assembly and drive

shaft cannot be separated even after performing the above pro-

cedure.

8. Remove wheel hub lock nut.

9. Remove strut assembly from steering knuckle. Refer to FSU-9, "

Exploded View".

10. Remove drive shaft from wheel hub and bearing assembly, suspend the drive shaft with suitable wire.

Refer to FAX-16, "

Exploded View".

1. Steering knuckle 2. Splash guard 3. Wheel hub and bearing assembly

4. Wheel hub lock nut 4. Cotter pin

Refer to GI-4, "

Components" for symbols in the figure.

JPDIF0194GB

JPDIG0070ZZ

Page 2437 of 5121

FRONT WHEEL HUB AND KNUCKLE

FAX-9

< ON-VEHICLE REPAIR >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

11. Temporarily tighten strut assembly and steering knuckle.

12. Remove wheel hub and bearing assembly, and then remove splash guard.

13. Remove steering outer socket from steering knuckle. Refer to ST-18, "

Exploded View".

14. Remove steering knuckle from transverse link and strut assembly.

INSTALLATION

Note the following, and install in the reverse order of the removal.

Install removed wheel hub and bearing assembly and steering knuckle and perform the final tightening of

each part under unladen conditions on the level surface.

Never reuse cotter pin.

InspectionINFOID:0000000003811078

INSPECTION AFTER REMOVAL

Check components for deformation, cracks, and other damage. Replace if necessary.

Ball Joint Inspection

Check boots of transverse link and steering outer socket ball joint for breakage, axial play, and torque. Refer to

FSU-12, "

Inspection" and ST-26, "Inspection".

INSPECTION AFTER INSTALLATION

1. Check wheel sensor harness for proper connection. Refer to BRC-57, "FRONT WHEEL SENSOR :

Exploded View" (without VDC), BRC-151, "FRONT WHEEL SENSOR : Exploded View". (with VDC).

2. Check the wheel alignment. Refer to FSU-7, "

Wheel Alignment Inspection".

3. Adjust neutral position of steering angle sensor (with VDC). Refer to BRC-66, "

ADJUSTMENT OF

STEERING ANGLE SENSOR NEUTRAL POSITION : Special Repair Requirement".

Page 2438 of 5121

FAX-10

< ON-VEHICLE REPAIR >

FRONT DRIVE SHAFT BOOT

FRONT DRIVE SHAFT BOOT

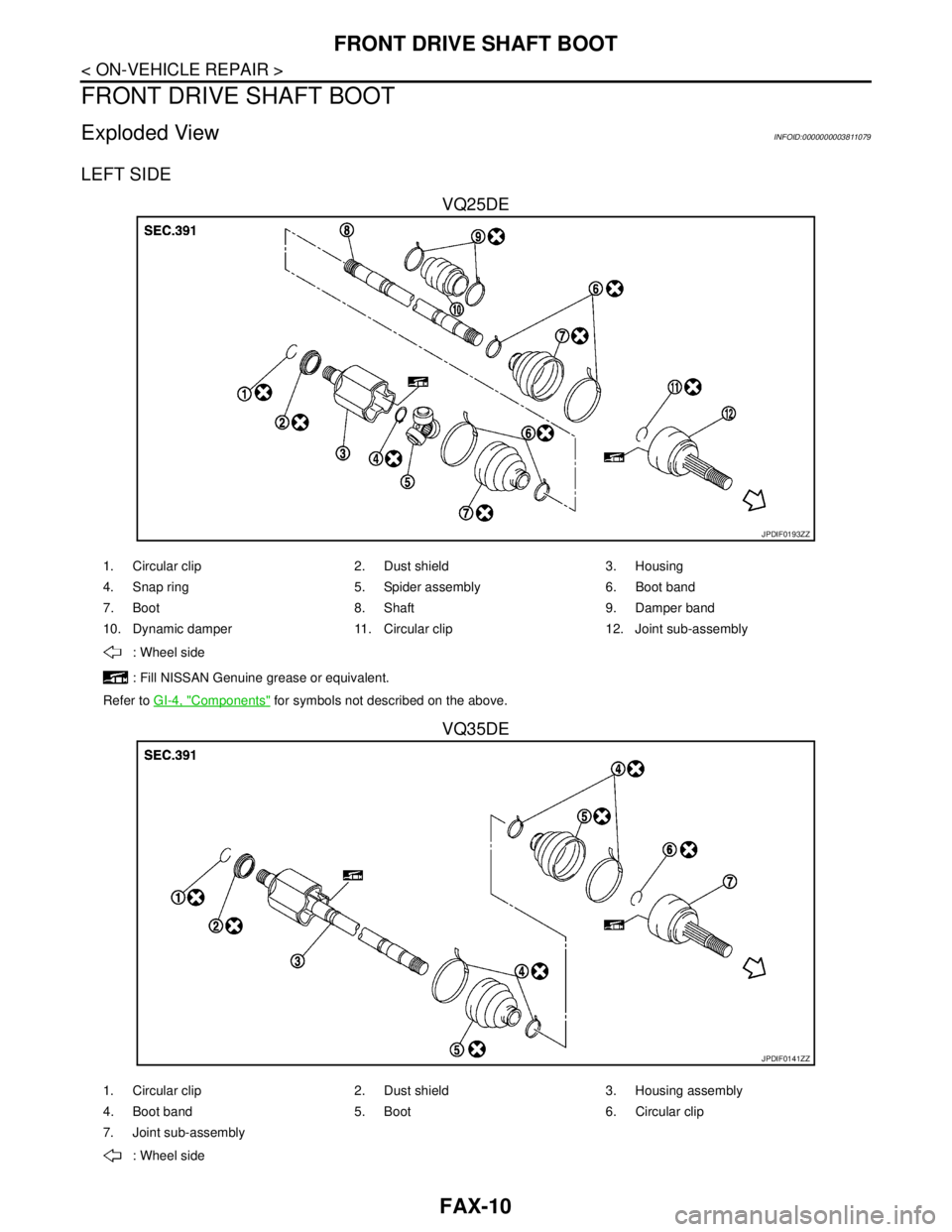

Exploded ViewINFOID:0000000003811079

LEFT SIDE

VQ25DE

VQ35DE

JPDIF0193ZZ

1. Circular clip 2. Dust shield 3. Housing

4. Snap ring 5. Spider assembly 6. Boot band

7. Boot 8. Shaft 9. Damper band

10. Dynamic damper 11. Circular clip 12. Joint sub-assembly

: Wheel side

: Fill NISSAN Genuine grease or equivalent.

Refer to GI-4, "

Components" for symbols not described on the above.

JPDIF0141ZZ

1. Circular clip 2. Dust shield 3. Housing assembly

4. Boot band 5. Boot 6. Circular clip

7. Joint sub-assembly

: Wheel side

Page 2439 of 5121

FRONT DRIVE SHAFT BOOT

FAX-11

< ON-VEHICLE REPAIR >

C

E

F

G

H

I

J

K

L

MA

B

FA X

N

O

P

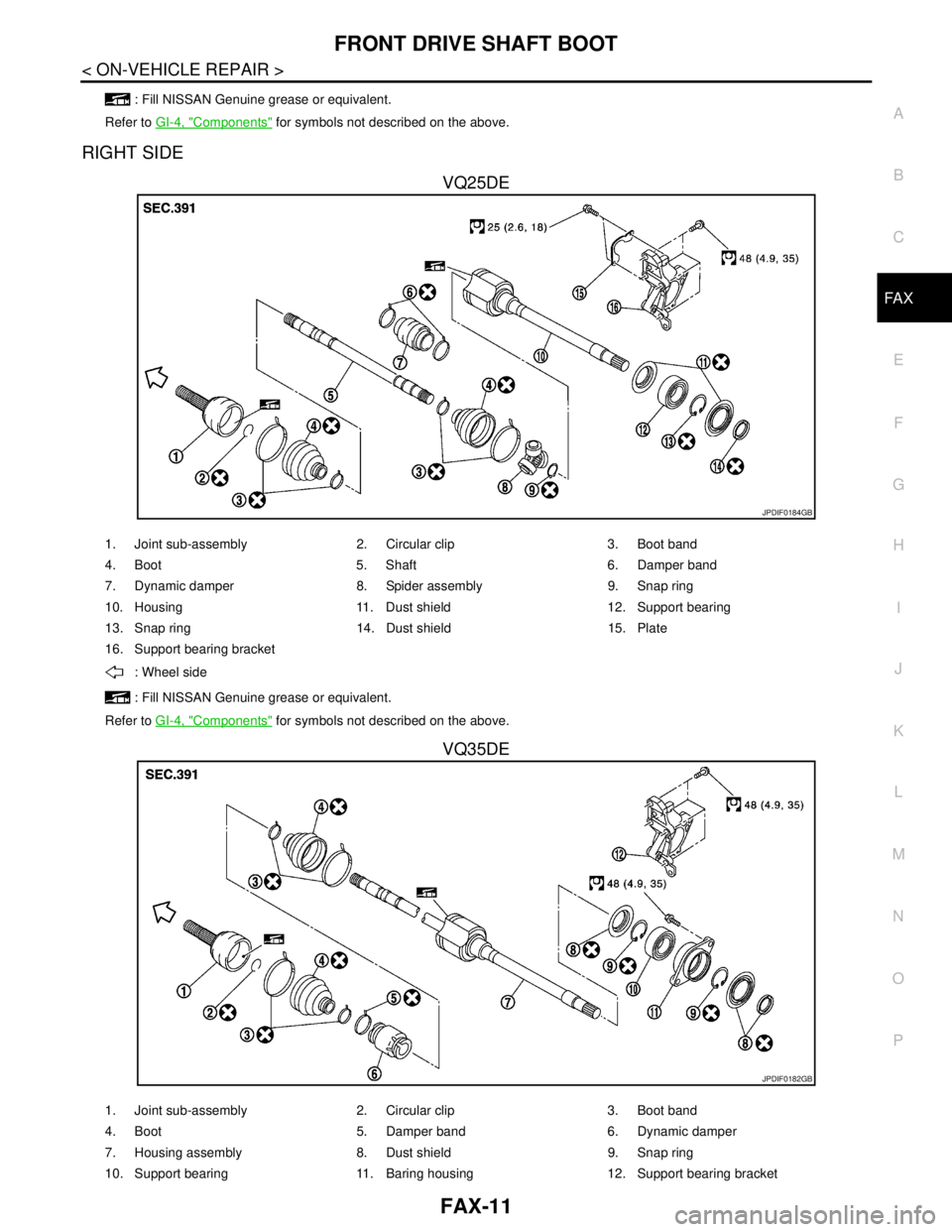

RIGHT SIDE

VQ25DE

VQ35DE

: Fill NISSAN Genuine grease or equivalent.

Refer to GI-4, "

Components" for symbols not described on the above.

JPDIF0184GB

1. Joint sub-assembly 2. Circular clip 3. Boot band

4. Boot 5. Shaft 6. Damper band

7. Dynamic damper 8. Spider assembly 9. Snap ring

10. Housing 11. Dust shield 12. Support bearing

13. Snap ring 14. Dust shield 15. Plate

16. Support bearing bracket

: Wheel side

: Fill NISSAN Genuine grease or equivalent.

Refer to GI-4, "

Components" for symbols not described on the above.

JPDIF0182GB

1. Joint sub-assembly 2. Circular clip 3. Boot band

4. Boot 5. Damper band 6. Dynamic damper

7. Housing assembly 8. Dust shield 9. Snap ring

10. Support bearing 11. Baring housing 12. Support bearing bracket

Page 2440 of 5121

FAX-12

< ON-VEHICLE REPAIR >

FRONT DRIVE SHAFT BOOT

WHEEL SIDE

WHEEL SIDE : Removal and InstallationINFOID:0000000003811080

REMOVAL

1. Remove tires.

2. Remove wheel sensor and sensor harness. Refer to BRC-57, "

FRONT WHEEL SENSOR : Exploded

View" (without VDC), BRC-151, "FRONT WHEEL SENSOR : Exploded View" (with VDC).

3. Remove lock plate of brake hose from strut assembly. Refer to BR-19, "

FRONT : Exploded View".

4. Remove caliper assembly. Hang caliper assembly not to interfere with work. Refer to BR-34, "

BRAKE

CALIPER ASSEMBLY : Exploded View".

5. Remove disc rotor. Refer to BR-35, "

BRAKE CALIPER ASSEMBLY : Removal and Installation".

6. Remove cotter pin, and then loosen wheel hub lock nut. Refer to FA X - 8 , "

Exploded View".

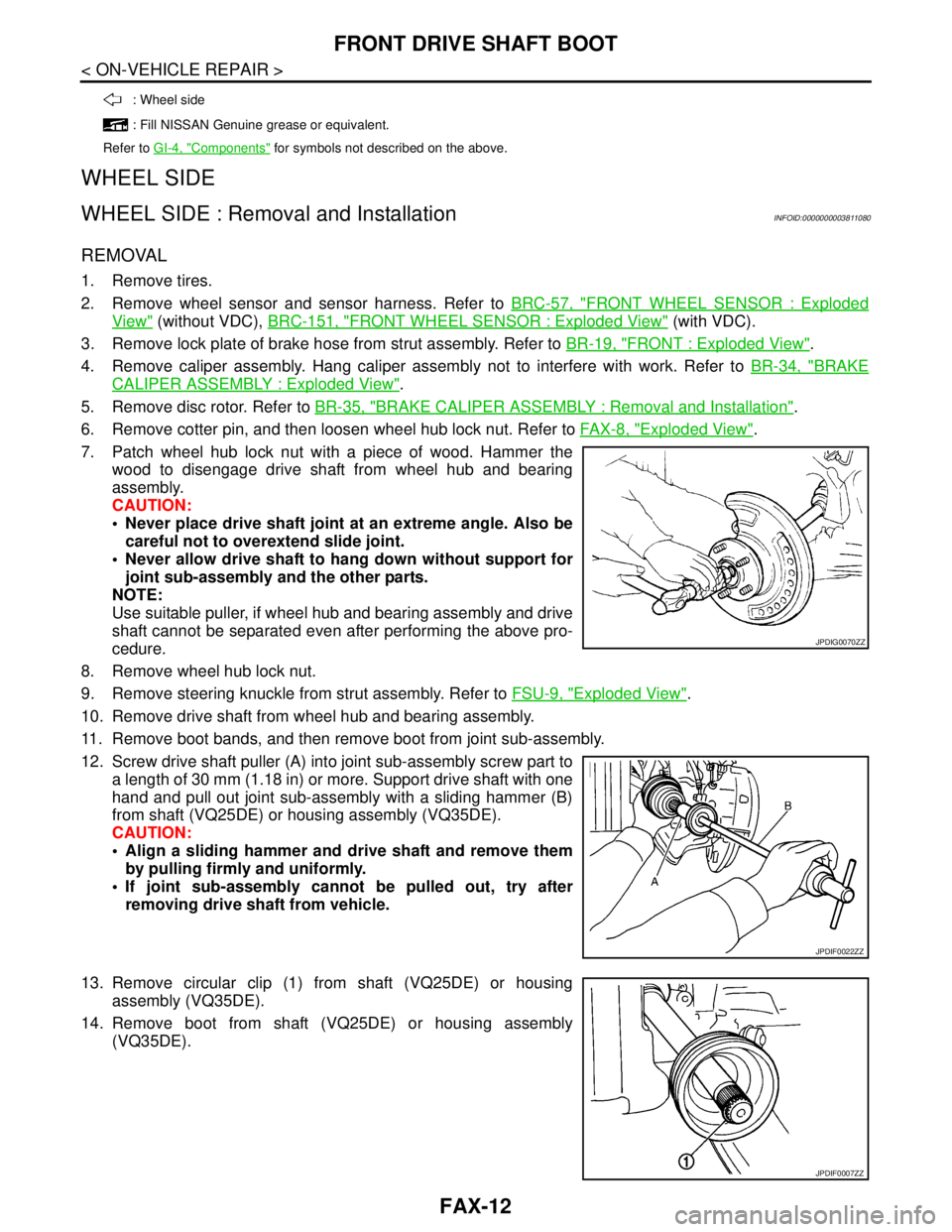

7. Patch wheel hub lock nut with a piece of wood. Hammer the

wood to disengage drive shaft from wheel hub and bearing

assembly.

CAUTION:

Never place drive shaft joint at an extreme angle. Also be

careful not to overextend slide joint.

Never allow drive shaft to hang down without support for

joint sub-assembly and the other parts.

NOTE:

Use suitable puller, if wheel hub and bearing assembly and drive

shaft cannot be separated even after performing the above pro-

cedure.

8. Remove wheel hub lock nut.

9. Remove steering knuckle from strut assembly. Refer to FSU-9, "

Exploded View".

10. Remove drive shaft from wheel hub and bearing assembly.

11. Remove boot bands, and then remove boot from joint sub-assembly.

12. Screw drive shaft puller (A) into joint sub-assembly screw part to

a length of 30 mm (1.18 in) or more. Support drive shaft with one

hand and pull out joint sub-assembly with a sliding hammer (B)

from shaft (VQ25DE) or housing assembly (VQ35DE).

CAUTION:

Align a sliding hammer and drive shaft and remove them

by pulling firmly and uniformly.

If joint sub-assembly cannot be pulled out, try after

removing drive shaft from vehicle.

13. Remove circular clip (1) from shaft (VQ25DE) or housing

assembly (VQ35DE).

14. Remove boot from shaft (VQ25DE) or housing assembly

(VQ35DE).

: Wheel side

: Fill NISSAN Genuine grease or equivalent.

Refer to GI-4, "

Components" for symbols not described on the above.

JPDIG0070ZZ

JPDIF0022ZZ

JPDIF0007ZZ