NISSAN TERRANO 2004 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 231 of 1833

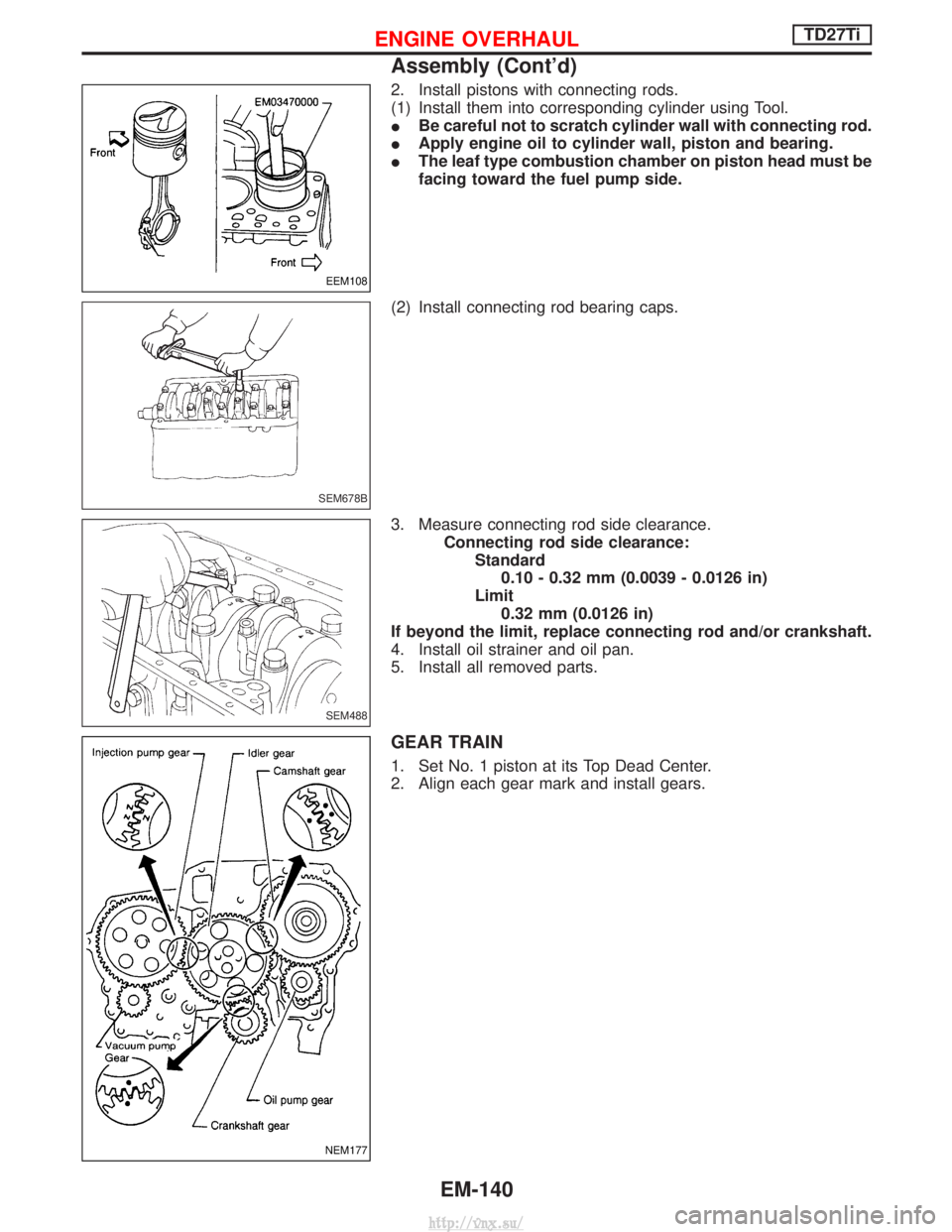

2. Install pistons with connecting rods.

(1) Install them into corresponding cylinder using Tool.

IBe careful not to scratch cylinder wall with connecting rod.

I Apply engine oil to cylinder wall, piston and bearing.

I The leaf type combustion chamber on piston head must be

facing toward the fuel pump side.

(2) Install connecting rod bearing caps.

3. Measure connecting rod side clearance. Connecting rod side clearance:Standard0.10 - 0.32 mm (0.0039 - 0.0126 in)

Limit 0.32 mm (0.0126 in)

If beyond the limit, replace connecting rod and/or crankshaft.

4. Install oil strainer and oil pan.

5. Install all removed parts.

GEAR TRAIN

1. Set No. 1 piston at its Top Dead Center.

2. Align each gear mark and install gears.

EEM108

SEM678B

SEM488

NEM177

ENGINE OVERHAULTD27Ti

Assembly (Cont'd)

EM-140

http://vnx.su/

Page 232 of 1833

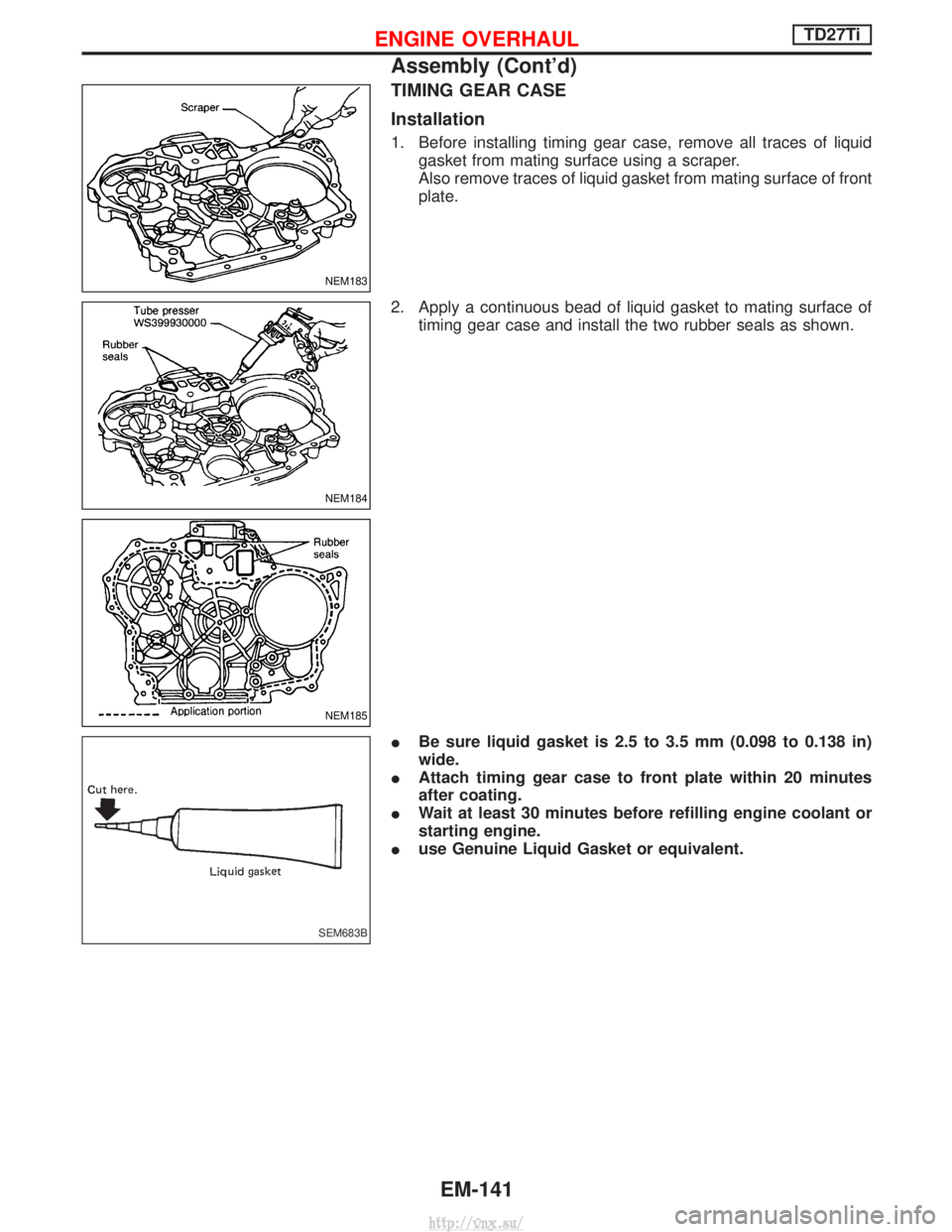

TIMING GEAR CASE

Installation

1. Before installing timing gear case, remove all traces of liquidgasket from mating surface using a scraper.

Also remove traces of liquid gasket from mating surface of front

plate.

2. Apply a continuous bead of liquid gasket to mating surface of timing gear case and install the two rubber seals as shown.

I Be sure liquid gasket is 2.5 to 3.5 mm (0.098 to 0.138 in)

wide.

I Attach timing gear case to front plate within 20 minutes

after coating.

I Wait at least 30 minutes before refilling engine coolant or

starting engine.

I use Genuine Liquid Gasket or equivalent.

NEM183

NEM184

NEM185

SEM683B

ENGINE OVERHAULTD27Ti

Assembly (Cont'd)

EM-141

http://vnx.su/

Page 233 of 1833

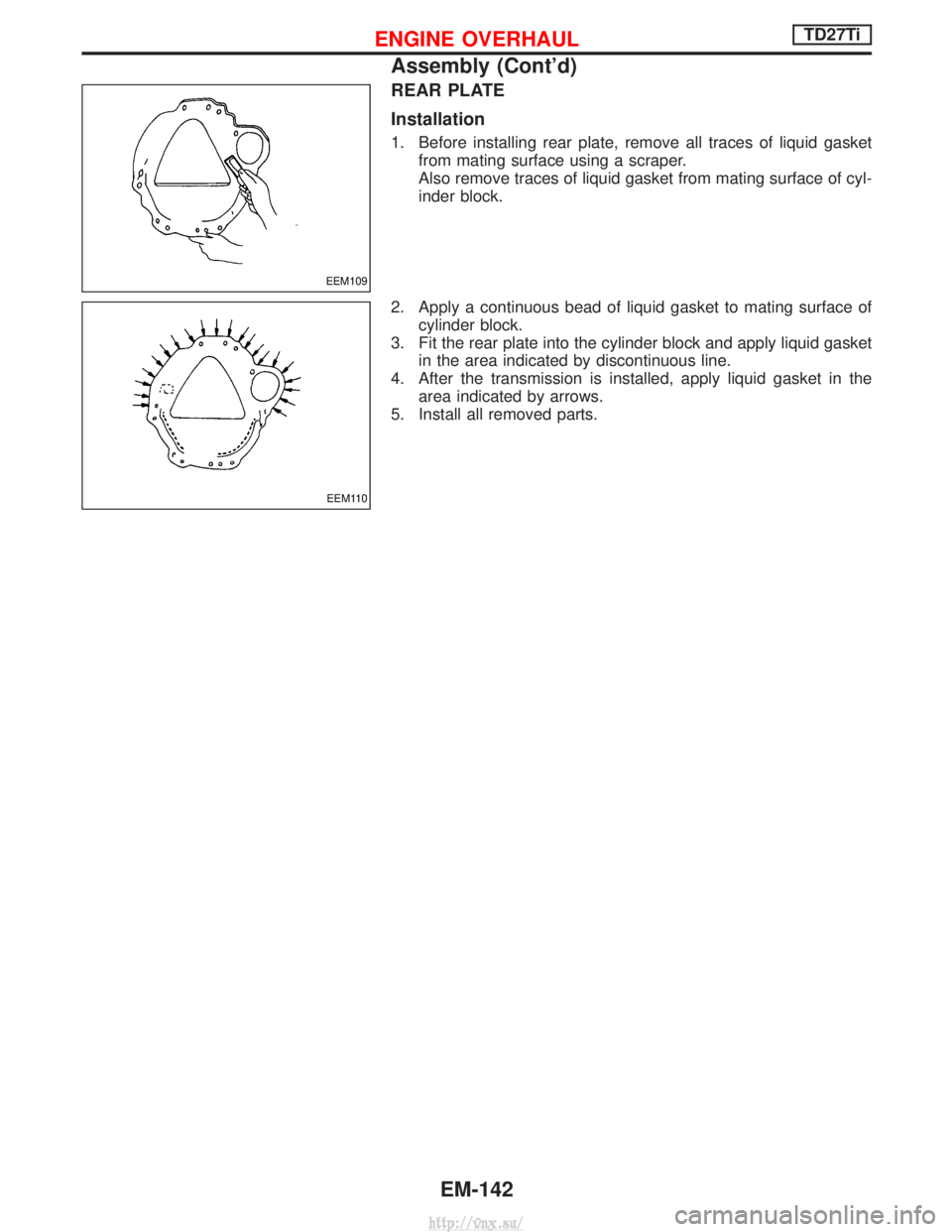

REAR PLATE

Installation

1. Before installing rear plate, remove all traces of liquid gasketfrom mating surface using a scraper.

Also remove traces of liquid gasket from mating surface of cyl-

inder block.

2. Apply a continuous bead of liquid gasket to mating surface of cylinder block.

3. Fit the rear plate into the cylinder block and apply liquid gasket in the area indicated by discontinuous line.

4. After the transmission is installed, apply liquid gasket in the area indicated by arrows.

5. Install all removed parts.

EEM109

EEM110

ENGINE OVERHAULTD27Ti

Assembly (Cont'd)

EM-142

http://vnx.su/

Page 234 of 1833

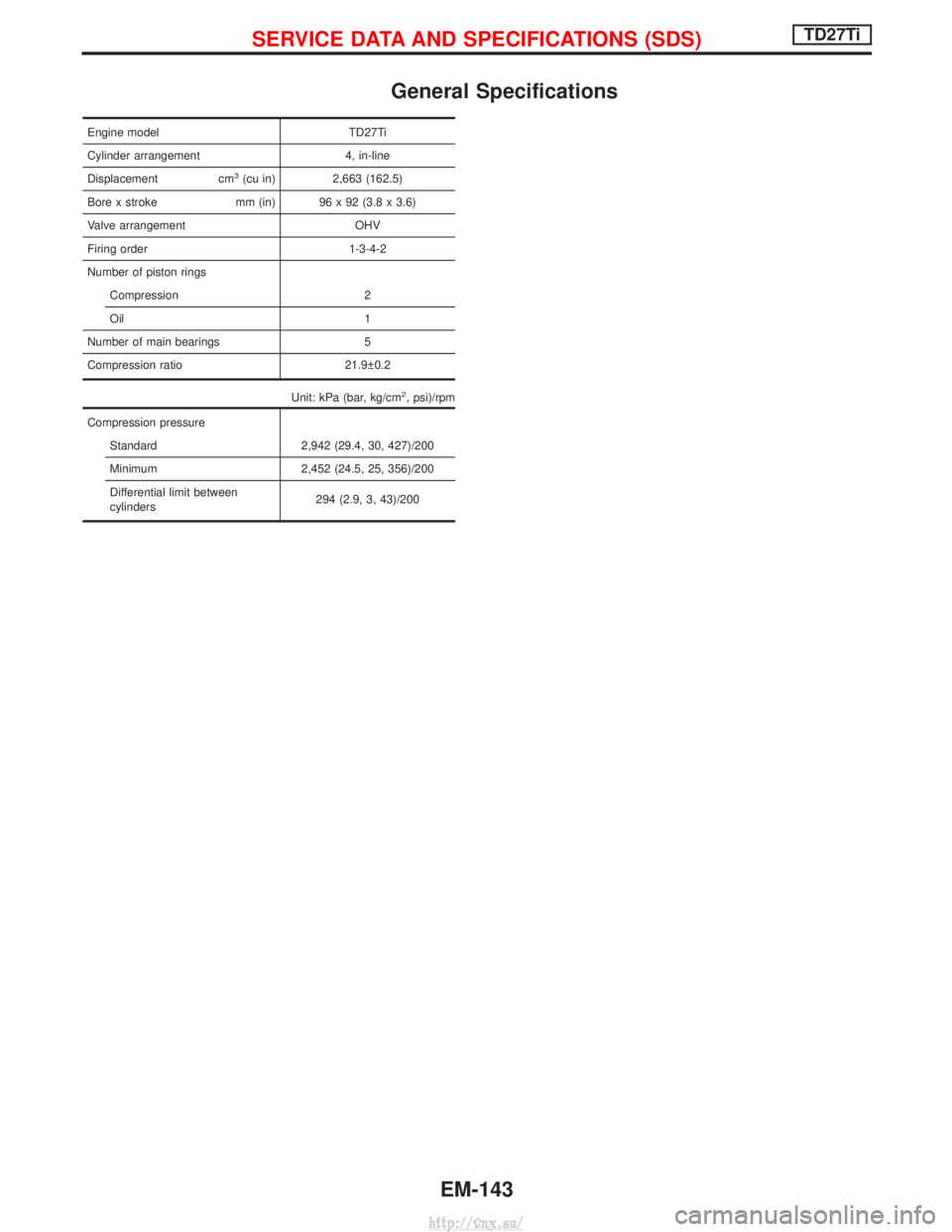

General Specifications

Engine modelTD27Ti

Cylinder arrangement 4, in-line

Displacement cm

3(cu in) 2,663 (162.5)

Bore x stroke mm (in) 96 x 92 (3.8 x 3.6)

Valve arrangement OHV

Firing order 1-3-4-2

Number of piston rings Compression 2

Oil 1

Number of main bearings 5

Compression ratio 21.9 0.2

Unit: kPa (bar, kg/cm

2, psi)/rpm

Compression pressureStandard 2,942 (29.4, 30, 427)/200

Minimum 2,452 (24.5, 25, 356)/200

Differential limit between

cylinders 294 (2.9, 3, 43)/200

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

EM-143

http://vnx.su/

Page 235 of 1833

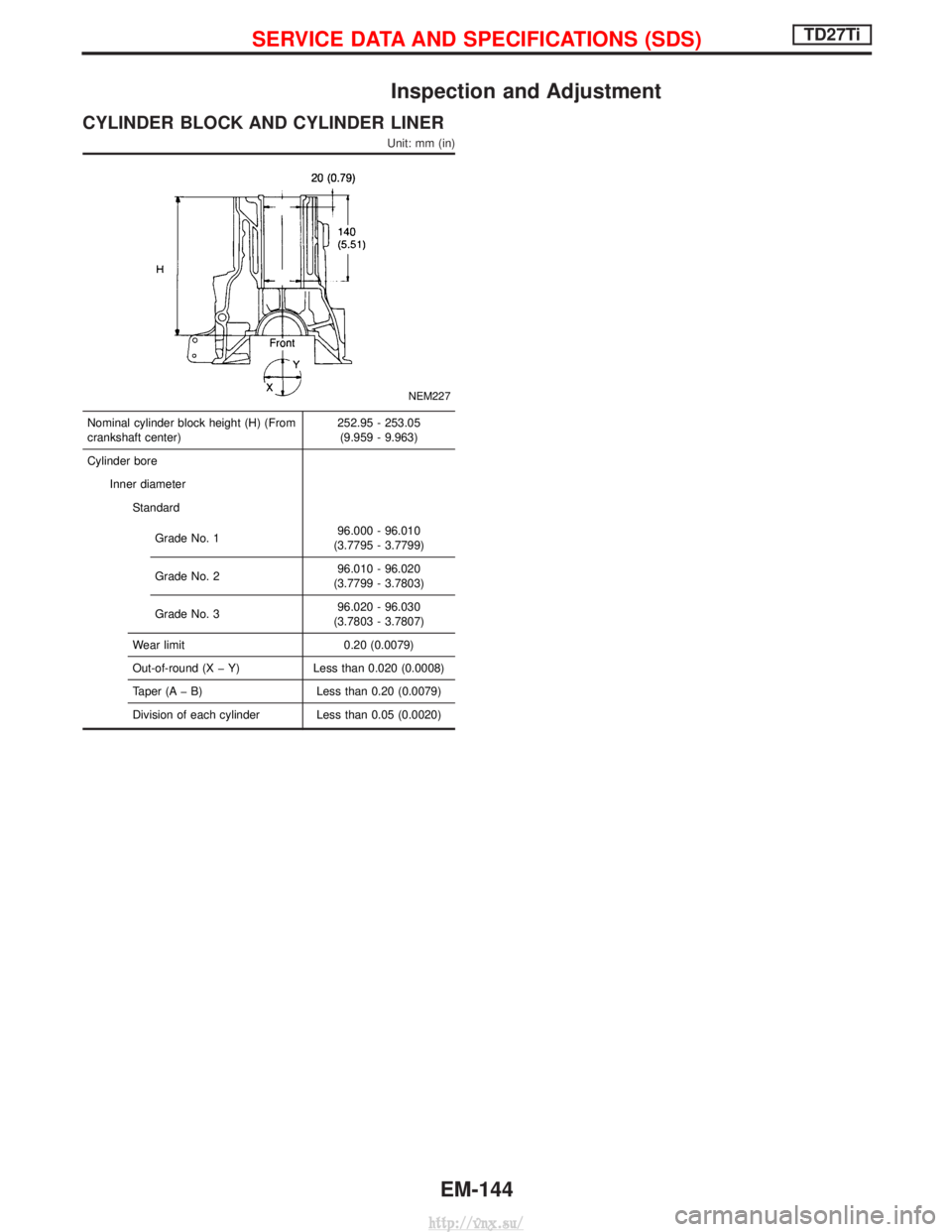

Inspection and Adjustment

CYLINDER BLOCK AND CYLINDER LINER

Unit: mm (in)

NEM227

Nominal cylinder block height (H) (From

crankshaft center)252.95 - 253.05

(9.959 - 9.963)

Cylinder bore Inner diameterStandard

Grade No. 1 96.000 - 96.010

(3.7795 - 3.7799)

Grade No. 2 96.010 - 96.020

(3.7799 - 3.7803)

Grade No. 3 96.020 - 96.030

(3.7803 - 3.7807)

Wear limit 0.20 (0.0079)

Out-of-round (X þ Y) Less than 0.020 (0.0008)

Taper (A þ B) Less than 0.20 (0.0079)

Division of each cylinder Less than 0.05 (0.0020)

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

EM-144

http://vnx.su/

Page 236 of 1833

VALVE GUIDE

Unit: mm (in)

StandardService

Valve guide outside

diameter 12.233 - 12.244

(0.4816 - 0.4820) Ð

Valve guide inner diam-

eter (Finished size) 8.000 - 8.015 (0.3150 - 0.3156)

Cylinder head valve

guide hole diameter 12.200 - 12.211

(0.4803 - 0.4807) Ð

Interference fit of valve

guide 0.022 - 0.044 (0.0009 - 0.0017)

Standard Limit

Valve to guide clearance

Intake 0.020 - 0.050

(0.0008 - 0.0020) 0.15 (0.0059)

Exhaust 0.040 - 0.070

(0.0016 - 0.0028) 0.15 (0.0059)

Valve deflection limit Intake 0.35 (0.0138)

Exhaust 0.35 (0.0138)

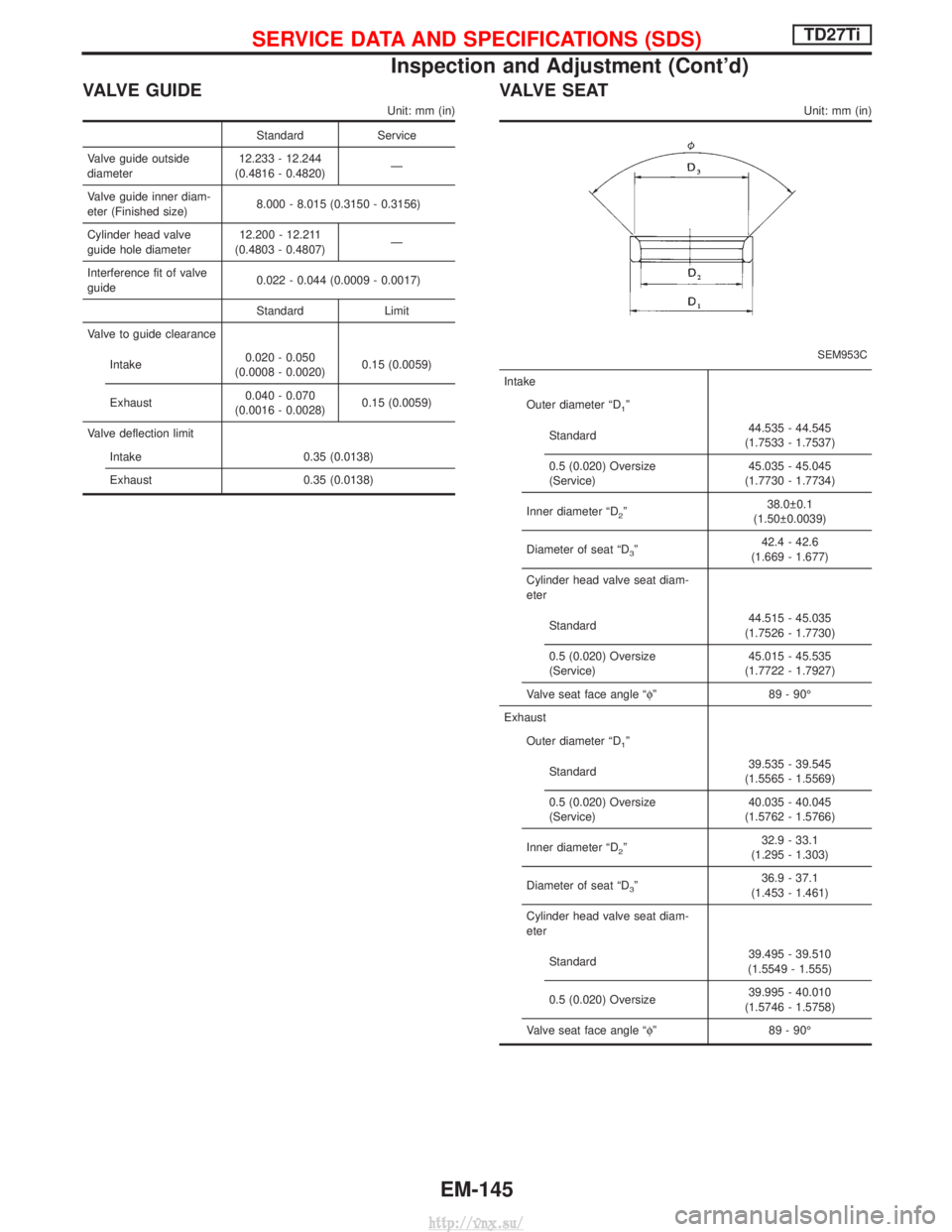

VA LV E S E AT

Unit: mm (in)

SEM953C

Intake

Outer diameter ªD

1º

Standard 44.535 - 44.545

(1.7533 - 1.7537)

0.5 (0.020) Oversize

(Service) 45.035 - 45.045

(1.7730 - 1.7734)

Inner diameter ªD

2º 38.0 0.1

(1.50 0.0039)

Diameter of seat ªD

3º 42.4 - 42.6

(1.669 - 1.677)

Cylinder head valve seat diam-

eter

Standard 44.515 - 45.035

(1.7526 - 1.7730)

0.5 (0.020) Oversize

(Service) 45.015 - 45.535

(1.7722 - 1.7927)

Valve seat face angle ªf º89 - 90É

Exhaust Outer diameter ªD

1º

Standard 39.535 - 39.545

(1.5565 - 1.5569)

0.5 (0.020) Oversize

(Service) 40.035 - 40.045

(1.5762 - 1.5766)

Inner diameter ªD

2º 32.9 - 33.1

(1.295 - 1.303)

Diameter of seat ªD

3º 36.9 - 37.1

(1.453 - 1.461)

Cylinder head valve seat diam-

eter

Standard 39.495 - 39.510

(1.5549 - 1.555)

0.5 (0.020) Oversize 39.995 - 40.010

(1.5746 - 1.5758)

Valve seat face angle ªf º89 - 90É

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

Inspection and Adjustment (Cont'd)

EM-145

http://vnx.su/

Page 237 of 1833

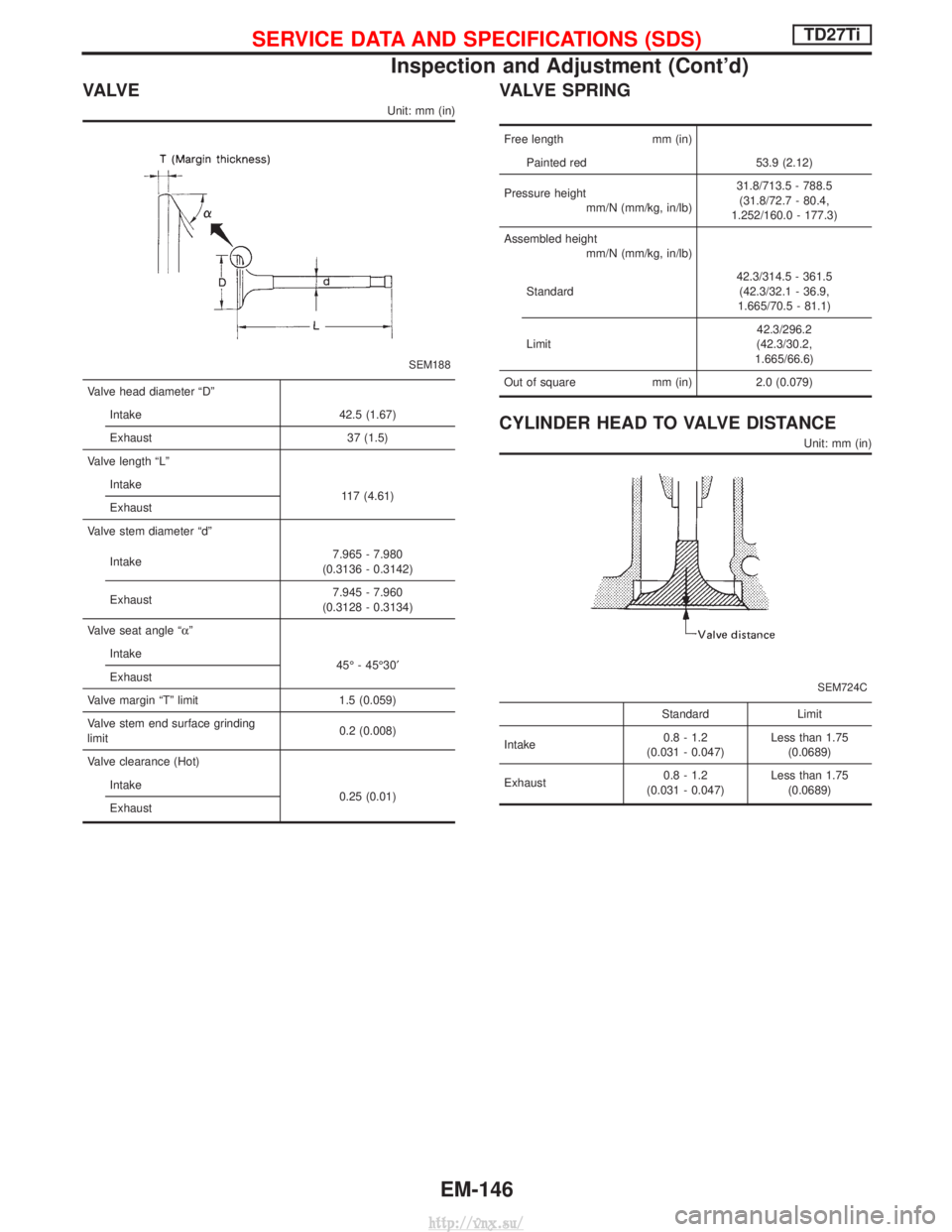

VA LV E

Unit: mm (in)

SEM188

Valve head diameter ªDºIntake 42.5 (1.67)

Exhaust 37 (1.5)

Valve length ªLº Intake 117 (4.61)

Exhaust

Valve stem diameter ªdº

Intake 7.965 - 7.980

(0.3136 - 0.3142)

Exhaust 7.945 - 7.960

(0.3128 - 0.3134)

Valve seat angle ªa º

Intake 45É - 45É30¢

Exhaust

Valve margin ªTº limit 1.5 (0.059)

Valve stem end surface grinding

limit 0.2 (0.008)

Valve clearance (Hot) Intake 0.25 (0.01)

Exhaust

VALVE SPRING

Free length mm (in)

Painted red 53.9 (2.12)

Pressure height mm/N (mm/kg, in/lb) 31.8/713.5 - 788.5

(31.8/72.7 - 80.4,

1.252/160.0 - 177.3)

Assembled height mm/N (mm/kg, in/lb)

Standard 42.3/314.5 - 361.5

(42.3/32.1 - 36.9,

1.665/70.5 - 81.1)

Limit 42.3/296.2

(42.3/30.2,

1.665/66.6)

Out of square mm (in)2.0 (0.079)

CYLINDER HEAD TO VALVE DISTANCE

Unit: mm (in)

SEM724C

Standard Limit

Intake 0.8 - 1.2

(0.031 - 0.047) Less than 1.75

(0.0689)

Exhaust 0.8 - 1.2

(0.031 - 0.047) Less than 1.75

(0.0689)

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

Inspection and Adjustment (Cont'd)

EM-146

http://vnx.su/

Page 238 of 1833

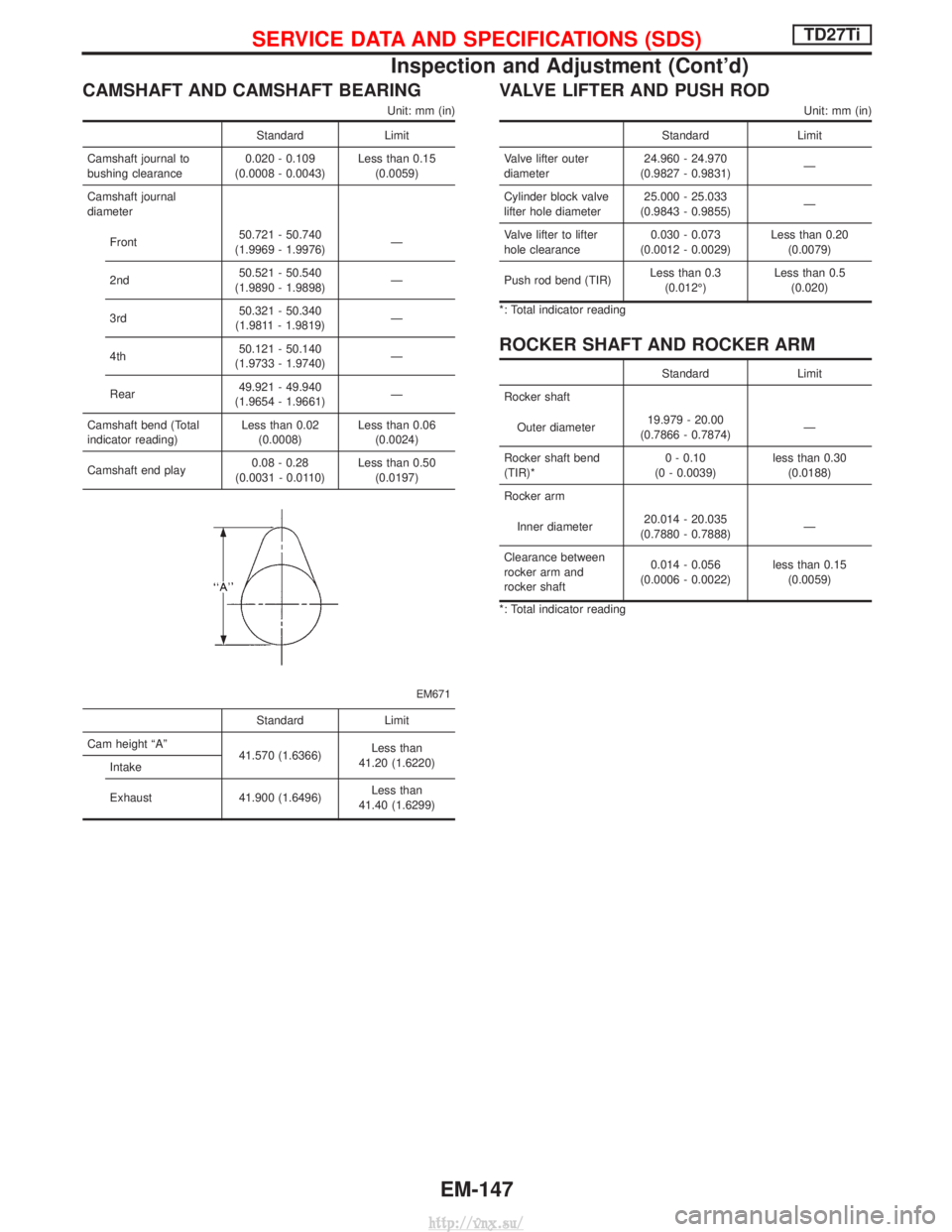

CAMSHAFT AND CAMSHAFT BEARING

Unit: mm (in)

StandardLimit

Camshaft journal to

bushing clearance 0.020 - 0.109

(0.0008 - 0.0043) Less than 0.15

(0.0059)

Camshaft journal

diameter

Front 50.721 - 50.740

(1.9969 - 1.9976) Ð

2nd 50.521 - 50.540

(1.9890 - 1.9898) Ð

3rd 50.321 - 50.340

(1.9811 - 1.9819) Ð

4th 50.121 - 50.140

(1.9733 - 1.9740) Ð

Rear 49.921 - 49.940

(1.9654 - 1.9661) Ð

Camshaft bend (Total

indicator reading) Less than 0.02

(0.0008) Less than 0.06

(0.0024)

Camshaft end play 0.08 - 0.28

(0.0031 - 0.0110) Less than 0.50

(0.0197)

EM671

Standard Limit

Cam height ªAº 41.570 (1.6366)Less than

41.20 (1.6220)

Intake

Exhaust 41.900 (1.6496) Less than

41.40 (1.6299)

VALVE LIFTER AND PUSH ROD

Unit: mm (in)

Standard Limit

Valve lifter outer

diameter 24.960 - 24.970

(0.9827 - 0.9831) Ð

Cylinder block valve

lifter hole diameter 25.000 - 25.033

(0.9843 - 0.9855) Ð

Valve lifter to lifter

hole clearance 0.030 - 0.073

(0.0012 - 0.0029) Less than 0.20

(0.0079)

Push rod bend (TIR) Less than 0.3

(0.012É) Less than 0.5

(0.020)

*: Total indicator reading

ROCKER SHAFT AND ROCKER ARM

Standard Limit

Rocker shaft

Outer diameter 19.979 - 20.00

(0.7866 - 0.7874) Ð

Rocker shaft bend

(TIR)* 0 - 0.10

(0 - 0.0039) less than 0.30

(0.0188)

Rocker arm

Inner diameter 20.014 - 20.035

(0.7880 - 0.7888) Ð

Clearance between

rocker arm and

rocker shaft 0.014 - 0.056

(0.0006 - 0.0022) less than 0.15

(0.0059)

*: Total indicator reading

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

Inspection and Adjustment (Cont'd)

EM-147

http://vnx.su/

Page 239 of 1833

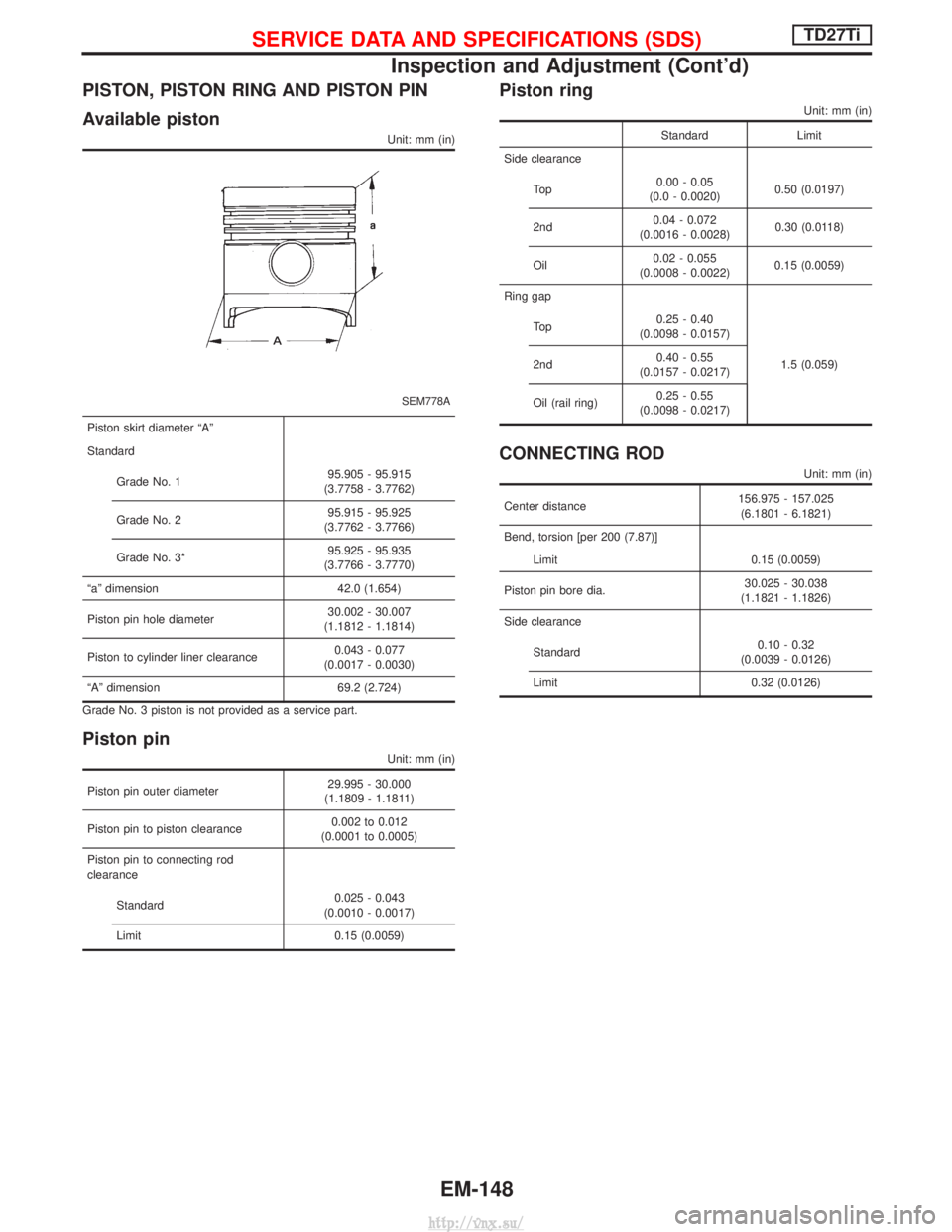

PISTON, PISTON RING AND PISTON PIN

Available piston

Unit: mm (in)

SEM778A

Piston skirt diameter ªAº

StandardGrade No. 1 95.905 - 95.915

(3.7758 - 3.7762)

Grade No. 2 95.915 - 95.925

(3.7762 - 3.7766)

Grade No. 3* 95.925 - 95.935

(3.7766 - 3.7770)

ªaº dimension 42.0 (1.654)

Piston pin hole diameter 30.002 - 30.007

(1.1812 - 1.1814)

Piston to cylinder liner clearance 0.043 - 0.077

(0.0017 - 0.0030)

ªAº dimension 69.2 (2.724)

Grade No. 3 piston is not provided as a service part.

Piston pin

Unit: mm (in)

Piston pin outer diameter 29.995 - 30.000

(1.1809 - 1.1811)

Piston pin to piston clearance 0.002 to 0.012

(0.0001 to 0.0005)

Piston pin to connecting rod

clearance

Standard 0.025 - 0.043

(0.0010 - 0.0017)

Limit 0.15 (0.0059)

Piston ring

Unit: mm (in)

Standard Limit

Side clearance

To p 0.00 - 0.05

(0.0 - 0.0020) 0.50 (0.0197)

2nd 0.04 - 0.072

(0.0016 - 0.0028) 0.30 (0.0118)

Oil 0.02 - 0.055

(0.0008 - 0.0022) 0.15 (0.0059)

Ring gap To p 0.25 - 0.40

(0.0098 - 0.0157)

1.5 (0.059)

2nd 0.40 - 0.55

(0.0157 - 0.0217)

Oil (rail ring) 0.25 - 0.55

(0.0098 - 0.0217)

CONNECTING ROD

Unit: mm (in)

Center distance 156.975 - 157.025

(6.1801 - 6.1821)

Bend, torsion [per 200 (7.87)] Limit 0.15 (0.0059)

Piston pin bore dia. 30.025 - 30.038

(1.1821 - 1.1826)

Side clearance

Standard 0.10 - 0.32

(0.0039 - 0.0126)

Limit 0.32 (0.0126)

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

Inspection and Adjustment (Cont'd)

EM-148

http://vnx.su/

Page 240 of 1833

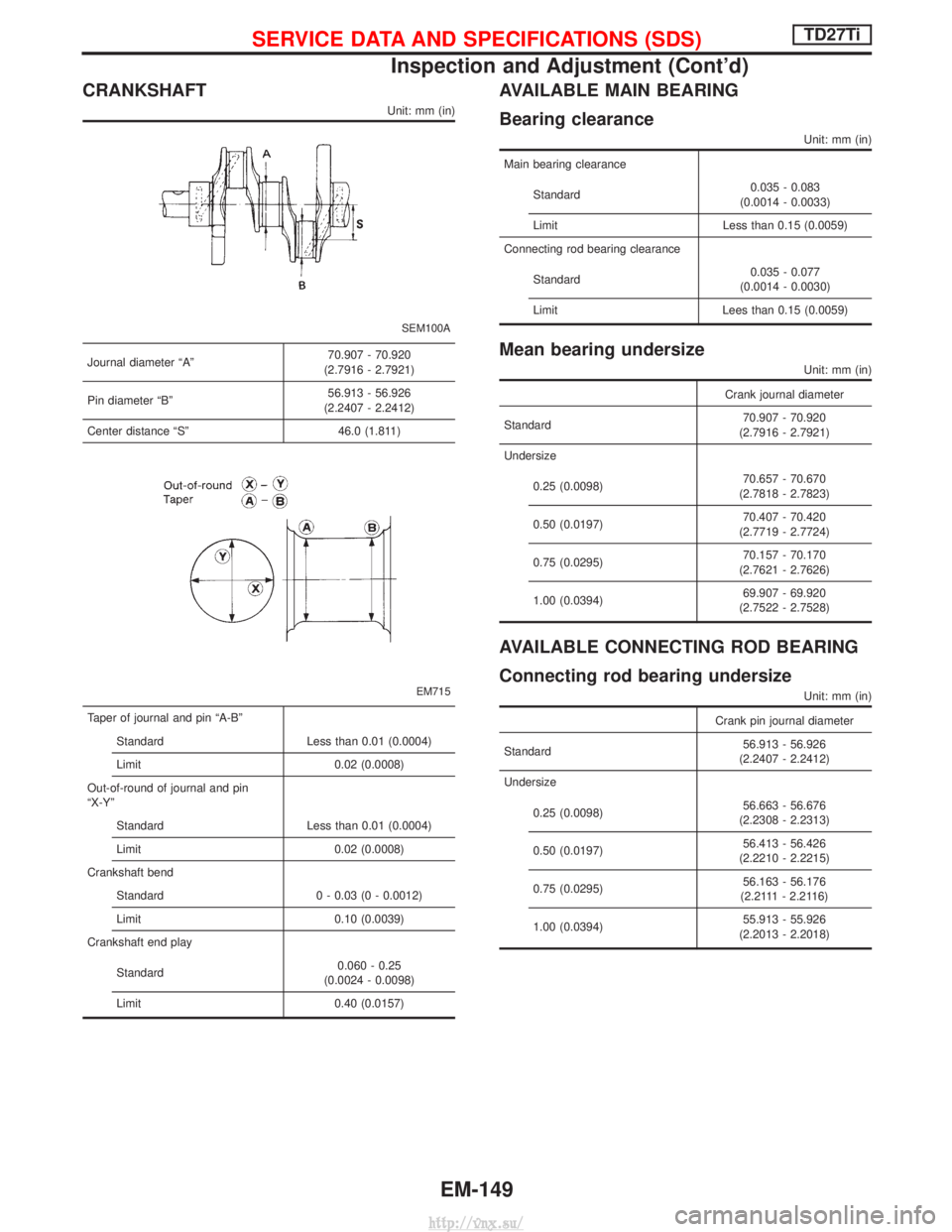

CRANKSHAFT

Unit: mm (in)

SEM100A

Journal diameter ªAº70.907 - 70.920

(2.7916 - 2.7921)

Pin diameter ªBº 56.913 - 56.926

(2.2407 - 2.2412)

Center distance ªSº 46.0 (1.811)

EM715

Taper of journal and pin ªA-Bº Standard Less than 0.01 (0.0004)

Limit 0.02 (0.0008)

Out-of-round of journal and pin

ªX-Yº Standard Less than 0.01 (0.0004)

Limit 0.02 (0.0008)

Crankshaft bend Standard 0 - 0.03 (0 - 0.0012)

Limit 0.10 (0.0039)

Crankshaft end play

Standard 0.060 - 0.25

(0.0024 - 0.0098)

Limit 0.40 (0.0157)

AVAILABLE MAIN BEARING

Bearing clearance

Unit: mm (in)

Main bearing clearance

Standard 0.035 - 0.083

(0.0014 - 0.0033)

Limit Less than 0.15 (0.0059)

Connecting rod bearing clearance

Standard 0.035 - 0.077

(0.0014 - 0.0030)

Limit Lees than 0.15 (0.0059)

Mean bearing undersize

Unit: mm (in)

Crank journal diameter

Standard 70.907 - 70.920

(2.7916 - 2.7921)

Undersize

0.25 (0.0098) 70.657 - 70.670

(2.7818 - 2.7823)

0.50 (0.0197) 70.407 - 70.420

(2.7719 - 2.7724)

0.75 (0.0295) 70.157 - 70.170

(2.7621 - 2.7626)

1.00 (0.0394) 69.907 - 69.920

(2.7522 - 2.7528)

AVAILABLE CONNECTING ROD BEARING

Connecting rod bearing undersize

Unit: mm (in)

Crank pin journal diameter

Standard 56.913 - 56.926

(2.2407 - 2.2412)

Undersize

0.25 (0.0098) 56.663 - 56.676

(2.2308 - 2.2313)

0.50 (0.0197) 56.413 - 56.426

(2.2210 - 2.2215)

0.75 (0.0295) 56.163 - 56.176

(2.2111 - 2.2116)

1.00 (0.0394) 55.913 - 55.926

(2.2013 - 2.2018)

SERVICE DATA AND SPECIFICATIONS (SDS)TD27Ti

Inspection and Adjustment (Cont'd)

EM-149

http://vnx.su/