NISSAN X-TRAIL 2001 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2001, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2001Pages: 3833, PDF Size: 39.49 MB

Page 3171 of 3833

REAR WINDOW DEFOGGER

GW-19

C

D

E

F

G

H

J

K

L

MA

B

GW

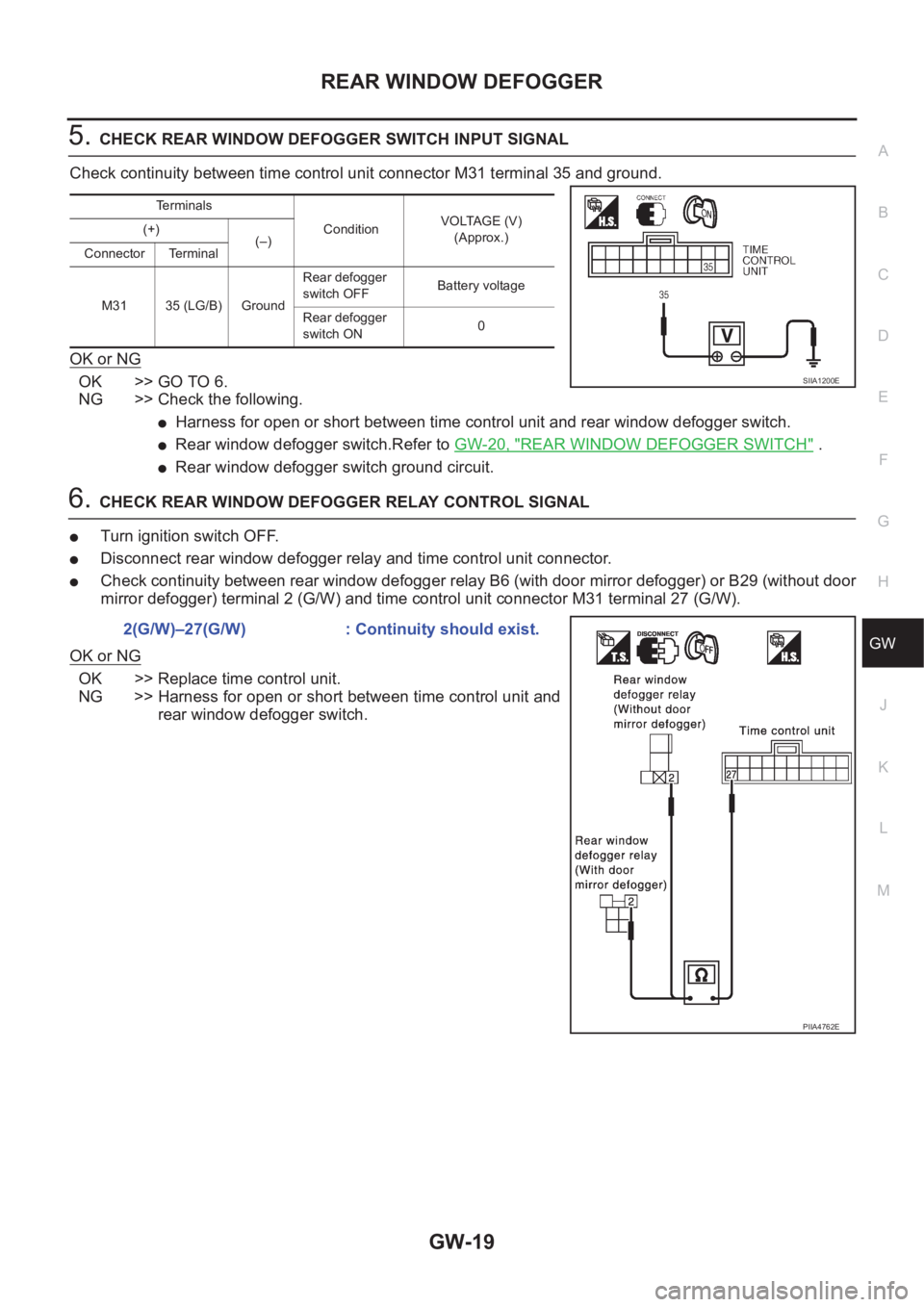

5.CHECK REAR WINDOW DEFOGGER SWITCH INPUT SIGNAL

Check continuity between time control unit connector M31 terminal 35 and ground.

OK or NG

OK >> GO TO 6.

NG >> Check the following.

●Harness for open or short between time control unit and rear window defogger switch.

●Rear window defogger switch.Refer to GW-20, "REAR WINDOW DEFOGGER SWITCH" .

●Rear window defogger switch ground circuit.

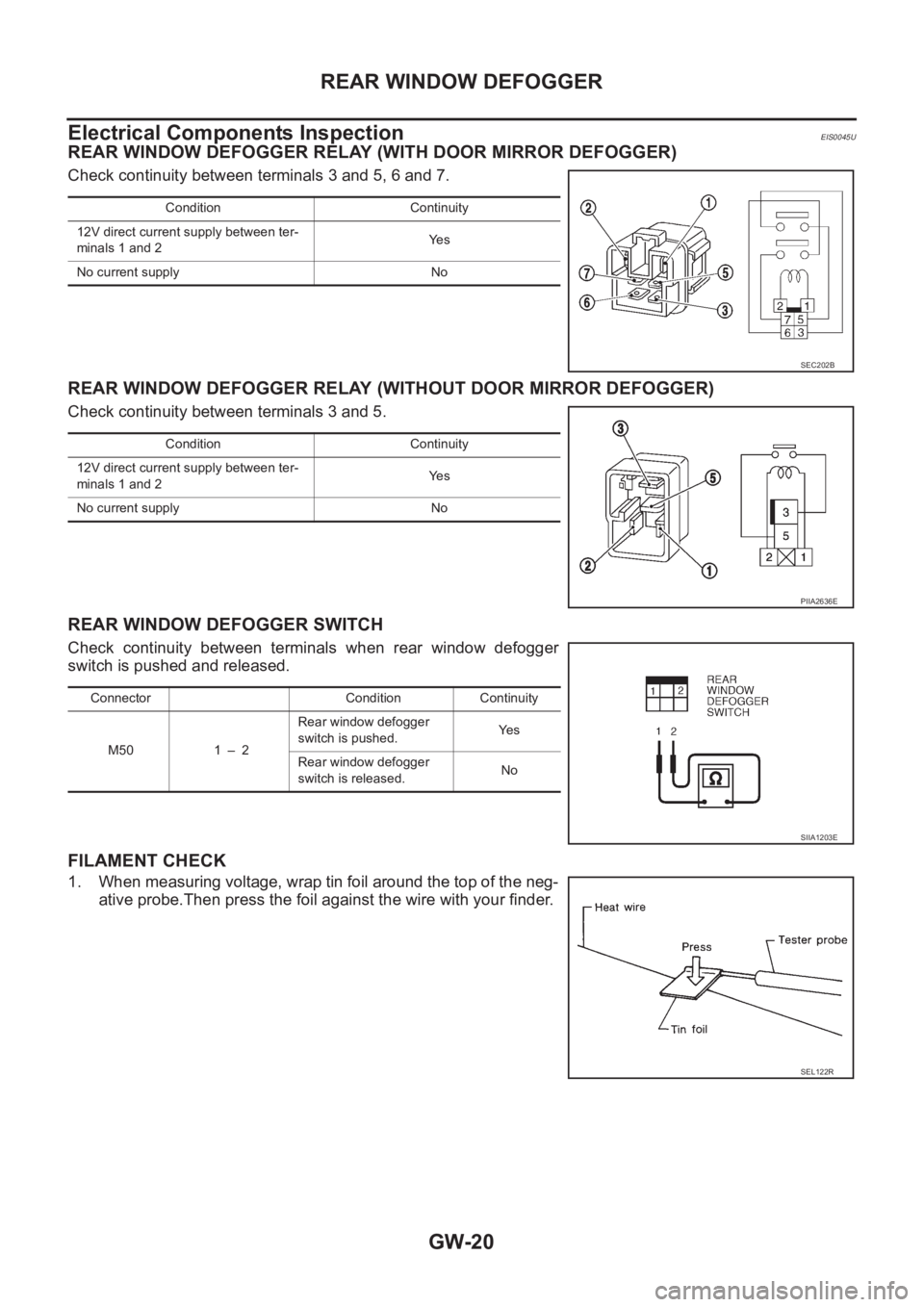

6.CHECK REAR WINDOW DEFOGGER RELAY CONTROL SIGNAL

●Turn ignition switch OFF.

●Disconnect rear window defogger relay and time control unit connector.

●Check continuity between rear window defogger relay B6 (with door mirror defogger) or B29 (without door

mirror defogger) terminal 2 (G/W) and time control unit connector M31 terminal 27 (G/W).

OK or NG

OK >> Replace time control unit.

NG >> Harness for open or short between time control unit and

rear window defogger switch.

Terminals

ConditionVOLTAGE (V)

(Approx.) (+)

(–)

Connector Terminal

M31 35 (LG/B) GroundRear defogger

switch OFFBattery voltage

Rear defogger

switch ON0

SIIA1200E

2(G/W)–27(G/W) : Continuity should exist.

PIIA4762E

Page 3172 of 3833

GW-20

REAR WINDOW DEFOGGER

Electrical Components Inspection

EIS0045U

REAR WINDOW DEFOGGER RELAY (WITH DOOR MIRROR DEFOGGER)

Check continuity between terminals 3 and 5, 6 and 7.

REAR WINDOW DEFOGGER RELAY (WITHOUT DOOR MIRROR DEFOGGER)

Check continuity between terminals 3 and 5.

REAR WINDOW DEFOGGER SWITCH

Check continuity between terminals when rear window defogger

switch is pushed and released.

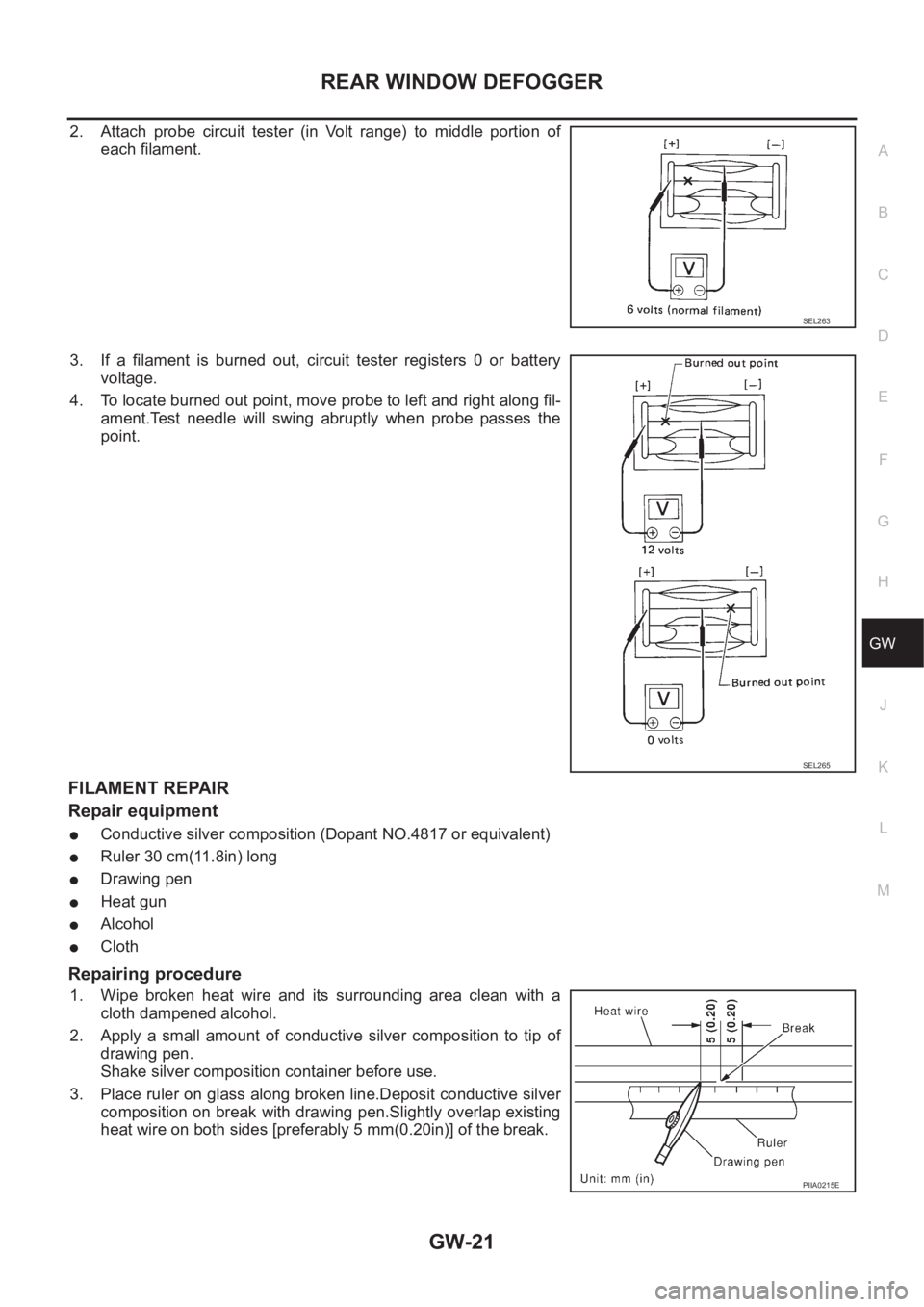

FILAMENT CHECK

1. When measuring voltage, wrap tin foil around the top of the neg-

ative probe.Then press the foil against the wire with your finder.

Condition Continuity

12V direct current supply between ter-

minals 1 and 2Ye s

No current supply No

SEC202B

Condition Continuity

12V direct current supply between ter-

minals 1 and 2Ye s

No current supply No

PIIA2636E

Connector Condition Continuity

M50 1 – 2Rear window defogger

switch is pushed.Ye s

Rear window defogger

switch is released.No

SIIA1203E

SEL122R

Page 3173 of 3833

REAR WINDOW DEFOGGER

GW-21

C

D

E

F

G

H

J

K

L

MA

B

GW

2. Attach probe circuit tester (in Volt range) to middle portion of

each filament.

3. If a filament is burned out, circuit tester registers 0 or battery

voltage.

4. To locate burned out point, move probe to left and right along fil-

ament.Test needle will swing abruptly when probe passes the

point.

FILAMENT REPAIR

Repair equipment

●Conductive silver composition (Dopant NO.4817 or equivalent)

●Ruler 30 cm(11.8in) long

●Drawing pen

●Heat gun

●Alcohol

●Cloth

Repairing procedure

1. Wipe broken heat wire and its surrounding area clean with a

cloth dampened alcohol.

2. Apply a small amount of conductive silver composition to tip of

drawing pen.

Shake silver composition container before use.

3. Place ruler on glass along broken line.Deposit conductive silver

composition on break with drawing pen.Slightly overlap existing

heat wire on both sides [preferably 5 mm(0.20in)] of the break.

SEL263

SEL265

PIIA0215E

Page 3174 of 3833

GW-22

REAR WINDOW DEFOGGER

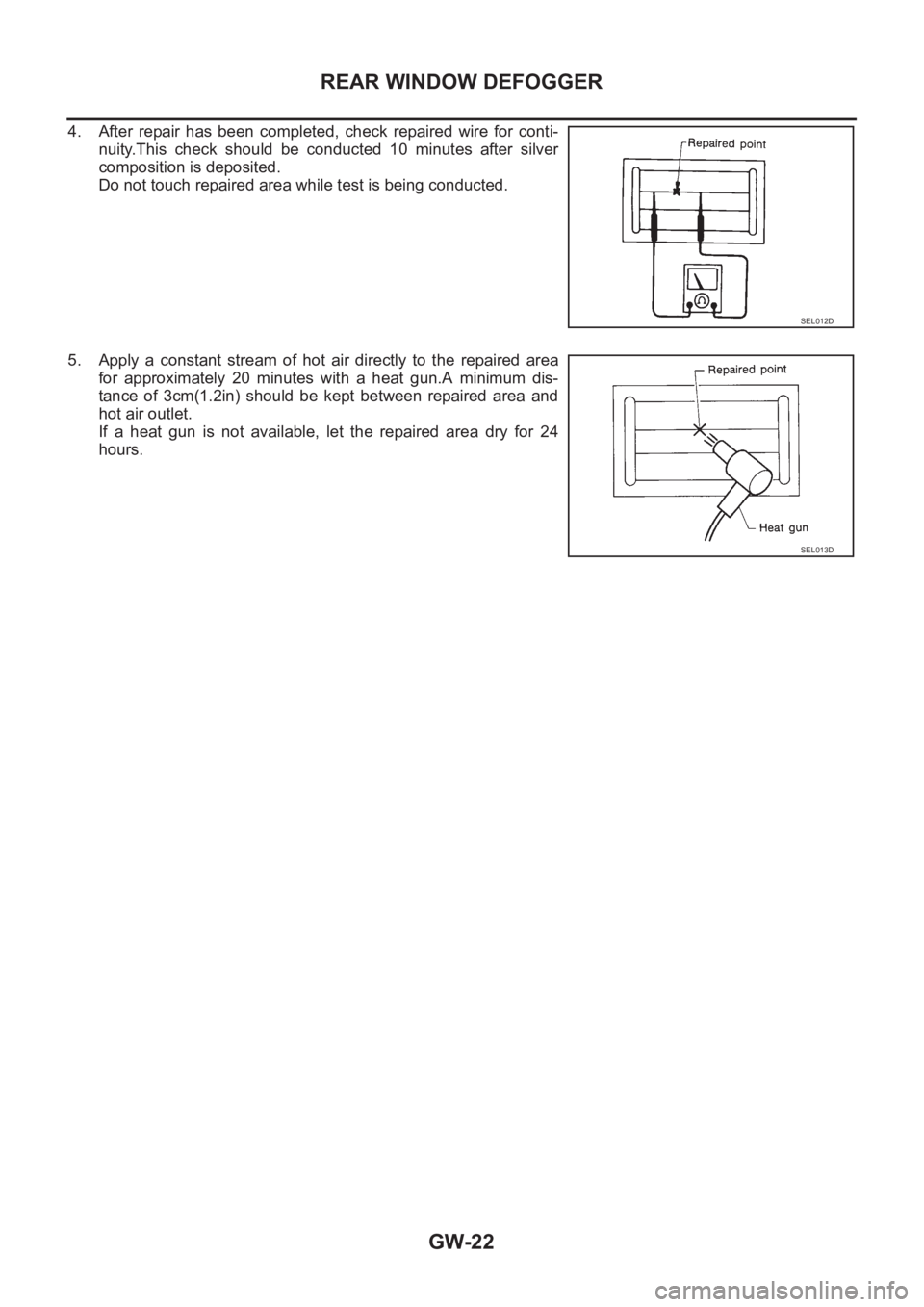

4. After repair has been completed, check repaired wire for conti-

nuity.This check should be conducted 10 minutes after silver

composition is deposited.

Do not touch repaired area while test is being conducted.

5. Apply a constant stream of hot air directly to the repaired area

for approximately 20 minutes with a heat gun.A minimum dis-

tance of 3cm(1.2in) should be kept between repaired area and

hot air outlet.

If a heat gun is not available, let the repaired area dry for 24

hours.

SEL012D

SEL013D

Page 3175 of 3833

POWER WINDOW SYSTEM

GW-23

C

D

E

F

G

H

J

K

L

MA

B

GW

POWER WINDOW SYSTEMPFP:25401

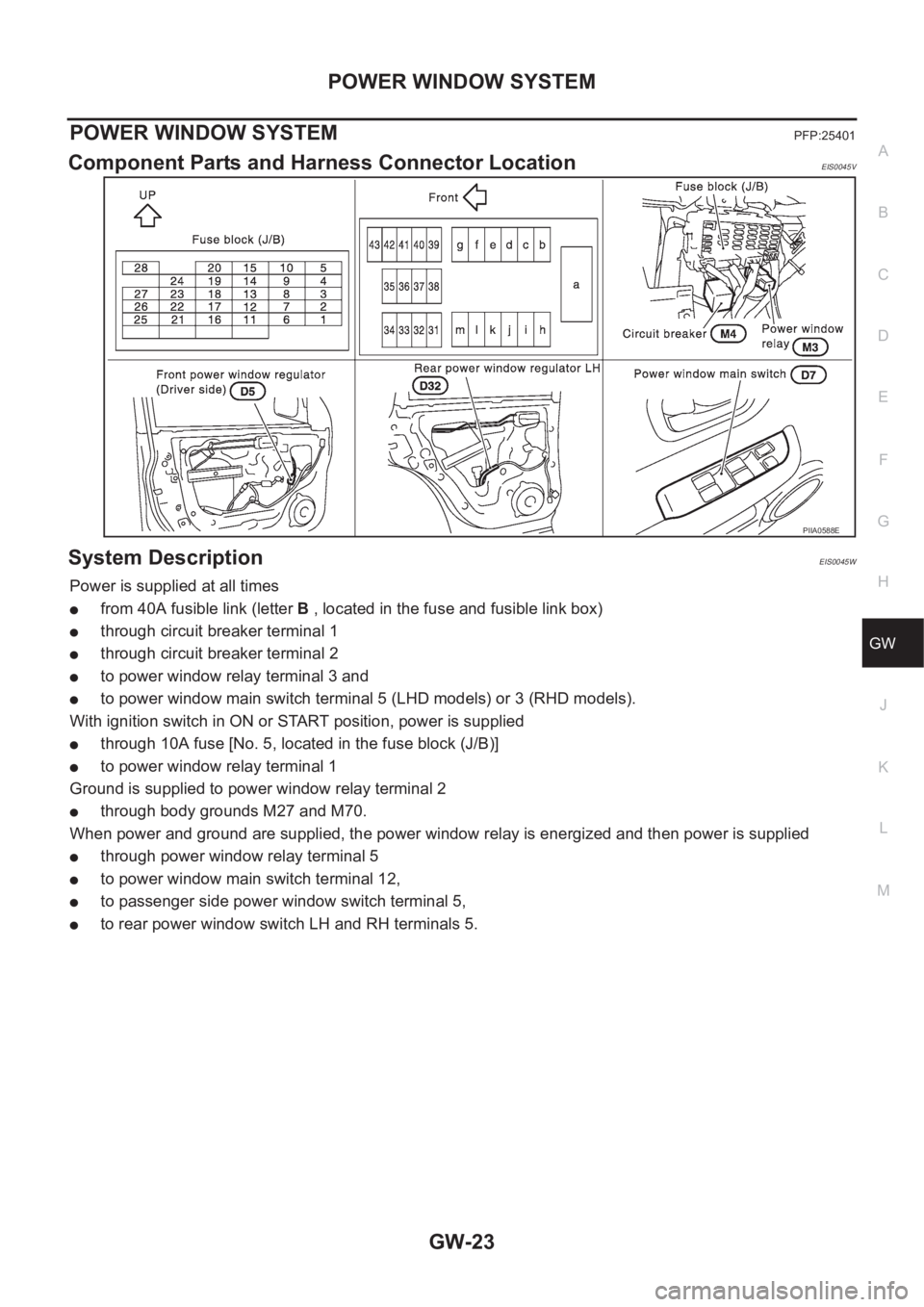

Component Parts and Harness Connector LocationEIS0045V

System DescriptionEIS0045W

Power is supplied at all times

●from 40A fusible link (letter B , located in the fuse and fusible link box)

●through circuit breaker terminal 1

●through circuit breaker terminal 2

●to power window relay terminal 3 and

●to power window main switch terminal 5 (LHD models) or 3 (RHD models).

With ignition switch in ON or START position, power is supplied

●through 10A fuse [No. 5, located in the fuse block (J/B)]

●to power window relay terminal 1

Ground is supplied to power window relay terminal 2

●through body grounds M27 and M70.

When power and ground are supplied, the power window relay is energized and then power is supplied

●through power window relay terminal 5

●to power window main switch terminal 12,

●to passenger side power window switch terminal 5,

●to rear power window switch LH and RH terminals 5.

PIIA0588E

Page 3176 of 3833

GW-24

POWER WINDOW SYSTEM

MANUAL OPERATION

Front door (Driver Side)

Ground is supplied

●to power window main switch terminal 19

●through body grounds M27 and M70.

WINDOW UP

When the driver's window switch in the power window main switch is pressed in the up position, power is sup-

plied

●to driver side power window regulator terminal 1

●through power window main switch terminal 2 (LHD models) or 6 (RHD models).

Ground is supplied

●to driver side power window regulator terminal 3

●through power window main switch terminal 1 (LHD models) or 7 (RHD models).

Then, the motor raises the window until the switch is released.

WINDOW DOWN

When the driver's window switch in the power window main switch is pressed in the down position, power is

supplied

●to driver side power window regulator terminal 3

●through power window main switch terminal 1(LHD models) or 7 (RHD models)

Ground is supplied

●to driver side power window regulator terminal 1

●through power window main switch terminal 2 (LHD models) or 6 (RHD models).

Then, the motor lowers the window until the switch is released.

Front door (Passenger Side)

Ground is supplied

●to power window main switch terminal 19

●through body grounds M27 and M70.

NOTE:

Numbers in parentheses are terminal numbers, when power window switch is pressed in the UP and DOWN

positions respectively.

POWER WINDOW MAIN SWITCH OPERATION

Power is supplied

●through power window main switch (4, 3) (LHD models) or (4, 5) (RHD models)

●to passenger side power window switch (3, 4).

The subsequent operation is the same as the passenger side power window switch operation.

PASSENGER SIDE POWER WINDOW SWITCH OPERATION

Power is supplied

●through passenger side power window switch (1, 2)

●to passenger side power window regulator (1, 2).

Ground is supplied

●to passenger side power window regulator (2, 1)

●through passenger side power window switch (2, 1)

●to passenger side power window switch (4, 3)

●through power window main switch (3, 4) (LHD models) or (5, 4) (RHD models).

Then, the motor raises or lowers the window until the switch is released.

Rear door

Rear door windows will raise and lower in the same manner as passenger's door window.

Page 3177 of 3833

POWER WINDOW SYSTEM

GW-25

C

D

E

F

G

H

J

K

L

MA

B

GW

AUTO OPERATION

The power window AUTO feature enables the driver to open or close the driver's window without holding the

window switch in the down or up position.

The AUTO feature operates on the driver's window.

POWER WINDOW LOCK

The power window lock is designed to lock operation of all windows except for driver's window.

When the lock switch is pressed to lock position, ground of the sub–switches in the power window main switch

is disconnected.This prevents the power window motors from operating.

TIMER FUNCTION

With the timer function, driver power window can be operated for approximately 15 minutes after ignition

switch is turned OFF (positions other than ON). However, the timer will be cancel when a specific signal, such

as driver door close (door switch OFF) → open (door switch ON), or ignition switch OFF → ON, is input.

DRIVER WINDOW ANTI–PINCH FUNCTION

During raising operation of driver power window, if power window main switch detects that foreign object is

pinched, power window lowers approximately 150 mm (5.91 in).

NOTE:

Depending on environment and driving conditions, if a similar impact or load is applied to power window, it

may lower.

Operation conditions

●Driver door window is between fully-open and just before fully-closed position (when the limit switch is

ON).

●During automatic operation when ignition switch is turned ON.

●During automatic or manual operation when ignition switch is other than ON position (when the timer

operates).

Page 3178 of 3833

GW-26

POWER WINDOW SYSTEM

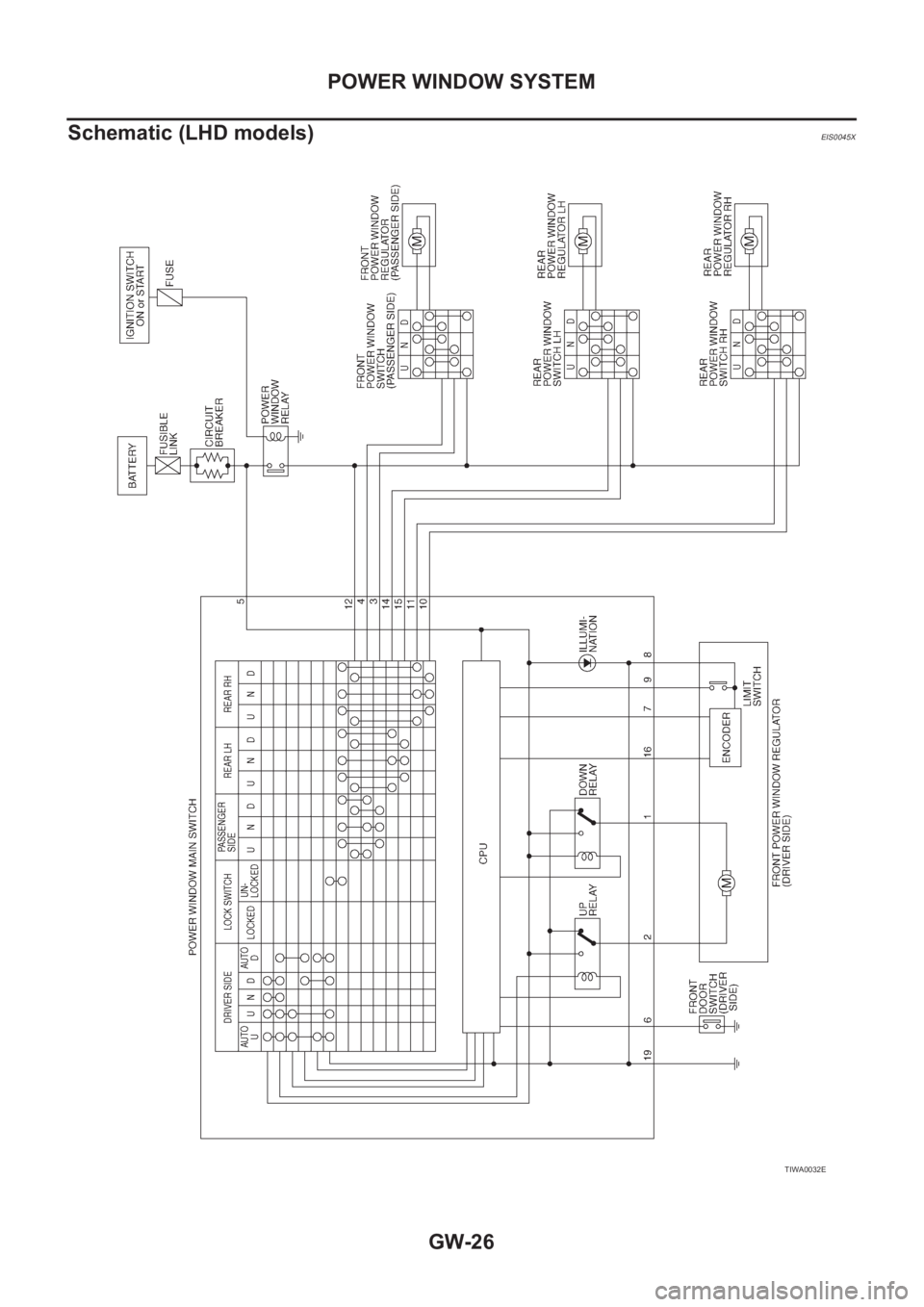

Schematic (LHD models)

EIS0045X

TIWA0032E

Page 3179 of 3833

POWER WINDOW SYSTEM

GW-27

C

D

E

F

G

H

J

K

L

MA

B

GW

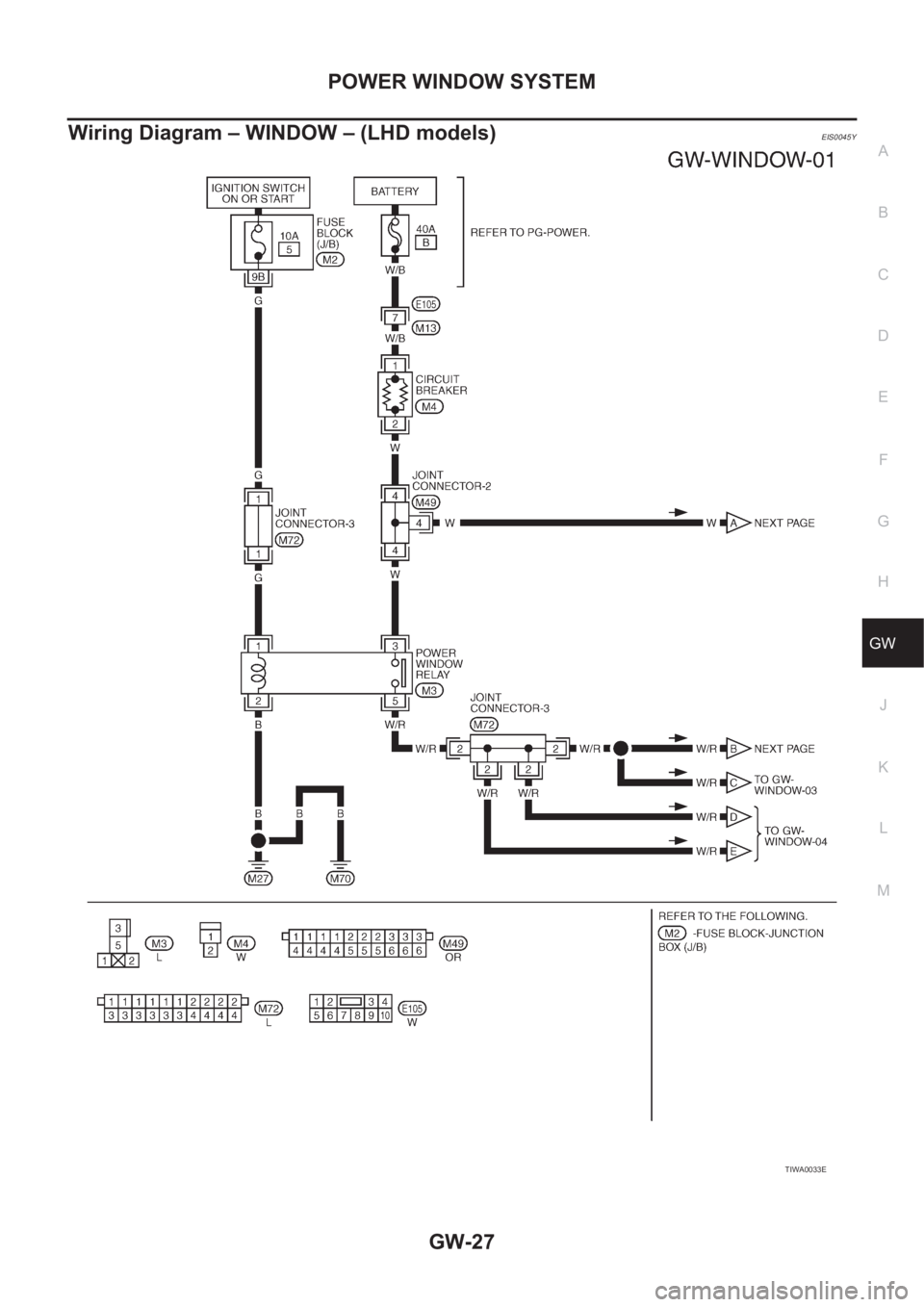

Wiring Diagram – WINDOW – (LHD models)EIS0045Y

TIWA0033E

Page 3180 of 3833

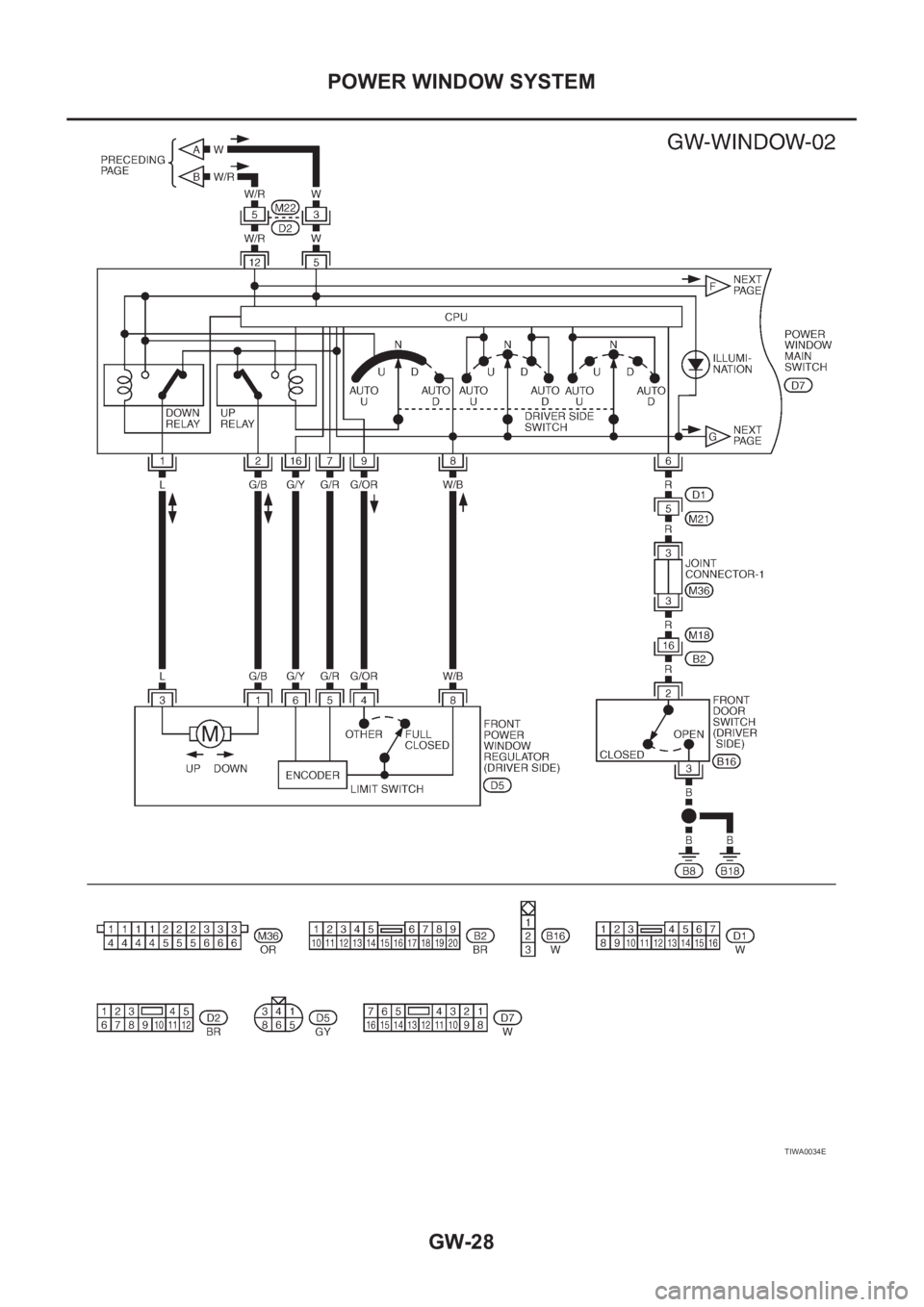

GW-28

POWER WINDOW SYSTEM

TIWA0034E