NISSAN TIIDA 2007 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 4261 of 5883

RECOMMENDED FLUIDS AND LUBRICANTS

MA-21

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

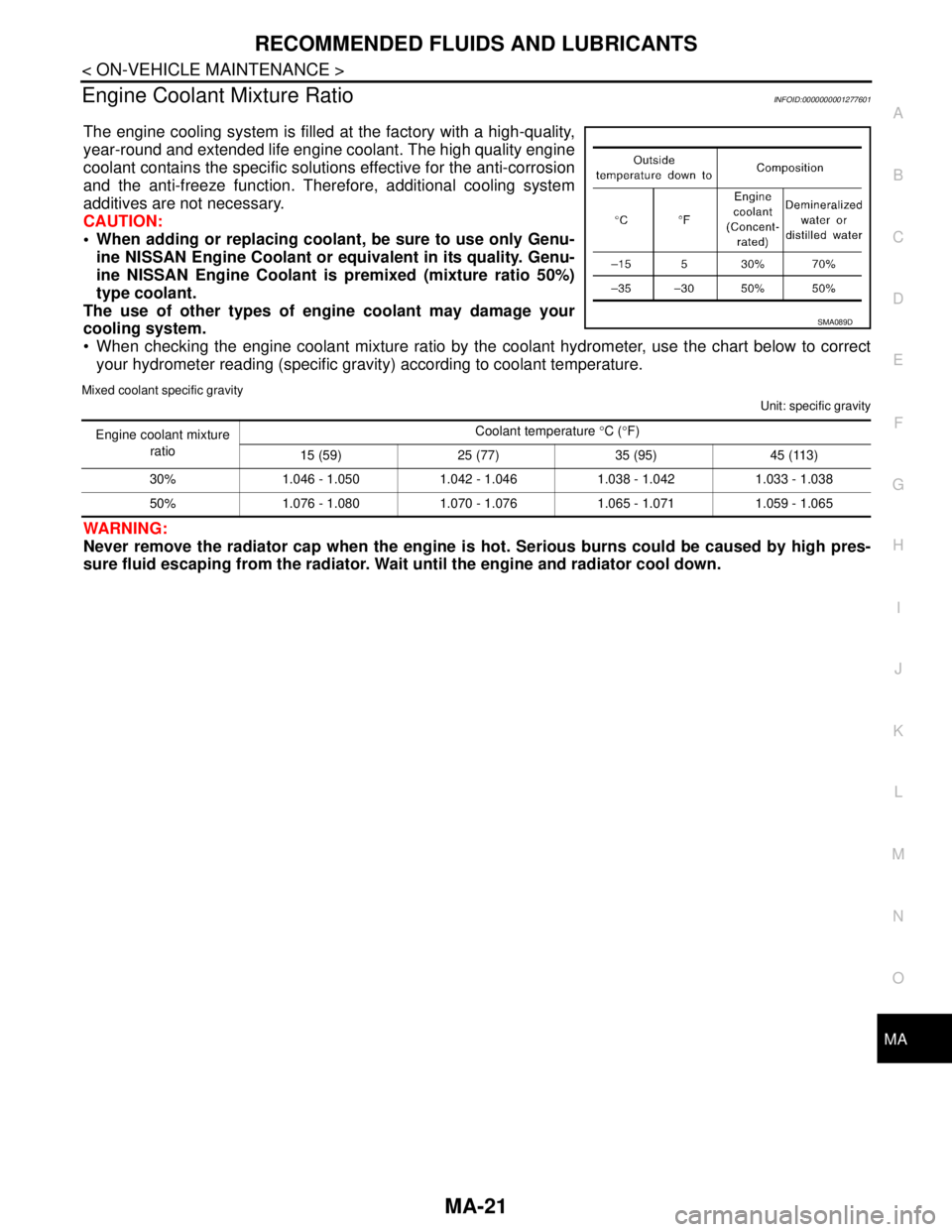

Engine Coolant Mixture RatioINFOID:0000000001277601

The engine cooling system is filled at the factory with a high-quality,

year-round and extended life engine coolant. The high quality engine

coolant contains the specific solutions effective for the anti-corrosion

and the anti-freeze function. Therefore, additional cooling system

additives are not necessary.

CAUTION:

When adding or replacing coolant, be sure to use only Genu-

ine NISSAN Engine Coolant or equivalent in its quality. Genu-

ine NISSAN Engine Coolant is premixed (mixture ratio 50%)

type coolant.

The use of other types of engine coolant may damage your

cooling system.

When checking the engine coolant mixture ratio by the coolant hydrometer, use the chart below to correct

your hydrometer reading (specific gravity) according to coolant temperature.

Mixed coolant specific gravity

Unit: specific gravity

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns could be caused by high pres-

sure fluid escaping from the radiator. Wait until the engine and radiator cool down.

SMA089D

Engine coolant mixture

ratioCoolant temperature °C (°F)

15 (59) 25 (77) 35 (95) 45 (113)

30% 1.046 - 1.050 1.042 - 1.046 1.038 - 1.042 1.033 - 1.038

50% 1.076 - 1.080 1.070 - 1.076 1.065 - 1.071 1.059 - 1.065

Page 4262 of 5883

MA-22

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE (HR16DE)

ENGINE MAINTENANCE (HR16DE)

DRIVE BELTS

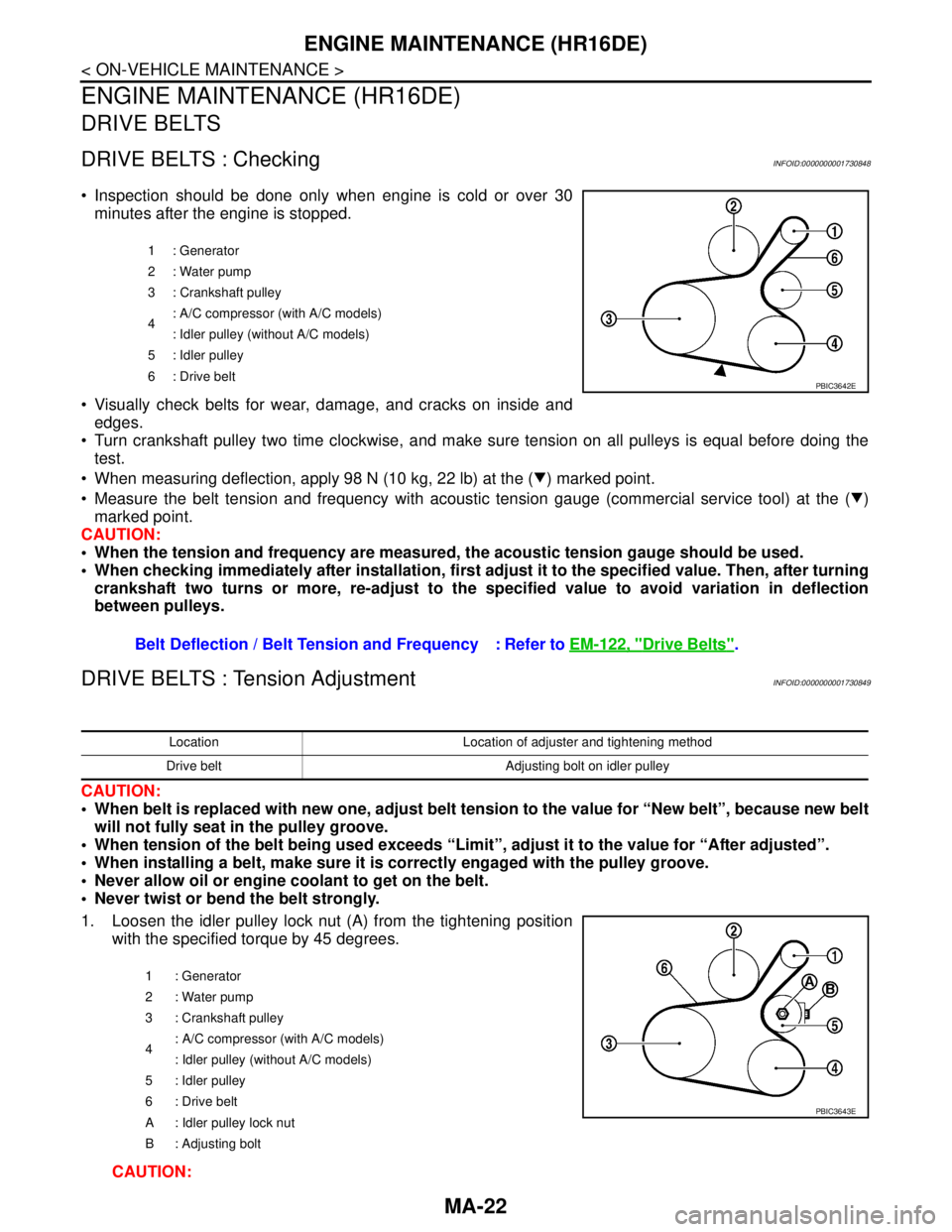

DRIVE BELTS : CheckingINFOID:0000000001730848

Inspection should be done only when engine is cold or over 30

minutes after the engine is stopped.

Visually check belts for wear, damage, and cracks on inside and

edges.

Turn crankshaft pulley two time clockwise, and make sure tension on all pulleys is equal before doing the

test.

When measuring deflection, apply 98 N (10 kg, 22 lb) at the ( ) marked point.

Measure the belt tension and frequency with acoustic tension gauge (commercial service tool) at the ( )

marked point.

CAUTION:

When the tension and frequency are measured, the acoustic tension gauge should be used.

When checking immediately after installation, first adjust it to the specified value. Then, after turning

crankshaft two turns or more, re-adjust to the specified value to avoid variation in deflection

between pulleys.

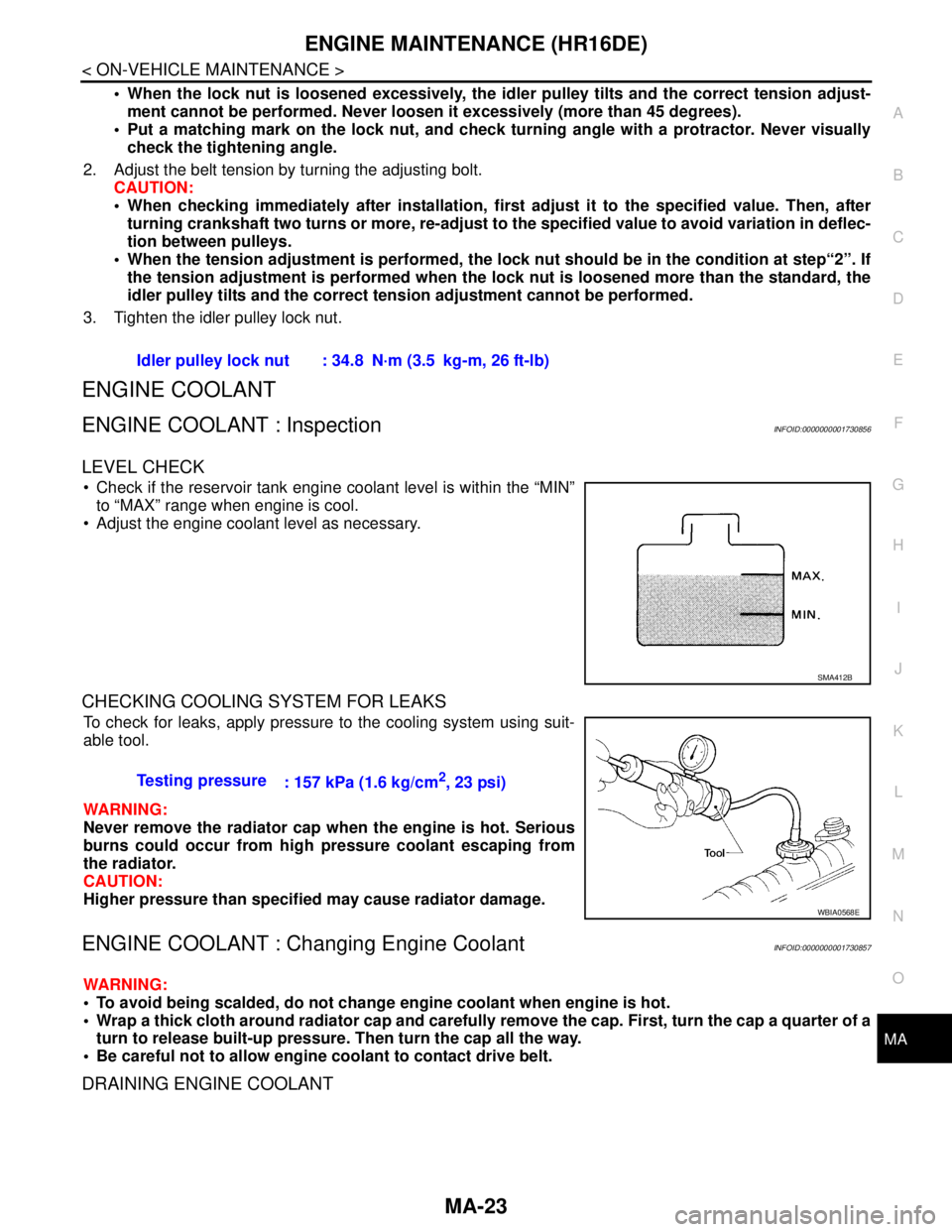

DRIVE BELTS : Tension AdjustmentINFOID:0000000001730849

CAUTION:

When belt is replaced with new one, adjust belt tension to the value for “New belt”, because new belt

will not fully seat in the pulley groove.

When tension of the belt being used exceeds “Limit”, adjust it to the value for “After adjusted”.

When installing a belt, make sure it is correctly engaged with the pulley groove.

Never allow oil or engine coolant to get on the belt.

Never twist or bend the belt strongly.

1. Loosen the idler pulley lock nut (A) from the tightening position

with the specified torque by 45 degrees.

CAUTION:

1 : Generator

2: Water pump

3 : Crankshaft pulley

4: A/C compressor (with A/C models)

: Idler pulley (without A/C models)

5 : Idler pulley

6: Drive belt

Belt Deflection / Belt Tension and Frequency : Refer to EM-122, "Drive Belts".

PBIC3642E

Location Location of adjuster and tightening method

Drive belt Adjusting bolt on idler pulley

1 : Generator

2: Water pump

3 : Crankshaft pulley

4: A/C compressor (with A/C models)

: Idler pulley (without A/C models)

5 : Idler pulley

6 : Drive belt

A : Idler pulley lock nut

B : Adjusting bolt

PBIC3643E

Page 4263 of 5883

ENGINE MAINTENANCE (HR16DE)

MA-23

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

When the lock nut is loosened excessively, the idler pulley tilts and the correct tension adjust-

ment cannot be performed. Never loosen it excessively (more than 45 degrees).

Put a matching mark on the lock nut, and check turning angle with a protractor. Never visually

check the tightening angle.

2. Adjust the belt tension by turning the adjusting bolt.

CAUTION:

When checking immediately after installation, first adjust it to the specified value. Then, after

turning crankshaft two turns or more, re-adjust to the specified value to avoid variation in deflec-

tion between pulleys.

When the tension adjustment is performed, the lock nut should be in the condition at step“2”. If

the tension adjustment is performed when the lock nut is loosened more than the standard, the

idler pulley tilts and the correct tension adjustment cannot be performed.

3. Tighten the idler pulley lock nut.

ENGINE COOLANT

ENGINE COOLANT : InspectionINFOID:0000000001730856

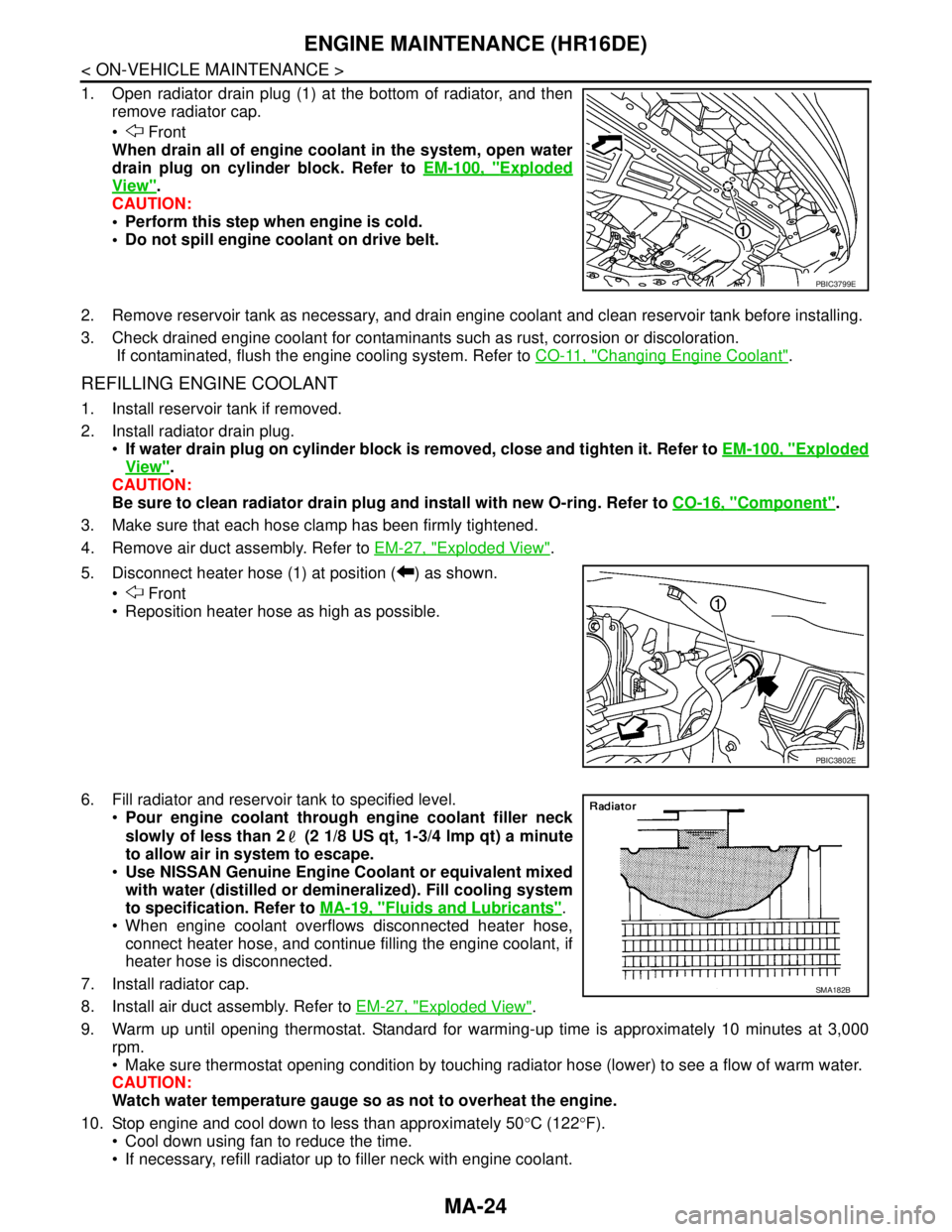

LEVEL CHECK

Check if the reservoir tank engine coolant level is within the “MIN”

to “MAX” range when engine is cool.

Adjust the engine coolant level as necessary.

CHECKING COOLING SYSTEM FOR LEAKS

To check for leaks, apply pressure to the cooling system using suit-

able tool.

WARNING:

Never remove the radiator cap when the engine is hot. Serious

burns could occur from high pressure coolant escaping from

the radiator.

CAUTION:

Higher pressure than specified may cause radiator damage.

ENGINE COOLANT : Changing Engine CoolantINFOID:0000000001730857

WARNING:

To avoid being scalded, do not change engine coolant when engine is hot.

Wrap a thick cloth around radiator cap and carefully remove the cap. First, turn the cap a quarter of a

turn to release built-up pressure. Then turn the cap all the way.

Be careful not to allow engine coolant to contact drive belt.

DRAINING ENGINE COOLANT

Idler pulley lock nut : 34.8 N·m (3.5 kg-m, 26 ft-lb)

SMA412B

Testing pressure

: 157 kPa (1.6 kg/cm2, 23 psi)

WBIA0568E

Page 4264 of 5883

MA-24

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE (HR16DE)

1. Open radiator drain plug (1) at the bottom of radiator, and then

remove radiator cap.

Front

When drain all of engine coolant in the system, open water

drain plug on cylinder block. Refer to EM-100, "

Exploded

View".

CAUTION:

Perform this step when engine is cold.

Do not spill engine coolant on drive belt.

2. Remove reservoir tank as necessary, and drain engine coolant and clean reservoir tank before installing.

3. Check drained engine coolant for contaminants such as rust, corrosion or discoloration.

If contaminated, flush the engine cooling system. Refer to CO-11, "

Changing Engine Coolant".

REFILLING ENGINE COOLANT

1. Install reservoir tank if removed.

2. Install radiator drain plug.

If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-100, "

Exploded

View".

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring. Refer to CO-16, "

Component".

3. Make sure that each hose clamp has been firmly tightened.

4. Remove air duct assembly. Refer to EM-27, "

Exploded View".

5. Disconnect heater hose (1) at position ( ) as shown.

Front

Reposition heater hose as high as possible.

6. Fill radiator and reservoir tank to specified level.

Pour engine coolant through engine coolant filler neck

slowly of less than 2 (2 1/8 US qt, 1-3/4 lmp qt) a minute

to allow air in system to escape.

Use NISSAN Genuine Engine Coolant or equivalent mixed

with water (distilled or demineralized). Fill cooling system

to specification. Refer to MA-19, "

Fluids and Lubricants".

When engine coolant overflows disconnected heater hose,

connect heater hose, and continue filling the engine coolant, if

heater hose is disconnected.

7. Install radiator cap.

8. Install air duct assembly. Refer to EM-27, "

Exploded View".

9. Warm up until opening thermostat. Standard for warming-up time is approximately 10 minutes at 3,000

rpm.

Make sure thermostat opening condition by touching radiator hose (lower) to see a flow of warm water.

CAUTION:

Watch water temperature gauge so as not to overheat the engine.

10. Stop engine and cool down to less than approximately 50°C (122°F).

Cool down using fan to reduce the time.

If necessary, refill radiator up to filler neck with engine coolant.

PBIC3799E

PBIC3802E

SMA182B

Page 4265 of 5883

ENGINE MAINTENANCE (HR16DE)

MA-25

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

11. Refill reservoir tank to “MAX” level line with engine coolant.

12. Repeat steps 6 through 11 two or more times with radiator cap installed until engine coolant level no

longer drops.

13. Check cooling system for leaks with engine running.

14. Warm up engine, and check for sound of engine coolant flow while running engine from idle up to 3,000

rpm with heater temperature controller set at several position between “COOL” and “WARM”.

Sound may be noticeable at heater unit.

15. Repeat step 14 three times.

16. If sound is heard, bleed air from cooling system by repeating steps 6 through 11 until engine coolant level

no longer drops.

FLUSHING COOLING SYSTEM

1. Install reservoir tank if removed.

2. Install radiator drain plug.

If water drain plug on cylinder block is removed, close and tighten it. Refer to EM-100, "

Exploded

View".

CAUTION:

Be sure to clean radiator drain plug and install with new O-ring. Refer to CO-16, "

Component".

3. Fill radiator and reservoir tank with water and reinstall radiator cap.

4. Run engine and warm it up to normal operating temperature.

5. Rev engine two or three times under no-load.

6. Stop engine and wait until it cools down.

7. Drain water from the cooling system. Refer to CO-11, "

Changing Engine Coolant".

8. Repeat steps 1 through 7 until clear water begins to drain from radiator.

RADIATOR

RADIATOR : Checking RadiatorINFOID:0000000001730858

Check radiator for mud or clogging. If necessary, clean radiator as follows.

Be careful not to bend or damage radiator fins.

When radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator shroud

and horns. Then tape harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from radiator.

4. Blow air into the back side of radiator core vertically downward.

Use compressed air lower than 490 kPa (4.9 bar, 5 kg/cm

2, 71 psi) and keep distance more than 30 cm

(11.8 in).

5. Blow air again into all the radiator core surfaces once per minute until no water sprays out.

FUEL LINES

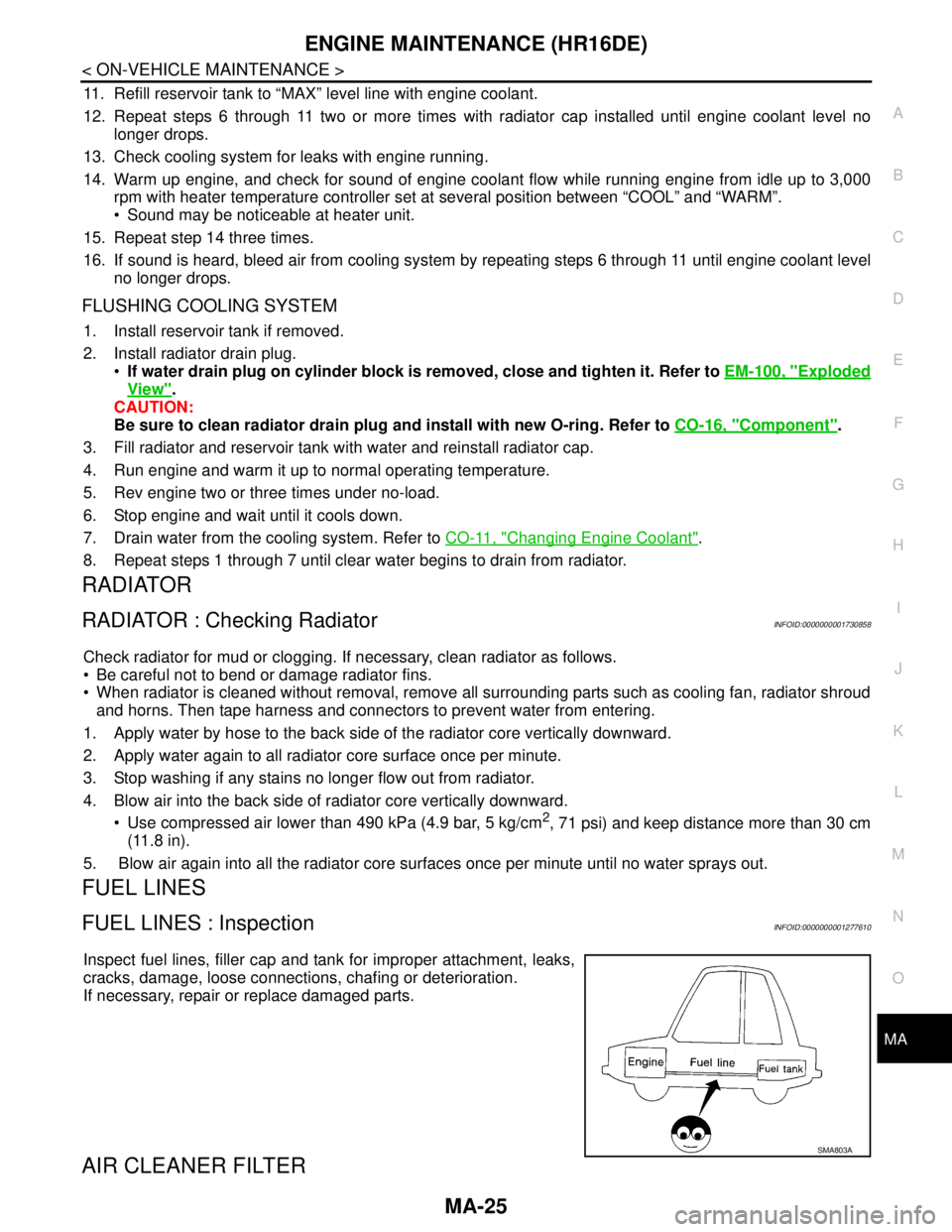

FUEL LINES : InspectionINFOID:0000000001277610

Inspect fuel lines, filler cap and tank for improper attachment, leaks,

cracks, damage, loose connections, chafing or deterioration.

If necessary, repair or replace damaged parts.

AIR CLEANER FILTER

SMA803A

Page 4266 of 5883

MA-26

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE (HR16DE)

AIR CLEANER FILTER : Removal and Installation

INFOID:0000000001730850

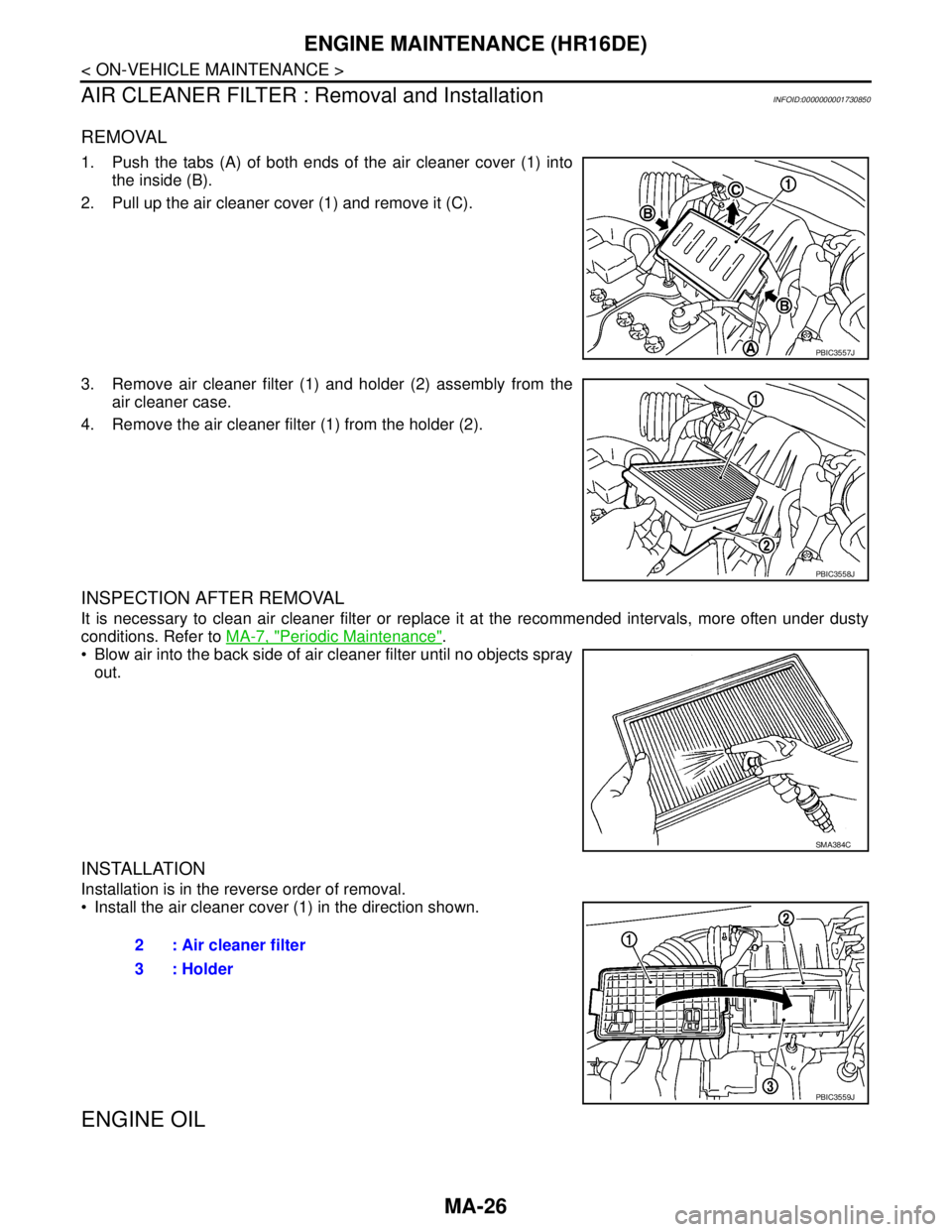

REMOVAL

1. Push the tabs (A) of both ends of the air cleaner cover (1) into

the inside (B).

2. Pull up the air cleaner cover (1) and remove it (C).

3. Remove air cleaner filter (1) and holder (2) assembly from the

air cleaner case.

4. Remove the air cleaner filter (1) from the holder (2).

INSPECTION AFTER REMOVAL

It is necessary to clean air cleaner filter or replace it at the recommended intervals, more often under dusty

conditions. Refer to MA-7, "

Periodic Maintenance".

Blow air into the back side of air cleaner filter until no objects spray

out.

INSTALLATION

Installation is in the reverse order of removal.

Install the air cleaner cover (1) in the direction shown.

ENGINE OIL

PBIC3557J

PBIC3558J

SMA384C

2 : Air cleaner filter

3 : Holder

PBIC3559J

Page 4267 of 5883

ENGINE MAINTENANCE (HR16DE)

MA-27

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

ENGINE OIL : DrainingINFOID:0000000001730852

WARNING:

Be careful not to get burned, as engine oil may be hot.

Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thoroughly with soap or hand cleaner as

soon as possible.

1. Warm up the engine, and check for engine oil leakage from engine components. Refer to LU-6, "

Inspec-

tion".

2. Stop the engine and wait for 10 minutes.

3. Loosen oil filler cap.

4. Remove drain plug and then drain engine oil.

ENGINE OIL : RefillingINFOID:0000000001730853

1. Install drain plug with new washer. Refer to EM-100, "Exploded View".

CAUTION:

Be sure to clean drain plug and install with new washer.

2. Refill with new engine oil.

Engine oil specification and viscosity: Refer to MA-19, "

Fluids and Lubricants".

CAUTION:

The refill capacity depends on the engine oil temperature and drain time. Use these specifica-

tions for reference only.

Always use oil level gauge to determine the proper amount of engine oil in the engine.

3. Warm up engine and check area around drain plug and oil filter for engine oil leakage.

4. Stop engine and wait for 10 minutes.

5. Check the engine oil level. Refer to LU-6, "

Inspection".

OIL FILTER

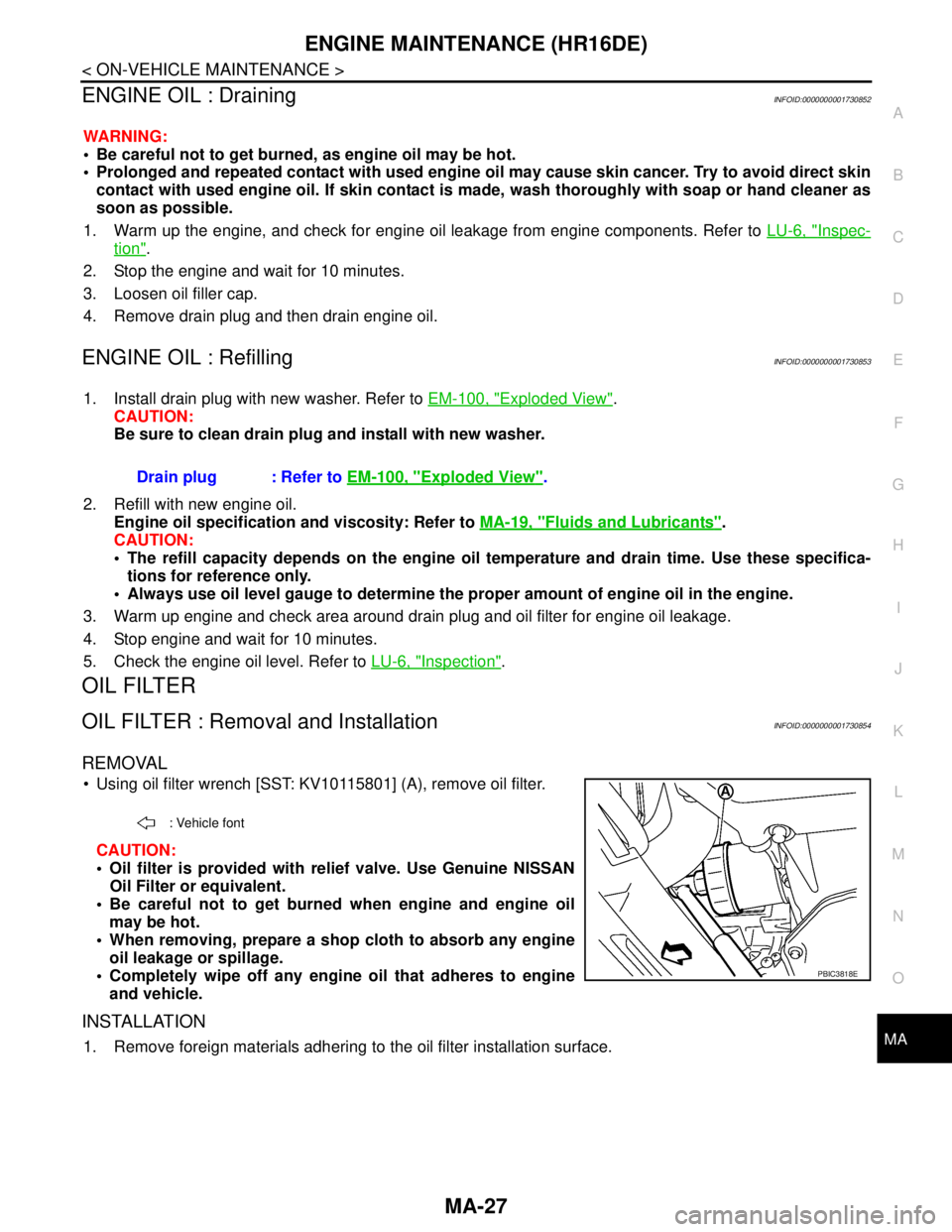

OIL FILTER : Removal and InstallationINFOID:0000000001730854

REMOVAL

Using oil filter wrench [SST: KV10115801] (A), remove oil filter.

CAUTION:

Oil filter is provided with relief valve. Use Genuine NISSAN

Oil Filter or equivalent.

Be careful not to get burned when engine and engine oil

may be hot.

When removing, prepare a shop cloth to absorb any engine

oil leakage or spillage.

Completely wipe off any engine oil that adheres to engine

and vehicle.

INSTALLATION

1. Remove foreign materials adhering to the oil filter installation surface.Drain plug : Refer to EM-100, "

Exploded View".

: Vehicle font

PBIC3818E

Page 4268 of 5883

MA-28

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE (HR16DE)

2. Apply new engine oil to the oil seal contact surface of new oil fil-

ter.

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn. Or tighten to specification.

OIL FILTER : InspectionINFOID:0000000001730855

INSPECTION AFTER INSTALLATION

1. Check the engine oil level. Refer to LU-6, "Inspection".

2. Start the engine, and check there is no leak of engine oil.

3. Stop the engine and wait for 10 minutes.

4. Check the engine oil level, and adjust the level. Refer to LU-6, "

Inspection".

SPARK PLUG

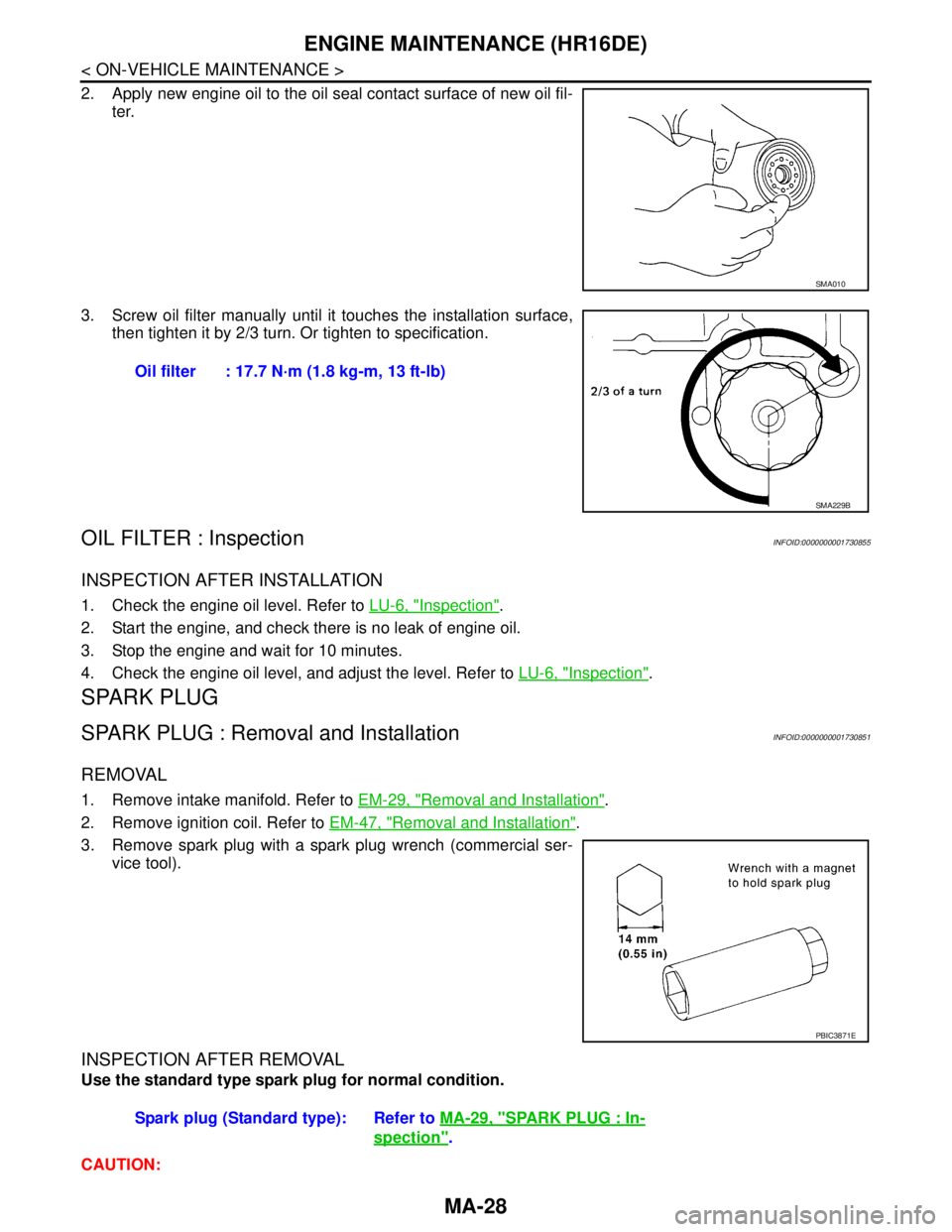

SPARK PLUG : Removal and InstallationINFOID:0000000001730851

REMOVAL

1. Remove intake manifold. Refer to EM-29, "Removal and Installation".

2. Remove ignition coil. Refer to EM-47, "

Removal and Installation".

3. Remove spark plug with a spark plug wrench (commercial ser-

vice tool).

INSPECTION AFTER REMOVAL

Use the standard type spark plug for normal condition.

CAUTION:

SMA010

Oil filter : 17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B

PBIC3871E

Spark plug (Standard type): Refer to MA-29, "SPARK PLUG : In-

spection".

Page 4269 of 5883

ENGINE MAINTENANCE (HR16DE)

MA-29

< ON-VEHICLE MAINTENANCE >

C

D

E

F

G

H

I

J

K

L

MB

MAN

OA

Never drop or shock spark plug.

Never use a wire brush for cleaning.

If plug tip is covered with carbon, spark plug cleaner may be

used.

Checking and adjusting plug gap is not required between

change intervals.

INSTALLATION

Installation is the reverse order of removal.

SPARK PLUG : InspectionINFOID:0000000001277617

INSPECTION AFTER REMOVAL

Use the standard type spark plug for normal condition.

CAUTION:

Never drop or shock spark plug.

Never use a wire brush for cleaning.

If plug tip is covered with carbon, spark plug cleaner may be

used.Cleaner air

pressure:Less than 588 kPa (6 kg/cm

2, 85 psi)

Cleaning time: Less than 20 seconds

SMA773C

JPBIA0031ZZ

Plug type : Platinum tipped

Make : NGK

Part number : PLZKAR6AP-11

Gap (nominal) : 1.1 mm (0.043 in)

Spark plug (Standard type): : PLZKAR6AP-11

Cleaner air pressure:

Less than 588 kPa (6 kg/cm

2, 85 psi)

Cleaning time:

Less than 20 seconds

SMA773C

Page 4270 of 5883

MA-30

< ON-VEHICLE MAINTENANCE >

ENGINE MAINTENANCE (HR16DE)

Checking and adjusting plug gap is not required between

change intervals.

EVAP VAPOR LINES

EVAP VAPOR LINES : InspectionINFOID:0000000001277618

Refer to FL-10, "Removal and Installation" .

JPBIA0031ZZ